Page 1

AP2337

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

Description

The AP2337 is single channel current-limited integrated hi ghside power switches optimized for hot-swap applications. The

devices have fast short-circuit response time for improved

overall system robustness and provide a complete protection

solution for application subject to heavy capacitive loads and

the prospect of short circuit. It offers reverse current blocking,

over-current, over-temperature and short-circuit protection,

as well as controlled rise time and under-voltage lockout

functionality.

The device is available in SOT23 package.

Features

• Input voltage range: 2.7V – 5.5V

• Fast short-circuit response time

• 1.5A accurate current limiting

NEW PRODUCT

• 110mΩ on-resistance

• Reverse Current Blocking

• Built-in soft-start with 2.5ms typical turn-on time

• Over Current Protection

• Over Voltage Protection

• Short circuit and thermal protection

• ESD protection: 3KV HBM, 300V MM

• Ambient temperature range: -40ºC to 85°C

• Available in “Green” Molding Compound (No Br, Sb)

• Lead Free Finish/ RoHS Compliant (Note 1)

• UL Recognized, File Number E322375 (to be completed)

• IEC60950-1 CB Scheme Certified (to be completed)

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at

http://www.diodes.com/products/lead_free.html.

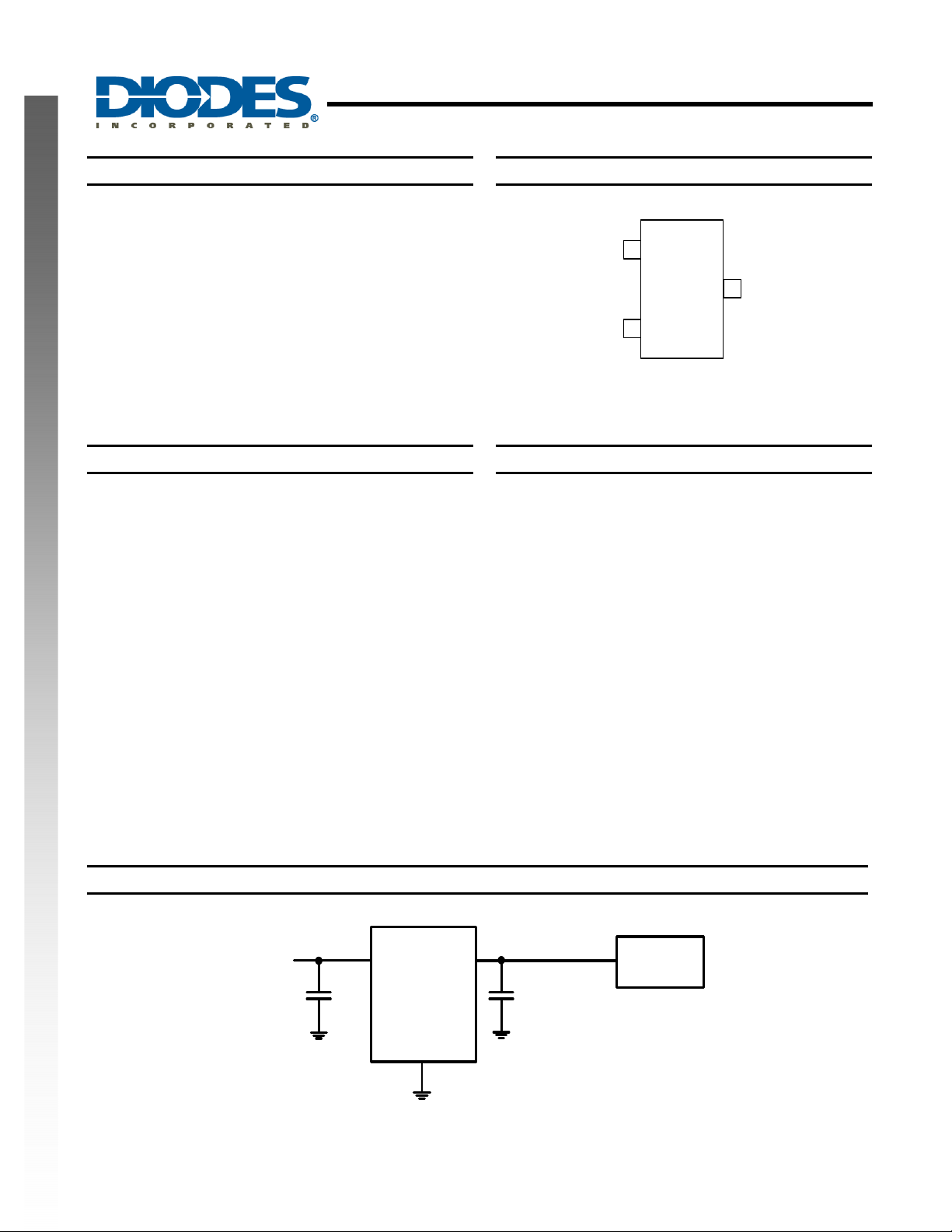

Pin Assignments

Applications

• LCD TVs & Monitors

• Set-Top-Boxes, Residential Gateways

• Laptops, Desktops, Servers

• Printers, Docking Stations, HUBs

• Smart phones, e-Readers

GND

OUT

( Top View )

