Page 1

A

L8808

COST EFFECTIVE LOW EMI 30V 1A BUCK LED DRIVER

Description

The AL8808 is a step-down DC/DC converter designed to drive LEDs

with a constant current. The device can drive up to 8 LEDs,

depending on the forward voltage of the LEDs, in series from a

voltage source of 6V to 30V. Series connection of the LEDs provides

identical LED currents resulting in uniform brightness and eliminating

the need for ballast resistors. The AL8808 switches at frequency up to

1MHz with controlled rise and fall times to reduce EMI. This allows

the use of small size external components, hence minimizing the PCB

area needed.

Maximum output current of AL8808 is set via an external resistor

connected between the V

by applying either an analog DC voltage or a PWM signal at the

CTRL input pin. An input voltage of 0.4V or lower at CTRL switches

off the output MOSFET simplifying PWM dimming.

NEW PRODUCT

and SET input pins. Dimming is achieved

IN

Applications

• MR16 Lamps

• General Illumination Lamps

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com for more information about Diodes Incorporated’s definitions of Halogen and Antimony free, "Green" and Lead-Free.

3. Halogen and Antimony free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl)

and <1000ppm antimony compounds.

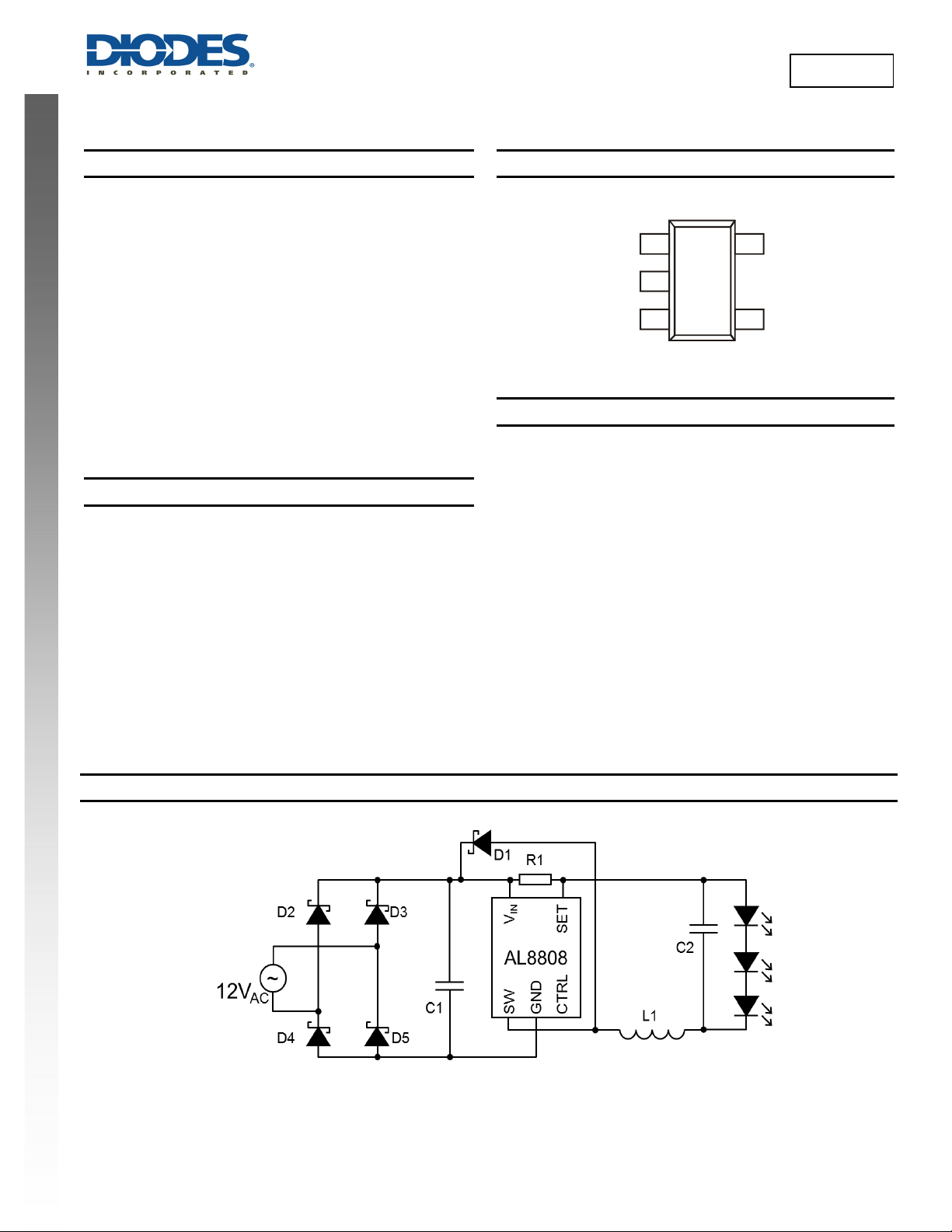

Pin Assignments

(Top View)

1

SW

GND

CTRL

2

3

54V

TSOT25

Features

• LED Driving Current Up to 1A

• Better Than 5% Accuracy

• High Efficiency Up to 96%

• Fast Controlled Falling Edges 7ns

• Operating Input Voltage from 6V to 30V

• High Switching Frequency Up to 1MHz

• PWM/DC Input for Dimming Control

• Built-In Output Open-Circuit Protection

• Built-In Over-Temperature Protection

• TSOT25: Available in “Green” Molding Compound (No Br, Sb)

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

IN

SET

Typical Applications Circuit

AL8808

Document number: DS35648 Rev. 2 - 2

1 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 2

r

i

a

M

e

n

o

a

a

M

e

g

e

u

t

p

a

p

e

n

e

a

e

C

d

f

V

o

m

m

e

a

e

m

e

o

a

w

r

a

e

0

l

l

b

P

c

e

a

t

o

g

o

a

u

T

p

h

e

h

k

p

c

o

s

o

i

n

d

e

n

e

r

2

d

i

t

h

R

e

o

s

2

g

0

5

0300

+

d

v

i

n

t

d

w

e

g

v

t

e

k

e

A

d

L8808

NEW PRODUCT

Pin Descr

Pin Number

1

2

3

4

5

Function

ptions

Pin Name

SW

GND

CTRL

SET

VIN

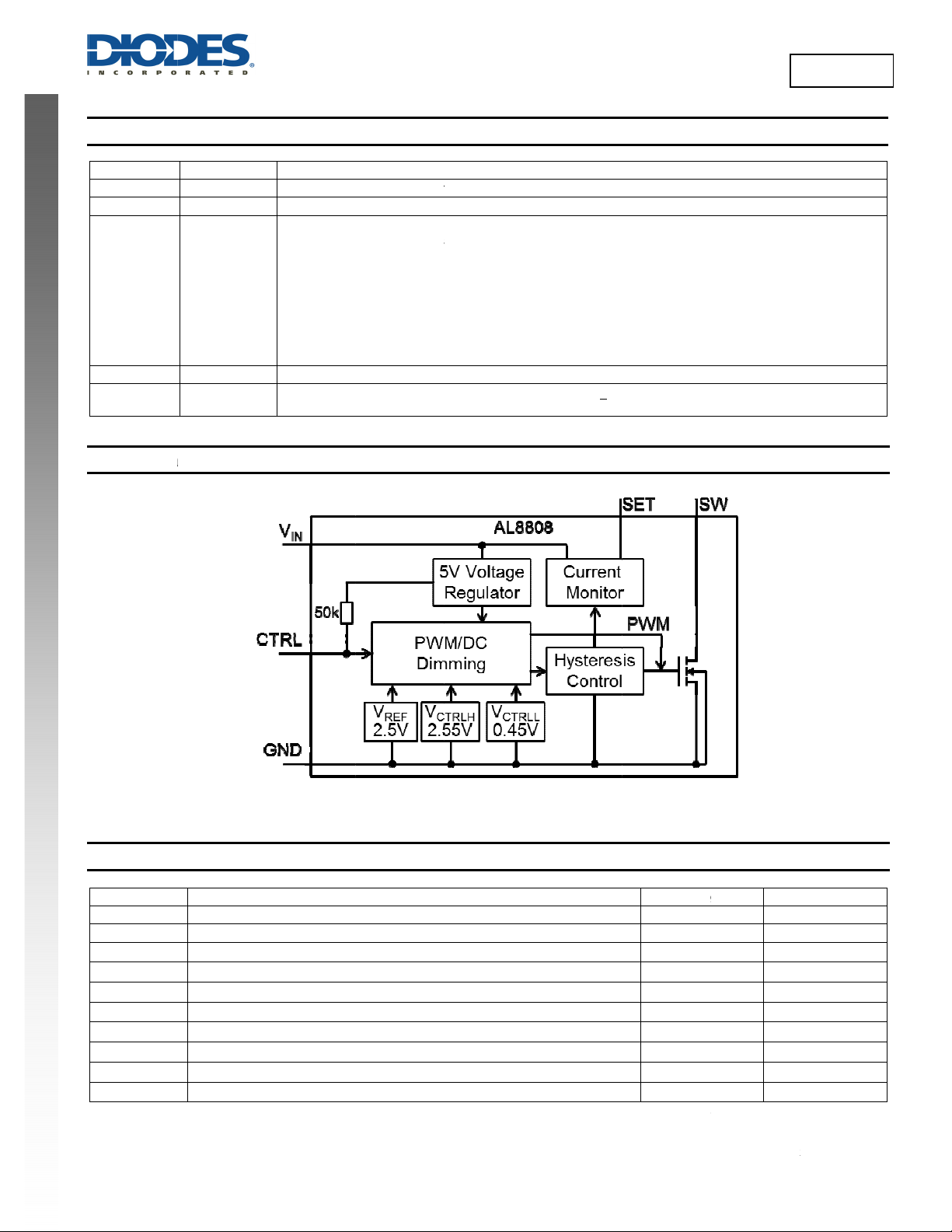

l Block Di

Switch Pin.

