Page 1

Three Phase Direct PWM Sensorless Motor Driver AM9800

Data Sheet

General Description

The AM9800 is a direct PWM driver IC designed for

three-phase brushless motors. Also, by using highly

silent PWM drive, switching current of the phase

with a smooth slope reduces the sound of slewing

motor, and makes high-efficiency drive a reality by a

synchronous commutation.

The device is build-in lock protection. When the fan

is locked, the device will enter the lockup protection

mode. It is also equipped with thermal shutdown

function and forward or reverse rotation selection. In

normal operation, supply current is less than 2mA,

but in PWM=0 mode it is just around 20µA.

The AM9800 is available in SSOP-16 package.

Features

• Speed Controllable by PWM Input Signal

• Sensorless Drive

• Soft Switched Drive

• Build-in Forward/Reverse Switching Circuit

• Power Saving Function in a Stopped State: 2mA

and PWM=0 State: 20µA

• Build-in Current Limiter Circuit

• Build-in Lock Protection and Auto-restart

• Built-in Over Current Protection

• Built-in Thermal Shutdown Circuit

• ESD Rating: 4000V (Human Body Model)

300V (Machine Model)

Applications

• CPU Cooler Fan in Notebook Personal

Computers

Figure 1. Package Type of AM9800

SSOP-16

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

1

Page 2

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

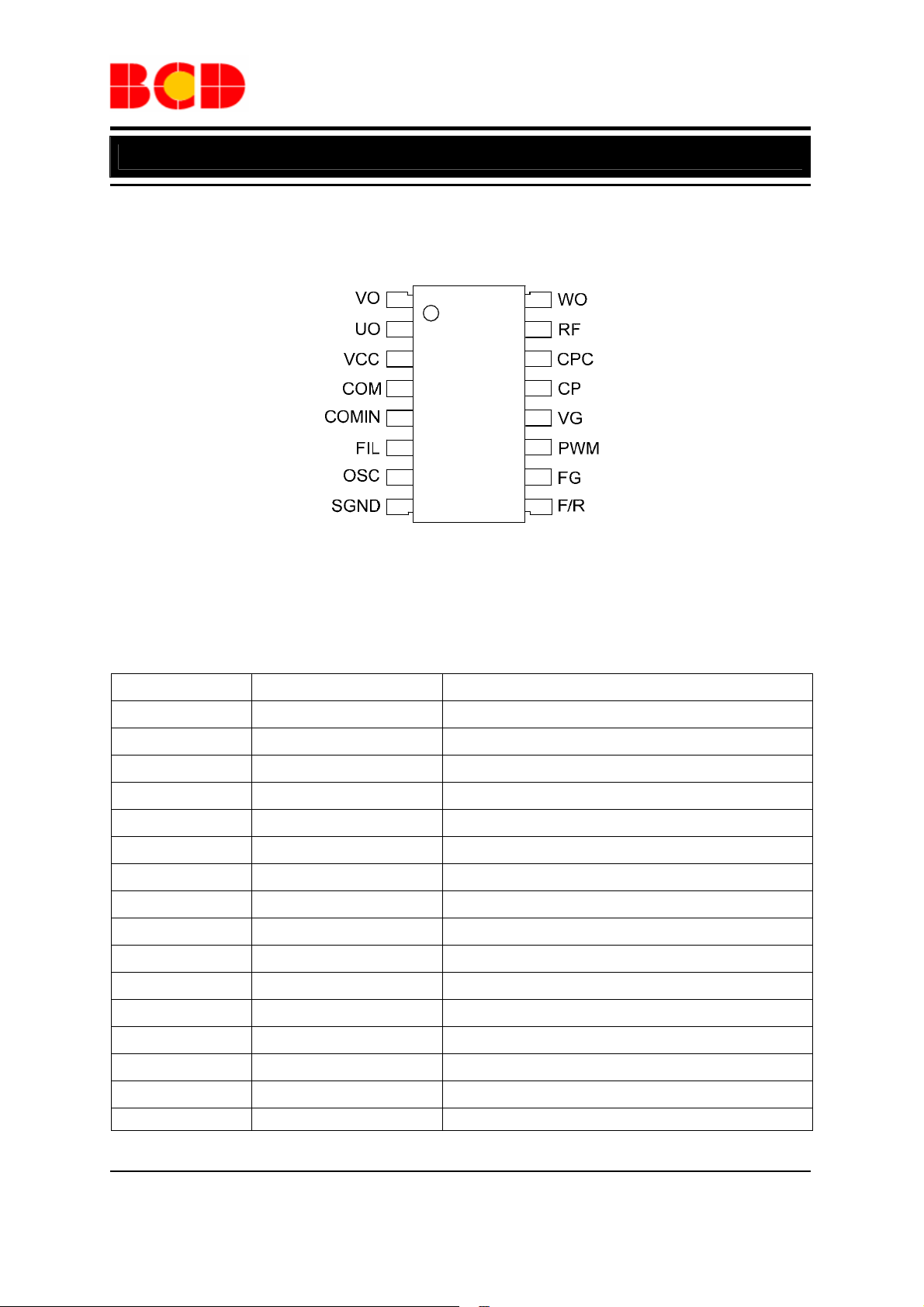

Pin Configuration

GS Package

(SSOP-16)

1

16

2

3

4

5

6

7

8

Figure 2. Pin Configuration of AM9800 (Top View)

