Page 1

AP2280

Single Channel Slew Rate Controlled Load Switch

Features

• Wide input voltage range: 1.5V – 6V

• Low R

• Turn-on slew rate controlled

• AP2280-1: 100us turn-on rise time

• AP2280-2: 1ms turn-on rise time

• Very low turn-on quiescent current: << 1uA

• Fast load discharge pin

• Temperature range -40ºC to 85°C

• SOT25 and DFN2018-6: Available in “Green” Molding

Compound (No Br, Sb)

• Lead Free Finish/ RoHS Compliant (Note 1)

: 80mΩ typical @ 5V

DS(ON)

Applications

• Smart Phones

• Personal Digital Assistant (PDA)

• Cell Phones

• GPS Navigators

• Bluetooth Headsets

• PMP/MP4

• Notebook and Pocket PC

Description

The AP2280 slew rate controlled load switch is a si ngle P -channel

MOSFET power switch designed for high-side load-switching or

power distribution applications. The MOSFET has a typical

of 80mΩ at 5V, allowing increased load current handling

R

DS(ON)

capability with a low forward voltage drop. The turn-on slew rate of

the device is controlled internally to reduce turn-on inrush current.

The AP2280 load switch is designed to operate from 1.5V t o 6.0V,

making it ideal for 1.8V, 2.5V, 3.3V, and 5V systems. The typical

quiescent supply current is only 0.004uA, making it ideal for

battery powered distribution system where the power

consumption is a concern.

