Page 1

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

General Description

The AP3033 is an inductor-based DC/DC boost converter designed to drive LED arrays. 1.3A switching

current allows AP3033 to be used in different 7' to 10'

LCD panel backlights (3S8P LED arrays typically).

A constant frequency 1MHz PWM control scheme is

employed in this IC, which means tiny external components can be used. Specifically, 1mm tall 10

inductor and 10

application is sufficient.

The over output voltage protection is equipped in

AP3033, which protects the IC under open load condition. The AP3033 includes UVLO, soft-start, standby

mode, current limit and OTSD to protect the circuit.

The AP3033 is available in standard TSOT-23-6 package.

µF output capacitor for the typical

µH

Features

· Up to 92% Efficiency

(V

· Up to 88% Efficiency

(V

· Fast 1MHz Switching Frequency

· Wide Input Voltage Range: 3V to 16V

· Low 200mV Feedback Voltage

· Output Over Voltage Protection

· Cycle by Cycle Current Limit: 1.3A

· High Frequency PWM Dimming

· Built-in Soft-start

· Built-in Thermal Shutdown Function

· Under Voltage Lockout

=9V, I

IN

=5V, I

IN

OUT

OUT

=160mA)

=160mA)

Applications

· 7' to 10' LCD Panels

· Digital Photo Frame

· GPS Receiver

· Netbook

· PDVD

TSOT-23-6

Figure 1. Package Type of AP3033

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

1

Page 2

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

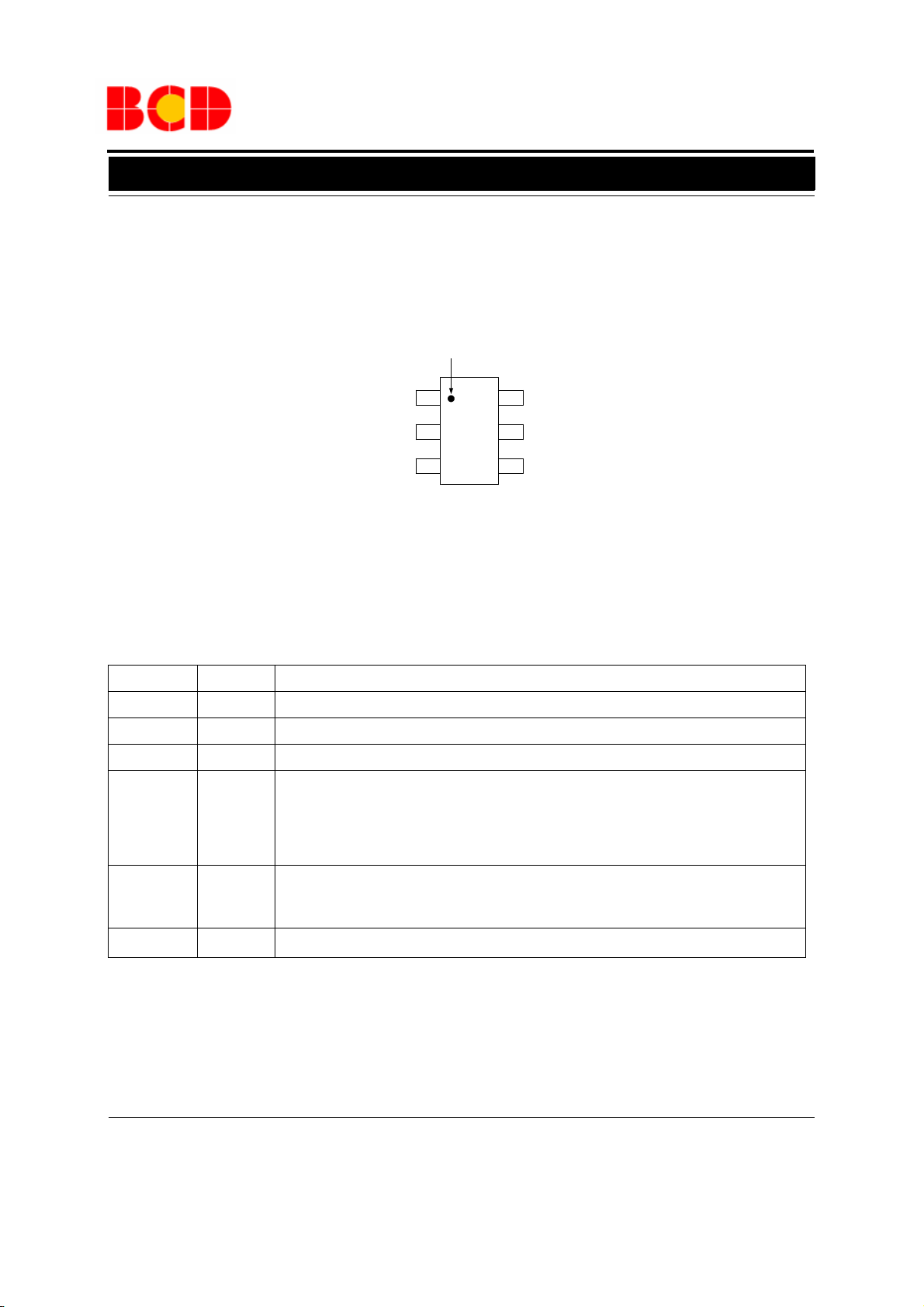

Pin Configuration

KT Package

(TSOT-23-6)

Pin 1 Dot by Marking

V

SW

GND

1

2

6

IN

OV

5

FB

34

CTRL

Figure 2. Pin Configuration of AP3033 (Top View)

Pin Description

Pin Number Pin Name Function

1 SW Switch Pin. Connect external inductor and Schottky

2 GND Ground Pin

3 FB Voltage Feedback Pin. Reference voltage is 200mV

Enable and Dimming Control Pin. Connect to a high input to enable the IC or a low input to

disable the IC. If logic low time is more than about 0.45ms and then enable the IC, the

4

5 OV Over-voltage Protection Input Pin. Connect to the output directly or connect to the V

CTRL

AP3033 will soft start to protect system departments. If logic low time is less than about

0.45ms and then enable the IC, the AP3033 will hold on standby mode and start directly to

achieve high frequency dimming

through a resistor divider to set the OVP voltage. On OVP condition, the output voltage will

