Page 1

AP1530

18V 3A 300KHz BUCK CONVERTER

Features

• Input voltage: 3.6V to 18V.

• Output voltage: 0.8V to V

• Duty ratio: 0% to 100% PWM control

• Oscillation frequency: 300kHz typ.

• Current Limit, Enable function

• Thermal Shutdown function

• Built-in internal SW P-channel MOS

• Lead Free package: SOP-8L

• SOP-8L: Available in “Green” Molding Compound

(No Br, Sb) (Note 1)

• Lead Free Finish/ RoHS Compliant (Note 2)

CC

.

Applications

• PCD Motherboard

• LCD Monitor

• Graphic Card

• DVD-Video Player

• Telecom Equipment

• ADSL Modem

• Printer and other Peripheral Equipment

• Microprocessor core supply

• Networking power supply

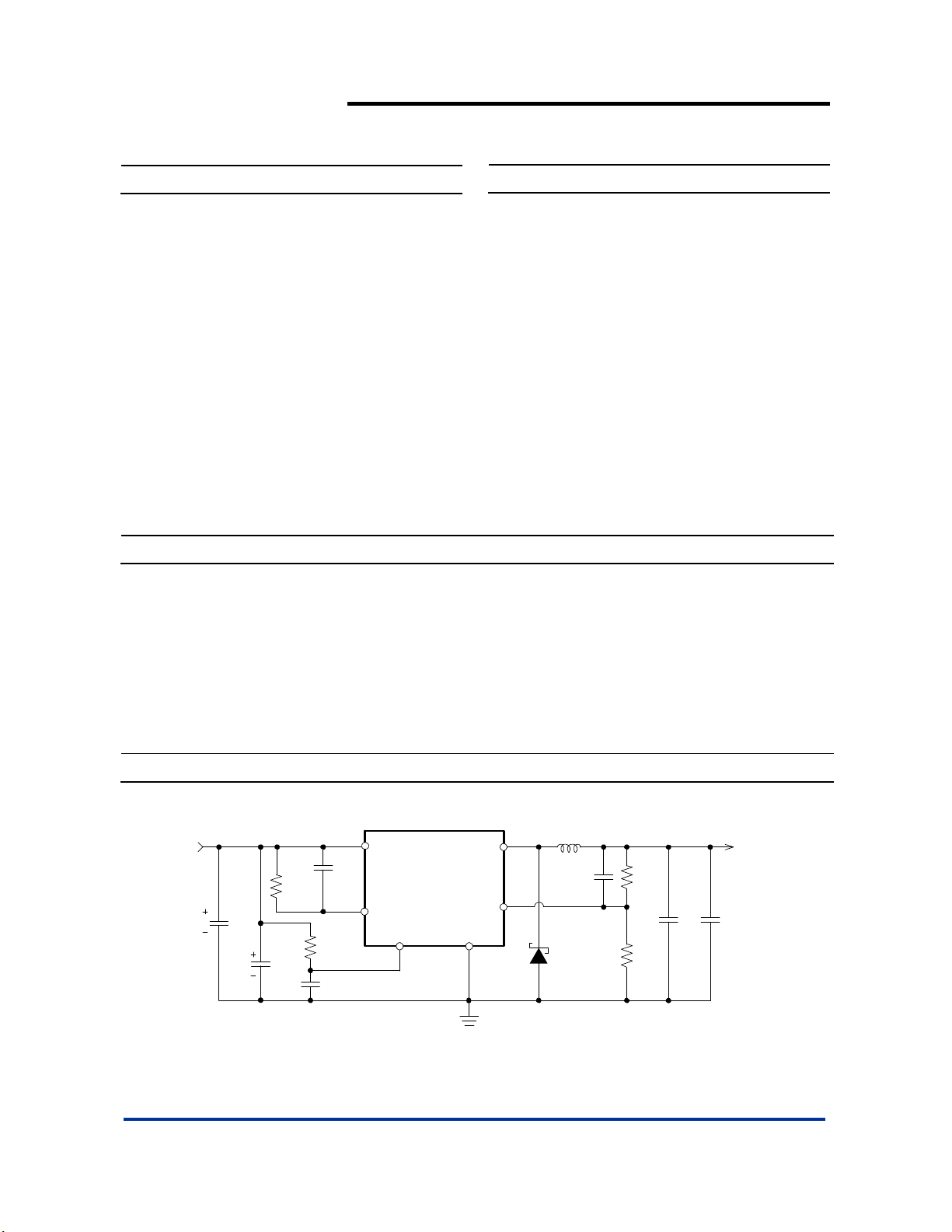

Typical Application Circuit

V

IN

R

OCSET

3K

C

IN

470uF

CVcc

0.1uF

R

100K

C

0.1uF

C

OCSET

Option

EN

EN

Vcc

OCSET

AP 1530

EN

General Description

AP1530 consists of step-down switching regulator with PWM

control. These devices include a reference voltage source,

oscillation circuit, error amplifier and internal PMOS.

AP1530 provides low-ripple power, high efficiency, and excellent

transient characteristics. The PWM control circuit is able to vary

the duty ratio linearly from 0 up to 100%. This converter also

contains an error amplifier circuit. An enable function, an over

current protection and a short circuit protection are built inside,