1

2

SOT23

IN

3

Typical Application Circuit

Power Supply

2.7V to 5.5V

AP2337

Document number: DS35060 Rev. 2 - 2

0.1µF

IN

OUT

GND

1 of 10

www.diodes.com

0.1µF

Load

October 2011

© Diodes Incorporated

Page 2

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

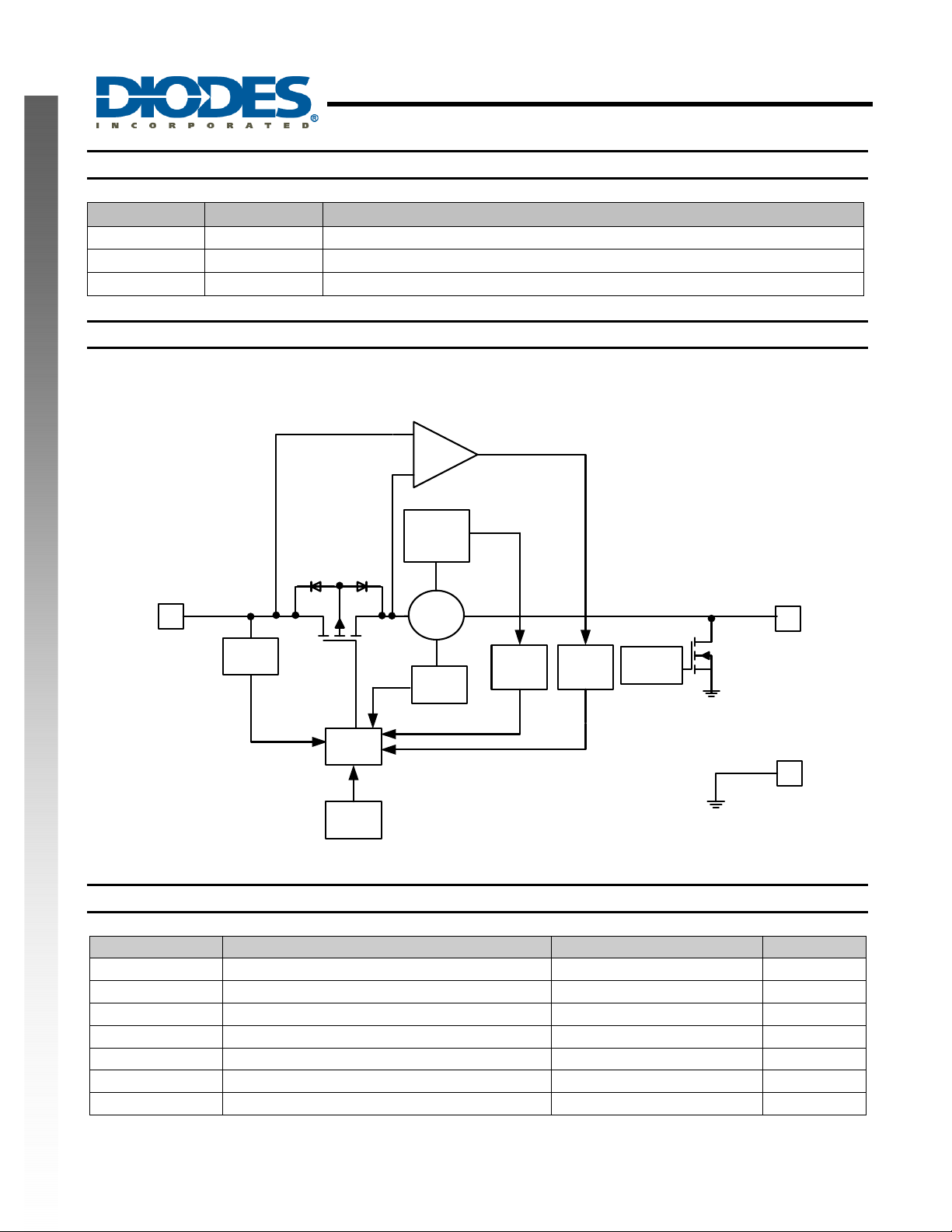

Pin Descriptions

Pin Name Pin Number Descriptions

GND

OUT

1 Ground

2 Switch output pin

IN 3 Voltage input pin

Function Block Diagram

Reverse

Voltage

Comparator

-

+

AP2337

NEW PRODUCT

IN

UVLO

Driver

Thermal

Sense

Reverse

Current

Limit

Current

Sense

Current

Limit

Absolute Maximum Ratings

Symbol Parameter Ratings Units

ESD HBM Human Body Model ESD Protection 3 KV

ESD MM Machine Model ESD Protection 300 V

VIN

V

OUT

I

load

T

Jmax

TST

Notes: 2. UL Recognized Rating from -30°C to 70°C (Diodes qualified TST from -65°C to 150°C)

Input Voltage 6.5 V

Output Voltage

Maximum Continuous Load Current Internal Limited A

Maximum Junction Temperature 150 °C

Storage Temperature Range (Note 2) -65 to 150 °C

0.6ms

Deglitch

Time

15us

Deglitch

Time

Discharge

Control

VIN + 0.3

OUT

GND

V

AP2337

Document number: DS35060 Rev. 2 - 2

2 of 10

www.diodes.com

October 2011

© Diodes Incorporated

Page 3

AP2337

A

Recommended Operating Conditions

Symbol

V

IN

I

OUT

T

Electrical Characteristics (T

Symbol Parameter Test Conditions (Note 3) Min Typ. Max Unit

V

Input UVLO

UVLO

I

Input quiescent current

Q

I

Reverse leakage current

REV

R

DS(ON)

