Diodes AP8802H User Manual

AP8802H

R

A

Description

The AP8802H is a step-down DC/DC converter designed to drive

LEDs with a constant current. The device can drive up to thirteen

LEDs, depending on the forward voltage of the LEDs, in series from

a voltage source of 8V to 60V. Series connection of the LEDs

provides identical LED currents resulting in uniform brightness and

eliminating the need for ballast resistors. The AP8802H switches at

frequency up to 700kHz. This allows the use of small size external

components, hence minimizing the PCB area needed.

Maximum output current of AP8802H is set via an external resistor

connected between the V

achieved by applying either a DC voltage or a PWM signal at the

CTRL input pin. An input voltage of 0.2V or lower at CTRL shuts

down the output at SW and puts the device into a low-current

standby state.

Features

• LED driving current up to 1A

PRELIMINARY

• High efficiency up to 95%

NEW PRODUCT

• Operating input voltage up to 60V

• 5% nominal accuracy

• High switching frequency up to 700kHz

• PWM/DC input for dimming control

• Built-in output open-circuit protection

• SO-8EP is available in “Green” Molding Compound (No Br, Sb)

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green" and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl)

and <1000ppm antimony compounds.

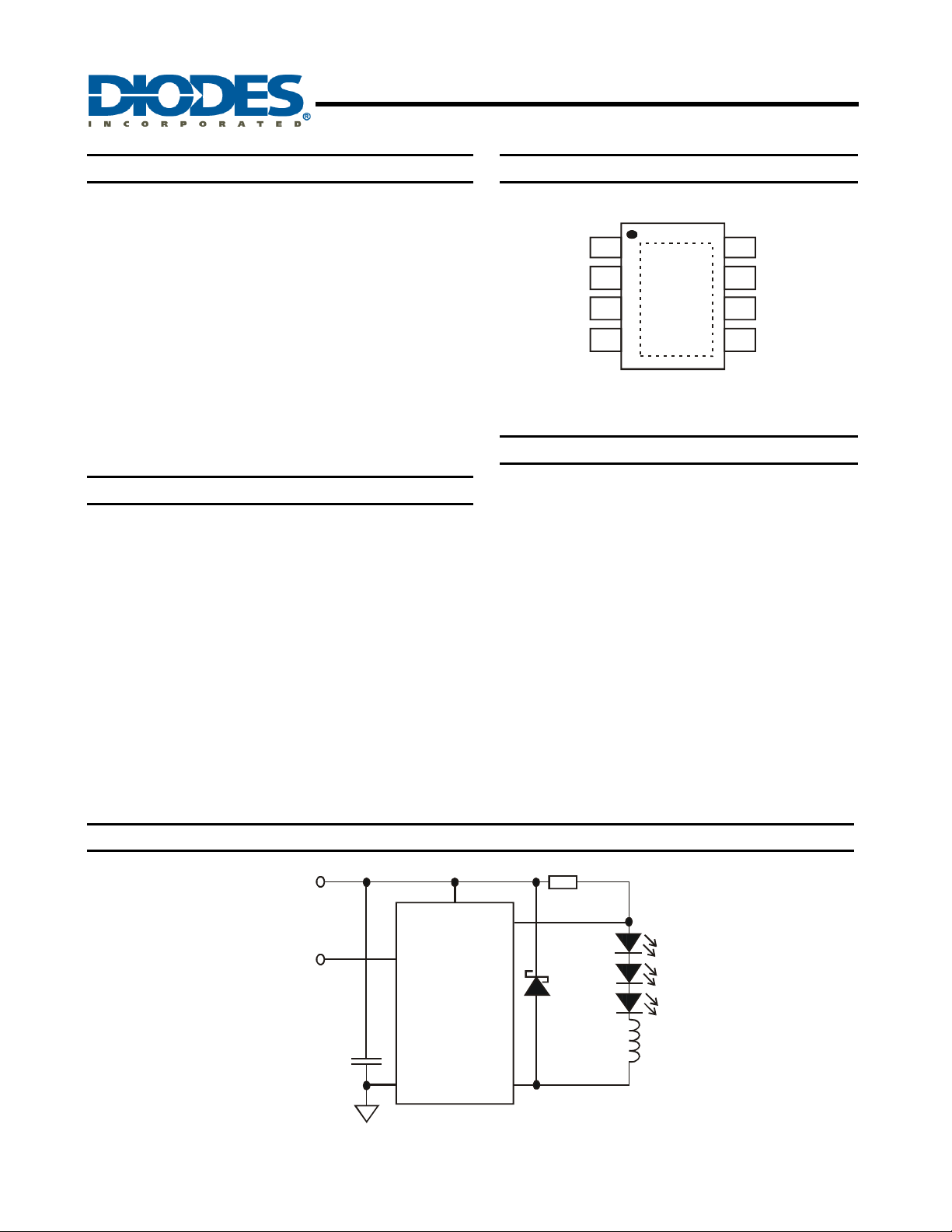

Typical Application Circuit

and SET input pins. Dimming is

IN

60V 1A LED STEP-DOWN CONVERTER

Pin Assignments

(Top View)

SET

GND

NC

V

IN

1

2

3

4

AP8802H

8

7

6

5

CTRL

GND

SW

SW

SO-8EP

Applications

• Commercial & industrial lighting

• Small LCD panel backlight

• Appliances interior lighting

• Architecture Detail lighting

SET

0.33

48V

V

IN

SET

Ω

CTRL

P8802H

D1

PDS3200

L1

C1

2.2µF

AP8802H

Document number: DS32227 Rev. 6 - 2

GND

1 of 14

www.diodes.com

SW

68µF

May 2012

© Diodes Incorporated

Pin Descriptions

Pin Name Function

SW Switch Pin. Connect inductor/freewheeling diode here, minimizing track length at this pin to reduce EMI.

GND GND pin

SET Set Nominal Output Current Pin. Configure the output current of the device.

Dual function dimming control pin with an input impedance approximately 50kΩ.

CTRL

If the CTRL pin is left open then its voltage will default to V

VIN

EP Exposed pad: Internally connected to IC substrate . It should be connected to GND and as large as possible thermal

