Page 1

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

General Description

The AP1662 is an active power factor control IC

which is designed mainly for use as a pre-converter

in electronic ballast, AC-DC adapter and off-line

SMPS applications.

.

The IC includes an internal start-up timer for

stand-alone applications, a one-quadrant multiplier to

realize near unity power factor and a zero current

detector to ensure DCM boundary conduction

operation.

The totem pole output stage is capable of driving

power MOSFET with 600mA source current and

800mA sink current.

Designed with advanced BiCMOS process, the

AP1662 features low start-up current, low operation

current and low power dissipation. The AP1662 also

has rich protection features including over-voltage

protection, input under-voltage lockout with

hysteresis and multiplier output clamp to limit

maximum peak current.

The AP1662 meets IEC61000-3-2 standard even at

one-quadrant load and THD lower than 10% at

high-end line voltage and full load.

The IC is available in SOIC-8 and DIP-8 packages.

Features

Comply with IEC61000-3-2 Standard

•

• Proprietary Design for Minimum THD

• Zero Current Detection Control for DCM

Boundary Conduction Mode

• Adjustable Output Voltage with Precise

Over-voltage Protection

• Low Start-up Current with 40µA Typical Value

• Low Quiescent Current with 2.5mA Typical

Va lu e

• 1% Precision Internal Reference Voltage @

T

=25°C

J

• Internal Start-up Timer

• Disable Function for Reduced Current

Consumption

• Totem Pole Output with 600mA Source and

800mA Sink Current Capability

• Under-voltage Lockout with 2.5V Hysteresis

Applications

• Electronic Ballast

• AC-DC Adapter

• Off-line SMPS

• Single Stage PFC LED Driver

SOIC-8 DIP-8

Figure 1. Package Types of AP1662

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

1

Page 2

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

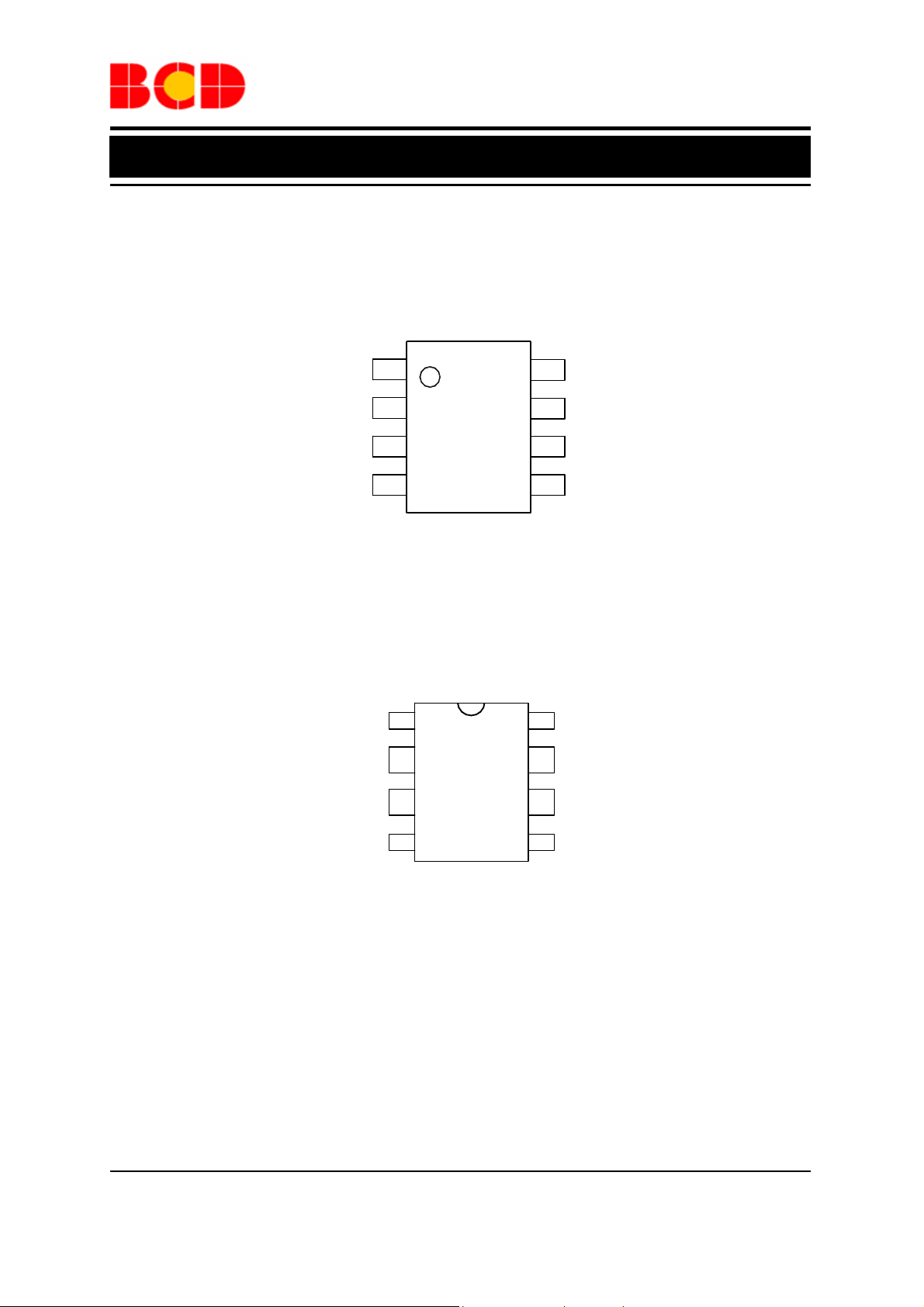

Pin Configuration

M Package

(SOIC-8)

