Direct Lift PP8S User Manual

PP8S

Four Post Lift

8,000 lbs. Capacity

(4,000 lbs. per axle)

Minimum wheelbase 100" at rated capacity

IMPORTANT

Installation and Service of Automotive Lifts

before installing lift.

Reference ANSI/ALI ALIS,

Safety Requirements for

INSTALLATION / OWNERS MANUAL

Read this manual thoroughly before installing, operating, or maintaining this lift. When done with installation be

sure to return documents to package and give all materials to lift owner/operator. When installation is complete

be sure to run lift up and down a few cycles with and without “typical” vehicle loaded on lift.

© October 2010 by Vehicle Service Group. All rights reserved. CO7513 IN50011

Rev. G 10/12/2010

TABLE OF CONTENTS

• IMPORTANT INFORMATION pg 2

• OWNER / EMPLOYER RESPONSIBILITY pg 3

• LOCKOUT / TAGOUT pg 3

• SAFETY PROCEDURES pg 4

• LIFT SPECIFICATIONS & FLOOR PLAN pg 6

• TOOLS REQUIRED pg 7

• INSTALLATION INSTRUCTIONS pg 7

• CASTER KIT ASSEMBLY / INSTALLATION pg 11

• FOUNDATION & ANCHORING REQUIREMENTS pg 13

• OPERATION INSTRUCTIONS pg 15

• PREVENTIVE MAINTENANCE SCHEDULE pg 17

• TROUBLESHOOTING pg 18

• CABLE INSPECTION GUIDE pg 20

• ILLUSTRATED PARTS LIST pg 27

IMPORTANT INFORMATION

Four Post Lifts

1. Always inspect the lift for damage and make note of any damage on the bill of lading.

2. In case of freight damage, call the truck line immediately and report the damage as a freight claim.

3. Make sure you have extra help or heavy duty lifting equipment when unloading and assembling the lift.

4. Please read the safety procedures and operating instructions in this manual before operating lift. Keep

this manual near lift at all times. Make sure all operators read this manual.

5. NOTE: Are you installing in a level location? (Lift must be anchored in place if slope is greater than

1/8" per foot.)

6. Make sure you have enough room to install the lock rods. You will need at least 9’ of clearance from

the opposite end of the power unit end of the lift and 6’ at the power unit end. (See floor plan on page 6).

The power unit may be installed on the driver’s front or the passenger rear corner.

7. Never raise a car until you have double checked all bolts, nuts and hose fittings.

8. Always lower the lift to locks before going under the vehicle or storing another vehicle underneath lift.

Never allow anyone to go under the lift when raising or lowering.

This is a vehicle lift installation/operation manual and no attempt is made or implied herein to instruct the user in

lifting methods particular to an individual application. Rather, the contents of this manual are intended as a basis

for operation and maintenance of the unit as it stands alone or as it is intended and anticipated to be used in

conjunction with other equipment.

Proper application of the equipment described herein is limited to the parameters detailed in the specifications

and the uses set forth in the descriptive passages. Any other proposed application of this equipment should be

documented and submitted in writing to the factory for examination. The user assumes full responsibility for any

equipment damage, personal injury, or alteration of the equipment described in this manual or any subsequent

damages.