PRELIMINARY

NEW PRODUCT

NC No connection

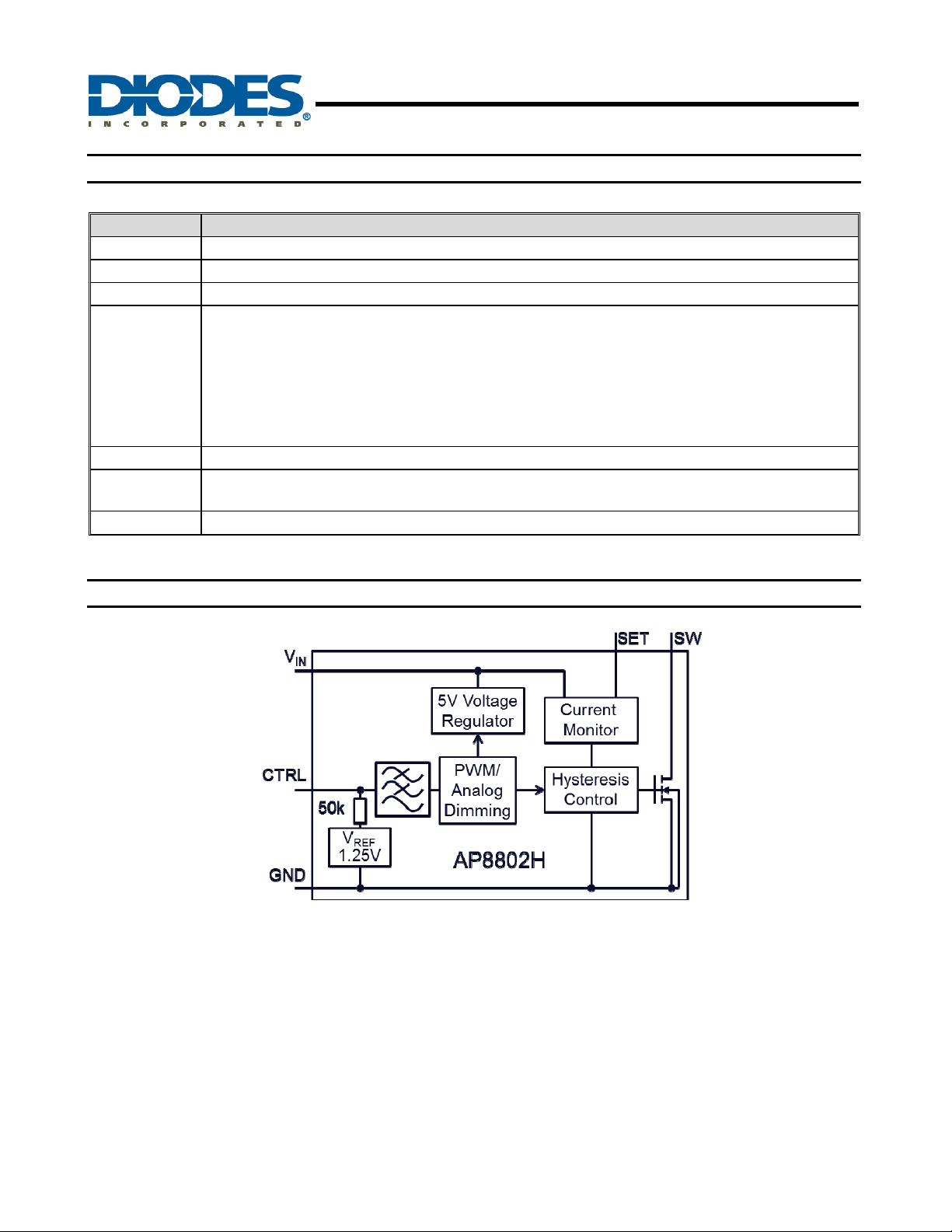

Functional Block Diagram

Input Supply Pin. Must be locally bypassed.

mass for improved thermal impedance and power dissipation capability. See Land Pad diagrams.

AP8802H

60V 1A LED STEP-DOWN CONVERTER

• Input voltage of 0.2V or lower forces the device into low current standby mode and shuts off the output.

• A PWM signal (driven by an open-drain/collector source) allows the output current to be adjusted over a wide

range up to 100%.

• An analog voltage between 0.3V and 2.5V adjusts the output current between 24% and 200% of the current

set by 0.2V/R

.

S

REF

AP8802H

Document number: DS32227 Rev. 6 - 2

Figure. 1 Functional Block Diagram

2 of 14

www.diodes.com

May 2012

© Diodes Incorporated

AP8802H

Absolute Maximum Ratings (Note 4)

Symbol Parameter Rating Unit

VIN VIN pin Voltage

VSW

V

CTRL

V

SENSE

TJ

T

LEAD

T

ST

Note: 4 All voltages unless otherwise stated are measured with respect to GND.

5. V

Caution: Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings

only; functional operation of the device at conditions between maximum recommended operating conditions and absolute maximum ratings is not

implied. Device reliability may be affected by exposure to absolute maximum rating conditions for extended periods of time.

Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when

handling and transporting these devices.

PRELIMINARY

Recommended Operating Conditions

NEW PRODUCT

Symbol Parameter Min Max Unit

VIN

V

CTRLDC

V

CTRLL

f

OSC

TA

Duty Cycle Using Inductor ≥ 100µH (Note 8) 0.10 0.95 —

Notes: 6. For 100% brightness either leave floating or connect to 1.25V relative to GND.

7. AP8802H will operate at higher frequencies but accuracy will be affected due to propagation delays.

8. For most applications the LED current will be within 5% over the duty cycle range specified. Duty cycle accuracy is also dependent on

propagation delay. Smaller size inductors can be used but LED current accuracy may be greater than 8% at extremes of duty cycle. This is most

noticeable at low duty cycles (less than 0.1) or when the input voltage is high and only one LED is being driven.

Electrical Characteristics (V

Symbol Parameter Conditions Min Typ Max Unit

I

OUT

IQ

V

THD

V

SENSEHYS

SET SET pin input current

V

REF

R

DS(ON)

I

SW_LEAKAGE

θ

JA

θ

JC

Notes: 9. Refer to figure 8 for the device derating curve.