INV VCC

1

8

COMP GD

2

7

MULT GND

3

6

CS ZCD

4

5

P Package

(DIP-8)

INV VCC

1

8

COMP GD

2

7

MULT GND

3

6

CS ZCD

4

5

Figure 2. Pin Configuration of AP1662 (Top View)

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

2

Page 3

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Pin Description

Pin Number Pin Name Function

1 INV Inverting input of the error amplifier

2 COMP Output of the error amplifier

3 MULT Input of the multiplier

4 CS Input of the current control loop comparator

5 ZCD

6 GND

7 GD Gate driver output

Zero current detection input. If it is connected to GND, the

device is disabled

Ground. Current return for gate driver and control circuits of

the IC

8 VCC Supply voltage of gate driver and control circuits of the IC

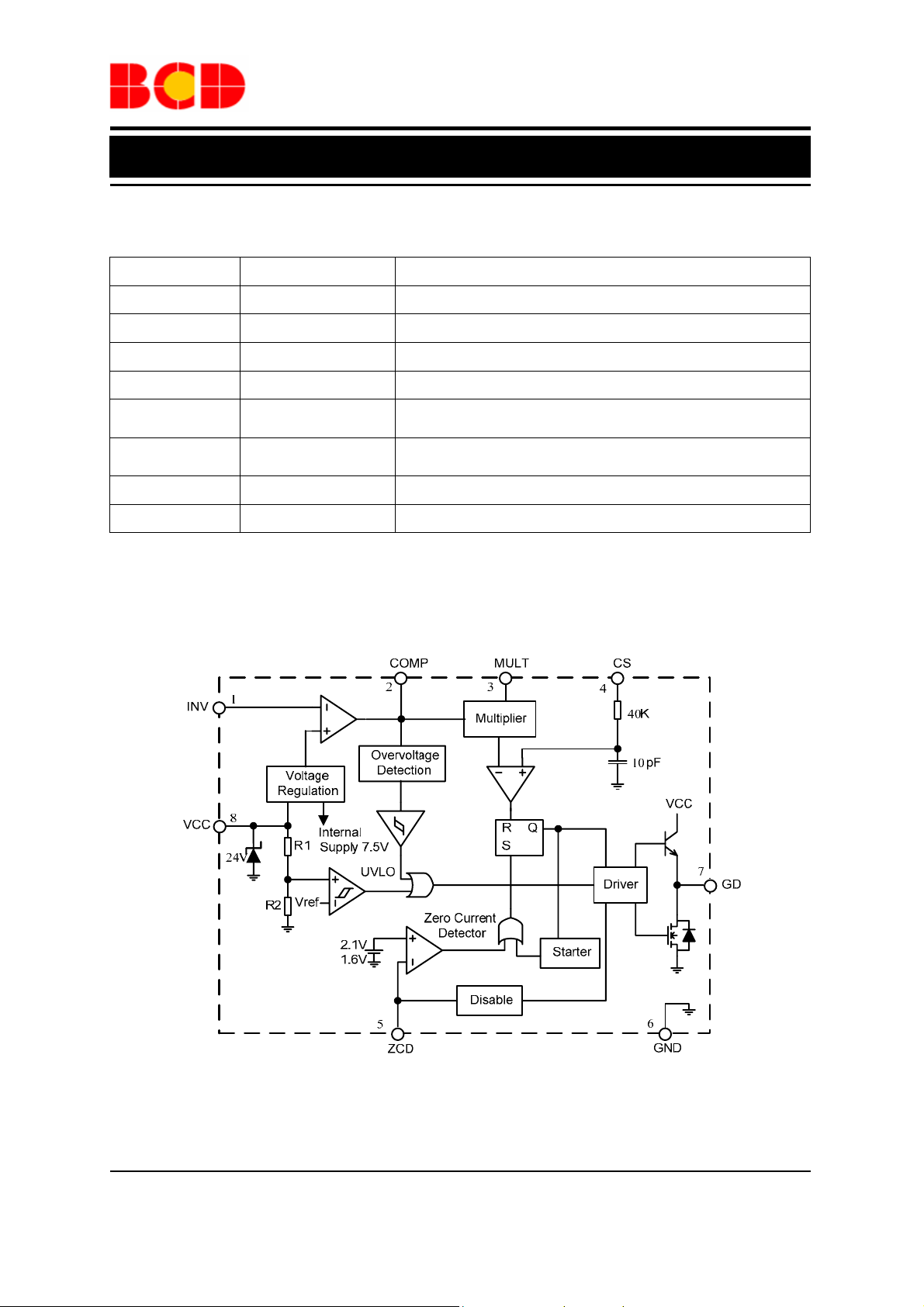

