Page 1

A

Description

L9910/ AL9910A/ AL9910-5/AL9910A-5

UNIVERSAL HIGH VOLTAGE HIGH BRIGHTNESS LED DRIVER

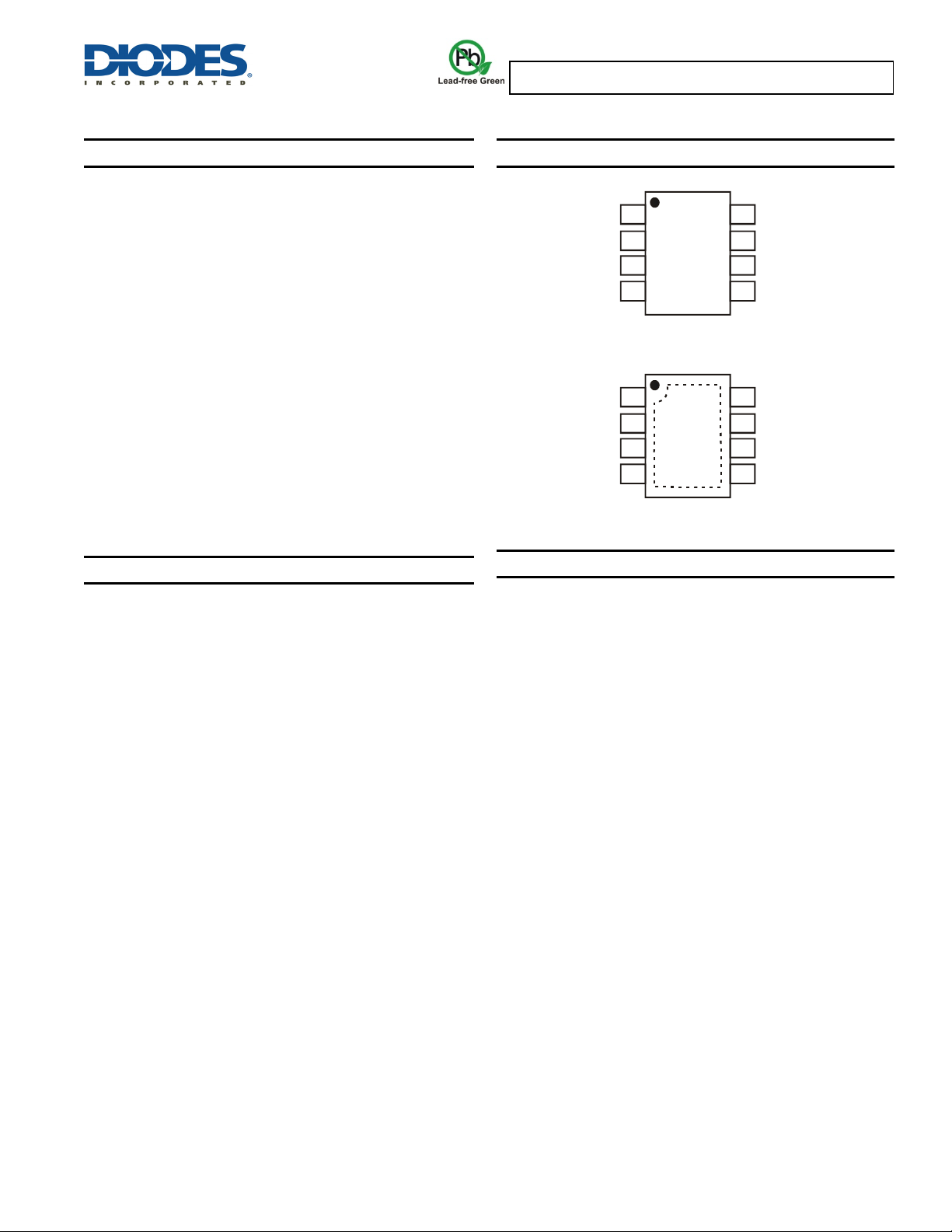

Pin Assignments

IN

IN

(Top View)

1

2

AL9910

3

4

SO-8

(Top View)

1

2

AL9910

3

4

SO-8EP

R

8

OSC

7

LD

V

6

DD

5

PWM_D

R

8

OSC

7

LD

V

6

DD

5

PWM_D

The AL9910/A high voltage PWM LED driver-controller provides an

efficient solution for offline high brightness LED lamps from rectified

line voltages ranging from 85V

external MOSFETs at switching frequencies up to 300kHz, with the

switching frequency determined by a single resistor. The AL9910

topology creates a constant current through the LEDs providing

constant light output. The output current is programmed by one

external resistor and is ultimately determined by the external

MOSFET chosen and therefore allows many low current LEDs to be

driven as well as a few high current LEDs.

The LED brightness can be varied by both Linear and PWM dimming

using the AL9910’s LD and PWM_D pins respectively. The PWM_D

input operates with duty ratio of 0-100% and frequency of up to

several kHz.

The AL9910 can withstand input voltages up to 500V which makes it

very resilient to transients at standard mains voltages. As well as

standard SO-8 package the AL9910 is available in the thermally

enhanced SO-8EP package.