10. Test condition for SO-8EP: Device mounted on FR-4 PCB, 2”x2”, 2oz copper, minimum recommended pad layout on top layer and thermal vias to

bottom layer ground plane. See Land pad diagram For better thermal performance, larger copper pad for heat-sink is needed.

SW Voltage -0.3 to +65 V

CTRL Pin Input Voltage -0.3 to +6 V

SET Voltage (Note 5) +0.3 to -5 V

Junction Temperature 150 °C

Lead Temperature Soldering 300 °C

Storage Temperature Range -65 to +150 °C

is measured with respect to V

SENSE

.

IN

Operating Input Voltage relative to GND 8.0 60.0 V

Voltage range for 24% to 200% DC dimming relative to GND (Note 6) 0.3 2.5 V

Voltage Low for PWM dimming relative to GND 0 0.2 V

Maximum Switching Frequency (Note 7) — 625 kHz

Ambient Temperature Range -40 +125 °C

= 12V, TA = +25°C, unless otherwise specified.)

IN

Continuous switch current (Note 9) — — 1 A

Quiescent Current - 75 120 μA

Internal Threshold Voltage 190 200 210 mV

Sense threshold hysteresis — 15 — %

V

SET

Internal Reference Voltage — 1.25 — V

On Resistance of MOSFET

Switch leakage current — - 8 μA

I

SW

= 0.8A

Thermal Resistance Junction-to-Ambient SO-8EP (Note 10) — 45 — °C/W

Thermal Resistance Junction-to-Case SO-8EP (Note 10) — 7 — °C/W

60V 1A LED STEP-DOWN CONVERTER

-0.3 to +65 V

= V

IN

-0.2

— 5 — μA

— 0.65 1.10 Ω

AP8802H

Document number: DS32227 Rev. 6 - 2