15

14

13

12

11

10

9

Pin Description

Pin Number Pin Name Function

1 VO Output pin (V), connected to the motor coil

2 UO Output pin (U), connected to the motor coil

3 VCC Supply voltage

4 COM Motor middle-point connection

5 COMIN Motor position detection comparator filter pin 1

6 FIL Motor position detection comparator filter pin 2

7 OSC OSC startup frequency setting

8 SGND Ground for IC

9 F/R Rotation direction switching

10 FG FG pulse output

11 PWM PWM signal input

12 VG Charge pump step-up output

13 CP Charge pump step-up pulse output pin

14 CPC Charge pump step-up pin

15 RF Output current detection

16 WO Output pin (W), connected to the motor coil

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

2

Page 3

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

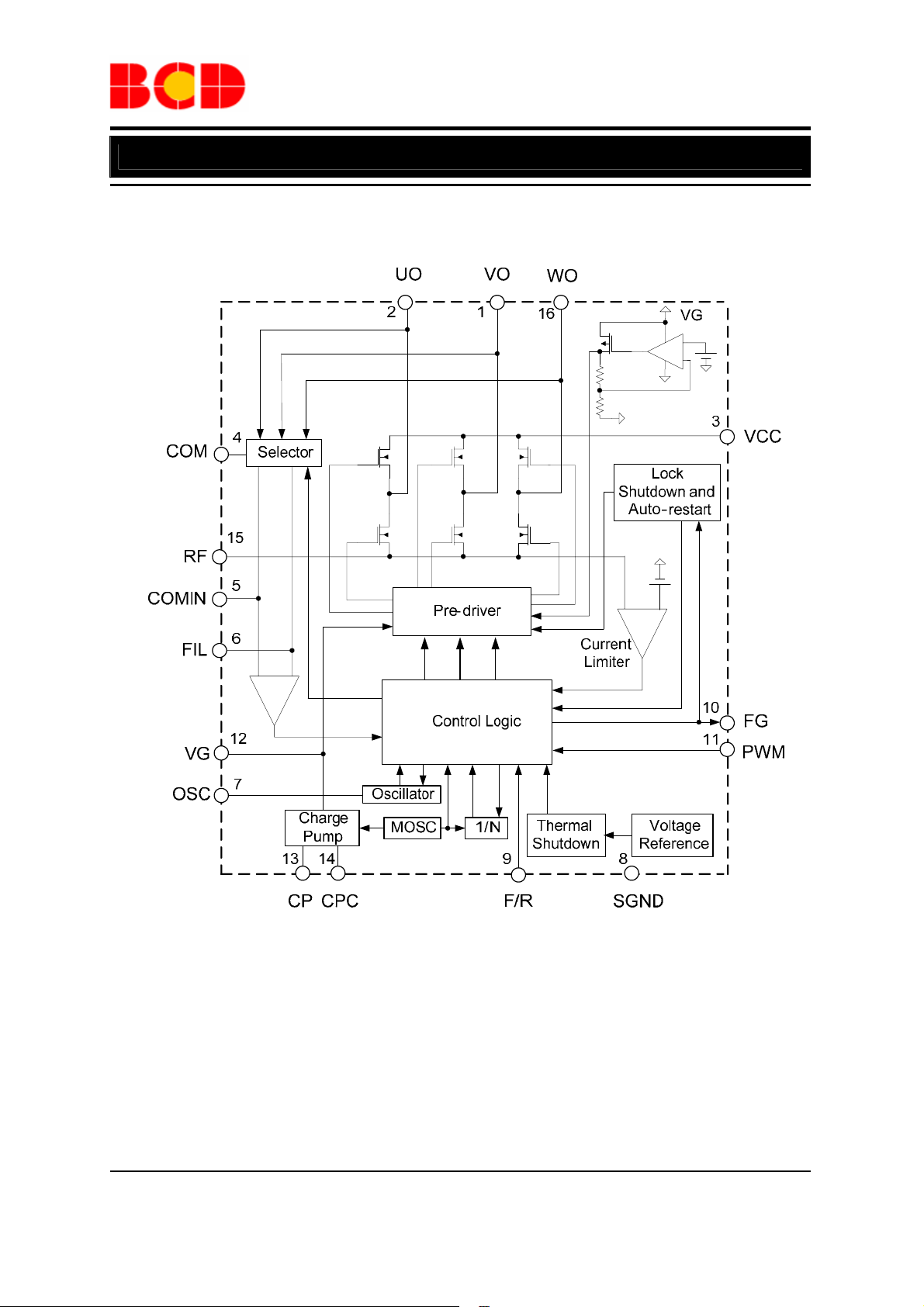

Functional Block Diagram

Figure 3. Functional Block Diagram of AM9800

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