be clamped

OUT

6V

Input Supply Pin. Must be locally bypassed

IN

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

2

Page 3

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

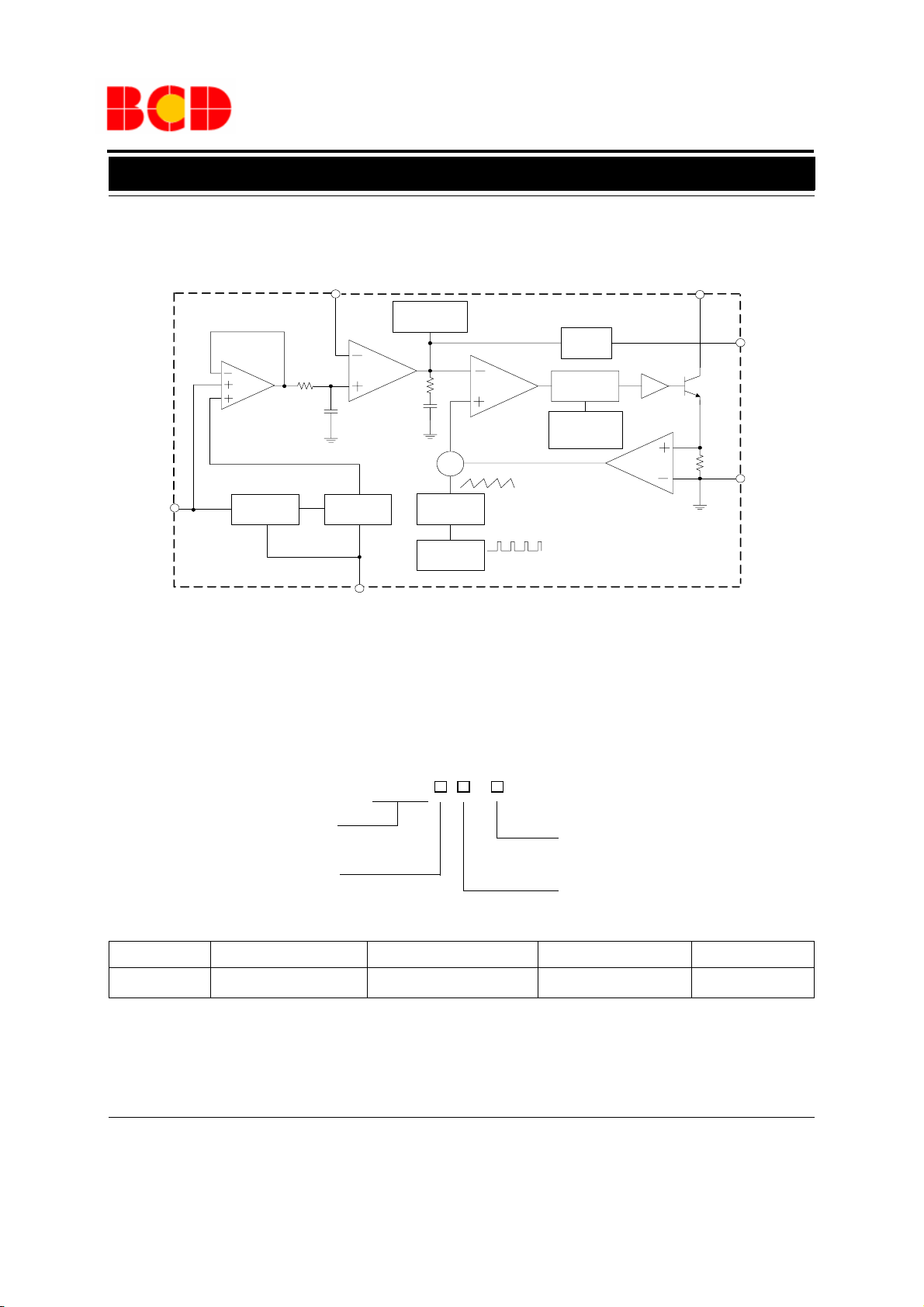

Functional Block Diagram

CTRL

FB

3

FB REF

R

C

200mV REF

4

STANDBY

V

REF

1.25V

V

6

IN

SOFT

START

OVP

A

1

A2

COMPARATOR

CONTROL

LOGIC

OVER

TEMPERATURE

DETECTOR

DRIVER

Σ

RAMP

GENERATOR

1MHz

OSCILLATOR

SW

1

5

OV

Q1

2

GND

Figure 3. Functional Block Diagram of AP3033

Ordering Information

AP3033 -

Circuit Type

Package

KT: TSOT-23-6

Package Temperature Range Part Number Marking ID Packing Type

TSOT-23-6

-40 to 85oC

AP3033KTTR-G1

BCD Semiconductor's Pb-free products, as designated with "G1" suffix in the part number, are RoHS compliant and green.