Functional Block Diagram

Figure 3. Functional Block Diagram of AP1662

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

3

Page 4

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

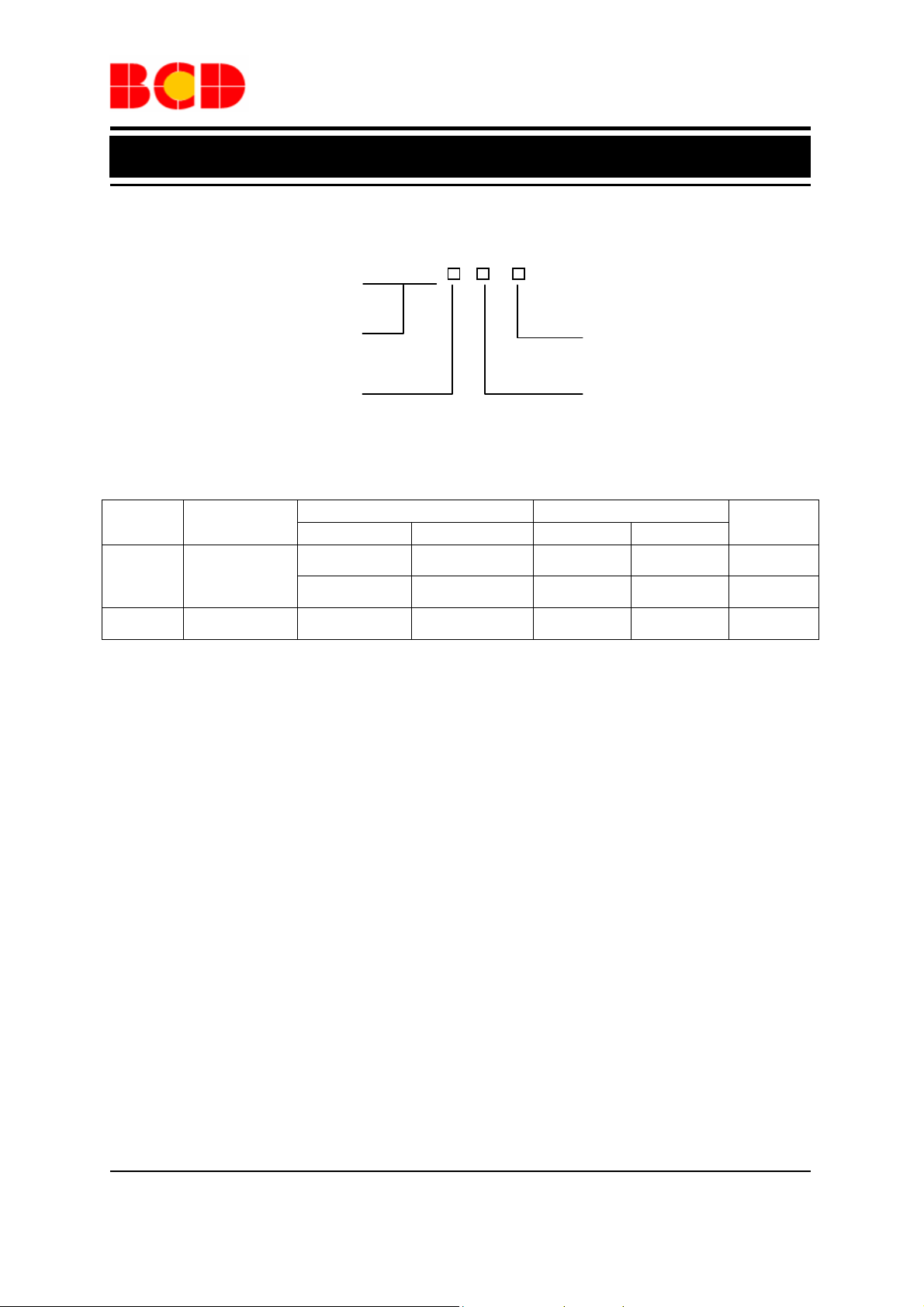

Ordering Information

AP1662 -

Circuit Type E1: Lead Free

Package

SOIC-8

G1: Green

Package Blank: Tube

M: SOIC-8

P: DIP-8

Temperature

Range

-40 to 105°C

TR: Tape & Reel

Part Number Marking ID

Lead Free Green Lead Free Green

AP1662M-E1 AP1662M-G1 1662M-E1 1662M-G1 Tube

AP1662MTR-E1 AP1662MTR-G1 1662M-E1 1662M-G1 Tape & Reel

Packing

Type

DIP-8

-40 to 105°C

AP1662P-E1 AP1662P-G1 AP1662P-E1 AP1662P-G1 Tube

BCD Semiconductor's Pb-free products, as designated with "E1" suffix in the part number, are RoHS compliant.

Products with “G1” suffix are available in green packages.