Features

• >90% Efficiency

• Universal Rectified 85 to 277V

• Input Voltage Up to 500V

• Internal Voltage Regulator Removes Start-Up Resistor

7.5V MOSFET Drive – AL9910

10V MOSFET Drive – AL9910A

• Tighter Current Sense Tolerance: 5% AL9910-5, AL9910A-5

• Drives LED Lamps with Both High and Low Current LEDs

• LED Brightness Control with Linear and PWM Dimming

• Internal Thermal Protection (OTP)

• Available in SO-8 and SO-8EP Packages

• Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

• Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

up to 277VAC. The AL9910 drives

AC

Input Range

AC

Applications

• LED Offline Lamps

• High Voltage DC-DC LED Driver

• Signage and Decorative LED Lighting

• Back Lighting of Flat Panel Displays

• General Purpose Constant Current Source

V

CS

GND

GATE

V

CS

GND

GATE

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

1 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Page 2

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

Typical Applications Circuit

C3

C3

D1

VACIN

VACIN

BR1

BR1

C1

C1

C2

C2

V

V

LD

LD

PWM_D

PWM_D

R

R

OSC

OSC

DD

DD

AL9910/A

AL9910/A

R

R

OSC

OSC

V

V

IN

IN

GND

GND

GATE

GATE

CS

CS

Q1

Q1

R

R

D1

SENSE

SENSE

L1

L1

Pin Descriptions

Pin

Name

VIN

SO-8 SO-8EP

Pin Number

1 1

Input Voltage

Function

CS 2 2 Senses LED string and external MOSFET switch current

GND 3 3 Device Ground

Gate 4 4 Drives the gate of the external MOSFET switch.

PWM_D 5 5 Low Frequency PWM Dimming pin, also Enable input. Internal 200kΩ pull-down to GND.

Internally regulated supply voltage.

7.5V nominal for AL9910 and AL9910-5

10V nominal for AL9910A.

VDD

6 6

Can supply up to 1 mA for external circuitry. A sufficient storage capacitor is used to provide storage when

the rectified AC input is near the zero crossing.

LD 7 7

Linear Dimming Input. Changes the current limit threshold at current sense comparator and changes the

average LED current.

Oscillator Control. A resistor connected between this pin and ground sets the PWM frequency. The devices

R

OSC

8 8

can be switched into constant off time (PFM) mode by connecting the external oscillator resistor between

pin and the gate of the external MOSFET.

R

OSC

EP PAD N/A EP Exposed Pad (bottom). Connect to GND directly underneath the package.

Functional Block Diagram

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

2 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Page 3

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

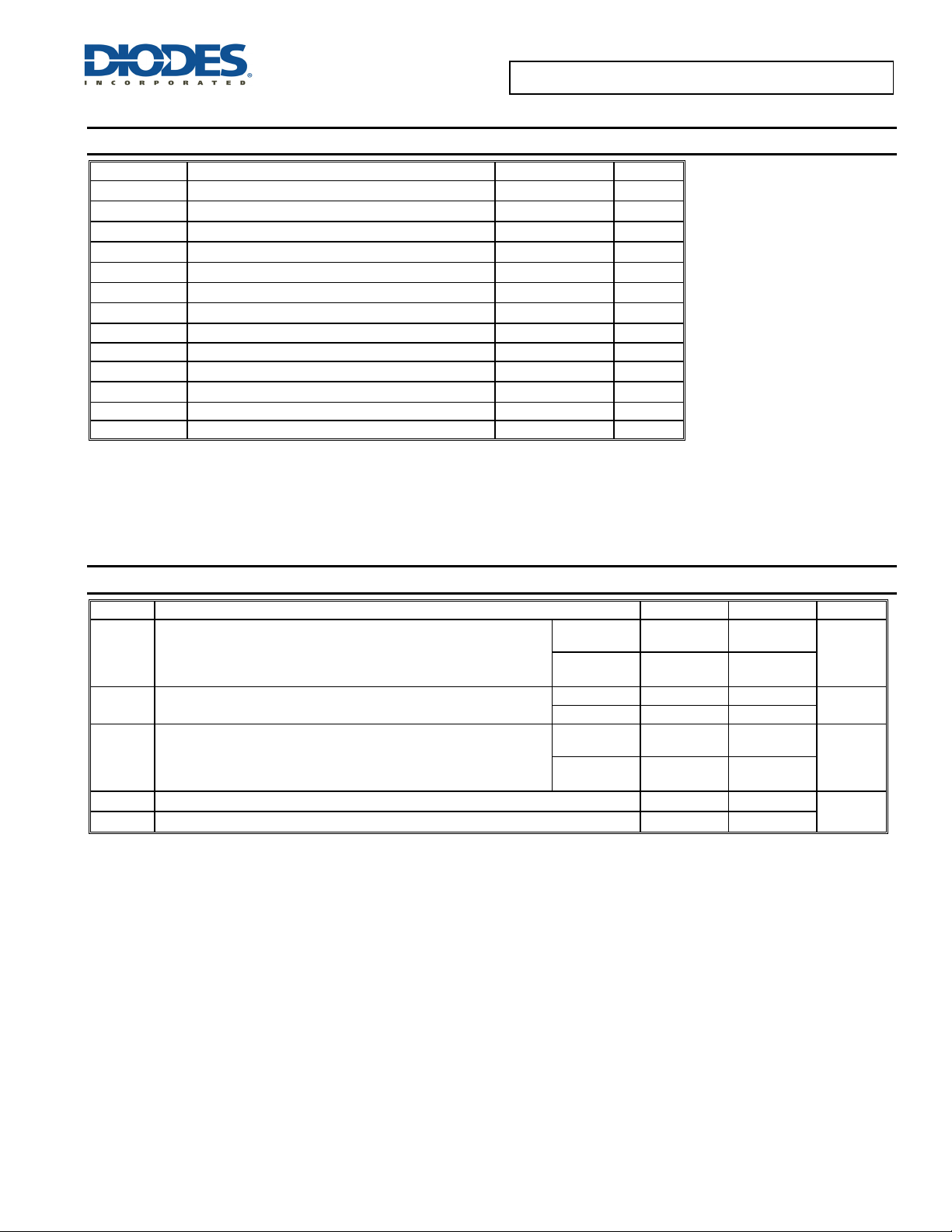

Absolute Maximum Ratings (Note 4) (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Ratings Unit