GND Pin

Dimming an

• Leave

(

• Drive t

• Drive w

I

OUTno

• Drive w

• A PWM

current

Set Nominal

Input Supply

section for

gram

onnect inducto

On/Off Control

loating for norm

= 5V, Giv

CTRL

voltage below

ith an analog vo

ith an analog vo

signal (low leve

to be adjusted

Output Current

Pin. Must be lo

ore information.

/freewheeling di

Input.

l operation.

s nominal avera

.4V to turn off o

tage (0.5V < V

tage > 2.6V out

l 0.4V and hig

elow the level s

in. Configure t

ally decoupled t

Function

de here, minim

ge output curre

tput current

< 2.5V) to a

C

RL

ut current will b

level > 2.6; tra

t by the resisto

e output current

o GND with > 2.

zing track lengt

t I

OUTnom

= 0.1/

just output curr

100% of I

OUTn

sition times les

connected to S

of the device.

µF X7R cerami

at this pin to re

)

S

nt from 20% to

m

than 1µs) allo

ET input pin.

c capacitor – se

uce EMI.

100% of

s the output

applications

Figure 1

.

AL8808 Bloc

Diagram

Absolute

aximum

Ratings

(@

T

A

= +25°C, unl

ss otherwise s

ecified.)

Symbol

ESD HBM

ESD MM

VIN

V

SET

VSW

V

CTRL

ISW

TJ

T

LEAD

T

ST

Caution: Stress

AL8808

Document numbe

s greater than th

functio

al operation of th

affecte

d by exposure to a

Semic

nductor devices

and tr

nsporting these d

: DS35648 Rev. 2

Human Body

Machine Mod

Continuous V

SET pin volta

SW voltage r

CTRL pin inp

Switch curren

Junction Tem

Lead Temper

Storage Tem

odel ESD Prot

l ESD Protectio

pin voltage rel

I

N

e relative to V

lative to GND

t voltage

erature

ture Soldering

erature Range

'Absolute Maxi

device at these

bsolute maximum

re ESD sensitive

vices.

- 2

Parameter

ction

n

tive to GND

pin

IN

um Ratings' spec

r any other condi

rating conditions f

nd may be dama

ified above, may

ions exceeding th

r extended period

ed by exposure t

2 of 20

ww.diodes.co

ause permanent

se indicated in th

of time.

ESD events. Sui

m

Ratin

2.5

20

-0.3 to

-5 to +

-0.3 to

-0.3 to

1.2

15

-55 to

amage to the de

s specification is

able ESD precaut

s

+33

0.3

+33

+6

150

ice. These are s

ot implied. Devic

ions should be ta

Unit

kV

V

V

V

V

V

A

°C

°C

°C

ess ratings only;

reliability may be

en when handling

January 201

© Diodes Incorporat

3

d

Page 3

A

Recommended Operating Conditions (@T

= +25°C, unless otherwise specified.)

A

Symbol Parameter Min Max Unit

VIN

V

CTRLH

V

CTRLDC

V

CTRLL

ISW

fSW

TJ

Note: 4. Subject to ambient temperature, input voltage and switching frequency. See applications section for suggested derating.

Electrical Characteristics (@ T

Symbol Parameter Conditions Min Typ Max Unit

V

NEW PRODUCT

INSU

V

INSH

IQ

IS

VTH

V

TH-H

I

SET

V

CTRL

R

CTRL

V

REF

R

DS(on)

I

SW_Lkg

tR

tF

T

OTP

T

OTP-Hyst

θJA

θJL

θJT

Notes: 5. Device mounted on FR-4 PCB (25mm x 25mm 1oz copper, minimum recommended pad layout on top layer and thermal vias to maximum area

bottom layer ground plane. For better thermal performance, larger copper pad for heat-sink is needed.

…Refer to Figure 42 for the device derating curve.

AL8808

Document number: DS35648 Rev. 2 - 2

Operating Input Voltage Relative to GND 6.0 30 V

Voltage High for PWM Dimming Relative to GND 2.6 5.5 V

Voltage Range for 20% to 100% DC Dimming Relative to GND 0.5 2.5 V

Voltage Low for PWM Dimming Relative to GND 0 0.4 V

Continuous Switch Current (Note 4) 1 A

Maximum Switching Frequency 1 MHz

Junction Temperature Range -40 +125 °C

= +25°C, VIN = 12V, CTRL pin floating; unless otherwise specified.)

