Page 1

A

P

L8807B

Description

The AL8807B is a step-down DC/DC converter designed to drive

LEDs with a constant current. The device can drive up to 9 LEDs,

depending on the forward voltage of the LEDs, in series from a

voltage source of 6V to 36V. Series connection of the LEDs provides

identical LED currents resulting in uniform brightness and eliminating

the need for ballast resistors. The AL8807B switches at frequency up

to 1MHz with controlled rise and fall times to reduce EMI. This

allows the use of small size external components, hence minimizing

the PCB area needed.

Maximum output current of AL8807B is set via an external resistor

connected between the V

achieved by applying a PWM signal at the CTRL input pin. An input

voltage of 0.4V or lower at CTRL switches off the output MOSFET

simplifying PWM dimming.

and SET input pins. Dimming is

IN

NEW PRODUCT

Features

LED driving current up to 1.3A

Better than 5% accuracy

High efficiency up to 96%

Optimally controlled switching speeds

Operating input voltage from 6V to 36V

PWM input for dimming control

Open-Circuit LED protection

LED Chain Short Circuited

Over-Temperature Protection

MSOP-8EP Available in “Green” Molding Compound (No Br,

Sb) with lead Free Finish/ RoHS Compliant

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

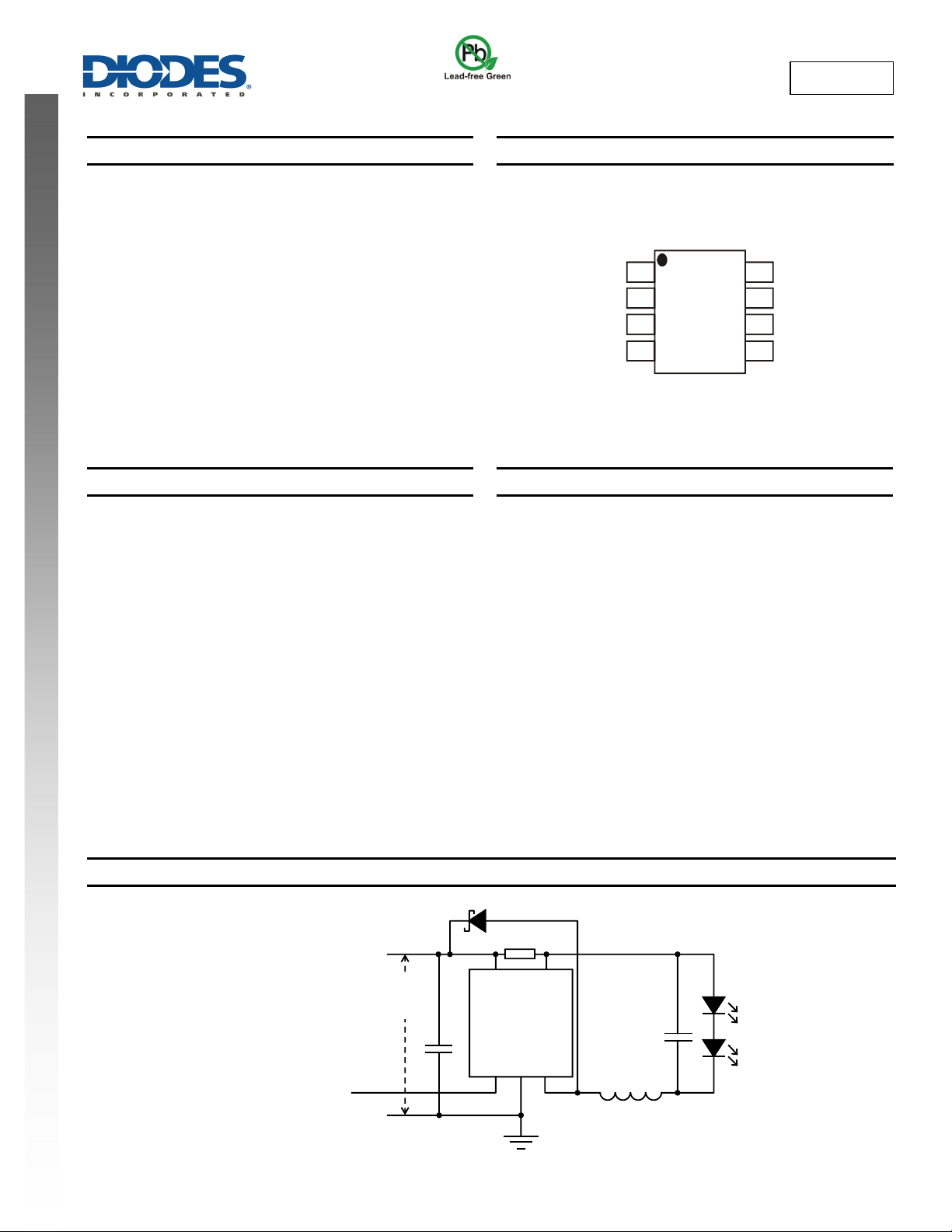

Pin Assignments

SET

GND

GND

CTRL

Applications

MR16 lamps

General illumination lamps

12V powered LED Lamps

24V powered LED Lamps

(Top View)

V

N/C

SW

SW

MSOP-8E

HIGH EFFICIENCY 36V 1.3A PWM DIMMABLE BUCK LED DRIVER

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free,

"Green" and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl)

and <1000ppm antimony compounds.

Typical Application Circuit

IN

AL88070B

Document number: DS36191 Rev. 1 - 2

PWM Dimming

Input:

VIN:

6 ~ 36V

D1

C1

www.diodes.com

R1

IN

V

AL8807B

GND

CTRL

1 of 18

SETSW

L1

C2

March 2014

© Diodes Incorporated

Page 2

A

Pin Descriptions

L8807B

Pin Name

SET 1 Set Nominal Output Current Pin. Configure the output current of the device.

GND 2, 3 GND Pins

CTRL 4

SW 5, 6 Switch Pin. Connect inductor/freewheeling diode here, minimizing track length at this pin to reduce EMI.