3

Page 4

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

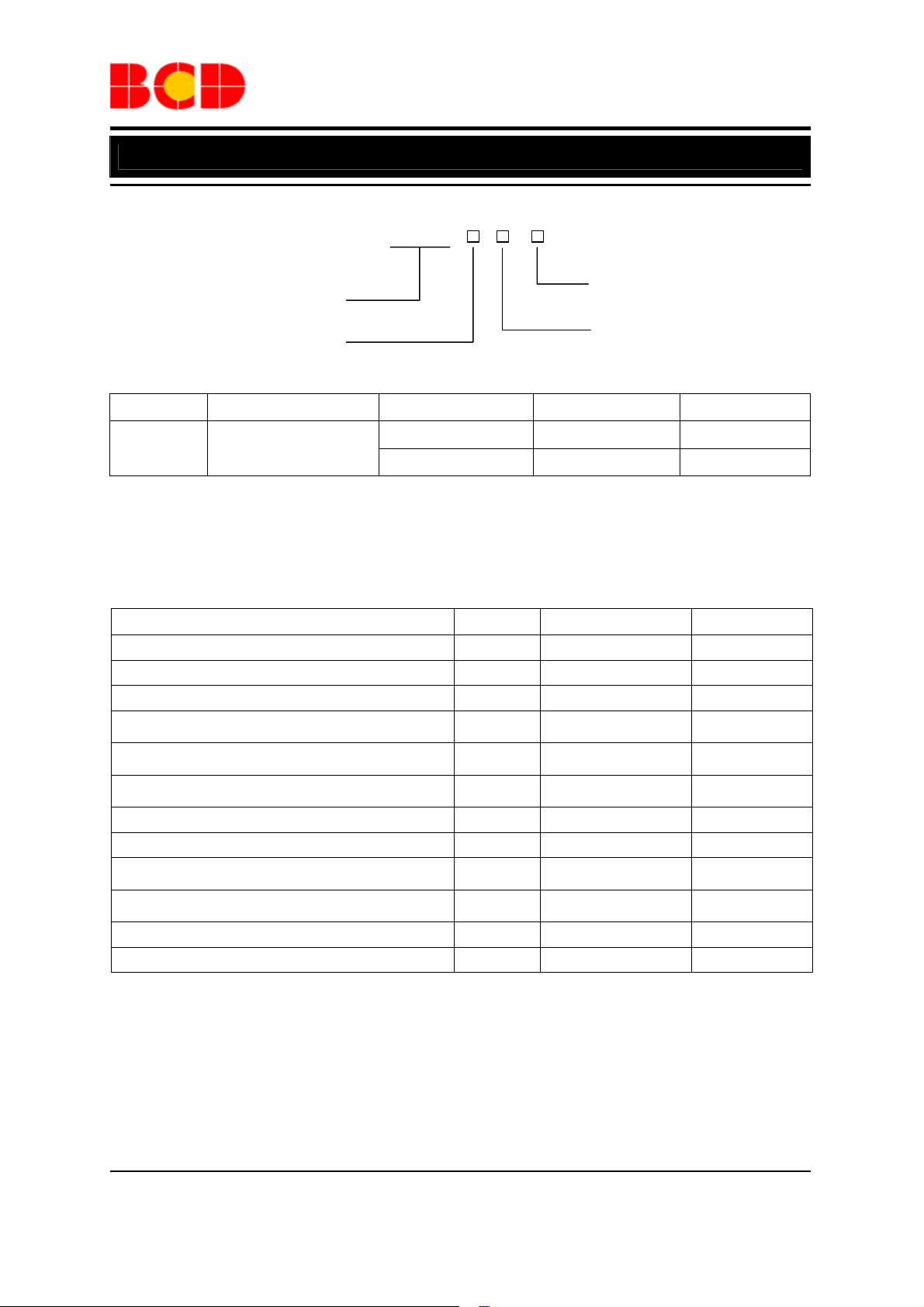

Ordering Information

AM9800 -

Circuit Type

Package

GS: SSOP-16

Package Temperature Range Part Number Marking ID Packing Type

G1: Green

TR: Tape & Reel

Blank: Tube

SSOP-16

-30 to 95°C

AM9800GS-G1 AM9800GS-G1 Tube

AM9800GSTR-G1 AM9800GS-G1 Tape & Reel

BCD Semiconductor's Pb-free products, as designated with "G1" suffix in the part number, are RoHS

compliant and green.

Absolute Maximum Ratings (TA=25°C, Note 1)

Parameter Symbol Value Unit

Supply Voltage VCC 6.5 V

Pre-drive Voltage (Gate Voltage) VG 10 V

Output Current I

PWM Input Withstand Voltage V

FG Output Withstand Voltage VFG 6 V

FG Output Current IFG 5 mA

Power Dissipation1 (Independent IC) PD1 0.3 W

Power Dissipation2 (Note 2) PD2 0.8 W

Ambient Temperature (Note 3) TA -40 to 105

0.7 A

OUT

V

PWM

V

CC

°C

Storage Temperature T

ESD (Human Body Model) 4000 V

ESD (Machine Model) 300 V

-55 to 150

STG

°C

Note 1: Stresses greater than those listed under “Absolute Maximum Ratings” may cause permanent damage to

the device. These are stress ratings only, and functional operation of the device at these or any other conditions

beyond those indicated under “Recommended Operating Conditions” is not implied. Exposure to “Absolute

Maximum Ratings” for extended periods may affect device reliability.

Note 2: When mounted on 76.1mm×114.3mm×1.6mm glass epoxy board.

Note 3: T

=150°C. Use the IC in the range where the temperature of the chip does not exceed TJ=150°C during

J

operation.

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

4

Page 5

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

Recommended Operating Conditions (TA=25°C)

Parameter Symbol Min Max Unit

Supply Voltage VCC 2.2 6 V

Operating Temperature TOP -30 95

°C

Electrical Characteristics

V

=5V, TA=25°C, unless otherwise specified.

