Diodes PDS760 User Manual

Features

• Guard Ring Die Construction for Transient Protection

• Low Power Loss, High Efficiency

• Low Reverse Leakage Current

• For Use in High Frequency Inverters, Free Wheeling, and

Polarity Protection Applications

• High Forward Surge Current Capability

• Lead-Free Finish; RoHS Compliant (Notes 1 & 2)

• Halogen and Antimony Free. “Green” Device (Note 3)

• Qualified to AEC-Q101 Standards for High Reliability

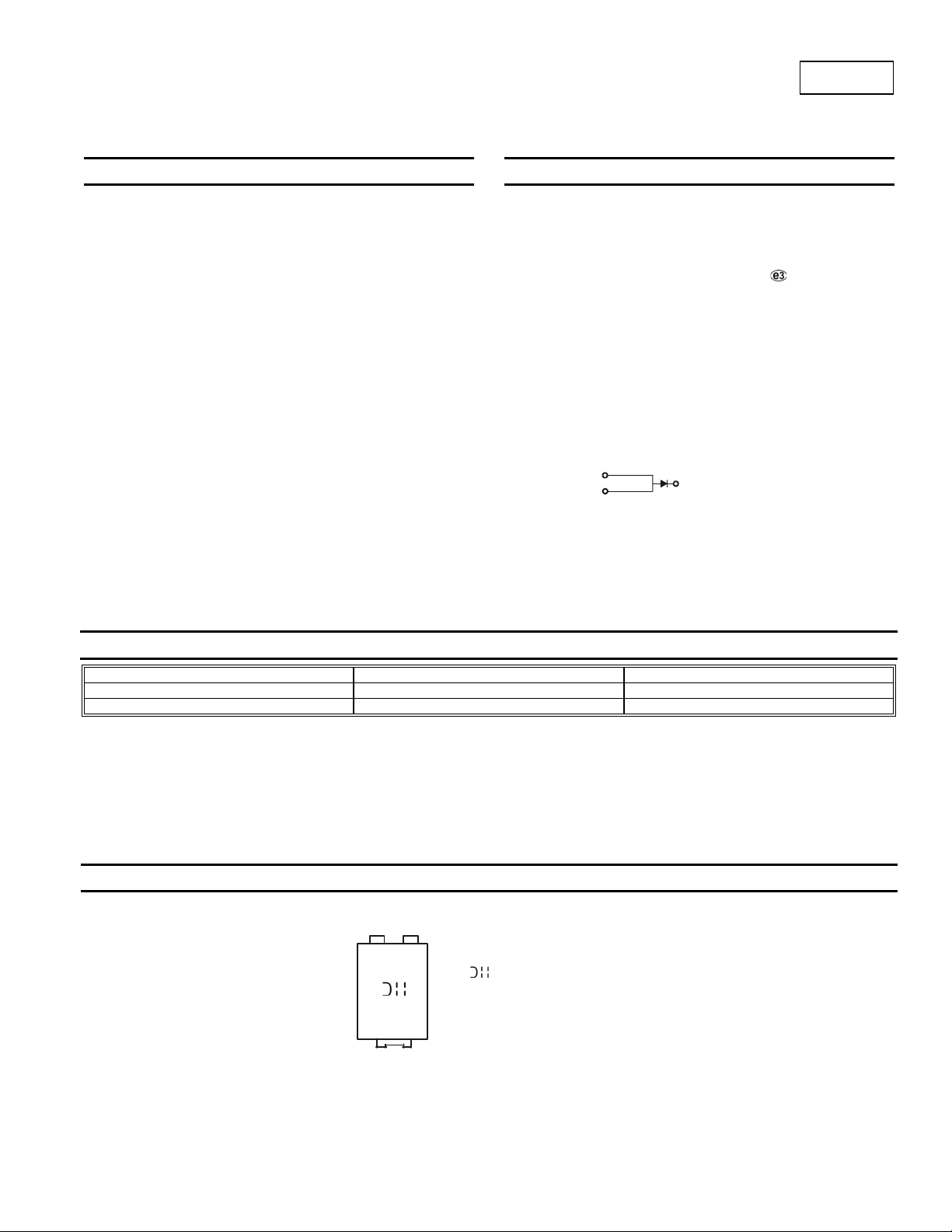

Top View

POWERDI5

Bottom View

Green

7A SCHOTTKY BARRIER RECTIFIER

Mechanical Data

• Case: POWERDI5

• Case Material: Molded Plastic, “Green” Molding Compound. UL

Flammability Classification Rating 94V-0

• Moisture Sensitivity: Level 1 per J-STD-020

• Terminals: Finish – Matte Tin annealed over Copper leadframe.

Solderable per MIL-STD-202, Method 208

• Polarity: See Diagram

• Weight: 0.096 grams (approximate)

LEFT PIN

RIGHT PIN

Note: Pins Left & Right must

be electrically connected

at the printed circuit board.

BOTTOMSIDE

HEAT SINK

PDS760

POWERDI

®

Ordering Information (Note 4)

Part Number Case Packaging

PDS760-13 POWERDI5 5000/Tape & Reel

PDS760-7 POWERDI5 1500/Tape & Reel

Notes: 1. EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant. All applicable RoHS exemptions applied.

2. See http://www.diodes.com for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green" and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

4. For packaging details, go to our website at http://www.diodes.com.

Marking Information

POWERDI is a registered trademark of Diodes Incorporated.

PDS760

Document number: DS30477 Rev. 13 - 2

S760

YYWWK

S760 = Product type marking code

= Manufacturers’ code marking

YYWW = Date code marking

YY = Last two digits of year (ex: 05 for 2005)

WW = Week code (01 - 53)

K = Factory Designator

1 of 5

www.diodes.com

October 2012

© Diodes Incorporated

)

θ

θ

θ

θ

(BR)

