Page 1

Description

The AP1507 is a monolithic IC designed for a step-down DC/DC

converter and is capable of driving a 3A load without an external

transistor. Due to reducing the number of external components, the

board space can be saved easily. The external shutdown function

can be controlled by logic level and then come into standby mode.

The internal compensation makes the feedback control have good

line and load regulation without an external design. Regarding the

protected function, the thermal shutdown is to prevent over

temperature operating from damaging the device, and current limit is

against over current operating of the output switch. If the current limit

function occurred and V

frequency will be reduced. The AP1507 series operates at a

switching frequency of 150KHz thus allowing smaller sized filter

components than what would be needed with lower frequency

switching regulators. Other features include a guaranteed +

tolerance on output voltage under specified input voltage and output

load conditions, and +

version included a fixed 3.3V, 5V, 12V, and an adjustable type.

AP1507 is available in a 5-lead TO-252 lead-free or green package.

Features

is down to 0.5V below, the switching

FB

4%

15% on the oscillator frequency. The output

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

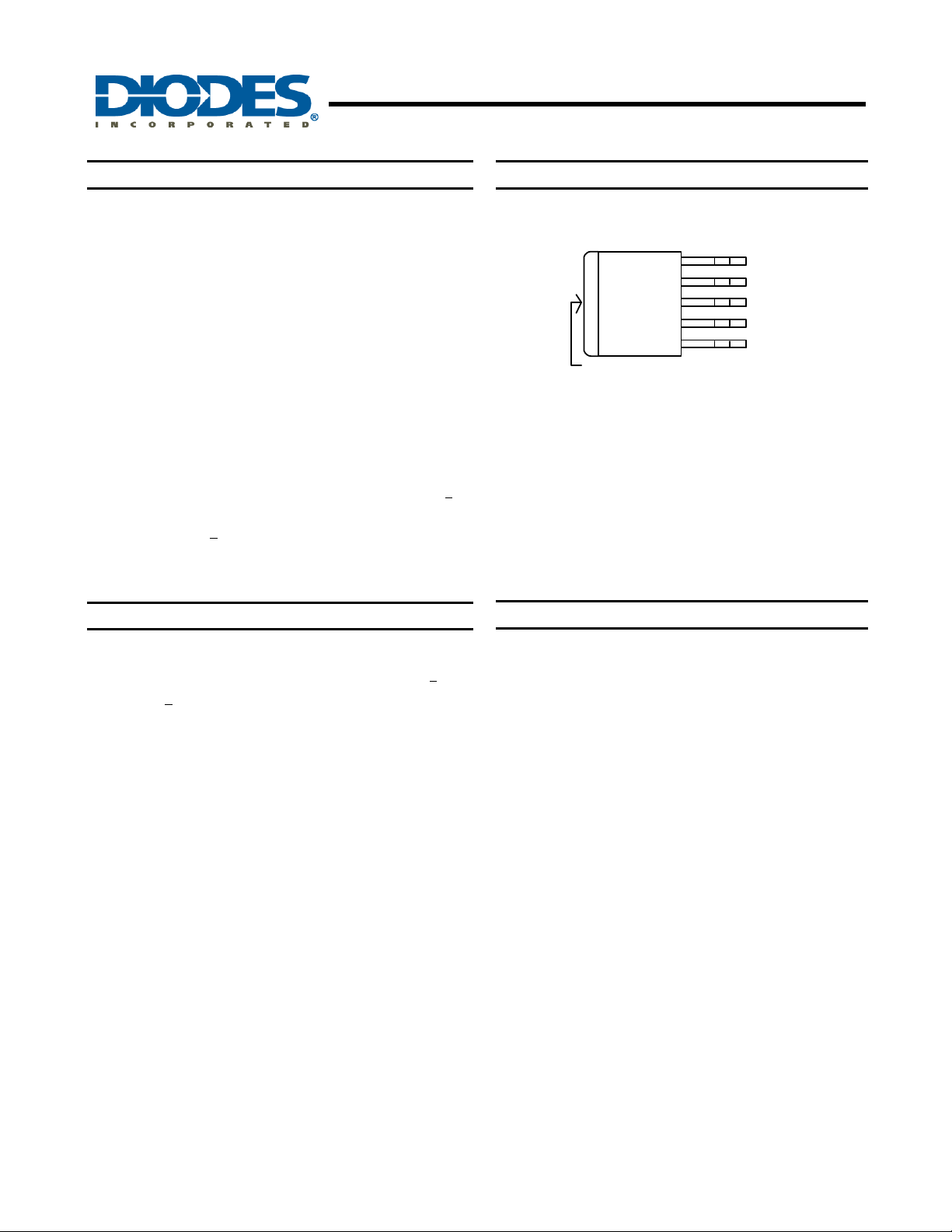

Pin Assignments

(Top View)