V

Maximum input voltage, VIN, to GND

IN(MAX)

VCS

VLD

V

PWM_D

V

GATE

V

DD(MAX)

Maximum CS input pin voltage relative to GND -0.3 to +0.45 V

Maximum LD input pin voltage relative to GND

Maximum PWM_D input pin voltage relative to GND

Maximum GATE pin voltage relative to GND

Maximum VDD pin voltage relative to GND

Continuous Power Dissipation (T

SO-8 (derate 6.3mW/°C above +25°C)

= +25°C)

A

-0.5 to +520 V

-0.3 to (VDD +0.3)

-0.3 to (VDD +0.3)

-0.3 to (VDD +0.3)

12 V

630 mW

V

V

V

SO-8EP (derate at 22mW/°C above 25°C) 2200 mW

TJ

TST

Junction Temperature Range +150 °C

Storage Temperature Range -65 to +150 °C

ESD HBM Human Body Model ESD Protection (Note 5) 1500 V

ESD MM Machine Model ESD Protection (Note 5) 300 V

Notes: 4. Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional

operation of the device at these or any other conditions above those listed in the operational sections of this specification is not implied. Exposure

to absolute maximum rating conditions for extended periods may affect device reliability.

All voltages are with respect to Ground. Currents are positive into, negative out of the specified terminal.

5. Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when

handling and transporting these devices

Recommended Operating Conditions (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Min Max Unit

AL9910

V

Input DC Supply Voltage Range

INDC

AL9910-5

AL9910A

Al9910A-5

Ambient Temperature Range (Note 6)

TA

AL9910_S

AL9910_SP -40 +105

AL9910

VDD Maximum Recommended Voltage Applied to VDD Pin (Note 7)

AL9910-5

AL9910A

AL9910A-5

V

EN(LO)

V

Notes: 6. Maximum ambient temperature range is limited by allowable power dissipation. The Exposed pad SO-8EP with its lower thermal impedance allows

the variants using this package to extend the allowable maximum ambient temperature range.

7. When using the AL9910 in isolated LED lamps an auxiliary winding might be used.

Pin PWM_D Input Low Voltage

Pin PWM_D Input High Voltage

EN(HI)

15.0 500

20.0 500

-40 +85

10

12

0 1

2.4

VDD

V

°C

V

V

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

3 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Page 4

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

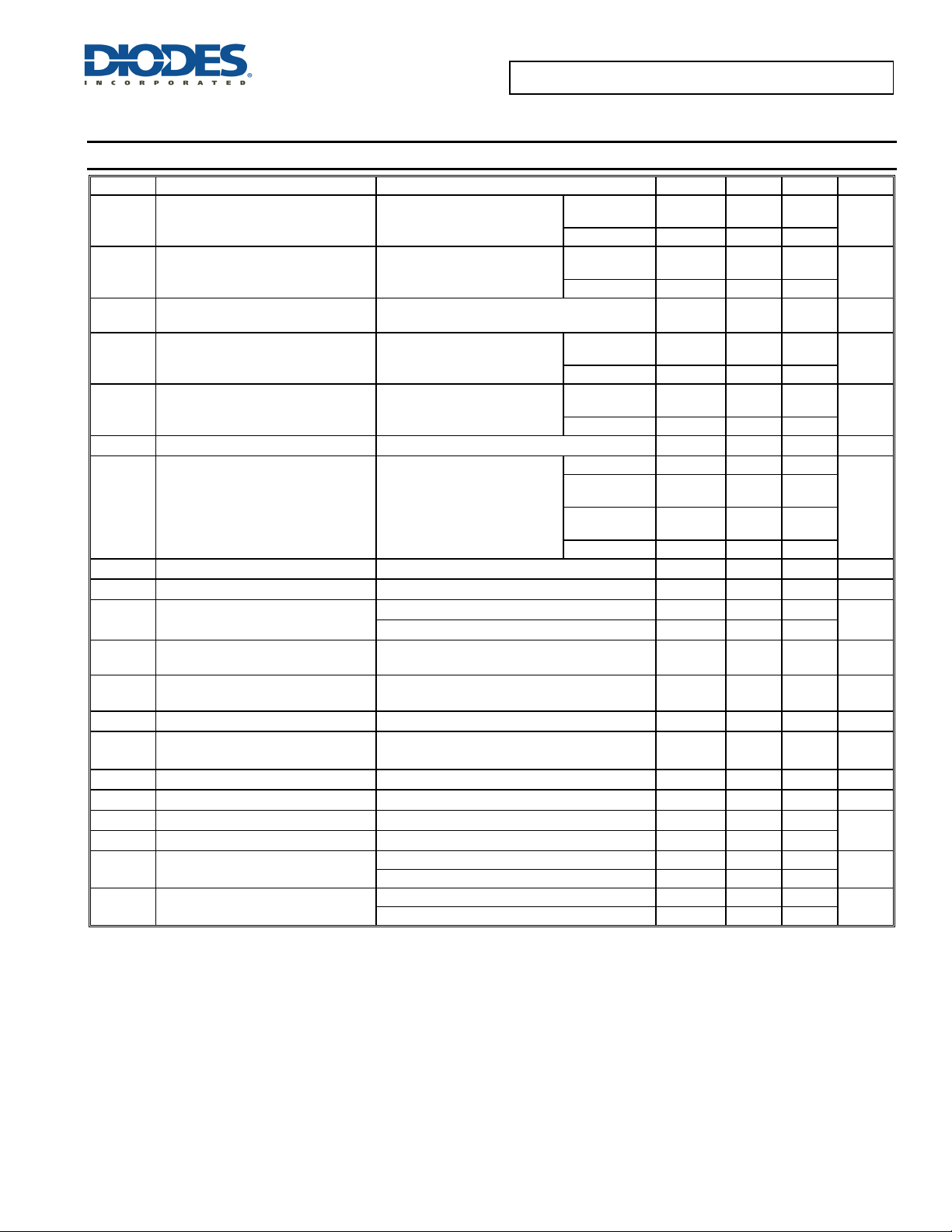

Electrical Characteristics (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Conditions Min Typ Max Unit