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

4

Page 5

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

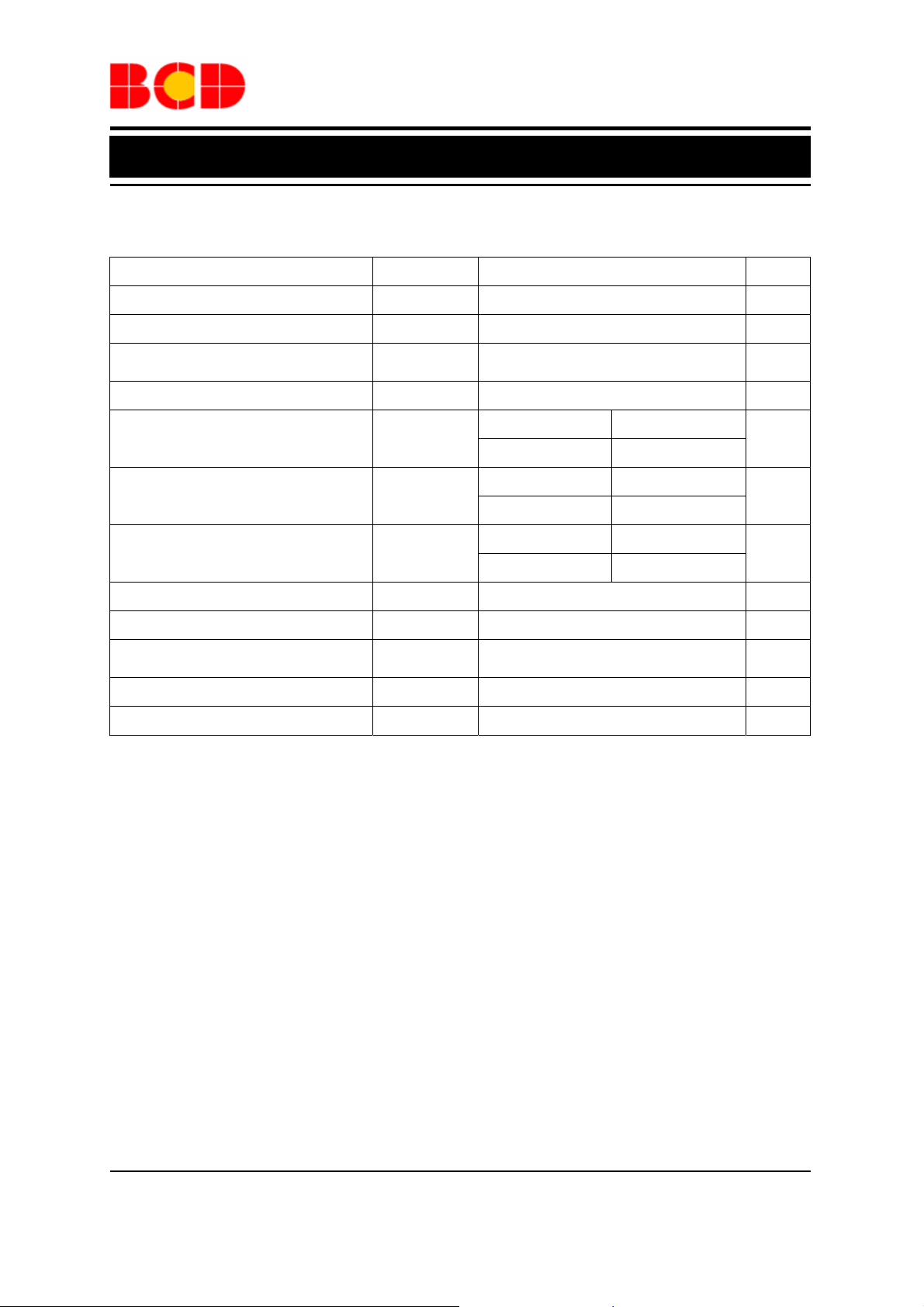

Absolute Maximum Ratings (Note 1)

Parameter Symbol Value Unit

Power Supply Voltage VCC Self-limited V

Operating Supply Current ICC 30 mA

Input/Output of Error Amplifier,

Input of Multiplier

Current Sense Input VCS -0.3 to 7 V

V

INV

V

, V

MULT

COMP

,

-0.3 to 7 V

Zero Current Detector Input I

Power Dissipation and Thermal

characteristics @ T

=50°C

A

Thermal Resistance

(Junction to Ambient)

P

R

ZCD

TOT

θJA

mA

Sink 10

DIP-8 1

W

SOIC-8 0.65

DIP-8 100

ºC/W

SOIC-8 150

Operating Junction Temperature TJ -40 to 150 ºC

Source -50

Storage Temperature Range T

Lead Temperature (Soldering, 10

Seconds)

ESD (Human Body Model) V

ESD (Machine Model) V

-65 to 150 ºC

STG

260 ºC

T

LEAD

ESD(HBM)

ESD(MM)

3000 V

200 V

Note 1: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to

the device. These are stress ratings only, and functional operation of the device at these or any other conditions

beyond those indicated under “Recommended Operating Conditions” is not implied. Exposure to “Absolute

Maximum Ratings” for extended periods may affect device reliability.