I

LIMIT

NEW PRODUCT

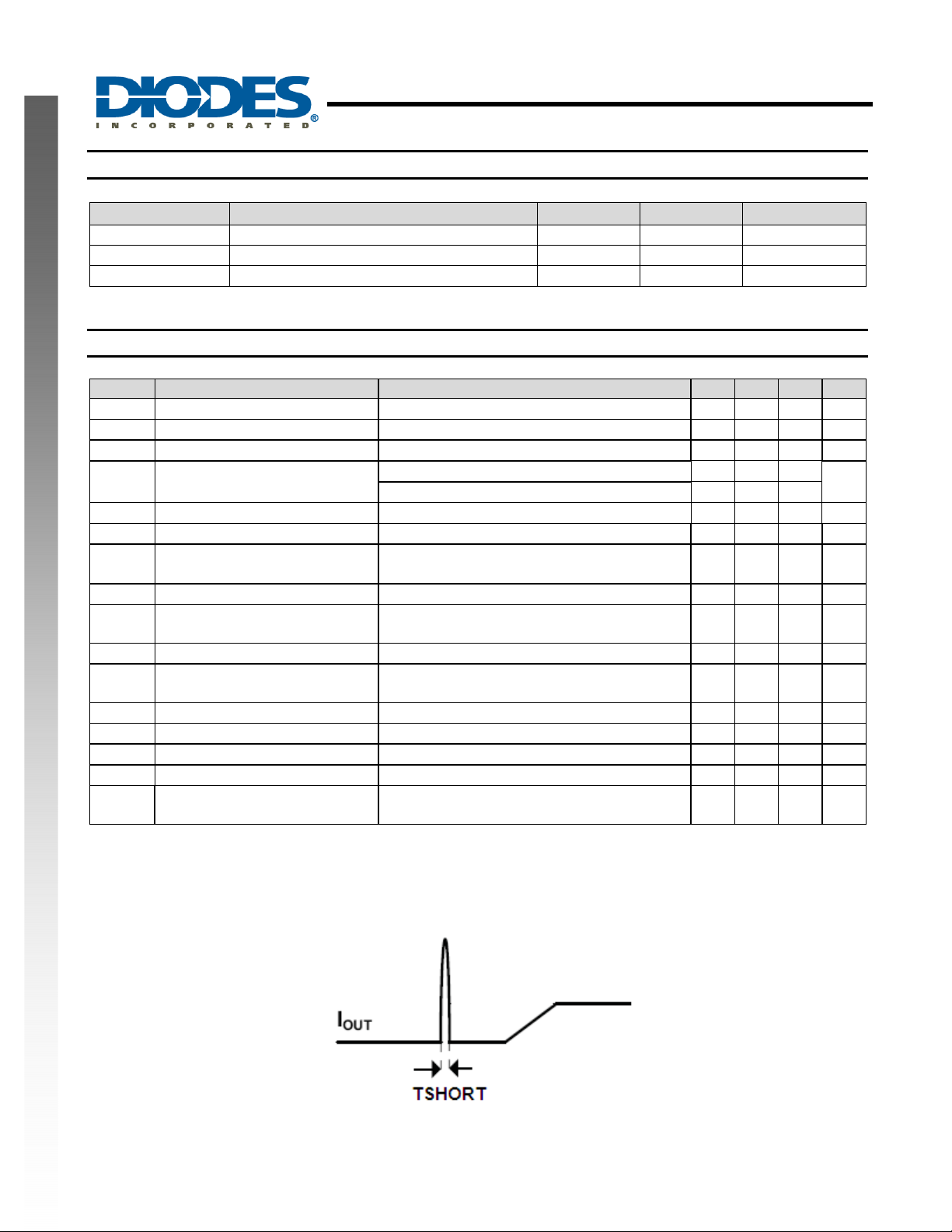

T

SHORT

I

ROCP

T

V

T

TON

T

T

SHDN

T

Notes: 3. Pulse-testing techniques maintain junction temperature close to ambient temperature; thermal effects must be taken into account separately.

4. During output over-voltage protection, the output draws approximately 60µA current.

5. Since the output turn-on slew rate is dependent on input supply slew rate, this limit is only applicable for input supply slew rate between 5V/0.2ms to

5V/1ms.