N/C 7 no connection

V

IN

EP EP

Pin

Number

8

NEW PRODUCT

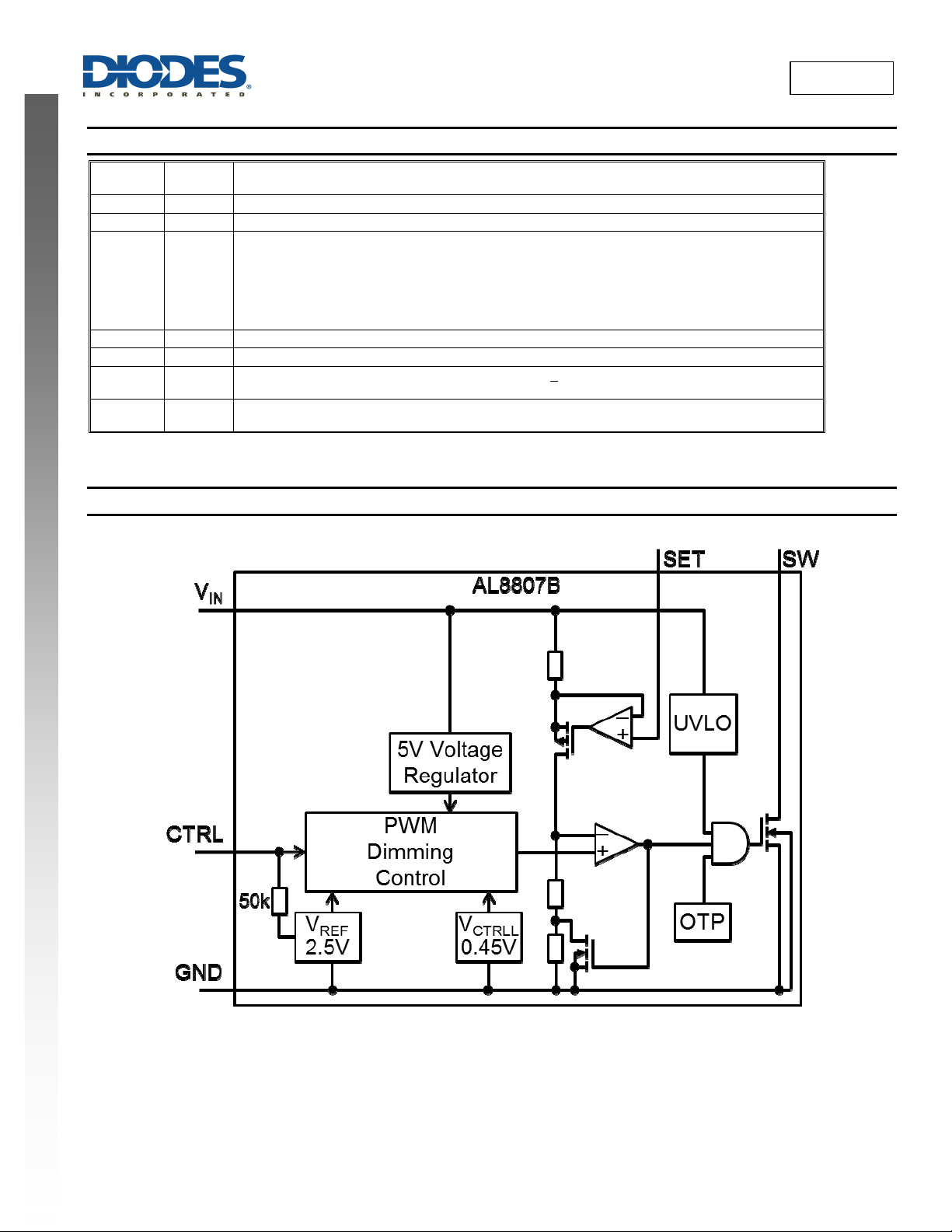

Functional Block Diagram

Function

Dimming and On/Off Control Input.

Leave floating for normal operation.

(V

= V

CTRL

Drive to voltage below 0.4V to turn off output current

A PWM signal ( 2.5V) allows the output current to be adjusted below the level set by the resistor

connected to SET input pin.

Input Supply Pin. Must be locally decoupled to GND with > 2.2µF X7R ceramic capacitor – see

applications section for more information.

Exposed pad/TAB connects to GND and thermal mass for enhanced thermal impedance. Should not be

used as electrical ground conduction path.

= 2.5V giving nominal average output current I

REF

= 0.1/RS)

OUTnom

AL88070B

Document number: DS36191 Rev. 1 - 2

2 of 18

www.diodes.com

March 2014

© Diodes Incorporated

Page 3

A

Absolute Maximum Ratings

Symbol Parameter Ratings Unit

ESD HBM Human Body Model ESD Protection 2.5 kV

ESD MM Machine Model ESD Protection 200 V

V

IN

V

SW

V

CTRL

I

SW-RMS

I

SW-PK

T

J

T

LEAD

T

ST

Caution: Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only;

NEW PRODUCT

Recommended Operating Conditions

Continuous VIN Pin Voltage Relative to GND

SW Voltage Relative to GND -0.3 to +40 V

CTRL Pin Input Voltage -0.3 to +6 V

DC or RMS Switch Current MSOP-8EP 1.6 A

Peak Switch Current (<10%) 2.5 A

Junction Temperature +150 °C

Lead Temperature Soldering +300 °C

Storage Temperature Range -65 to +150 °C

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability may be

affected by exposure to absolute maximum rating conditions for extended periods of time.

Semiconductor devices are ESD sensitive and may be damaged by exposure to ESD events. Suitable ESD precautions should be taken when handling

and transporting these devices.

-0.3 to +40 V

L8807B

Symbol Parameter Min Max Unit

V

IN

V

CTRLH

V

CTRLL

f

SW

I

SW

T

J

Electrical Characteristics (V

Symbol Parameter Conditions Min Typ Max Unit

V

INSU

V

INSH

IQ

IS

VTH

V

TH-H

I

SET

R

CTRL

V

REF

R

DS(ON)

tR

tF

T

OTP

T

OTP-Hyst

I

SW_Leakage

JA

JC

Notes: 4. AL8807B does not have a low power standby mode but current consumption is reduced when output switch is inhibited: V

tested with V

5. Refer to figure 39 for the device derating curve.

6. Test condition for MSOP-8EP: Device mounted on FR-4 PCB (51mm x 51mm 2oz copper, minimum recommended pad layout on top layer and

thermal vias to bottom layer with maximum area ground plane. For better thermal performance, larger copper pad for heat-sink is needed.

7. Dominant conduction path is via exposed pad.

Operating Input Voltage Relative to GND 6.0 36 V

Voltage High for PWM Dimming Relative to GND 2.5 5.5 V

Voltage Low for PWM Dimming Relative to GND 0 0.4 V

Maximum Switching Frequency — 1 MHz

Continuous Switch Current MSOP-8EP — 1.3 A

Junction Temperature Range -40 +125 °C

= 12V, @TA = +25°C, unless otherwise specified.)