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

5

Page 6

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

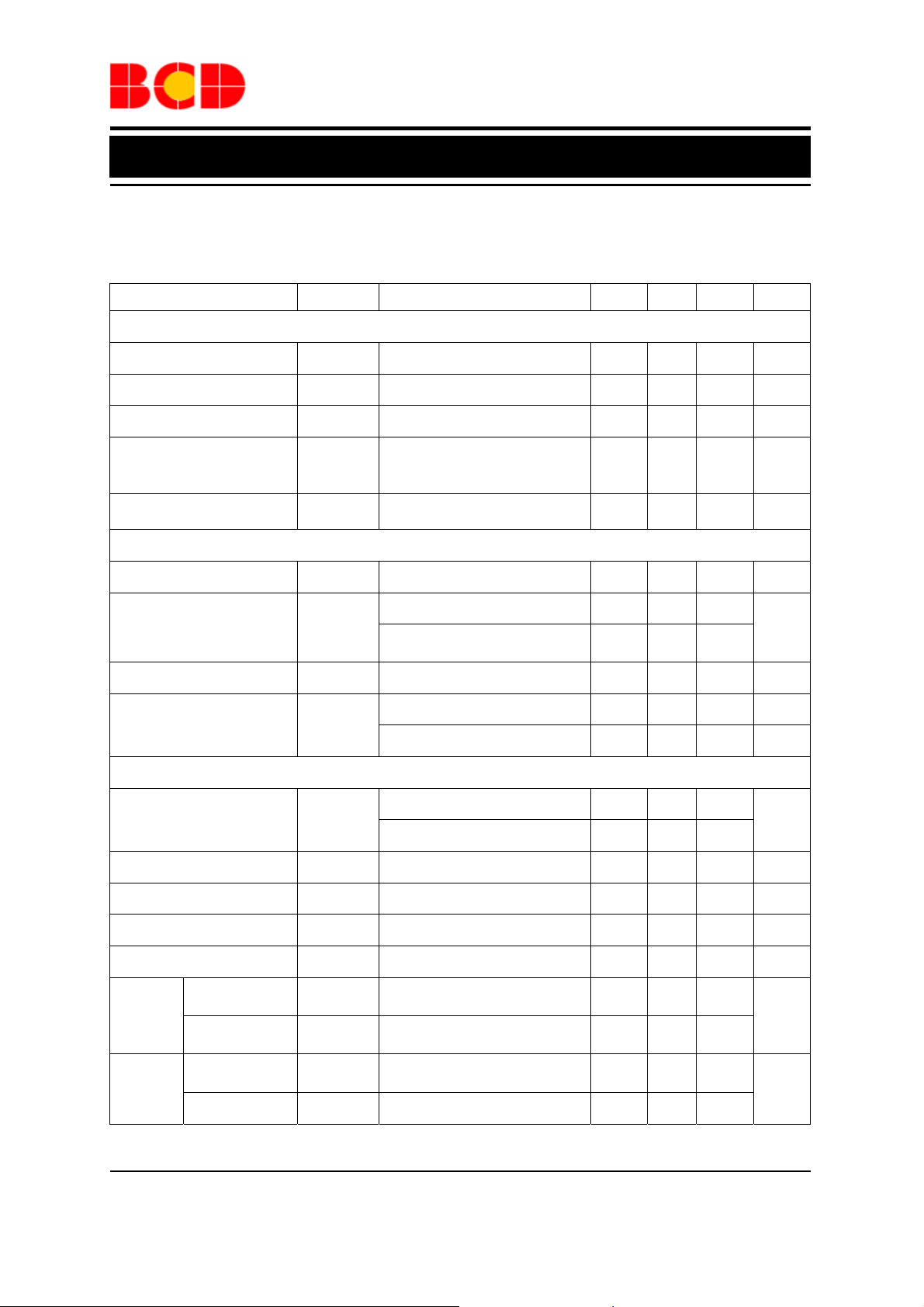

Electrical Characteristics

V

=12V, TJ =-25°C to 125°C, CO=1nF, unless otherwise specified.

CC

Parameter Symbol Test Conditions Min Typ Max Unit

Under Voltage Lockout Section

Turn-on Threshold V

Turn-off Threshold V

Hysteresis V

VCC Rising 11 12 13 V

CC-ON

VCC Falling 8.7 9.5 10.3 V

CC-OFF

2.2 2.5 2.8 V

CC-HYS

VCC Operating Range VCC After turn-on 10.3 22 V

Zener Voltage V

ICC=20mA 22 24 V

Z

Total Supply Current Section

Start-up Current I

START-UP

Operating Supply Current ICC

Quiescent Current IQ After turn on 2.5 3.75 mA

Quiescent Current IQ

VCC=11V before turn-on 40 70

Frequency=70kHz 3.5 5

In OVP condition

=2.7V

V

INV

≤150mV, VCC>V

V

ZCD

V

≤150mV, VCC<V

ZCD

CC-OFF

CC-OFF

1.4 2.2

2.2 mA

20 50 90

µA

mA

µA

Error Amplifier Section

=25ºC 2.465 2.5 2.535

T

Voltage Feedback Input

Threshold

V

INV

J

10.3V<VCC<20V 2.44 2.56

V

Line Regulation VCC=10.3V to 20V 2 5 mV

Input Bias Current I

V

INV

=0 to 3V -0.1 -1

INV

µA

Voltage Gain GV Open Loop 60 80 dB

Gain Bandwidth GB 1 MHz

Output

Voltage

Output

Current

Upper Clamp

Voltage

Lower Clamp

Voltage

Source

Current

Sink Current I

V

V

I

COMP-H

COMP-L

COMP-H

COMP-L

I

SOURCE

I

SINK

V

COMP

V

COMP

=0.5mA 5.15 5.55 5.85

V

=0.5mA 2.1 2.25 2.4

=4V, V

=2.4V -2 -4 -8

INV

mA

=4V, V

=2.6V 2.5 4.5

INV

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

6

Page 7

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Electrical Characteristics (Continued)

V

=12V, TJ =-25°C to 125°C, CO=1nF, unless otherwise specified.