and when OCP or SCP happens, the operation frequency will be

reduced from 300kHz to 50kHz. Also, an internal compensation

block is built in to minimum external component count.

With the addition of an internal P-channel Power MOS, a coil,

capacitors, and a diode connected externally, these ICs can

function as step-down switching regulators. They serve as ideal

power supply units for portable devices when coupled with the

SOP-8L package, providing such outstanding features as low

current consumption. Since this converter can accommodate an

input voltage up to 18V, it is also suitable for the operation via an

AC adapter.

V

= 5V/3A

Output

FB

V

SS

L1

22uH

Cc

Option

D1*

R

A

6.8K

R

B

1.3K

OUT

+

+

C

0.1uF 470uF

-

-

C

OUT

V

OUT

* Suggested DIODES Power Schottky P/N: B340 series or PDS340.

x (

V

FB

=

= 0.7K~5K ohm

R

B

1+

R

/R

)

B

A

AP1530 Rev. 7 1 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 2

Ordering Information

AP1530

18V 3A 300KHz BUCK CONVERTER

AP 1 5 3 0 S X - 13

Package Packing

S : SOP-8L

Device

AP1530SL-13 S SOP-8L 2500/Tape & Reel -13

AP1530SG-13 S SOP-8L 2500/Tape & Reel -13

Notes: 1. EU Directive 2002/95/EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at

2. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf.

http://www.diodes.com/products/lead_free.html.

Package

Code

Packaging

(Note 2)