5 SD

4 FB

3 GND

2 Output

1 V

IN

Metal Tab GND

TO252-5L

Applications

• Output Voltage: 3.3V, 5V, 12V and Adjustable Output Version

• Adjustable Version Output Voltage Range, 1.23V to 18V +

• 150KHz +

• Voltage Mode Non-Synchronous PWM Control

• Thermal-Shutdown and Current-Limit Protection

• ON/OFF Shutdown Control Input

• Operating Voltage can be up to 22V

• Output Load Current: 3A

• Low Power Standby Mode

• Built-in Switching Transistor On Chip

• AP1507-XXD5L-XX

Totally Lead-Free; RoHS Compliant (Notes 1 & 2)

• AP1507-XXD5-XX

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green" and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl)

and <1000ppm antimony compounds.

15% Fixed Switching Frequency

4%

• Simple High-Efficiency Step-Down Regulator

• On-Card Switching Regulators

• Positive to Negative Converter

AP1507

Document number: DS31067 Rev. 3 - 2

1 of 12

www.diodes.com

May 2012

© Diodes Incorporated

Page 2

×

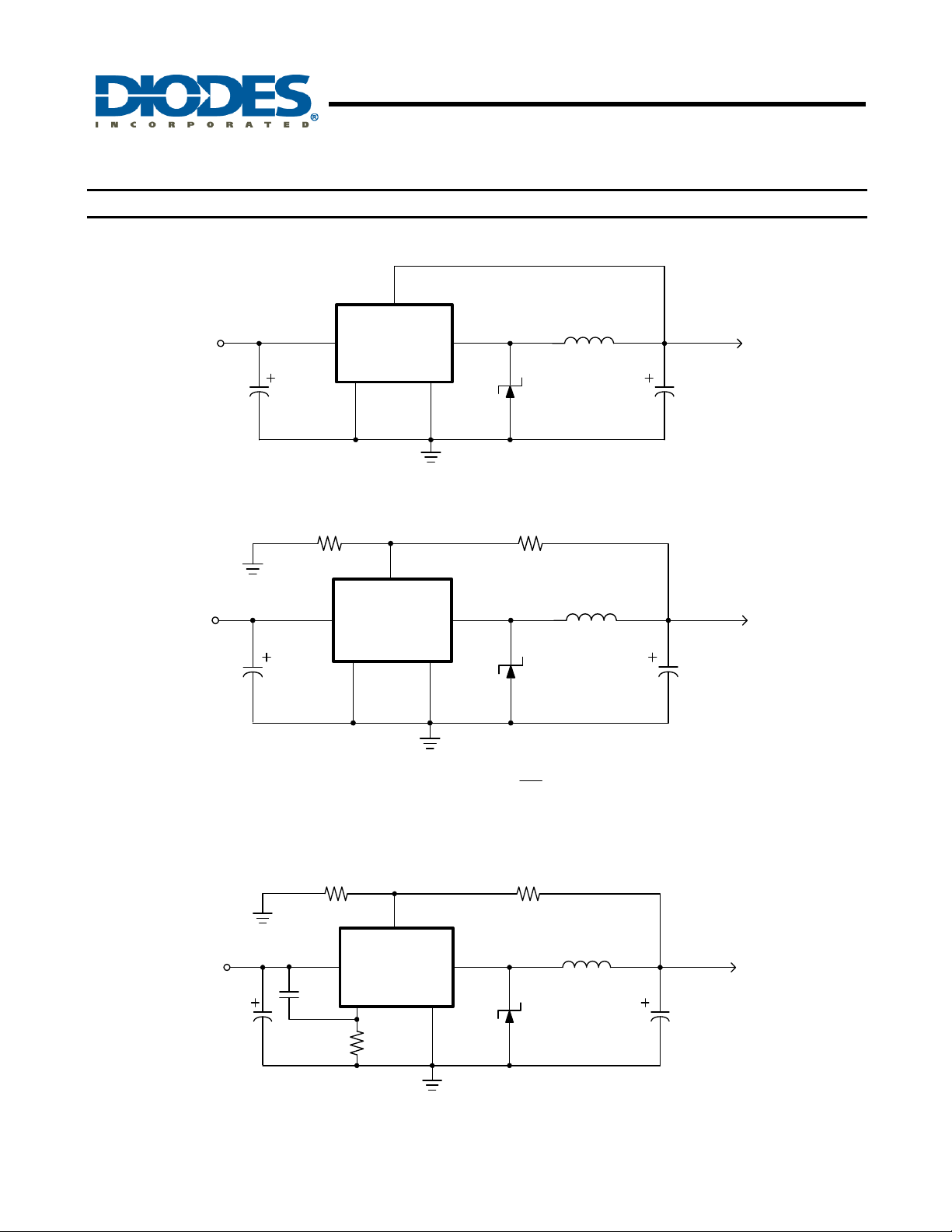

Typical Application Circuit

(1) Fixed Type Circuit

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

12V

DC Input

C

in

Capacitor

(2) Adjustable Type Circuit

12V

DC Input

C

in

Capacitor

FB

4

AP1507

12

V

in

-33

SD

Output

35

GND

R2

FB

4

12

V

in

AP1507

Output

35

SD

GND

L1

33uH

Inductor

D1

Schottky

Diode

R1

L1

47uH

D1

Schottky Diode

3.3V/3A

Output Load

Co

Capacitor

5V/ 3A

Output Load

Co

Capacitor

V

= V

OUT

FB

(1 +

R1

)

