Page 1

A

L8811

Boost/Buck/Inverting DC-DC CONVERTER

Description

The AL8811 is a monolithic control circuit containing the primary

functions required for DC-to-DC converters. These devices consist of

an internal temperature compensated reference, comparator,

controlled duty cycle oscillator with an active current limit circuit, driver

and high current output switch. This series is specifically designed for

incorporating in Boost, Buck and voltage-inverting applications with a

minimum number of external components.

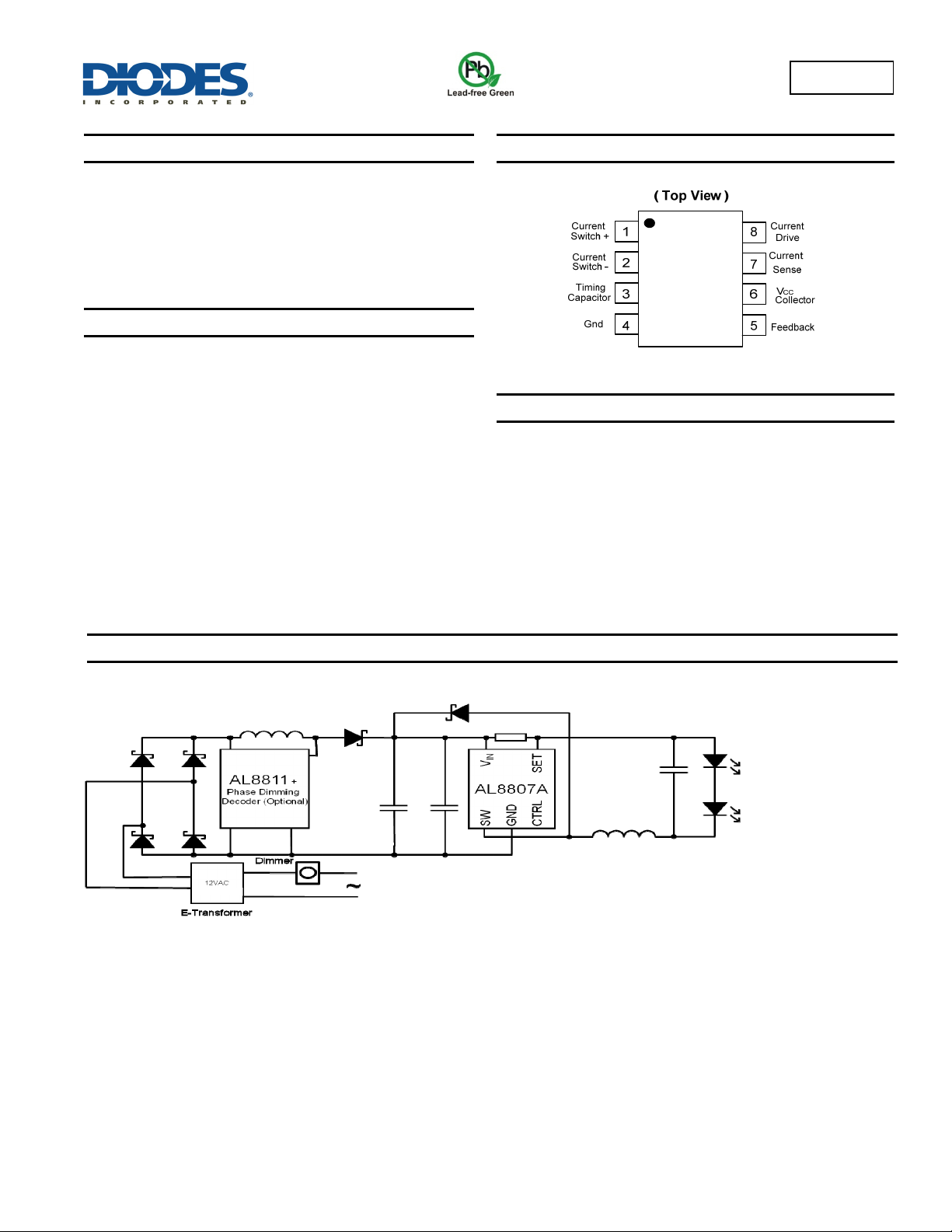

Pin Assignments

Features

Operation from 3.0V to 20V Input

Low Standby Current

Current Limiting

Output Switch Current to 1.6A

Output Voltage Adjustable

Frequency Operation to 100 kHz

Precision 2% Reference