6. Device mounted on FR-4 substrate PCB, 2oz copper, with minimum recommended pad layout.

7. Applicable for output voltage slew rate ≤ 5V/30μs.

Switch on-resistance

Over-load current limit

IOS

Short-circuit current

Short-circuit response time

Reverse current limit Above UVLO 0.3 0.5 0.7 A

Deglitch time from reverse current

Trig

trigger to MOSFET turn off

Output over-voltage trip point Above UVLO (Note 4) 110% 120%

OVP

Debounce time from output over-

OVP

voltage to MOSFET turn off

Output turn-on time (Note 5)

Discharge time

DIS

Thermal shutdown threshold 150 °C

Thermal shutdown hysteresis 20 °C

HYS

Thermal Resistance Junction-to-

θ

JA

Ambient

Input voltage 2.7 5.5 V

Output Current 0 1.0 A

Operating Ambient Temperature -40 85

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

Parameter Min Max Units

= 25oC, V

A

= +5.0V, unless otherwise stated)

IN

VIN rising

Above UVLO, I

VIN = 0V, V

= 5V, I

V

IN

OUT

VIN = 3.3V, I

VIN = 5V, V

= 0

OUT

= 5V, I

OUT

= 1A

= 1A

OUT

= 4V, CL=10μF

OUT

REV

at VIN

OUT connected to ground, CL=10μF

From V

< 0.6V to I

OUT

= 0A (OUT shorted to

OUT

GND) (See Figure. 1)(Note 7)

2.00 2.65 V

65 110 μA

0.01 0.1 μA

110 140 mΩ

140 170

1.1 1.5 1.9 A

0.2 0.6 1.0 A

5 μs

0.6 ms

15 μs

CL = 1μF, R

CL= 1μF, from UVLO to V

= 5Ω (UVLO to 90% V

load

OUT

< 0.3V

OUT-NOM

)

1 4 ms

500 μs

(Note 6) 180

°C

VIN

o

C/W

Figure 1. Short Circuit Response Time

AP2337

Document number: DS35060 Rev. 2 - 2

3 of 10

www.diodes.com

October 2011

© Diodes Incorporated

Page 4

µ

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

Typical Performance Characteristics

UVLO Increasing

AP2337

UVLO Decreasing

NEW PRODUCT

1ms/div

Over-Load Current Limit

=

50ms/div

Output Over Voltage Trip Point

OV trip at

114% of Vin,

Vin=5V

5ms/div

Short Circuit Current Limit

=

100us/div

Debounce time from output over-voltage to

MOSFET turn off

(Zoom in at red portion of previous waveform)

TOVP

12

s

500us/div

20us/div

AP2337

Document number: DS35060 Rev. 2 - 2

4 of 10

www.diodes.com

October 2011

© Diodes Incorporated

Page 5

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

Typical Performance Characteristics (cont.)

Deglitch time from reverse current trigger to

MOSFET turn off

AP2337

Reverse Current Limit

NEW PRODUCT

500us/div

Output Turn-on Time

1ms/div

500us/div

Discharge Time

5ms/div

AP2337

Document number: DS35060 Rev. 2 - 2

5 of 10

www.diodes.com

October 2011

© Diodes Incorporated

Page 6

P

PLY CUR

R

A

5

ON-S

A

E RESIS

A

C

E

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

Typical Performance Characteristics (cont.)

95

AP2337

0.615

NEW PRODUCT

90

85

)

80

ENT (µ

75

70

65

SU

60

55

50

Fig. 1 Quiescent Supply Current vs. Ambient Temperature

3.

2.5

1.5

OUTPUT TURN ON-TIME (ms)

0.5

1.46

-20020406080-40

AMBIENT TEMPERATURE (°C)

3

2

1

C = 1µF

L

Ω

R = 5

0

2.533.544.555.5

Fig. 3 Output Turn On-Time vs. Input Voltage

INPUT VOLTAGE (V)

L

0.61

0.605

0.6

0.595

0.59

0.585

0.58

SHORT CIRCUIT CURRENT (mA)

0.575

0.57

6

Fig. 2 Short Circuit Output Current vs. Ambient T e mperature

200

180

160

Ω

(m )

140

N

120

T

100

80

T

T

60

40

20

600

-20 0 20 40 60 80-40

AMBIENT TEMPERATURE (°C)

