Page 1

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

Features

• Output voltage: 3.3V, 5V, 12V and adjustable output

version

• Adjustable version output vo l tag e range, 1.23V to

• 150Khz +

• Voltage mode non-synchronous PWM control

• Thermal-shutdown and current-limit protection

• ON/OFF shutdown control input

• Operating voltage can be up to 40V

• Output load current: 5A

• Low power standb y mode

• Built-in switching transistor on chip

• Lead Free packages: TO263-5L and TO220-5L(R)

• TO263-5L and TO220-5L(R): Available in “Green”

• Lead Free Finish/ RoHS Compliant (Note 1)

4%

37V+

Molding Compound (No Br, Sb)

15% fixed switching frequency

Applications

• Simple High-efficiency step-down regulator

• On-card switching regulators

• Positive to negative converter

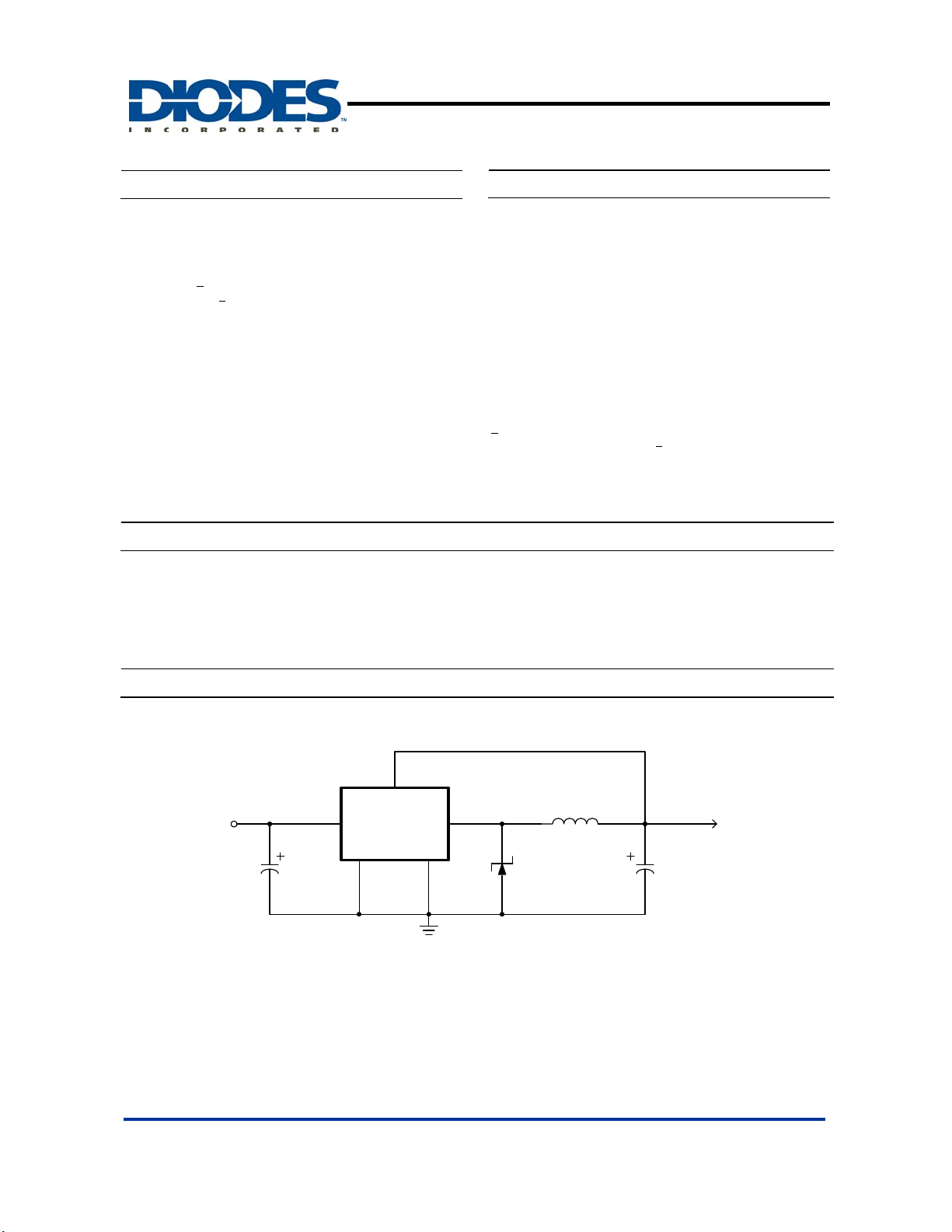

Typical Application Circuit

(1) Fixed Type Circuit

General Description

The AP1501A series are monolithic ICs that are designed for a

step-down DC/DC converter, and possess the ability to drive a

5A load without additional transistor component. Due to reducing

the number of external component, the board space can be

saved easily. The external shutdown function can be controlled

by logic level and then come into standby mode. The internal

compensation makes feedback control have good line and load

regulation without external design. Regarding protected function,

thermal shutdown is to prevent over temperature operating from

damage, and current limit is against over current operating of the

output switch. The AP1501A series operates at a switching

frequency of 150Khz thus allowing smaller sized filter

components than what would be needed with lower frequency

switching regulators. Other features include a guaranteed

4% tolerance on output voltage under specified input voltage

+

and output load conditions, and +

The output version includes fixed 3.3V, 5V, 12V, and an

adjustable type. The packages are available in a standard 5-lead

TO263 and TO220 packages.