A

Internal Regulator Start Up Voltage

Internal Regulator Hysteresis Threshold

Quiescent Current

Input Supply Current

VIN rising

VIN falling

VIN = 30V, output not switching

fSW = 250kHz

5.6 V

200 mV

350 µA

450 µA

Set Current Threshold Voltage 95 100 105 mV

Set Threshold Hysteresis ±20 mV

SET Pin Input Current

V

= V

IN

-0.1

SET

16 µA

Open Circuit CTRL Pin Voltage 5 V

CTRL Pin Input Resistance Referred to internal 5V regulator. 50 k

Internal Reference Voltage 2.5 V

On Resistance of SW MOSFET

Switch Leakage Current

SW Rise Time

SW Fall Time 5 ns

Over-Temperature Shutdown

Over-Temperature Hysteresis 10 °C

ISW = 0.35A

VIN = 30V, V

V

= 100 ±20mV, fSW = 250kHz

SENSE

CTRL

= 0.4V, V

SENSE

= 0V

VSW = 0.1V to 12V to 0.1V, CL = 15pF

0.35

0.5 µA

7 ns

145 °C

Thermal Resistance Junction-to-Ambient TSOT25 (Note 5) 209

Thermal Resistance Junction-to-Lead TSOT25 (Note 5) 57

Thermal Resistance Junction-to-Top TSOT25 (Note 5) 13

3 of 20

www.diodes.com

L8808

°C/W

January 2013

© Diodes Incorporated

Page 4

A

P

U

T

C

URRENT

F

REQ

UENCY

H

CUR

RENT

CTRL PIN CUR

REN

T

C

U

R

R

T ER

ROR

C

R

R

UTY CYC

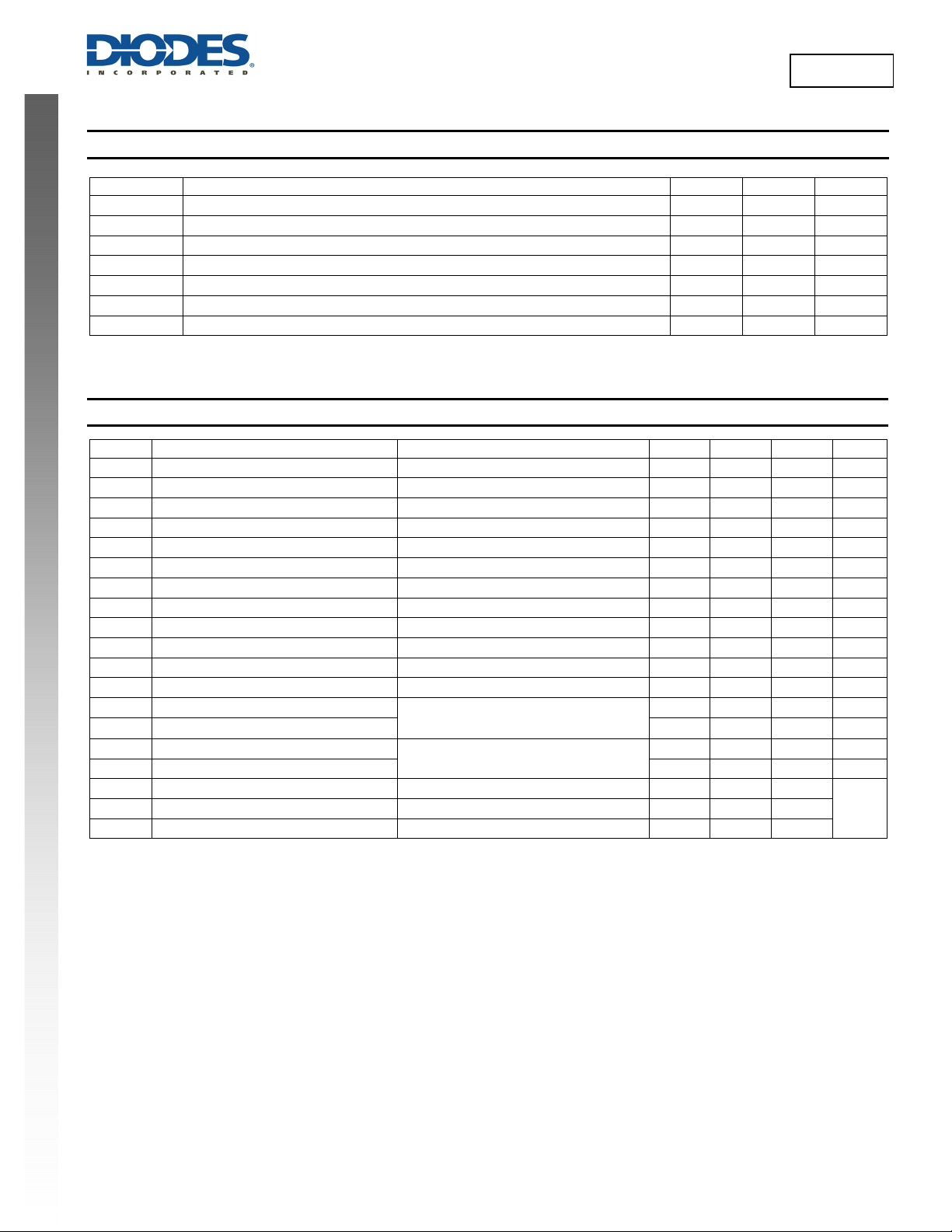

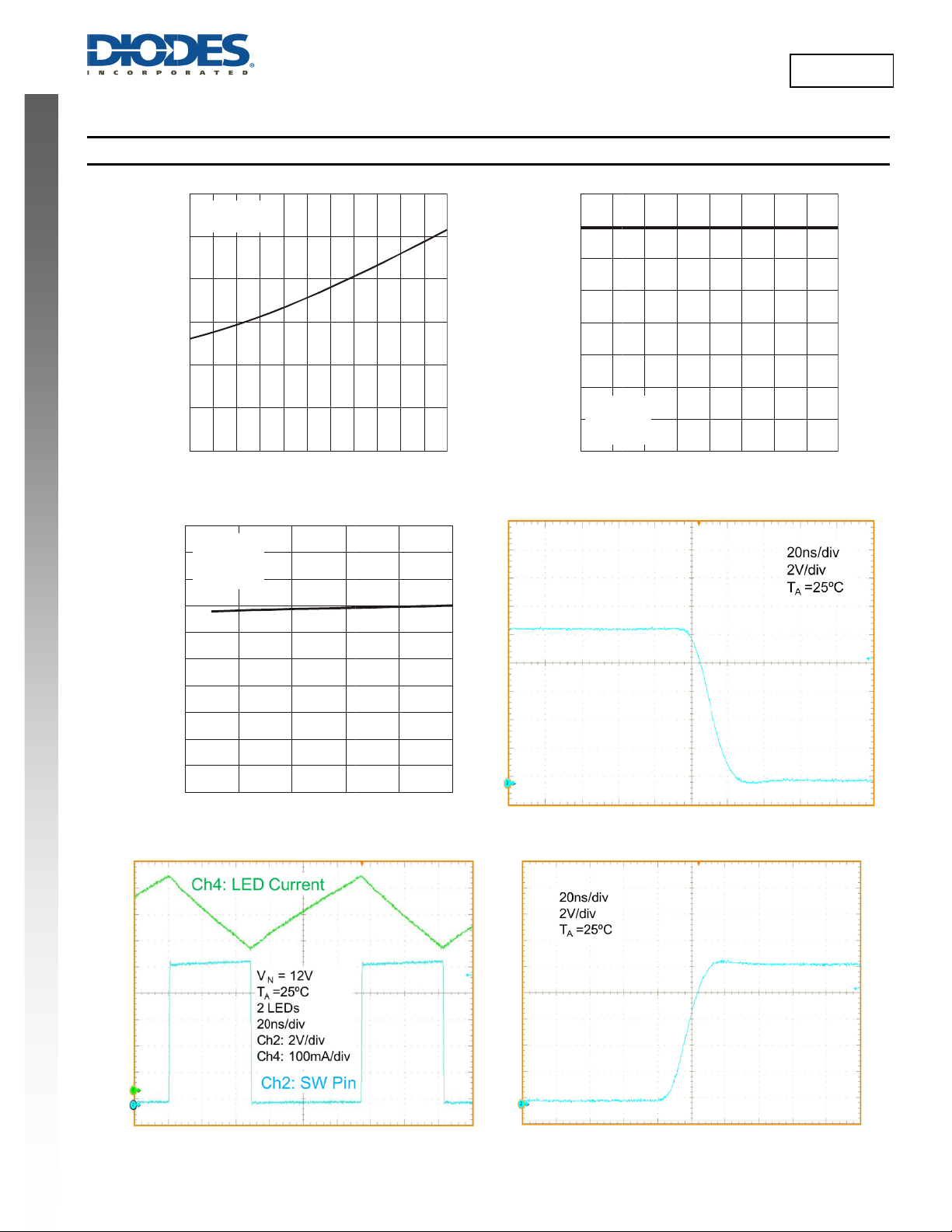

Typical Performance Characteristics (@ T

NEW PRODUCT

400

350

300

(µA)

250

200

150

IN

100

50

0

0 3 6 9 12 15 18 21 24 27 30

INPUT VOLTAGE (V)

Figure 2. Supply Current vs. Input Voltage

1.2

R

T = +25°C

A

V= 12V

IN

1.0

L = 68µH

1 LED

0.8

(A)

SET

R

0.6

0.4

LED

0.2

V = 0V

CTRL

V = V

SET IN

T = +25°C

A

= 100m

= 150m

SET

R

= 300m

SET

L8808

= +25°C, unless otherwise stated.)

A

900

800

700

z)

600

(k

500

400

300

200

100

0

20

Ω

0

-20

(µA)

Ω

-40

-60

-80

Ω

-100

L = 33µH

L = 100µH

T = +25°C

A

V = 12V

IN

R = 150m

SET

1 LED

L = 68µH

Ω

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

V

(V)

= 150m

CTRL

CTRL

Ω

Figure 3. Switching Frequency vs. V

T = +25°C, V = 12V

AIN

L = 68µH, R

1 LED

SET

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

V

(V)

Figure 4. LED Current vs. V

CTRL

CTRL

6

T = +25°C, V = 12V

AIN

L = 68µH, R

1 LED, f = 500Hz

5

PWM

SET

= 150m

Ω

(%)

4

3

EN

2

LED

1

0

020406080100

PWM DUTY CYCLE (%)

Figure 6. I vs. PWM Duty Cycle

LED

0.9

LED

0.6

U

ENT (A)

0.3

0.0

-120

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

V

(V)

Figure 5. I vs. V

CTRL

CTRL CTRL

100

90

80

70

60

LE (%)

50

40

D

30

20

T = +25°C, R = 150m

A SET

10

L = 33µH, L = 68µH, L = 100µH

0

6 9 12 15 18 21 24 27 30

INPUT VOLTAGE V

Ω

(V)

CTRL

Figure 7. Duty Cycle vs. Input Voltage

AL8808

Document number: DS35648 Rev. 2 - 2

4 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 5

r

e

OSFET R

0

040302010

0

5

0

5

0

5

0

5

0

5

0

e

S

2

W

e

a

5

T

T

S

w

t

C

w

u

r

M

OSFET R

=

V

°

p

r

8

O

a

e

A

L8808

NEW PRODUCT

Typical P

Ω

(m )

DS(ON)

SW M

0.5

0.4

0.4

Ω

0.3

rformanc

6

0

V = Open

CTRL

V = V = 1

SET IN

5

0

0

0

0

0

0

-40 -25 -10 5

Figure 8.

V = 12V

IN

V = V

SET IN

T = +25°C

A

CTRL = Floating

Charact

V

20 35

AMBI

ENT TEMPERA

SW R vs

50 6

DS(ON)

ristics

(con

80 95 110 1

URE (°C)

. Temperature

.) (@ TA = +25°

25

, unless other

400

350

300

Ω

(m )

250

DS(ON)

200

150

100

SW

V

CTRL

V =

50

SET

T = 25

A

0

69

ise stated.)

Open

IN

C

12 15 1

Fig

ure 9. SW R

DS(

V

IN

21 24

(V)

vs. Input Volt

N)

27 30

ge

0.3

DS(ON)

0.2

0.2

0.1

SW MOSFET R ( )

0.1

0.0

0.0

0200

S

Figure 10.

400 600

ITCH CURREN

SW R vs.

DS(ON)

800 1

(mA)

witch Current

000

Fig

re 11. SW Out

ut Fall Time

Figure 12.