I

INSD

VDD

I

DD(ext)

UVLO

Shut-Down Mode Supply Current

Internally Regulated Voltage

Current Available for External

V

DD

Circuitry

V

Under Voltage Lockout Threshold V

DD

Pin PWM_D to GND,

V

IN

V

IN

l

DD(ext)

V

IN

DD

= V

= V

= V

rising

(Note 6)

IN(MIN)

~500V, (Note 8)

IN(MIN)

= 0, Gate pin open

to 100V (Notes 8 & 9)

IN(MIN)

AL9910

AL9910-5

AL9910A

AL9910

AL9910-5

AL9910A 9 10 11

AL9910

AL9910-5

0.50 1

0.65

1.2

7.0 7.5 8.0

1.0 mA

6.4 6.7 7

mA

V

V

AL9910A 8 9 10

∆UVLO

V

Under Voltage Lockout Hysteresis V

DD

falling

DD

AL9910

AL9910-5

500

mV

AL9910A 750

R

PWM_D

V

CS(HI)

PWM_D Pull-Down Resistance

Current Sense Threshold Voltage

V

= 5V

PWM_D

Full ambient temperature range

(Note 10)

AL9910

AL9910A

AL9910A-5

150 200 250 kΩ

225 250 275

230 255 280

mV

242 255 267

AL9910-5 237.5 250 262.5

V

GATE(HI)

V

GATE(LO)

f

D

t

BLANK

t

DELAY

t

t

T

Notes: 8. V

9. Also limited by package power dissipation limit, whichever is lower.

10. Full ambient temperature range for AL9910-5S, AL9910AS and AL9910S is -40 to +85°C; for AL9910-5SP, AL9910ASP and AL9910SP is

-40°C to +105°C.

11. Device mounted on FR-4 PCB (25mm x 25mm 1oz copper, minimum recommended pad layout on top. For better thermal performance, larger

copper pad for heat-sink is needed.

12. Device mounted on FR-4 PCB (51mm x 51mm 2oz copper, minimum recommended pad layout on top layer and thermal vias to bottom layer ground

plane. For better thermal performance, larger copper pad for heat-sink is needed.

GATE High Output Voltage

GATE Low Output Voltage

Oscillator Frequency

OSC

Maximum Oscillator PWM Duty Cycle

MAXhf

Linear Dimming Pin Voltage Range

VLD

Current Sense Blanking Interval

Delay From CS Trip to GATE lo

GATE Output Rise Time

RISE

GATE Output Fall Time

FALL

Thermal Shut Down

TSD

Thermal Shut Down Hysteresis

SDH

Thermal Resistance Junction-to-

θJA

Ambient

Thermal Resistance Junction-to-Case

θJC

for the AL9910 is 15V and for the AL9910A it is 20V.

IN(MIN)

I

= 10mA VDD -0.3

OUT

I

= -10mA

OUT

R

= 1MΩ

OSC

R

= 226kΩ

OSC

= 25kHz, at GATE,

f

PWMhf

CS to GND.

Full ambient temperature range (Note 10),

V

= 20V

IN

VCS = 0.45V, VLD = VDD

V

= 20V, VLD = 0.15,

IN

= 0 to 0.22V after T

V

CS

C

= 500pF

GATE

C

= 500pF

GATE

BLANK

0 0.3 V

20 25 30

80 100 120

100 %

0

160 250 440 ns

300 ns

30 50 ns

30 50 ns

150

50

SO-8 (Note 11) 110

SO-8EP (Note 12) 66

SO-8 (Note 11)

