Page 1

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

Features

• Up to 88% Max power efficiency

• Wide input voltage range: 2.7V ~ 5.5V

• 1x, 1.5x, and 2x charge-pump modes

• Drive up to 4 white LEDs

• Default maximum current setting: 20mA each channel

• 120mA maximum output current through 4 channels

• Programmable switching frequency, default 1.2MHz

• Spread Spectrum Control with 10% frequency deviatio n

• 1-wire Serial Digital Interface (SDI) or PWM for dimming

control

• Soft-start during power-up and mode switching

• Soft-stop during s hutdown

• Short-circuit protection

• Over-voltage protection and under-voltage lockout

• Low shutdown curr ent < 6

• Industry-leading low profile package

• Lead Free package: DFN3030-12

• DFN3030-12: Available in “Green” Molding Compound

(No Br, Sb)

• Lead Free Finish / RoHS Compliant (Note 1)

µA

Applications

• Mobile Phone

• PDA (Personal Digital Assistant)

• White LED Backlighting

• Camera Flash LED Lighting

• LCD Modules

• Portable Devices

General Description

The AP3154A is a high efficiency charge-pump white LED driver

with 1x, 1.5x, 2x operating modes. The AP3154A operates on

power supplies from 2.7v to 5.5v. It drives up to four channels of

white LEDs while the intensity of each channel is configured by

varying the respective current levels. Each channel can supply up

to 30mA current. Up to four channels can be ganged together to

provide maximum load current of 120mA. By default, all

4 channels are set to the minimum current level after the chip is

enabled or back from shutdown mode.

The Serial Digital Interface (SDI) provides the capability to

configure the current for each LED channel. Some other key

features, such as Up Spread Spectrum Control, different

charge-pump switching frequencies (0.6MHz/1.2MHz/1.8MHz),

and PWM dimming control, can also be programmed through the

interface.

The AP3154A has a built-in soft-start circuit to minimize the inrush

current during power-up and mode switching. Various protections

such as short-circuit, over-voltage, under-voltage, and thermal

shutdown are integrated to ensure system reliability. The

quiescent current of AP3154A during shutdown is less than 6

µA.

