Page 1

Description

These devices are precision timing circuits capable of

producing accurate time delays or oscillation. In the timedelay or monostable mode of operation, the timed interval is

controlled by a single external resistor and capacitor network.

In the astable mode of operation, the frequency and duty

cycle can be controlled independently with two external

resistors and a single external capacitor.

The threshold and trigger levels normally are t wo-thirds and

one-third, respectively, of V

by use of the control-voltage terminal. When the trigger input

falls below the trigger level, the flip-flop is set, and the out put

goes high. If the trigger input is above the trigger level and

the threshold input is above the threshold level, the flip-flop is

reset and the output is low. The reset (RESET) input can

override all other inputs and can be used to initiate a new

timing cycle. When RESET goes low, the flip-flop is reset,

and the output goes low. When the output is low, a lowimpedance path is provided between discharge (DISCH) and

NEW PRODUCT

ground.

The output circuit is capable of sinking or sourcing current up

to 200mA. Operation is specified for supplies of 5V to 15V.

With a 5-V supply, output levels are compatible with TTL

inputs.

Features

. These levels can be altered

CC

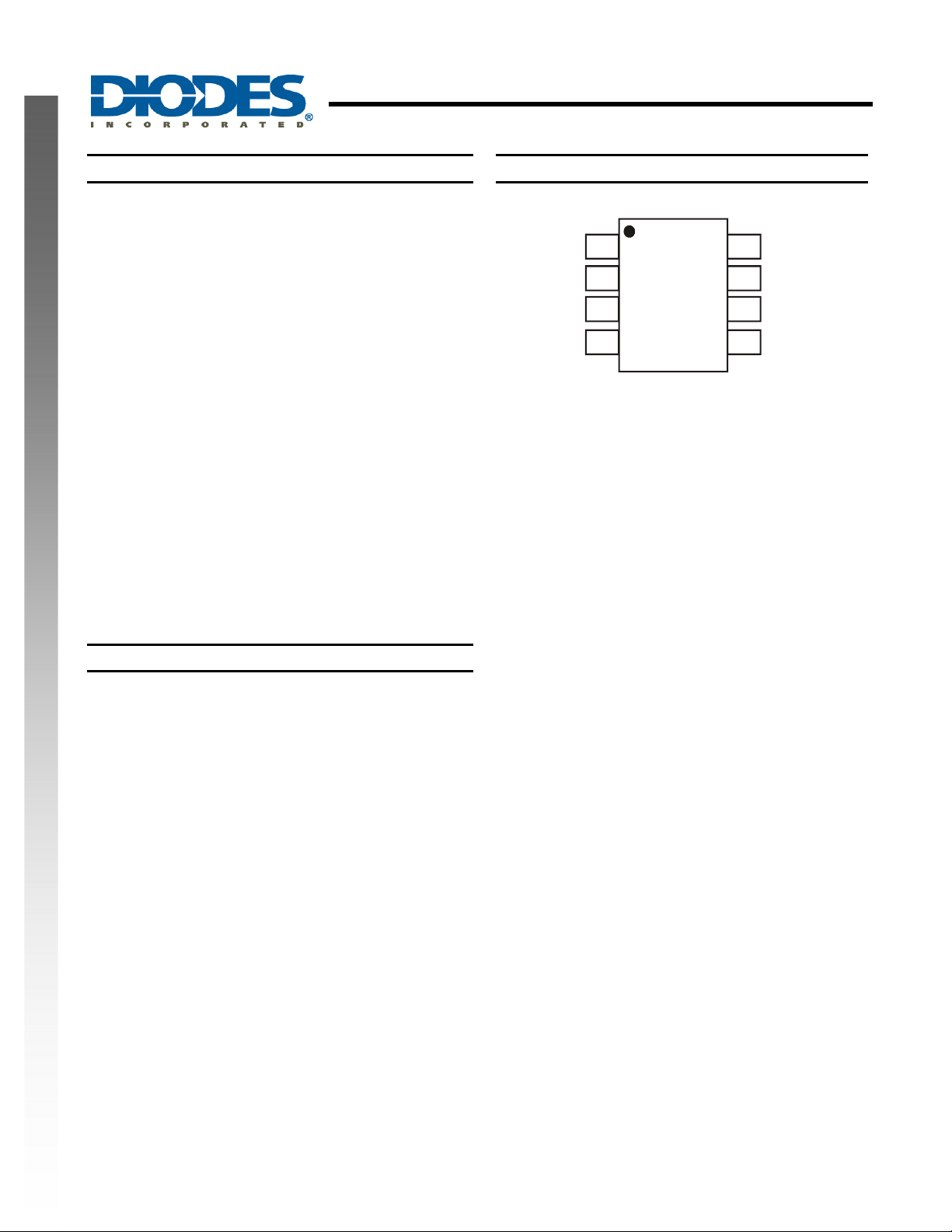

NE555/SA555/NA555

Pin Assignments

(Top View)

GND

TRIG

OUT

RESET

PRECISION TIMERS

SO-8

V

CC

DISCH

THRES

CONT

• Timing from microseconds to hours

• Astable or monostable operation

• Adjustable duty cycle

• TTL compatible output can source or sink up to 200mA

• “Green” Molding Compound (No Br, Sb)

• Lead Free Finish/ RoHS Compliant (Note 1)

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at

http://www.diodes.com/products/lead_free.html.

