Diodes PD3S130L User Manual

Please click here to visit our online spice models database.

Features

• Ultra-Small Surface Mount Package

• Guard Ring Die Construction for Transient Protection

• High Surge Capability

• Lead Free Finish, RoHS Compliant (Note 1)

• "Green" Molding Compound (No Br, Sb)

• Qualified to AEC-Q101 Standards for High Reliability

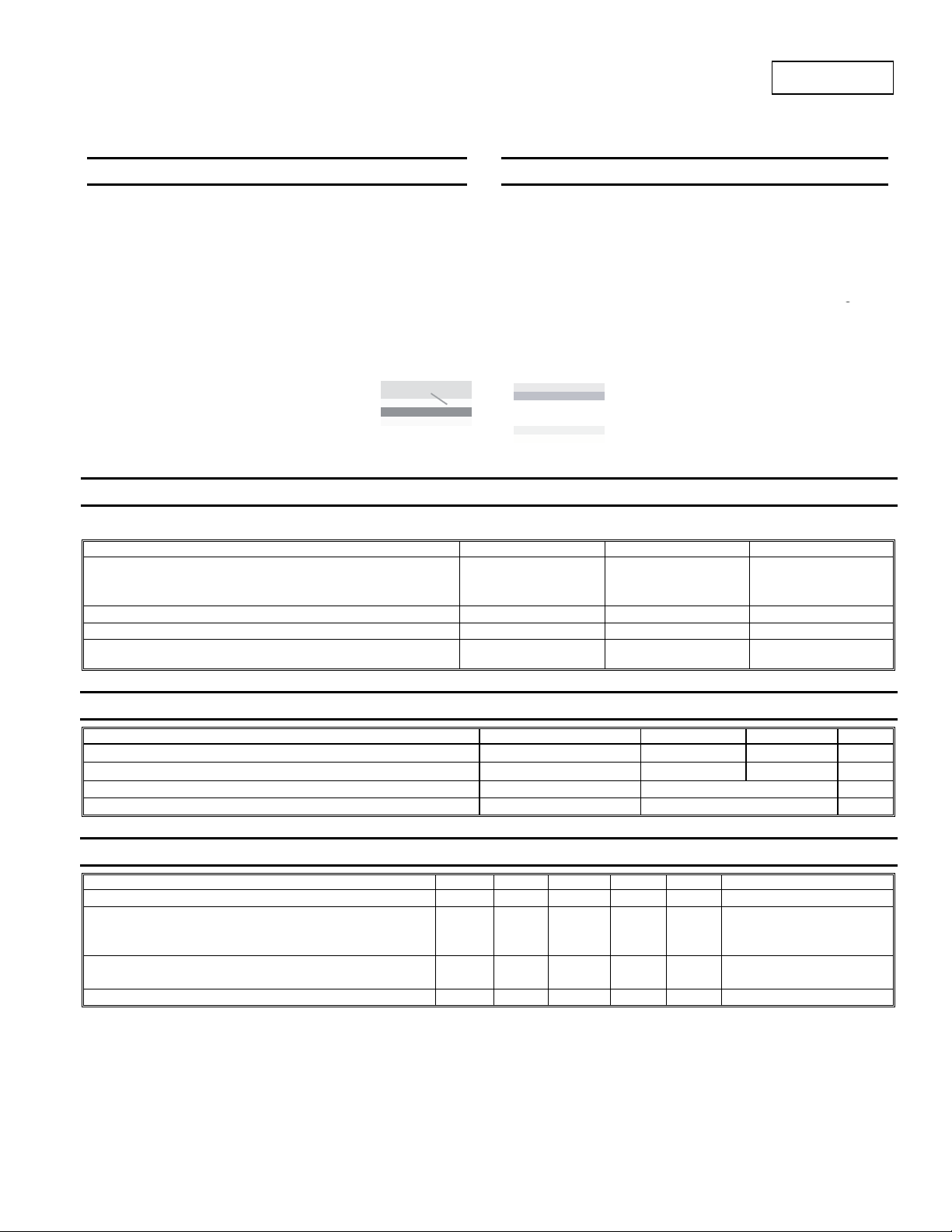

Maximum Ratings @T

Single phase, half wave, 60Hz, resistive or inductive load.

For capacitance load, derate current by 20%.

