Page 1

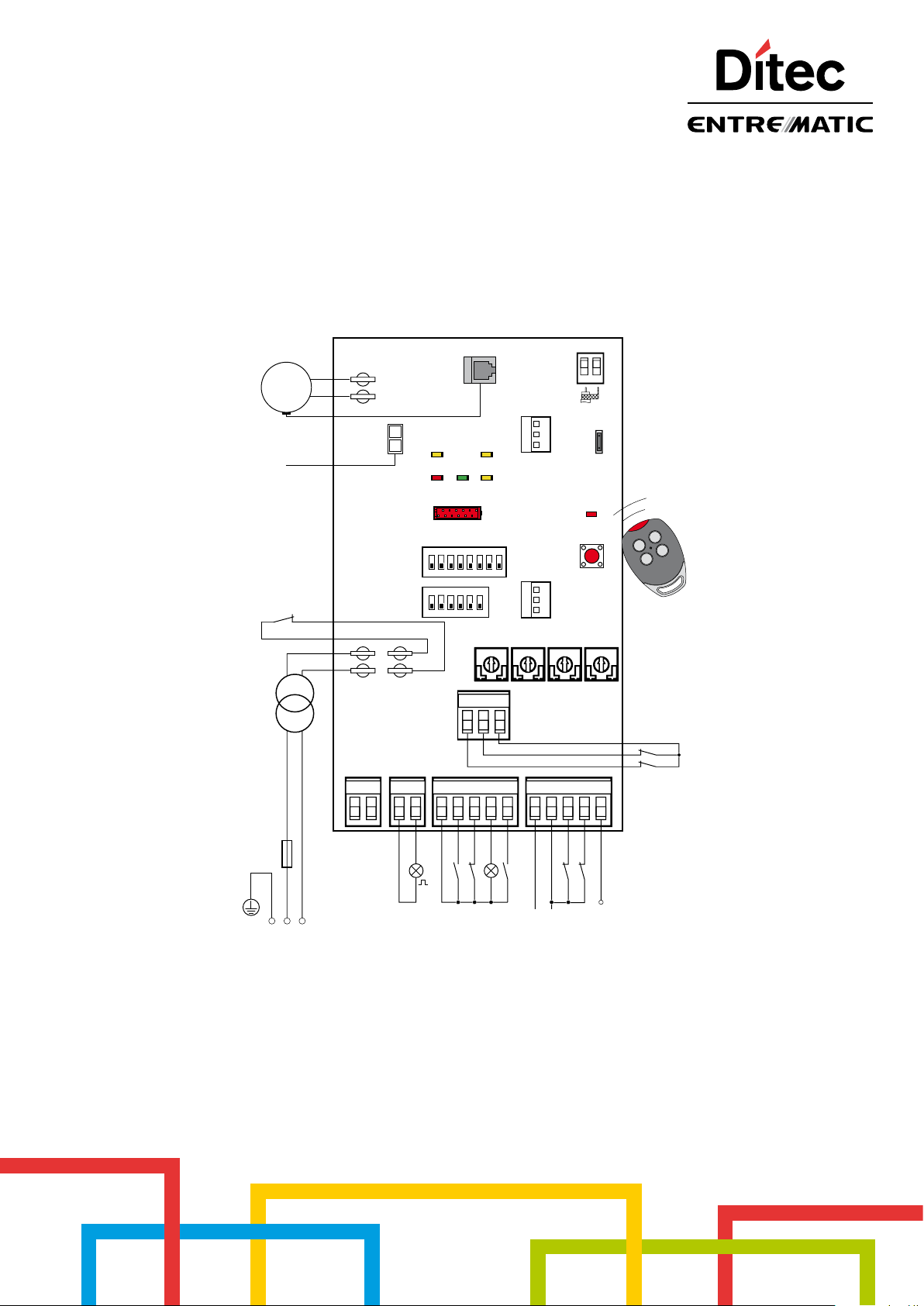

Ditec EL31R

Installation Manual for control panel for 24V automations with built-in radio.

IP1851EN

BATK3

Safety switch

Transformer

Motor

24V=

EL31R

-M

+M

SAFETY24V~

14 0

B

A

T

B

ENC

11IN

SA

1ON23456 78

1ON23456

POWER

COM

12

VAAVC TC R1

1112 0

1591320 016841CNO

AUX

JR1

SIG

PRG

A

N

T

GOL4

Limit switch

Limit switch

F1

Power supply

Stop

Step-by-step

Flashing light

Partial opening

Accessories output

Gate open indicator light

www.ditecentrematic.com

Safety stop

Safety reopening

Safety test

Page 2

2

IP1851EN - 2013-05-06

Page 3

Index

i

Subject Page

1. General safety precautions 4

2. EC declaration of conformity 5

3. Technical specifications 5

3.1 Applications

4. Commands 6

4.1 Self-controlled safety edge

5. CROSS outputs and accessories 7

6. QIK outputs and accessories 8

7. Settings 9

7.1 Tri mme r s

7.2 CROSS dip-switches

7.3 QIK dip-switches

7.4 Jumper

7.5 Signals

8. Radio 12

9. Working modes for sliding gates 13

10. Start-up 13

10.1 CROSS start-up

10.2 QIK start-up

11. Troubleshooting 15

12. Application example for sliding gates 16

13. Application example for barriers 16

14. Application example for parallel automations 17

15. Example of operator present function mode 18

5

6

9

9

10

10

11

13

14

Key

This symbol indicates instructions or notes regarding safety, to which special attention must be paid.

This symbol indicates useful information for the correct functioning of the product.