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

1 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 2

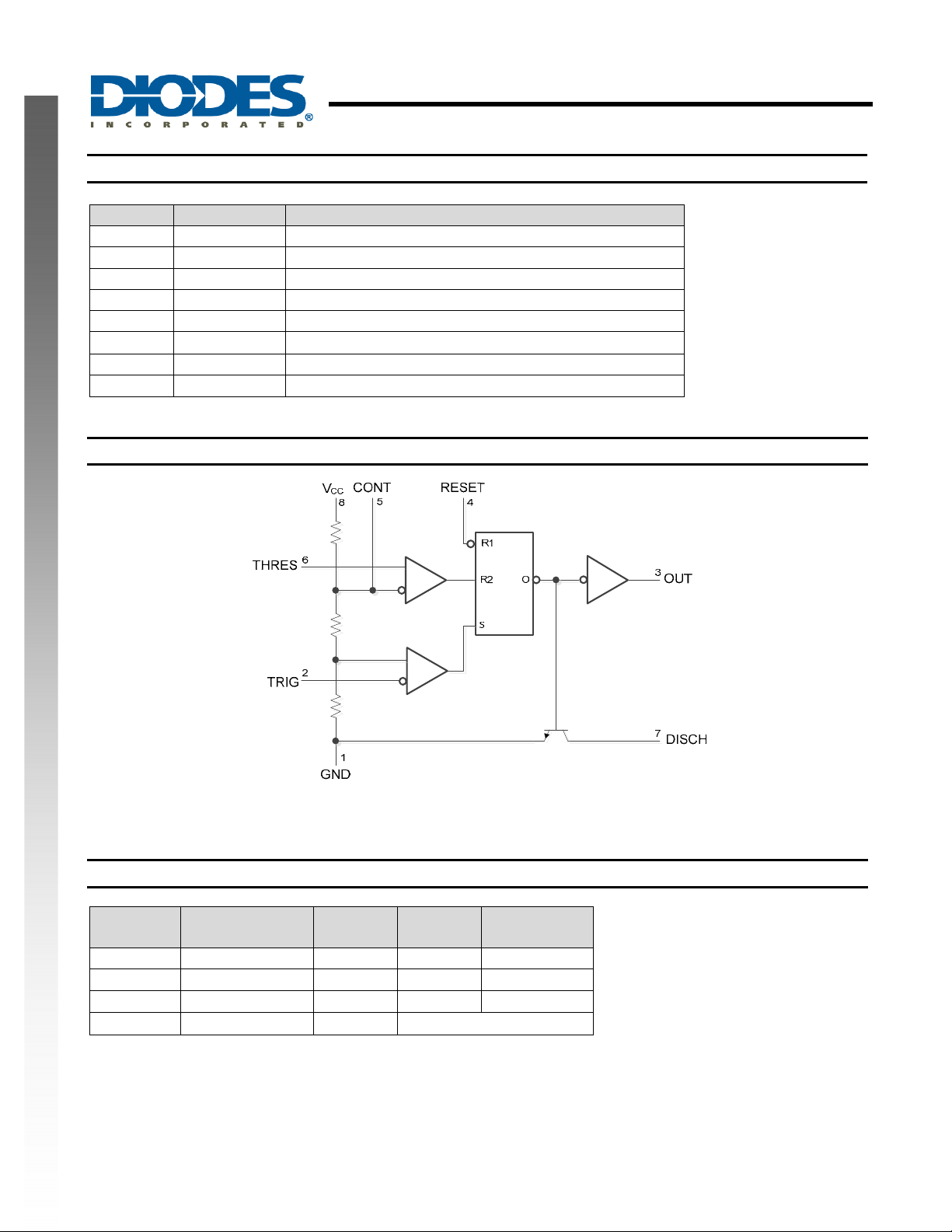

Pin Descriptions

Pin Name Pin Number Description

GND 1 Ground

TRIG 2

OUT 3 Timer output

RESET 4 Reset active low

CONT 5 External adjustment of internal threshold and trigger voltages

THRES 6

DISCH 7 Low impedance discharge path

VCC

Functional Block Diagram

NEW PRODUCT

Functional Table

Pin Name

GND Irrelevant Irrelevant Low On

TRIG

OUT

RESET

Nominal Trigger

Voltage

<1/3V

<1/3V

<1/3V

Trigger set 1/3V

Threshold set to 2/3 V

8 Chip supply voltage

CC

RESET can override TRIG, which can override THRESH

Threshold

Voltage

CC

<2/3VCC

CC

<2/3VCC

CC

Irrelevant High Off

NE555/SA555/NA555

CC

Output

Low On

As previously established

Discharge

Switch

PRECISION TIMERS

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

2 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 3

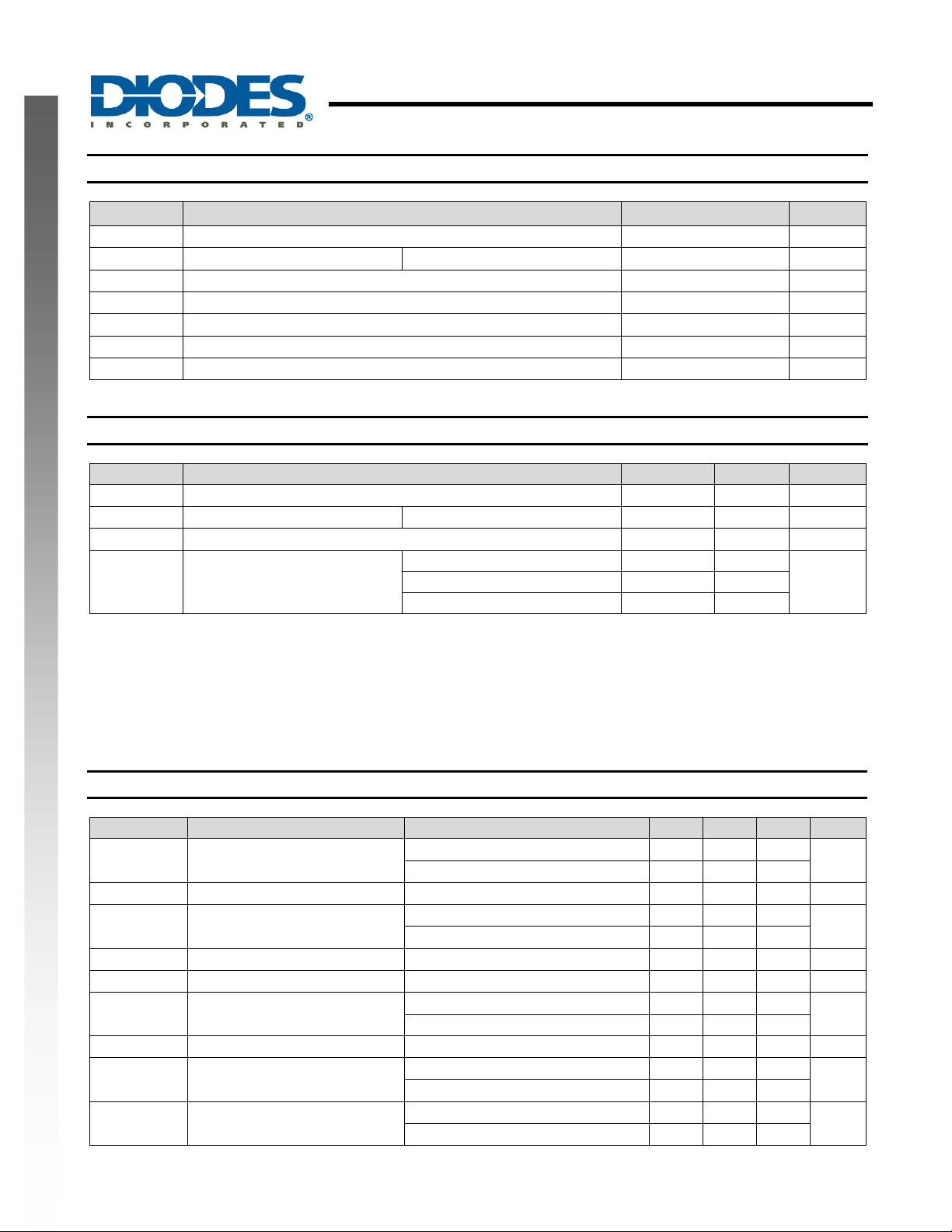

NE555/SA555/NA555

Absolute Maximum Ratings (Note 2) @ T

Symbol Parameter Rating Unit

VCC

VI

IO

θ

JA

θ

JC

TJ

T

STG

Supply voltage (Note 3) 18 V

Input voltage CONT, RESET, THRES, TRIG

Output current ±225 mA

Package thermal resistance Junction-to-Ambient

Package thermal resistance Junction-to-Case

Junction temperature 150 °C

Storage temperature -65 to 150 °C

Recommended Operating Conditions (T

Symbol Parameter Min Max Unit

VCC

VI

NEW PRODUCT

IO

TA

Notes: 2. Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings only.

Functional operation of the device at these or any other conditions beyond those indicated under "recommended operating conditions" is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

3. All voltage values are with respect ground.

4. Maximum power dissipation is a function of T

is P

5. Maximum power dissipation is a function of T

is P

Supply voltage 4.5

Input voltage CONT, RESET, THRES, TRIG

Output current

Operating Ambient Temperature

(max), θJA, and TA. The maximum allowable power dissipation at any allowable ambient temperature

= (TJ(max) – TA)/θJA. Operating at the absolute maximum TJ of 150°C can affect reliability.