R2

V

= 1.23V, R2 = 1K ~ 3K

FB

(3) Delay Start Circuit

R2

FB

12V

4

DC Input

12

AP1507

in

35

SD

R

DELAY

C

in

Capacitor

C

DELAY

0.1uF

V

10K

AP1507

Document number: DS31067 Rev. 3 - 2

www.diodes.com

GND

Output

2 of 12

R1

L1

47uH

D1

Schottky Diode

5V/ 3A

Output Load

Co

Capacitor

May 2012

© Diodes Incorporated

Page 3

Pin Descriptions

Pin Number Pin Name Description

V

1

2 Output Switching Output

3 GND Ground

4 FB Output Voltage Feedback Control

5 SD

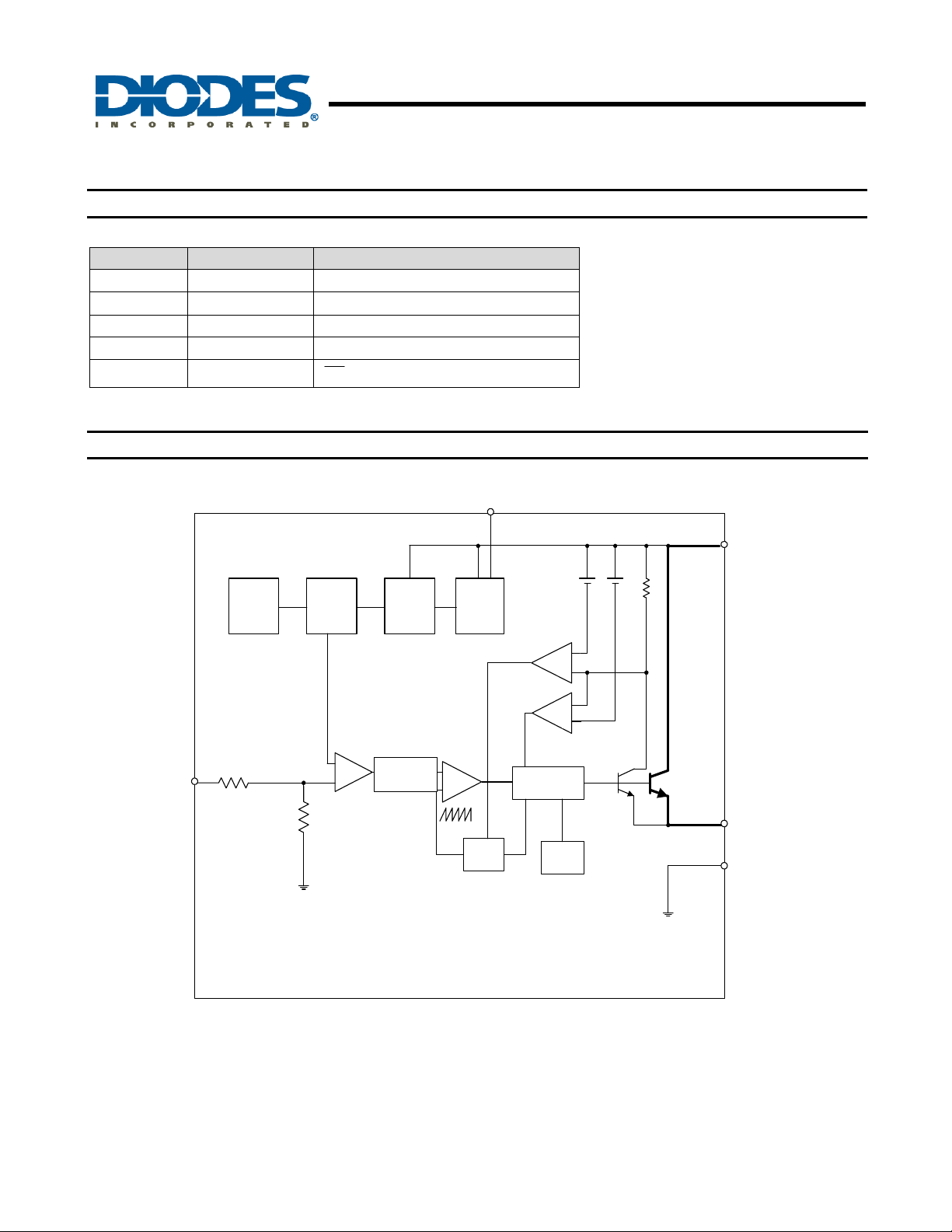

Functional Block Diagram

IN

Operating Voltage Input

ON / OFF Shutdown

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

SD

FB

Current

Source

Bias

1.235V

Reference

+

_

Amp

2.5V

Regulator

Frequency

Compen-

sation

_

Comp

+

Start

Up

150kHz

OSC.