IP1851EN - 2013-05-06

3

Page 4

1. General safety precautions

This installation manual is intended for qualified personnel only.

Installation, electrical connections and adjustments must be performed in accordance with Good Working Methods and in

compliance with the present standards.

Read the instructions carefully before installing the product. Bad installation could be dangerous.

The packaging materials (plastic, polystyrene, etc.) should not be discarded in the environment or lef t within reach of children,

as these are a potential source of danger.

Before installing the product, make sure it is in perfect condition.

Do not install the product in explosive areas and atmospheres: the presence of inflammable gas or fumes represents a serious

safety hazard.

The safety devices (photocells, safety edges, emergency stops, etc.) must be installed taking into account: applicable laws and

directives, Good Working Methods, installation premises, system operating logic and the forces developed by the automation.

Before connecting the power supply, make sure the plate data correspond to that of the mains power supply. An omnipolar disconnection switch with minimum contact gaps of 3 mm must be included in the mains supply.

Check that upstream of the electrical installation there is an adequate residual current circuit breaker and a suitable overcurrent

cutout.

When requested, connect the automation to an effective earthing system that complies with current safety standards.

During installation, maintenance and repair operations, cut off the power supply before opening the cover to access the

electrical parts.

The electronic parts must be handled using earthed antistatic conductive arms. The manufacturer of the motorisation declines

all responsibility in the event of component parts being fitted that are not compatible with the safe and correct operation.

Use original spare parts only for repairs or replacements of products.

1.1 Installation precautions

Fix the control panel permanently. Pass the cables along the lower side of the container.

If they are accessible, block the cables with cable glands (not supplied). Keep the line and motor conductors separated from the

command conductors by at least 8mm in the terminal boards connection points (e.g. using straps).

Connect together the protection conductors (yellow/green) of the line and the motors, using the clamp supplied.

At the end of the installation, close the container.

4

IP1851EN - 2013-05-06

Page 5

2. EC Declaration of Conformity

i

The manufacturer Entrematic Group AB, with headquarters in Lodjursgatan 10, SE-261 44 Landskrona, Sweden,

declares that the EL31R type control panel complies with the conditions of the following EC directives:

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

R&TTE Directive 1999/5/EC

Landskrona, 29-01-2013 Marco Pietro Zini

(President & CEO)

3. Technical specifications

CROSS3E

Storage module 3M1CR3

Power supply 230 V~ 50/60 Hz 230 V~ 50/60 Hz 230 V~ 50/60 Hz 230 V~ 50/60 Hz

F1 fuse F1.6A F1.6A F2A F1.6A

Motor output 24 V

Accessories power supply 24 V

Temperature min -20° C max +55° C min -20° C max +55° C min -20° C max +55° C min -20° C max +55° C

Degree of protection IP24D IP24D IP24D IP24D

Radio frequency 433.92 MHz 4 3 3.92 MHz 433.9 2 MHz 43 3.92 MHz

Storable transmitters 100 (200 - BIXMR2) 100 (200 - BIXMR2) 100 (200 - BIXMR2) 100 (200 - BIXMR2)

N.B.: The given operating and performance features can only be guaranteed with the use of DITEC accessories and safety

devices.