22

SO-8EP (Note 12) 9

VDD

-

250 mV

V

kHz

°C

°C/W

°C/W

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

4 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Page 5

A

5

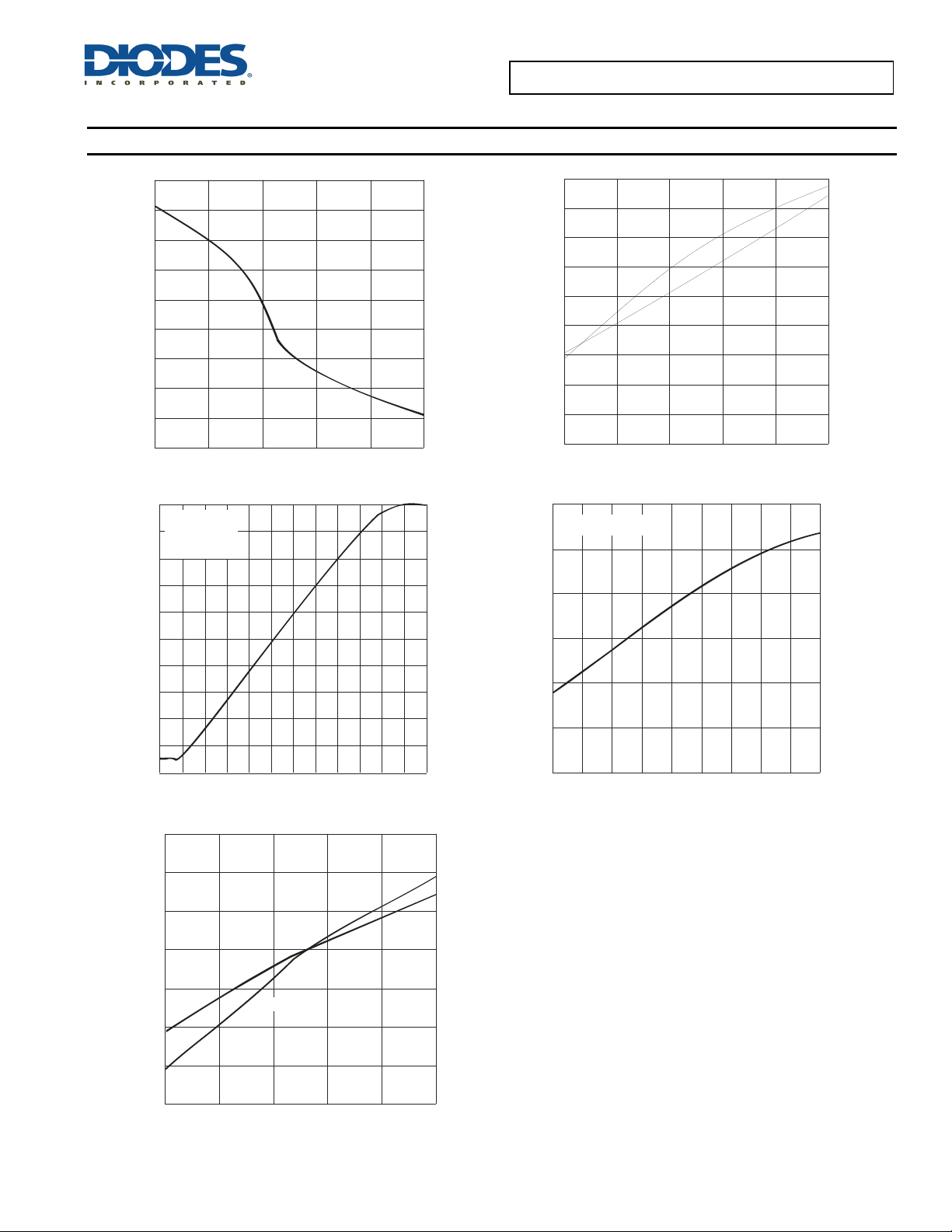

Typical Characteristics

3.0

2.5

2.0

L9910/ AL9910A/ AL9910-5/AL9910A-5

460

440

V = 400V

420

IN

1.5

1.0

0.5

0.0

-0.5

CURRENT SENS E THRESHOLD (mV)

-1.0

-1.5

-40 -15 10 35 60 85

AMBIE NT TEMP ER ATURE (°C)

Change in Current Sense Thresho ld vs. Ambient Temperatu re

100

I = 281mA

LED

90

V = 264V

IN

T = 23.5C

A

80

70

60

50

OUT MAX

I (%)

40

30

20

10

0

050

100 150 200 250 300

V DIMMING CONTROL (mV)

LD

I vs. V Dimming Control

OUT MAX LD

1.

400

V = 15V

IN

380

360

340

INPUT CURRENT (µA)

320

300

280

-40 -15 10 35 60 85

AMBIEN T TE MPE RATURE ( C)

°

Input Current vs. Ambient Temperatu re

450

I = 180mA

LED(NOM )

400

350

300

250

200

SHORT CIRCUIT OUTPUT CURRE NT (mA)

150

85 10 5 12 5 145 165 185 205 22 5

I NPUT V OLTAG E (V )

RMS

180mA LED Driver Short Ci rcu it Out put Current vs. I nput Voltage

245 26 5

1.0

0.5

0.0

R = 226k

OSC

Ω

-0.5

R = 1M

Ω

OSC

-1.0

CHANGE IN FREQUENCY (%)

-1.5

-2.0

-40 -15 10 35 60 85

AMBIE NT TEMPER ATURE ( °C)

Chan ge in Os cill ation Frequency vs. Ambie nt Temp erature

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

5 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Page 6

A

5

5

R

Typical Characteristics (cont.) measured using AL9910EV4

200

15 LEDs

190

14 LEDs

L9910/ AL9910A/ AL9910-5/AL9910A-5

9

18 LEDs

180

16 LEDs

170

OUT MAX

I (mA)

160

150

140

17 LEDs

18 LEDs

85 105 12 5 14 5 16 5 185 205 225 245 26 5

INPUT VOLTAGE (V )

RMS

180mA LED Driver Output Current vs. Input Voltage

0.9

18 LEDs

0.9

0.85

16 LEDs

0.8

POWER FACTO

15 LEDs

0.75

17 LEDs

90

17 LEDs

14 LEDs

EFFICIENCY (%)

85

80

105 125 145 165 185 205 225 245 26585

I NPUT V OLTAGE (V )

180mA LED Driver Efficiency vs. Inpu t Voltage

16 LEDs

15 LEDs

RMS

12

18 LEDs

17 LEDs

10

8

15 LEDs

POWER (W)

14 LEDs

16 LEDs

6

14 LEDs

0.7

85 105 12 5 14 5 165 18 5 20 5 225 245 26 5

INPUT VOLTAGE (V )

RMS

180mA L ED Driver Power Factor vs. In put Voltage

4

85 105 12 5 145 165 18 5 20 5 22 5 245 26 5

INPUT VOLTAGE (V )

RMS

180mA LED Driver Inp ut P ower Dissipation v s. Inp ut Voltage

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

6 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Page 7

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

Application Information

The AL9910 is very versatile and is capable of operating in isolated or non-isolated topologies. It can also be made to operate in continuous as

well as discontinuous conduction mode.