2

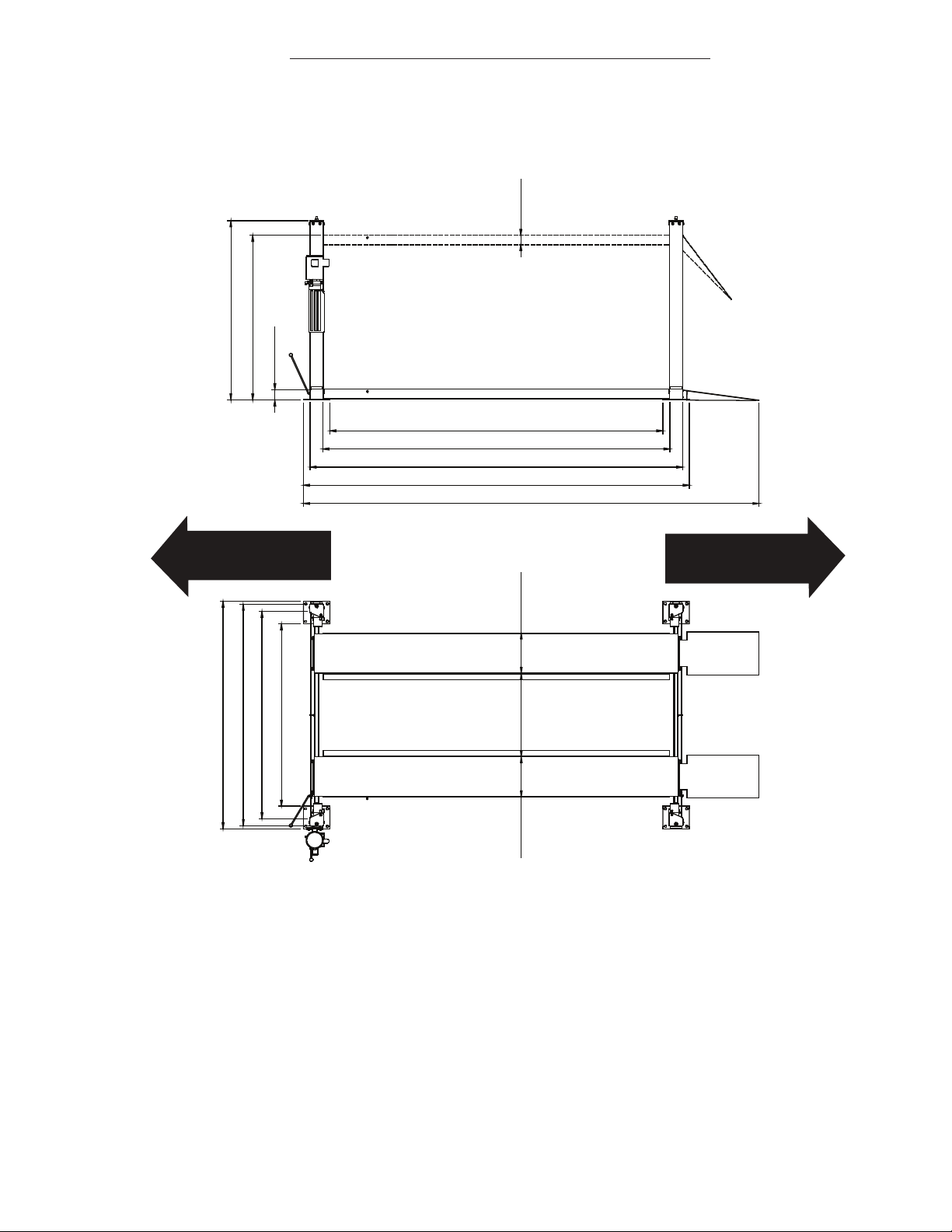

LIFT SPECIFICATIONS & FLOOR PLAN

4 1/ 2"

72 1/ 2"

81 1/ 2"

4 1/ 2"

151 1/ 2"

158"

169 1/ 2"

175 1/ 2"

207 1/ 2"

YOU WILL NEED A MIN. OF 6’

CLEARANCE IN FRONT TO

INSTALL HANDLE ROD

94"

83"

100 3/ 4"

103 1/ 2"

38" 18 1/ 2"

YOU WILL NEED A MIN. OF

9’ CLEARANCE IN REAR

TO INSTALL “T” ROD

18 1/ 2"

Technical Data

Lifting Height 72-1/2”

Overall Length with Ramps 207-1/2”

Overall Length without Ramps 175-1/2”

Overall Width 103-1/2”

Height Of Columns 81-1/2”

Runway Width 18-1/2”

Runway Height 4-1/2”

Clearance Between Runways 38”

Capacity 8000 lbs.

3

TOOLS REQUIRED

• Set of metric wrenches and/or sockets

• Adjustable wrench

• Locking pliers

• 25’ Tape measure

• Step Ladder

• *3 Gallons of Hydraulic Oil

*Recommended Oil: ISO 32 Light Hydraulic Oil

INSTALLATION INSTRUCTIONS

1. Remove plastic wrap from top runway and remove all hardware, safety lock rods, hoses and cables. You

should also find this manual in the top runway.