CC

Parameter Symbol Conditions Min Typ Max Unit

Supply Current 1 I

Supply Current 2 I

VG Output Voltage VG 9.7 V

Upper Transistor Resistance R

Lower Transistor Resistance R

Upper & Lower Transistor

Resistance Total

OSC Frequency f

PWM Pin High-level Input

Voltage

PWM Pin Low-level Input

Voltage

V

R

ON(H+L)

V

PWMH

V

PWML

CC1

CC2

ONH

ONL

OSC

PWM=VCC

V

PWM

I

OUT

I

OUT

I

OUT

C

OSC

V

0 VCC×0.2 V

2 2.5 mA

=0V 20 50

=0.5A 1 1.5 Ω

=0.5A 1 1.5 Ω

=0.5A 2 3 Ω

=2200pF 1.0 kHz

×0.8 V

CC

CC

µA

V

PWM Pin Input Current I

PWM Input Frequency f

V

PWM

20 25 50 kHz

PWM

=0V -50 -20

PWM

µA

FG Low Level Voltage VFG IFG=0.5mA 0.2 V

RF Limiter Voltage VRF RF=0.5Ω 0.225 0.25 0.275 V

Lock Detection ON Time tON 2 s

Lock Detection OFF Time t

Thermal Protection

Temperature

Temperature Hysteresis

Width

4 s

OFF

T

175

SD

∆T

25

SD

°C

°C

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

5

Page 6

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

Typical Performance Characteristics

2.5

2.0

1.5

1.0

Supply Current (mA)

0.5

TA=25oC

V

PWM=VCC

25

20

15

10

Supply Current (µA)

5

TA=25oC

V

=0V

PWM

0.0

0123456

Supply Voltage (V)

0

0123456

Supply Voltage (V)

Figure 4. Supply Current vs. Supply Voltage Figure 5. Supply Current vs. Supply Voltage

700

600

500

400

300

200

Saturation Voltage (mV)

100

VCC=5V, TA=25oC

V

SAT-UP

V

SAT-DOWN

0

0 100 200 300 400 500 600

Figure 6. Saturation Voltage vs. Output Current Figure 7. Power Dissipation vs. Temperature (Note 2)

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

Output Current (mA)

1000

800

600

400

Power Dissipation (mW)

200

0

-40-20 0 20406080100

Ambient Temperature (

o

C)

6

Page 7

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

T ypical Application

1

VO

2

UO

3

VCC

1

F

1000pF

2200pF

4

5

6

7

8

COM

COMIN

FIL

OSC

SGND

PWM

WO

RF

CPC

CP

VG

FG

F/R

16

15

14

13

12

11

10

R

F

0.5

0.1

F

F

0.1

PWM Control Signal

R

FG

10k

9

FG Output

V

PWM

f=20k to

FG

50kHz

Figure 8. Typical Application of AM9800

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

7

Page 8

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

Application Information

1. Reverse Connection of Power Supply

Connector

Reverse connection of power supply connector may

break IC. Some methods such as inserting a diode

between power supply and VCC terminal can be

taken to avoid the reverse connection destruction.

2. Power Supply Line

Back electromotive force (EMF) causes regenerated

current to the power supply line, so insert a capacitor

(recommended value: 1µF or larger) as close as

possible to the space between the power supply pin

(VCC pin) and ground pin (SGND pin) for routing

regenerated current.

3. GND Potential and External Components

Ensure that the potential of GND terminal is the

minimum potential in any operating condition.

External components connected to the ground must

be connected with lines that are as short as possible

and external components connected between IC pins

must be placed as close to the pins as possible.

4. Mounting Failures

In the process of attaching IC to the printed board,

more attention must be paid to the direction and

location of the IC, since mounting failures may also

break IC. In addition, destruction is also possible

when the circuit is shorted by foreign substance

between outputs or between output and power supply

or between output and GND.

5. Thermal Shutdown Circuit

Considering the power dissipation under actual

operating condition, the thermal design must be

applied with sufficient margin.

AM9800 features thermal shutdown (TSD) circuit

(protection temperature is 175°C typical and

hysteresis width is 25°C typical). When the chip

temperature reaches the TSD circuit temperature, the

output terminal becomes an open state. TSD circuit is

designed simply for the purpose of intercepting IC

from overheating. Make sure that the IC should not

be used again after this circuit operating. Figure 9

shows a fan rotates normally first and then enter into

OTP mode since the chip temperature reaches 175°C.

Finally the chip temperature decreases below 150°C,

then OTP mode is canceled and the fan rotates

normally again.