15% on the oscillator frequency.

12V

DC Input

Cin

Capacitor

12

Vin

4

AP1501A

-33

SD

FB

35

Gnd

Output

Inductor

D1

Schottky

Diode

L1

18uH

3.3V/5A

Output Load

Co

Capacitor

AP1501A Rev. 10 1 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 2

×

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

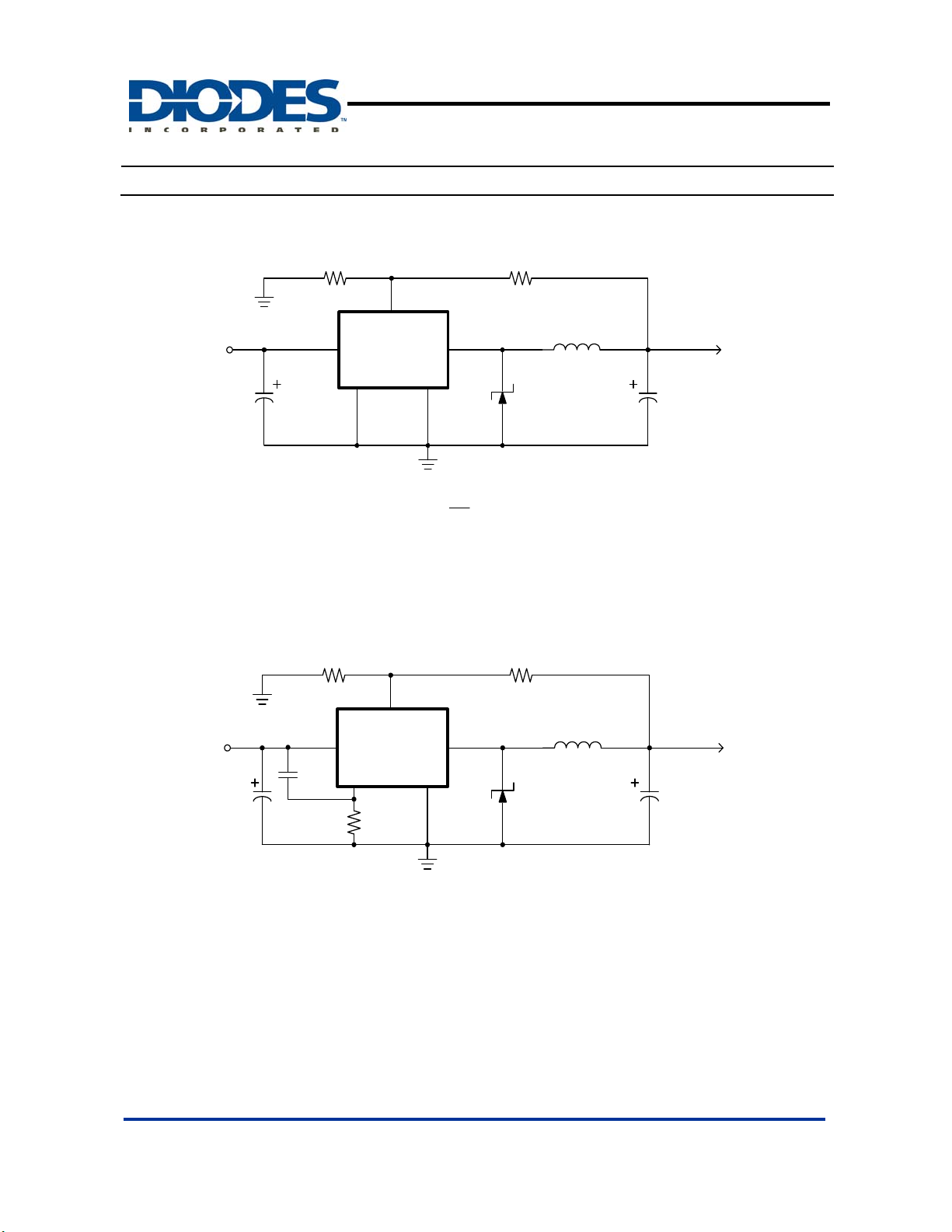

Typical Application Circuit (Continued)

(2) Adjustable Type Circuit

R2

FB

12V

DC Input

Cin

Capacitor

(3) Delay Start Circuit

12

Vin

V

V

R2 = 1K ~ 3K

AP1501A

SD

= V

out

= 1.23V

FB

4

Output

35

Gnd

R1

(1 +

FB

)