D

= (TJ(max) – TC)/θJA. Operating at the absolute maximum TJ of 150°C can affect reliability.

D

J

(max), θJC, and TA. The maximum allowable power dissipation at any allowable ambient temperature

J

Electrical Characteristics (V

= 5V to 15V, TA = 25°C unless otherwise stated)

CC

Symbol Parameter Test conditions Min Typ. Max Unit

VTH

ITH

VTR

ITR

V

RST

I

RST

I

DIS

V

DIS

V

CON

Threshold voltage level

Threshold current

(Note 6) 30 250 nA

Trigger voltage level

Trigger current TRIG at 0V 0.5 2 µA

RESET voltage level 0.3 0.7 1 V

RESET current

DISCH switch off-state current 20 100 nA

DISCH saturation voltage with

output low (Note 7)

CONT voltage (open circuit)

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

= 25°C unless otherwise stated

A

(Note 4) 130 °C/W

(Note 5) 15 °C/W

= 25°C)

A

NE555 0 70

SA555 -40 85

NA555 -40 105

V

= 15V

CC

V

= 5V

CC

= 15V

V

CC

V

= 5V

CC

RESET at V

CC

RESET at 0V -0.4 -1.5

= 15V, I

V

CC

VCC = 5V, I

V

= 15V

CC

V

= 5V

CC

www.diodes.com

DIS

DIS

3 of 14

= 15mA

= 4.5mA

PRECISION TIMERS

VCC

16 V

8.8 10 11.2

2.4 3.3 4.2

4.5 5 5.6

1.1 1.67 2.2

0.1 0.4

180 480

80 200

9 10 11

2.6 3.3 4

V

±200 mA

CC

February 2012

© Diodes Incorporated

V

V

°C

V

V

mA

mV

V

Page 4

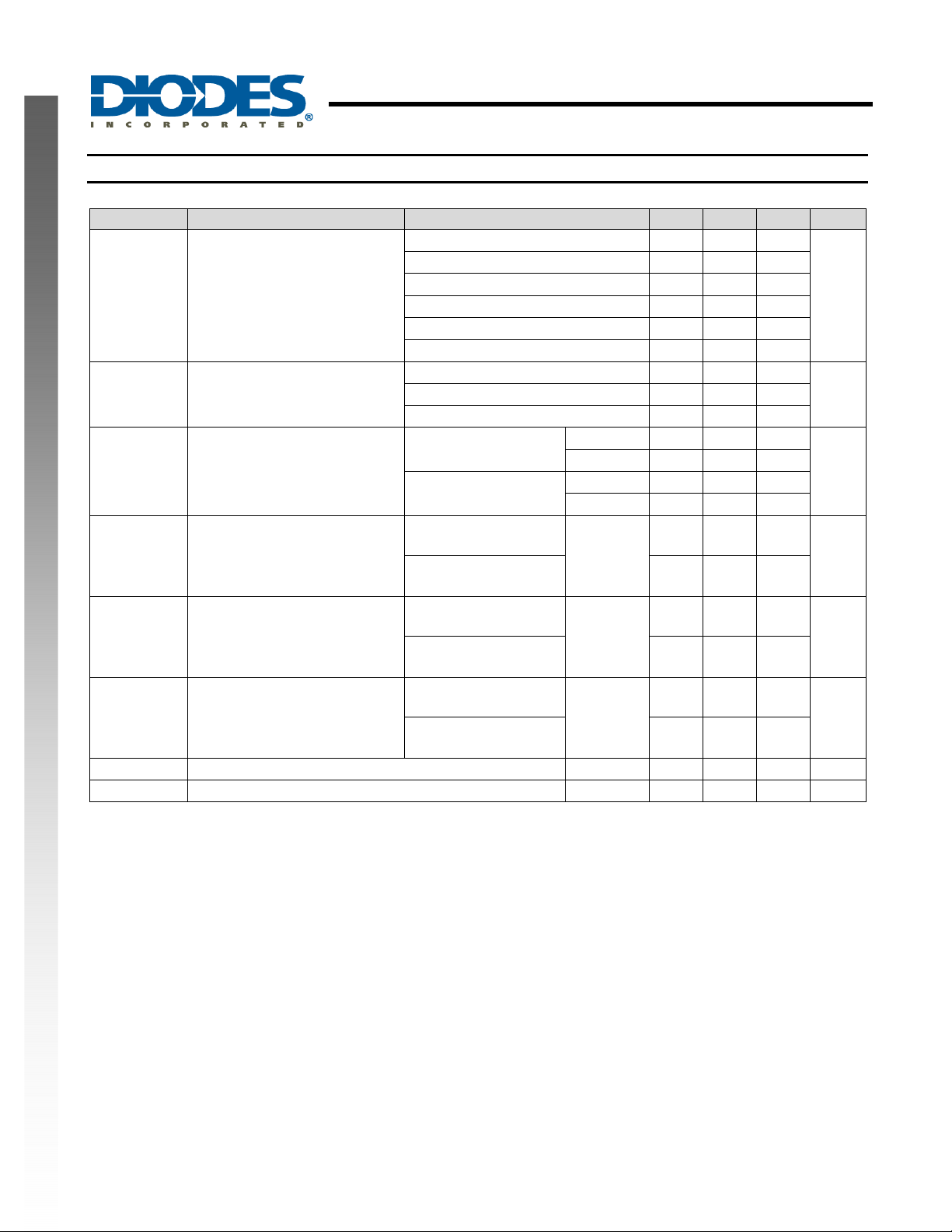

NE555/SA555/NA555

Electrical Characteristics (V

Symbol Parameter Test conditions Min Typ. Max Unit

VOL

VOH

ICC

NEW PRODUCT

TER

TTC

T

VCC

TRI

TFA

Notes: 6. This parameter influences the maximum value of the timing resistors RA and RB in the circuit of Figure 12. For example, when VCC = 5 V, the

maximum value is R = R