AL8808

Document numbe

: DS35648 Rev. 2

teady State W

- 2

veforms

5 of 20

ww.diodes.co

m

Figu

e 13. SW Outp

ut Rise Time

© Diodes Incorporat

January 201

3

d

Page 6

A

C

C

Y

C

URREN

T

TCHING F

REQ

UENC

Y

H

CUR

RENT

U

T

Y CYC

CUR

R

T

L8808

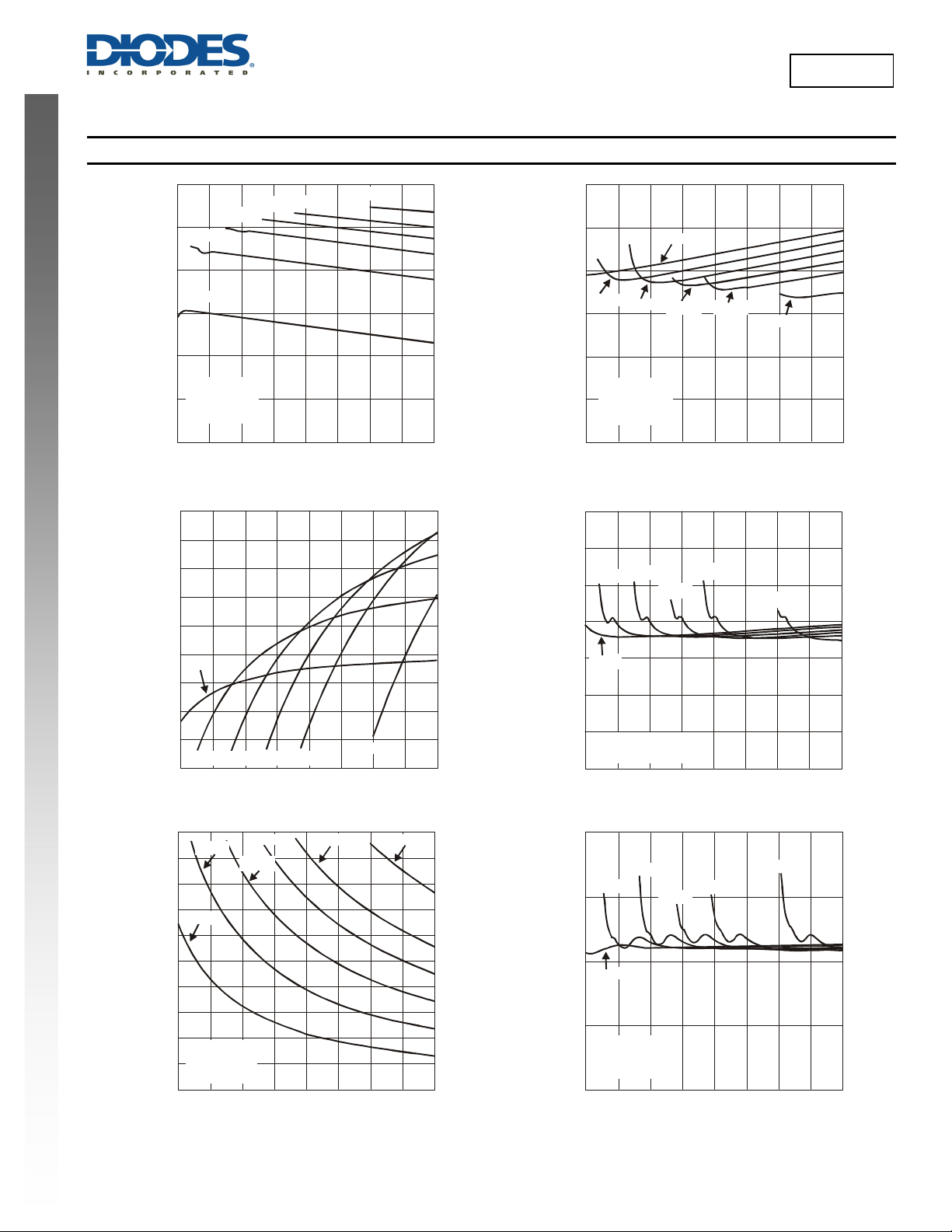

Typical Performance Characteristics (L = 68µH, T

NEW PRODUCT

100

95

3 LEDs

2 LEDs

5 LEDs

4 LEDs

90

(%)

1 LED

85

IEN

80

EFFI

T = 25°C

A

L= 68µH

75

R = 150m

SET

Ω

70

6 9 12 15 18 21 24 27 30

INPUT VOLTAGE (V)

Figure 14. Efficiency vs. Input Voltage

450

400

z)

350

(k

300

250

7 LEDs

= +25°C, unless otherwise stated.)

A

0.36

0.35

0.34

(A)

2 LEDs

0.33

0.32

LED

0.31

0.30

6 9 12 15 18 21 24 27 30

Figure 15. 330mA LED Current vs. Input Voltage

0.74

0.72

2 LEDs

0.70

(A)

0.68

3 LEDs

T = 25°C

A

L= 68µH

R = 300m

SET

3 LEDs

1 LED

4 LEDs

Ω

5 LEDs

INPUT VOLTAGE (V)

5 LEDs

4 LEDs

7 LEDs

7 LEDs

200

150

1 LED

LED

0.66

0.64

1 LED

100

SWI

50

5 LEDs

3 LEDs

4 LEDs

2 LEDs

0

6 9 12 15 18 21 24 27 30

7 LEDs

INPUT VOLTAGE (V)

Figure 16. Switching Frequency vs. Input Voltage

100

90

2 LEDs

4 LEDs

3 LEDs

5 LEDs

80

70

1 LED

60

LE (%)

50

7 LEDs

0.62

T = 25°C, V

A

L= 68µH, R = 150m

0.60

6 9 12 15 18 21 24 27 30

SET

IN

= 12V

Ω

INPUT VOLTAGE (V)

Figure 17. 670mA LED Current vs. Input Voltage

1.10

7 LEDs

1.05

2 LEDs

3 LEDs

4 LEDs

5 LEDs

(A)

EN

1.00

1 LED

40

30

D

20

T = 25°C

A

L= 68µH

10

R = 150m

SET

0

6 9 12 15 18 21 24 27 30

Ω

INPUT VOLTAGE (V)

Figure 18. Duty Cycle vs. Input Voltage

LED

0.95

T = 25°C

A

L= 68µH

R = 100m

SET

0.90

6 9 12 15 18 21 24 27 30

Ω

INPUT VOLTAGE (V)

Figure 19. 1A LED Current vs. Input Voltage

AL8808

Document number: DS35648 Rev. 2 - 2

6 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 7

A

T

O

R

OM TAR

GET

C

URR

T

TCHIN

G FREQ

U

NCY

H

TIO

R

OM TAR

GET

5

TCHIN

G FREQ

UENCY

H

O

N FR

O

R

G

5

TCHING FR

Q

U

C

Y

H

L8808

Typical Performance Characteristics (670mA LED Current; T

= +25°C unless otherwise stated.)

A

NEW PRODUCT

5

2 LEDs

(%)

EN

-1

3 LEDs

4 LEDs

3

1

1 LED

5 LEDs

7 LEDs

N F

I

-3

T = 25°C,

A

L = 33µH

DEVIA

-5

R = 150m

SET

Ω

186 9 12 15 21 24 27 30

INPUT VOLTAGE (V)

Figure 20. LED Current Deviation vs. Input Voltage

(%)

3 LEDs

2 LEDs

4

4 LEDs

3

5 LEDs

7 LEDs

2

1

0

1 LED

-1

N F

-2

-3

T = 25°C,

DEVIA

A

L = 68µH

-4

R = 150m

SET

Ω

-5

186 9 12 15 21 24 27 30

INPUT VOLTAGE (V)

Figure 22. LED Curr ent Deviation vs. Input Voltage

800

T = 25°C,

A

L = 33µH

z)

(k

E

700

600

500

R = 150m

SET

Ω

400

1 LED

300

200

SWI

100

0

2 LEDs

3 LEDs

4 LEDs

5 LEDs

186 9 12 15 21 24 27 30

7 LEDs

INPUT VOLTAGE (V)

Figure 21. Switching Frequency vs. Input Voltage

450

400

z)

350

(k

300

250

200

150

100

SWI

50

0

186 9 12 15 21 24 27 30

INPUT VOLTAGE (V)

Figure 23. Switching Frequency vs. Input Voltage

250

4

2 LEDs

3

ET (%)

2

1

M TA

0

1 LED

-1

3 LEDs

4 LEDs

7 LEDs

z)

(k

EN

E

200

150

100

5 LEDs

-2

-3

T = 25°C,

DEVIATI

A

L = 100µH

-4

-5

R = 150m

SET

Ω

186 9 12 15 21 24 27 30

INPUT VOLTAGE (V)

Figure 24. LED Current Deviation vs. Input Voltage

50

SWI

0

186 9 12 15 21 24 27 30

INPUT VOLTAGE (V)

Figure 25. Switching Frequency vs. Input Voltage

AL8808

Document number: DS35648 Rev. 2 - 2

7 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 8

A

A

ON F

ROM

A

R

CUR

R

%

C

G F

REQ

C

Y

D

A

TIO

N FRO

M TAR

GET CUR

REN

T (%

TCHIN

G F

REQ

UENCY

H

5

D

TIO

N

F

R

O

M T

R

G

T

C

U

R

R

N

T

T

C

H

G

R

Q

U

C

Y

H

Typical Performance Characteristics (1A LED Current) T

5

)

NEW PRODUCT

2 LEDs

4

ENT (

3

2

1

GET

1 LED

0

T

-1

-2

-3

TI

T = 25°C

A

L = 33µH

-4

R = 100m

DEVI

SET

-5

Figure 26. LED Current Deviation vs. Input Voltage

4 LEDs

3 LEDs

Ω

5 LEDs 7 LEDs

18151269 30272421

INPUT VOLTAGE (V)

L8808

= +25°C unless otherwise stated.)