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

3

G1: Green

TR: Tape and Reel

L8G

Tape & Reel

Page 4

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

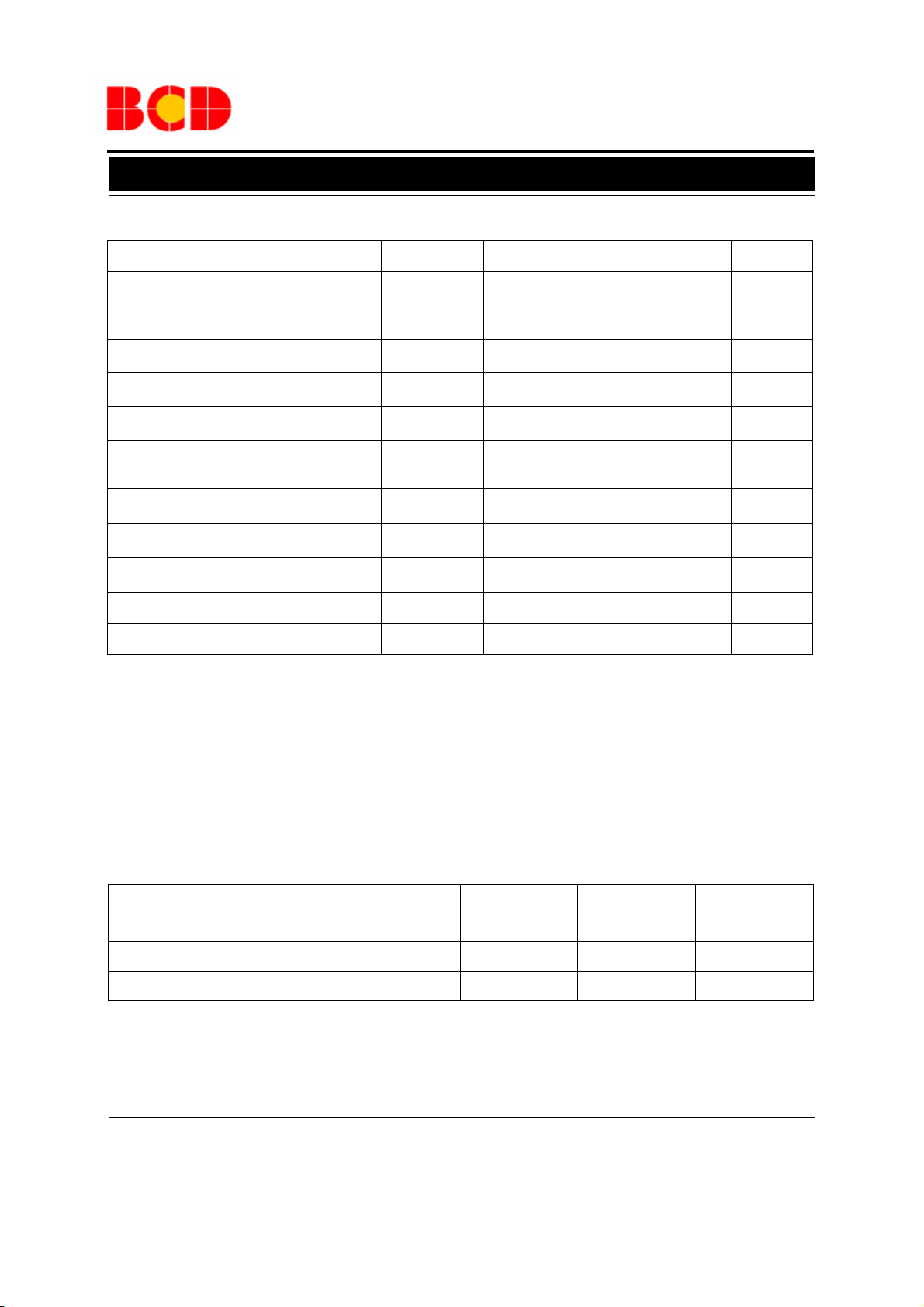

Absolute Maximum Ratings (Note 1)

Parameter Symbol Value Unit

Input Voltage V

SW Voltage V

FB Voltage V

OV Voltage V

CTRL Voltage V

Thermal Resistance

IN

SW

FB

OV

CTRL

θ

JA

20 V

38 V

20 V

20 V

20 V

265

o

C/W

(Junction to Ambient, No Heat Sink)

Operating Junction Temperature T

Storage Temperature Range T

Lead Temperature (Soldering, 10sec) T

LEAD

J

STG

150

-65 to 150

260

o

C

o

C

o

C

ESD (Machine Model) 600 V

ESD (Human Body Model) 4000 V

Note 1: Stresses greater than those listed under "Absolute Maximum Ratings" may cause permanent damage to the device.