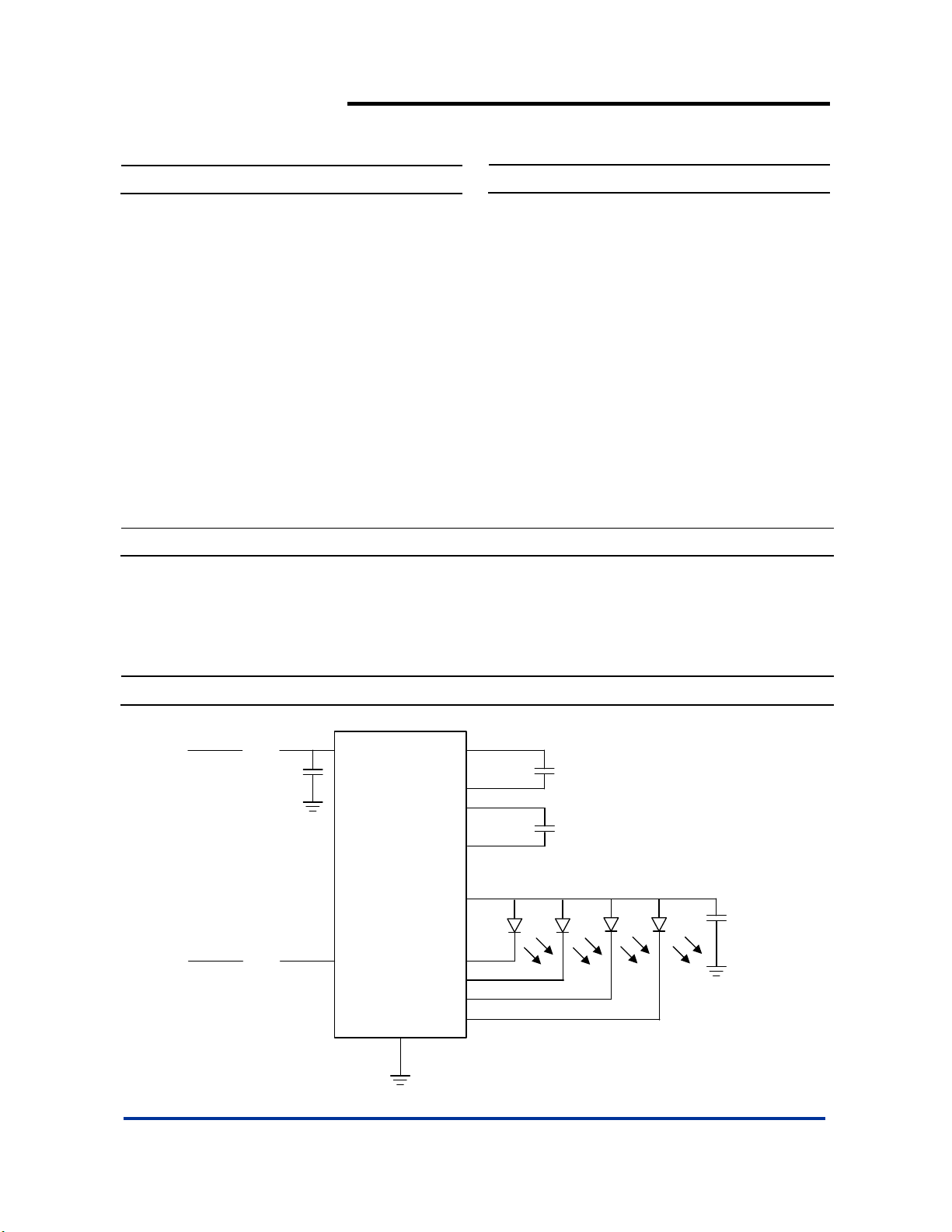

Typical Application Circuit

8

V

IN

V

IN

1uF

C

IN

AP3154A

2

SDI

SDI

GND

9

AP3154A Rev. 1 1 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

V

C2

C2

C1

C1

OUT

D4

D3

D2

D1

6

P

N

P

N

1uF

C

7

2

3

1uF

C

4

1

5

D4

LED

D3

LED

D2

LED

D1

LED

1uF

C

OUT

1

12

11

10

Page 2

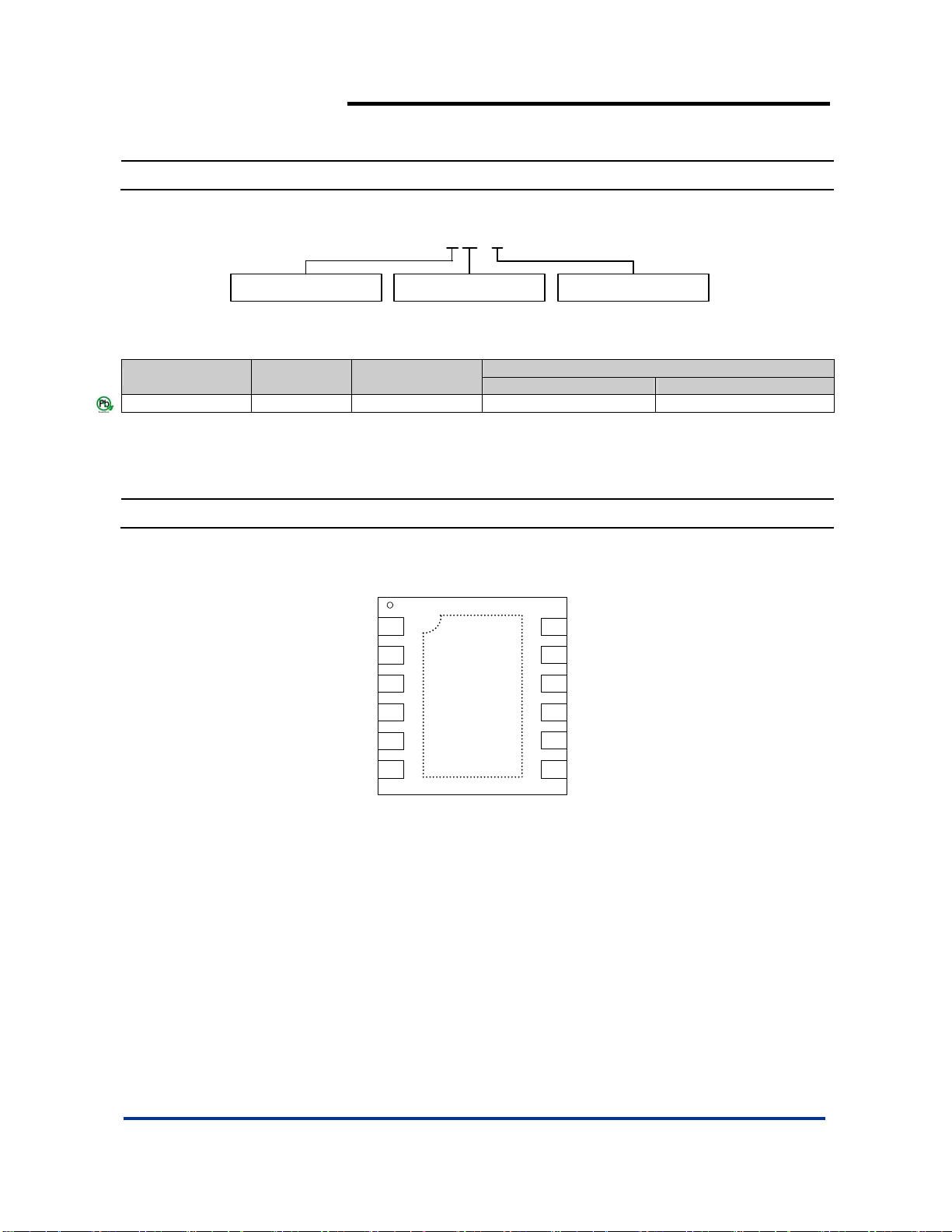

Ordering Information

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

AP 3154 A F G - 7

Package

F : DFN3030-12

Green

G : Green

Packing

7 : Tape & Reel

Device

Package

Code

Packaging

(Note 2)