Lead Free

L : Lead Free

G : Green

13 : Tape & Reel

13” Tape and Reel

Quantity Part Number Suffix

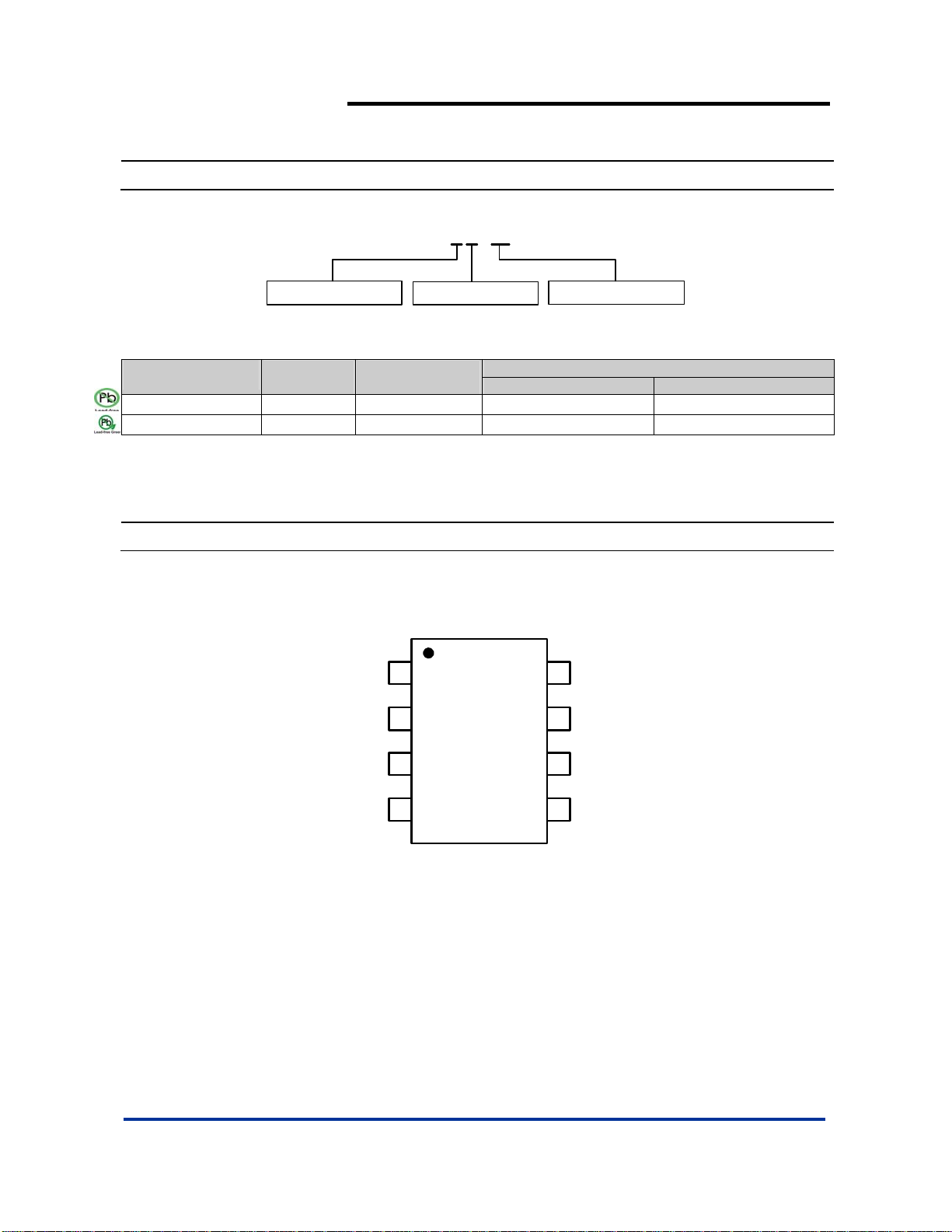

Pin Assignments

(1) SOP-8L

( Top View )

FB

EN

1

2

Vss

8

Vss

7

OCSET

AP1530 Rev. 7 2 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

3

4

V

CC

6

5

Output

Output

Page 3

18V 3A 300KHz BUCK CONVERTER

Pin Descriptions

Pin Name Pin No. Description

FB 1 Feedback pin

Power-off pin

H: Normal operation

EN 2

OCSET 3 Add an external resistor to set max output current

VCC 4 IC power supply pin

(Step-down operation)

L: Step-down operation stopped

(All circuits deactivated)