IN

Internal Regulator Start Up Threshold

Internal Regulator Hysteresis Threshold

Quiescent Current Output not switching (Note 4) — — 350 µA

Input Supply Current CTRL pin floating f = 250kHz — 1.8 5 mA

Set Current Threshold Voltage

Set Threshold Hysteresis

SET Pin Input Current

CTRL Pin Input Resistance Referred to internal reference — 50 — k

Internal Reference Voltage

On Resistance of SW MOSFET

SW Rise Time

SW Fall Time — 20 — ns

Over-Temperature Shutdown

Over-Temperature Hysteresis

Switch Leakage Current

Thermal Resistance Junction-toAmbient (Note 5)

Thermal Resistance Junction-to-case

(Note 7)

2.5V.

CTRL

VIN rising

VIN falling

—

—

V

= VIN-0.1

SET

ISW = 1A

V

= 100 ±20mV fSW = 250kHz

SENSE

VSW = 0.1V~12V~0.1V CL = 15pF

—

—

VIN =36V

(Note 6) — 69 — °C/W

(Note 6) — 4.3 — —

— — 5.9 V

100 — 300 mV

95 100 105 mV

— ±15 — mV

— 16 22 µA

— 2.5 — V

— 0.25 0.4

— 12 — ns

— 155 — °C

— 55 — °C

— — 0.5 A

= 0V. Parameter is

SENSE

AL88070B

Document number: DS36191 Rev. 1 - 2

3 of 18

www.diodes.com

March 2014

© Diodes Incorporated

Page 4

A

A

(°C)