CC

Parameter Symbol Test Conditions Min Typ Max Unit

Multiplier Section

Linear Input Voltage

Range

Output Maximum

Slope

△V

0 to 3

V

MULT

△ VCS/

MULT

Gain k V

Current Sense Section

V

: 0 to 0.5V,

MULT

=Upper Clamp Voltage

V

COMP

=1V, V

MULT

COMP

1.65 1.9

=4V 0.6 0.75 0.9 1/V

0 to

3.5

V

Input Bias Current ICS VCS=0V -1

V

Current Sense Offset

Voltage

Current Sense

Reference Clamp

V

V

Delay to Output t

CS-OFFSET

CS-CLAMP

d(H-L

) 200 350

=0V 30

MULT

V

=2.5V 5

MULT

= Upper Clamp

V

COMP

Voltage, V

MULT

= 2.5V

1.6 1.7 1.8

µA

mV

V

ns

Zero Current Detection Section

Arming Voltage

(positive-going edge)

Triggering Voltage

(negative-going edge)

Upper Clamp Voltage V

Lower Clamp Voltage

Source Current

Capability

Sink Current

Capability

Sink Bias Current I

(Note 2) 2.1

V

ZCDA

(Note 2) 1.6

V

ZCDT

=20µA 4.5 5.1 5.9

I

ZCD

ZCD-H

V

ZCD-L

I

ZCD-SR

I

ZCD-SN

ZCD-B

I

=3mA 4.7 5.2 6.1

ZCD

I

= -3mA 0.3 0.65 1

ZCD

-2.5 -10

3

1V ≤ V

≤ 4.5 V 2

ZCD

V

V

V

V

mA

mA

µA

Disable Threshold V

Disable Hysteresis V

Restart Current After

Disable

ZCD-DIS

ZCD-HYS

I

ZCD-RES

150 200 250

100

V

ZCD<VDIS

, VCC>V

-80 -120

CC-OFF

mV

mV

µA

Note 2: Limits over the full temperature are guaranteed by design, but not tested in production.

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

7

Page 8

K

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Electrical Characteristics (Continued)

V

=12V, TJ =-25°C to 125°C, CO=1nF, unless otherwise specified.

CC

Parameter Symbol Test Conditions Min Typ Max Unit

Drive Output Section

I

GD-SOURCE

V

Dropout Voltage

Output Voltage Rise

Time

Output Voltage Fall Time tF 30 70

Output Clamp Voltage V

UVLO Saturation VOS

OH

VOL I

t

R

O-CLAMP

I

GD-SOURCE

GD-SINK

40 80

I

GD-SOURCE

V

CC

V

CC

I

SIN

=200mA 2.5 3

=20mA 2 2.8

=200mA 0.9 1.9

=20V

=0 to V

=10mA

=5mA

CC-ON

,

9 11 13

1.1

Output Over Voltage Section

OVP Triggering Current I

Static OVP Threshold V

OVP

OVP_TH

35 40 45 µA

2.1 2.25 2.4

Starter

Start Timer Period t

START

75 130 300

V

ns

ns

V

V

V

µs

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

8

Page 9

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Typical Performance Characteristics

3.0

2.5

2.0

1.5

1.0

Supply Current (mA)

0.5

0.0

0 5 10 15 20 25

Supply Voltage (V)

CO=1nF

f=70kHz

=25oC

T

J

12.5

12.0

11.5

11.0

10.5

Voltage (V)

10.0

9.5

9.0

-50 0 50 100 150

V

CC-OFF

Junction Temperature (oC)

V

CC-ON

Figure 4. Supply Current vs. Supply Voltage Figure 5. Start-up & UVLO vs. T

8

4

2

1

(mA)

CC

I

0.0625

0.03125

VCC=12V

0.5

C

=1nF

O

0.25

f=70kHz

0.125

-50 0 50 100 150

Junction Temperature (

Quiescent

Disabled or during OVP

Before start-up

o

C)

28

27

26

(V)

25

CC-CLAMP

V

24

23

22

-50 0 50 100 150

Junction Temperature (oC)

Figure 6. ICC Consumption vs. TJ Figure 7. VCC Zener Voltage vs. TJ

J

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

9

Page 10

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Typical Performance Characteristics (Continued)

2.60

2.55

2.50

(V)

REF

V

2.45

2.40

-50 0 50 100 150

Junction Temperature (

Figure 8. Feedback Reference Voltage vs. TJ Figure 9. OVP Current vs. T

500

400

300

(ns)

200

d(H-L)

t

100

0

-50 0 50 100 150

Junction Temperature (

Figure 10. Delay-to-Output vs. TJ Figure 11. E/A Output Clamp Levels vs. TJ

VCC=12V

O

C)

VCC=12V

o

C)

43.0

42.5

42.0

41.5

41.0

(µA)

OVP

I

40.5

40.0

39.5

39.0

-50 0 50 100 150

Junction Temperature (

6.0

5.5

5.0

4.5

(V)

4.0

COMP

V

3.5

3.0

2.5

2.0

-50 0 50 100 150

Upper Clamp

Lower Clamp

Junction Temperature (oC)

VCC=12V

o

C)

J

VCC=12V

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

10

Page 11

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Typical Performance Characteristics (Continued)

2.0

1.0

1.8

1.6

(V)

1.4

CS-CLAMP

V

1.2

1.0

-50 0 50 100 150

Junction Temperature (

VCC=12V

V

COMP

o

C)