Comp

Comp

Pre-

Driver

Thermal

Shutdown

200mV

+

_

_

+

220mV

3A

Switch

V

IN

Output

GND

AP1507

Document number: DS31067 Rev. 3 - 2

3 of 12

www.diodes.com

May 2012

© Diodes Incorporated

Page 4

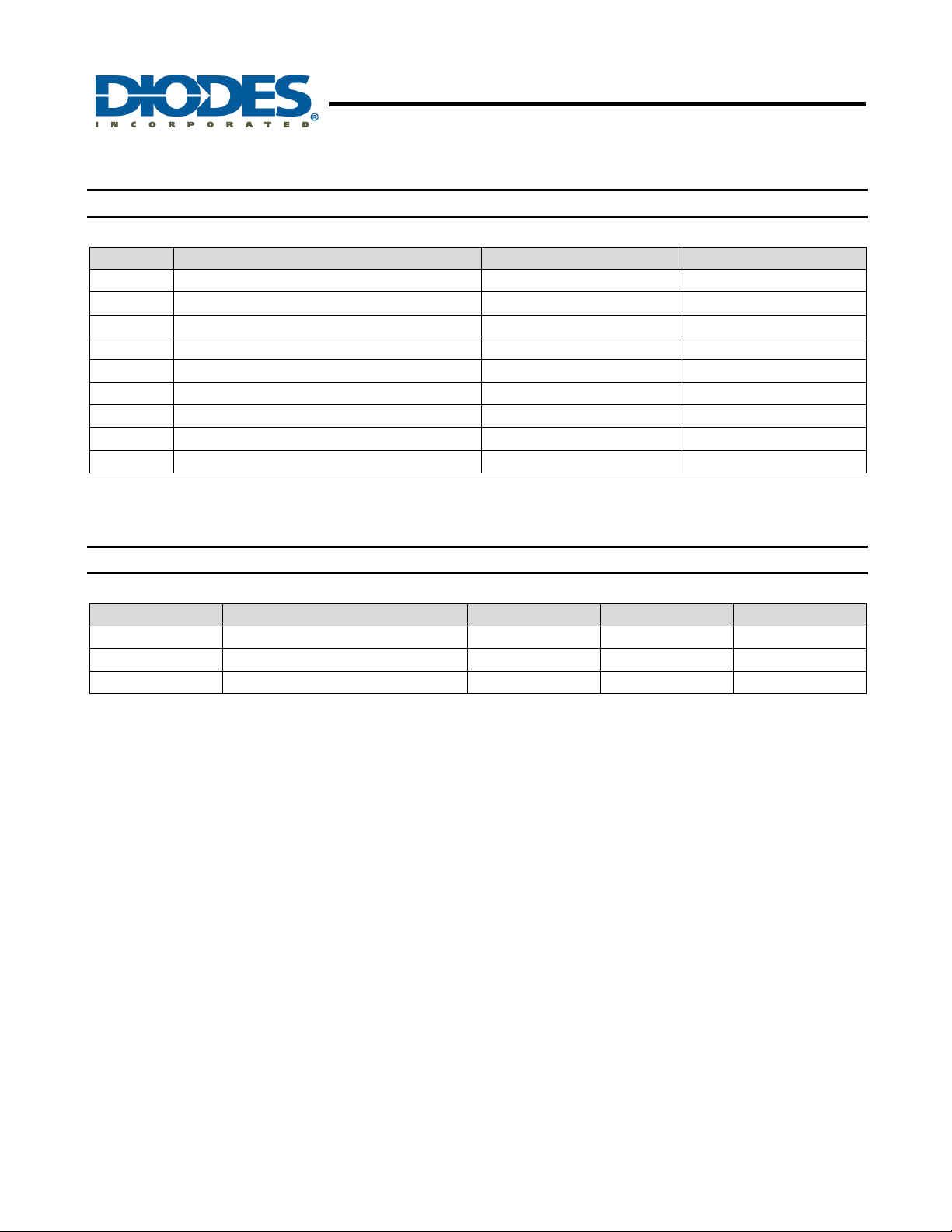

AP1507

Absolute Maximum Ratings (T

Symbol Parameter Rating Unit

ESD HBM Human Body Model ESD Protection 2 KV

ESD MM Machine Model ESD Protection 200 V

VCC

VSD

VFB

V

OUT

PD

TST

TJ

Note: 4. Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings

only; functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device

reliability may be affected by exposure to absolute maximum rating conditions for extended periods of time.

Supply Voltage +24 V

ON/OFF Pin Input Voltage -0.3 to +18 V

Feedback Pin Voltage -0.3 to +18 V

Output Voltage to Ground -1 V

Power Dissipation Internally Limited W

Storage Temperature -65 to +150

Operating Junction Temperature -40 to +125

Recommended Operating Conditions (T

Symbol Parameter Min Max Unit

I

OUT

VOP

TA

Output Current 0 3 A

Operating Voltage 4.5 22 V

Operating Ambient Temperature -20 +85

= 25°C) (Note4)

A

150KHz, 3A PWM BUCK DC/DC CONVERTER

o

C

o

C

= 25°C)

A

o

C

AP1507

Document number: DS31067 Rev. 3 - 2

4 of 12

www.diodes.com

May 2012

© Diodes Incorporated

Page 5

AP1507

Electrical Characteristics (All Output Voltage Versions)

Unless otherwise specified, V