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

Applications

Low Voltage LED Lighting such as MR-16

General Purpose DC-DC Converter

MSOP-8

Typical Application Diagram

Electronic Transformer compatible MR16 lamp Simplified Schematic

AL8811

Document number: DS36090 Rev. 2 - 2

1 of 11

www.diodes.com

June 2013

© Diodes Incorporated

Page 2

A

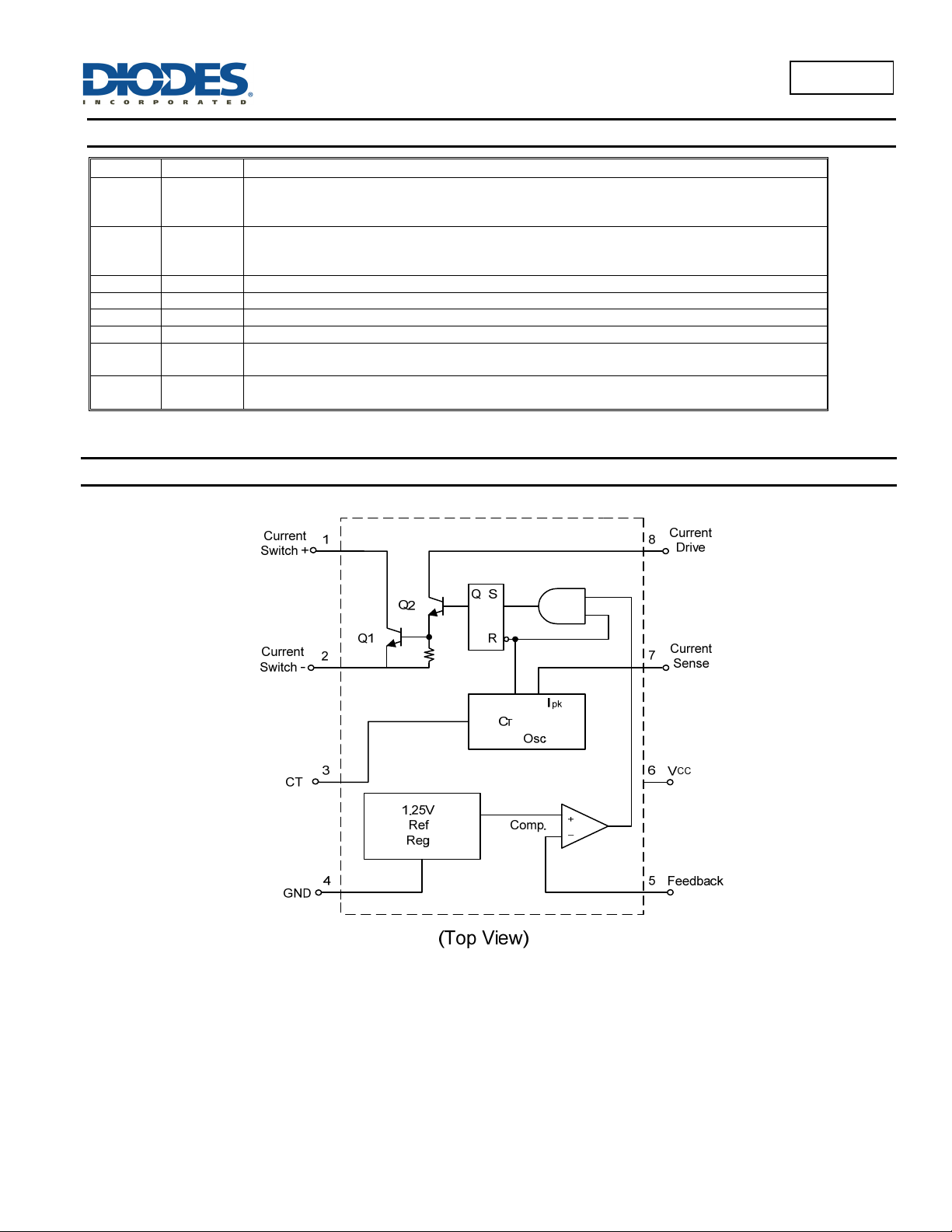

Pin Descriptions

Pin Name Pin Number Descriptions

Current

Switch+

Current

Switch-

CT 3 Timing Capacitor to control the switching frequency

GND 4

Feedback 5 Feedback pin for inverting input of internal comparator

VCC 6 Supply voltage pin

Current

Sense

Current

Drive

1

2

7

8

Internal switch transistor collector:

Connect to Inductor for boost converter.