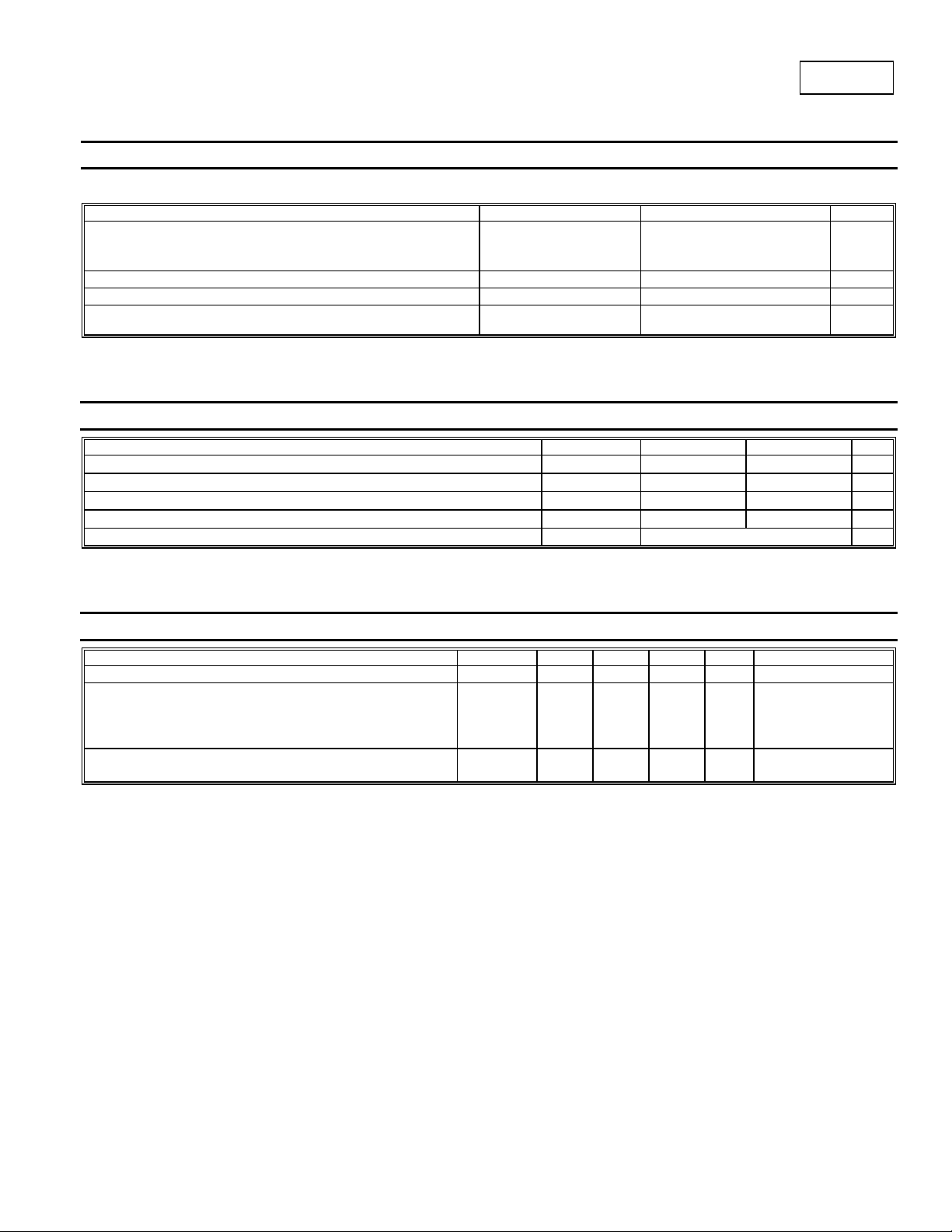

Maximum Ratings (@T

= +25°C, unless otherwise specified.)

A

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitance load, derate current by 20%.

Characteristic Symbol Value Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Rectified Output Current

Non-Repetitive Peak Forward Surge Current

8.3ms Single half sine-wave Superimposed on Rated Load

Thermal Characteristics

Characteristic Symbol Typ Max Unit

Thermal Resistance Junction to Soldering Point

Thermal Resistance Junction to Ambient Air (Note 5) TA = +25°C

Thermal Resistance Junction to Ambient Air (Note 6) TA = +25°C

Thermal Resistance Junction to Ambient Air (Note 7) TA = +25°C

Operating and Storage Temperature Range

V

V

V

RRM

RWM

V

R

R(RMS

I

O

I

FSM

PDS760

R

JS

R

JA

R

JA

R

JA

, T

T

J

STG

60 V

42 V

7 A

275 A

⎯

85

70

45

1.5

⎯

⎯

⎯

-65 to +150

°C/W

°C/W

°C/W

°C/W

°C

Electrical Characteristics (@T

= +25°C, unless otherwise specified.)

A

