Page 1

A

L5802

Description

The AL5802 combines a high gain NPN transistor with a pre-biased

NPN transistor to make a simple small footprint LED driver.

The LED current is set by an external resistor connected from REXT

pin (6) to GND pin (4), the internal high gain transistor develops

approximately 0.6V across the external resistor.

The AL5802 open-collector output can operate from 0.8V to 30V

enabling it to operate from 5V to 24V power supplies without

additional components.

PWM dimming of the LED current can be achieved by either driving

NEW PRODUCT

the BIAS pin (2) with a low impedance voltage source, or driving the

EN pin (3) with an external open-collector NPN transistor or opendrain N-channel MOSFET.

The AL5802 is available in a SOT26 package and is ideal for driving

20mA to 120mA LED currents.

Features

ADVANCE INFORMATION

Reference voltage VRSET = 0.65V

-40 to +125°C temperature range

0.8V to 30V open-collector output

Negative temperature co-efficient – automatically reduces the

LED current at high temperatures

Low thermal impedance SOT26 with copper leadframe

Totally Lead-Free & Fully RoHS Compliant (Notes 1 & 2)

Halogen and Antimony Free. “Green” Device (Note 3)

Qualified to AEC-Q101 Standards for High Reliability

30V, ADJUSTABLE CURRENT SINK LINEAR LED DRIVER

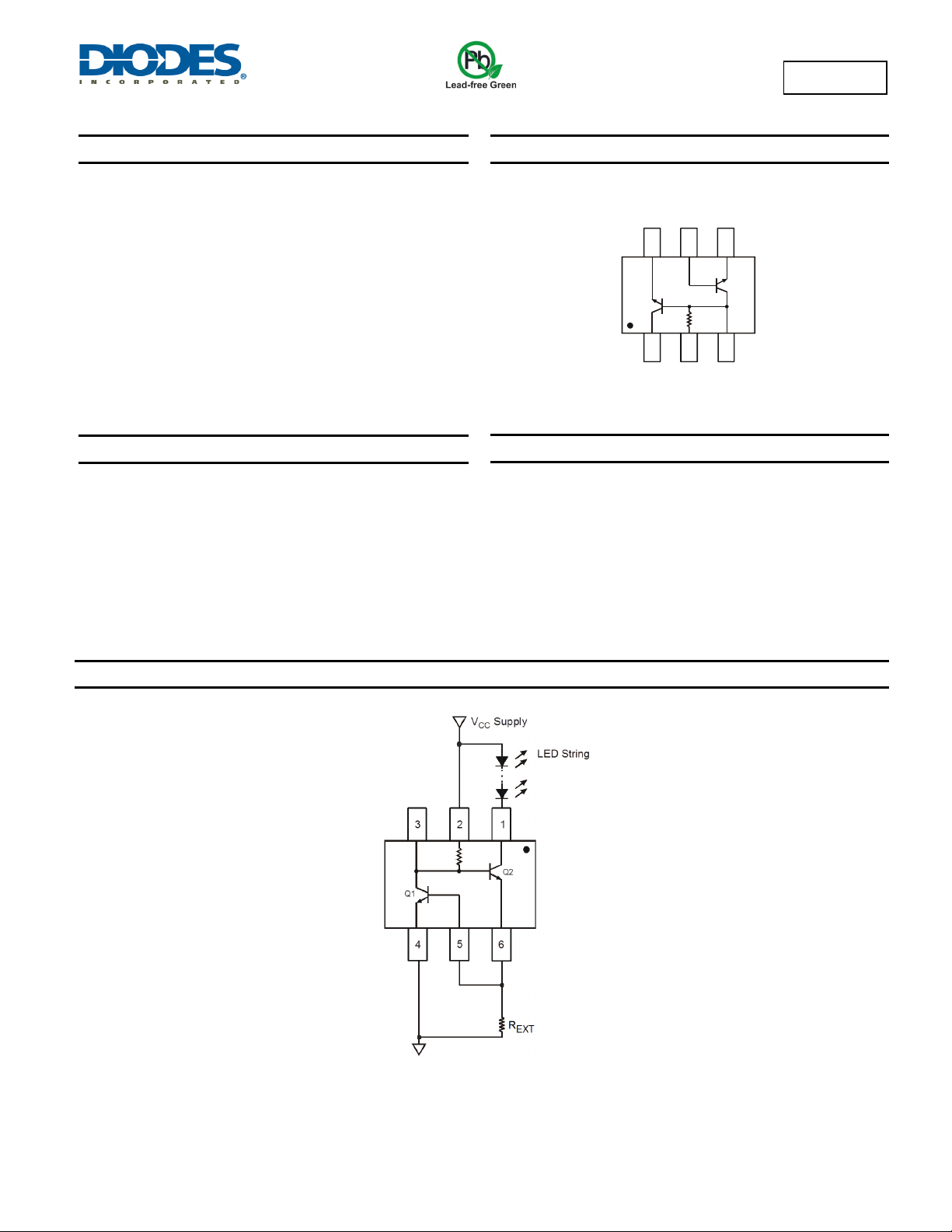

Pin Assignments

(Top View)

654

Q1

Q2

123

SOT26

Applications

Linear LED driver

LED signs

Offline LED luminaries

Typical Application Circuit

Notes: 1. No purposely added lead. Fully EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant.