A

600

T = 25°C

A

L = 33µ H

500

R = 100m

SET

Ω

(kHz)

400

UEN

300

1 LED

200

HIN

100

SWIT

2 LEDs 3 LEDs 4 LEDs

0

5 LEDs

18151269 30272421

INPUT VOLTAGE (V)

Figure 27. Switching Frequency vs. Input Voltage

7 LEDs

5

)

4

2 LEDs

3

3 LEDs

4 LEDs

5 LEDs

7 LEDs

2

1

0

1 LED

-1

-2

-3

T = 25°C

A

L = 68µ H

-4

EVI

-5

R = 100m

SET

Ω

18151269 30272421

INPUT VOLTAGE (V)

Figure 28. LED Current Deviation vs. Input Voltage

(%)

E

E

A

4 LEDs

2 LEDs

4

3 LEDs

5 LEDs

3

2

1

0

1 LED

7 LEDs

-1

-2

-3

T = 25°C

A

L = 100µH

-4

EVIA

-5

R = 100m

SET

Ω

18151269 30272421

INPUT VOLTAGE (V)

Figure 30. LED Current Deviation vs. Input Voltage

300

z)

250

(k

200

150

100

50

SWI

0

18151269 30272421

INPUT VOLTAGE (V)

Figure 29. Switching Frequency vs. Input Voltage

200

180

z)

160

(k

140

EN

120

E

100

F

1 LED

80

IN

60

40

SWI

20

0

18151269 30272421

INPUT VOLTAGE (V)

Figure 31. Switching Frequency vs. Input Voltage

AL8808

Document number: DS35648 Rev. 2 - 2

8 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 9

r

o

a

a

d

e

g

n

d

n

a

C

n

o

i

L

t

a

e

o

a

n

d

o

n

b

o

o

c

g

o

p

a

e

W

e

r

a

A

w

0

d

r

e

y

E

b

V

L

e

V

=

h

0

c

y

A

e

y

a

w

s

o

y

R

T

a

R

≈

b

s

h

g

r

t

E

e

a

o

a

o

e

m

o

n

t

8

5

t

e

u

i

w

o

e

5

i

f

e

A

n

a

p

s

n

o

s

L8808

NEW PRODUCT

Applicati

AL8808 Oper

In normal oper

inductor L1, an

voltage and the

This rising curr

voltage to the in

When this volta

L1, the LEDs a

of the LEDs an

This decaying c

applied at the i

This switch-on-

n Informa

tion

tion, when volt

the LEDs. Th

inductor L1.

nt produces a v

put of the intern

e reaches an i

d the schottky

the schottky di

urrent produces

put of the inter

nd-off cycle con

ion

ge is applied at

current ramps

ltage ramp acr

l comparator.

ternally set up

iode D1, and b

de.

a falling voltag

al comparator.

tinues to provid

+VIN, the AL88

up linearly, an

ss R1. The inte

er threshold, th

ck to the suppl

at R1, which is

hen this voltag

the average L

8 internal swit

the ramp rate

nal circuit of the

internal switch

rail, but it deca

sensed by the

e falls to the int

D current set b

h is turned on.

is determined

AL8808 sense

is turned off. T

s, with the rate

L8808. A volta

rnally set lowe

the sense resis

Current starts t

y the input volt

the voltage acr

e inductor curr

of decay deter

e proportional t

threshold, the i

or R1.

flow through s

ge (+VIN) min

ss R1 and appl

nt continues to

ined by the for

the sense volt

ternal switch is

nse resistor R1

s the LED chai

es a proportion

flow through R1

ard voltage dro

age across R1 i

turned on agai

,

l

,

.

LED Current

The LED curre

connected from

with CTRL left fl

If the CTRL pin

For example for

ontrol

t is controlled

the CTRL pin t

ating. If the CT

s driven by an e

a desired LED

y the resistor R

an internal 5V

RL pin is left flo

xternal voltage (

urrent of 660m

Figure 32.

(in Figure 32)

1

egulator. When

ting or driven a

higher than 0.5

and V

CTRL

R

When the CTR

AL8808

Document numbe

voltage is brou

: DS35648 Rev. 2

ht below 0.4V, t

- 2

he output switc

Where

I

Wher

=2.5

SET

Typical Applic

connected bet

the CTRL pin i

ove 2.5V the n

V

TH

=

I

LED

VTH is nominall

and lower than

ED

V

REF

or with the CT

V

TH

I

LED

is turned off wh

ww.diodes.co

V

CTRL

=

V

REF

is nomin

=

9 of 20

1R

1.0

66.0

tion Circuit

een VIN and S

left floating it g

minal average o

100mV.

2.5V), the aver

V

H

1

lly 2.5V

L pin left open

Ωm150

ich allows PWM

m

T pins. The AL

utput current in

ge LED current

the resulting res

dimming.

ts pulled up to

808 has an int

V - increasing

he LED(s) is de

is:

istor is:

rnal 50k resist

ts noise rejectio

ined as:

January 201

© Diodes Incorporat

r

n

3

d

Page 10

A

CUR

R

T

RAT

O

C

R

ROR

CUR

R

N

T

O

C

U

R

R

N

T

R

ROR

Application Information (cont.)

Analog Dimming

The CTRL pin can be driven by an external analog voltage (V

defined by R1. The LED current decreases linearly with the CTRL voltage when 0.5V V

Note that 100% brightness is achieved when either the CTRL pin is left floating or pulled above 2.5V by an external voltage source.

For 2.6V V

5.5V the LED current will not get overdriven and will be set the current according to the equation V

CTRL

reference voltage). See Figure 33 below.

110

T = 25°C

A

100

V = 12V

90

80

70

IN

L = 68µH

(%)

I

EN

60

NEW PRODUCT

50

40

30

20

10

DIMMED : 100% LED

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Figure 33. LED Current Dimming Ration and

Typical Error vs. Control Voltage

PWM Dimming

LED current can be adjusted digitally, by applying a low frequency Pulse Width Modulated (PWM) logic signal to the CTRL pin to turn the device

on and off. This will produce an average output current proportional to the duty cycle of the control signal. In particular, a PWM signal with a

max resolution of 10bit (~0.1% duty cycle) can be applied to the CTRL pin to change the output current to a value below the nominal average

value set by resistor R

. To achieve this resolution the PWM frequency has to be lower than 500Hz, however higher dimming frequencies can

SET

be used, at the expense of dimming dynamic range and accuracy.

Typically, for a PWM frequency of 500Hz the accuracy is better than 2% for PWM ranging from 5% to 100%.

0.8

V = 12V

IN

T = +25°C

A

0.7

L = 68µH

(A)

0.6

0.5

R = 150m

SET

1 LED

Ω

E

0.4

0.3

LED

0.2

0.1

0

50 60010203040 9010070 80

PWM DUTY CYCLE (%)

Figure 34. PWM Dimming at 500Hz

), to adjust the output current to a value below the nominal average value

CTRL

2.5V.

CTRL

= 2.5V (the internal

CTRL

2.2

2.0

Dimmed LED Current Ratio

1.8

TYPI

1.6

1.4

AL E

1.2

1.0

(%)

0.8

0.6

LED Current Error

0.4

0.2

0.0

V (V)

CTRL

10

9

8

(%)

7

6

E

5

E

4

3

AD

L

2

1

10

Figure 35. Low Duty Cycle PWM Dimming at 500Hz

V = 12V

IN

T = +25°C

A

L = 68µH

R = 150m

SET

1 LED

Ω

7.50.0 2.5 5.0 15.010.0 12.5

PWM DUTY CYCLE (%)

L8808

AL8808

Document number: DS35648 Rev. 2 - 2

10 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 11

r

o

n

s

W

e

e

e

d

a

t

e

o

M

e

o

H

H

e

e

e

e

P

e

m

w

g

s

.

e

r

c

c

c

y

s

w

u

W

e

g

d

t

w

t

u

r

n

a

t

e

e

e

u

m

u

A

e

e

A

A

g

s

g

s

d

o

s

s

Applicati

PWM Dimmi

The CTRL pin i

output stage.

The ultimate P

lower switching

the accuracy/lin

At the start of

threshold isn’t r

Greater PWM

frequency.