2. Find the end of the hose that is already mounted to the cylinder and tighten the elbow that attaches the

hose to the side of the runway using the jam nut. Also, check the fitting at the cylinder end and make

sure it is tight.

3. Extend cylinder rod out of the cylinder to about 18” from end of runway. This can be done by pulling or

pushing on the 1/2” plate on the end of the cylinder. Make sure that the 1/2” plate is threaded tight

against the cylinder rod. Also, be sure the 1/4” plate is on the rod and hand tighten the lock nut on the

end of the cylinder.

4. Unbolt the top runway from the shipping plates at each end of the package. Be sure to secure runway

with a hoist to prevent runway from falling. Runway will need to be turned over so it is no longer upside

down. Place this runway in your bay with the hydraulic fitting facing toward the outside (see Page 1).

5. Next, unbolt the four columns from the package and place the column with the power unit mounting

bracket at the end of the previously unpacked runway nearest to the hydraulic fitting. Stand these

columns on their base plates with the locking ladders facing to the outside (front or rear) and the pulleys

toward the inside (see Fig. 1).

6. Unpack the bottom runway. Lay the approach ramps near the approach end of the lift and set out the

remaining parts away from the lift. Place the two cross rails at each end of the lift with the locks toward

the outside (front or rear) of the lift (see Fig. 1). Remove the shipping brackets from the bottom runway

and turn over placing the runway in the bay next to the other runway with the “L” shaped side facing the

“L” shaped side of the other runway.

4

7. If you have a means for securely lifting cross rails high enough to lower them into the top of the columns,

then remove the top plates from the top of the columns while columns are standing. If you don’t have a

means for securely lifting them up, then you will need to lay the columns down and remove the top plates

to allow the cross rails to be slid into the columns.

8. Slide each cross rail into the front or rear two columns by holding the lock lever down, to allow the rail

to slide past the locking positions. Leave the cross rail locked in the lowest position on the column.

Repeat this step for the other cross rail (see Fig. 1).

9. Position the front cross rail columns at 170.5” from the rear cross rail columns by measuring from the

outsides of the columns. Square the lift by measuring diagonally between the right, front column to the

same position on the left rear column. Compare your measurement between the left front column and

the right rear column. This should be within 1/2” to allow some forgiveness to bolt on runways.

10. Lift the runways onto the cross rails and bolt them in place using the 3/4” holes towards the outside of

the cross rails. The four drop-in ramp plates will be used with the spacer side facing the lift and through bolted from the outside of the cross rail, through the runway using bolts provided with washers, lock

washers and nuts (see Fig. 2).

11. After runways are bolted on, install the column top plates back to their original columns and tighten.

12. CABLE INSTALLATION - Lay out all cables and measure from end to end to determine correct cable

positions (see Fig. 3).

13. Since the nub end of the cable is easier to feed through the pulley, start with the pulley at the end of the

cross bar and work your way back to the cylinder (see Fig. 3).

14. Install cable nubs onto appropriate slots in 1/2” plate and secure with slots on 1/4” plate. Tighten the

nubs so the nylock nut is fully threaded onto the head of the cylinder. The cable bracket should still be

able to move freely on the cylinder head.

15. Run the threaded cable ends into the hole in the top caps and secure with washer and nylock nut. Hand

tighten only, final adjustment will be made later. Do tighten the nylock nut on the end of the cylinder at

this time.

16. HYDRAULIC ASSEMBLY - Be sure wiring is in compliance with your local electrical codes.

5

17. Find the four 5/16” bolts, nuts and lock washers and attach the power unit to the mounting bracket on the

column.

18. Remove dust cover from the port on the side of the power unit and attach the “O” ring elbow. Do not

over tighten. The backing nut and “O” ring will complete the seal to the power unit.

19. Install the 3/8” hose to the fitting on the side of the runway and connect opposite end to the fitting on the

power unit. Tighten JIC fittings carefully, do not over tighten.