These are stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated

under "Recommended Operating Conditions" is not implied. Exposure to "Absolute Maximum Ratings" for extended periods

may affect device reliability.

Recommended Operating Conditions

Parameter Symbol Min Max Unit

Operating Temperature Range TOP -40 85

Input Voltage V

CTRL Voltage V

IN

CTRL

3 16

16 V

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

4

o

C

V

Page 5

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

Electrical Characteristics

(VIN=5.0V, V

=5.0V, TA=25oC, unless otherwise specified.)

CTRL

Parameter Symbol Conditions Min Typ Max Unit

Operating Voltage V

Quiescent Current I

Shutdown Quiescent Current I

Feedback Voltage (Note 2)

FB Pin Bias Current I

IN

Q

SHDN

V

FB

FB

VFB=VIN, no switching 4.0 5.0 6.0 mA

V

=0V 50 µA

CTRL

I

=20mA, 3 LEDs,

OUT

=-40oC to 85oC

T

A

3.0 16

188 200 212 mV

35 100 nA

Switching Frequency f 0.75 1 1.3 MHz

Maximum Duty Cycle D

Switch Current Limit I

Switch V

Saturation Voltage V

CE

MAX

LIMIT

CESATISW

Switch Leakage Current V

CTRL Pin Voltage V

CTRL Pin Bias Current I

OVP Voltage V

Soft-start Time t

Standby Time t

Thermal Shutdown T

CTRL

CTRL

OVP

SS

STB

OTSD

D=60% 1.2 1.3 A

=0.6A 350 mV

=38V 0.01 5 µA

SW

90 93 %

1.2 V

60 µA

17 V

80 µs

0.45 ms

150

V

o

C

Note 2: The bold type specifications of full temperature range are guaranteed by design (GBD).

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

5

Page 6

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

Typical Performance Characteristics

(WLED forward voltage (VF)=3.2V at IF=20mA, unless otherwise noted.)

100

80

60

40

Efficiency (%)

20

0

0 50 100 150 200 250 300

VIN=5V,V

µH,T

L=10

Output Current (mA)

Figure 4. Efficiency vs. Output Current

2.6

2.5

2.4

2.3

2.2

2.1

Minimum Operating Voltage (V)

2.0

-40-200 20406080100120

Case Temperature (0C)

OUT

=10V

=250C

A

100

80

60

40

Efficiency (%)

20

V

OUT

=10V, I

=160mA,

OUT

L=10µH, TA=250C

0

456789

Input Voltage (V)

Figure 5. Efficiency vs. Input Voltage

7.0

6.5

6.0

5.5

5.0

4.5

4.0

Quiescent Current (mA)

3.5

3.0

246810121416

VFB=VIN, TA=250C

Input Voltage (V)

Figure 6. Minimum Operating Voltage vs.

CaseTemperature

Figure 7. Quiescent Current vs. Input Voltage

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

6

Page 7

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

Typical Performance Characteristics (Continued)

(WLED forward voltage (VF)=3.2V at IF=20mA, unless otherwise noted.)

220

210

200

190

180

170

Feedback Voltage (V)

160

150

-40 -20 0 20 40 60 80 100 120

Case Temperature (0C)

Figure 8. Feedback Voltage vs. Case Temperature

1.8

1.5

1.2

1000

900

800

700

600

500

400

300

Saturation Voltage (mV)

200

100

0.2 0.4 0.6 0.8 1.0

TC=-400C

TC=250C

TC=850C

Switch Current (A)

Figure 9. Saturation Voltage vs. Switch Current

20

19

18

17

0.9

Frequency (MHz)

0.6

0.3

0.0

-40-200 20406080100120

Case Temperature (0C)

Figure 10. Frequency vs. Case Temperature

16

15

OVP Voltage (V)

14

13

12

-40-200 20406080100120

Case Temperature (0C)

Figure 11.