7. No protection against excessive pin 7 current is necessary providing package dissipation rating is not exceeded

9. Values specified are for a device in a monostable circuit similar to Figure 9, with the following component values: R

10. Values specified are for a device in an astable circuit similar to Figure 12, with the following component values: R

Low level output voltage

High level output voltage

Supply current

Initial error of timing interval

(Note 8)

Temperature coefficient of timing

interval

Supply voltage sensitivity of

timing interval

Output pulse rise time

Output pulse fall time

+ RB ≉ 3.4MΩ, and for VCC = 15 V, the maximum value is 10MΩ.

A

8. Timing interval error is defined as the difference between the measured value and the average value of a random sample from ea ch process run.

= 5V to 15V, TA = 25°C unless otherwise stated)

CC

V

= 15V, I

CC

V

= 15V, I

CC

V

= 15V, I

CC

V

= 15V, I

CC

V

= 5V, I

CC

V

= 5V, I

CC

= 15V, I

V

CC

V

= 15V, I

CC

V

= 5V, I

CC

Output low, no load

Output high, no load

Each time, monostable

(Note 9)

Each time, astable

= 10mA

OL

= 50mA

OL

= 100mA

OL

= 200mA

OL

= 5mA

OL

= 8mA

OL

= -100mA

OH

= -200mA

OH

= -100mA

OH

V

= 15V

CC

V

= 5V

CC

= 15V

V

CC

V

= 5V

CC

(Note 10)

Each time, monostable

(Note 9)

Each time, astable

T

= full

A

range

(Note 10)

Each time, monostable

(Note 9)

Each time, astable

(Note 10)

CL = 15pF

CL = 15pF

PRECISION TIMERS

0.1 0.25

0.4 0.75

2 2.5

2.5

0.1 0.35

0.15 0.4

12.75 13.3

12.5

2.75 3.3

10 15

3 6

9 13

2 5

1 3

2.25

50

150

0.1 0.5

0.3

100 300 ns

100 300 ns

= 2kΩ to 100kΩ, C = 0.1uF.

A

= 1kΩ to 100kΩ, C = 0.1uF.