3 of 14

www.diodes.com

May 2012

© Diodes Incorporated

O

TCH

G SUPPLY

C

URRENT

CTR

O

T

G

2

CTR

OLTAG

CUR

REN

T

T

C

H

N

G F

R

Q

U

N

C

Y

H

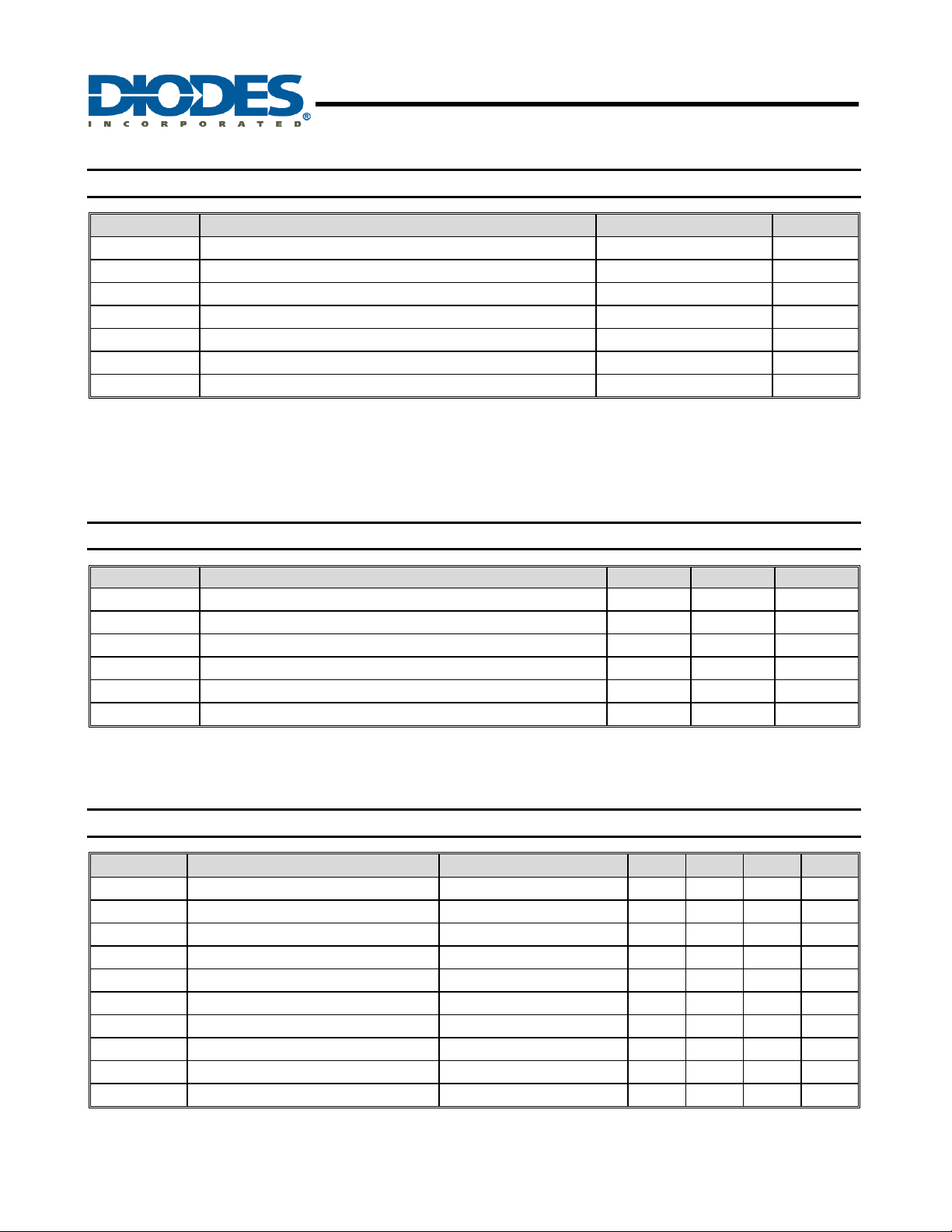

Typical Characteristics

0.9

(mA)

0.8

0.7

AP8802H

60V 1A LED STEP-DOWN CONVERTER

1.256

1.254

0.6

0.5

0.4

IN

0.3

0.2

0.1

N-SWI

N

0

06055510 15 20 25 30 35 40 5045

Figure. 2 Supply Current (not switching) vs. Input Voltage

PRELIMINARY

1.

NEW PRODUCT

1.0

0.8

E (V)

0.6

L V

0.4

0.2

0

-40 125-25 110-10 5 20 35 50 65 9580

Figure. 4 R vs. Ambient Temperature

1200

INPUT VOLTAGE (V)

AMBIENT TEMPERATURE (°C)

DS(ON)

1.252

E (V)

A

L

1.250

L V

1.248

1.246

1.244

-40 125-25 110-10 5 20 35 50 65 9580

AMBIENT TEMPERATURE (°C)

1000

(mA)

LED

Figure. 3 V vs. Ambient Temperature

900

800

700

600

500

400

300

200

100

0

0 0.5 1.0 1.5 2.0 2.5

800

CTRL

R RESISTANCE ( )

SET

Figure. 5 LED Current vs. R

Ω

SET

R = 0.3

R = 0.2

Ω

1000

800

600

400

LED CURRENT (mA)

200

0

0 0.5 1.0 1.5 2.0 2.5

Figure. 6 LED Current vs. V

SET

CTRL VOLTAGE (V)

AP8802H

Document number: DS32227 Rev. 6 - 2

SET

R = 0.68

SET

CTRL

Ω

Ω

4 of 14

www.diodes.com

700

z)

(k

600

500

E

E

400

300

I

200

SWI

100

0

02.50.5 1.0 1.5 2.0

Figure. 7 Switching Frequency vs. V

CTRL VOLTAGE (V)