R2

R1

L1

22uH

D1

Schottky Diode

5V/ 5A

Output Load

Co

Capacitor

12V

DC Input

Cin

Capacitor

R2

FB

4

12

AP1501A

SD

R

DELAY

10K

C

DELAY

0.1uF

Vin

Output

35

Gnd

R1

L1

22uH

D1

Schottky Diode

5V/ 5A

Output Lo ad

Co

Capacitor

AP1501A Rev. 10 2 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 3

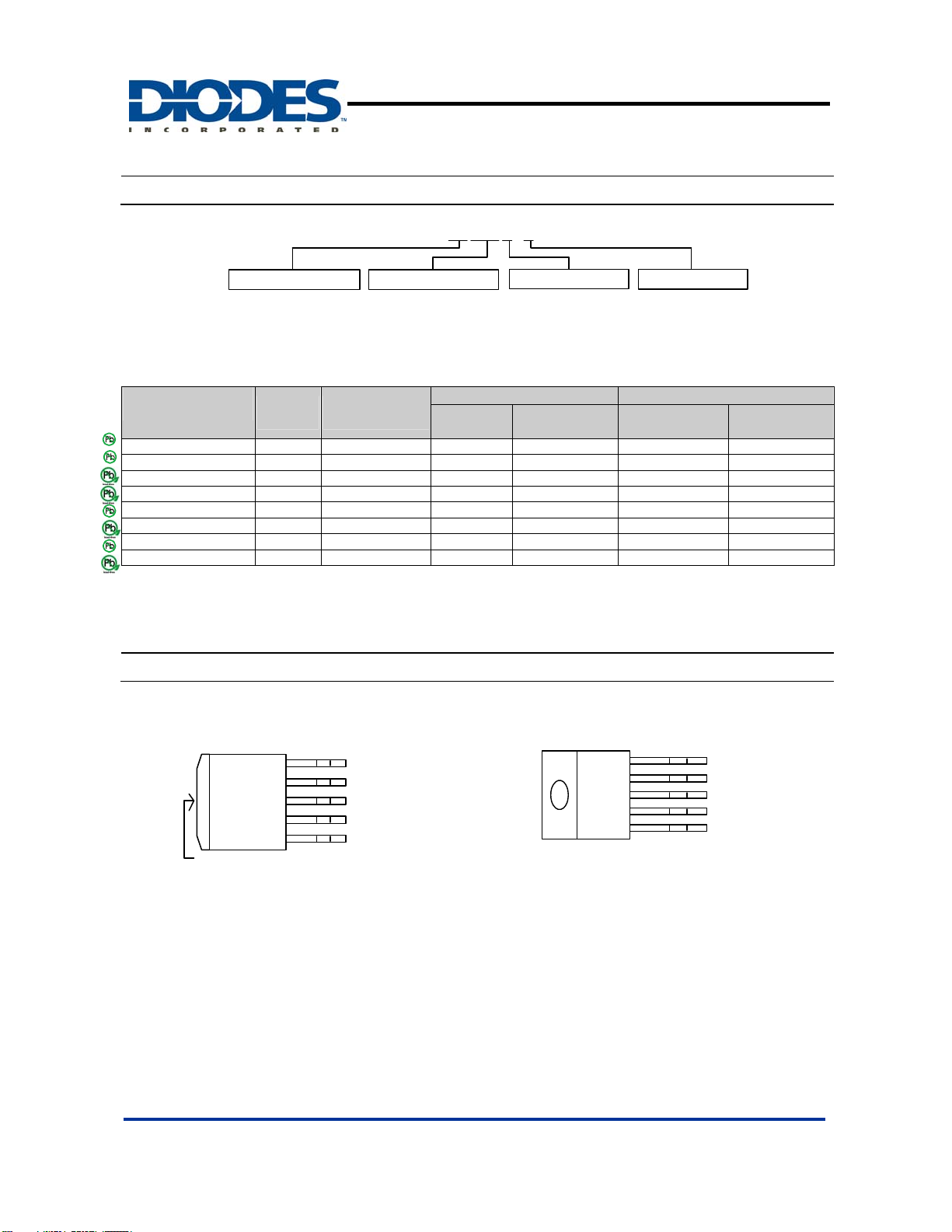

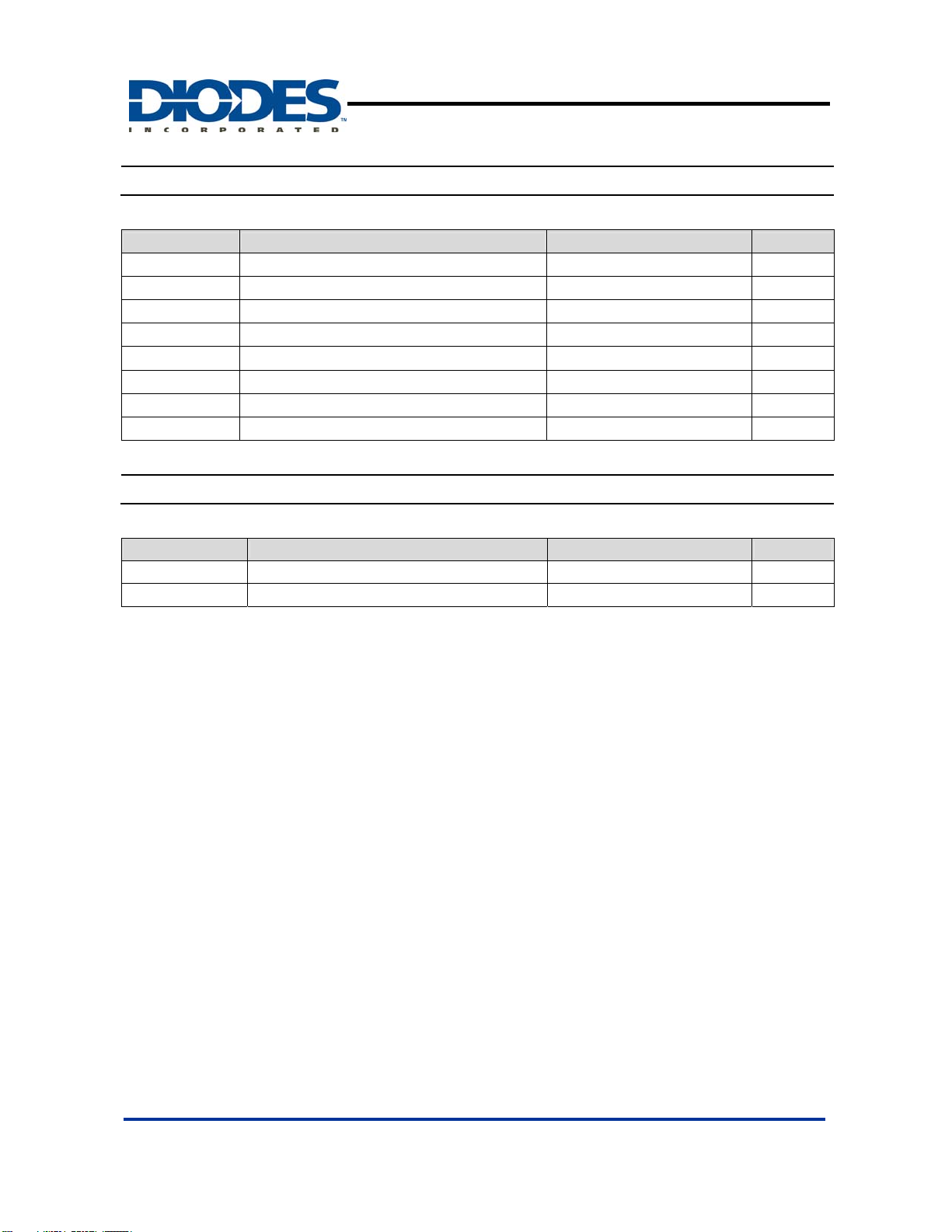

Ordering Information

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

AP1501A - XX

XXX X - X

Output Version

Blank : Adjustable

33 : 3.3V

50 : 5.0V

12 : 12V

Package

K5 : TO263-5L

T5 : TO220-5L

T5R : TO220-5L(R)

Lead Free

L : Lead Free

G : Green

Packing

U : Tube

13 : Tape & Reel

Device

Lead-free

AP1501A-XXK5L-U K5 TO263-5L 50 -U NA NA

Lead-free

AP1501A-XXK5L-13 K5 TO263-5L NA NA 800/Tape & Reel -13

AP1501A-XXK5G-U K5 TO263-5L 50 -U NA NA

AP1501A-XXK5G-13 K5 TO263-5L NA NA 800/Tape & Reel -13

AP1501A-XXT5L-U T5 TO220-5L 50 -U NA NA

Lead-free

AP1501A-XXT5G-U T5 TO220-5L 50 -U NA NA

AP1501A-XXT5RL-U T5R TO220-5L(R) 50 -U NA NA

Lead-free

AP1501A-XXT5RG-U T5R TO220-5L(R) 50 -U NA NA

Notes: 1. EU Directive 2002/95/ EC (RoHS). All applicable RoHS exemptions applied. Please visit our website at

http://www.diodes.com/datasheets/ap02001.pdf.

http://www.diodes.com/products/lead_free.html

2. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

Package

Code

Packaging

(Note 2)

Quantity Part Number

Tube 13” Tape and Reel

Quantity Part Number

Suffix

Suffix

Pin Assignments

( Top View )

( Top View )

5 SD

4 FB

3 Gnd

2 Output

1 V

IN

Metal Tab GND

TO263-5L

5 SD

4 FB

3 Gnd

2 Output

1 V

IN

TO220-5L/TO220-5L(R)