The three figure

from a 12V rail

n Informa

g

(cont.)

designed to b

M dimming res

frequencies and

arity of the PW

ach PWM cycl

ached then the

imming dynami

s below show 0.

t +25°C for a n

ion

(cont.)

driven by both

lution is determ

/or higher PWM

dimming.

the LED curr

accuracy will be

c ranges can b

2% duty cycle

minal LED curr

3.3V and 5V lo

ined by the num

frequencies the

nt needs to re

greatly affected

achieved by

WM pulse resol

nt of 670mA

.

ic levels directl

ber of full LED

number of full s

tart from zero

educing the P

ution with differ

from a logic ou

witching cycles

itching cycles

p to the uppe

M dimming fre

nt PWM freque

tput with either

hat can be achi

hat can be achi

threshold level

quency and/or i

cies and differe

n open drain o

ved during the

ved is reduced

(nominally 120

ncreasing the

nt inductor valu

L8808

tput or push pu

PWM on-time.

thereby reducin

mV/R

L8808 switchin

s driving 2 LED

SET

). If thi

ll

t

NEW PRODUCT

Figure 36. 0

.2% PWM Duty

68µ

Cycle at 100Hz

Inductance

PWM Frequen

y and

ure 37. 0.2% P

Fi

WM Duty Cycl

22µH Ind

at 100Hz PWM

ctance

Frequency an

Figure 38. 0

.2% PWM Duty

22µ

Cycle at 500Hz

Inductance

PWM Frequen

y and

As can be obse

value.

rved from Figur

37 greater di

ming accuracy

an be achieve

by reducing bo

th the PWM di

ming frequency

and the induct

r

AL8808

Document numbe

: DS35648 Rev. 2

- 2

11 of 20

ww.diodes.co

m

January 201

© Diodes Incorporat

3

d

Page 12

NEW PRODUCT

r

o

S

s

s

c

e

e

L

p

d

a

t

p

s

a

a

t

w

s

E

u

e

t

p

h

f

a

n

t

e

o

c

s

(

h

g

i

a

t

a

n

r

f

r

f

d

w

g

a

w

c

a

p

S

h

y

a

a

o

h

a

f

o

p

n

e

s

p

v

1

h

p

v

t

C

e

a

L

g

a

w

n

x

p

w

r

n

d

h

o

w

a

n

x

r

a

t

c

n

l

-

y

s

1

(

o

p

a

v

8

u

e

t

l

v

y

t

p

F

e

t

a

e

A

e

e

e

g

V

r

t

o

M

e

e

D

u

Applicati

Start-up and

On initial power

than 0.45V (typi

the output start

This will cause

the upper LED

The AL8808 do

accuracy.

Soft start can b

rail on the CTR

The external ca

occurs it is esse

This is achieve

the control volta

Adding this cap

dimming accura

n Informa

oft Start

up the device

cal). This cause

switching the L

ome additional i

urrent threshold

s not have in-b

easily implem

pin will charge

acitor slows up

ntial that the ca

by increasing t

ge at the input o

citor increases

cy depending o

ion

(cont.)

ill not start swit

a slight delay

D current will b

nput current to t

level by slowin

ilt soft-start act

nted by adding

he external cap

the ramp-up of

acitor is large e

e time taken fo

the comparato

the time taken

the delay intro

hing until the p

dependent on r

uild up to the up

I

LED

at of charging t

down the rise o

on allowing ver

n external cap

citor up to 5V.

the CTRL pin v

ough to keep t

the CTRL volt

.

or the output t

uced.

ower supply ha

mp rate of inpu

er threshold le

V

CTRL

=

SPK

e input bulk ca

f the CTRL pin

fast control of

citor from the

ltage thereby r

e CTRL pin volt

ge to rise to the

reach 90% of i

V5.2

reached appro

t voltage and in

el:

.0

×

2.1

1R

acitance. One

oltage – implem

he output Powe

TRL pin to grou

ducing the LED

ge below 2.5V

upper (turn-off)

ts final value, t

imately 5.6V o

ut bulk capacit

ay of reducing

enting a soft-sta

MOSFET swit

d. The internal

current via ana

uring the ramp

threshold and b

is delay is 25µ

the CTRL pin

nce of the AL8

his additional c

rt.

h which improv

pull-up resistor

og dimming. To

up of the input

slowing down

/nF, but will im

L8808

oltage is great

08 circuit). Onc

rrent is to reduc

s PWM dimmin

o the internal 5

ensure soft-sta

oltage.

he rate of rise

act on the PW

r

t

f

Figure

Reducing Ou

Peak to peak ri

A value of 1F

capacitor value

Note that the c

voltage. By add

altering the me

AL8808

Document numbe

put Ripple

ple current in th

will reduce the

.

pacitor will not

ing this capacit

n current value.

: DS35648 Rev. 2

39. Soft Start

LED(s) can be

supply ripple c

affect operatin

r the current w

- 2

ith 100nF Ca

reduced, if requ

urrent significa

frequency or

veform through

acitor on CTR

ired, by shuntin

tly in the typic

fficiency, but it

the LED(s) cha

12 of 20

ww.diodes.co

pin (VIN = 24V,

a capacitor C2

l case. Proporti

ill increase st

ges from a tria

m

I

= 667mA,

LED

across the LED

nally lower rip

rt-up delay, by

gular ramp to

LED)

s) as shown in

le can be achi

reducing the ra

more sinusoid

igure 32.

ved with high

e of rise of LE

l version witho

January 201

© Diodes Incorporat

r

t

3

d

Page 13

r

o

e

e

c

o

o

r

M

q

m

−

m

L

r

u

l

t

s

o

t

a

L

o

d

s

r

L

o

u

x

−

G

r

s

e

d

a

c

o

s

d

t

i

D

(

o

n

W

t

m

e

w

e

s

p

u

d

b

w

T

)

3

5

1

c

4

V

H

c

n

t

s

r

T

o

e

e

n

q

n

e

c

n

m

v

m

e

C

d

q

u

c

o

t

o

i

e

c

m

e

A

L8808

Applicati

Inductor Sel

Recommended

data for select

required switchi

LED current ac

n Informa

ction

inductor values

d component v

ng frequency.

uracy (due to pr

ion

(cont.)

for the AL8808

lues. The indu

ower inductor v

pagation delay

are in the rang

tance used will

alues can be u

) and increase

33µH to 100µ

depend on a

ed to increase t

ower dissipatio

. Note that th

ombination of I

he switching fre

(due to switchi

AL8808 Web

put voltage an

uency and red

g losses).

alculator provid

LED chain vo

ce solution siz

es performance

ltage to set the

but may affect

NEW PRODUCT

Figure 4

++

RrR

S

LS

rR

LS

0. Inductor Val

evice as possi

higher than the

n the table belo

CR

V)

093 2.

213 1.

124 1.

operating duty

with reference t

)

ernally set to 0.

inal}

d load current (

Part

=

V

IN

=

V

is the

uld be mounte

should have a

utput current.

use with the A

No.

TRF

ue should be ch

uations can be

e:

e:

D

ED

inductance (H)

resistance ()

rent sense resi

quired LED curr

pply voltage (V)

peak-peak rippl

otal LED forwar

witch resistance

de forward volt

: DS35648 Rev. 2

The inductor sh

The chosen coil

required mean

Suitable coils fo

MSS1038-333

MSS1038-683

NPIS64D330

The inductor val

The following e

Switch ‘On’ ti

t

ON

Switch ‘Off’ ti

t

OFF

Where:

L is the coil

is the coil

r

L

is the cu

R

S

I

is the re

avg

V

is the s

IN

I is the coi

V

LED

RSW is the

VD is the di

AL8808

Document numbe

L

−

IV

AVGLED

Δ

++

IV

AV

as close to the

aturation curren

8807 are listed

L

(µH)

33 0.

68 0.

33 0.

sen to maintai

sed as a guide,

Δ

I

(

IL

()

x

+

tance ()

nt (A)

e current (A) {In

voltage (V)

() {=0.35 no

ge at the requir

- 2

e with Input Vol

le with low resi

peak output cu

:

I

SA

(A

ycle and switch

o Figure 1 - Op

x I

AVG

)

13 of 20

ww.diodes.co

}

age and Numb

tance/stray indu

rent and a conti

Manufactu

ilCraft www.coi

C

NIC www.nicco

'on'/'off' times o

rating wavefor

m

r of LEDs

tance connecti

uous current ra

rer

lcraft.com

p.com

er the supply v

s.

Figur

41. Typical Sw

ns to the SW pi

ing above the

ltage and load

tching Wavefor

n.

urrent range.

January 201

© Diodes Incorporat

3

d

Page 14

A

Application Information (cont.)

Capacitor Selection

The small size of ceramic capacitors makes them ideal for AL8808 applications. X7R type is recommended because it retains capacitance value

over wider voltage and temperature ranges than other types such as Y5V or Z5U. X5R is a useful compromise over a restricted temperature

range. Note that even X7R capacitance reduces significantly with increased DC bias voltage. At 50% of rated voltage, the capacitance loss is

between about 10% to 50% of nominal. Therefore it is often necessary to select a voltage rating which is at least twice the operating voltage.

Input Capacitor

In Figure 32, the input capacitor C1 is required as a reservoir. Diode D1 switches at a rate of typically up to 400kHz. The power supply has a

finite impedance, often including a wiring inductance value of the order of 100nH to 1uH or more depending upon the system design. C1 is

required to limit the power supply voltage and current ripple both to allow stable regulation of the LED current, and also to meet EMC

requirements.

A 2.2F input capacitor is sufficient for most DC powered applications of AL8808. This depends upon the operating voltage and current and the

maximum level of ripple required. Additional capacitors may be required in parallel for EMC purposes. This is described below in a separate

section.

However, if operated from a rectified low voltage AC source, such as MR16, then the input capacitance will need to be significantly increased to

NEW PRODUCT

provide enough reservoir charge when the input voltage falls below the minimum operating voltage of the AL8808 or the LED chain voltage

Output Capacitor

In Figure 32, the output capacitor C2 is normally required to limit the load voltage and current ripple, in order to meet EMC requirements. A value

of 0.1µF to 1µF is sufficient for many requirements, depending on voltage and current conditions. Additional capacitors may be required in parallel

for EMC purposes. This is described below in a separate section.