Quantity Part Number Suffix

7” Tape and Reel

AP3154AFG-7 F DFN3030-12 3000/Tape & Reel -7

Notes: 1. EU Directi ve 2 002/95/EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at

http://www.diodes.com/datasheets/ap02001.pdf.

http://www.diodes.com/products/lead_free.html

2. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

Pin Assignment

( Top View )

V

D4

C1

C1

OUT

C2

1

2

3

P

4

N

5

P

Exposed

Pad

12

D3

11

D2SDI

10

D1

9

GND

8

V

IN

76

C2

N

DFN3030-12

AP3154A Rev. 1 2 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 3

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

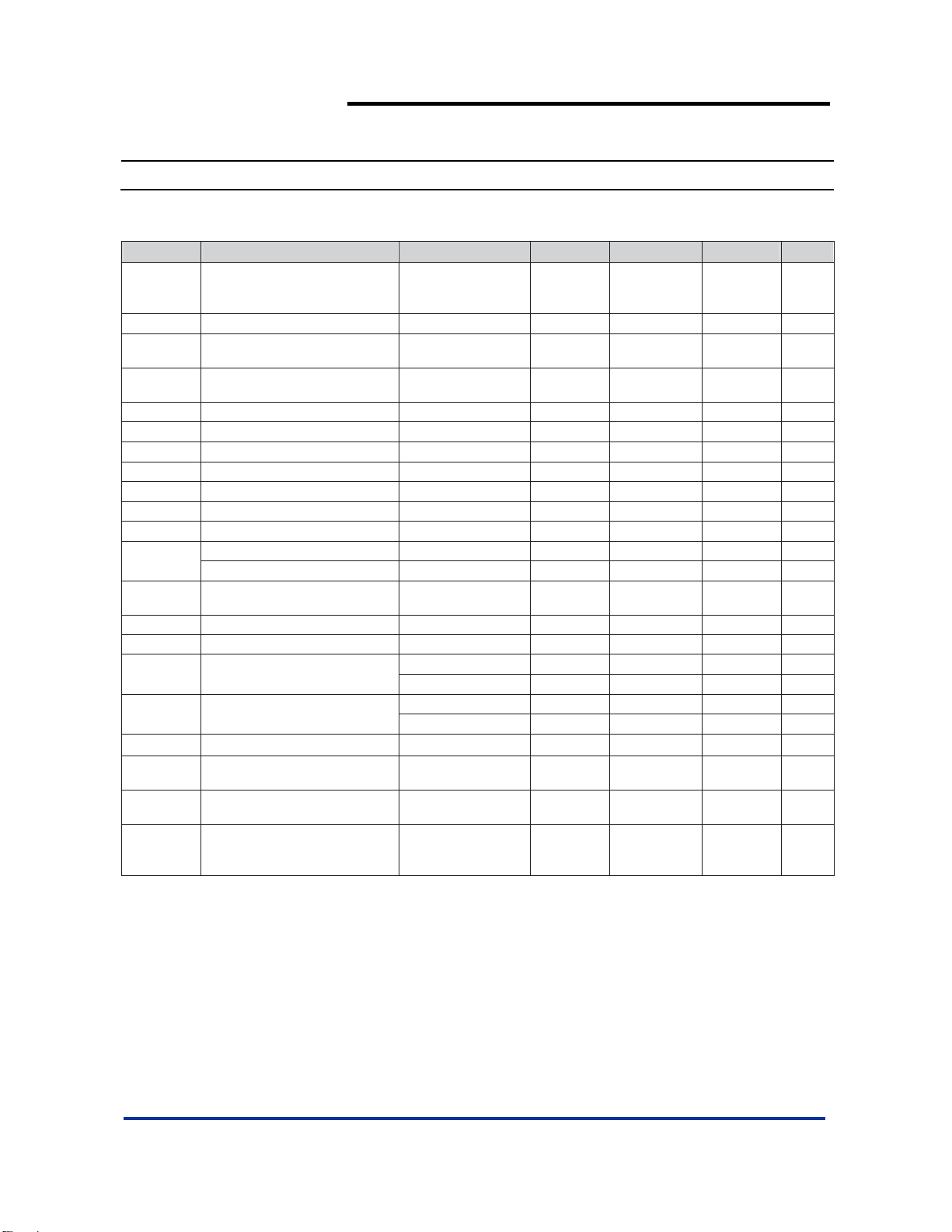

Pin Descriptions

Pin Name Pin # Description

D4 1 Current Sink Input #4. Connect to V

SDI 2 1-wire Serial Digital Interface Input / PWM input

C1P 3 Positive Terminal of Flying Capacitor. Connect a 1µF capacitor between C1P and C1N.

C1N 4 Negative Terminal of Flying Capacitor.

V

OUT

5

The charge pump output voltage to drive load circuit. Connect a 1µF capacitor

between this pin and ground.

C2P 6 Positive Terminal of Flying Capacitor. Connect a 1µF capa citor between C2P and C2N.

C2N 7 Negative Terminal of Flying Capacitor.

VIN 8 Input Power Source. Connect a 1µF capacitor between this pin and ground.

GND 9 Ground.