R

p

R

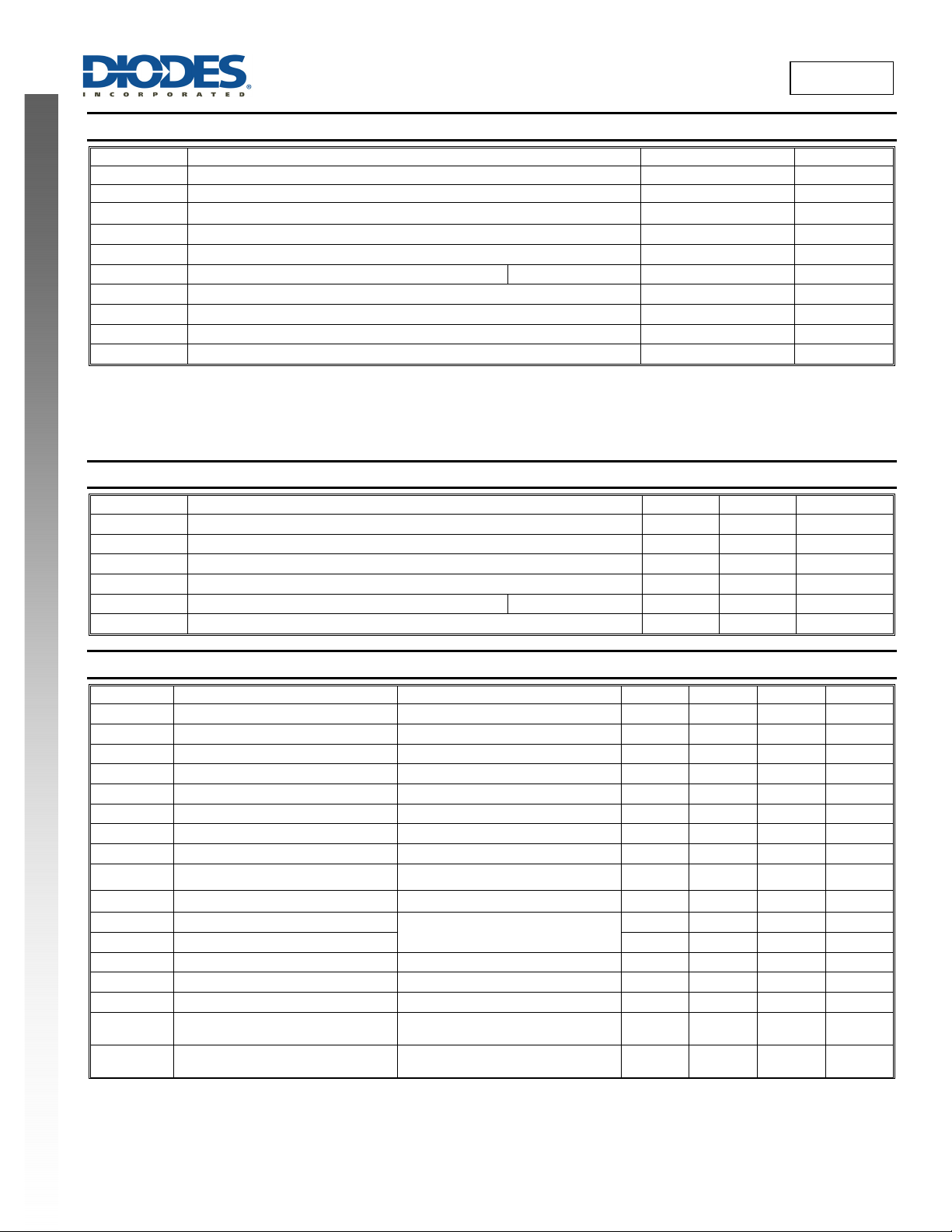

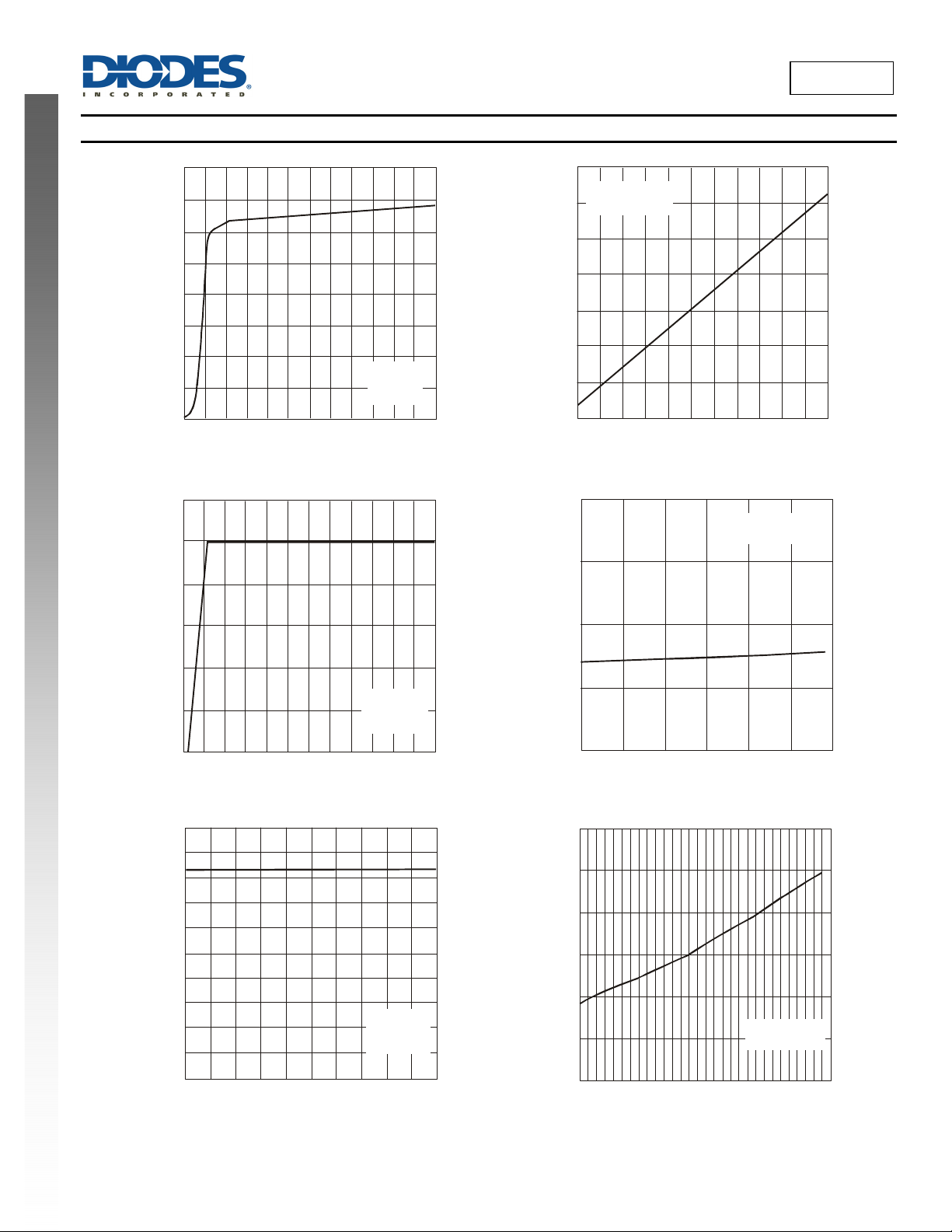

Typical Performance Characteristics (@T

NEW PRODUCT

400

350

300

250

200

IN

I (µA)

150

100

50

0

0 3 6 9 15 18 21 24 27 30 33

12 36

V (V)

IN

Figure 1. Supply Current (not switching) vs.

Input Voltage

3

2.5

2

V = 0V

CTRL

V = V

SET IN

T = 25°C

A

= +25°C, unless otherwise specified.)

A

80

V = V = 12V

SET IN

60

T = 25°C

A

40

)

20

CTRL

0

I (µ

-20

-40

-60

0.0 0.5 1.0 1.5 2.5 3.0 3.5 4.0 4.5 5.0

2.0 5.0

V (V)

Figure 2 I

2.52

2.51

CTRL

CTRL

vs. V

CTRL

V = Open

CTRL

V = V= 12V

SET IN

L8807B

1.5

CTRL

V (V)

2.50

CTRL

V (V)

1

V = Open

CTRL

0.5

0

0 3 6 9 12 18 21 24 27 30 36

Figure 3 V

15 33

V (V)

IN

vs. Input Voltage

CTRL

(CTRL Pin open circuit)

V = V

SET IN

T = 25°C

A

300

2.49

2.48

-40 -15 10 35 60 85 110

AMBIENT TEMPERATURE

Figure 4 V

vs. Temperature

CTRL

400

270

240

210

180

(m )

150

DS(ON)

120

90

60

30

0

6 9 12 18 21 24 27 30 36

15 33

Figure 5 SW R

V (V)

IN

vs. Input Voltage

DS(ON)

V = Open

CTRL

V = V

SET IN

T = 25°C

A

350

300

(m )

250

DS(ON)

200

150

100

-40 -15 35 60 11010 85

Ambient Tem

Figure 6 SW R

eratur e (C)

vs. Temperature

DS(ON)

V = Open

CTRL

V = V= 12V

SET IN

AL88070B

Document number: DS36191 Rev. 1 - 2

4 of 18

www.diodes.com

March 2014

© Diodes Incorporated

Page 5

A

Typical Performance Characteristics

(cont.) (@TA = +25°C, unless otherwise specified.)