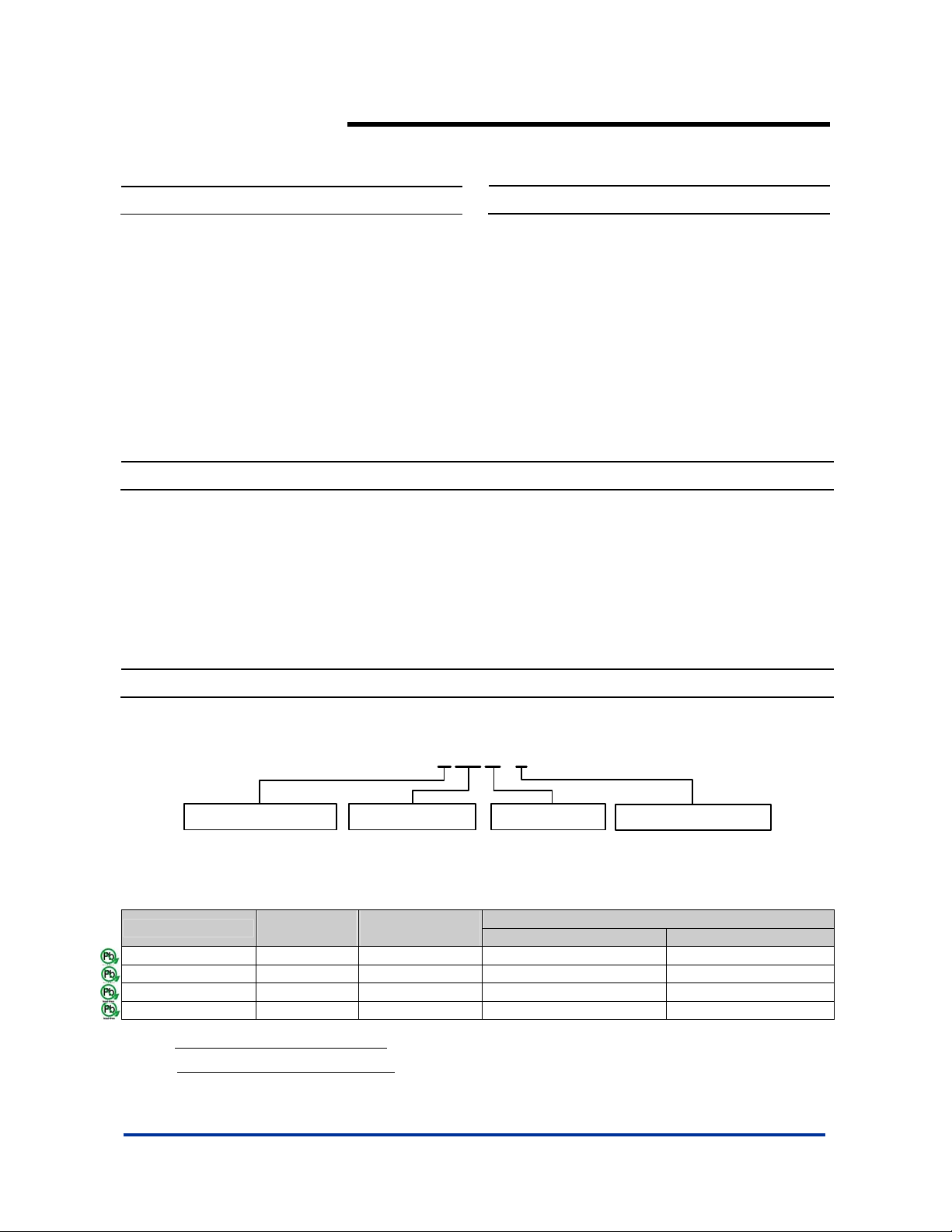

Ordering Information

Turn- on rise time

1 : 100us

2 : 1ms

AP2280 - X XX G - 7

Package

W : SOT25

FM : DFN2018-6

Green

G : Green

Packing

7 : Tape & Reel

Device

Package

Code

Packaging

(Note 2)

Quantity Part Number Suffix

AP2280-1WG-7 W SOT25 3000/Tape & Reel -7

AP2280-2WG-7 W SOT25 3000/Tape & Reel -7

AP2280-1FMG-7 FM DFN2018-6 3000/Tape & Reel -7

AP2280-2FMG-7 FM DFN2018-6 3000/Tape & Reel -7

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at

http://www.diodes.com/products/lead_free.html

2. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf.

.