V

V

IN

IN

V

V

IN

IN

V

V

DD

LD

LD

DD

V

V

DD

DD

LDO

LDO

250mV

250mV

OTP

OTP

7.5/10V

7.5/10V

OSC

OSC

S

S

RO

RO

R

R

OSC

OSC

GATE

GATE

CS

CS

R

PWM _D

PWM _D

100k

100k

GND

GND

AL9910/AL9910A

AL9910/AL9910A

R

SENSE

SENSE

Figure 1 Functional Block Diagram

The AL9910 contains a high voltage LDO (see Figure 1) the output of the LDO provides a power rail to the internal circuitry including the gate

driver. A UVLO on the output of the LDO prevents incorrect operation at low input voltage to the V

IN

pin.

In a non-isolated Buck LED driver when the gate pin goes high the external power MOSFET Q1 is turned on causing current to flow through the

LEDs, inductor (L1) and current sense resistor (R

). When the voltage across R

SENSE

exceeds the current sense pin threshold the external

SENSE

MOSFET Q1 is turned off. The stored energy in the inductor causes the current to continue to flow through the LEDs via diode D1.

The AL9910’s LDO provides all power to the rest of the IC including Gate drive this removes the need for large high power start-up resistors. This

means that operate correctly it requires around 0.5mA from the high voltage power rail. The LDO can also be used to supply up to 1mA to external

circuits.

The AL9910 operates and regulates by limiting the peak current of the external MOSFET; the peak current sense threshold is nominally set at

250mV.

The same basic operation is true for isolated topologies, however in these the energy stored in the transformer delivers energy to LEDs during the

off-cycle of the external MOSFET.

Design Parameters

Setting the LED Current

In the non-isolated buck converter topology, figure 1, the average LED current is not the peak current divided by 2 - however, there is a certain

error due to the difference between the peak and the average current in the inductor. The following equation accounts for this error:

R

SENSE

=

()

mV250

+

RIPPLELED

.

))I*5.0(I

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

7 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Page 8

A

(

(

)

L9910/ AL9910A/ AL9910-5/AL9910A-5

Applications Information (cont.)

Setting Operating Frequency

The AL9910 is capable of operating over a 25 and 300 kHz switching frequency range. The switching frequency is programmed by connecting an

external resistor between R

osc

=

t

OSC

The switching frequency is the reciprocal of the oscillator period. Typical values for R

When driving smaller numbers of LEDs, care should be taken to ensure that t

switching frequency by increasing the R

When operating in buck mode the designer must keep in mind that the input voltage must be maintained higher than 2 times the forward voltage

drop across the LEDs. This limitation is related to the output current instability that may develop when the AL9910 operates at a duty cycle greater

than 0.5. This instability reveals itself as an oscillation of the output current at a sub-harmonic (SBO) of the switching frequency.

The best solution is to adopt the so-called constant off-time operation as shown in Figure 2. The resistor (R

default, to set operating frequency. To force the AL9910 to enter constant OFF time mode R

This will decrease the duty cycle from 50% by increasing the total period, t

25

pin and ground. The corresponding oscillator period is:

OSC

+

22R

µs with R

OSC

in kΩ

OSC

value. Reducing the switching frequency will also improve the efficiency.

V

V

IN

IN

OFF

ON

+ tON.

vary from 75kΩ to 1MΩ

OSC

> t

. The simplest way to do this is to reduce/limit the

BLANK

is connected to the gate of the external MOSFET.

OSC

) is, connected to ground by

OSC

V

V

DD

DD

LD

LD

PWM_D

PWM_D

R

R

OSC

OSC

The oscillator period equation above now defines the AL9910 off time, t

When using this mode the nominal switching frequency is chosen and from the nominal input and output voltages the off-time can be calculated:

⎛

V

⎜

1t ∗

OFF

From this the timing resistor, R

−=

⎜

V

⎝

⎞

1

)nom(OUT

⎟

⎟

f

OSC)nom(IN

⎠

, can be calculated:

OSC

Figure 2. Constant Off-Time Configuration

OFFOSC

V

V

IN

IN

AL9910/A

AL9910/A

GND

GND

.

OFF

)

GATE

GATE

CS

CS

R

R

OSC

OSC

Ω−∗=

Q1

Q1

)k(2225)µs(tR

Inductor Selection

The non-isolated buck circuit, Figure 1, is usually selected and it has two operation modes: continuous and discontinuous conduction modes. A

buck power stage can be designed to operate in continuous mode for load current above a certain level usually 15% to 30% of full load. Usually,

the input voltage range, the output voltage and load current are defined by the power stage specification. This leaves the inductor value as the

only design parameter to maintain continuous conduction mode. The minimum value of inductor to maintain continuous conduction mode can be

determined by the following example.

The required inductor value is determined from the desired peak-to-peak LED ripple current in the inductor; typically around 30% of the nominal

LED current.

DVV

×−

L =

The next step is determining the total voltage drop across the LED string. For example, when the string consists of 10 High-Brightness LEDs and

each diode has a forward voltage drop of 3.0V at its nominal current; the total LED voltage V

()

LEDsIN

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

Where D is duty cycle

fI3.0

××

OSCLED

8 of 15

www.diodes.com

LEDS

is 30V.

May 2014

© Diodes Incorporated

Page 9

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

Applications Information (cont.)