20. LOCK LINKAGE ASSEMBLY - The single point safety lock is a system of connecting rods and linkage that

disengage the four lock latches that secure the lift to each column. Locate the six rods:

a. 2 - long rods

b. 2 - short rods

c. 1 - handle rod

d. 1 - T rod

Also locate hardware:

a. 1 - rod coupling with 2 jam nuts

b. 8 - heim ends with connecting nuts and bolts

c. 2 - spacers

21. Slip spacer over threaded end of handle rod and insert rod into hole on cross bar near power column.

22. Slip spacer over threaded end of T-rod and insert end into hole located on opposite cross rail, taking care

to run rod through rod guide located under ramp.

23. Thread jam nuts onto ends of handle rod and T-rod. Attach the handle rod to the T-rod using the rod

coupling. Adjust coupling to take the slack out of the rods. The rods should remain free enough to move

with no slack. Do not tighten coupler or lock nuts at this time.

24. Locate the two long rods and remove one end from each rod and slide off the eye bolt. Attach eye bolts

to center of cross rails by threading 1/2 of the way in and tighten jam nut.

6

25. Attach short rod on the Tside lock and to the bottom of the T and hand tighten. Slide long rod through the

eye bolt and attach one end to the top side of the T. Attach the other end of the long rod to the lock on

the other side. Repeat this process for the other end of the lift. The locking rods should be in perfect

alignment since the lift is still sitting in the lock position. Tighten all jam nuts, making sure the linkage

does not bind.

26. Go back to the coupler that attaches the T rod to the handle rod and tighten the jam nuts. Do not adjust

coupler, only tighten the jam nuts.

27. FINAL ADJUSTMENTS - Fill the tank with three gallons of R & O, ISO32 Hydraulic Oil (Available at any

auto supply store). Dexron III Transmission Fluid can also be used.

28. Check over cables and make sure they are all in their pulleys. Press the up switch on the power unit and

the fluid will start to pump into the cylinder. The lift will eventually rise after the cylinder fills up. Once

the lift is raised off of the locks, release the up switch and pull the lock lever to disengage the locks and

lower the lift with the lowering lever on the power unit. Hold lever after lift reaches the very bottom until

you hear all of the air escape.

29. Raise the lift up to the point where the square block above the lock aligns with the second column lock,

and stop. Look at each column lock to determine the highest point. Adjust the cable on the highest point

column until three threads pass through the nylock nut. Now adjust the other three cables to match this

height.

NOTE: There will be some initial stretching of the cables in the beginning. It will be necessary to readjust the

cables a week after first use, then every six months thereafter. Run the lift up and down a few times to insure

that the locks are engaging uniformly and that the safety release mechanisms are functioning properly. Readjust

if necessary.

After the cables are installed and adjusted, unbolt the sheave covers (Item # 69), Figure # 2. Slide the sheave

covers up the cable until you can access the cable sheave. Install the 8mm cable retention bolts into the

threaded holes by the sheaves at the end of the crossbeams (Item # 101and 102) Figure # 2. Assure they extend

across the width of the sheaves and the bolt heads do not interfere with the sheaves. Install the 8mm lock nuts

to the end of the bolts to lock them into position. Re-install sheave covers.