A

V

V

mA

%

ppm/°C

%/V

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

4 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 5

O

EVEL OUTP

O

G

E

O

OUTPU

T VOLTAG

O

OUTPU

T VOLTAG

OLTAG

ROP

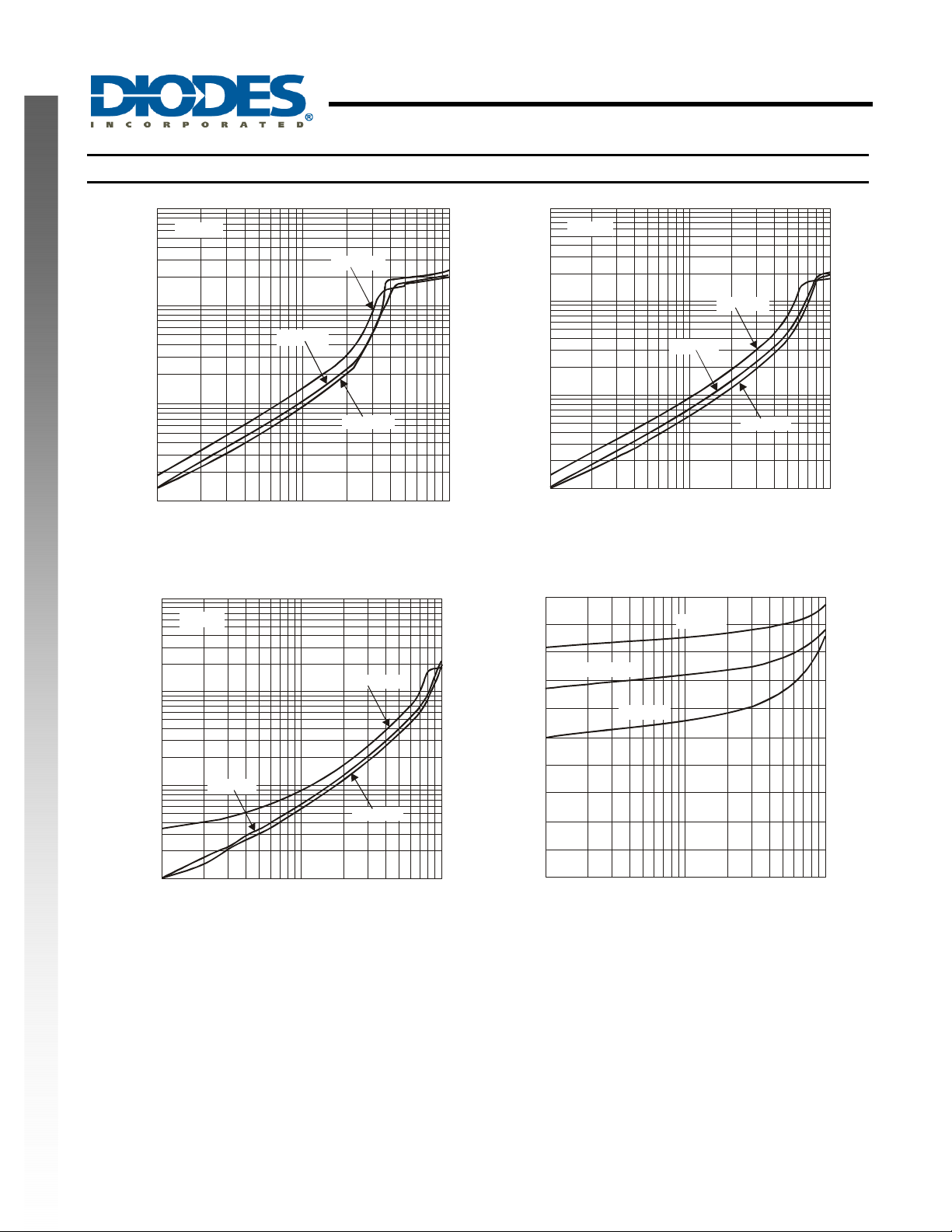

Typical Performance Characteristics

NEW PRODUCT

10

7

(V)

4

2

LTA

1

0.7

UT V

0.4

0.2

0.1

0.07

W - L

0.04

OL

0.02

V - L

0.01

12 7 701004020104

V = 5V

CC

T = 25°C

A

I - LOW LEVEL OUTPUT CURRENT (mA)

OL

Low Level Out put Voltage vs.

Low Level Output Current @ V = 5V

T = 105°C

A

T = -40°C

A

CC

NE555/SA555/NA555

PRECISION TIMERS

10

7

V = 10V

CC

4

E (V)

2

1

0.7

0.4

0.2

0.1

0.07

W - LEVEL

0.04

OL

0.02

V - L

0.01

12 7 701004020104

I - LOW LEVEL OUTPUT CURRENT (mA)

OL

Low Level Output Voltage vs.

Low Level Output Current @ V = 10V

T = 25°C

A

T = 105°C

A

T = -40°C

A

CC

10

7

4

E (V)

2

1

0.7

0.4

0.2

0.1

0.07

W - LEVEL

0.04

OL

0.02

V - L

0.01

12 7 701004020104

V = 15V

CC

T = 105°C

A

T = 25°C

A

T = -40°C

A

I - LOW LEVEL OUTPUT CURRENT (mA)

OL

Low Level Output Voltage vs.

Low Level Output Cu r r ent @ V = 15V

CC

2

1.8

1.6

(V)

1.4

1.2

E D

1

0.8

0.6

CC OH

0.4

(V - V ) V

0.2

0

12 7 701004020104

T = -40°C

A

T = 25°C

A

T = 105°C

A

V = 5V to 15V

CC

I - HIGH LEVEL OUTPUT CURRENT (mA)

OH

Drop Between Sup ply Voltage and Ou tput vs.

High Leve l Output Cur r ent

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

5 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 6

P

U

U

RATIO

N R

T

U

Typical Performance Characteristics

14

Output Low, No Load

12

10

T = -40°C

A

NE555/SA555/NA555

PRECISION TIMERS

(cont.)

1000

900

800

700

NEW PRODUCT

8

6

4

CC

I - SUPPLY CURRENT (mA)

2

0

5 6 7 9 14 15131211108

1.015

1.01

1.005

1

CC

@ V = 10V

0.995

T = 105

A

T = 25

°C

A

V - SUPPLY VOLTAGE (V)

CC

Supply Cu r r ent vs. Supply Voltage

600

°C

500

400

300

200

PD

T - PROPAGATION DELAY TIME (ns)

100

1.015

E

1.01

1.005

IVE to VAL

ELA

A

@ T = 25°C

0.995

0

0 0.05 0.15 0.35 0.40.30.250.20.1

LOWEST LEVEL of TRIGGER PULSE -xV

Propagation Delay Time vs.