8 A 24 V 9.5 A 24 V 14 A 24 V 7 A

0.3 A 24 V 0.3 A 24 V 0.3 A 24 V 0.3 A

ALTA5EH

CROSS5EH

CROSS5EH1

3M1CR5

3M1CR5C5

ALTA7EH

CROSS7EH

CROSS7EH1

3M1CR7

3M1CR7C5

QIK7EH

QIK7YEH

3M1QK

3M1QKC7

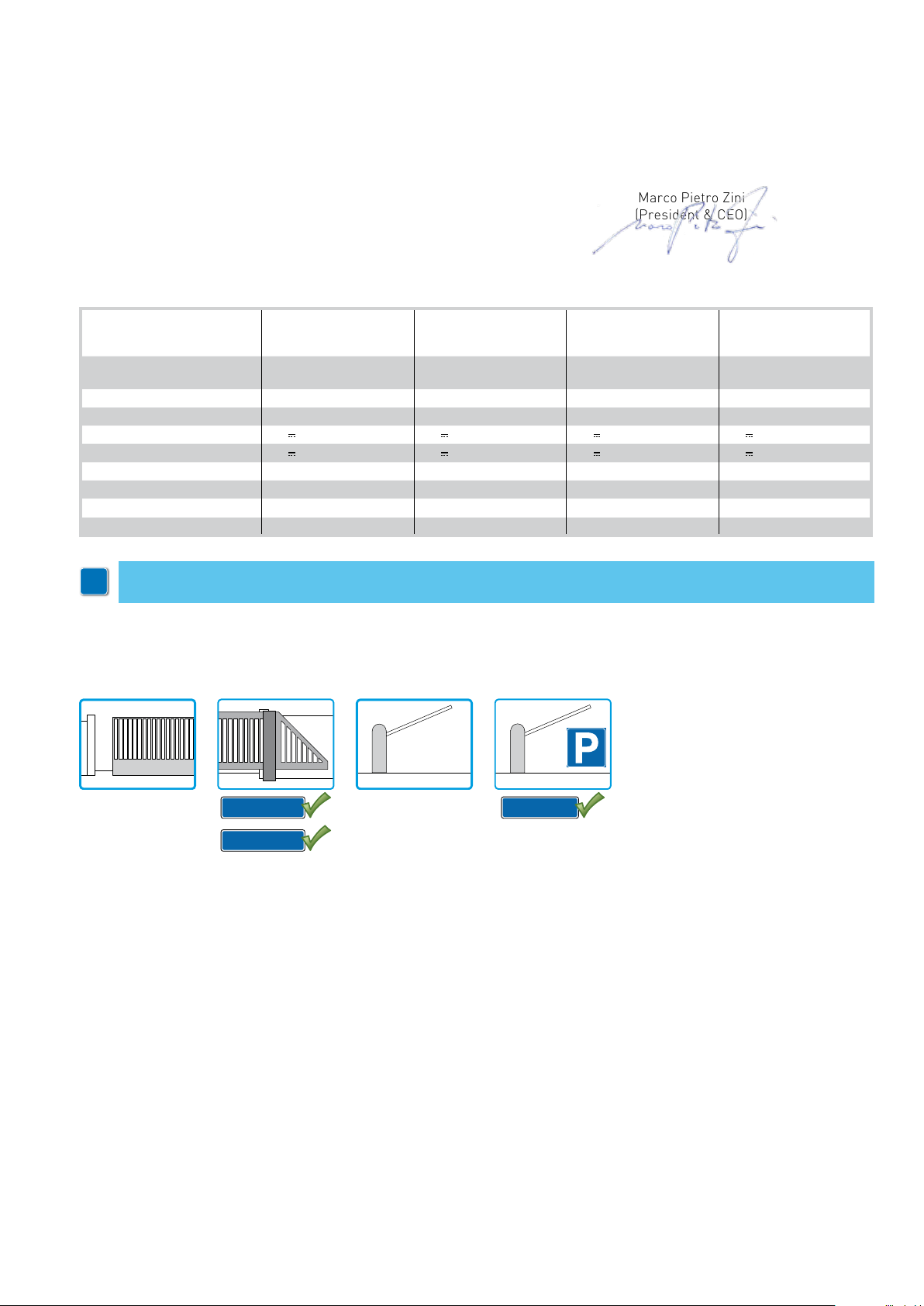

3.1 Applications

IP1851EN - 2013-05-06

3M1CR5C5

3M1CR7C5

3M1QKC7

5

Page 6

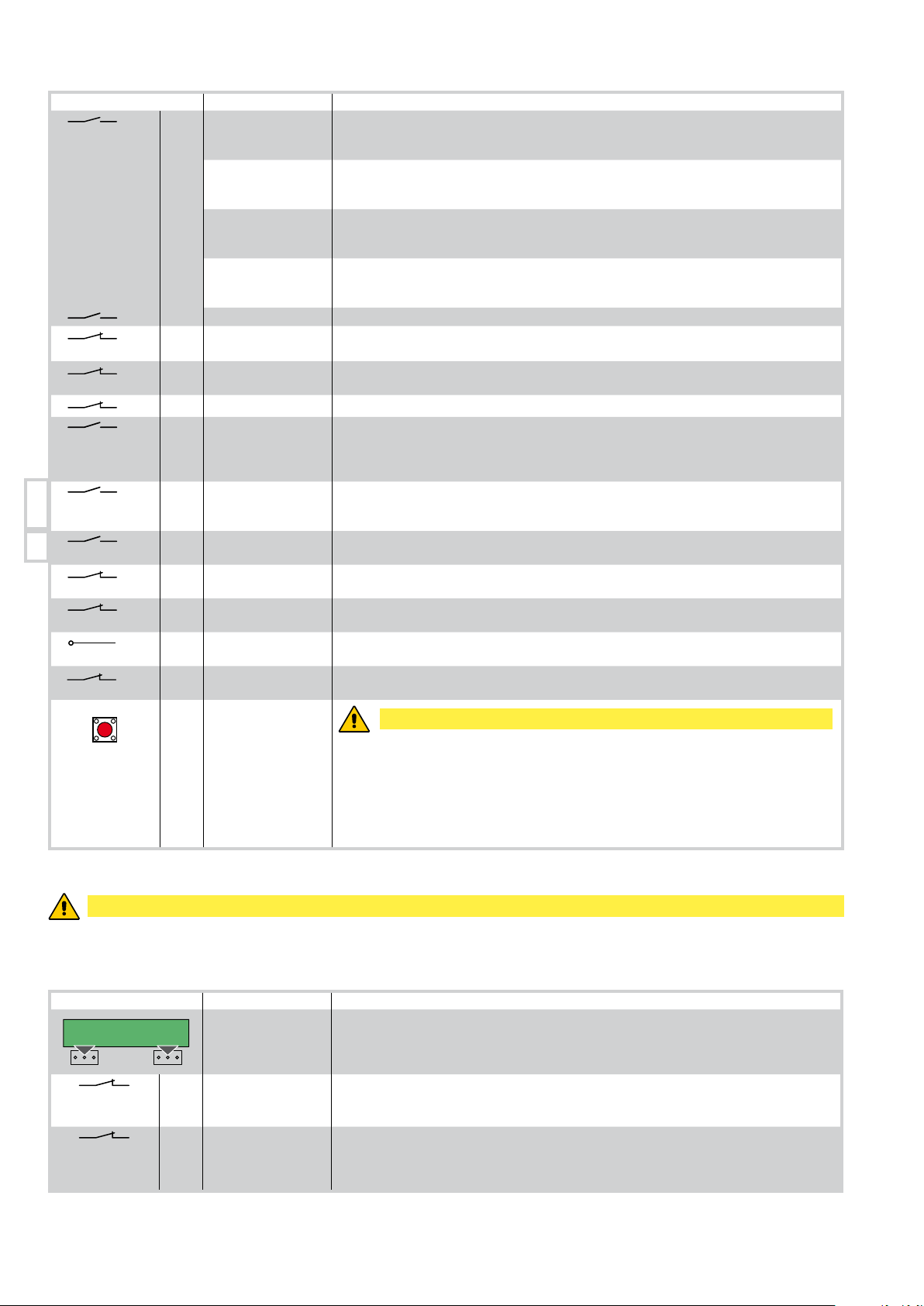

4. Commands

PRG

Command Function Description

1

1

1

1

1

1

1

CROSSQIK

1

0

0

41

5 N.O. STEP-BY-STEP

WITH AUTOMATIC

CLOSING

STEP-BY-STEP

WITHOUT AUTOMATIC

CLOSING

OPENING

WITH AUTOMATIC

CLOSING

OPENING WITHOUT

AUTOMATIC

CLOSING

6 N.O. CLOSING With DIP2B=ON, opening of the safety contact stops and prevents any movement.

6 N.C. OPENING

SAFETY CONTACT

8 N.C. REVERSAL

SAFETY CONTACT

9 N.C. STOP Opening the safety contact stops the current operation.

9 N.O. OPERATOR PRESENT

CONTROL

20 N.O. PARTIAL

OPENING

20 N.O. AUTOMATIC

CLOSING

11 N.C. CLOSING LIMIT

SWITCH

12 N.C. OPENING LIMIT

SWITCH

SAFETY TEST With DIP6A=ON, connecting terminal 41 enables a safety edge test cycle before every operation.

N.C. SAFETY SWITCH The SAFETY SWITCH contact is connected to the release system of the automation. Opening

N.O. TRANSMITTER

STORAGE AND

CANCELLATION

With DIP1A=OFF and TC<MAX, closing of the contact activates an opening or closing operation

in the following sequence: opening-stop-closing-opening.

N.B.: the stop is not permanent, but has the duration set with the TC trimmer.

With DIP1A=OFF and TC=MAX, closing of the contact activates an opening or closing operation

in the following sequence: opening-stop-closing-opening.

With DIP1A=ON and TC<MAX, closing of the contact activates an opening operation.

With DIP1A=ON and TC=MAX, closing of the contact activates an opening operation.

N.B.: Once the automation stops, command 1-5 performs the opposite operation to the one

performed before the stop.

With DIP2B=OFF, closing of the contact activates a closing operation.

Opening the safety contact triggers a reversal of the movement (reopening) during the closing

operation.

Opening of contact 1-9 enables the operator present function.

- opening with operator present 1-5 [with DIP1A=ON and TC=MAX];

- closing with operator present 1-6 [with DIP2B=OFF].

N.B.: any safety devices, automatic closing and plug-in cards in the AUX housing are disabled.

With DIP3B=ON, closing of the contact activates a partial opening operation.

Once the automation stops, the partial opening control performs the opposite operation to the

one performed before the stop.

With DIP3B=OFF, permanent closing of the contact enables automatic closing.

Opening of the contact stops the closing operation.

Opening of the contact stops the opening operation.