Specifications with boldface type are for full operating temperature range, the other type are for T

Symbol Parameter Conditions Min Typ Max Unit

IFB

Feedback Bias Current

F

Oscillator Frequency

OSC

F

V

I

LEAK

Oscillator Frequency of Short

SCP

Circuit Protect

Saturation Voltage

SAT

Max. Duty Cycle (ON)

DC

Min. Duty Cycle (OFF)

ICL

Current Limit

Output = 0V

Output = -1V

IQ

Quiescent Current

I

STBY

Standby Quiescent

Current

VIL

ON/OFF Pin Logic Input Threshold

Voltage

VIH

IH

ON/OFF Pin Logic Input Current

IL

ON/OFF Pin Input Current

θ

Thermal Resistance TO252-5L Junction to Case 10

JA

Thermal Resistance

θ

with copper area of approximately

JC

2cm ×2cm

AP1507

Document number: DS31067 Rev. 3 - 2

= 12V for 3.3V, 5V, adjustable version and V

IN

= 1.3V

V

FB

( Adjustable Version Only )

When current limit Occurred and

< 0.5V, TA = 25oC

V

FB

= 3A

I

OUT

No Outside Circuit

= 0V Force Driver On

V

FB

V

= 0V Force Driver On

FB

V

= 12V Force Driver Off

FB

Peak Current

No Outside Circuit

V

= 0V Force Driver On

FB

Output

leakage

current

No Outside Circuit

V

=12V Force Driver Off

FB

V

= 22V

IN

V

= 12V Force Driver Off

FB

ON/OFF Pin = 5V

V

= 22V

IN

Low (Regulator ON) High (Regulator OFF) 2.0 V

= 2.5V (OFF)

LOGIC

V

= 0.5V (ON)

LOGIC

TO252-5L

150KHz, 3A PWM BUCK DC/DC CONVERTER

= 18V for the 12V version. I

IN

Junction to

Ambient

5 of 12

www.diodes.com

= 25°C.