Connect to VCC for Buck or Inverting converter

Internal switch transistor emitter:

Connect to GND for boost converter

Connect to Inductor for buck or inverting converter

Peak Current Sense Input by monitoring the voltage drop across an external current sense

resistor to limit the peak current through the switch

Current drive collector:

Normally connected to VCC directly or via a resistor.

L8811

Functional Diagram

AL8811

Document number: DS36090 Rev. 2 - 2

2 of 11

www.diodes.com

June 2013

© Diodes Incorporated

Page 3

A

L8811

Absolute Maximum Ratings (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Rating Unit

VCC

VIR

V

C (SWITCH)

V

E (SWITCH)

V

CE (SWITCH)

V

C (DRIVER)

I

C (DRIVER)

ISW

PD

JA

TMJ

T

STG

Power Supply Voltage 20 V

Comparator Input Voltage Range -0.3 to +36 V

“Current Switch +” Collector Voltage 36 V

„Current Switch –„ Emitter Voltage (V

“Current Switch” Collector to Emitter Voltage 36 V

“Current Drive” Collector Voltage 36 V

1 = 36V)

PIN

36 V

“Current Drive” Collector Current 100 mA

“Current Switch” Current 1.6 A

Power Dissipation (Note 4) 600 mW

Thermal Resistance 130

Maximum Junction Temperature +150

Storage Temperature Range -65 to +150

C/W

C

C

ESD HBM Human Body Model ESD Protection 1 kV

ESD MM Machine Model ESD Protection 150 V

Caution: Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only;

Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when handling

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may be

affected by exposure to absolute maximum rating conditions for extended periods of time.

and transporting these devices.