D1 10 Current Sink Input #1. Connect to V

D2 11 Current Sink Input #2. Connect to V

D3 12 Current Sink Input #3. Connect to V

GND

EP PAD

Exposed Pad (bottom). Connect to groun d u n d e r n ea th t he package.

when un-used.

OUT

when un-used.

OUT

when un-used.

OUT

when un-used.

OUT

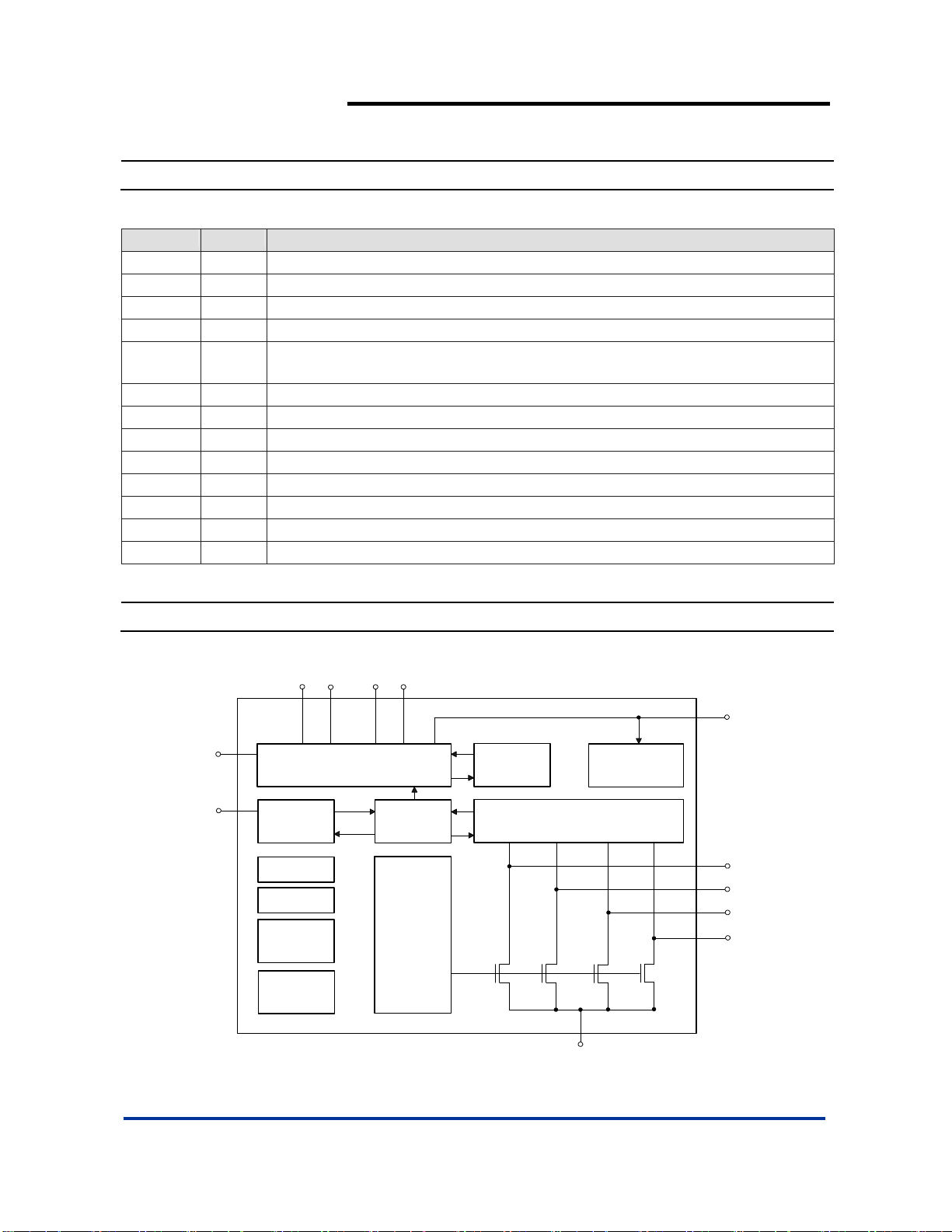

Block Diagram

V

IN

SDI

C2

P

SERIAL

DIGITAL

INTERFACE

BANDGAP

OSCILLATOR

OVER

TEMPERATURE

PROTECTION

UNDER

VOLTAGE

LOCKOUT

C1

C2

N

CHARGE PUMP

SWITCHES

C1

P

DIGITAL

CONTROL

BLOCK

CURRENT

CONTROL

N

V

OUT

SHORT

CIRCUIT

PROTECTION

OUTPUT VOLTAGE REGULATION

LED SHORT CIRCUIT DETECTION

&

GND

OVER

VOLTAGE

PROTECTION

D1

D2

D3

D4

AP3154A Rev. 1 3 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 4

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

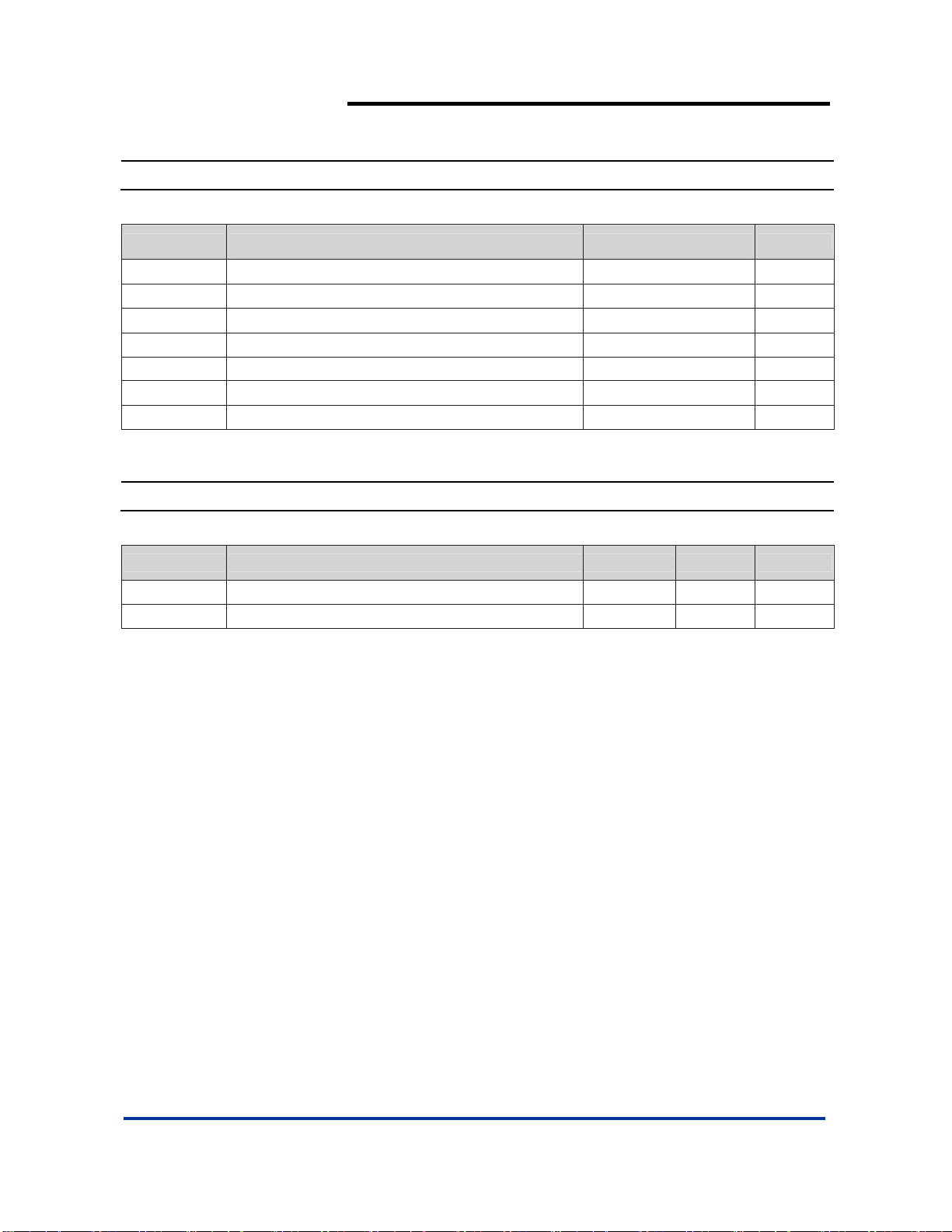

Absolute Maximum Ratings (Notes 3)

Symbol Description Value Units

ESD HBM Human Body Model ESD Protection

ESD MM Machine Model ESD Protection 200 V

V

IN

VSDI SDI to GND Voltage -0.3 to VIN + 0.3 V

I

OUT

PD Maximum Power Dissipation 0.85 W

TJ Operating Junction Temperature Range -40 to 150 °C

Notes: 3. Exceeding Absolute Maximum Ratings will cause permanent damage to the device.

Input Voltage -0.3 to 6 V

Maximum DC Output Current 150 mA

2

Recommended Operating Conditions

Symbol Parameter Min Max Units

VIN

TA

Input Voltage 2.7 5.5 V

Operating Ambient Temperature

-40 85 °C

KV

AP3154A Rev. 1 4 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 5

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

Electrical Characteristics

= C

C

IN

Symbol Description Conditions Min Typ. Max Units

I

V

V

Notes: 4. Determined by the average current levels of all active channels.

= C1 = C2 = 1.0µF; TA = 25°C, VIN = 3.5V. Unless otherwise stated.