J

-10

127 150 173

110 173

10 30 50 KHz

1.4

100

0

3.6 4.5

-200 µA

-5 mA

5 10 mA

70

-0.01

-0.1 -1

50

LOAD

1.3

= 0.5A

-50

-100

1.6

1.7

5.5

6.5

150

200

0.6

© Diodes Incorporated

nA

KHz

V

%

A

µA

V

µA

o

C/W

o

C/W

May 2012

Page 6

150KHz, 3A PWM BUCK DC/DC CONVERTER

Electrical Characteristics (All Output Voltage Versions)

Specifications with boldface type are for full operating temperature range, the other type are for T

Symbol Parameter Conditions

VIN < 22V

5V <

AP1507-ADJ

AP1507-3.3V

AP1507-5V

AP1507-12V

V

FB

Output Feedback

η Efficiency

V

OUT

Output Voltage

η Efficiency

V

OUT

Output Voltage

η Efficiency

V

OUT

Output Voltage

η Efficiency

0.2A <

I

Programmed for 3V

V

OUT

V

= 12V, I

IN

VIN < 22V

5.5V <

0.2A <

I

V

= 12V, I

IN

VIN < 22V

8V <

0.2A <

I

V

= 12V, I

IN

VIN < 22V

15V <

I

0.2A <

V

= 16V, I

IN

LOAD

LOAD

LOAD

LOAD

< 3A

LOAD

< 3A

LOAD

< 3A

LOAD

< 3A

LOAD

= 3A

= 3A

= 3A

= 3A

V

MIN

1.193

1.18

3.168

3.135

4.8

4.75

11.52

11.4

AP1507

Document number: DS31067 Rev. 3 - 2

6 of 12

www.diodes.com

AP1507

= 25ºC.

J

Typ.

1.23

74 %

3.3

75 %

5

80 %

12

89 %

V

MAX

1.267

1.28

3.432

3.465

5.2

5.25

12.48

12.6

May 2012

© Diodes Incorporated

Unit

V

V

V

V

Page 7

C

C

Y

C

C

Y

R

O

O

G

CH CUR

R

Y

CUR

R

A

Y

CUR

R

Typical Characteristics

83

82

81

80

79

(%)

78

77

IEN

76

EFFI

75

V = 12V

74

73

IN

V = 5V

OUT

I = 3A

O

72

-50 -30 -10 10 30 50 70 90 130110 150

TEMPERATURE (°C)

Efficiency vs. Temperature

1.6

1.5

1.4

E (V)

1.3

LTA

1.2

N V

1.1

ATI

1

0.9

V = 12V

SATU

CC

V = 0V

FB

0.8

V = 0V

SD

0.7

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

Saturati on Voltage vs. Temperatur e

15

V = 12V

CC

14

No Load

V = 0V

ON

13

Switch ON

)

12

11

ENT (m

10

09

08

SUPPL

07

06

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

78

77

76

75

(%)

74

IEN

73

EFFI

72

71

70

1.6

3A

2A

1.4

1.2

ENT LIMIT (A)

1A

0.5A

1.1

0.9

SWIT

0.7

60

55

50

ENT (µA)

45

40

SUPPL

35

V = 12V

IN

V = 3.3V

OUT

I = 3A

O

-50 -30 -10 10 30 50 70 90 130110 150

TEMPERATURE (°C)

Efficiency vs. Temperature

V = 12V

CC

V = 0V

FB

-50 -25 0 25 50 75 100 125

TEMPERATURE (°C)

Switch Current Limit vs. Temperature

V = 12V

CC

No Load

V = 5V

OFF

Switch OFF

05

-50 -30 -10 10 30 50 70 90 130110 150

TEMPERATURE (°C)

Supply Current vs. T emperature

AP1507

Document number: DS31067 Rev. 3 - 2

7 of 12

www.diodes.com

30

-50 -30 -10 10 30 50 70 90 130110 150

TEMPERATURE (°C)

Supply Current vs. Temperature

© Diodes Incorporated

May 2012

Page 8

T

H

R

H

O

OLTAG

REQ

UENC

Y

H

CK CUR

REN

T

5

Typical Characteristics (cont.)