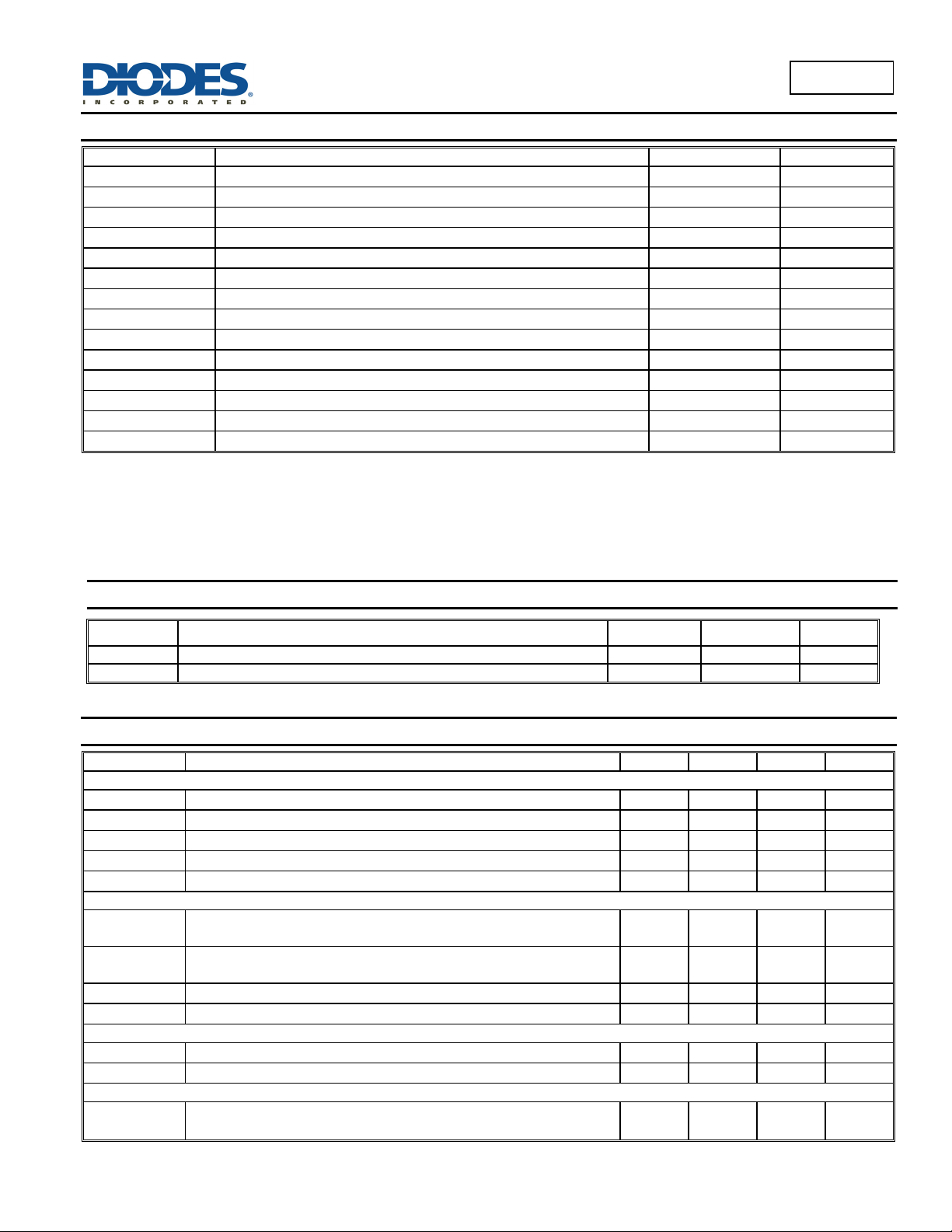

Recommended Operating Conditions

Symbol Parameter Min

Max

Unit

VCC Supply Voltage 3 20 V

TOP

Operating Junction Temperature Range

-40

Electrical Characteristics (@ V

= 5V, TA = +25°C, unless otherwise specified.)

CC

Symbol Parameter Min Typ Max Unit

OSCILLATOR

f

OSC

I

CHG

I

DISCHG

I

DISCHG

V

IPK (SENSE)

Frequency (V

5 = 0V, CT = 1.0nF, TA = +25°C)

PIN

Charge Current (VCC = 5.0V to 20V, TA = +25°C)

Discharge Current (VCC = 5.0V to 20V, TA = +25°C)

/ I

Discharge to Charge Current Ratio (Pin 7 to VCC, TA = +25°C)

CHG

Current Limit Sense Voltage (I

CHG

= I

DISCHG

, TA = +25°C)

24 33 42 kHz

24 30 42 µA

140 200 260 µA

5.2 6.5 7.5 —

300 400 450 mV

OUTPUT SWITCH (Note 4)

V

CE(sat)

V

CE(sat)

Saturation Voltage, Darlington Connection

(I

= 1.0A, Pins 1, 8 connected)

SW

Saturation Voltage, Darlington Connection

(I

= 1.0A, ID = 50mA, Forced ß 20)

SW

hFE DC Current Gain (ISW = 1.0A, VCE = 5.0V, TA = +25°C)

I

Collector Off-State Current (VCE = 20V)

C(off)

— 1.0 1.3 V

— 0.45 0.7 V

50 75 — —

— 0.01 100 µA

COMPARATOR

Vth Threshold Voltage TA = +25°C

Reg

Threshold Voltage Line Regulation (VCC = 3.0V to 20V)

(LINE)

1.225 1.25 1.275 V

— 1.4 6.0 mV

TOTAL DEVICE

ICC

Supply Current (V

> Vth Pin 2 = Gnd, remaining pins open)