If the test fails the SA LED flashes and the test is repeated.

the release contact stops the operation.

Transmitter storage:

- press the PRG key (the SIG LED turns on),

- proceed with transmission from the transmitter to be stored (the SIG LED flashes),

- wait 10 s for storage to be completed (the SIG LED turns off).

Transmitter cancellation:

- press the PRG key for 3 s (the SIG LED flashes),

- press the PRG key again for 3 s (the SIG LED flashes faster).

WARNING: the storage module must be inserted.

WARNING: make a jumper for all N.C. contacts if not in use. The terminals with the same number are equal.

4.1 SOFA1-SOFA2 or GOPAVRS self-controlled safety edge

Command Function Description

SAFETY TEST Place the SOFA1-SOFA2 or GOPAVRS device into the special housing for AUX plug-in cards.

With DIP6A=ON, connecting terminal 41 enables a safety edge test cycle before every operation.

If the test fails the SA LED flashes and the test is repeated.

Connect the output contact of the device to terminals 1-6 on the control panel (in series with

STOP

SAFET Y CONTACT

the photocell output contact, if installed).

WARNING: if not used, make a jumper for terminals 41-6.

Connect the output contact of the device to terminals 1-8 on the control panel (in series with

the photocell output contact, if installed).

WARNING: if not used, make a jumper for terminals 41-8.

6

1

1

SOFA1-SOFA2

GOPAV

6 N.C. SAFETY

8 N.C. REVERSE

IP1851EN - 2013-05-06

Page 7

+

COM

BAT

LN

5. Sliding gates outputs and accessories

Output Value - Accessories Description

Accessories power supply.

0-1

AUX

15913 20

24 V 0.3 A

SOFA1-SOFA2

GOPAV

STORAGE

MODULE

BATK3

2x12 V 2Ah

24 V

3 W

Power supply output for external accessories, including automation status lamps.

The control panel is fitted with a housing for a plug-in card, such as radio receivers, magnetic

loops, etc.

Operating of the plug-in card is selected by DIP1A.

WARNING: the plug-in cards must be inserted and removed with the power supply disconnected.

The storage module allows remote controls to be stored and the type of control panel application

to be defined (see TECHNICAL SPECIFICATIONS on page 4).

If the control panel is replaced, the storage module being used can be inserted in the new control

panel.

WARNING: the storage module must be inserted and removed with the power supply disconnected.

Barrier operation.

The batteries are kept charged when the power supply is on. If the power supply is off, the panel

is powered by the batteries until the power is re-establish or until the battery voltage drops below

the safety threshold. The panel turns off in the last case.

WARNING: the batteries must always be connected to the control panel for charging. Periodically

check the efficiency of the batteries.