1.7

1.6

1.5

E (V)

1.4

1.3

LD V

1.2

1.1

ES

1.0

0.9

0.8

-50 -30 -10 10 30 50 70 90 130110 150

TEMPERATURE (°C)

Threshold Voltage vs. Temperature

170

V = 12V

CC

I = 500mA

O

165

V= 5V

OUT

z)

160

(K

155

V = 12V

CC

I = 100mA

O

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

10

0

-10

-20

-30

-40

-50

-60

-70

ON/OFF CURRENT (nA)

-80

V = 12V

IN

-90

-100

0 3 6 9 12 15 18 21

ON/OFF VOLTAGE (V)

(nA)

-10

-20

ON/OFF Current vs. ON/OFF Voltage

10

V = 12V

CC

V = 5V

OUT

0

V = 1.3V

FB

150

-30

F

FEEDBA

145

140

-50 -30 -10 10 30 50 70 90 130110 150

TEMPERATURE (°C)

Frequency vs. Temperat u r e

3.

-40

-50

-50 -30 -10 10 30 50 70 90 130110 150

TEMPERATURE (°C)

Feedba c k C ur r e nt vs. Temperature

3.45

3.4

3.35

3.3

3.25

3.2

3.15

3.1

3.05

VOLTAGE OUTPUT (V)

3.0

V = 12V

IN

I = 3A

O

2.95

2.9

-40 -2 0 20 40 60 80 100 140120 160

TEMPERATURE (°C)

Output Voltage vs. Tempera ture

AP1507

Document number: DS31067 Rev. 3 - 2

8 of 12

www.diodes.com

May 2012

© Diodes Incorporated

Page 9

Application Information

Pin Functions

+V

IN

This is the positive input supply for the IC switching regulator.

A suitable input bypass capacitor must be present at this pin to

minimize voltage transients and to supply the switching currents

needed by the regulator.

Ground

Circuit ground.

Output

Internal switch. The voltage at this pin switches between

(+V

– V

IN

approximately V

circuitry, the PC board copper area connected to this pin should

be kept at a minimum.

Feedback (FB)

Senses the regulated output voltage to complete the feedback

loop.

ON/OFF (SD)

Allows the switching regulator circuit to be shutdown using logic

level signals thus dropping the total input supply current to

approximately 150uA. Pulling this pin below a threshold voltage

of approximately 1.3V turns the regulator on, and pulling this pin

above 1.3V (up to a maximum of 18V) shuts the regulator down.

If this shutdown feature is not needed, the ON/OFF pin can be

wired to the ground pin.

Thermal Considerations

The TO-252 surface mount package tab is designed to be

soldered to the copper on a printed circuit board. The copper

and the board are the heat sink for this package and the other

heat producing components, such as the catch diode and

inductor. The PC board copper area that the package is

soldered to should be at least 0.8 in

2 or more square inches of 2 oz. additional copper area which

improves the thermal characteristics. With copper areas greater

AP1507

Document number: DS31067 Rev. 3 - 2

) and approximately – 0.5V, with a duty cycle of

SAT

/ VIN. To minimize coupling to sensitive

OUT

2

, and ideally should have

www.diodes.com

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

than approximately 6in

dissipation are realized. If further thermal improvements are

needed, double sided, multi-layer PC board with large copper

areas and/or airflow will be recommended.

The AP1507 (TO-252 package) junction temperature rises

above ambient temperature with a 3A load for various input and

output voltages. This data was taken with the circuit operating

as a buck-switching regulator with all components mounted on a

PC board to simulate the junction temperature under actual

operating conditions. This curve can be used for a quick check

for the approximate junction temperature for various conditions,

but there are many factors that can affect the junction

temperature. When load currents higher than 3A are used,

double sided or multi-layer PC boards with large copper areas

and/or airflow might be needed, especially for high ambient

temperatures and high output voltages.

For the best thermal performance, wide copper traces and

generous amounts of printed circuit board copper should be

used in the board layout. (One exception to this is the output

(switch) pin, which should not have large areas of copper.)

Large areas of copper provide the best transfer of heat (lower

thermal resistance) to the surrounding air, and moving air lowers

the thermal resistance even further.