V

PIN 5

= 5.0V to 20V, CT =1.0nF, Pin 7 = VCC,

CC

— 3.5 mA

—

AL8811

Document number: DS36090 Rev. 2 - 2

3 of 11

www.diodes.com

+105

C

June 2013

© Diodes Incorporated

Page 4

A

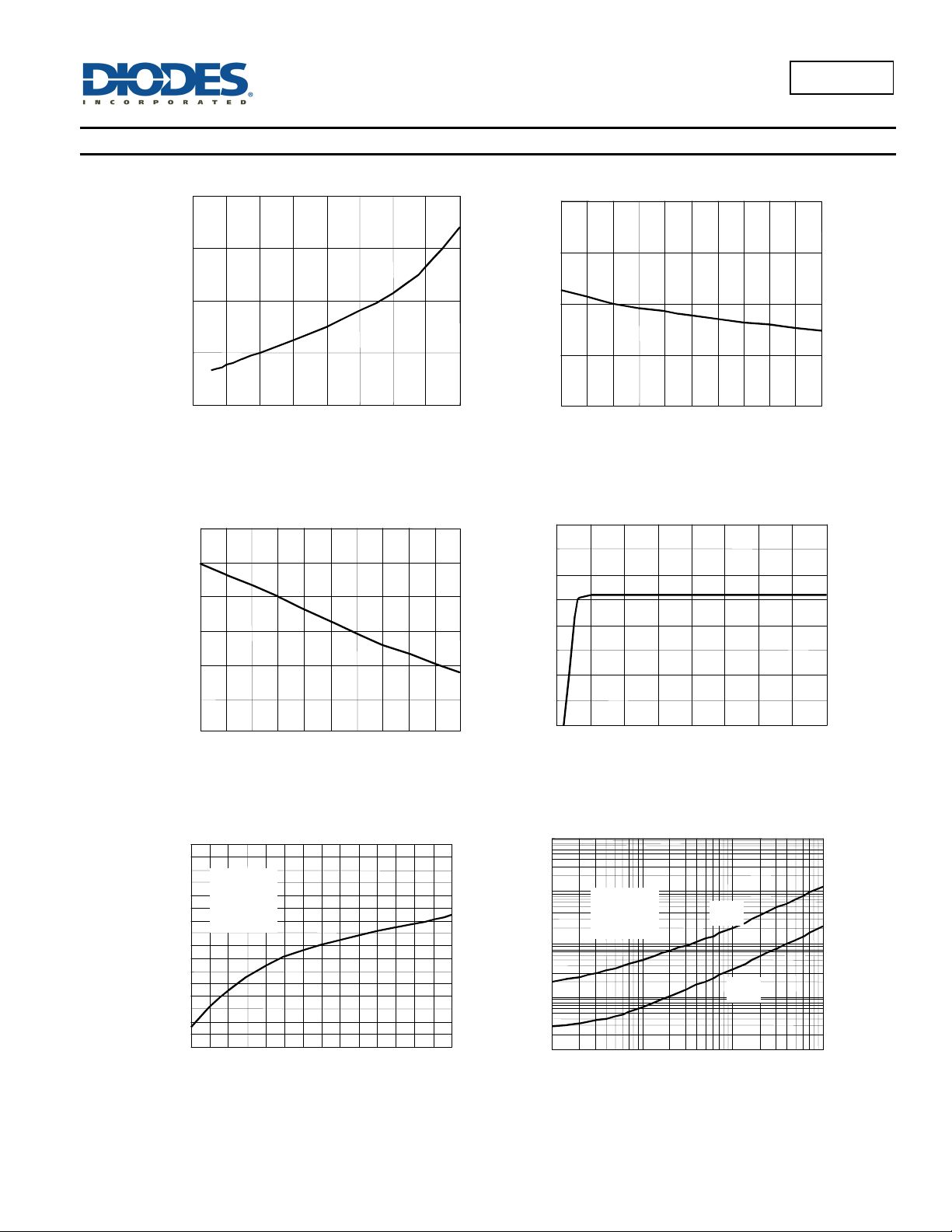

Typical Performance Characteristics

Figure 1. Vce(sat) versus le

1.4

L8811

Figure 2. Reference Voltage versus Temp.

1.26

1.2

1

0.8

Vce(sat), Saturation Voltage (V)

0.6

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

Ie, Emitter Current (A)

Figure 3. Current Limit Sense Voltage

versus Temperature

440

420

400

380

360

Current Sense Voltage (mV)

340

320

0 102030 40 50 6070 8090100

Temperature (oC)

1.255

1.25

Reference Voltage (V)

1.245

1.24

0 102030405060708090100

Temperature (oC)

Figure 4. Standby Supply Current

versus Supply Voltage

4.0

3.5

3.0

2.5

2.0

1.5

1.0

Icc, Supply Current (mA)

0.5

0.0

0 5 10 15 20 25 30 35 40

Vcc, Supply Voltage (V)

Figure 5. Emitter Follower Configuration

Output Saturation Voltage vs. Emitter Current

1.8

1.75

Vcc=2~10V

Pin1,7,8=Vcc

Pin3,5=GND

1.7

T

=25oC

A

10W

Pin2=5

1.65

( sat), (V)

1.6

CE

V

1.55

1.5

1.45

1.4

100 300 500 700 900 1100 1300 1500

AL8811

Document number: DS36090 Rev. 2 - 2

I

E

(mA)