0

-20 0 20 40 60 80-40

Fig. 4 Switch On-Resistance vs. Ambient T e mperature

AMBIENT TEMPERATURE (°C)

1.45

1.44

1.43

1.42

OVERLOAD CURRENT LIMIT (A)

1.41

1.4

Fig. 5 Current Limit Trip Threshold vs. Ambient Temperature

AP2337

Document number: DS35060 Rev. 2 - 2

-20 0 20 40 60 80-40

AMBIENT TEMPERATURE (°C)

6 of 10

www.diodes.com

580

560

540

520

REVERSE CURRENT LIMIT (mA)

500

480

Fig. 6 Reverse Cu r r ent Limit vs. A mbient Temperature

-20 0 20 40 60 80-40

AMBIENT TEMPERATURE (°C)

October 2011

© Diodes Incorporated

Page 7

AP2337

Application Note

Protection Features:

Under-voltage Lockout (UVLO)

Whenever the input voltage falls below UVLO threshold (~2.5V), the power switch is turned off. This facilitates the design of

hot-insertion systems where it is not possible to turn off the power switch before input power is removed.

Over-current and Short Circuit Protection

An internal sensing FET is employed to check for over-current conditions. Unlik e current-sense resistors, sense F ETs do not

increase the series resistance of the current path. When an overcurrent condition is detected, the device maintains a constant

output current and reduces the output voltage accordingly. Compl ete shutdown occurs only if the fault stays long enough to

activate thermal limiting.

The different overload conditions and the corresponding response of the AP2337 are ou tlined below:

NO Conditions Explanation Behavior of the AP2337

Short circuit condition at

1

start-up

NEW PRODUCT

Short-circuit or

2

Overcurrent condition

Gradual increase from

nominal operating current

3

to I

Reverse Current Protection

The USB specification does not allow an output device to source current back into the USB port. In a normal MOSFET

switch, current will flow in reverse direction (from the output side to the input side) when the output side voltag e is hig her than

the input side. A reverse current limit feature is implemented in the AP2337 to limit such back currents. This circuit is

activated by the difference between the output voltage and the input voltage (100mV TYP). After the reverse current circuit

has tripped (reached the reverse current trip threshold), the current rises until I

600us, output device is disabled and shutdown. This is called the "Deglitc h time from reverse current trigger to MOSFET turn

off”. Recovery from IROCP occurs when the output voltage falls to 101% of input voltage.

Over-Voltage Protection

The device has an output over-voltage protection that triggers when the output voltage reaches 114% (TYP) of input

voltage. When this fault condition stays on for longer than 15us (This is called the “Debounce time from output over-voltage to

MOSFET turn off” ) output device is disabled and shutdo wn. Recovery from ROVP occurs when the output voltage falls to

101% of input voltage.

LIMIT

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

Output is shorted before

input voltage is applied or

before the part is powered

up.

Short-Circuit or Overload

condition that occurs when

the part is powered up and

above UVLO.

Load increases gradually

until the current-limit

threshold.

The IC senses the short circuit and immediately

clamps output current to a certain safe level

namely I

• At the instance the overload occurs, higher

current may flow for a very short period of

time before the current limit function can

react.

• After the current limit function has tripped

(reached the over-current trip threshold), the

device switches into current limiting mode

and the current is clamped at I

The current rises until I

has been reached, the device switches into its

current limiting mode and is clamped at I

short

/I

short

LIMIT

. Once the threshold

LIMIT

LIMIT

level. When the fault exists for more than

ROCP

.

.

AP2337

Document number: DS35060 Rev. 2 - 2

7 of 10

www.diodes.com

October 2011

© Diodes Incorporated

Page 8

AP2337

Application Note (cont.)