AP1530

Output 5, 6

VSS 7, 8 GND Pin

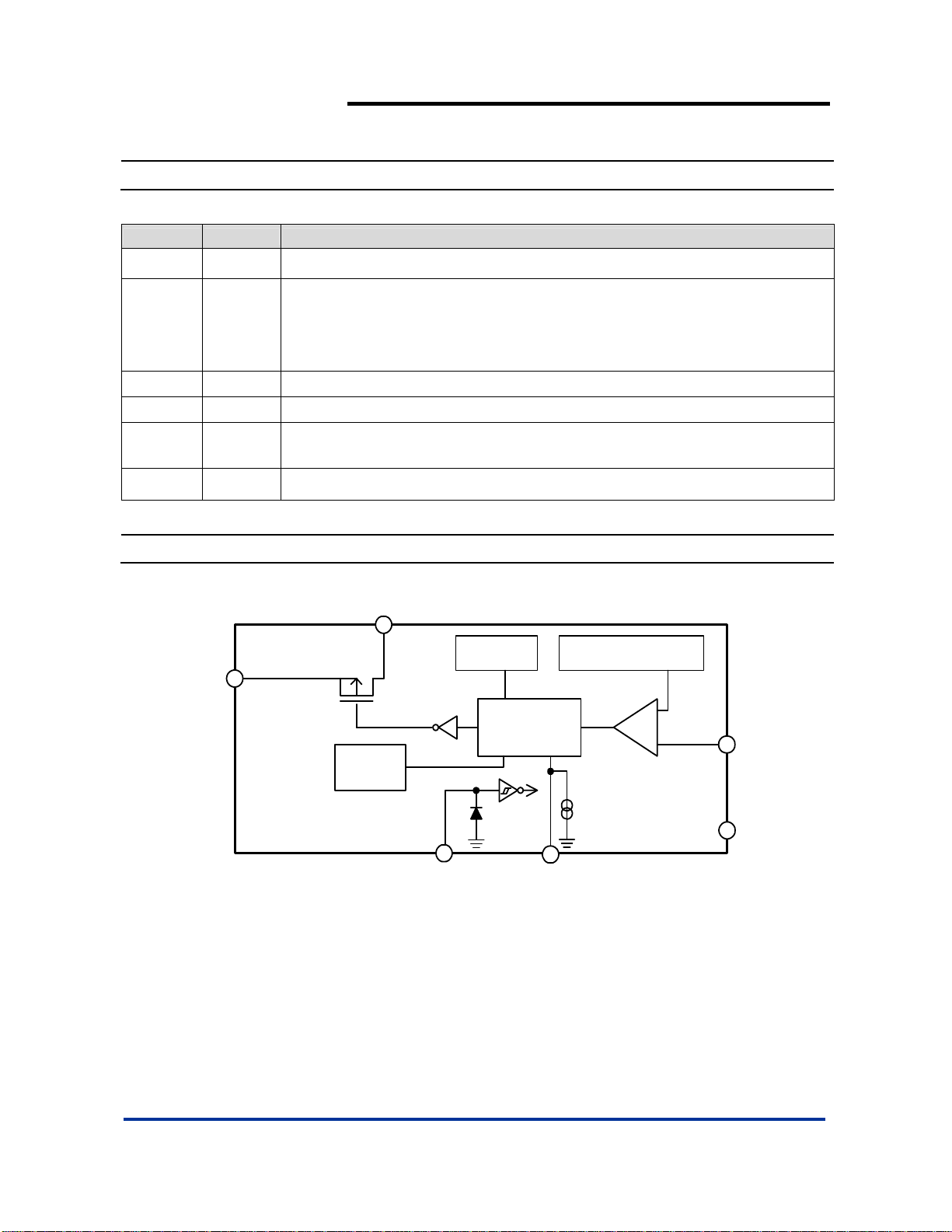

Block Diagram

Vcc

Switch Pin. Connect external inductor/diode here. Minimize trace area at this pin to