CTRL

May 2012

© Diodes Incorporated

F

FIC

C

Y

TCHIN

G F

REQ

UENCY

H

UTY CYC

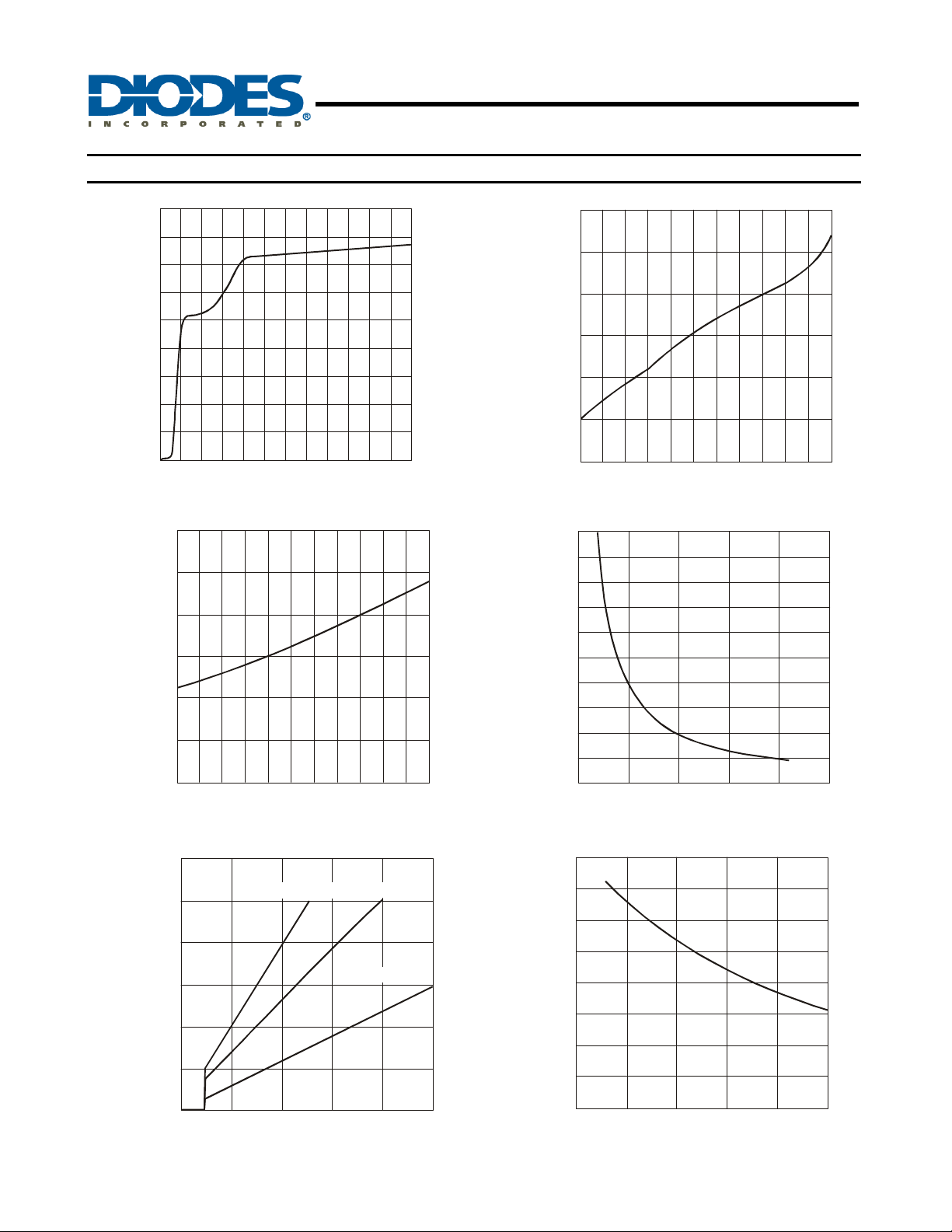

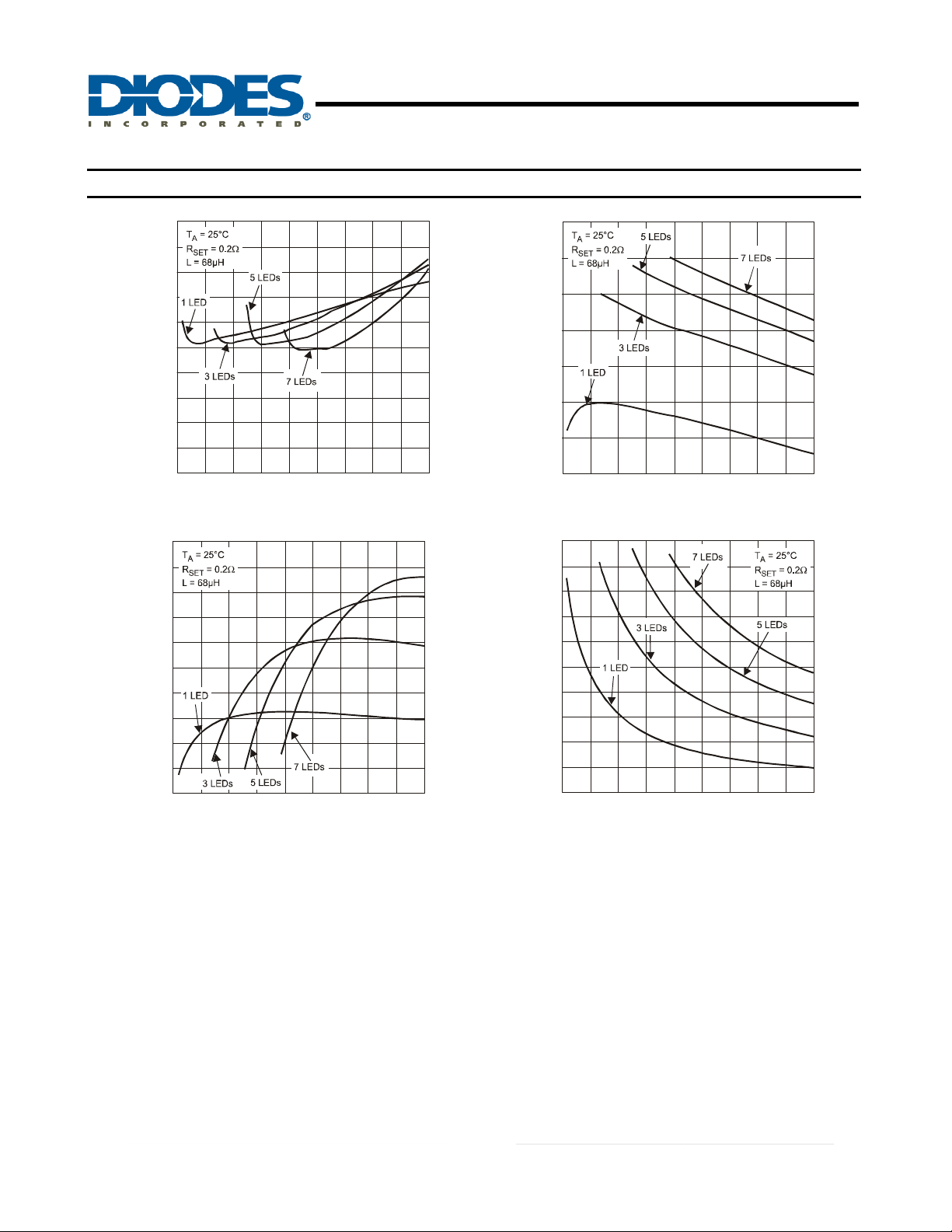

Typical Characteristics (T

10

8

6

4

2

0

-2

-4

-6

OUTPUT CURRENT DEVIATION (%)

-8

-10

6 1218 48546024 30 36 42

PRELIMINARY

NEW PRODUCT

z)

(k

Figure. 8 LED Current vs. Input Voltage

500

450

400

350

= +25°C, VIN = 60V, L = 68µH; unless otherwise stated.)

A

INPUT VOLTAGE (V)

AP8802H

60V 1A LED STEP-DOWN CONVERTER

100

95

90

(%)

85

IEN

80

E

75

70

65

61218 48546024 30 36 42

Figur e. 9 Efficiency vs. Input Voltage

100

90

80

70

INPUT VOLTAGE (V)

300

250

200

150

100

SWI

50

0

6 1218 48546024 30 36 42

Figure. 10 Switching Frequency vs. Input Voltage

INPUT VOLTAGE (V)

60

LE (%)

50

40

D

30

20

10

0

6 1218 48546024 30 36 42

Figure. 11 Duty Cycle vs. Input Voltage

SUPPLY VOLTAGE (V)

Figure. 12 Steady State Waveforms

AP8802H

Document number: DS32227 Rev. 6 - 2

Figure. 13 Start-Up Showing LED Current Soft Start

5 of 14

www.diodes.com

© Diodes Incorporated

May 2012

Loading...

Loading...