2. See http://www.diodes.com/quality/lead_free.html for more information about Diodes Incorporated’s definitions of Halogen- and Antimony-free, "Green"

and Lead-free.

3. Halogen- and Antimony-free "Green” products are defined as those which contain <900ppm bromine, <900ppm chlorine (<1500ppm total Br + Cl) and

<1000ppm antimony compounds.

AL5802

Document number: DS35516 Rev. 9 - 2

1 of 11

www.diodes.com

March 2014

© Diodes Incorporated

Page 2

A

Pin Descriptions

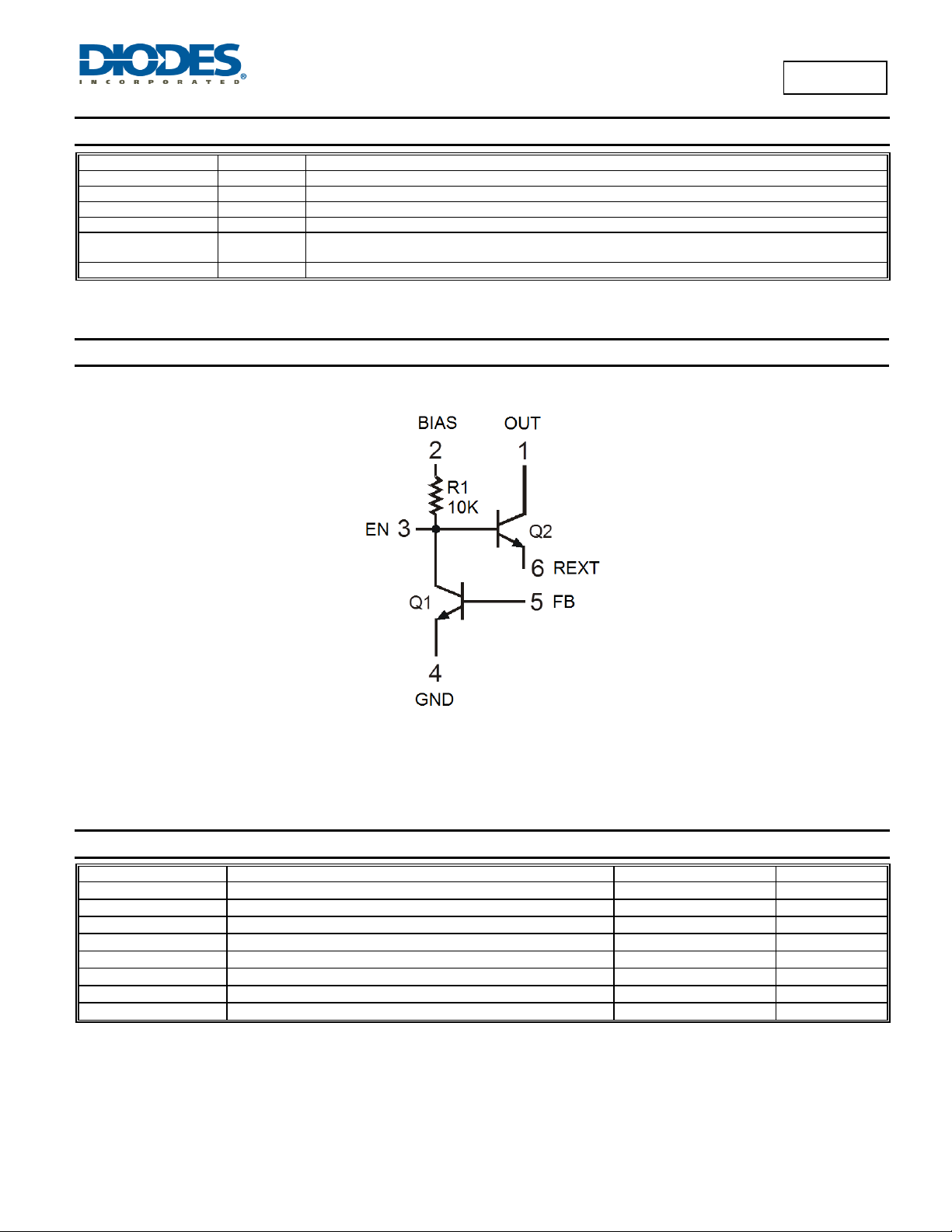

Pin Number Name Function

1 OUT Open-collector LED driver output

2 BIAS Biases the open collector output transistor

3 EN Enable pin for PWM dimming. Provides access to the base of Q2 and collector of Q1

4 GND Ground reference point for setting LED current

5 FB

6 REXT Current sense pin. LED current sensing resistor should be connected from here to GND.

NEW PRODUCT

Functional Block Diagram

ADVANCE INFORMATION

L5802

Feedback pin.

Should be connected to pin 6.