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

VUO

5V/div

VVO

5V/div

VWO

5V/div

IWO

100mA/div

Time 1s/div

Figure 9. OTP Function

6. F/R Function

A high level input causes the current to flow into the

motor in the order of U, V, and W and a low level

input in the order of U, W, and V. When the motor is

used with the F/R pin open, the built-in resistor

enables the F/R pin to GND. Changing the order of

current application turns the motor to rotate in the

opposite direction. Switching H/L of F/R (pin 9)

terminal should not be done during the motor rotation.

It should be done once the motor stops. F/R terminal

should be connected to VCC or GND for reducing

PWM noise. Figure 10 shows a rotating fan’s

waveform at forward mode (F/R pin is connected to

SGND pin).

VUO

5V/div

VVO

5V/div

VWO

5V/div

IWO

200mA/div

Figure 10. Rotation Mode Waveform (Forward Mode)

Time 1ms/div

7. PWM Mode

The output transistor is on when a high-level voltage

is input to the PWM pin (pin 11), and is off when a

low-level voltage is input. PWM controls the speed

of the motor by inputting the pulse in accordance

with the duty cycle to the PWM pin. When the motor

is operated with the PWM pin open, the built-in

resistor enables the PWM pin to change to high-level

voltage and the motor speed rises to full speed. When

the PWM pin is fixed at low-level voltage, the motor

decelerates, and after the motor stops, it enters

“Power Saving Mode”. Figure 11 shows a rotating

fan’s waveform at PWM Mode.

8

Page 9

v

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

Application Information (Continued)

VUO

5V/div

VVO

5V/div

VWO

5V/div

-IWO

100mA/div

Figure 11. Rotation Mode Waveform (PWM Mode)

(f=25kHz, V

Time 5ms/di

=5V, VL=0V, Duty Cycle=50%)

H

8. Soft Switching Circuit

AM9800 adopts variable duty soft switching to

minimize the motor drive noise. Figure 12 shows

how soft switching circuit works during the fan

rotation.

VUO

5V/div

VVO

5V/div

VWO

5V/div

-IWO

200mA/div

Figure 12. Soft Switching Waveform

Time 200µs/div

9. Current Limiter Circuit

The driver current is detected by connecting a resistor

between RF pin (pin 15) and ground. The current

limiter circuit limits the output current peak value to

a level determined by the equation I=V

(V

=0.25V typical).

RF

RF/RF

10. OSC Circuit

A capacitor must be connected between OSC pin (Pin

7) and ground. When a capacitor is connected, the

OSC pin starts self-oscillation, and its frequency

becomes the startup frequency. Figure 13 shows a fan

system’s OSC Waveform.

V

OSC

100mV/div

Figure 13. OSC Waveform (C

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

Time 500µs/div

=2200pF)

OSC

11.Position Detector Comparator Circuit

for Rotor

The position detector comparator circuit for the rotor

is a comparator for detecting rotor positional

information with the back EMF signal generated

when the motor rotates. The IC determines the timing

at which the output block applies current to the motor

based on the position information obtained here. A

capacitor (between 1000 and 10000pF) must be

connected between COMIN pin (pin 5) and the FIL

pin (pin 6) to prevent any motor startup misoperation

that is caused by the comparator input noise.

12.FG Output Circuit

FG output pin (pin 10) provides a pulse signal

equivalent to what provided by systems using a

Hall-effect sensor. A pull-up resistor (10kΩ is

recommended) must be connected between FG pin

and the power supply. Figure 14 shows the FG output

signal when the fan rotates.

VUO

5V/div

VVO

5V/div

VFG

5V/div

Figure 14. FG Output Signal

Time 5ms/div

13. Lock Shutdown and Auto Restart

This IC detects the rotation of the motor by internal

circuit block, and adjusts lock detection ON time (t

and lock detection OFF time (t

t

ON

and t

are shown as below:

OFF

) by internal counter.