=Upper Clamp

0.8

VCC=12V

V

=4V

0.6

0.4

Multiplier Gain

0.2

0.0

-50 0 50 100 150

Junction Temperature (

COMP

V

=1V

MULT

o

C)

Figure 12. V

CS-CLAMP

0

-2

-4

(mA)

ZCD

I

-6

-8

-50 0 50 100 150

Junction Temperature (

Figure 14. ZCD Source Capability vs. TJ Figure 15. ZCD Clamp Levels vs. TJ

vs. TJ Figure 13. Multiplier Gain vs. T

VCC=12V

V

ZCD

=Lower Clamp

o

C)

7

6

5

4

(V)

ZCD

3

V

2

1

0

-50 0 50 100 150

Junction Temperature (

Upper Clamp

Lower Clamp

VCC=12V

I

= + 2.5mA

ZCD

o

C)

J

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

11

Page 12

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Typical Performance Characteristics (Continued)

200

190

180

170

160

(µS)

START

150

t

140

130

120

-50 0 50 100 150

Junction Temperature (

1.8

VCC=12V

o

C)

1.6

1.4

1.2

1.0

(V)

CS

0.8

V

0.6

0.4

0.2

0.0

0.00.51.01.52.02.53.03.54.04.5

V

=5.0

COMP

=4.5

COMP

V

V

=MAX

COMP

V

V

=4.0

COMP

V

(V)

MULT

COMP

V

V

V

V

=3.5

COMP

COMP

COMP

COMP

=3.2

=3.0

=2.8

=2.6

Figure 16. Start-up Timer vs. TJ Figure 17. Multiplier Characteristics

I

GD

(mA)

6

5

4

(V)

3

GD

V

2

1

0

0 200 400 600 800 1000

TJ=25oC

VCC=11V

SINK

Figure 18. Gate-driver Output Low Saturation Figure 19. Gate-driver Output High Saturation

VGD (V)

V

-2.0

CC

-2.5

V

CC

-3.0

V

CC

V

-3.5

CC

V

-4.0

CC

0 100 200 300 400 500 600 700

TJ=25oC

VCC=11V

SOURCE

I

(mA)

GD

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

12

Page 13

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Typical Performance Characteristics (Continued)

15

1.1

(V)

V

1.0

0.9

0.8

GD_OFF

0.7

0.6

14

13

(V)

12

GD_CLAMP

V

11

VCC=20V

VCC=0V

10

-50 0 50 100 150

Junction Temperature (

o

C)

0.5

-50 0 50 100 150

Junction Temperature (oC)

Figure 20. Gate-driver Clamp vs. TJ Figure 21. UVLO Saturation vs. T

J

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

13

Page 14

∆

×−×

=

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Functional Block Description

AP1662 is a high performance power factor

correction controller which operates in DCM

boundary conduction mode. The PFC converter's

switch will be turned on when the inductor current

reduces to zero and turned off when the sensed

inductor current reaches the required reference which

is decided by the output of multiplier.

Error Amplifier and Over-Voltage

Protection

The error amplifier regulates the PFC output voltage.

The internal reference on the non-inverting input of

the error amplifier is 2.5V. The error amplifier's

inverting input (INV) is connected to an external

resistor divider which senses the output voltage. The

output of error amplifier is one of the two inputs of

multiplier. A compensation loop is connected outside

between INV and the error amplifier output.

Normally, the compensation loop bandwidth is set

very low to realize high power factor for PFC

converter.

To make the over voltage protection fast, the internal

OVP function is added. If the output over voltage

happens, excess current will flow into the output pin

of the error amplifier through the feedback

compensation capacitor. (see Figure 22) The AP1662

monitors the current flowing into the error amplifier

output pin. When the detected current is higher than

40µA, the dynamic OVP is triggered. The IC will be

Figure 22. Error Amplifier and OVP Block

disabled and the drive signal is stopped. If the output

over voltage lasts so long that the output of error

amplifier goes below 2.25V, static OVP will take

place. Also the IC will be disabled until the output of

error amplifier goes back to its linear region. R1 and

R2 (see Fig. 22) will be selected as below:

1

V

R

R

O

1

−=

5.22

V

V

OVP

40

A

µ

R

1

=

Multiplier

The multiplier has two inputs. One (Pin 3) is the

divided AC sinusoidal voltage which makes the

current sense comparator threshold voltage vary from

zero to peak value. The other input is the output of

error amplifier (Pin 2). In this way, the input average

current wave will be sinusoidal as well as reflects the

load status. Accordingly a high power factor and

good THD are achieved. The multiplier transfer

character is designed to be linear over a wide

dynamic range, namely, 0V to 3V for Pin 3 and 2V to

5.8V for Pin 2. The relationship between the

multiplier output and inputs is described as below

equation:

VVkV

)5.2(

MULTCOMPCS

where VCS (Multiplier output) is the reference for the

current sense, k is the multiplier gain, V

COMP

voltage on pin 2 (error amplifier output) and V

the voltage on pin 3.