AP1501A Rev. 10 3 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 4

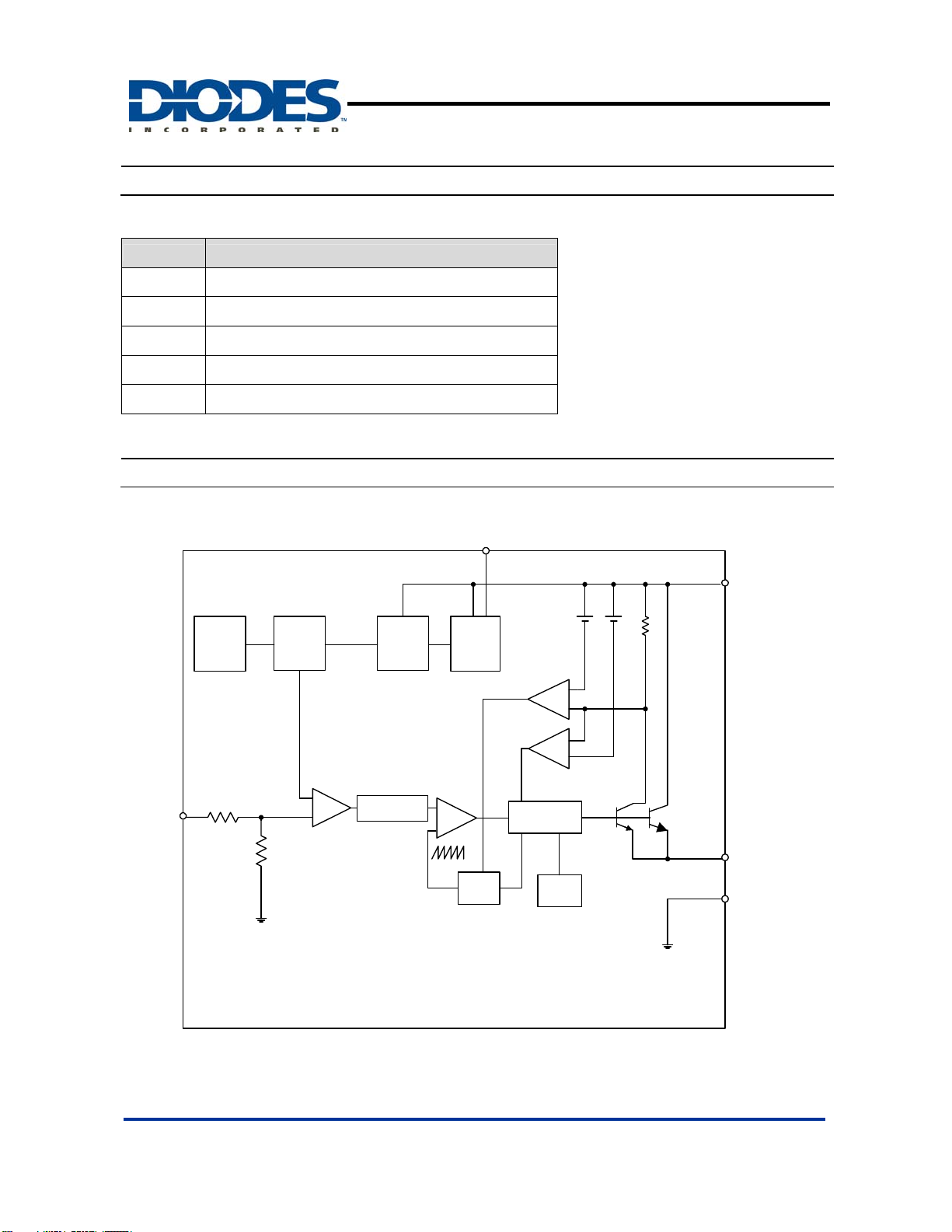

AP1501A

Pin Descriptions

Name Description

VIN Operating voltage input

Output Switching output

Gnd Ground

FB Output voltage feedback control

SD ON/OFF shutdown

Block Diagram

150KHz, 5A PWM BUCK DC/DC CONVERTER

SD

V

IN

220mV200mV

FB

Current

Source

bias

1.235V

Reference

+

_

Amp

2.5V

Regulator

Freq.

Compensation

_

Comp

+

Start

up

Comp

Comp

Pre-driver

+

_

_

+

5A

Switch

Output

150kHz

OSC.