Dimming

The LED brightness can be dimmed either linearly (using the LD pin) or via pulse width modulation (using the PWM-D pin); or a combination of

both - depending on the application. Pulling the PWM_D pin to ground will turn off the AL9910. When disabled, the AL9910’s quiescent current is

typically 0.5mA (0.65 for AL9910A). Reducing the LD voltage will reduce the LED current but it will not entirely turn off the external power

transistor and hence the LED current – this is due to the finite blanking period. Only the PWM_D pin will turn off the power transistor.

Linear dimming is accomplished by applying a 45mV to 250mV analog signal to the LD pin. This overrides the default 250mV threshold level of the

CS pin and reduces the output current. If an input voltage greater than 250mV is applied to the LD then the output current will not change.

The LD pin also provides a simple cost effective solution to soft start; by connecting a capacitor to the LD pin down to ground at initial power up

the LD pin will be held low causing the sense threshold to be low. As the capacitor charges up the current sense threshold will increase thereby

causing the average LED current to increase.

PWM dimming is achieved by applying an external PWM signal to the PWM_D pin. The LED current is proportional to the PWM duty cycle and the

light output can be adjusted between zero and 100%. The PWM signal enables and disables the AL9910 - modulating the LED current. The

ultimate accuracy of the PWM dimming method is limited only by the minimum gate pulse width, which is a fraction of a percentage of the low

frequency duty cycle. PWM dimming of the LED light can be achieved by turning on and off the converter with low frequency 50Hz to 1000Hz TTL

logic level signal.

With both modes of dimming it is not possible to achieve average brightness levels higher than the one set by the current sense threshold level of

the AL9910. If a greater LED current is required then a smaller sense resistor should be used

Output Open Circuit Protection

The non-isolated buck LED driver topology provides inherent protection against an open circuit condition in the LED string due to the LEDs being

connected in series with the inductor. Should the LED string become open circuit then no switching occurs and the circuit can be permanently left

in this state with damage to the rest of the circuit.

AC/DC Off-Line LED Driver

The AL9910 is a cost-effective off-line buck LED driver-controller specifically designed for driving LED strings. It is suitable for being used with

either rectified AC line or any DC voltage between 15V to 500V. See Figure 3 for typical circuit.

LED +

LED +

VACIN

VACIN

BR1

BR1

C1

C1

Figure 3. Typical Application Circuit (without PFC)

Buck Design Equations:

V

LEDs

=D

t =

ON

≥L

R

SENSE

V

IN

D

f

osc

t)VV(

×−

ONLEDsIN

I3.0

×

LED

=

25.0

LEDLED

where I

))3.0I(5.0(I

××+

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

C2

C2

LED

V

V

DD

DD

AL9910/A

AL9910/A

LD

LD

PWM_D

PWM_D

R

R

OSC

OSC

R

R

OSC

OSC

x 0.3 = I

RIPPLE

9 of 15

www.diodes.com

GND

GND

C3

C3

D1

V

V

IN

IN

Q1

Q1

GATE

GATE

CS

CS

D1

R

R

SENSE

SENSE

L1

L1

LED -

LED -

May 2014

© Diodes Incorporated

Page 10

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

Applications Information (cont.)

Design Example

For an AC line voltage of 120V the nominal rectified input voltage VIN = 120V*1.41 = 169V. From this and the LED chain voltage the duty cycle

can be determined:

D = V

From the switching frequency, for example f

t

ON

The value of the inductor for an LED current of 350mA is determined as follows:

L = (V

Input Bulk Capacitor

For Offline lamps an input bulk capacitor is required to ensure that the rectified AC voltage is held above twice the LED string voltage throughout

the AC line cycle. The value can be calculated from:

C

Where

D : Capacity charge work period, generally about 0.2 to 0.25

f : Input frequency for full range (85 to 265V

L

If the capacitor has a 15% voltage ripple then a simplified formula for the minimum value of the bulk input capacitor approximates to:

C

Power Factor Correction

If power factor improvement is required then for the input power less than 25W, a simple passive power factor correction circuit can be added to

the AL9910 typical application circuit. Figure 4 shows that passive PFC circuitry (3 current steering diodes and 2 identical capacitors) does not

significantly affect the rest of the circuit. Simple passive PFC improves the line current harmonic distortion and achieves a power factor greater

than 0.85.

/VIN = 30/169 = 0.177

LEDs

= D/f

IN

ch

VΔ

MIN

≥

=

= 3.5 µs

OSC

- V

IN

LEDs

Should be set 10 to15% of

MAX_DC

VACIN

VACIN

) * tON /(0.3 * I

−×

0.06VI ××

LEDsLED

2

V

IN

BR1

BR1

= 50kHz, the required on-time of the external MOSFET can be calculated:

OSC

) = 4.6mH

LED

)D1(P

CHIN

Vf2V2

Δ×××

MAX_DCLMIN_LINE

)

RMS

V2

MIN_LINE

Passive PFC

Passive PFC

C1

C1

V

V

IN

V

V

LD

LD

DD

DD

IN

AL9910/A

AL9910/A

GATE

GATE

Q1

Q1

D1

D1

L1

L1

C4

C4

LED +

LED +

LED -

LED -

CS

PWM_D

PWM_D

R

C2

C2

C3

C3

R

OSC

OSC

GND

GND

Figure 4. Typical Application Circuit with Passive PFC

CS

R

R

SENSE

SENSE

R

R

OSC

OSC

Each of these identical capacitors should be rated for half of the input voltage and have twice as much capacitance as the calculated C

buck converter circuit without passive PFC (see above section on bulk capacitor calculation).

For further design information please see AN75 from the Diodes website.

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

10 of 15

www.diodes.com

© Diodes Incorporated

of the

MIN

May 2014

Page 11

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

Applications Information (cont.)