7” Tape and Reel

AP2280 Rev. 6 1 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 2

Single Channel Slew Rate Controlled Load Switch

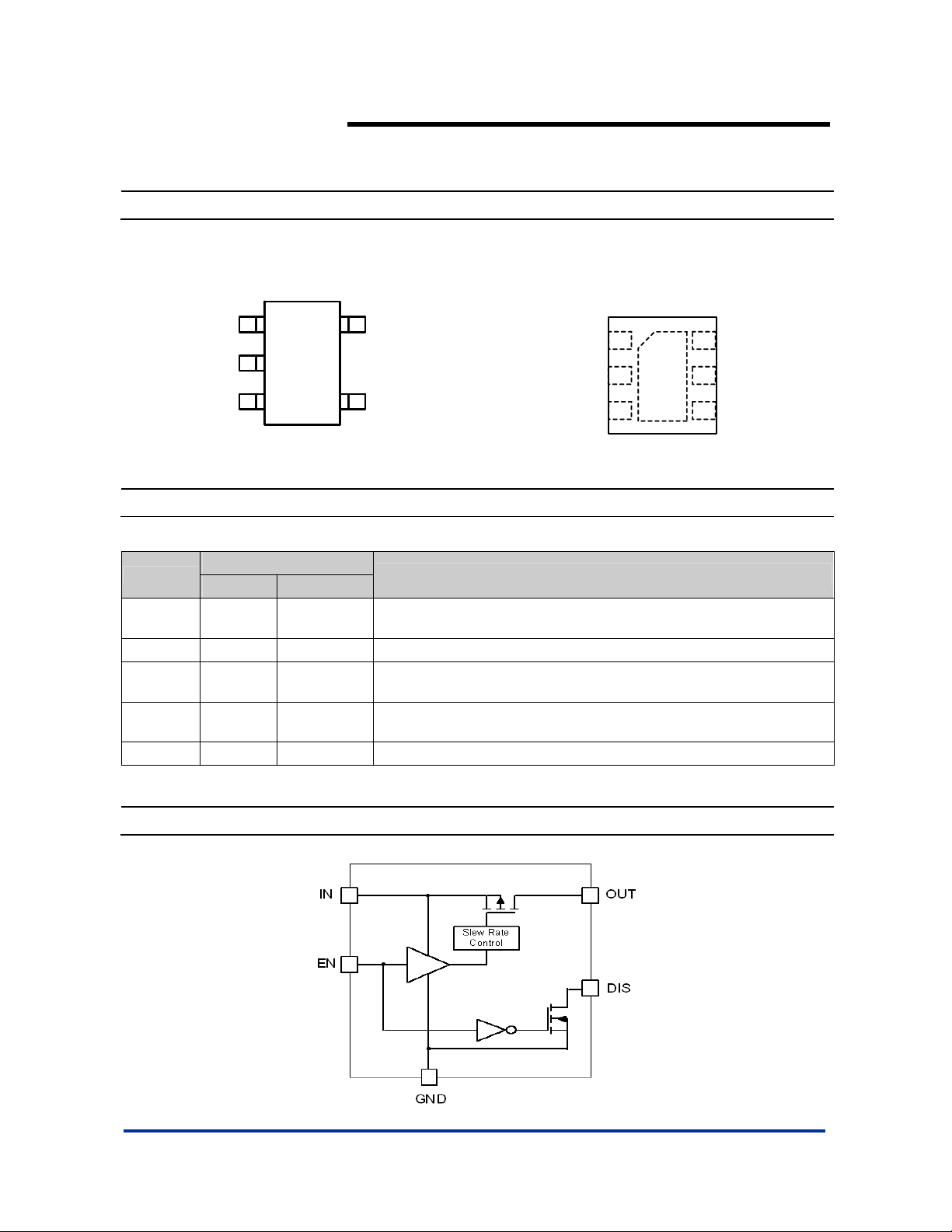

Pin Assignments

(1) SOT25 (2) DFN2018-6

GND

OUT IN

Pin Description

Pin Name

DIS 1 3

GND 2 2 Ground.

OUT

IN

EN 5 4 Enable input, active high

( Top View )

DIS

1

2

Pin Number

SOT25 DFN2018-6

3 1

4 5, 6

5

EN

43

Discharge pin. If DIS pin is tied to OUT pin externally, the output voltage

will be discharged to ground when disabled.

Voltage output pin. This is the pin to the P-channel MOSFET drain.

Bypass to ground through a 0.1uF capacitor.

Voltage input pin. This is the pin to the P-channel MOSFET source.

Bypass to ground through a 1µF capacitor.

( Top View )