OUT

1X Mode

IQ Quiescent Current

Fosc=1.2MHz,

1.2 mA

SDI=HIGH, no load

I

Shutd own Current SDI = 0 0.3 6 µA

SHDN

I

Current Accuracy

IDX

D-Match

SINK

(Note 4)

Current Matching

(Note 5)

= 20mA -10 10 %

I

SINK

V

: D1=D2=D3=D4

F

I

= 2, 20mA

D

5 %

TSS Soft-start Time 1 ms

F

Switching Clock Frequency 0.6/1.2/1.8 MHz

CLK

F

Spread Spectrum Enabled +10 %

SSP

SDI Threshold Low VIN = 2.7V to 5.5V 0.4 V

SDI(L)

SDI Threshold High VIN = 2.7V to 5.5V 1.6 V

SDI(H)

T

SDI Low Time 0.05 50 µs

SLO

T

SDI High Time 0.05 50 µs

SHI

f

T

T

T

T

T

I

PWM

PWM

PLO

OFF

SEP

I

SDI

SCP

θ

θ

PWM Frequency (Range 1) 0.2 1.5 KHz

PWM Frequency (Range 2) 20 30 KHz

PWM Signal Period

PWM Signal Lo w (LED off) 1 T

PWM Signal High (LED on) 1 T

PHI

Chip Disable (held low)

Interval betw ee n S D I

sequences (held high)

PWM 65 100 ms

No PWM 512 800 µs

PWM 65 100 ms

No PWM 512 800 µs

f

PWM

1/

-Max

1/ f

-Min µs

PWM

– 1 µs

PWM

– 1 µs

PWM

SDI Input Leakage -1 1 µA

Short to GND hold

V

OUT

Current

Thermal Resistance1 –

JA

Junction to Ambient

Maximum Thermal

Resistance1 –

JC

Junction to Case

5. Defined as the deviation of any sink current from the average of all active current channels.

6. Device mounted on FR-4 substrate PC board, 2oz copper, with minimum recommended pad layout.

500 mA

DFN3030-12

(Note 6)

DFN3030-12

(Note 6)

160 °C/W

21 °C/W

AP3154A Rev. 1 5 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 6

120mA HIGH EFFICIENCY WHITE LED DRIVER

Typical Performance Characteristics

Efficienc y vs. Suppl y Vo l tage

AP3154A

Turn-On to 1X Mode

= 4.2V; 20mA Load)

(V

IN

Turn-On from 1.5X Mode

= 3.5V; 20mA Load)

(V

IN

Turn-Off from 1.5X Mode

= 3.5V; 20mA Load)

(V

IN

Turn-On to 2X Mode

= 2.7V; 20mA Load)

(V

IN

Current Matching vs. Temperature

AP3154A Rev. 1 6 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 7

120mA HIGH EFFICIENCY WHITE LED DRIVER

Typical Performance Characteristics (Continued)

Load Characteristics

= 3.5V; 1.5X Mo de; 14mA Load)

(V

IN

= 2.7V; 2X Mode; 14mA Load)

(V

IN

AP3154A

Load Characteristics

Load Characteristics

= 3.5V; 1.5X Mo de; 20mA Load)

(V

IN

Load Characteristics

= 2.7V; 2X Mode; 20mA Load)

(V

IN

Load Characteristics

= 3.5V; 1.5X Mo de; 30mA Load)

(V

IN

Load Characteristics

= 3.1V; 2X Mode; 30mA Load)

(V

IN

AP3154A Rev. 1 7 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 8

120mA HIGH EFFICIENCY WHITE LED DRIVER

Typical Performance Characteristics (Continued)

Enable Threshold High vs. Input Voltage

Enable Threshold Low vs. Input Voltage

AP3154A

PWM Dimming Operation

= 3.5V; 20mA Lo ad; Duty=1:1; f=1KHz)

(V

IN

PWM Dimming Operation

= 3.5V; 20mA L oad; Duty=1:11; f=1KHz)

(V

IN

PWM Dimming Operation

= 3.5V; 20mA L oad; Duty=11:1; f=1KHz)

(V

IN

AP3154A Rev. 1 8 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 9

)

)

)

,

)

)

)

)

120mA HIGH EFFICIENCY WHITE LED DRIVER

Functional Description

General Functional Description

The AP3154A is designed for white LED applications. An

internal comparator circuit compares the voltage at each constan t

current sink input against a reference voltage. To ensure

maximum power efficiency, the most appropriate switching mode

(x1, x1.5, x2) is automatically selected.

In applications, only four external components are required: two

1µF ceramic flying capacitors (C

capacitor each for input and output (C

AP3154A drives up to four white LEDs with a maximum current of

30mA each. A total of 120mA is provided to the four channels.

Through SDI, the current into each channel can be configured in

accordance to specific protocol and pre-defined values.

Maximum output current can be set to one of the four possible

scales: 2mA, 14mA, 20mA, 30mA. Among these, the ‘2mA’

setting is called “low current mode”. This would be useful for

applications which require very low operating current, e.g.

transmissive LCD panels.

For each maximum output current scale, there are 16 current

level settings separated from one another by approximately

1dB. While level-16 corresponds to maximum current output,

level-1 corresponds to zero output current. As the current level

varies logarithmically, intensity of the LED changes in a linear

fashion.

By default, all 4 channels are set to current level 1 (minimum

current level) after the chip is enabled or back from shutdown

mode.

The current level at the individual channels is config ured via SDI

which supports data rate up to 10MHz. It allows the main

controller in the system to be offloaded to perform more

mission-critical functions.

Serial Digital Interface

SDI is a general purpose 1-wire digital interface designed to

transport digital controls for power management ICs such as

AP3154A. The current levels of the four channels can be

configured either together or individ ually. Up to 16 current

levels are allowed. A generic system controller can easily

support the SDI protocol via bit-banging over its general

purpose I/Os.