reduce EMI

Output

Oscillation

Circuit

PWM-Switched

Control Circuit

Thermal

Shutdown

EN

EN

Reference Voltage Source

+

-

100uA

OCSET

FB

VssV

AP1530 Rev. 7 3 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 4

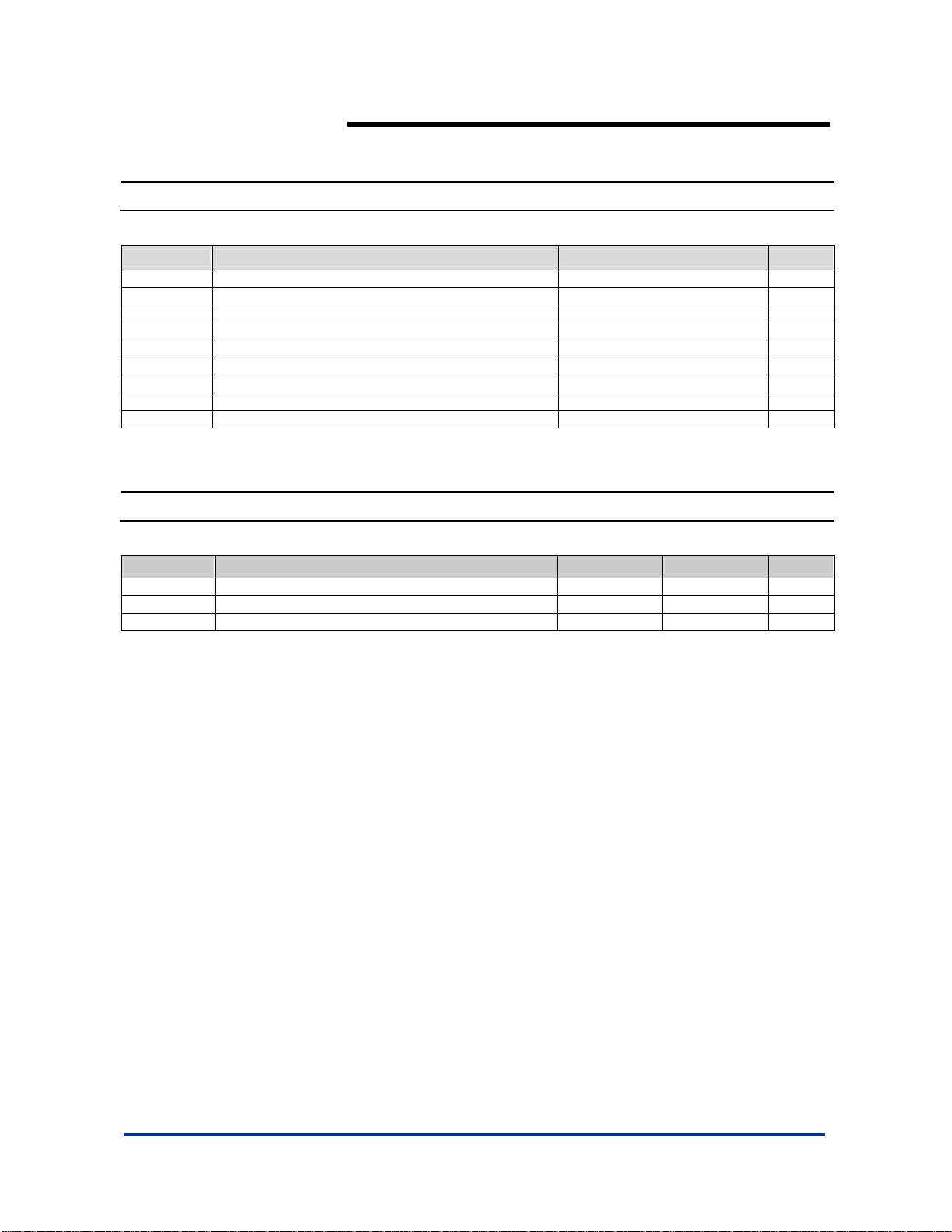

AP1530

18V 3A 300KHz BUCK CONVERTER

Absolute Maximum Ratings

Symbol Parameter Rating Unit

ESD HBM Human Body Model ESD Protection 5 KV

ESD MM Machine Model ESD Protection 500 V

VCC VCC Pin Voltage VSS - 0.3 to VSS + 20 V

VFB Feedback Pin Voltage VSS - 0.3 to VCC V

VEN EN Pin Voltage VSS - 0.3 to VIN + 0.3 V

V

Switch Pin Voltage VSS - 0.3 to VIN + 0.3 V

OUTPUT

PD Power Dissipation Internally limited mW

TJ Operating Junction Temperature Range -40 to +125

T

Storage Temperature Range -65 to +150

ST

Caution: The absolute maximum ratings are rated values exceeding which the product could suffer physical damage. These values must therefore not be

exceeded under any conditions.