OUT

GND

DIS

Description

1

2

3

AP2280

6

IN

5

IN

4

EN

Block Diagram

AP2280 Rev. 6

2 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 3

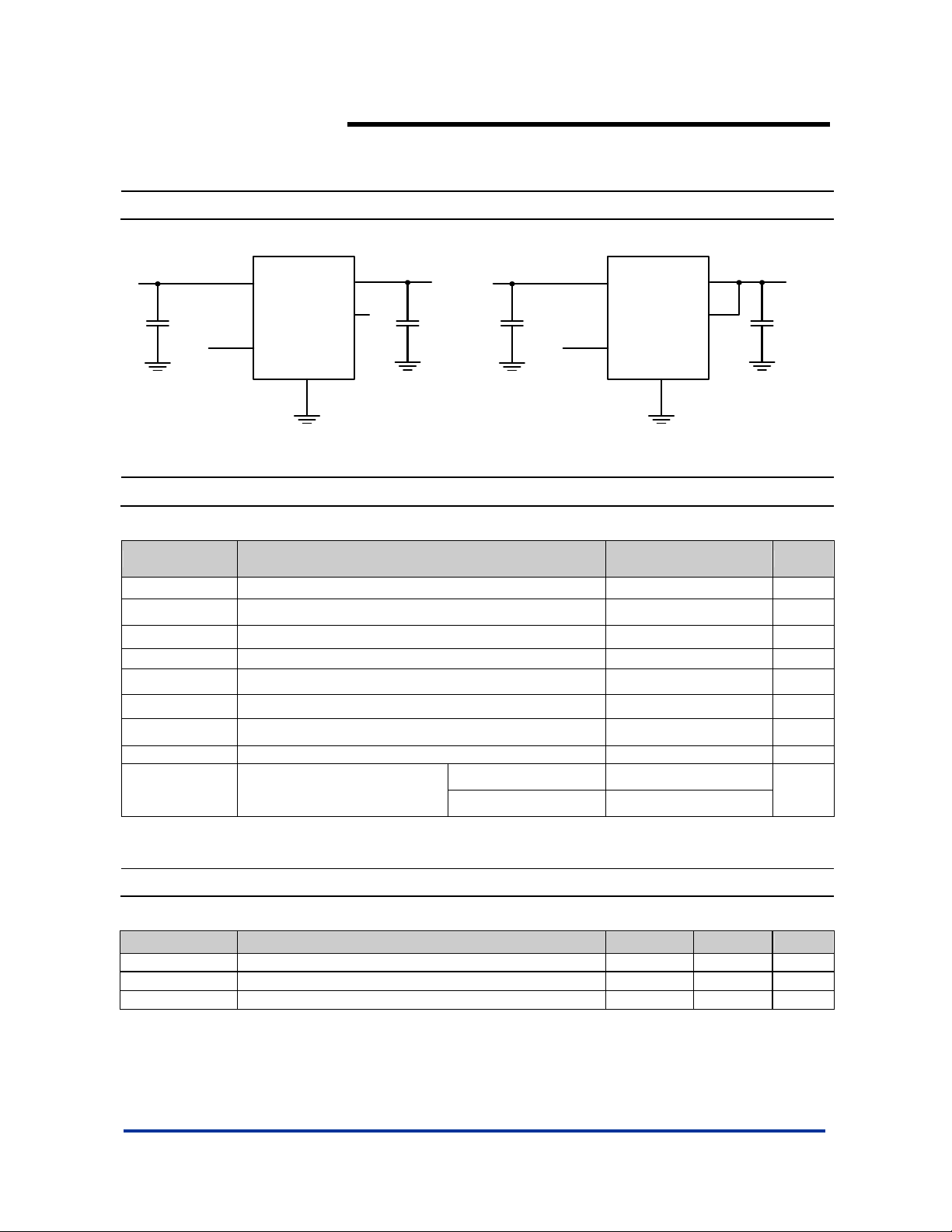

T ypical Application Circuits

V

IN

IN

OUT

AP2280

Single Channel Slew Rate Controlled Load Switch

V

OUT

V

IN

IN

OUT

V

OUT

1uF

Enable

EN

GND

DIS

0.1uF

1uF

Enable

EN

DIS

GND

For applications without output discharge For applications with output discharge

Absolute Maximum Ratings

Symbol Parameter Ratings Units

ESD HBM Human Body Model ESD Protection 4 KV

ESD MM Machine Model ESD Protection 400 V

VIN Input Voltage 6.5 V

V

Output Voltage VIN + 0.3

OUT

VEN Enable Voltage 6.5 V

I

Maximum Continuous Load Current 2 A

load

T

Maximum Junction Temperature 125 °C

J(max)

TST Storage Temperature Range -65 ~ 150 °C

SOT25 (Note 3, 5) 750

PD Power Dissipation

DFN2018-6 (Note 3, 6) 1260

Notes: 3. Ratings apply to ambient temperature at 25°C

Recommended Operating Conditions

Symbol Parameter Min Max Units

V

IN

I

OUT

T

A

Notes: 4. Maximum output current depends on application conditions. Please refer to the application note section.

Input voltage 1.5 6.0 V

Output Current (Note 4) 0 2.0 A

Operating Ambient Te mperature -40 85

0.1uF

V

mW

°C

AP2280 Rev. 6

3 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 4

⎯

μ

)