N.B.: the operating temperature of the rechargeable batteries is approximately +5°C/+40°C.

Automation status light (proportional)

The light goes off when the automation is closed.

The light comes on when the automation is open.

The light flashes with a variable frequency while the automation is operating.

14 0

CNO

LAMPH

25 W

24 V

LUXK3E

LUXK7

230 V~ 60 W

230 V~ 400 W

Flashing light.

The flashing light activates simultaneously with the opening and closing operation.

Internal courtesy light.

A courtesy light that turns on for 180 seconds with every opening (total or partial), step-by-step

and closing command can be connected in series to the NO contact.

WARNING: use a double insulated cable

External courtesy light.

An external courtesy light that turns on for 180 seconds with every opening (total or partial), stepby-step and closing command can be connected.

WARNING: use a double insulated cable

IP1851EN - 2013-05-06

7

Page 8

+

COM

BAT

LN

6. Barrier outputs and accessories

Output Value - Accessories Description

Accessories power supply.

0-1

AUX

15913 20

24 V 0.3 A

SOFA1-SOFA2

GOPAV

STORAGE

MODULE

BATK3

2x12 V 2Ah

24 V 3 W

Power supply output for external accessories, including automation status lamps.

The control panel is fitted with a housing for a plug-in card, such as radio receivers, magnetic

loops, etc.

Operating of the plug-in card is selected by DIP1A.

WARNING: the plug-in cards must be inserted and removed with the power supply disconnected.

The storage module allows remote controls to be stored and the type of control panel application

to be defined (see TECHNICAL SPECIFICATIONS on page 4).

If the control panel is replaced, the storage module being used can be inserted in the new control

panel.

WARNING: the storage module must be inserted and removed with the power supply disconnected.

Barrier operation.

The batteries are kept charged when the power supply is on. If the power supply is off, the panel

is powered by the batteries until the power is re-establish or until the battery voltage drops below

the safety threshold. The panel turns off in the last case.

WARNING: the batteries must always be connected to the control panel for charging. Periodically

check the efficiency of the batteries.

N.B.: the operating temperature of the rechargeable batteries is approximately +5°C/+40°C.

Automation status lamp (proportional)

The light goes off when the automation is closed.

The light comes on when the automation is open.

The light flashes with a variable frequency while the automation is operating.

14 0

CNO

14 0

Flashing light.

WITH DIP5A=OFF it is activated during the opening and closing operations.

LAMPH

24 V 25 W

External courtesy light.

With DIP5A=OFF, a courtesy light can be connected in series to the NO contact, which activates

for 180 s on each opening (total or partial), step-by-step and closing command.

230 V~ 400 W

WARNING: use a double insulated cable

014NOC

LAMPH

24 V

25 W

Flashing light.

WITH DIP5A=ON it is activated during the opening and closing operations.

Lighting kit.

With DIP5A=ON, on with barrier closed, flashing with barrier operating and off with barrier open.

QIKLUX

24 V 300 mA max

14 0

Electric block.

With DIP5A=ON it is activated with the barrier closed.

QIKAFE

24 V 300 mA max

8

IP1851EN - 2013-05-06

Page 9

7. Settings

120 s

7.1 Trimmers

Trimmer Description

VA - VC

VA - Opening speed adjustment. Adjusts the opening speed.

VC - Closing speed adjustment. Adjusts the closing speed.

MIN

TC

MIN=0 s MAX=disabled

TC

MIN=0 s MAX=120 s

CROSS

MIN

QIK

MAX

MAX

Setting automatic closing time.

From 0 to 120 s.

With DIP3A=OFF, once a safety switch has been activated, the counter starts as soon as the safety switch is released (for example, after passing through the photocells), and lasts for a period of time set with TC (50%).

WARNING: with QIK automations, automatic closing is immediate.

With DIP3A=ON, the counter starts when automation is opened and lasts for the entire duration set with TC (100%).

N.B.: after the activation of the stop command, once contact 1-9 has closed again, automatic closing is only enabled after a total, partial or step-by-step opening command.

With DIP3B=OFF, permanent closing of contact 1-20 enables automatic closing.

Power setting.

The control panel is equipped with a safety device that stops motion if an obstacle is encountered during the opening operation and reverses motion during the closing operation.

Adjustment of power and stop distance.

It adjusts the power of the automation.

With DIP7B=OFF, it adjusts the closing bar stop distance.

7.2 Sliding gates dip-switches

DIP A Description OFF

DIP1A Command functions 1-5.

N.B.: it also sets operating on the AUX

plug-in card.

DIP2A Selecting opening direction.

The opening direction is intended by viewing the automation from the side being examined.

DIP3A Automatic closing time restore 50% 100%

DIP4A Automation status at power on.

Indicates how the control panel considers

automation when powered up.

DIP5A Preflashing for 3 seconds. Disabled during opening.

Step-by-step Opening.

Opening to the right. Opening to the left.

Open.

N.B.: with limit switches installed, we recommend setting DIP4A=OFF.

Enabled only with automatic closing with

TC >3 s.

ON

Closed.

N.B.: if the automatic closing function is

not used, we recommend setting DIP4=ON.

Enabled for both opening and closing.

DIP6A Safety test terminal 41. Disabled. Enabled.

DIP B Description OFF

DIP1B Reversal safety contact operation. With automation stopped and contact 1-8

DIP2B Command functions 1-6. Closing. Stop.

DIP3B Command functions 1-20. Automatic closing on. Partial opening command.

DIP4B Selection of maximum working forces lim-

DIP5B Encoder selection. Automation without encoder.

DIP6B Current profile.

DIP7B Approach speed adjustment. Normal. Reduced.