Recommended Operating Conditions

Symbol Parameter Min Max Unit

VIN Input Voltage 3.6 18 V

I

Output Current 0 3 A

OUT

TA Operating Ambient Temperature -20 85

o

C

o

C

o

C

AP1530 Rev. 7 4 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 5

A

AP1530

18V 3A 300KHz BUCK CONVERTER

Electrical Characteristics

IN = 12V, T

(V

Symbol Parameter Conditions Min Typ. Max Unit

VFB Feedback Voltage I

IFB Feedback Bias Current I

ISW Switch Current -- 3.5 - - A

I

SHDN

∆V

OUT

/VIN

∆V

OUT

/V

OUT

f

Oscillation Frequency Measure waveform at SW pin 240 300 360 kHz

OSC

f

OSC1

VIH

VIL Evaluate oscillation stop at SW pin - - 0.8

I

ENH

I

-- - -10 - µ

ENL

I

OCSET

TSS Soft-Start Time -- 0.3 2 5 ms

T

SHDN

T

Thermal shutdown hysteresis - 55 - °C

HYS

R

DSON

EFFI Efficiency

θ

JA

θ

JC

Notes: 3. Test condition SOP-8L: Device mounted on FR-4 substrate 2oz copper, minimum recommended pad layout, and single side.

For better thermal performance, please arrange larger copper pad of layout for heatsink.

=25°C, unless otherwise specified)

A

=0.1A 0.784 0.8 0.816 V

OUT

=0.1A - 0.1 0.5 µA

OUT

Current Consumption During

Power Off

Line Regulation V

Load Regulation I

Frequency of Current Limit or

Short Circui t Protection

EN Pin Input Voltage

EN Pin Input Leakage Current

VEN =0V - 10 - µA

=5V~18V - 1 2 %

IN

=0.1 to 3A - 0.2 0.5 %

OUT

Measure waveform at SW pin - 50 - kHz

Evaluate oscillation at SW pin 2.0 - -

V

-- - 20 - µA

OCSET Pin Bias Current -- 75 90 105 µA

Thermal shutdown threshold - 150 - °C

V

=5V, VFB=0V - 110 150

Internal MOSFET R

Thermal Resistance

Junction-to-Ambient

Thermal Resistance

Junction-to-Case

DS(ON)

IN

VIN=12V, VFB=0V - 70 100

V

=12V, V

IN

=3A

I

OUT

OUT

= 5V

- 92 - %

mΩ

SOP-8L (Note 3) - 134 - oC/W

SOP-8L (Note 3) - 22 - oC/W

AP1530 Rev. 7 5 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 6

Typical Performance Characteristics

VIN vs. Frequency

(V

=3.3V; I

340

338

336

334

332

(kHz)

330

328

OSC

F

326

324

322

320

OUT

2 4 6 8 10121416182022

OUT

V

=0.2A)

(V)

IN

AP1530

18V 3A 300KHz BUCK CONVERTER

VIN vs. V

(V

=3.3V; I

0.820

0.815

0.810

0.805

(V)

0.800

FB

V

0.795

0.790

0.785

0.780

2 4 6 8 10 12 14 16 18 20 22

OUT

OUT

V

FB

=0.1A)

(V)

IN

Line R egulation

3.40

OUT

=3.3V; I

OUT

=0.2A)

(V

3.35

3.30

3.25

(V)

3.20

OUT

3.15

V

3.10

3.05

3.00

246810121416182022

(V)

V

IN

Efficiency

100%

VIN=5V; V

90%

80%

70%

60%

50%

40%

30%

Efficiency (%)

20%

10%

0%

0 0.5 1 1.5 2 2.5 3

OUT

I

OUT

=3.3V

(A)

Load Regulation

5.00

(VIN=12V; V

4.99

4.98

4.97

(A)

4.96

OUT

4.95

V

4.94

4.93

4.92

0 0.5 1 1.5 2 2.5 3

=5V)

OUT

(A)

I

OUT

AP1530 Rev. 7 6 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 7

A

18V 3A 300KHz BUCK CONVERTER

Typical Performance Characteristics (Continued)