AP2280

Single Channel Slew Rate Controlled Load Switch

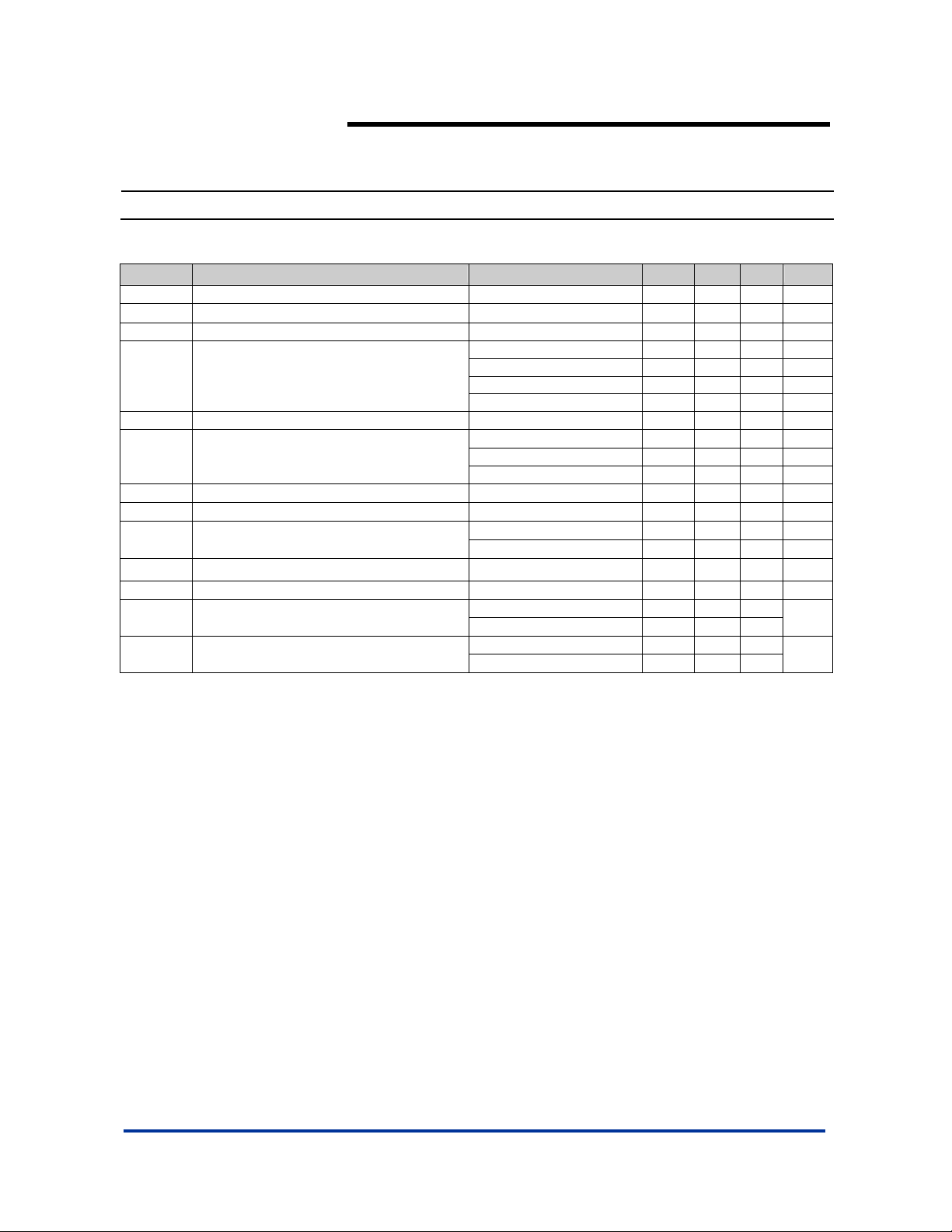

Electrical Characteristics

= 25oC, V

(T

A

Symbol Parameters Test Conditions Min Typ. Max Unit

I

Q

I

SHDN

I

LEAK

R

DS(ON)

V

IL

V

IH

I

SINK

T

D(ON)

T

ON

T

D(OFF)

R

DISCH

θ

JA

θ

JC

Notes: 5. Test condition for SOT25: Device mounted on FR-4 substrate PC board, with minimum recommended pad layout.

6. Test condition for DFN2018-6: Device mounted on FR-4 2-layer board, 2oz copper, with minimum recommended pad on top layer and 3 vias to

bottom layer 1.0"x1.4" ground plane.

AP2280 Rev. 6

= VEN = 5.0V, unless otherwise stated)

IN

Input Quiescent Current VEN = VIN, I

Input Shutdown Current VEN = 0V, OUT open

Input Leakage Current VEN = 0V, OUT grounded

V

= 5.0V 80 105 m

IN

Switch on-resistance

VIN = 3.3V 92 120 m

VIN = 1.8V 150 200 m

OUT

= 0

⎯

⎯

0.004 1

0.004 1

0.01 1

VIN = 1.5V 200 250 m

EN Input Logic Low Voltage VIN = 1.5V to 6V 0.4 V

1.4 V

1.7 V

⎯

1

1

100 150

1000 1500

0.4 1

EN Input Logic High Voltage

EN Input leakage V

Output turn-on delay time

Output turn-on rise time

Output turn-off delay time

1.5V ≤ V

≤ 2.7V

IN

2.7V < VIN < 5.25V 1.6 V

VIN ≥ 5.25V

= 5V

EN

R

=10Ω

load

AP2280-1, R

AP2280-2, R

R

=10Ω

load

load

load

=10Ω

=10Ω

Discharge FET on-resistance VEN = GND 20 40

Thermal Resistance Junction-to-Ambient

Thermal Resistance Junction-to-case

4 of 12 FEBRUARY 2009

SOT25 (Note 5) 160

DFN2018-6 (Note 6

93

SOT25 (Note 5) 38

DFN2018-6 (Note 6) 41

www.diodes.com © Diodes Incorporated

μA

μA

μA

μS

μS

μS

μS

o

C/W

o

C/W

A

Page 5

Single Channel Slew Rate Controlled Load Switch

Typical Performance Characteristics

AP2280

Quiescent Current vs. Input Voltage

0.01

0.008

0.006

0.004

0.002

Quiescent Current (uA)