Characteristic Symbol Value Unit

Peak Repetitive Reverse Voltage

Working Peak Reverse Voltage

DC Blocking Voltage

RMS Reverse Voltage

Average Forward Current (See also figure 4)

Non-Repetitive Peak Forward Surge Current 8.3ms

Single Half Sine-Wave Superimposed on Rated Load

= 25°C unless otherwise specified

A

Top View

PD3S130L

1.0A SURFACE MOUNT SCHOTTKY BARRIER RECTIFIER

PowerDI

®

323

Mechanical Data

• Case: PowerDI®323

• Case Material: Molded Plastic, “Green” Molding Compound.

UL Flammability Classification Rating 94V-0

• Moisture Sensitivity: Level 1 per J-STD-020D

• Polarity: Cathode Band

• Terminals: Finish - Matte Tin annealed over Copper

leadframe. Solderable per MIL-STD-202, Method 208

• Marking Information: See Page 3

• Ordering Information: See Page 3

• Weight: 0.006 grams (approximate)

Bottom View

V

V

V

R(RMS)

I

F(AV)

I

RRM

RWM

VR

FSM

30 V

21 V

1.0 A

22 A

Thermal Characteristics

Characteristic Symbol Typ Max Unit

Thermal Resistance Junction to Soldering Point

Thermal Resistance Junction to Ambient Air (Note 2)

Operating Temperature Range

Storage Temperature Range

Electrical Characteristics @T

Characteristic Symbol Min Typ Max Unit Test Condition

Reverse Breakdown Voltage (Note 3)

Forward Voltage

Leakage Current (Note 3)

Total Capacitance

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied, see EU Directive 2002/95/EC Annex Notes.

PowerDI is a registered trademark of Diodes Incorporated.

PD3S130L

Document number: DS30671 Rev. 9 - 2

2. FR-4 PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com/datasheets/ap02001.pdf. T

3. Short duration pulse test used to minimize self-heating effect.

= 25°C unless otherwise specified

A

1 of 3

30

⎯

⎯

⎯

⎯

⎯

V

(BR)R

VF

IR

CT ⎯

www.diodes.com

R

JS

θ

R

JA

θ

TJ

T

STG

⎯ ⎯

0.25

0.33

0.39

40

0.37

40

0.33

0.37

0.42

250

1.5

⎯

⎯

177

-65 to +125

-65 to +150

V

IR = 1.5mA

IF = 0.1A

V

IF = 0.7A

IF = 1.0A

VR = 5V, TA = 25°C

μA

mA

VR = 30V, TA = 25°C

pF

VR = 10V, f = 1.0MHz

= 25°C.

A

6.0

⎯

June 2008

© Diodes Incorporated

°C/W

°C/W

°C

°C

P, P

OWER

P

TIO

NSTAN

TANEO

US F

O

R

RD CUR

REN

T

C, TOT

CAPACITAN

C

F

NSTAN

TANEO

US R

R

CUR

REN

T

T

R

T

T T

PERATUR

C

R

G

FORWAR

C

URREN

T

PD3S130L

0.9

0.8

0.7

N (W)

0.6

A

0.5

DISSI

0.4

10,000

(mA)

1,000

100

WA

10

0.3

D

0.2

1

0.1

0.1

F

I, I

0.200.4

V , INSTANT ANEOU S FORWARD VOL TAGE (V)