Thermal

Shutdown

Gnd

AP1501A Rev. 10 4 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 5

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

Absolute Maximum Ratings

Symbol Parameter Rating Unit

ESD MM Machine Model ESD Protection 400 V

VCC Supply Voltage +45 V

VSD ON/OFF Pin input voltage -0.3 to +40 V

VFB Feedback Pin voltage -0.3 to +40 V

V

Output voltage to Ground -1 V

OUT

PD Power dissipation Internally limited W

TST Storage temperature -65 to +150

TJ Operating Junction Temperature -20 to +125

Recommended Operating Conditions

Symbol Parameter Rating Units

VOP Operating voltage 4.5 to 40 V

TA Operating Ambient Temperature -20 to 85

o

C

o

C

o

C

AP1501A Rev. 10 5 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 6

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

Electrical Characteristics ( All Output Voltage Versions )

Unless otherwise specified, V

Specifications with boldface type are for full operating temperature range, the other type are for T

Symbol Parameter Conditions Min Typ. Max Unit

IFB Feedback Bias Current

F

Oscillator Frequency

OSC

V

Saturation Voltage

SAT

DC

Max. Duty Cycle(ON) V

Min. Duty Cycle(OFF) V

ICL Current Limit

Output = 0V

IL

Output = -1V V

IQ Quiescent Current V

I

STBY

VIL

VIH High (regulator OFF) 2.0

Standby Quiescent

Current

ON/OFF Pin Logic Input

Threshold Voltage

= 12V for 3.3V, 5V, adjustable version and V

IN

= 1.3V

V

FB

(Adjustable version only)

I

= 5A

OUT

no outside circuit

= 0V force driver on

V

FB

= 0V force driver on 100

FB

= 12V force driver of f 0

FB

peak current

no outside circuit

V

= 0 force driver on

FB

Output

Leakage

Current

no outside circuit

V

= 12 force driver off (Note 3)

FB

= 40V 2 60 mA

IN

= 12 force driver off 5 10 mA

FB

ON/OFF pin = 5V

= 40V

V

IN

Low (regulator ON)

= 24V for the 12V version. I

IN

J

40

127 150 173

110 173

1.5

5.5 6.0

200 uA

150

= 25ºC.

LOAD

1.3

= 0.5A

60

100

Khz

1.6

1.7

6.5

7.5

250

300

0.6

nA

V

%

A

uA

V

ON/OFF Pin Logic

IH

Input Current

ON/OFF Pin Input

IL

Current

θ

θ

Notes: 3. Feedback pin removed from output and connected to 0V to force the output transistor switch ON. Feedback pin removed from output

and connected to 12V for the 3.3V, 5V, and the ADJ. version, and 15V for the 12V version, to force the output transistor switch OFF.

4. Test condition: Device mounted with copper area of approximately 3in

Thermal Resistance

JA

Junction-to-Ambient

Thermal Resistance

JC

Junction-to-Case

V

= 2.5V (OFF) 15 25

LOGIC

V

= 0.5V (ON) 0.02 5

LOGIC

TO263-5L (Note 4) 37

o

TO220-5L(R) (Note 4) 31

TO263-5L (Note 4) 6

o

TO220-5L(R) (Note 4) 5

2

, 1oz, no air flow.

uA

C/W

C/W

AP1501A Rev. 10 6 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 7

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

Electrical Characteristics ( Continued )

Specifications with boldface type are for full operating temperature range, the other type are for TJ = 25ºC.

AP1501A-ADJ

AP1501A-3.3V

AP1501A-5V

AP1501A-12V

Symbol Parameter Conditions Typ. Limit Unit

5V <

V

FB

η

V

OUT

η

V

OUT

η

V

OUT

η

Output

Feedback

Efficiency V

Output Voltage

Efficiency V

Output Voltage

Efficiency V

Output Voltage

Efficiency V

VIN < 40V

0.2A <

I

< 5A

LOAD

programmed for 3V

V

OUT

= 12V, I

IN

5.5V <

0.2A <

= 12V, I

IN

8V <

0.2A <

= 12V, I

IN

15V <

0.2A <

= 16V, I

IN

LOAD

VIN < 40V

I

< 5A

LOAD

LOAD

VIN < 40V

I

< 5A

LOAD

LOAD

VIN < 40V

I

< 5A

LOAD

LOAD

1.23

=5A 72 %

3.3

=5A 71 %

= 5A 78 %

12

= 5A 88 %

5

1.193/1.18

1.267/1.28

3.168/3.135

3.432/3.465

4.8/4.75

5.2/5.25

11.52/

12.48/

11.4

12.6

V

V

MIN

V

MAX

V

V

MIN

V

MAX

V

V

MIN

V

MAX

V

V

MIN

V

MAX

AP1501A Rev. 10 7 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 8

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

Typical Performance Characteristics

Typical Performance Characteristics

Normalized Output Voltage

Efficiency

5.10

5.05

5.00

4.95

OUTPUT VOLTAGE CHANGE

4.90

1.7

1.6

1.5

1.4

SATURATION VOLTAGE (V)

1.3

1.2

VIN=20V, I

Normalized at T

-50 -25 0 25 50 75 100 125

JUNCTION TEMPERA TU RE(°C)

LOAD

=3A

= 25°C

J

Switch Saturation Voltage

1 : -40oC

o

C

2 : 25

o

3 : 125

C

1

2

3

2.0

SWITCH CURRENT(A)