Current Sense/Current Sense

Comparator

The PFC switch's turn-on current is sensed through

an external resistor in series with the switch. When

the sensed voltage exceeds the threshold voltage (the

multiplier output), the current sense comparator will

become low and the external MOSFET will be turned

off. This insures a cycle-by-cycle current mode

control operation. The maximum current sense

reference is 1.8V. The max value usually happens at

startup process or abnormal conditions such as short

load.

is the

is

MULT

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

14

Page 15

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Functional Block Description

(Continued)

Zero Current Detection

AP1662 is a DCM boundary conduction current

mode PFC controller. Usually, the zero current

detection (ZCD) voltage signal comes from the

auxiliary winding of the boost inductor. When the

ZCD pin voltage decreases below 1.6V, the gate

drive signal becomes high to turn on the external

MOSFET. 500mV of hysteresis is provided to avoid

false triggering. The ZCD pin can be used for

disabling the IC. Making its voltage below 0.15V or

short to the ground will disable the device thus

reduce the IC supply current consumption.

Typical Application

Figure 23. 85 to 265V Wide Range Input 90W PFC Demo Board Electrical Schematic Circuit

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

15

Page 16

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Mechanical Dimensions

SOIC-8 Unit: mm(inch)

4.700(0.185)

5.100(0.201)

7

°

7

°

1.270(0.050)

TYP

0.100(0.004)

0.300(0.012)

1.350(0.053)

1.750(0.069)

0.675(0.027)

0.725(0.029)

D

2

D

1

:

0

0.320(0.013)

5.800(0.228)

6.200(0.244)

0.800(0.031)

°

8

°

8

0.200(0.008)

0

°

8

°

1°

5°

0.450(0.017)

0.800(0.031)

)

6

0

0

.

0

(

0

5

1

.

0

R

1.000(0.039)

0.330(0.013)

0.510(0.020)

R0.150(0.006)

3.800(0.150)

4.000(0.157)

0.190(0.007)

0.250(0.010)

0.900(0.035)

Note: Eject hole, oriented hole and mold mark is optional.

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

16

Page 17

Data Sheet

HIGH PERFORMANCE POWER FACTOR CORRECTOR AP1662

Mechanical Dimensions (Continued)

DIP-8 Unit: mm(inch)

0.700(0.028)

°

6

1.524(0.060) TYP

7.620(0.300)TYP

°

6

5°

3.710(0.146)

4.310(0.170)

3.000(0.118)

3.600(0.142)

0.254(0.010)TYP

R0.750(0.030)

Φ3.000(0.118)

Depth

0.100(0.004)

0.200(0.008)

4

°

0.360(0.014)

0.560(0.022)

0.130(0.005)MIN

9.000(0.354)

9.400(0.370)

3.200(0.126)

3.600(0.142)

0.510(0.020)MIN

2.540(0.100) TYP

6.200(0.244)

6.600(0.260)

4

0.204(0.008)

0.360(0.014)

8.200(0.323)

9.400(0.370)

Note: Eject hole, oriented hole and mold mark is optional.

Jul. 2012 Rev. 1. 3 BCD Semiconductor Manufacturing Limited

17

Page 18

BCD Semiconductor Manufacturing Limited

IMPORTANT NOTICE

IMPORTANT NOTICE

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

other rights nor the rights of others.

other rights nor the rights of others.

http://www.bcdsemi.com

MAIN SITE

MAIN SITE

- Headquarters

BCD Semiconductor Manufacturing Limited

BCD Semiconductor Manufactur ing Limited

- Wafer Fab

No. 1600, Zi Xing Road, Shanghai ZiZhu Science-based Industrial Park, 200241, China

Shanghai SIM-BCD Semiconductor Manufacturing Limited

Tel: +86-21-24162266, Fax: +86-21-24162277

800, Yi Shan Road, Shanghai 200233, China

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

REGIONAL SALES OFFICE

Shenzhen Office

REGIONAL SALES OFFICE

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd., Shenzhen Office

Shenzhen Office

Unit A Room 1203, Skyworth Bldg., Gaoxin Ave.1.S., Nanshan District, Shenzhen,

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd. Shenzhen Office

China

Advanced Analog Circuits (Shanghai) Corporation Shenzhen Office

Tel: +86-755-8826 7951

Room E, 5F, Noble Center, No.1006, 3rd Fuzhong Road, Futian District, Shenzhen 518026, China

Fax: +86-755-8826 7865

Tel: +86-755-8826 7951

Fax: +86-755-8826 7865

- Wafer Fab

BCD Semiconductor Manufacturing Limited

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd.

- IC Design Group

800 Yi Shan Road, Shanghai 200233, China

Advanced Analog Circuits (Shanghai) Corporation

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

8F, Zone B, 900, Yi Shan Road, Shanghai 200233, China

Tel: +86-21-6495 9539, Fax: +86-21-6485 9673

Taiwan Office

BCD Semiconductor (Taiwan) Company Limited

Taiwan Office

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

BCD Semiconductor (Taiwan) Company Limited

Tai wan

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

Tel: +886-2-2656 2808

Taiwan

Fax: +886-2-2656 2806

Tel: +886-2-2656 2808

Fax: +886-2-2656 2806

USA Office

BCD Semiconductor Corp.

USA Office

30920 Huntwood Ave. Hayward,

BCD Semiconductor Corporation

CA 94544, USA

30920 Huntwood Ave. Hayward,

Tel : +1-510-324-2988

CA 94544, U.S.A

Fax: +1-510-324-2788

Tel : +1-510-324-2988

Fax: +1-510-324-2788

Loading...

Loading...