Characteristic Symbol Min Typ Max Unit Test Condition

Reverse Breakdown Voltage (Note 8)

V

R

60

⎯

Forward Voltage

V

F

⎯

⎯

⎯

Reverse Leakage Current (Note 8)

Notes: 5. FR-4 PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com.

6. Polymide PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com.

7. Polymide PCB, 2 oz. Copper. Cathode pad dimensions 9.4mm x 7.2mm. Anode pad dimensions 2.7mm x 1.6mm.

8. Short duration pulse test used to minimize self-heating effect.

9. Polymide PCB, 2 oz. Copper. Cathode pad dimensions 18.8 mm x 14.4 mm. Anode pad dimensions 5.6 mm x 3.0 mm.

I

R

⎯

⎯

⎯ ⎯

0.48

0.41

0.56

0.50

6

4

0.54

0.47

0.62

0.56

200

20

V

V

μA

mA

IR = 0.2mA

I

= 3.5A, TS = +25°C

F

I

= 3.5A, TS = +125°C

F

= 7A, T

I

F

I

= 7A, TS = +125°C

F

= +25°C, VR = 60V

T

S

= +125°C, VR = 60V

T

S

= +25°C

S

POWERDI is a registered trademark of Diodes Incorporated.

PDS760

Document number: DS30477 Rev. 13 - 2

2 of 5

www.diodes.com

October 2012

© Diodes Incorporated

Loading...

Loading...