L8807B

NEW PRODUCT

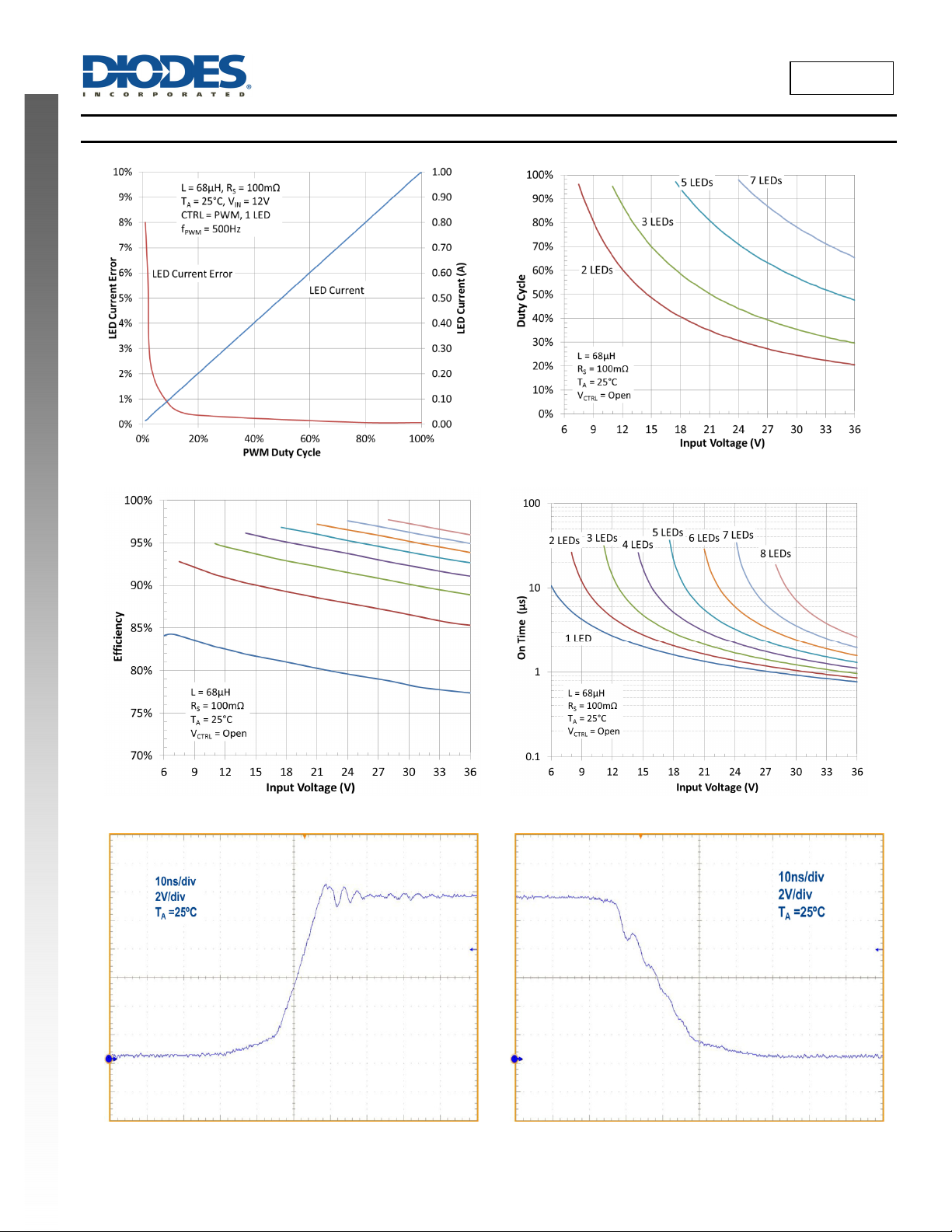

Figure 7 I

Figure 9. Efficiency vs. Input Voltage

vs. PWM Duty Cycle

LED

Figure 8. Duty Cycle vs. Input Voltage

Figure 10. On-time vs. Input Voltage

Figure. 11 SW Output Rise Time Figure. 12 SW Output Fall Time

AL88070B

Document number: DS36191 Rev. 1 - 2

5 of 18

www.diodes.com

March 2014

© Diodes Incorporated

Page 6

A

Typical Performance Characteristics

(670mA LED current) (@TA = +25°C, unless otherwise specified.)

L8807B

NEW PRODUCT

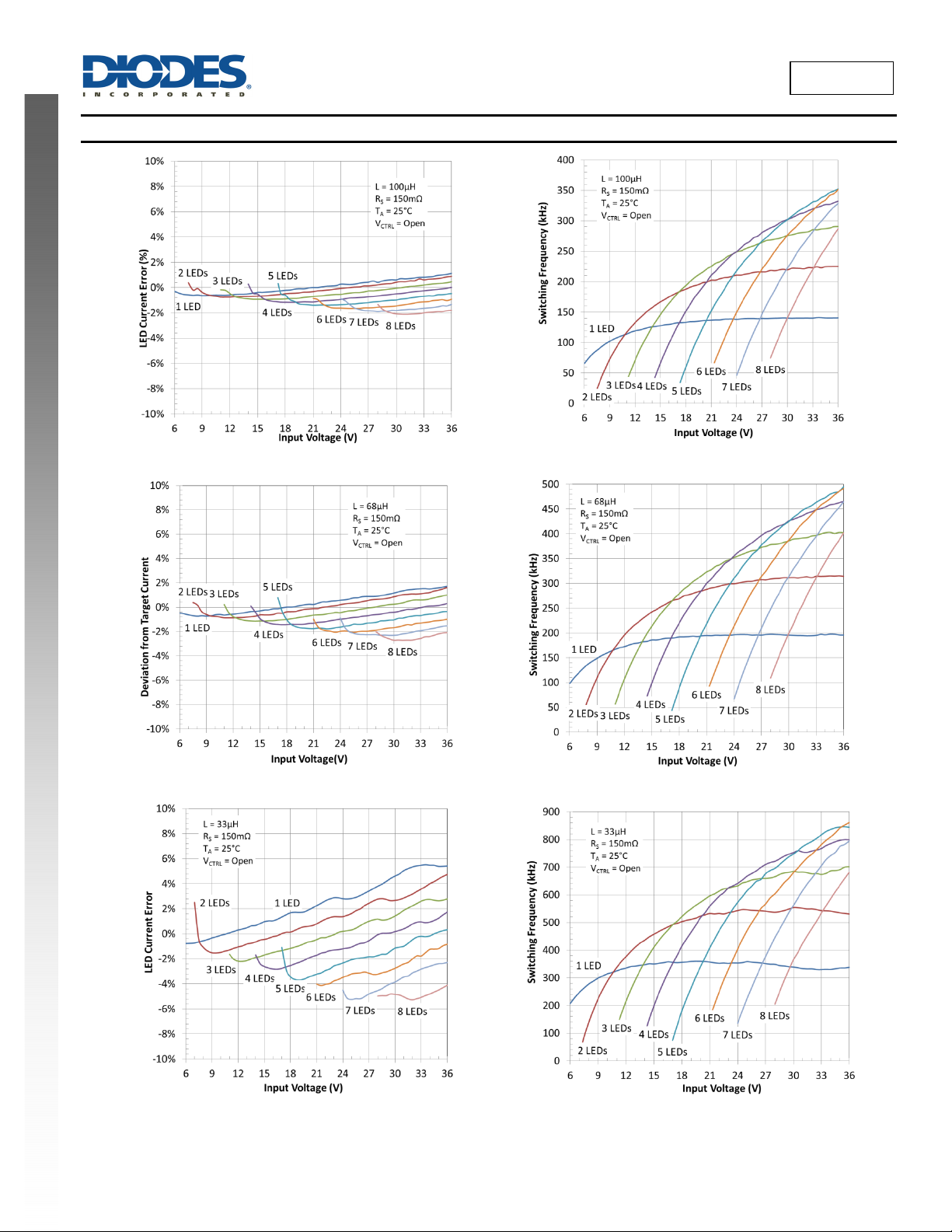

Figure 13. LED Current Deviation vs. Input Voltage

Figure 15. LED Current Deviation vs. Input Voltage

Figure 14. Switching Frequency vs. Input Voltage

Figure 16. Switching Frequency vs. Input Voltage

AL88070B

Document number: DS36191 Rev. 1 - 2

Figure 17. LED Current Deviation vs. Input Voltage

6 of 18

www.diodes.com

Figure 18. Switching Frequency vs. Input Voltage

© Diodes Incorporated

March 2014

Page 7

A

Typical Performance Characteristics

(1A LED currentMSOP-8EP) (@TA = +25°C, unless otherwise specified.)