DIP8B Electronic antifreeze system.

IP1851EN - 2013-05-06

it and adjustment of stop distance.

(Automations with encoder only).

Maintains motor efficiency even at low

ambient temperatures.

ON

With automation stopped and 1-8 open, all

open, opening operations are permitted.

Normal closing force and reduced stop

distance that changes according to speed.

N.B.: stop limit switches must be installed.

Disabled. Enabled.

Enabled. Disabled.

operations are disabled.

Reduced closing force and longer stop

distance irrespective of speed.

Automation with encoder.

9

Page 10

7.3 Barrier dip-switches

DIP A Description OFF

DIP1A Command functions 1-5.

N.B.: it also sets operating on the AUX

plug-in card.

DIP2A Selecting opening direction.

The opening direction is intended by viewing the automation from the side being

examined.

DIP3A Automatic closing time restore 0% 100%

DIP4A Automation status at power on.

Indicates how the control panel considers

automation when powered up.

DIP5A Operating of output 0-14 and C-NO con-

tact.

Preflashing for 3 seconds. Enabled only with automatic closing with TC >3 s.

DIP6A Safety test terminal 41. Disabled. Enabled.

DIP B Description OFF

DIP1B Reversal safety contact operation. With automation stopped and contact 1-8

DIP2B Command functions 1-6. Closing. Stop.

DIP3B Preflashing for 3 seconds.

After intervention of safety switch 1-8 and

with immediate closing DIP3A=OFF

DIP4B Selection of maximum working forces lim-

it and adjustment of stop distance.

Step-by-step Opening.

Opening to the right. Opening to the left.

Open.

N.B.: with limit switches installed, we recommend setting DIP4A=OFF.

Flashing light and courtesy light. Flashing light, lighting kit and electric

open, opening operations are permitted.

Disabled Enabled

Normal closing force and reduced stop

distance that changes according to speed.

ON

Closed.

N.B.: if the automatic closing function is

not used, we recommend setting DIP4=ON.

block.

ON

With automation stopped and 1-8 open, all

operations are disabled.

Reduced closing force and longer stop

distance irrespective of speed.

DIP5B Stopping type selection. Immediate. Normal.

DIP7B Stop distance adjustment during closing. It allows the adjustment of the stop dis-

tance by means of trimmer R1.

DIP8B Electronic antifreeze system.

Maintains motor efficiency even at low

ambient temperatures.

Enabled. Disabled.

Stopping fixed at 30°.

7.4 Jumpers

Jumper Description OFF ON

JR1 Built-in radio receiver Disabled Enabled

10

IP1851EN - 2013-05-06

Page 11

7.5 Signals

LED On Flashing

POWER

ALARM

IN

SA

11

12

SIG

Power supply on. Encoder not working or DIP5B selection is not con-

sistent with the encoder actually being or not being there.

Current overload on flashing light out-

put.

Shortcircuiting of flashing light

driver.

Command received or change in status of a dip-switch.

At least one of the safety contacts is open or DIP6A selection is

not consistent with the connection of terminals 6-8.

0-11 limit switch contact is open.

0-12 limit switch contact is open.

Transmitter enabling/storage phase. Radio transmission of a stored remote control received.

Safety test failure (terminal 41).

Operations count performed (only when control panel is switched

on):

= 1000 operations

= 10000 operations

Radio transmission of an unstored remote control received.

Transmitter being cancelled.

Damaged storage.

/

/

/

IP1851EN - 2013-05-06

11

Page 12

8. Radio

i

ANT

JR1

COM

SIG

PRG

CH1 CH2

CH3CH4

10 s

1 2 3

The control panel is equipped with a radio receiver with a frequency of 433.92 MHz.

The antenna consists of a rigid wire, 173 mm long, connected to the ANT clamp.

It is possible to increase the range of the radio by connecting the antenna of the flashing lights, or by installing the tuned BIXAL antenna.

N.B.: To connect the external antenna to the control panel, use a coaxial cable, type RG58 (max. 10 m).

Check that the storage module is inserted in the COM connector.

Up to 100 remote controls can be stored in the storage module.

WARNING: if the radio receiver on the control panel is not used, set JR1=OFF and remove the storage module.

Transmitter storage:

- Press the PRG key on the radio receiver or on the control panel; the SIG indicator LED lights up;

- Proceed with transmission by pressing the CH keys on the remote control that you want to store (within the range of the radio

receiver). The remote control is now stored. During this phase, the SIG indicator LED flashes. When the SIG LED comes on

again, you can validate another remote control. Validate all the new remote controls by making a transmission as indicated;

- You automatically exit the procedure 10 seconds after the last transmission, or you can press the PRG key again (the SIG LED

goes off).

Up to four CH keys of a single remote control can be stored.

- If only one (any) CH key of the remote control is stored, command 1-5 (step-by-step/opening) is carried out;

- If 2-4 CH keys of a single remote control are stored, the functions matched with the CH keys are as follows:

• CH1=command1-5step-by-step/opening;

• CH2=partialopeningcommand,itcausestheautomationtoopenforabout1m;

• CH3=commandtoswitchon/offthecourtesylight;

• CH4=stopcommand,equivalenttoimpulsivecommand1-9.

Transmitter cancellation:

- Hold down the PRG key for 3 s; the SIG LED starts to flash;

- To cancel all the remote controls from the memory, press the PRG key again, keeping it pressed for 3 s;

- To cancel a single remote control, press any one of the previously memorised CH keys of the remote control to be cancelled;

- The cancellation is confirmed by the quick flashing of the SIG LED.