1000

100

10

, Output Switch On-Off Time(us)

on-off

t

0.1

4 of 11

www.diodes.com

Figure 6.Output Switch On-Off Time versus

Oscillator Timing Capacitor

V

= 5.0V

CC

Pin 7 = V

CC

Pin 5 = GND

T

= 25oC

A

1

0.01 0.1 1 10

CT, Oscillator Timing Capacitor (

t

on

t

off

nF)

© Diodes Incorporated

June 2013

Page 5

A

Application Circuit

(1) Boost Converter

Test Conditions Results

Line Regulation

Load Regulation

Output Ripple

Efficiency

V

= 9V to 12V, IO = 200mA

IN

V

= 12V, IO = 50mA to 200mA

IN

V

= 12V, IO = 200mA 500mVPP

IN

V

= 12V, IO = 200mA

IN

20mV = ±0.035%

15mV = ±0.035%

80%

L8811

AL8811

Document number: DS36090 Rev. 2 - 2

5 of 11

www.diodes.com

June 2013

© Diodes Incorporated

Page 6

A

Application Circuit (cont.)

(2) Electronic Transformer compatible triac dimmable MR16/GU5.3 lamp for 120Vac

L8811

Circuit Description

This design consists of three sections:

1) The input PFC circuit converts the 12V

2) The output Buck LED Driver drives the three LEDs in series at a fixed current (AL8807A).

3) Finally, the phase-detect circuit generates a voltage proportional to the phase of the incoming AC voltage (when triac dimming is used).

AC input voltage to a DC voltage around 30V (AL8811).

PFC Circuit

The AL8811 Boost converter is a simple “Constant ON time controller”. By keeping the same ON time throughout the AC cycle, the circuit will

draw a current that will closely match the voltage and result in a constant input current. This eliminates the classic peak current problem with a

bridge rectifier and a large input filter capacitor.

The PFC circuit includes the input bridge rectifier, EMI filter (if needed) and the AL8811 Boost converter. The AC input voltage is rectified by the

bridge circuit and filtered by C1, R1, C4, and C5. This first filter removes the high frequency that is generated by the Electronic Transformer in the

range of 20-30 KHz. An additional diode rectifier circuit (D5, C2) is used to generate a voltage that is used to power the circuit that will turn on/off

the external MOSFET of the Boost converter. This circuit is very important as the gate drive of the MOSFET has to be greater than 3-4 volts

throughout the AC cycle. The external MOSFET is used to reduce the heat dissipation in the AL8811.

The AL8811 has a current limit resistor R3 which sets the maximum current allowed through the inductor L1. The output voltage is set by the

divider R6, R5 to an output of around 35 volts. The output voltage is filtered by the two capacitors C8 and C9. These two capacitors store energy

that will be used when the input voltage is low during the AC cycle.

AL8811

Document number: DS36090 Rev. 2 - 2

6 of 11

www.diodes.com

June 2013

© Diodes Incorporated

Page 7

A

L8811

Application Circuit (cont.)

Buck LED Driver

The AL8807A is a step-down DC-DC converter designed to drive LEDs with a constant current. The current through the LED is controlled by R11.

In the present Evaluation board, the current is set to around 660mA based on a resistor value of 0.15Ω. The current is set using the “CTRL” input

pin which in this new version of the IC can vary from 0 to 2.5V, controlling the current from 0mA to the maximum current at 2.5V. This control input

pin is used to lower the LED current as the TRIAC dims the LED. In this way, the energy stored in the two output capacitors of the PFC circuit will

be able to provide current throughout the AC cycle.

TRIAC Phase Detection Circuit

The phase of the TRIAC is detected by using an additional rectifier circuit that generates a voltage in proportional to the phase of the TRIAC Driver.

This is done by rectifying the input AC voltage and averaging the energy using a resistor to charge a capacitor. Two additional resistors in series,

R12 and R8, slowly discharge this circuit so it will follow the input phase change. The two resistors, R12 and R8, are used to scale the voltage so

the range is from 0 to 2.6V to the Buck LED driver control pin.

A simple transistor emitter follower circuit is used to drive a 1KΩ resistor in the emitter circuit. This low resistance is needed to drive the input

control pin of the AL8807A LED driver because the pin outputs a small current of 50uA, which limits the lowest control voltage to around 50 mV.

Setting the LED output current (AL8807A):

The LED output current is set using resister R11 and the formula:

= V

I

LED

For a current of 660mA, R11 is about 0.15Ω

/ R11 where VTH is equal to 0.1V

TH

.