L8807B

NEW PRODUCT

Figure 19. LED Current Deviation vs. Input Voltage

Figure 21. LED Current Deviation vs. Input Voltage

Figure 20. Switching Frequency vs. Input Voltage

Figure 22. Switching Frequency vs. Input Voltage

AL88070B

Document number: DS36191 Rev. 1 - 2

Figure 23. LED Current Deviation vs. Input Voltage

Figure 24. Switching Frequency vs. Input Voltage

7 of 18

www.diodes.com

© Diodes Incorporated

March 2014

Page 8

A

Typical Performance Characteristics

L8807B

(1.3A LED current MSOP-8EP) (@TA = +25°C, unless otherwise specified.)

NEW PRODUCT

Figure 25. LED Current Deviation vs. Input Voltage

Figure 27. LED Current Deviation vs. Input Voltage

Figure 26. Switching Frequency vs. Input Voltage

Figure 28. Switching Frequency vs. Input Voltage

AL88070B

Document number: DS36191 Rev. 1 - 2

Figure 29. LED Current Deviation vs. Input Voltage

Figure 30. Switching Frequency vs. Input Voltage

8 of 18

www.diodes.com

© Diodes Incorporated

March 2014

Page 9

A

Application Information

The AL8807B is a hysteretic (also known as equal ripple) LED driver with integrated power switch. It is available in two packages that provide a

PCB area-power dissipation capability compromise. It is recommended that at higher LED currents/smaller PCBs that the MSOP-8EP version is

used to maximize the allowable LED current over a wider ambient temperature range.

AL8807B Operation

In normal operation, when voltage is applied at +VIN, the AL8807B internal switch is turned on. Current starts to flow through sense resistor R1,

inductor L1, and the LEDs. The current ramps up linearly, and the ramp rate is determined by the input voltage +Vin and the inductor L1.

This rising current produces a voltage ramp across R

proportional voltage to the input of the internal comparator.

When this voltage reaches an internally set upper threshold, the internal switch is turned off. The inductor current continues to flow through R

the LEDs and the Schottky diode D1, and back to the supply rail, but it decays, with the rate of decay determined by the forward voltage drop of

the LEDs and the Schottky diode.

This decaying current produces a falling voltage at R

applied at the input of the internal comparator. When this voltage falls to the internally set lower threshold, the internal switch is turned on again.

This switch-on-and-off cycle continues to provide the average LED current set by the sense resistor R

NEW PRODUCT

LED Current Control

The LED current is controlled by the resistor R1 in Figure 31.

. The internal circuit of the AL8807B senses the voltage across R1 and applies a

1

, which is sensed by the AL8807B. A voltage proportional to the sense voltage across R1 is

1

.

1

L8807B

1

, L1,

R1

D1

VIN:

6 ~ 36V

C1

PWM Dimming

Input:

Figure 31 Typical Application Circuit

Connected between V

I

LED

For example for a desired LED current of 660mA and a default voltage V

1R

and SET the nominal average output current in the LED(s) is defined as:

IN

V

THD

1R

V

THD

I

LED

1.0

66.0

AL88070B

Document number: DS36191 Rev. 1 - 2

IN

V

AL8807B

GND

CTRL

m150

SETSW

C2

L1

www.diodes.com

Ch4: LED Current

VIN= 12V

=25ºC

T

A

2 LEDs

20ns/div

No C2

Ch2: 2V/div

Ch4: 100mA/div

Ch2: SW Pin

Figure 32 Typical Operating Waveform (C2 not fitted)

=2.5V the resulting resistor is:

CTRL

9 of 18

March 2014

© Diodes Incorporated

Page 10

A

L8807B

Applications Information

(cont.)

PWM Dimming

LED current can be adjusted digitally, by applying a low frequency Pulse Width Modulated (PWM) logic signal to the CTRL pin to turn the device

on and off.

This will produce an average output current proportional to the duty cycle of the control signal. In particular, a PWM signal with a max resolution of

10bit can be applied to the CTRL pin to change the output current to a value below the nominal average value set by resistor R

SET

NEW PRODUCT

While the PWM pin is high, the AL8807B switches as normal. When the PWM pin is brought low the output switch is turned off causing the SW pin

to go high (one Schottky voltage drop above V

to zero. The time taken for the inductor current is dependent on the LED current, inductor value and LED chain voltage.

As the duty cycle gets smaller or PWM dimming frequency increases then fewer normal hysteretic switching cycles occur which will affect the

overall average LED current.

Figure 33 PWM Dimming waveforms (f

). It remains high (one Schottky voltage drop above VIN) until the current through the inductor falls

IN

= 500Hz, 25% Duty Cycle f

PWM

SW(N OM)

= 530kHz)

.

To achieve high resolution the PWM frequency has to be much lower than the nominal switching frequency and the LED current output filter

capacitor across the LEDs must not be used. The figures above have an LED current output filter present.

AL88070B

Document number: DS36191 Rev. 1 - 2

Figure 34 PWM Dimming waveforms (f

www.diodes.com

= 500Hz, 2% Duty Cycle f

PWM

10 of 18

SW(N OM)

= 530kHz)

March 2014

© Diodes Incorporated

Page 11

A

L8807B

Applications Information

Figures 35 and 36 show the PWM dimming performance of the AL8807B with a range of PWM frequencies with a nominal switching frequency of

530kHz.

(cont.)

NEW PRODUCT

Looking at difference between duty cycle and percentage of full scale LED current yields a “Linearity Error”:

The accuracy of the PWM dimming is affected by both the PWM frequency and also the switching frequency of the AL8807B. For best

accuracy/resolution the switching frequency should be increased while the PWM frequency should be reduced.

The CTRL pin is designed to be driven by both 3.3V and 5V logic levels directly from a logic output with either an open drain output or push pull

output stage.

Figure 35 PWM Dimming at 530kHz nominal switching frequency

Figure 36 PWM Dimming Non-Linearity at 530kHz nominal switching frequency

AL88070B

Document number: DS36191 Rev. 1 - 2

11 of 18

www.diodes.com

March 2014

© Diodes Incorporated

Page 12

A

Applications Information

(cont.)

Reducing Output Ripple

Peak to peak ripple current in the LED(s) can be reduced, if required, by shunting a capacitor C2 across the LED(s) as shown already in the circuit

schematic.

A value of 1F will reduce the supply ripple current by a factor three (approx.). Proportionally lower ripple can be achieved with higher capacitor

values. Note that the capacitor will not affect operating frequency or efficiency, but it will increase start-up delay, by reducing the rate of rise of

LED voltage. By adding this capacitor the current waveform through the LED(s) changes from a triangular ramp to a more sinusoidal version

without altering the mean current value.