For further information see the user manual for GOL series remote controls.

If the control panel is replaced, the storage module being used can be inserted in the new control panel.

WARNING: the storage module must be inserted and removed with the power supply disconnected.

For further information see the user manual for GOL series remote controls.

12

IP1851EN - 2013-05-06

Page 13

9. Working modes for sliding gates

i

The control panel can work in the following 3 modes:

• automationswithencoder(DIP5B=ON)andwithoutstoplimitswitches,

the automation stops on the mechanical stops;

• automationswithencoder(DIP5B=ON)andwithstoplimitswitches,

the automation stops after the stop limit switches have tripped;

• automationswithoutencoder(DIP5B=OFF)andwithstoplimitswitches,

the automation stops after the stop limit switches have tripped.

In the automations with encoder (DIP5B=ON), by selecting DIP6B=ON, the control panel activates an innovative automatic detection

system for the current necessary to move the automation at any point of the opening and closing operation.

The current stored profile shows the forces necessary for correct movement, taking the frictions into consideration.

The current profile is automatically updated every time an operation is completed (opening-closing) and it gradually adapts to the

frictions resulting from progressive and natural ageing of the gate frame, reducing the need to service.

N.B.: The current profile is kept stored even in the event of a power failure.

10. Start-up

10.1 Starting the sliding gates

WARNING The operations related to point 6 are performed without safeties.

The trimmer can only be adjusted with the automation idle.

The automation automatically slows when approaching the end stops or stop limit switches.

After start-up the control panel receives a RESET and the first operation is performed at

reduced speed (automation position acquisition).

1- Make a jumper for NC safety contacts.

2- Check that the storage module corresponding to the type of application selected is correctly plugged in.

3- Adjust the opening and closing stop limit switches, if any.

N.B.: limit switches must be kept pressed until the operation has been completed.

4- Set TC=MAX and R1=50%.

Select the desired opening direction with DIP2A.

Set DIP4B=OFF and DIP6B=OFF.

5- Manually move the sliding gate and make sure the entire stroke slides evenly and without friction.

6- Switch on and check the automation is operating correctly with the subsequent opening and closing commands.

Check that the limit switches are activated if used.

7- Connect the safety devices (removing the relative jumpers) and check they function correctly.

8- If desired, adjust the automatic closing time with the TC trimmer.

WARNING: the automatic closing time after a safety device has triggered depends on the DIP3A setting.

9- Set the desired opening and closing speed with the VA and VC trimmers.

10- Connect any other accessories and check they are functioning.

11- Set the obstacle thrust with the R1 trimmer.

To enable the current profile (see chapter 9) proceed as indicated:

•setDIP6B=ON(anypreviouslystoredcurrentproleisreset);

•perform2completeoperations(opening-closing).

12- For correct operating of the sliding gate with the correct operating forces, we recommend using the following settings:

•gatewithoutrubberedges:DIP4B=ONandDIP7B=ON;

•gatewithrubberedges:DIP4B=ONandDIP7B=OFF;

•gatewithself-controlledsafetyedges:DIP4B=OFFandDIP7B=OFF.

WARNING: After adjusting, check that the working forces exerted by the door wings comply with standards EN12453-EN12445.

IP1851EN - 2013-05-06

N.B.: in the event of servicing or if the control panel is to be replaced, repeat the start-up procedure.

13

Page 14

10.2. Starting the barriers

i

WARNING The operations related to point 6 are performed without safeties.

The trimmer can only be adjusted with the automation idle.

The automation automatically slows when approaching the end stops or stop limit switches.

After start-up the control panel receives a RESET and the first operation is performed at

reduced speed (automation position acquisition).

1- Make a jumper for NC safety contacts.

2- Check that the storage module corresponding to the type of application selected is correctly plugged in.

3- Adjust the opening and closing stop limit switches, if any.

N.B.: limit switches must be kept pressed until the operation has been completed.

4- Set TC=MAX and R1=50%.

Select the desired opening direction with DIP2A.

Set DIP4B=OFF and DIP6B=OFF.

5- Manually move the barrier bar and make sure it is correctly balanced.

6- Switch on and check the automation is operating correctly with the subsequent opening and closing commands.

Check that the limit switches are activated if used.

7- Connect the safety devices (removing the relative jumpers) and check they function correctly.

8- If desired, adjust the automatic closing time with the TC trimmer.

WARNING: the automatic closing time after a safety device has triggered depends on the DIP3A setting.

9- Set the desired opening and closing speed with the VA and VC trimmers.

WARNING: with QIK automations, for correct operation with a bar longer than 4.5 m, adjust the VA and VC trimmers to no more

than 50%.

10- Connect any other accessories and check they are functioning.

N.B.: in the event of servicing or if the control panel is to be replaced, repeat the start-up procedure.

14

IP1851EN - 2013-05-06

Page 15

11. Troubleshooting

Problem Possible causes Operation

The automation does not open or close. No power.

(POWER ALARM LED off).

Short circuited accessories.

(POWER ALARM LED off).

Blown line fuse.

(POWER ALARM LED off).

Safety contacts are open.

(SA LED on).

Safety contacts not correctly connected or selfcontrolled safety edge not functioning correctly.

(flashing SA LED).

SAFETY SWITCH release microswitch open.

(LEDs 11 and 12 on).

No storage module or incorrect storage module.

(SA and POWER ALARM LEDs flashing alternatively).

The remote control does not work. Check the correct memorisation of the transmit-

Photocells activated.

(SA LED on).

The automatic closing does not work. Check that the TC trimmer is not set at the

The external safety devices are not activated. Incorrect connections between the photocells

and the control panel.