Thermal Protection

Thermal protection prevents the IC from damage when the die temperature exceeds s afe margins. This mainly occurs when

heavy-overload or short-circuit faults are present for extended perio ds of time. The AP2337 implements a thermal sen sing to

monitor the operating junction temperature of the power distribution switch. Once the die temperature rises to approximately

150°C, the Thermal protection feature gets activated as follows: The inter nal thermal sense circuitry turns the power switch

off thus preventing the power switch from damage. Hysteresis in the thermal sense circuit allows the device to cool d own to

approximately 20°C before the output is turned back o n. This built-in thermal hysteresis feature is an excellent feature, as it

avoids undesirable oscillations of the thermal protectio n circuit. The switch continues to cycle in this manner until the load

fault is removed, resulting in a pulsed output.

Discharge Function

When input voltage is pulled, the discharge function is active. The output capacitor is discharged through an internal NMOS

that has a discharge resistance of 100Ω. Hence, the output voltage drops down to zero. The time taken for discharge is

dependent on the RC time constant of the resistance and the output capacitor. Discharge time is calculated when UVLO

falling threshold is reached to output voltage reaching 300mV.

Power Dissipation and Junction Temperature

NEW PRODUCT

The low on-resistance of the internal MOSFET allows the sm all surface-mount packages to pass large current. Using the

maximum operating ambient temperature (T

PD = R

DS(ON)

Finally, calculate the junction temperature:

T

= PD x R

J

Where:

= Ambient temperature °C

T

A

R

= Thermal resistance

θJA

P

= Total power dissipation

D

θJA

× I

+ TA

2

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

) and R

A

, the power dissipation can be calculated by:

DS(ON)

Ordering Information

AP 2337 SA - 7

Package

SA : SOT23

Device Package Code

AP2337SA-7 SA SOT23 3000/Tape & Reel -7

Notes: 7. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf.

Packaging

(Note 7)

AP2337

Document number: DS35060 Rev. 2 - 2

8 of 10

www.diodes.com

Packing

7 : Tape & Reel

7” Tape and Reel

Quantity Part Number Suffix

October 2011

© Diodes Incorporated

Page 9

Marking Information

AP2337

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

( Top View )

Package Outline Dimensions

NEW PRODUCT

SOT23

K

F

J

AP2337

Document number: DS35060 Rev. 2 - 2

XX

3

Y W

X

XX : Identification code

: Year 0~9

Y

: Week : A~Z : 1~26 week;

W

a~z : 27~52 week; z represents

52 and 53 week

: A~Z : Internal code

1 2

X

Device Package Identification Code

AP2337SA-7 SOT23 KM

A

C

B

H

K1

D

G

L

M

Dim Min Max Typ

A 0.37 0.51 0.40

B 1.20 1.40 1.30

C 2.30 2.50 2.40

D 0.89 1.03 0.915

F 0.45 0.60 0.535

G 1.78 2.05 1.83

H 2.80 3.00 2.90

J 0.013 0.10 0.05

K 0.903 1.10 1.00

K1 - - 0.400

L 0.45 0.61 0.55

M 0.085 0.18 0.11

α

9 of 10

www.diodes.com

SOT23

0° 8° -

All Dimensions in mm

October 2011

© Diodes Incorporated

Page 10

AP2337

1.0A SINGLE CHANNEL CURRENT-LIMITED LOAD SWITCH

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products des cribed herein in such applications shall

assume all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes

Incorporated website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales

channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify

and hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of,

directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and

markings noted herein may also be covered by one or more United States, international or foreign trademarks.

NEW PRODUCT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the

express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause

the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life sup port devices or systems,

and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-relat ed requirements concerning their products

and any use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systemsrelated information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and

its representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or

systems.

Copyright © 2011, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in acc ordance with instructions for use provided in the

IMPORTANT NOTICE

LIFE SUPPORT

AP2337

Document number: DS35060 Rev. 2 - 2

10 of 10

www.diodes.com

October 2011

© Diodes Incorporated

Loading...

Loading...