F

0.6 0.8 1.0

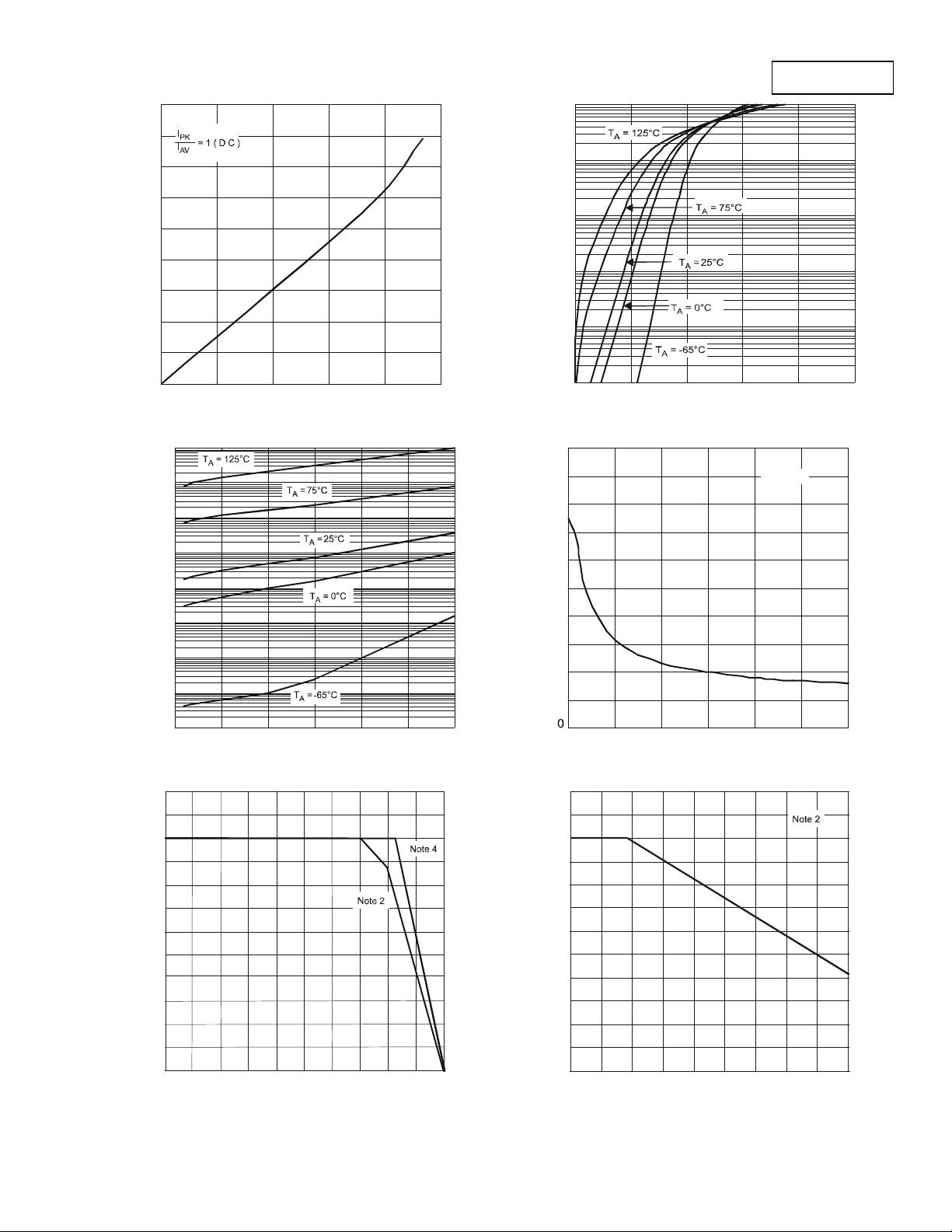

Fig. 2 Typical Forward Ch ar acteristics

200

f = 1MHz

)

E (p

180

160

140

120

100,000

(uA)

10,000

1,000

100

SE

0

0

0.5 1.0 1.5

I , AVERAGE FORWARD CURRENT (A)

F(AV)

Fig. 1 Forward Power Dissipation

2.0 2.5

AL

100

80

EVE

10

1

60

I, I

R

0.001

(A)

0.1

0.01

0

V , INSTANTANEOUS REVERSE VOLTAGE (V)

R

10 15 20

5

Fig. 3 Typical Reverse Characteristics

1.2

1.0

0.8

25

30

T

40

20

0 5 10 15 20 25 30

V , DC REVERSE VOLTAGE (V)

R

Fig. 4 Total Capacitance vs. Reverse Voltage

150

)

E (°

125

100

D

EM

0.6

E

0.4

A

75

50

ED AMBIEN

0.2

F(AV)

I, AVE

0

0255075

T , AMBIENT TEMPERATURE (°C)

A

Fig. 5 Forward Current Derating Curve

Notes: 4. Polymide PCB, 2 oz. Copper, minimum recommended pad layout per http://www.diodes.com/datasheets/ap02001.pdf.

100

125

A

25

, DE

A

0

0

Fig. 6 Oper at ing Tempe r ature Derati ng

10 20 30

V , DC REVERSE VOL TAGE (V)

R

owerDI is a registered trademark of Diodes Incorporated.

P

PD3S130L

Document number: DS30671 Rev. 9 - 2

2 of 3

www.diodes.com

June 2008

© Diodes Incorporated

Loading...

Loading...