Lowest Volt age Level of Tr igger Pulse

1

CC

0.99

PULSE DURATION RELATIVE to VALUE

0.985

02015105

V - SUPPLY VOLTAGE (V)

CC

Normal ized Output Pulse Dur ation

(Monostable Mode) vs. Supply Voltage

LSE D

0.0985

0.99

-75 -50 0 100 125755025-25

T - FREE AIR TEMPERATURE (°C)

A

Normal ized Output Pulse Du r at io n

(Monostable Mode) vs. Free-Air Temperatu r e

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

6 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 7

NE555/SA555/NA555

Typical Applications Characteristics

Monostable Operation

For monostable operation, any of the ‘555 timers can be connected as shown in Figure 1. If the output is low, application of a

negative-going pulse to the trigger (TRIG) sets the internal flip-flop and drives the output high. Capacit or C is then charged

through RA until the voltage across the capacitor reaches the thresh old voltage of the threshold (THRES) input. If TRIG has

returned to a high level, the output of the threshold comparator resets the internal flip-flop, drives the output low, and

discharges C.

NEW PRODUCT

Monostable operation is initiated when TRIG voltage falls below the trigger threshold. Once initiated, the sequenc e ends onl y

if TRIG is high for at least 10μs before the end of the timing interval. When the trigger is grounde d, the comparator storage

time can be as long as 10μs, which limits the minimum monostable pulse width to 10μs. Because of the threshold level and

saturation voltage of Q1, the output pulse duration is approximately tW = 1.1RAC. Figure 3 is a plot of the time constant for

various values of RA and C. The threshold levels and charge rates both are dir ectly proportional to the supply voltage, VCC.

The timing interval is, therefore, independent of the supply voltage, so long as the supply voltage is constant durin g the time

interval.

Applying a negative-going trigger pulse simultaneously to RESET and TRIG during the timing interval discharges C and

reinitiates the cycle, commencing on the positive edge of the reset pulse. T he output is held low as l ong as the reset pulse is

low. To prevent false triggering, when RESET is not used, it should be connected to V

Input

R

A

C

V

CC

(5V to 15V)

8

V

CC

OUT

3

4

7

6

2

5

CONT

RESET

DISCH

THRES

TRIG

GND

1

Fig 1. Monostable operation

R

L

Output

.

CC

PRECISION TIMERS

Fig. 2 Typical Monostable Waveforms

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

Fig. 3 Output Pulse Duration vs. Capacitance

7 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 8

NE555/SA555/NA555

Typical Applications Characteristics (cont.)

Astable Operation

As shown in Figure 4, adding a second resistor, RB, to the circuit of Figure 1 and connecting the trigger input to the threshold

input causes the timer to self-trigger and run as a multivibrator. The capacitor C charges through R

discharges through R

This astable connection results in capacitor C charging and discharg ing between the threshold-voltag e level (≉0.67V

the trigger-voltage level (≉0.33V

and duty cycle) are independent of the supply voltage.

R

A

NEW PRODUCT

R

B

C

. Therefore, the duty cycle is controlled by the values of RA and RB.

B

). As in the monostable circuit, charge and discharge times (and, therefore, the frequency

CC

V

CC

(5V to 15V)

0.01µF

Open

(See Note A)

4

RESET

7

DISCH

6

THRES

2

TRIG

CONT

5

GND

1

V

OUT

CC

R

8

L

3

Output

PRECISION TIMERS

and RB and then

A

CC

) and

Decoupling CONT voltage to ground with a capacitor can

improve operation. This should be evaluated for individual

applications.

Fig. 4 Circuit for Astable Operation

Fig. 5 Typical Astable Waveforms

Figure 5 shows typical waveforms generated during astable operation. The output high-level duration tH and low-level

duration t

can be calculated as follows:

L

t

= 0.693(RA +RB)C

H

t

= 0.693(RB)C

L

Other useful equations are:

period = tH + tL = 0.693(RA + 2RB)C

frequency = 1.44/(R

+ 2RB)C

A

output driver duty cycle = t

/(tH + tL) = RB/(RA + 2RB)

L

output waveform duty cycle = t

/(tH + tL) = 1 – RB/(RA + 2RB)

H

low to high ratio = t

= RB/(RA + RB)

L/tH

Fig. 6 Free Running Frequency

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

8 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 9

NE555/SA555/NA555

Typical Applications Characteristics (cont.)

Missing Pulse Detector

The circuit shown in Figure 7 can be used to detect a missing p ulse or abnormall y long spacing bet ween consecutive pulses

in a train of pulses. The timing interval of the monostable circuit is retriggered continuousl y by the input pulse train as long as

the pulse spacing is less than the timing interval. A longer pulse spacing, missing pulse, or terminated pulse train perm its the

timing interval to be completed, thereby generating an output pulse as shown in Figure 8.