Diode Selection

For maximum efficiency and performance, the flywheel rectifier (D1) should be a fast low capacitance Schottky diode with low reverse leakage at

the maximum operating voltage and temperature. The silicon PN diode is not suitable because of its increased power loss, due to a combination

of lower forward voltage and reduced recovery time. The use of a Super-Barrier-Rectifier (SBR) is not recommended for use as a flywheel diode

in this application. (However the SBR provides significant advantages when used with an AC power input as a bridge rectifier driving V

It is important to select D1 with a peak current rating above the peak coil current and a continuous current rating higher than the maximum output

load current. In particular, it is recommended to have a diode voltage rating at least 15% higher than V

safe operation during the switching and a mean current rating at least 10% higher than the peak diode current. The power rating is verified by

calculating the power loss through the diode. In practice, the voltage rating selection is often increased by up to about 50% to obtain a better

compromise with loss due to reverse leakage current at higher temperature. Also the current rating is typically selected to provide a margin of up

to about 50%.

Schottky diodes, e.g. DFLS240L or DFLS140, with their low forward voltage drop and fast reverse recovery, are the ideal choice for AL8808

applications. Leakage current is sufficiently limited for the application.

AL8808

Document number: DS35648 Rev. 2 - 2

14 of 20

www.diodes.com

to ensure

IN

© Diodes Incorporated

L8808

.)

IN

January 2013

Page 15

A

P

O

R

PATIO

Application Information (cont.)

Thermal Considerations

For continuous conduction mode of operation, the absolute maximum junction temperature must not be exceeded. The maximum power

dissipation depends on several factors: the thermal resistance of the IC package (

between junction and ambient temperature.

The maximum power dissipation can be calculated using the following formula:

TT

−

A)MAX(J

P

=

)MAX(D

θ

JA

where

T

T

is the maximum operating junction temperature; for the AL8808 this is +125°C.

J(MAX)

is the ambient temperature, and

A

is the junction to ambient thermal resistance.

JA

The major thermal path for the TSOT25 package is pin 2 (GND pin) and it is important for minimizing the

mass is associated with pin 2. The thermal impedance from the AL8808 junction to pin 2 is approximately 57°C/W.

The AL8808’s

NEW PRODUCT

area on bottom layer with 1oz copper standing in still air is approximately 209°C/W. Yielding a maximum power dissipation at 25°C of 0.47W

on a 25 x 25mm double sided FR4 PCB with minimum recommended pad layout on top layer and thermal vias to maximum

JA

The AL8808’s

on a 25 x 25mm double sided FR4 PCB with maximum area top and bottom with vias is approximately 151°C/W; which gives a

JA

maximum power dissipation at 25°C of 0. 66W.

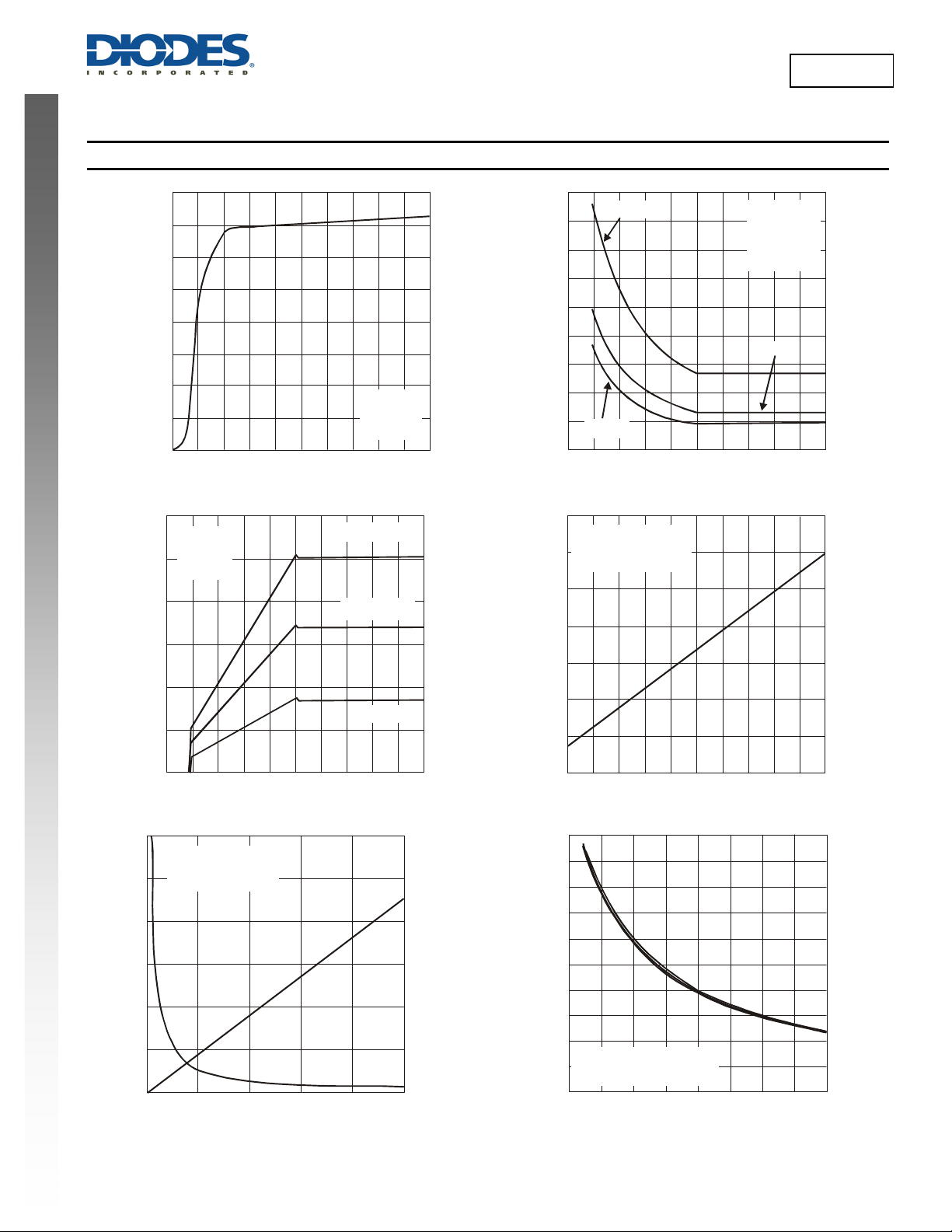

Figure 42 shows the power derating of the AL8808 on different area PCB with maximum area on bottom of PCB with 1 and 2oz copper standing in

still air.

1.0

2

(50mm) with 2oz Cu max area top

0.9

0.8

0.7

N (W)

0.6

2

(50mm) with 1oz Cu max area top

2

(25mm) with 2oz Cu max area top

2

(25mm) with 1oz Cu min area top

2

(25mm) with 2oz Cu min area top

), PCB layout, airflow surrounding the IC, and difference

JC

that a suitable area and thermal

JA

L8808

0.5

2

DISSI

WE

0.4

(50mm) with 1oz Cu min area top

2

(25mm) with 1oz Cu min area top

0.3

0.2

0.1

0

-10 5-40 -25 50 6520 35 110 12580 95

AMBIENT TEMPERATURE (C)

Figure 42. Derating Curve for Different PCB

AL8808

Document number: DS35648 Rev. 2 - 2

15 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 16

r

o

o

d

g

g

h

e

u

m

d

e

m

r

h

i

g

c

d

t

t

C

a

o

a

t

y

e

o

C

o

a

s

f

g

s

R

S

s

p

T

a

a

s

a

e

e

t

c

t

o

e

b

u

f

c

o

o

n

a

w

a

e

d

e

o

t

o

g

t

M

n

d

S

a

e

a

f

c

i

h

F

f

n

n

c

n

m

e

n

e

e

d

s

e

c

e

s

t

i

e

e

d

B

c

g

d

e

s

h

s

b

c

s

f

a

o

y

p

c

e

c

n

T

p

i

d

h

d

n

f

b

p

w

s

m

o

e

o

e

d

n

u

e

A

h

e

n

T

p

s

o

e

y

e

M

e

a

d

o

e

n

s

y

L8808

NEW PRODUCT

Applicati

EMI and Lay

The AL8808 is

decoupling and

switching spee

due to switchin

The turn-on ed

and PCB tracks

between the Sc

The tracks from

short as possibl

There is an ind

estimate the pri

and length will

The resonant fr

diode. An exa

n Informa

ut Considera

a switching reg

layout of the P

s of the internal

losses and radi

e (falling edge)

. After the Sch

ottky diode cap

the SW pin to

.

ctance internall

ary resonant fr

ominate the siz

quency of any

ple of good lay

ion

(cont.)

ions

ulator with fast

B.To help with

power MOSFE

ted EMI.

dominates the r

ttky diode rever

citance and th

he Anode of th

in the AL8808

equency. If the t

of the inductan

oscillation is de

ut is shown in Fi

edges and me

these effects th

. The rise an

diated EMI whi

e recovery time

track inductanc

Schottky diod

his can be assu

rack is capable

e.

ermined by the

gure 44 - the str

sures small dif

AL8808 has b

fall times are

ch is due to an

of around 5ns

e, L

, D1, and then

med to be arou

combined indu

ay track inducta

, See

TRACK

f handling 1A i

erential voltage

een developed

ontrolled to get

nteraction betw

as occurred; th

igure 43.