AP1530 Vout Ripple

(Vin= 12V; Vout= 3.3V; Iout= 0.1A)

(Vin= 12V; Vout= 3.3V; Iout= 3A)

AP1530

P1530 Vout Ripple

Test Circuit

+

-

open

FB

open

FBV

+

-

Oscillation

V

A

V

CC

+

-

OCSET

EN

V

OUTPUT OUTPUT

CC

OCSET

A

EN

V

SS

Enable function test Feedback function test

OUTPUT

V

CC

OCSET

EN

V

SS

FB

SS

Operation fun c tion test

AP1530 Rev. 7 7 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 8

AP1530

18V 3A 300KHz BUCK CONVERTER

Functional Description

PWM Control

The AP1530 is a DC/DC converter that employs pulse width

modulation (PWM) scheme. Its pulse width varies in the range of

0% to 99%, based on the output current loading. The output

ripple voltage caused by the PWM high frequency switching can

easily be reduced through an output filter. Therefore, this

converter provides a low ripple output supply over a broad range

of input voltage & output current loading

Under Voltage Lockout

The under voltage lockout circuit of the AP1530 assures that the

high-side MOSFET driver remains in the off state whenever the

supply voltage drops below 3.3V. Normal operation resumes

once V

Current Limit Protection

The current limit threshold is set by external resistor R

connected from V

current I

at OCSET pin. When the PWM voltage is less than the voltage at

OCSET, an over-cur rent condition is triggered.

The current limit threshold is given by the following equation:

where,

I

resistance; F

inductor value will affect the ripple current ΔI.

The above equation is recommended for input voltage range of

5V to 18V. For input voltage lower than 5V or ambient

temperature over 100°C, higher R

The recommended minimum R

rises above 3.5V.

CC

supply to OCSET pin. The internal sink

CC

(90uA typical) across this resistor sets the voltage

OCSET

×=×

RIRI

OCSETOCSETDS(ON)PEAK

Δ

I)(

II

=Δ

OUT

−

S

xLF

(V) R

I

is the output peak current; R

PEAK

V

is the PWM frequency (300KHz typical). Also, the

S

(V) V

IN

4 0.8 3.9K

5 3.3 3.0K

12 5 3.0K

18 12 3.0K

+>

(MAX) OUTPEAK

2

VV

OCSET

V

OUTIN

OCSET

OUT

x

IN

V

is the MOSFET ON

DS (ON)

is recommended.

value is summarized below:

OCSET

OCSET

(Ω)

AP1530 Rev. 7 8 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Inductor Selection

For most designs, the operates with inductors of 22µH to

33µH. The inductor value can be derived from the following

equation:

−

VV

=

L ×

fs

Where ΔI

ripple current and small value inductors result in high ripple

current. Choose inductor ripple current approximately 15% of the

maximum load current 3A, ∆I

the inductor should be at least equal to the maximum load current

plus half the ripple current to prevent core saturation

(3A+0.225A).

Input Capacitor Selection

This capacitor should be located close to the IC using short leads

and the voltage rating should be approximately 1.5 times the

maximum input volta ge. The RMS current rati ng requirement for

the input capacitor of a buck regulator is approximately 1⁄2 the

DC l oad current. A low ESR input capacitor sized for maximum

RMS current must be used. A 47 0µF low ESR c apacitor for most

applications is sufficient.

Output Capacitor Selection

The output capacitor is required to filter the output voltage and

provides regulator loop stability. The important capacitor

parameters are the 100KHz Equivalent Series Resistance (ESR),

the RMS ripples current rating, voltage rating and capacitance

value. For the output capacitor, the ESR value is the most

important parameter . The output ripple can be calculated fro m

the following formula.

The bulk capacitor’s ESR will determine the output ripple voltage

and the initial voltage drop after a high slew-rate transient.

An aluminum electrolytic capacitor's ESR value is related to the

capacitance and its voltage rating. In most case, higher voltage

electrolytic capacitors have lower ESR values. Most of the time,

capacitors with much higher voltage ratings may be needed to

provide the low ESR values required for low output ripple v oltage .