Capacitor Selection

The small size of ceramic capacitors makes them ideal for AL8807B applications. X5R and X7R types are recommended because they retain their

capacitance over wider voltage and temperature ranges than other types such as Z5U.

A 2.2F input capacitor is sufficient for most intended applications of AL8807B; however a 4.7F input capacitor is suggested for input voltages

approaching 36V.

Diode Selection

For maximum efficiency and performance, the rectifier (D1) should be a fast low capacitance Schottky diode with low reverse leakage at the

NEW PRODUCT

maximum operating voltage and temperature. The Schottky diode also provides better efficiency than silicon PN diodes, due to a combination of

lower forward voltage and reduced recovery time.

It is important to select parts with a peak current rating above the peak coil current and a continuous current rating higher than the maximum

output load current. In particular, it is recommended to have a diode voltage rating at least 15% higher than the operating voltage to ensure safe

operation during the switching and a current rating at least 10% higher than the average diode current. The power rating is verified by calculating

the power loss through the diode.

Schottky diodes, e.g. B240 or B140, with their low forward voltage drop and fast reverse recovery, are the ideal choice for AL8807B applications.

Inductor Selection

Recommended inductor values for the AL8807B are in the range 33H to 100H.

Higher values of inductance are recommended at higher supply voltages in order to minimize errors due to switching delays, which result in

increased ripple and lower efficiency. Higher values of inductance also result in a smaller change in output current over the supply voltage range.

(See graphs).

L8807B

The inductor should be mounted as close to the device as possible with low resistance/stray inductance connections to the SW pin.

AL88070B

Document number: DS36191 Rev. 1 - 2

Figure 37 Inductor value with input voltage and number of LEDs

12 of 18

www.diodes.com

March 2014

© Diodes Incorporated

Page 13

A

Applications Information (cont.)

Inductor Selection (cont.)

The chosen coil should have a saturation current higher than the peak output current and a continuous current rating above the required mean

output current.

Suitable coils for use with the AL8807B are listed in the table below:

Part No.

L

(µH)

MSS1038-333 33 0.093 2.3

MSS1038-683 68 0.213 1.5

DCR

(V)

I

SAT

(A)

Manufacturer

CoilCraft www.coilcraft.com

NPIS64D330MTRF 33 0.124 1.1 NIC www.niccomp.com

The inductor value should be chosen to maintain operating duty cycle and switch 'on'/'off' times over the supply voltage and load current range.

The following equations can be used as a guide, with reference to Figure 38 – typical switching waveforms.

Switch ‘On’ time

t

ON

NEW PRODUCT

Switch ‘Off’ time

Where:

L is the coil inductance (H)

r

R

I

I is the coil peak-peak ripple current (A)

{Internally set to 0.3 x Iavg}

V

V

R

V

t

OFF

is the coil resistance ()

L

is the current sense resistance ()

S

is the required LED current (A)

avg

is the supply voltage (V)

IN

is the total LED forward voltage (V)

LED

is the switch resistance () {=0.5 nominal}

SW

is the diode forward voltage at the required load current (V)

D

IL

x

IVV

IL

x

IVV

RrR

SWLSAVGLEDIN

rR

LSAVGDLED

Figure 38 Typical Switching Waveform

Off

VIN= 12V

T

=25ºC

A

2 LEDs

20ns/div

SW Pin: 2V/div

On

Thermal Protection

The AL8807B includes Over-Temperature Protection (OTP) circuitry that will turn off the device if its junction temperature gets too high. This is to

protect the device from excessive heat damage. The OTP circuitry includes thermal hysteresis that will cause the device to restart normal

operation once its junction temperature has cooled down by approximately 55°C.

Thermal Considerations

For continuous conduction mode of operation, the absolute maximum junction temperature must not be exceeded. The maximum power

dissipation depends on several factors: the thermal resistance of the IC package

between junction and ambient temperature.

The maximum power dissipation can be calculated using the following formula:

where

P

= (T

D(MAX)

is the maximum operating junction temperature Maximum recommended = 125°C

T

J(MAX)

is the ambient temperature, and

T

A

is the junction to ambient thermal resistance.

JA

J(MAX)

TA) /

JA

, is layout dependent and package dependent; the AL8807BMP’s JA on an FR4 51x51mm PCB with 2oz copper standing in still air is

JA

approximately 69°C/W.

So the maximum power dissipation at T

= (125°C 25°C) / (69°C/W) = 1.41W for the above dimensioned PCB

P

D(MAX)

= +25°C is:

A

AL88070B

Document number: DS36191 Rev. 1 - 2

13 of 18

www.diodes.com

, PCB layout, airflow surrounding the IC, and difference

JA

© Diodes Incorporated

L8807B

March 2014

Page 14

A

L8807B

Applications Information

Figure 39, shows the power derating of the AL8807BMP on an FR4 51x51mm PCB with 2oz copper standing in still air. Changing the PCB

dimensions, material, amount of metal associated with the thermal and other PCB components will change the AL8807BMP’s junction-ambient

thermal impedance.

NEW PRODUCT

(cont.)

1600

1400

1200

1000

800

600

400

Power dissipation (mW)

200

0

-40 -25 -10 5 20 35 50 65 80 95 110 125

Figure 39 Derating Curve for Different PCB

MSOP-8EP

Ambient temperature (°C)

Soft-Start

The AL8807B does not have in-built soft-start action; this can be seen in Figure 40.

Figure 40 LED Current Start-up (V

At power–up V

Out turn-on threshold at around 5.6V. This causes the CTRL pin voltage to rise and reaches 2.5V – 100% LED current - before the AL8807B

fully turns on. When the AL8807B turns on, its output switch turns on causing the inductor current to increase until it reaches the upper threshold

of the sense current level and the switching process begins.

As the CTRL pin only has PWM functionality, placing a capacitor on the CTRL pin will have no effect on the ramp-up of the LED current; the

capacitor will just delay the ramp-up of the LED current and delay/extend the ramp-down of the LED current.

If some form of extra soft-start is required then the AL8807, AL8807A or PAM2861 should be considered.

AL88070B

Document number: DS36191 Rev. 1 - 2

rises exponentially, due to the bulk capacitor, the internal reference will reach 2.5V before VIN reaches the Under-Voltage Lock-

IN

www.diodes.com

IN

14 of 18

= 12V, I

= 667mA, 2 LEDs)

LED

March 2014

© Diodes Incorporated

Page 15

A

L8807B

Applications Information (cont.)