rom D1’s catho

d 1nH. For PC

creasing the thi

tance in the tra

ce should be le

; as a result o

o minimise radi

the right compr

en the Schottk

falling edge of

e to the decou

tracks a figure

kness will hav

ck and the effe

ss than 5nH.

this care has

ted emissions

mise between

diode (D1), S

the SW pin see

ling capacitors

of 0.5nH per m

a minor effect

tive capacitanc

to be taken wit

y controlling th

ower dissipatio

itching MOSFE

a resonant loo

C1 should be a

can be used t

n the inductanc

of the Schottk

Figure

PCB constructi

ound areas are

the g

(EMC

) operation and

capacitor C1 as

less t

an about 5mm.

the in

put current pas

tic inductance o

paras

more

round via hole

sense resistor

D1 anode, the

capacitor C2 a

itor and its cop

capa

impe

ance coupling d

: DS35648 Rev. 2

Figure 43. P

Summary:

1. Use a

2. Place

3. Place

4. Place

5. Place

AL8808

Document numbe

B Loop Reson

n with copper f

tightly connect

lso to minimize

close as possib

To ensure the

es directly thro

the copper tra

close to the gr

1 as close as p

W pin and the i

close as poss

er trace such th

ue to the added

- 2

ance

il on top and b

d together usin

device tempera

le to VIN, and as

est possible E

gh the capacito

e. Ensure low i

und pad.

ssible to VIN an

ductor as close

ible to L1 and

t the input curr

parasitic induct

ttom. Provide

plated via hol

ures by spreadi

close as possib

I filtering (great

r mounting pad.

ductance conn

SET.

together as pos

ET. To ensur

nt passes dire

nce of the copp

16 of 20

ww.diodes.co

aximum covera

s placed at reg

g the dissipate

le to the cathod

st attenuation),

This minimize

ction between t

ible to avoid rin

the best possi

tly through the

r trace.

m

44. Recomme

e of copper gro

ular intervals.

heat.

of D1. The se

place the capac

common impe

e capacitor an

ging.

le EMI filtering

apacitor mounti

ded PCB Layo

und plane on b

his is required

aration of these

tor and its copp

ance coupling

its ground con

(greatest atten

g pad. This mi

ut

th sides. Ensur

both for low E

nodes should b

r trace such th

ue to the adde

ection. Use 2

ation), place th

nimizes commo

January 201

© Diodes Incorporat

I

t

r

3

d

Page 17

A

Application Information (cont.)

EMI and Layout Considerations (cont.)

EMC Design

In addition to the layout instructions above, it may be necessary to take further measures to reduce electromagnetic interference (EMI) and meet

EMC requirements. This depends on the speed of the switching transitions. The fast switching edges include spectral harmonics spreading into

the UHF frequency range towards 500MHz. In this respect, AL8808 has been optimized to shape the switching current waveform to minimize EMI

while maintaining fast enough switching for high power efficiency. However, depending on the physical system design it may be necessary to add

additional filtering to reduce radiated and conducted emissions. The required circuit changes depend on a number of system design aspects

including the PCB size, the housing design and the length of external connecting wires.

Radiated Emission

Typically, the filtering required to control radiated emission consists of one or two additional capacitors placed close to the connecting points of the

wires. Very often the frequency range requiring most attenuation is in the region of 100MHz to 500MHz. In order to provide best attenuation in

this frequency range, use a capacitor of 1000pF to 2200pF with COG dielectric type, rated 50V or 100V. This capacitor provides very low ESR in

this frequency range. Place two such capacitors, one near the V

the best possible EMI filtering (greatest attenuation), place the capacitor and its copper trace such that the input or output current passes directly

NEW PRODUCT

through the capacitor mounting pad. This minimizes common impedance coupling due to the added parasitic inductance of the copper trace.

Conducted Emission

Conducted emission limits sometimes require filtering in the lower frequency range, from the switching frequency itself (Typically 200kHz) up to

about 30MHz. Usually the requirement only applies on the input side. The existing power supply may already include suitable measures. If

necessary add an input capacitor to reduce the ripple in this frequency range. Again the capacitors and their copper traces should be carefully

placed to avoid inductive common impedance coupling. Sometimes an additional series filter inductor may be added to achieve the desired

attenuation. An additional shunt capacitor to ground is connected resulting in a pi-filter configuration.

wire connection and one near the output connection to L1. Again, to ensure

IN

L8808

AL8808

Document number: DS35648 Rev. 2 - 2

17 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Page 18

r

o

o

s

u

u

d

t

f

a

a

n

s

o

j

a

t

n

r

e

a

a

o

o

o

m

t

8

n

e

w

o

i

r

w

o

t

u

e

o

w

h

w

n

d

t

c

m

e

w

p

h

a

8

4

a

s

a

o

e

t

a

L

p

o

s

s

t

v

r

s

o

8

a

c

t

l

n

E

w

r

e

l

c

t

o

t

h

e

A

o

a

e

3

e

e

n

c

n

t

e

g

Applicati

Fault Conditi

The AL8808 ha

VIN and the SW

If the LEDs sho

the expected c

dramatically an

LEDs.

The on-time of

inductor. The of

32) causing a m

n Informa

n Operation

by default ope

pin will then fall

ld become sho

rrent - so no

the switching f

he internal pow

-time is signific

uch slower dec

ion

(cont.)

LED protectio

to GND. No exc

ted together the

xcessive heat

requency will m

er MOSFET sw

ntly increased b

y in inductor cu

. If the LEDs s

ssive voltages

AL8808 will co

ill be generate

st likely decrea

tch is significan

ecause the reve

rent.

ould become o

ill be seen by t

tinue to switch

within the AL

se. See Figure

ly reduced bec

rse voltage acro

en circuit the A

e AL8808.

nd the current t

808. However,

5 for an exam

use almost all

s the inductor i

8808 will stop

hrough the AL8

the duty cycle

le of this behav

f the input volt

now just the S

scillating; the S

08’s internal s

at which it ope

ior at 24V input

ge is now dev

hottky diode vo

L8808

T pin will rise t

itch will still be

ates will chang

voltage driving

loped across th

tage (See Figur

t

NEW PRODUCT

Figure 45. S

High Temper

The AL8808 is

temperature in

temperatures a

AL8808 off. Thi

The OTP shutd

never switch-off

unction temper

AL8808

Document numbe

ture Operati

high efficiency

excess of 100°

d hence juncti

will allow the ju

wn junction te

with a junction

ture of the AL8

: DS35648 Rev. 2

n and Protec

switching LED d

C given the c

n temperature

nction temperat

perature of th

emperature bel

08.

- 2

itching Chara

tion

river capable of

rrect thermal i

hen the Over-T

re of the AL880

AL8808 is app

w +125°C allo

teristics (norm

operating juncti

pedance to fr

mperature Pro

8 to cool down

roximately +145

ing the designe

18 of 20

ww.diodes.co

l open to shor

n temperatures

e air. If a fault

ection (OTP) of

nd potentially gi

°C with a hyste

r to design the

m

LED chain)

up to +125°C. T

should occur

the AL8808 wi

ing an opportu

esis of +10°C.

ystem thermally

his allows it ope

hat leads to in

l cut in turning

ity for the fault t

This means tha

to fully utilize t

rate with ambie

reased ambie

he output of th

clear itself.

the AL8808 wi

e wide operatin

January 201

© Diodes Incorporat

t

t

ll

3

d

Page 19

A

A

X

θ

Ordering Information

L8808XX

L8808

X-

PackingPackage

WT : TSOT25 7 : 7” Tape & Reel

Part Number Package Code Packaging

AL8808WT-7 WT TSOT25 3000/Tape & Reel -7

Marking Information

TSOT25

NEW PRODUCT

(Top View)

W

7

4

XX

: Identification code

: Year 0~9

Y

X

W

: Week : A~Z : 1~26 week;

a~z : 27~52 week; z represents

52 and 53 week

X

: A~Z : Internal code

5

Y

XX

1 2 3

Part Number Package Identification Code

AL8808WT-7 TSOT25 B9

Package Outline Dimensions (All dimensions in mm.)

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

E1

A2

A

A1

AL8808

Document number: DS35648 Rev. 2 - 2

D

e1

E

c

L

4x 1

e

5x b

θ

19 of 20

www.diodes.com

7” Tape and Reel

Quantity Part Number Suffix

TSOT25

Dim Min Max Typ

A

A1 0.01 0.10

A2 0.84 0.90

D

E

L2

E1

b 0.30 0.45

c 0.12 0.20

e

e1

L 0.30 0.50

L2

θ 0° 8° 4°

θ1 4° 12°

All Dimensions in mm

1.00

−

− −

− −

− −

− −

− −

− −

−

−

−

2.90

2.80

1.60

−

−

0.95

1.90

0.25

−

January 2013

© Diodes Incorporated

Page 20

A

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for latest version.

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

NEW PRODUCT

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2013, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

Y1

C C

X (5x)

Y (5x)

IMPORTANT NOTICE

LIFE SUPPORT

Dimensions Value (in mm)

C

X

Y

Y1

0.950

0.700

1.000

3.199

L8808

AL8808

Document number: DS35648 Rev. 2 - 2

20 of 20

www.diodes.com

January 2013

© Diodes Incorporated

Loading...

Loading...