OVP Voltage vs. Case Temperature

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

7

Page 8

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

Typical Performance Characteristics (Continued)

(WLED forward voltage (VF)=3.2V at IF=20mA, unless otherwise noted.)

1.8

1.6

1.4

1.2

1.0

0.8

0.6

Current Limit (A)

0.4

0.2

0.0

10 20 30 40 50 60 70 80 90

Duty Cycle (%)

Figure 12. Current Limit vs. Duty Cycle

TC=-400C

TC=250C

TC=850C

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

8

Page 9

Preliminary Datasheet

×

WHITE LED STEP-UP CONVERTER AP3033

Application Information

Operation

The AP3033 is a boost DC-DC converter which uses a

constant frequency, current mode control scheme to

provide excellent line and load regulation. Operation

can be best understood by referring to Figure 3 and

Figure 17.

At the start of each oscillator cycle, switch Q1 turns on.

The switch current will increase linearly. The voltage

on sense resistor is proportional to the switch current.

The output of the current sense amplifier is added to a

stabilizing ramp and the result is fed into the noninversion input of the PWM comparator A2. When this

voltage exceeds the output voltage level of the error

amplifier A1, the switch is turned off.

It is clear that the voltage level at inversion input of A2

sets the peak current level to keep the output in

regulation. This voltage level is the output signal of

error amplifier A1, and is the amplified signal of the

voltage difference between feedback voltage and

reference voltage of 200mV. So, a constant output

current can be provided by this operation mode.

LED Current Control

Refer to Figure 17, the LED current is controlled by the

feedback resistor R

determined by the regulator's feedback threshold

accuracy and is independent of the LED's forward

voltage variation. So the precise resistors are preferred.

The resistance of R

LED current since the feedback reference is fixed at

200mV. The relation for R

(I

)can be expressed as below:

LED

mV

ISET

200

=

I

LED

R

Over Voltage Protection

The AP3033 has an internal open load protection

circuit. When the LEDs are disconnected from circuit

or fail open, the output voltage is clamped at about

17V. The AP3033 will switch at a low frequency, and

minimize current to avoid input voltage drop.

. LEDs' current accuracy is

ISET

is in inverse proportion to the

ISET

and LED current

ISET

Soft Start

The AP3033 has an internal soft start circuit to limit

the inrush current during startup. If logic low time on

CTRL pin is more than about 0.45ms and then enable

the IC, the AP3033 will start smoothly to protect system departments. The time of startup is controlled by

internal soft-start capacitor. Details please refer to

Figure 13.

V

CTRL

2V/div

V

SW

5V/div

V

O

5V/div

I

L

500mA/div

Figure 13. Soft-start Waveform

V

=5V, 3×8 LEDs, I

IN

Time 80µs/div

LED

=160mA

Dimming Control

For controlling LED brightness, the AP3033 provides

typically 200mV feedback voltage when the CTRL pin

is pulled constantly high. However, CTRL pin allows a

PWM signal to reduce this regulation voltage by

changing the PWM duty cycle to achieve LED

brightness dimming control. Detail circuit, as show in

Figure 14. The relationship between the duty cycle and

LED current can be expressed as below:

200

=

I

LED

where D

PWM

200mV is internal reference voltage.

200mV

Ctrl

Figure 14. Bolck Diagram of Programmable

FB Voltage Using PWM Signal

DmV

PWM

R

ISET

is the duty cycle of PWM signal and

A

FB

EA

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

9

Page 10

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

Application Information (Continued)

Two other typical types of dimming control circuit are

presented as below.

(1) Using DC Voltage to Change the Effective Feedback Voltage

Adding a constant DC voltage through a resistor

divider to FB pin can control the dimming. Changing

the DC voltage or resistor between the FB Pin and the

DC voltage can get appropriate luminous intensity.

Comparing with all kinds of PWM signal control, this

method features a stable output voltage and LEDs

current. Please refer to Figure 15.