0

1.0 2.0 3.0 4.0 5.0 6.0

Input Voltag e (V)

R

vs. Input Voltage

DS(ON)

300.00

250.00

200.00

(m)

150.00

DS(ON)

R

100.00

50.00

1.522.533.544.555.56

Input Voltage (V)

I=100mA

I=500mA

I=1A

I=2A

Quiescent Current vs. Temperature

0.020

0.015

0.010

0.005

Quiescent Current (uA)

0.000

-40 -20 0 20 40 60 80 100

VIN=1.8V

VIN=3.3V

VIN=5.0V

Temperature (0C)

R

vs. Temperature

DS(ON)

200.00

180.00

160.00

140.00

120.00

(m)

100.00

80.00

DS(ON)

60.00

R

40.00

20.00

0.00

-50 -25 0 25 50 75 100

VIN =1.8V

VIN =3.3V

VIN =5V

Temperature (0C)

ENABLE Threshold vs. Input Voltage

1.8

1.6

1.4

1.2

1

0.8

0.6

ON/OFF Threshold (V)

0.4

1.522.533.544.555.5

Input Voltage (V)

AP2280 Rev. 6

5 of 12 FEBRUARY 2009

Input Shutdown Current vs. Temperature

VIN=5V

0.010

0.008

0.006

(uA)

0.004

SHDN

VIL (V)

VIH (V)

I

0.002

0.000

-40-200 20406080100

Temperature (0C)

www.diodes.com © Diodes Incorporated

Page 6

Single Channel Slew Rate Controlled Load Switch

Typical Performance Characteristics (Continued)

AP2280-1 Turn-On

(VIN=3.3V, RL=7)

V

V

(2V/div)

EN

V

(2V/div)

OUT

I

(500mA/div)

IN

(2V/div)

EN

V

(2V/div)

OUT

I

(500mA/div)

IN

AP2280

AP2280-1 Turn-Off

(VIN=3.3V, RL=7)

V

(2V/div)

EN

V

(2V/div)

OUT

I

(500mA/div)

IN

Time (50s/div)

AP2280-1 Turn-On

(VIN=5V, RL=10)

Time (50s/div)

V

(2V/div)

EN

V

(2V/div)

OUT

I

(500mA/div)

IN

Time (5s/div)

AP2280-1 Turn-Off

(VIN=5V, RL=10)

Time (5s/div)

AP2280 Rev. 6

6 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 7

Single Channel Slew Rate Controlled Load Switch

Typical Performance Characteristics (Continued)

AP2280-2 Turn-On

(VIN=3.3V, RL=7)

V

(2V/div)

V

(2V/div)

EN

V

(2V/div)

OUT

I

(500mA/div)

IN

EN

V

(2V/div)

OUT

I

(500mA/div)

IN

AP2280

AP2280-2 Turn-Off

(VIN=3.3V, RL=7)

V

(2V/div)

EN

V

(2V/div)

OUT

I

(500mA/div)

IN

Time (500s/div)

AP2280-2 Turn-On

(VIN=5V, RL=10)

Time (500s/div)

V

(2V/div)

EN

V

(2V/div)

OUT

I

(200mA/div)

IN

Time (5s/div)

AP2280-2 Turn-Off

(VIN=5V, RL=10)

Time (5s/div)

AP2280 Rev. 6

7 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 8

Single Channel Slew Rate Controlled Load Switch

Application Note

Input Capacitor

A 1μF capacitor is recommended to connect

between IN and GND pins to decouple input power

supply glitch and noise. The input capacitor has no

specific type or ESR (Equivalent Series Resistance)

requirement. However, for higher current

application, ceramic capacitors are recommended

due to their capability to withstand input current

surges from low impedance sources, such as

batteries in portable applications. This input

capacitor must be located as close as possible to

the device to assure input stability and less noise.

For PCB layout, a wide copper trace is required for

both IN and GND.

Output Capacitor

A 0.1μF capacitor is recommended to connect

between OUT and GND pins to stabilize and

accommodate load transient condition. The output

capacitor has no specific type or ESR requirement.

The amount of the capacitance may be increased

without limit. For PCB layout, the output capacitor

must be placed as close as possible to OUT and

GND pins, and keep the traces as short as

possible.