Setting the PFC Variables (AL8811)

The choice for the size of the boost converter inductor selected in this design is based on a compromise which it is able to support a peak current to

around 1.5A since the average input voltage will be around 12-14V.

The boost converter (AL8811) includes a current limit resistor R3 which will limit the current through the inductor and thus the power delivered to the

output load. The formula for the resistor is:

PK(switch)

= 0.33V / R3

7 of 11

www.diodes.com

June 2013

© Diodes Incorporated

I

For a current limit of 1A, R3 is 0.33Ω.

In this evaluation design, this value was selected based on having three LEDs in series drawing about 660mA. It was found that two 68µF

capacitors mounted in parallel would just fit into the cavity of the MR16 bulb. The important design goal is to have the PFC circuit, which is used to

always draw current from the Electronic Transformer.

AL8811

Document number: DS36090 Rev. 2 - 2

Page 8

A

Application Circuit (cont.)

(3) Buck Converter

Test Conditions Results

Line Regulation

Load Regulation

Output Ripple

Efficiency

V

= 12V to 20V, IO = 500mA

IN

= 20V, IO = 50mA to 500mA

V

IN

V

= 20V, IO = 500mA 160mVPP

IN

V

= 20V, IO = 500mA

IN

L8811

20mV = ±0.2%

5mV = ±0.05%

82%

1

SQ

R

CT

Comp.

Osc

I pk

+

_

R2

36k

1.0uH

Vout

+

100

Optional Filter

Vout

5.0V/500mA

CO

Q2

Q1

2

B240

3

L100uH

CT

1.25V

470

pF

4

+

470uF

Ref

Reg

8

7

Rsc

0.11

6

C

VC

+

5

Vin

20

470

uF

R125k

AL8811

Document number: DS36090 Rev. 2 - 2

8 of 11

www.diodes.com

June 2013

© Diodes Incorporated

Page 9

A

Application Circuit (cont.)

(4) Voltage Inverting Converter

Test Conditions Results

Line Regulation

Load Regulation

Output Ripple

Efficiency

V

= 4.5V to 6.0V, IO = 100mA

in

V

= 5.0V, IO = 20mA to 100mA

in

V

= 5.0V, IO = 100mA 500mVPP

in

V

= 5.0V, IO = 100mA

in

L8811

20mV = ±0.08%

30mV = ±0.12%

60%

AL8811

Document number: DS36090 Rev. 2 - 2

9 of 11

www.diodes.com

June 2013

© Diodes Incorporated

Page 10

A

Ordering Information

L8811

Part Number Package Code Packaging

AL8811M8-13 M8 MSOP-8 NA NA 2500/Tape & Reel -13

Quantity Part Number Suffix Quantity Part Number Suffix

Tube 13” Tape and Reel

Marking Information

(1) MSOP-8

( Top View )

87 65

Internal Code

Logo

Y W X

Y : Year : 0~9

W : Week : A~Z : 1~26 week;

Part Number

AL8811

a~z : 27~52 week; z represents

52 and 53 week

234

1

Package Outline Dimensions (All dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

AL8811

Document number: DS36090 Rev. 2 - 2

y

A2

A1

D

4

x

1

0

°

0.25

E

x

1

b

e

Gauge Plane

Seating Plane

A3

A

4

x

1

Detail C

E3

E1

0

°

a

L

c

See Detail C

10 of 11

www.diodes.com

MSOP-8

Dim Min Max Typ

A - 1.10 A1 0.05 0.15 0.10

A2 0.75 0.95 0.86

A3 0.29 0.49 0.39

b 0.22 0.38 0.30

c 0.08 0.23 0.15

D 2.90 3.10 3.00

E 4.70 5.10 4.90

E1 2.90 3.10 3.00

E3 2.85 3.05 2.95

e - - 0.65

L 0.40 0.80 0.60

a 0° 8° 4°

x - - 0.750

y - - 0.750

All Dimensions in mm

June 2013

© Diodes Incorporated

Page 11

A

L8811

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2013, Diodes Incorporated

www.diodes.com

AL8811

Document number: DS36090 Rev. 2 - 2

Y1

X C

Y

IMPORTANT NOTICE

LIFE SUPPORT

www.diodes.com

11 of 11

Dimensions Value (in mm)

C 0.650

X 0.450

Y 1.350

Y1 5.300

June 2013

© Diodes Incorporated

Loading...

Loading...