PCB Layout Guide

If you need low T

SW pins(5& 6) and Vss pins(7& 8)on the SOP-8L package are

internally connected to die pad, The evaluation board should be

allowed for maximum copper area at output (SW) pins.

1. Connect FB circuits (R

2. Connect C3 to Vcc and Vss pin as closely as possible to get

3. Connect R4 to Vcc and OCSET pin as closely as possible.

4. Connect ground side of the C2 & D1 & C4 as closely as

is inductor Ripple Current. Large value inductors lower

L

L

& TJ or large PD (Power Dissipation), The dual

C

, R2, C1) as closely as possible and

keep away from inductor flux for pure V

good power filter effect.

possible and use ground plane for best performance.

1

V

OUTOUTIN

V

IN

ESR

FB

.

I

Δ×

=0.45A. The DC current rating of

×=

ΔIV

LRIPPLE

Page 9

V

Functional Description (Continued)

Keep the gap of exposed pads from short circuit.

Top Side Layout Guid e

AP1530

18V 3A 300KHz BUCK CONVERTER

Recommended exposed-pads gap: 30~40mil

(0.75~1mm)

Use vias to conduct the heat into the backside of

PCB layer. The heat si nk at output (SW) pins shoul d

be allowed for maximum solder-painted area.

Bottom Side Layout Guide

Brown: IC exposed pads.

Red: recommended layout.

Reference pads layout dimension:

Output: 90 x 50 mil

ss: 90 x 60 mil

AP1530 Rev. 7 9 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 10

Functional Description (Continued)

V

IN

Vcc

Output

AP1530

18V 3A 300KHz BUCK CONVERTER

L1

V

OUT

R4

C2

C3

Marking Information

(1) SOP-8L

Logo

Part Number

C7

Option

R5

C6

Figure: Layout numbering comparison

OCSET

EN

AP1530

FB

V

SS

( Top View )

8

5

L : Lead Free

G : Green

: Year : 08, 09,10~

YY

WW : Week : 01~52; 52

: Internal Code

X

AP1530

YY

WW X

X

41

R2

R1

+

+

-

C8

C4

-

C1

Option

D1

represents 52 and 53 week

AP1530 Rev. 7 10 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 11

Package Information ( All Dimensions in mm )

(1) Package Type: SOP-8L

0.254

0.62/0.82

Gauge Plane

Seating Plane

3.85/3.95

5.90/6.10

0.10/0.20

Detail "A"

AP1530

18V 3A 300KHz BUCK CONVERTER

7°~9°

1.27typ

8x-0.60

6x-1.27

8x-1.55

Land Pattern Recommendation

0.3/0.5

4.85/4.95

(Unit: mm)

0.35max.

45°

0.15/0.25

1.30/1.50

1.75max.

5.4

7°~9°

Detail "A"

0°/8°

AP1530 Rev. 7 11 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Page 12

AP1530

18V 3A 300KHz BUCK CONVERTER

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS

DOCUMENT, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other

changes without further notice to this document and any product described herein. Diodes Incorporated does not assume any

liability arising out of the application or use of this docum ent or any product described herein; neither does Diodes Incorporated

convey any license under its patent or trademark rights, nor the rights of others. Any Customer or user of this document or products

described herein in such applications shall assume all risks of such use and will agree to hold Diodes Incorporated and all the

companies whose products are represented on Diodes Incorporated website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized

sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall

indemnify and hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized

application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names

and markings noted herein may also be covered by one or more United States, international or foreign trademarks.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems

without the express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided

in the labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected

to cause the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or

systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements

concerning their products and any use of Diodes Incorporated products in such safety-critical, life support devices or systems,

notwithstanding any devices- or systems-related information or support that may be provided by Diodes Incorporated. Further,

Customers must fully indemnify Diodes Incorporated and its representat ives against any damages arising out of the use of Diodes

Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2009, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

AP1530 Rev. 7 12 of 12 NOVEMBER 2009

DS31092 www.diodes.com © Diodes Incorporated

Loading...

Loading...