3

45

100

95

90

85

5V

80

EFFICIENCY (%)

75

3.3V

70

65

8101520253035

INPUT VOLTAGE

5A Load

40

Switch Current Limit

7.5

VIN=12V, V

7.0

6.5

SWITCH CURRENT LIMIT (A)

6.0

5.5

-50 -25 0 25 50 75 100 125

JUNCTION TEMPERATURE(°C)

OUT

=5V

Operating Quiescent Current

25.0

20.0

15.0

10.0

SUPPLY CURRENT (mA )

5.0

0.0

-50 -25 0 25 50 75 100 125

JUNCTION TEMPERATURE(°C)

Switch ON

Switch OFF

200.0

160.0

120.0

80.0

CURRENT (uA)

40.0

Shutdown Quiescent Current

1

2

3

0.0

10 20 30 40

SUPPLY VOLTAGE (V)

V

ON/OFF

1 : -40

2 : 25

3 : 125

o

o

=5V

C

C

o

C

AP1501A Rev. 10 8 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 9

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

Typical Performance Characteristics (Continued)

Minimum Operating Supply Voltage

5.0

5.0

ON/OFF Threshold Voltage

4.0

3.0

2.0

V

1.0

SUPPLY VOLTAGE (V)

0.0

OUT

I

LOAD

-50 -25 0 25 50 75 100 125

JUNCTION TEMPERATURE (oC)

ON/OFF Pin Current (Sinking)

150.0

120.0

90.0

60.0

CURRENT (uA)

30.0

VIN=40V

-40

0.0

1.45 10152022232425

=1.23V

=120mA

o

C TJ 125oC

≤≤

ON/OFF PIN VOLTAGE (V)

4.0

3.0

2.0

1.0

THRESHOLD VOLTAGE (V)

0.0

-50

0

-25

JUNCTION TEMPERATURE (oC)

Switch Frequency

200.0

150.0

100.0

50.0

FREQUENCY (kHz)

0.0

-50 -25 0 25 50 75 100 125

JUNCTION TEMPERATURE (oC)

25 50 75

100 125

Feedback Pin Bias Current

50.0

40.0

30.0

20.0

Adjustable Version Only

BIAS CURRENT (nA)

10.0

0.0

-50 -25 0 25 50 75 100 125

o

JUNCTION TEMPERATURE(

C)

AP1501A Rev. 10 9 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 10

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

Functional Description

Pin Functions

+V

IN

This is the positive input supply for the IC switching regulator. A suitable

input bypass capacitor must be present at this pin to minimize voltage

transients and to supply the switching currents needed by the regulator.

Ground

Circuit ground.

Output

Internal switch. The voltage at this pin switches between (+V

and approximately – 0.5V, with a duty cycle of approximately

/ VIN. To minimize coupling to sensitive circuitry, the PC board

V

OUT

copper area connected to this pin should be kept a mini mum.

Feedback

Senses the regulated output voltage to complete the fee dback loop.

ON/OFF

Allows the switching regulator circuit to be shutdown using logic level

signals thus dropping the total input supply current to approximately

150uA. Pulling this pin below a threshold voltage of approximately

1.3V turns the regulator on, and pulling this pin above 1.3V (up to a

maximum of 40V) shuts the regulator down. If this shutdown feature is

not needed, the ON/OFF pin can be wired to the ground pin or it can be

left open, in either case the regulator will be in the ON condition.

Thermal Considerations

The AP1501A is available in two packages, a 5-pin surface mount

TO-263 and TO-220.

The TO-220 package needs a heat sink under mo st conditions. The size

of the heat sink depends on the input voltage, the output voltage, the

load current and the ambient temperature. The AP1501A junction

temperature rises above ambient temperature for a 5A load a nd different

input and output voltages. The data for these curves was taken with the

AP1501A (TO-220 package) operating as a buck switching regulator in

an ambient temperature of 25

numbers are all approximate and there are many factors that can affect

these temperatures. Higher ambient temperatures require more heat

sinking.

The TO-263 surface mount package tab is designed to be soldered to

the copper on a printed circuit board. The copper and the board are the

heat sink for this package and the other heat producing components,

such as the catch diode and inductor. The PC board copper area that

the package is soldered to should be at least 0.8 in

have 2 or more square inches of 2 oz. Additional copper area improves

the thermal characteristics, but with copper areas greater than

approximately 6 in

realized. If further thermal improvements are needed, double sided,

multilayer PC boards with large copper areas and/or airflow are

recommended.

2

, only small improvements in heat dissipation are

o

C (still air). These temperature rise

2

, and ideally should

IN

– V

SAT

)

The AP1501A (TO-263 package) junction temperature rise above

ambient temperature with a 2A load for various input and output voltages.