NEW PRODUCT

PRECISION TIMERS

Fig. 7 Circuit for Missing Pulse Dectector

Frequency Divider

By adjusting the length of the timing cycle, the basic circuit of Figure 1 can be made to operate as a freq uency divider. Figur e

9 shows a divide-by-three circuit that makes use of the fact that retriggering cannot occur during the timing cycle.

Fig. 8 Timing Waveforms for Missing Pulse

Dectector

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

Fig. 9 Divide by Three Circuit Waveforms

9 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 10

NE555/SA555/NA555

Typical Applications Characteristics (cont.)

Pulse Width Modulation

The operation of the timer can be modified by modulating the internal threshold and trigger volta ges, which is accomplished

by applying an external voltage (or current) to CONT. Figure 10 shows a circuit for pulse-width modulation. A cont inuous

input pulse train triggers the monostable circuit, and a control signal modulates the threshold voltage. Figure 11 shows the

resulting output pulse-width modulation. While a sine-wave modulation signal is shown, any wave shape could be used.

NEW PRODUCT

PRECISION TIMERS

Fig 10. Circuit for Pulse width modulation

Pulse Position Modulation

As shown in Figure 12, any of these timers can be used as a pulse-position modulator. This application modulates the

threshold voltage and, thereby, the time delay, of a free-runn ing oscillator. Figure 13 shows a triangular-wave modulation

signal for such a circuit; however, any wave shape could be used.

Fig 11. Pulse width modulation timing diagrams

Fig 12. Circuit for pulse position modulation

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

Fig 13. Pulse position modulation timing diagrams

10 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 11

NE555/SA555/NA555

Typical Applications Characteristics (cont.)

Sequential Timer

Many applications, such as computers, require signals for initializing co nditions during start-up. Other applications, such as

test equipment, require activation of test signals in sequence. These timing circuits can be connected to provide such

sequential control. The timers can be used in various combinations of astable or monostable circuit connections, with or

without modulation, for extremely flexible waveform control. Figure 14 shows a sequencer circuit with possible applications in

many systems, and Figure 15 shows the output waveforms.

NEW PRODUCT

Fig 14. Circuit for Sequential Timer

PRECISION TIMERS

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

Fig 15. Sequential timer waveforms

11 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 12

NE555/SA555/NA555

Ordering Information

XXXXX X -X

XXXXX X -X

Device

NE555S-13 0 to 70°C S SO-8 2500/Tape & Reel -13

SA555S-13 -40 to 85°C S SO-8 2500/Tape & Reel -13

NA555S-13 -40 to 105°C S SO-8 2500/Tape & Reel -13

Notes: 10. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf.

NEW PRODUCT

Operating

Temperature

Device

Device

NE555

NE555

SA555

SA555

NA555

NA555

Package

Code

Package

Package

S : SO-8

S : SO-8

Packaging

(Note 10)

Marking Information

SO-8

Packing

Packing

13 : Tape & Reel

13 : Tape & Reel

:

:

Quantity Part Number Suffix

PRECISION TIMERS

13” Tape and Reel

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

12 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 13

Package Outline Dimensions (All Dimensions in mm)

SO-8

e

D

NEW PRODUCT

Suggested Pad Layout

SO-8

b

X

Y

C2

E1

E

A2

A1

Detail ‘A’

h

A3

A

L

°

45

C1

Dimensions Value (in mm)

X 0.60

Y 1.55

C1 5.4

C2 1.27

0.254

Gaug e Plane

Seating Plane

7°~9

°

Detail ‘A’

NE555/SA555/NA555

PRECISION TIMERS

Dim Min Max

SO-8

A - 1.75

A1 0.10 0.20

A2 1.30 1.50

A3 0.15 0.25

b 0.3 0.5

D 4.85 4.95

E 5.90 6.10

E1 3.85 3.95

e 1.27 Typ

h - 0.35

L 0.62 0.82

0° 8°

θ

All Dimensions in mm

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

13 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Page 14

NE555/SA555/NA555

PRECISION TIMERS

NEW PRODUCT

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS

DOCUMENT, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other

changes without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability

arising out of the application or use of this document or any product described herein; neither does Diodes Incorporated convey any

license under its patent or trademark rights, nor the rights of others. Any Customer or user of this document or products described

herein in such applications shall assume all risks of such use and will agree to hold Diodes Incorporated and all the companies

whose products are represented on Diodes Incorporated website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized

sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall

indemnify and hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names

and markings noted herein may also be covered by one or more United States, international or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without

the express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided

in the labeling can be reasonably expected to result in significant injury to the user.

B. A crit ical component is any component in a life support device or system whose failure to perform can be reasonably expected

to cause the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or

systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements

concerning their products and any use of Diodes Incorporated products in such safety-critical, life support devices or systems,

notwithstanding any devices- or systems-related information or support that may be provided by Diodes Incorporated. Further,

Customers must fully indemnify Diodes Incorporated and its representatives against any damages arising out of the use of Diodes

Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

NE555/SA555/NA555

Document number: DS35112 Rev. 4 - 2

14 of 14

www.diodes.com

February 2012

© Diodes Incorporated

Loading...

Loading...