7

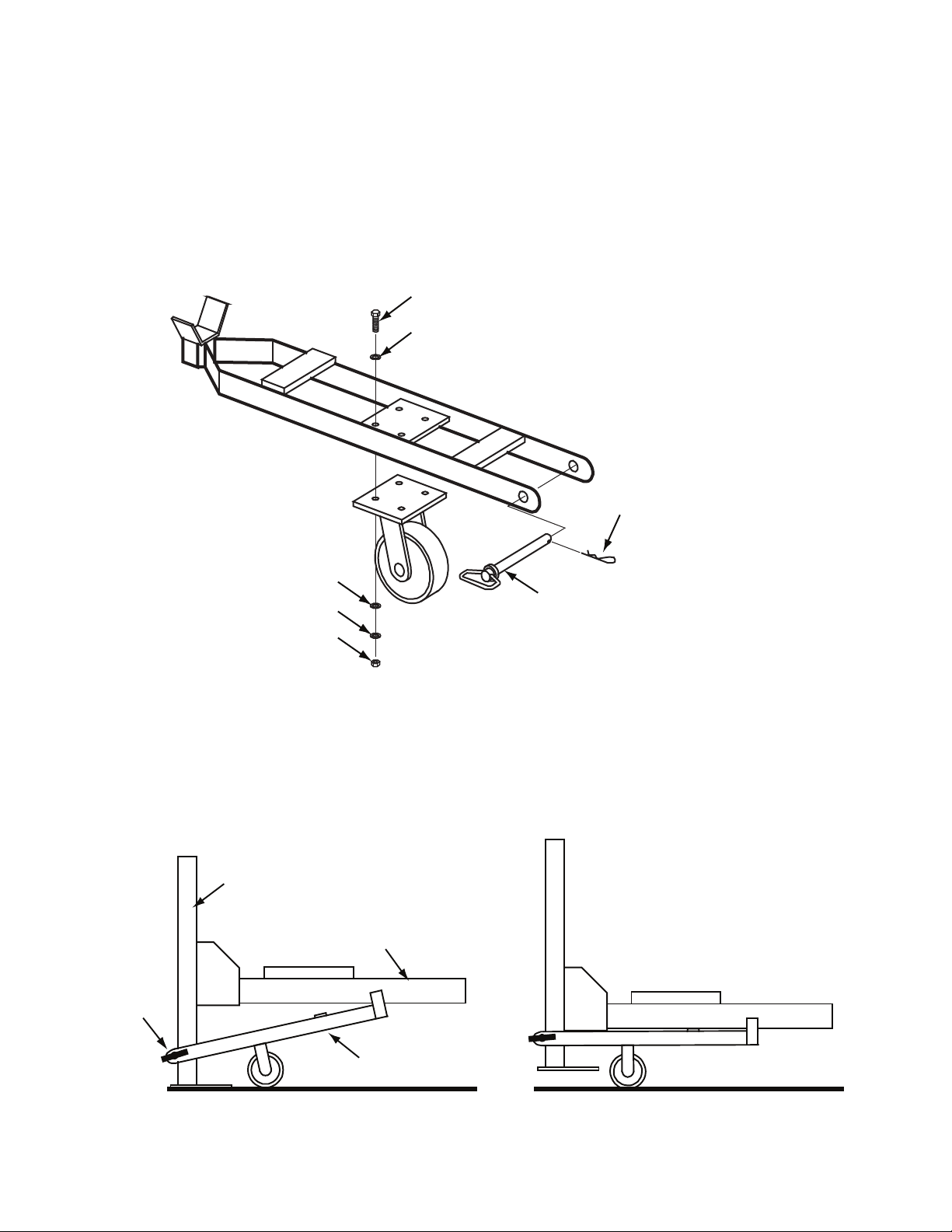

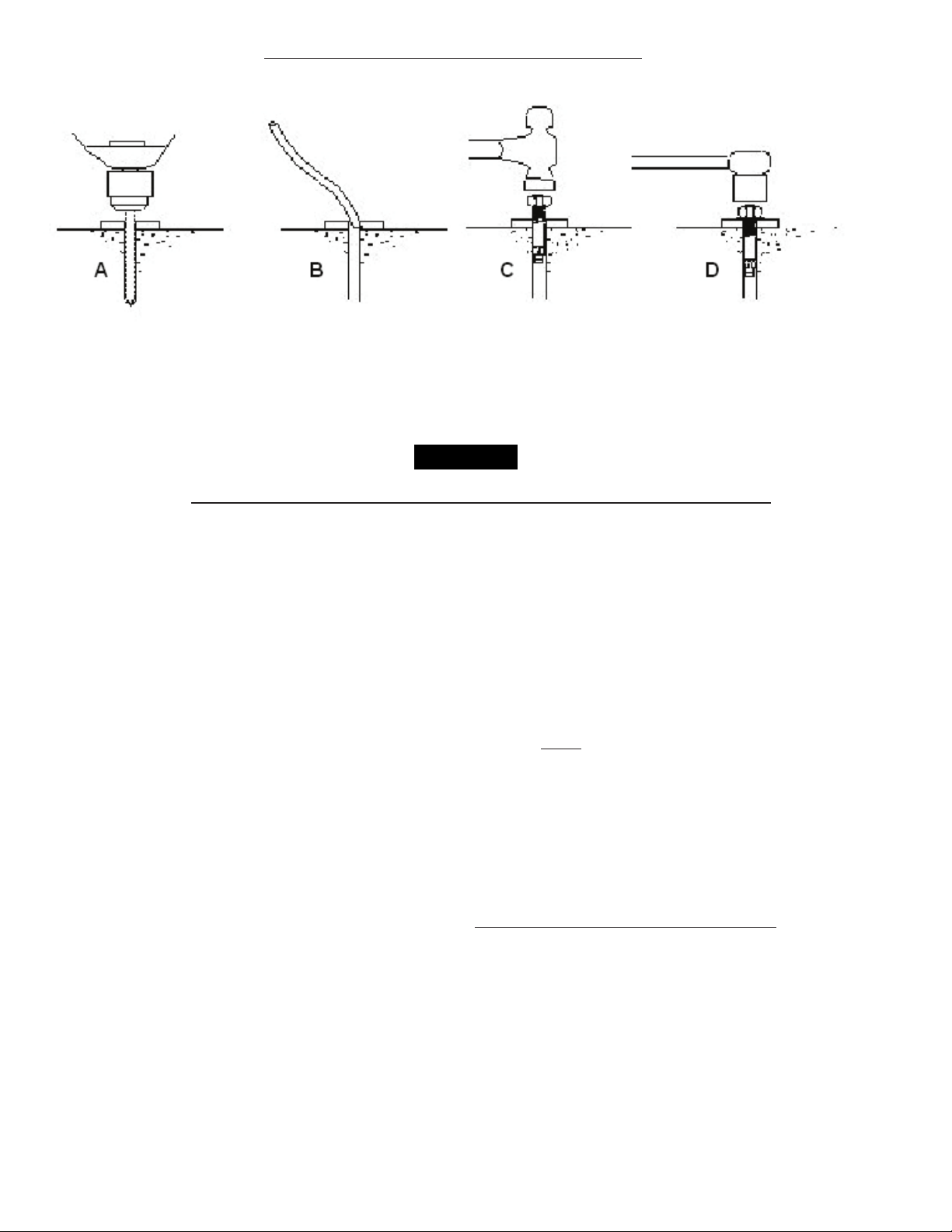

OPTIONAL CASTER KIT

1. Install caster wheels to caster frames as shown.

NOTE: Hitch Pin and Hairpin Clip will be used to attach casters to lift in following steps. DO NOT Install at this

time.

M10 x 1-3/8” Bolt

Ø10 Flat Washer

Hairpin Clip

Ø10 Flat Washer

Ø10 Lock Washer

M10 Nut

Hitch Pin

1. Raise lift 2' - 3' high.

2. Place caster assemblies under crossbeams as shown. Secure with Hitchpin and Hairpin Clip.

3. Lower lift and the columns will automatically raise off the floor.

Column

Crossbeam

Lower Lift and weight of crossbeam

will automatically raise columns off

the ground.

Hitch Pin &

Hairpin Clip

Caster

8

FOUNDATION REQUIREMENTS

Concrete shall have compression strength of at least 3,000 PSI and a minimum thickness of 4”.

CAUTION!

DO NOT use on asphalt or similar unstable surfaces.

SPECIAL NOTE

This Lift does not require bolting to the floor

(BUT)

If you choose the option to anchor the Lift to the floor please follow

the detailed instructions and criteria below.

FOUNDATION and ANCHORING REQUIREMENTS

1. Concrete shall have compression strength of at least 3,000 PSI and a minimum thickness of 4” in order

to achieve a minimum anchor embedment of 3 ¼”. NOTE: When using (¾” x 5 ½”) long anchors; if the

top of the anchor exceeds 2 ¼” above the floor grade, you DO NOT have enough embedment.

2. Maintain a 6” minimum distance from any slab edge or seam. Hole to hole spacing should be a

minimum 6 ½” in any direction. Hole depth should be a minimum of 4”.

3. Shim each column base as required until each column is plumb. If one column has to be elevated to

match the plane of the other column, full size base shim plates should be used. Torque anchors to 85

ft-lbs. Shim thickness MUST NOT exceed ½” when using the 5 ½” long anchors with the lift. Adjust the

column extensions plumb.