AP3033

FB

V

DC

R2R3

Figure 15. Dimming Control

Using DC Voltage

Effective

Feedback Voltage

R1

(2) Using Filtered PWM Signal to Change the Effective Feedback Voltage

The filtered PWM signal can be considered as a

varying and adjustable DC voltage, please refer to Figure 16.

AP3033

FB

PWM

R4

R3

C

R2

Figure 16. Dimming Control

Using Filtered PWM

Voltage

Effective

Feedback Voltage

R1

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

10

Page 11

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

Typical Application

V

IN

5V

L10µH

D

V

OUT

C

IN

10 µF

On/Off

V

IN

AP3033

CTRL

Figure 17. Typical Application of AP3033 (3S8P WLEDs)

GND

SW

OV

FB

C

OUT

µ

10 F

R

3S8P

ISET

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

11

Page 12

Preliminary Datasheet

WHITE LED STEP-UP CONVERTER AP3033

Mechanical Dimensions

TSOT-23-6 Unit: mm(inch)

°

2.800(0.110)

3.000(0.118)

R0.100(0.004)

MIN

0

8

°

1.500(0.059)

1.700(0.067)

0.000(0.000)

0.100(0.004)

0.950(0.037)

BSC

0.700(0.028)

0.900(0.035)

Pin 1 Dot by

Marking

1.900(0.075)

BSC

0.350(0.014)

0.510(0.020)

2.600(0.102)

3.000(0.118)

1.000(0.039)

MAX

GAUGE

PLANE

0.370(0.015)

MIN

0.100(0.004)

0.250(0.010)

0.250(0.010)

BSC

Jan. 2010 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

12

Page 13

BCD Semiconductor Manufacturing Limited

IMPORTANT NOTICE

IMPORTANT NOTICE

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

other rights nor the rights of others.

other rights nor the rights of others.

http://www.bcdsemi.com

MAIN SITE

MAIN SITE

- Headquarters

BCD Semiconductor Manufacturing Limited

BCD Semiconductor Manufactur ing Limited

- Wafer Fab

No. 1600, Zi Xing Road, Shanghai ZiZhu Science-based Industrial Park, 200241, China

Shanghai SIM-BCD Semiconductor Manufacturing Limited

Tel: +86-21-24162266, Fax: +86-21-24162277

800, Yi Shan Road, Shanghai 200233, China

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

REGIONAL SALES OFFICE

Shenzhen Office

REGIONAL SALES OFFICE

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd., Shenzhen Office

Shenzhen Office

Unit A Room 1203, Skyworth Bldg., Gaoxin Ave.1.S., Nanshan District, Shenzhen,

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd. Shenzhen Office

China

Advanced Analog Circuits (Shanghai) Corporation Shenzhen Office

Tel: +86-755-8826 7951

Room E, 5F, Noble Center, No.1006, 3rd Fuzhong Road, Futian District, Shenzhen 518026, China

Fax: +86-755-8826 7865

Tel: +86-755-8826 7951

Fax: +86-755-8826 7865

- Wafer Fab

BCD Semiconductor Manufacturing Limited

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd.

- IC Design Group

800 Yi Shan Road, Shanghai 200233, China

Advanced Analog Circuits (Shanghai) Corporation

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

8F, Zone B, 900, Yi Shan Road, Shanghai 200233, China

Tel: +86-21-6495 9539, Fax: +86-21-6485 9673

Taiwan Office

BCD Semiconductor (Taiwan) Company Limited

Taiwan Office

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

BCD Semiconductor (Taiwan) Company Limited

Tai wan

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

Tel: +886-2-2656 2808

Taiwan

Fax: +886-2-2656 2806

Tel: +886-2-2656 2808

Fax: +886-2-2656 2806

USA Office

BCD Semiconductor Corp.

USA Office

30920 Huntwood Ave. Hayward,

BCD Semiconductor Corporation

CA 94544, USA

30920 Huntwood Ave. Hayward,

Tel : +1-510-324-2988

CA 94544, U.S.A

Fax: +1-510-324-2788

Tel : +1-510-324-2988

Fax: +1-510-324-2788

Loading...

Loading...