The SDI protocol is simple yet flexible enough to

accommodate different switching clock frequencies. Any

sequence of negative-edged pulses of 63 or less ( see tab le 1),

separated by T

a channel configuration event. In the future, the number of

pulses can be extended to support additional commands.

In addition to th e SDI protocol, dimmi ng control can also be

achieved by presenting a timing-specific PWM signaling a t the

SDI pin.

at the SDI pin is interpreted by AP3154A as

SEP

and C2), one 1µF ceramic

1

, C

).

IN

OUT

AP3154A

Number

of Falling

Edges

1 Current level step up (1 up to level 16)

2 Current level step down (16 down to level 1

3 Current level set to 16 (maximum current level

4 Current level set to 1 (minimum current level

5 All 4 Channels in dimming control

6CH2

7 CH1 and CH2 in dimming control

8 CH3 and CH4 in dimming control

9 CH1 in dimming control

10 CH2 in dimming control

11 CH3 in dimming control

12 CH4 in dimming control

13 Low-Current Mode (Maximum Current set to 2mA

14 Maximum Current set to 14mA (All channels

15 Maximum Current set to 20mA (All channels

16 Maximum Current set to 30mA (All channels

17 10% Up Spread Spectrum Control Enable/Disable

19 Switching Frequency set to 1.2Mhz

20 Switching Frequency set to 1.8Mhz

21~62 Reserved

63 PWM Dimming Control Enable/Disable

Dimming Control Current Level Setting

AP3154A supports four maximum output current scales including

30mA, 20mA, 14mA, and 2mA low-current scales. For each

maximum current scale, there are 16 current level settings

separated from one ano the r b y appr omi mat el y 1dB (s ee tab le 2).

By default, maximu m current scale is set to 20mA and dimming

control current level is set to maximum (level 16).

Through SDI, certain channels or all four channels can be

selected, and dimming control level for these ch a nnels can be set

to maximum (level 16), minimum (l evel1), up from minimum to

maximum or down from maximum to minimum (see table 1).

Dimming

Control

Current

Levels

16 20.0 30.0 14.0 2.0

15 17.8 26.7 12.5 1.78

14 15.9 23.8 11.1 1.59

13 14.3 21.4 10.0 1.43

12 12.7 19.0 8.9 1.27

11 11.1 16.7 7.8 1.11

10 10.2 15.2 7.1 1.02

9 8.9 13.3 6.2 0.89

8 7.9 11.9 5.6 0.79

7 7.0 10.5 4.9 0.70

6 6.3 9.5 4.4 0.63

5 5.7 8.6 4.0 0.57

4 5.1 7.6 3.5 0.51

3 4.4 6.7 3.1 0.44

2 4.1 6.2 2.9 0.41

1 0.05 0.05 0.05 0.05

I

out

(20mA)

Table 2: Dimming Control Current Level

Command Description

CH3 and CH4 in dimming control

I

out

(30mA)

I

out

(14mA)

Low-Current

(2mA)

AP3154A Rev. 1 9 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 10

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

Functional Description (Continued)

Disabled Current Sinks

Unused current channels must be disabled by connecting the

sinks to V

disabled channel.

Soft-Start and Soft-Stop

Soft-start and Soft-stop function are incorporated to prevent

excessive inrush current during power-up, mode switching,

power-down, transition out of stand-by mode.

Short-Circuit Prote ction

Short-circuit protection function is incorporated to prevent

excessive load current when either flying cap terminals or output

pin electrically tied to a very low voltage or ground.

Over-Voltage Protection

Over-voltage protection function is incorporated to limit the

output voltage under a safe value to avoid on-chip device

breakdown.

Under-Voltage Lockout

Under-voltage lockout feature disables the device when the

input voltage drops below UVLO threshold.

with only a small sense current flowing through the

OUT

Serial Digital Interface

SDI Command Timing

For an SDI command to be successfully receiv ed by th e AP3154A , all SDI timing sp ecifications sh ould b e satisfied. When no command is

being sent the SDI pin should be held high. If the SD I pin go es low and stays low for a time length o f be tween TSLO(min) and T SLO(max)

and then goes high and stays high for between TSHI(min) and TSHI(max), one falling edge is registered by the AP3154A. The total

number of falling edges registered before the SDI pin is held high for longer than the maximum separation time TSEP(max) identifies the

command that has been received by the AP3154A. The next series of falling edges before another separation time TSEP represents the

next command. In other words, the AP3154A counts the number of consecutive falling edges on the SDI pin and a different number

represents a different command.

Each command is executed after it is successfully received. If at any time the SDI pin is held low for longer than the maxi mum chip

disable time TOFF(max), the AP3154A is disabled and enters the shutdown mode. All internal registers are reset to default. Setting

the SDI pin high again will re-enable the AP3154A and bring it out of the shutdown mode.