4. If anchors do not tighten to 85 ft-lbs. installation torque, replace the concrete under each column base

with a 4’ x 4’ x 6” thick 3,000 PSI minimum concrete pad keyed under and flush with the top of existing

floor. Allow concrete to cure before installing lifts and anchors (typically 2 to 3 weeks).

9

ANCHORING TIP INSTRUCTIONS

CAUTION!

Anchors must be at least 6” from the edge of the slab or any seam.

1. Use a concrete hammer drill with a carbide tip, solid drill bit the same diameter as the anchor,

¾”. (.775 to .787 inches diameter). Do not use excessively worn bits or bits which have been

incorrectly sharpened.

2. Keep the drill in a perpendicular line while drilling.

3. Let the drill do the work. Do not apply excessive pressure. Lift the drill up and down

occasionally to remove residue to reduce binding.

4. Drill the hole to depth equal to the length of anchor. Note: Drilling thru concrete (recommended)

will allow the anchor to be driven thru the bottom of foundation if the threads are damaged or if

the lift will need to be relocated.

5. For better holding power blow dust from the hole.

6. Place a flat washer and hex nut over threaded end of anchor, leaving approximately ½ inch of

thread exposed carefully tap anchor. Do not damage threads. Tap anchor into the concrete until

nut and flat washer are against base plate. Do not use an impact wrench to tighten! Tighten the

nut, two or three turns on average concrete (28-day cure). If the concrete is very hard only one

or two turns may be required. Check each anchor bolt with torque wrench set to 85 foot pounds.

10

CAUTION NOTE !!

LUBRICATE ALL CABLE SHEAVES, BEARINGS, AND SHAFTS WITH GREASE PRIOR TO OPERATING THE LIFT. LUBRICATE

ALL ON AN ANNUAL BASIS.

Motors and all electrical components are not sealed against the weather and moisture. Install this lift in a

protected indoor location. Failure by the owner to provide the recommended shelter could result in

unsatisfactory lift performance, property damage, or personal injury.

OWNER / EMPLOYER RESPONSIBILITIES

The Owner / Employer:

• Shall ensure that lift operators are qualified and that they are trained in the safe use and operation of the lift using the

manufacturer’s operating instructions; ALI/SM01-1, ALI Lifting it Right safety manual; ALI/ST-90 ALI Safety Tips card;

ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation,

Inspection and Maintenance; ALI/WL Series, ALI Uniform Warning Label Decals/Placards; and in the case of frame

engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/Quick Reference Guide for Frame Engaging Lifts.

• Shall establish procedures to periodically inspect the lift in accordance with the lift manufacturer’s instructions or

ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation,

Inspection and Maintenance; and The Employer Shall ensure that lift inspectors are qualified and that they are

adequately trained in the inspection of the lift.

• Shall establish procedures to periodically maintain the lift in accordance with the lift manufacturer’s instructions or

ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation,

Inspection and Maintenance; and The Employer Shall ensure that lift maintenance personnel are qualified and that

they are adequately trained in the maintenance of the lift.

• Shall maintain the periodic inspection and maintenance records recommended by the manufacturer or ANSI/ALI

ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for Operation, Inspection and

Maintenance.

• Shall display the lift manufacturer’s operating instructions; ALI/SM 93-1, ALI Lifting it Right safety manual; ALI/ST-90

ALI Safety Tips card; ANSI/ALI ALOIM-2008, American National Standard for Automotive Lifts-Safety Requirements for

Operation, Inspection and Maintenance; and in the case of frame engaging lifts, ALI/LP-GUIDE, Vehicle Lifting Points/

Quick Reference Guide for Frame Engaging Lifts; in a conspicuous location in the lift area convenient to the operator.

• Shall not modify the lift in any manner without the prior written consent of the manufacturer.

• Shall provide necessary lockout/tagout means for energy sources per ANSI Z244.1-1982 (R1993), Safety Requirements

for the Lockout/Tagout of Energy Sources, before beginning any lift repairs.

Lift Lockout/Tagout Procedure

Purpose

This procedure establishes the minimum requirements for the lockout of energy that could cause injury to personnel by the operation of lifts in need of repair or being serviced. All employees shall comply with this

procedure.

11

Loading...

Loading...