EMI and Layout Considerations

The AL8807B is a switching regulator with fast edges and measures small differential voltages; as a result of this care has to be taken with

decoupling and layout of the PCB.To help with these effects the AL8807B has been developed to minimise radiated emissions by controlling the

switching speeds of the internal power MOSFET. The rise and fall times are controlled to get the right compromise between power dissipation

due to switching losses and radiated EMI. The turn-on edge (falling edge) dominates the radiated EMI which is due to an interaction between the

Schottky diode (D1), Switching MOSFET and PCB tracks. After the Schottky diode reverse recovery time of around 5ns has occurred; the falling

edge of the SW pin sees a resonant loop between the Schottky diode capacitance and the track inductance, L

The tracks from the SW pin to the Anode of the Schottky diode, D1, and then from D1’s cathode to the decoupling capacitors C1 should be as

short as possible. There is an inductance internally in the AL8807B this can be assumed to be around 1nH. For PCB tracks a figure of 0.5nH per

mm can be used to estimate the primary resonant frequency. If the track is capable of handling 1A increasing the thickness will have a minor

effect on the inductance and length will dominate the size of the inductance. The resonant frequency of any oscillation is determined by the

combined inductance in the track and the effective capacitance of the Schottky diode.

An example of good layout is shown in Figure 42 (showing SOT25 package) - the stray track inductance should be less than 5nH.

, See Figure 41.

TRACK

NEW PRODUCT

D1

C

D1

L

TRAC K

~5nH

SW

C

1

100nF

AL8807B

GND

Figure 41 PCB Loop Resonance

Recommendations for minimising radiated EMI and other transients and thermal considerations are:

1. The decoupling capacitor (C1) has to be placed as close as possible to the V

2. The freewheeling diode’s (D1) anode, the SW pin and the inductor have to be placed as close as possible to each other to avoid ringing.

3. The Ground return path from C1 must be a low impedance path with the ground plane as large as possible

4. The LED current sense resistor (R1) has to be placed as close as possible to the V

5. The majority of the conducted heat from the AL8807B is through the GND pin 2. A maximum earth plane with thermal vias into a

second earth plane will minimise self-heating

6. To reduce emissions via long leads on the supply input and LEDs low RF impedance capacitors (C2 and C5) should be used at the

point the wires are joined to the PCB

AL88070B

Document number: DS36191 Rev. 1 - 2

15 of 18

www.diodes.com

Figure 42 Recommended PCB Layout

pin and D1 Cathode

IN

and SET pins.

IN

March 2014

© Diodes Incorporated

Page 16

A

L8807B

Applications Information

(cont.)

Fault Condition Operation

Open Circuit LEDs

The AL8807B has by default open LED protection. If the LEDs should become open circuit the AL8807B will stop oscillating; the SET pin will rise

to VIN and the SW pin will then fall to GND. No excessive voltages will be seen by the AL8807B.

LED Chain Shorted Together

If the LED chain should become shorted together (the anode of the top LED becomes shorted to the cathode of the bottom LED) the AL8807B will

continue to switch and the current through the AL8807B’s internal switch will still be at the expected current - so no excessive heat will be

generated within the AL8807B. However, the duty cycle at which it operates will change dramatically and the switching frequency will most likely

decrease. See Figure 43 for an example of this behavior at 24V input voltage driving 3 LEDs.

The on-time of the internal power MOSFET switch is significantly reduced because almost all of the input voltage is now developed across the

inductor. The off-time is significantly increased because the reverse voltage across the inductor is now just the Schottky diode voltage (See Figure

43) causing a much slower decay in inductor current.

NEW PRODUCT

Figure 43 Switching Characteristics (normal operation to LED chain shorted out)

High Temperature Operation and Protection

The AL8807B is a high efficiency switching LED driver capable of operating junction temperatures up to +125°C. This allows it operate with

ambient temperature in excess of +100°C given the correct thermal impedance to free air. If a fault should occur that leads to increased ambient

temperatures and hence junction temperature then the Over-Temperature Protection (OTP) of the AL8807B will cut-in, turning the output of the

AL8807B off. This will allow the junction temperature of the AL8807B to cool down and potentially giving an opportunity for the fault to clear itself.

The OTP shutdown junction temperature of the AL8807B is approximately +155°C with a hysteresis of +55°C. This means that the AL8807B will

never switch-off with a junction temperature below +125°C allowing the designer to design the system thermally to fully utilize the wide operating

junction temperature of the AL8807B.

AL88070B

Document number: DS36191 Rev. 1 - 2

www.diodes.com

16 of 18

March 2014

© Diodes Incorporated

Page 17

A

Ordering Information

L8807B

Part Number Package Code Packaging

AL8807BMP-13 MP MSOP-8EP 2500 12mm -13

Marking Information

(1) MSOP-8EP

NEW PRODUCT

(Top View)

8 7 6 5

Logo

Part Number

AL8807B

Y W X E

1 2 3 4

Part Number Package

AL8807BMP-13 MSOP-8EP

Package Outline Dimensions

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

(1) MSOP-8EP

D

(All dimensions in mm.)

x

y

E

E2

1

e

A1

A

D

8Xb

A3

A2

D1

E3

E1

Gauge Plane

Seating Plane

See Detail C

0.25

4

X

1

0

°

Detail C

c

Packing: 13” Tape and Reel

Quantity Tape Width Part Number Suffix

A~Z : Green

MSOP-8EP

Y : Year : 0~9

W : Week: A~Z : 1~26 week;

a~z : 27~52 week;

z represents 52 and 53 week

MSOP-8EP

Dim Min Max Typ

A - 1.10 -

4

X

1

0

°

a

L

A1 0.05 0.15 0.10

A2 0.75 0.95 0.86

A3 0.29 0.49 0.39

b 0.22 0.38 0.30

c 0.08 0.23 0.15

D 2.90 3.10 3.00

D1 1.60 2.00 1.80

E 4.70 5.10 4.90

E1 2.90 3.10 3.00

E2 1.30 1.70 1.50

E3 2.85 3.05 2.95

e - - 0.65

L 0.40 0.80 0.60

a 0° 8° 4°

x - - 0.750

y - - 0.750

All Dimensions in mm

AL88070B

Document number: DS36191 Rev. 1 - 2

17 of 18

www.diodes.com

March 2014

© Diodes Incorporated

Page 18

A

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

1) MSOP-8EP

X C

NEW PRODUCT

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

G

Y2

X1

AL88070B

Document number: DS36191 Rev. 1 - 2

Y

Y1

IMPORTANT NOTICE

LIFE SUPPORT

18 of 18

www.diodes.com

Dimensions

C 0.650

G 0.450

X 0.450

X1 2.000

Y 1.350

Y1 1.700

Y2 5.300

Value

(in mm)

© Diodes Incorporated

L8807B

March 2014

Loading...

Loading...