This data was taken with the circuit operating as a buck switching

regulator with all components mounted on a PC board to simulate the

junction temperature under actual operating conditions. This curve can

be used for a quick c heck for the a pproximate j unction temp erature for

various conditions, but be aware that there are many factors that can

affect the junction temperature. When load currents higher than 3A are

used, double sided or multilayer PC boards with large copper areas

and/or airflow might be needed, especially for high ambient te mperatures

and high output voltages.

For the best thermal performance, wide copper traces and generous

amounts of printed circuit board copper should be used in the board

layout. (Once exception to this is the output (switch) pin, w hich should not

have large areas of copper.) Large areas of copper provide the best

transfer of heat (lower thermal resistance) to the surrounding air, and

moving air lowers the thermal resistance even furthe r.

Package thermal resistance and junction temperature rise numbers are

all approximate, and there are many factors that will affect these

numbers. Some of these factors include board size, shape, thickness,

position, location, and even board temperatu re. Other factors are, trace

width, total printed circuit copper area, copper thickness, single or

double-sided, multilayer board and the amount of solder on the board.

The effectiveness of the PC board to dissipate heat al so depends on the

size, quantity and spacing of other components on the board, as well as

whether the surrounding air is still or moving.

Furthermore, some of these components such as the catch diode will

add heat to the PC board and the heat can vary as the input voltage

changes. For the inductor, depending on the physical size, type of core

material and the DC resistance, it could either act as a heat sink taking

heat away from the board, or it could add heat to the board.

AP1501A Rev. 10 10 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 11

Marking Information

(1) TO263-5L

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

( Top View )

Logo

Output Type :

1501A : ADJ

1501A33 : 3.3V

1501A50 : 5.0V

1501A12 : 12V

(2) TO220-5L(R)

Output Type :

1501A : ADJ

1501A33 : 3.3V

1501A50 : 5.0V

1501A12 : 12V

1501A XX

YY WW

( Top View )

X

1501AXX

YY WW X X

X

L : Lead Free

G : Green

ID code

Xth week : 01~52

Year :

"08" = 2008

"09" = 2009

~

Logo

L : Lead Free

G : Green

ID code

Xth week: 01~52

Year:

"08" = 2008

"09" = 2009

~

AP1501A Rev. 10 11 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 12

150KHz, 5A PWM BUCK DC/DC CONVERTER

Package Information (All Dimensions in mm)

(1) Package Type: TO263-5L

AP1501A

(2) Package Type: TO220-5L

AP1501A Rev. 10 12 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 13

150KHz, 5A PWM BUCK DC/DC CONVERTER

Package Information (Continued)

(3) Package Type: TO220-5L(R) Mechanical drawing

AP1501A

AP1501A Rev. 10 13 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Page 14

AP1501A

150KHz, 5A PWM BUCK DC/DC CONVERTER

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS

DOCUMENT, INCLUDING, BU T NOT LIMI TED TO, T HE IMPLIE D WARRANT IES OF ME RCHANTABILIT Y AND FI TNESS FOR A

PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other

changes without further notice to this document and any product described herein. Diodes Incorporated does not assume any

liability arisi ng out of the application or use of this document or any product descr ibed herein; neither does Diode s Incorporated

convey any license under its patent or trademark rig hts, nor the rights of othe rs. Any Customer or user of this docume nt or products

described herein in such applications shall assume all risks of such use and will agree to hold Diodes Incorporated and all the

companies whose products are represented on Diodes Incorporated website, harmless against all damages.

Diodes Incorporat ed does not warrant or accept a ny liabil ity whatsoeve r in respect of any p roducts purc hase d through unau thori zed

sales channel.

Should Customers purch ase or use Diodes Incorpo rated products for an y unintended or unau thorized applic ation, Customers sh all

indemnify and hold Dio des Inc orporated and its re presen tatives harmle ss against all cla ims, d amages, expens es, a nd attor ney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized

application.

Products described here in may be covered by one or more Unit ed States, i nternationa l or foreign patents p ending. Product n ames

and markings noted herein may also be covered by one or more United States, i nte rnational or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems

without the express written approval of the Chief Executi ve Off icer of Diodes Incorporate d. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided

in the labeling can be reasonably expected to result in significant injury to the user.

B. A critic al comp onent is any com ponent i n a life suppor t devic e or system whose f ailure to pe rform ca n be reasonabl y expect ed

to cause the failure of the life support device or to affect its safety or effectiveness.

Customers repres ent that th ey have all necessar y expertis e in th e safety a nd regul ator y ramific ations of t heir lif e support devic es or

systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements

concerning their products and any use of Diodes Incorporated products in such safety-critical, life support devices or systems,

notwithstandin g any devices- or systems-related i nformation or support that may be provided by Diod es Incorporated. Further,

Customers must full y indemnify Diode s Incorporat ed and its represent atives ag ainst any damages ari sing out of th e use of Diodes

Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2009, Diodes Incorporated

www.diodes.com

AP1501A Rev. 10 14 of 14 SEPTEMBER 2009

DS31191

www.diodes.com © Diodes Incorporated

Loading...

Loading...