The automation opens/closes briefly and then

stops.

The remote control has limited range and

does not work with the automation moving.

Encoder disconnected, false encoder contacts,

encoder fault.

(flashing POWER ALARM LED).

Motor leads crossed.

(flashing POWER ALARM LED).

There is a presence of friction. Manually check that the automation moves

The radio transmission is impeded by metal

structures and reinforced concrete walls.

Check that the control panel is powered correctly.

Disconnect all accessories from terminals 0-1

(a voltage of 24V= must be present) and reconnect them one at a time.

Replace fuse F1.

Check that the safety contacts are closed correctly (NC).

Check the DIP6A setting.

Check connections to terminals 6-8 on control

panel and connections to the self-controlled

safety edge.

Check that the hatch is closed correctly and the

microswitch makes contact.

Switch the automation off and plug in the correct

storage module.

ters on the built-in radio. If there is a fault with

the radio receiver that is built into the control

panel, the remote control codes can be read by

removing the storage module.

Check that the photocells are clean and operating correctly.

maximum or check the DIP3B=ON setting.

Connect NC safety contacts together in series

and remove any jumpers on the control panel

terminal board.

Check that the encoder is connected correctly,

clean the contacts by connecting and disconnecting the encoder plug on the contacts, replace encoder.

Check the DIP5B setting.

Check the motor leads.

freely and check the R1 adjustment.

Install the antenna outside.

Substitute the transmitter batteries.

IP1851EN - 2013-05-06

15

Page 16

12. Application example for sliding gates

i

B

B

B

When using the control panel for sliding automation applications:

- Select the correct opening direction with DIP2A

(Example 1). When using the control panel for sliding gate

applications:

- connect the opening and closing limit switch NC contacts

to terminals 0-11-12 if required.

With this configuration, the wing stops when the limit

switches are activated.

(Example 2). The remote control can be used with stepby-step functioning and, at the same time, terminal 5 with

opening function by making the connections indicated and

setting DIP1A=OFF.

N.B.: if the self-controlled safety edge SOFA1SOFA2 is used, make the connections indicated in

paragraph 4.1.

DIP2B=ON

DIP1A=ON

DIP2B=ON

DIP3B=ON

DIP1A=OFF

1ON23456 7

A

1ON23456

1ON23456 7

A

1ON23456

14 0

14 0

VA VC TC R1

1112 0

1591320 016841CNO

VA VC TC R1

1112 0

1591320 016841CNO

<MAX

<MAX

Closing limit switch

Closing limit switch

Opening limit switch

Opening limit switch

Closing limit switch

Closing limit switch

Opening limit switch

Opening limit switch

WARNING: with CROSS5EH1 and CROSS7EH1 automations with a limit switch and without encoder,

you must set DIP5B=OFF and DIP6B=OFF.

13. Application example for barriers

When using the control panel for barrier applications:

- Select the correct opening direction with DIP2A.

Connect the opening and closing limit switch NC contacts

to terminals 0-11-12.

With this configuration, the barrier stops when the limit

switches are activated.

DIP2B=ON

DIP5B=ON

DIP1A=ON

A

1ON23456 7

1ON23456

14 0

Opening

Opening

Partial opening

VA VC TC R1

1112 0

1591320 016841CNO

Partial opening

<MAX

Closing limit switch

Closing limit switch

Opening limit switch

Opening limit switch

16

IP1851EN - 2013-05-06

Page 17

14. Example of parallel automations

i

A B

BIXLR22

B

DIP1A=ON

A

DIP2A=ON

JR1=NO

JR2=CH1

JR1 JR2

1

2

3

4

1ON23456 7

1ON23456

A B

1

2

3

4

ANTOUT2

JR1 JR1

B

1ON23456 7

A

1ON23456

DIP1A=ON

1591320 016841 1591320 016841

A B

It is possible to command two automations [A] and [B] in parallel with the connections and settings indicated in the figure.

Step-by-step commands (1-5) and radio controls are like an opening command.

To manage both automations with a single remote control, do not use the radio receivers on the control panels (JR1=OFF), but insert

a BIXLR22 radio receiver.

Adjust TC, VA and VC trimmers in the same position on both control panels.

N.B.: the opening and closing movements may not be synchronised.

IP1851EN - 2013-05-06

17

Page 18

15. Operator present function modes

B

When the control panel is used in “operator present”

function mode:

- disconnect terminal 9;

- set the opening direction with DIP2A=OFF;

In this state, the opening (1-5) and closing (1-6) controls

function only if held in the pressed position, and the automation stops when the controls are released.

The automatic closing and radio controls are disabled.

DIP2B=OFF

DIP1A=ON

1ON23456 78

A

1ON23456

14 0

VA VC TC R1

1112 0

1591320 016841CNO

<MAX50% 50%

Closing limit switch

Closing limit switch

Opening limit switch

Opening limit switch

18

IP1851EN - 2013-05-06

Page 19

All the rights concerning this material are the exclusive property of Entrematic Group AB.

Although the contents of this publication have been drawn up with the greatest care, Entrematic Group AB cannot be held responsible in any way for any damage

caused by mistakes or omissions in this publication. We reserve the right to make changes without prior notice. Copying, scanning and changing in any way are

expressly forbidden unless authorised in writing by Entrematic Group AB.

IP1851EN - 2013-05-06

19

Page 20

IP1851EN - 2013-05-06

Entrematic Italy S.p.A.

ViaMons.Ban,3•21042CaronnoP.lla(VA)Italy

Tel. +39 02 963911 - Fax +39 02 9650314

www.ditecentrematic.com

Loading...

Loading...