DC-DC Buck LED Driver

The design procedure for an ac input buck LED driver outlined in the previous chapters equally applies DC input LED drivers.

When driving long LED chains care should be taken not to induce SBO – maximum LED chain voltage should be less half of V

maximum duty cycle should be kept below 50% or use of constant off-time removes this issue.

DC-DC Boost LED Driver

Due to the topology of the AL9910 LED driver-controller it is capable of being used in boost configurations – at reduced accuracy. The accuracy

can be improved by measuring the LED current with an op amp and use the op amp’s output to drive the LD pin.

A Boost LED driver is used when the forward voltage drop of the LED string is higher than the input supply voltage. For example, the Boost

topology can be appropriate when input voltage is supplied by a 48V power supply and the LED string consists of twenty HB LEDs, as the case

may be for a street light.

L1

V

C1

V

IN

V

DD

PWM_D

IN

AL9910/A

Q1

GATE

C2

LD

R

OSC

GND

CS

D1

C3

. So either

IN

R

OSC

In a Boost converter, when the external MOSFET is ON the energy is stored in the inductor which is then delivered to the output when the external

MOSFET switches OFF. If the energy stored in the inductor is not fully depleted by the next switching cycle (continuous conduction mode) the

DC conversion between input and output voltage is given by:

VV

V

IN

D

=

f

OSC

∗

Î

D1

−

OSC

D

tV

∗

ONIN

I3.0

LED

V

=

OUT

From the switching frequency, f

From this the required inductor value can be determined by:

The Boost topology LED driver requires an output capacitor to deliver current to the LED string during the time that the external MOSFET is on.

In boost LED driver topologies if the LEDs should become open circuit damage may occur to the power switch and so some form of detection

should be present to provide Over-voltage detection/protection.

t =

ON

L

=

−

INOUT

V

OUT

, the on-time of the MOSFET can be calculated:

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

Figure 5. Boost LED Driver

11 of 15

www.diodes.com

R

SENSE

May 2014

© Diodes Incorporated

Page 12

A

A

XXXXX

Ordering Information

L9910

L9910/ AL9910A/ AL9910-5/AL9910A-5

-13

Variant

Blank : 7.5V V

A : 10V V

Part Number

AL9910-5S-13 ±5% S SO-8 2500/Tape & Reel -13

AL9910-5SP-13 ±5% SP SO-8EP 2500/Tape & Reel -13

AL9910A-5S-13 ±5% S SO-8 2500/Tape & Reel -13

AL9910A-5SP-13 ±5% SP SO-8EP 2500/Tape & Reel -13

AL9910AS-13 ±10% S SO-8 2500/Tape & Reel -13

AL9910ASP-13 ±10% SP SO-8EP 2500/Tape & Reel -13

AL9910S-13 ±10% S SO-8 2500/Tape & Reel -13

AL9910SP-13 ±10% SP SO-8EP 2500/Tape & Reel -13

Tolerance

V

CS

V Tolerance

CS

DD

DD

Blank : 10%

Package

Code

-5 : 5%

SP : SO-8EP

Packaging

Package Packing

S : SO-8

13 : 13” Tape & Reel

13” Tape and Reel

Quantity Part Number Suffix

Marking Information

(1) SO-8

(2) SO-8EP

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

12 of 15

www.diodes.com

© Diodes Incorporated

May 2014

Page 13

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

Package Outline Dimensions (All dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

(1) SO-8

E1

A2

E

A1

Detail ‘A’

h

°

45

A3

A

L

0.254

Gauge Plan e

Seating Plane

7°~9

°

Detail ‘A’

e

b

D

(2) SO-8EP

85

14

E1

F

Exposed Pad

H

A1

b

4° ± 3°

A

7

°

Bottom View

N

E

45

°

E0

Q

C

L

Gauge Plane

Seating Plane

9° (All si des)

e

D

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

13 of 15

www.diodes.com

Dim Min Max

SO-8EP (SOP-8L-EP)

Dim Min Max Typ

A 1.40 1.50 1.45

A1 0.00 0.13 -

b 0.30 0.50 0.40

C 0.15 0.25 0.20

D 4.85 4.95 4.90

E 3.80 3.90 3.85

E0 3.85 3.95 3.90

E1 5.90 6.10 6.00

e - - 1.27

F 2.75 3.35 3.05

H 2.11 2.71 2.41

L 0.62 0.82 0.72

N - - 0.35

Q 0.60 0.70 0.65

All Dimensions in mm

SO-8

A - 1.75

A1 0.10 0.20

A2 1.30 1.50

A3 0.15 0.25

b 0.3 0.5

D 4.85 4.95

E 5.90 6.10

E1 3.85 3.95

e 1.27 Typ

h - 0.35

L 0.62 0.82

0° 8°

θ

All Dimensions in mm

May 2014

© Diodes Incorporated

Page 14

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

(1) SO-8

X

(2) SO-8EP

C1

C2

Y

X2

Dimensions Value (in mm)

X 0.60

Y 1.55

C1 5.4

C2 1.27

Y2

Y1

X1

Y

C

X

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

14 of 15

www.diodes.com

Dimensions

Value

(in mm)

C 1.270

X 0.802

X1 3.502

X2 4.612

Y 1.505

Y1 2.613

Y2 6.500

May 2014

© Diodes Incorporated

Page 15

A

L9910/ AL9910A/ AL9910-5/AL9910A-5

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

IMPORTANT NOTICE

LIFE SUPPORT

AL9910/ AL9910A/ AL9910-5/ AL9910-5A

Document number: DS35103 Rev. 9 - 2

15 of 15

www.diodes.com

May 2014

© Diodes Incorporated

Loading...

Loading...