Enable/Shutdown Operation

The AP2280 is turned on by setting the EN pin high,

and is turned off by pulling it low. To ensure proper

operation, the signal source used to drive the EN

pin must be able to swing above and below the

specified turn-on/off voltage thresholds listed in the

Electrical Characteristics section under V

Discharge Operation

The AP2280 off ers discharge opti on that helps to

discharge the output when disabled. To use this

feature, the DIS pin is connected to OUT pin

externally. If this feature is not used, the DIS pin

should be left open.

and VIH.

IL

AP2280

Power Dissipation

The device power dissipation and proper sizing of

the thermal plane is critical to avoid thermal

shutdown and ensuring reliable operation. Power

dissipation of the device depends on input voltage

and load conditions and can be calculated by:

However, the maximum power dissipation that can

be handled by the device depends on the

maximum junction to ambient thermal resistance,

maximum ambient temperature, and maximum

device junction temperature, which can be

approximated by the equation below:

For example at V

For I

=2A, the maximum power dissipation

OUT

calculated using equation (1) is P

=160°C/W and equation (2) , the calculat ed

on

JA

junction temperature rise from ambient is

approximately 51°C. Since the maximum junction

temperature is 125°C, the operating ambient

temperature must be kept below 74°C to safely

operate the devi c e .

On the other hand, at T

calculated maximum power dissipation from

equation (2) is P

operating maximum continuous current is 1.77A.

For other ap plication con ditions, th e users should

recalculate the device maxi m um po we r dissipation

based on the operating conditions.

2

xRIP = (1)

OUTD

DSON

)T(max@P

=

AD

=5V, the typical R

IN

=85°C and VIN=5V, the

A

=0.25W. Hence the safe

Dmax

−°+

θ

JA

DSON

=0.32W. Based

D

)TC125(

A

(2)

= 80m.

AP2280 Rev. 6

8 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 9

Marking Information

(1) SOT25

AP2280

Single Channel Slew Rate Controlled Load Switch

( Top View )

(2) DFN2018-6

W X

7

4

: Identification code

XX

: Year 0~9

Y

: Week : A~Z : 1~26 week;

W

a~z : 27~52 week; z represents

52 and 53 week

: A~Z : Green

X

5

XX

Y

1 2 3

Device Package type Identification Code

AP2280-1W SOT25 UA

AP2280-2W SOT25 UB

( Top View )

XX : Identification code

: Year 0~9

Y

: Week : A~Z : 1~26 week;

W

a~z : 27~52 week; z represents

.

Y

XX

W X

52 and 53 week

X

: A~Z : Green

Device Package type Identification Code

AP2280-1FM DFN2018-6 UC

AP2280-2FM DFN2018-6 UD

AP2280 Rev. 6

9 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 10

Single Channel Slew Rate Controlled Load Switch

Package Information (All Dimensions in mm)

(1) Package type: SOT25

AP2280

AP2280 Rev. 6

10 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 11

Package Information (Continued)

(2) Package type: DFN2018-6

AP2280

Single Channel Slew Rate Controlled Load Switch

6X-

2X-

0.10 C

0.08 C

0.25 B

0.545/0.605

0/0.05

B

Pin #1 ID

1.95/2.075

A

0.25

2X-

0.50Typ

Bottom View

Side View

1.75/1.875

C

L

1.3/1.5

0.30Typ

0.15/0.25

0.13Typ

Seating Plane

C

A

0.2/0.3

C

L

0.9/1.1

C

0.10

AB

AP2280 Rev. 6

11 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Page 12

Taping Orientation

AP2280

Single Channel Slew Rate Controlled Load Switch

Notes: 7. The taping orientation of the other package type can be found on our website at http://www.diodes.com/datasheets/ap0 2007.pdf.

IMPORTANT NOTICE

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes without further

notice to any product herein. Diodes Incorporated does not assume any liability arising out of the application or use of any product described herein; neither

does it convey any license under its patent rights, nor the rights of others. The user of products in such applications shall assume all risks of such use and will

agree to hold Diodes Incorporated and all the companies whose products are represented on our website, harmless against all damages.

LIFE SUPPORT

Diodes Incorporated products are not authorized for use as critical components in life support devices or systems without the expressed written approval of the

President of Diodes Incorporated.

AP2280 Rev. 6

12 of 12 FEBRUARY 2009

www.diodes.com © Diodes Incorporated

Loading...

Loading...