The AP3154A enters the SDI mode by default when it is first powered up. The first SDI command 63 (63 falling edges) will put the

AP3154A into the PWM mode, where a high level on the SDI pin turns the LEDs on, a low level turns the LEDs off and the duty cycle

determines the average LED brightness. The next SDI command 63 will put the AP3154A back into the SDI mode. It should be pointed

out that the PWM mode is for dimming control only and configuration settings have to be done in the SDI mode.

Channel Configuration Example

The following timing diagram is a dimming control example. In this example, the first command (command 10) selects Channel 2 as the

configuration target and the second command (command 2) sets the Channel 2 current level to one step lower while the other channels

remain unchanged.

Thermal Shutdown

When the die temperature exceeds the thermal limit, the device

will be disabled and enter stand-by mode. The operation will be

resumed whenever the die cools off sufficiently.

Switching Frequency

By default, AP3154A is working at 1.2Mhz switching frequency.

It can also work at 0.6MHz or 1.8MHz switching frequency set

through SDI. User can choose the appropriate switching

frequency with consideration of noise immunity, input/output

voltage ripple requirement, and capacitor selection etc.

Up Spread Spectrum Control

When this feature is enabled through SDI, the switching

frequency periodically varies between 100% and 110% of

nominal frequency. It flattens the peak energy on nominal

frequency over a range of frequency band so that EMI effect is

significantly reduced.

PWM Dimming Control

The AP3154A provides flexible dimming control with either

16-level SDI protocol control or PWM dimming control through

SDI pin. When PWM dimming control is enabled, the sink

current is adjusted by the duty cycle of the signal applied on SDI

pin.

AP3154A Rev. 1 10 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 11

Serial Digital Interface (Continued)

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

Marking Information

(1) DFN3030-12

Part Number Package Identification Code

AP3154A DFN3030-12 F9

( Top View )

XX

X

Y

W

: F9 : AP3154A

XX

Y

: Year : 0~9

: Week : A~Z : 1~26 week;

W

a~z : 27~52 week;

z : represents 52 and 53

: A~Z : Green

X

AP3154A Rev. 1 11 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 12

120mA HIGH EFFICIENCY WHITE LED DRIVER

Package Information (All Dimensions in mm)

(1) Package type: DFN3030-12

0.57/0.63

0.10 C

AP3154A

2x-

0.08 C

0.25 B

B

2.9 / 3.1

2x

0/0.05

R

0

1.5 / 1.7

0.45typ

A

0.25

.

3

2.9 / 3.1

2.3 / 2.5

0.18/0.28

Bottom View

Seating plane

C

0.15max.

A

0.25/0.55

0.10

M C A B

AP3154A Rev. 1 12 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 13

Taping Orientation

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

Notes: 7. The taping orientation of the other package type can be found on our website at http://www.diodes.com/datasheets/ap02007.pdf

AP3154A Rev. 1 13 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Page 14

AP3154A

120mA HIGH EFFICIENCY WHITE LED DRIVER

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS

DOCUMENT, INCLUDING, BU T NOT LIMI TED TO, T HE IMPLIE D WARRANT IES OF ME RCHANTABILIT Y AND FI TNESS FOR A

PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other

changes without further notice to t his document and any product described herein. Diodes Incorporated does not assume any

liability arisi ng out of the application or use of this document or any product descr ibed herein; neither does Diode s Incorporated

convey any license under its patent or trademark rig hts, nor the rights of othe rs. Any Customer or user of this docume nt or products

described herein in such applications shall assume all risks of such use and will agree to hold Diodes Incorporated and all the

companies whose products are represented on Diodes Incorporated website, harmless against all damages.

Diodes Incorporat ed does not warrant or accept a ny liabil ity whatsoeve r in respect of any p roducts purc hase d through unau thori zed

sales channel.

Should Customers purch ase or use Diodes Incorpo rated products for an y unintended or unau thorized applic ation, Customers sh all

indemnify and hold Dio des Inc orporated and its re presen tatives harmle ss against all cla ims, d amages, expens es, a nd attor ney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized

application.

Products described here in may be covered by one or more Unit ed States, i nternationa l or foreign patents p ending. Product n ames

and markings noted herein may also be covered by one or more United States, i nte rn ational or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems

without the express written approval of the Chief Execut i ve Off icer of Diodes Incorporate d. As us e d herei n:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into t he body, or

2. support or sustain life and whose failure to perform when properly used in accordance wi th instructions for use provided

in the labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any c omponent in a life sup port devic e or system whose f ailure to perform c an be reasona bly expect ed

to cause the failure of the life support device or to affect its safety or effectiveness.

Customers repres ent that th ey have all necessar y expertis e in th e safety a nd regul ator y ramific ations of t heir lif e support devic es or

systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements

concerning their products and any use of Diodes Incorporated products in such safety-critical, life support devices or systems,

notwithstandin g a ny de vices- or systems-related information or support that may be provided by Diodes Inc orporated. Further,

Customers must full y indemnify Diode s Incorporat ed and its represent atives ag ainst any damages ari sing out of th e use of Diodes

Incorporated products in suc h safety-critical, life support devices or sys tems.

Copyright © 2009, Diodes Incorporated

www.diodes.com

AP3154A Rev. 1 14 of 14 AUGUST 2009

www.diodes.com © Diodes Incorporated

Loading...

Loading...