Package thermal resistance and junction temperature rise

numbers are all approximate, and there are many factors that

will affect these numbers. Some of these factors include board

size, shape, thickness, position, location, and even board

temperature. Other factors are trace width, total printed circuit

copper area, copper thickness, single or double-sided, multilayer board and the amount of solder on the board. The

effectiveness of the PC board to dissipate heat also depends on

the size, quantity and spacing of other components on the

board, as well as whether the surrounding air is still or moving.

Furthermore, some of these components such as the catch

diode will add heat to the PC board and the heat can vary as the

input voltage changes. For the inductor, depending on the

physical size, type of core material and the DC resistance, it

could either act as a heat sink taking heat away from the board,

or it could add heat to the board.

9 of 12

2

, only small improvements in heat

May 2012

© Diodes Incorporated

Page 10

Ordering Information

AP1507 - XX

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

XX X X

Output Version

Blank : Adjustable

33 : 3.3V

Package

D5 : TO252-5L

Lead Free

L

: Lead Free

Blank : Green

Packing

-U : Tube

-13 : Tape & Reel

50 : 5.0V

12 : 12V

Device Package Code

Pb

AP1507-XXD5L-XX D5 TO252-5L 80 -U 2500/Tape & Reel -13

Lead-Free

AP1507-XXD5-XX D5 TO252-5L Not available 2500/Tape & Reel -13

Note: 5. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf

Packaging

(Note 5)

Tube/Bulk 13” Tape and Reel

Quantity

Part Number

Suffix

Quantity Part Number Suffix

Marking Information

(1) TO252-5L

( Top view )

Output Type :

Blank : Adjustable

1507-33 : 3.3V

1507-50 : 5.0V

1507-12 : 12V

AP1507

Document number: DS31067 Rev. 3 - 2

Logo

1507 - XX

YY WW X

10 of 12

www.diodes.com

Internal code

X

L : Lead Free

Blank : Green

Xth Week : 01~52

Year :

"07" = 2007

"08" = 2008

May 2012

© Diodes Incorporated

Page 11

2

150KHz, 3A PWM BUCK DC/DC CONVERTER

Package Outline Dimensions (All Dimensions in mm)

Package Type: TO252-5L

5X b2

E

b3

L3

D

e

5X b

A

c2

A2

H

A1

L

a

E1

Suggested Pad Layout

Package Type: TO252-5L

Y1

Y

X

C1

TO252-5L

Dim Min Max Typ

A 2.19 2.39 2.29

A1 0.00 0.13 0.08

A2 0.97 1.17 1.07

b 0.51 0.71 0.583

b2 0.61 0.79 0.70

b3 5.21 5.46 5.33

c2 0.45 0.58 0.531

D 6.00 6.20 6.10

D1 5.21

e

E 6.45 6.70 6.58

E1 4.32

H 9.40 10.41 9.91

L 1.40 1.78 1.59

L3 0.88 1.27 1.08

a 0° 10°

All Dimensions in mm

Dimensions Value (in mm)

X 5.6

X1 0.6

Y 11.0

Y1 5.6

Y2 2.0

C1 7.2

C2 1.27

− −

− −

− −

AP1507

1.27

−

Y2

C

AP1507

Document number: DS31067 Rev. 3 - 2

X1

www.diodes.com

11 of 12

May 2012

© Diodes Incorporated

Page 12

AP1507

150KHz, 3A PWM BUCK DC/DC CONVERTER

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS

DOCUMENT, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other

changes without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability

arising out of the application or use of this document or any produc t described herein; neither does Diodes Incorporated convey any

license under its patent or trademark rights, nor the rights of others. Any Customer or user of this document or products described

herein in such applications shall assume all risks of such use and will agree t o hold Diodes Incorporated and all the companies

whose products are represented on Diodes Incorporated website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized

sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall

indemnify and hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names

and markings noted herein may also be covered by one or more United States, international or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without

the express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided

in the labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected

to cause the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or

systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements

concerning their products and any use of Diodes Incorporated products in such safety-critical, life support devices or systems,

notwithstanding any devices- or systems-related information or support that may be provided by Diodes Incorporated. Further,

Customers must fully indemnify Diodes Incorporated and its representatives against any damages arising out of the use of Diodes

Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

AP1507

Document number: DS31067 Rev. 3 - 2

12 of 12

www.diodes.com

May 2012

© Diodes Incorporated

Loading...

Loading...