OFF

VUO

5V/div

VVO

5V/div

VWO

5V/div

Figure 15. Lock Mode

9

Time 1s/div

ON

)

Page 10

Data Sheet

Three Phase Direct PWM Sensorless Motor Driver AM9800

Mechanical Dimensions

SSOP-16 Unit: mm(inch)

3.800(0.150)

4.000(0.157)

0.200(0.008)

0.300(0.012)

°

7

0.900(0.035)1.000(0.039)

5.800(0.228)

6.200(0.244)

°

8

°

8

0.200(0.008)

0.250(0.010)

Note: Eject hole, oriented hole and mold mark is optional.

0.650(0.026)

0.750(0.030)

0.800(0.031)

Φ

0.150(0.006)

0.250(0.010)

SEE

DETAIL A

0.635(0.025)

BSC

0.100(0.004)

0.250(0.010)

1.350(0.053)

1.550(0.061)

0.020(0.001)

0.050(0.002)

0.400(0.016)

1.270(0.050)

R0.150(0.006)

°

0

°

8

DETAIL A

°

7

4.700(0.185)

5.100(0.201)

1.350(0.053)

1.750(0.069)

0.250(0.010)

R0.150(0.006)

Sep. 2012 Rev. 1. 0 BCD Semiconductor Manufacturing Limited

10

Page 11

BCD Semiconductor Manufacturing Limited

IMPORTANT NOTICE

IMPORTANT NOTICE

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

BCD Semiconductor Manufacturing Limited reserves the right to make changes without further notice to any products or specifi-

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

cations herein. BCD Semiconductor Manufacturing Limited does not assume any responsibility for use of any its products for any

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

particular purpose, nor does BCD Semiconductor Manufacturing Limited assume any liability arising out of the application or use

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

of any its products or circuits. BCD Semiconductor Manufacturing Limited does not convey any license under its patent rights or

other rights nor the rights of others.

other rights nor the rights of others.

http://www.bcdsemi.com

MAIN SITE

MAIN SITE

- Headquarters

BCD Semiconductor Manufacturing Limited

BCD Semiconductor Manufactur ing Limited

- Wafer Fab

No. 1600, Zi Xing Road, Shanghai ZiZhu Science-based Industrial Park, 200241, China

Shanghai SIM-BCD Semiconductor Manufacturing Limited

Tel: +86-21-24162266, Fax: +86-21-24162277

800, Yi Shan Road, Shanghai 200233, China

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

REGIONAL SALES OFFICE

Shenzhen Office

REGIONAL SALES OFFICE

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd., Shenzhen Office

Shenzhen Office

Unit A Room 1203, Skyworth Bldg., Gaoxin Ave.1.S., Nanshan District, Shenzhen,

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd. Shenzhen Office

China

Advanced Analog Circuits (Shanghai) Corporation Shenzhen Office

Tel: +86-755-8826 7951

Room E, 5F, Noble Center, No.1006, 3rd Fuzhong Road, Futian District, Shenzhen 518026, China

Fax: +86-755-8826 7865

Tel: +86-755-8826 7951

Fax: +86-755-8826 7865

- Wafer Fab

BCD Semiconductor Manufacturing Limited

Shanghai SIM-BCD Semiconductor Manufacturing Co., Ltd.

- IC Design Group

800 Yi Shan Road, Shanghai 200233, China

Advanced Analog Circuits (Shanghai) Corporation

Tel: +86-21-6485 1491, Fax: +86-21-5450 0008

8F, Zone B, 900, Yi Shan Road, Shanghai 200233, China

Tel: +86-21-6495 9539, Fax: +86-21-6485 9673

Taiwan Office

BCD Semiconductor (Taiwan) Company Limited

Taiwan Office

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

BCD Semiconductor (Taiwan) Company Limited

Tai wan

4F, 298-1, Rui Guang Road, Nei-Hu District, Taipei,

Tel: +886-2-2656 2808

Taiwan

Fax: +886-2-2656 2806

Tel: +886-2-2656 2808

Fax: +886-2-2656 2806

USA Office

BCD Semiconductor Corporation

30920 Huntwood Ave. Hayward,

CA 94544, U.S.A

Tel : +1-510-324-2988

Fax: +1-510-324-2788

USA Office

BCD Semiconductor Corp.

30920 Huntwood Ave. Hayward,

CA 94544, USA

Tel : +1-510-324-2988

Fax: +1-510-324-2788

Loading...

Loading...