Fig. 1 Block Diagram

Absolute Maximum Ratings

Symbol Characteristics Values Unit

V

OUT

V

BIAS

V

FB

V

EN

V

REXT

I

OUT

T

J

T

ST

These are stress ratings only. Operation outside the absolute maximum ratings may cause device failure.

Operation at the absolute maximum rating for extended periods may reduce device reliability.

Note: 4. With pins 5 and 6 connected together.

AL5802

Document number: DS35516 Rev. 9 - 2

Output voltage relative to GND

BIAS voltage relative to GND (Note 4)

LED voltage relative to GND

EN voltage relative to GND

REXT voltage relative to GND

Output current

Operating junction temperature

Storage temperature

2 of 11

www.diodes.com

30 V

30 V

6 V

6 V

6 V

150 mA

-40 to +150 °C

-55 to +150 °C

March 2014

© Diodes Incorporated

Page 3

A

(BR)

(BR)

)

)

(BR)

(BR)

(BR)

)

L5802

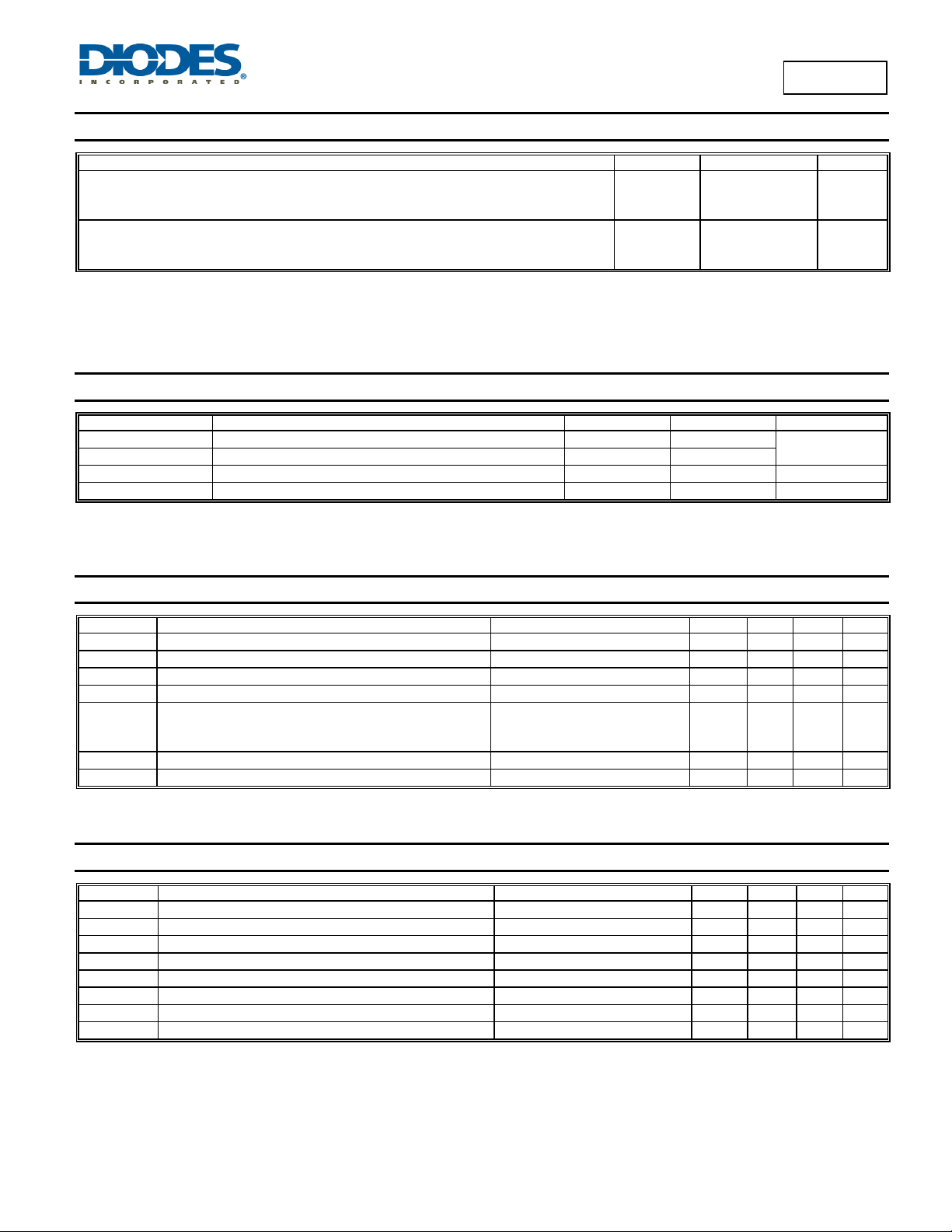

Package Thermal Data

Characteristic Symbol Value Unit

Power Dissipation (Note 5) @ TA = +25°C

Power Dissipation (Note 6) @ T

Power Dissipation (Note 7) @ T

= +25°C

A

= +25°C

A

P

D

Thermal Resistance, Junction to Ambient Air (Note 5) @ TA = +25°C

Thermal Resistance, Junction to Ambient Air (Note 6) @ T

Thermal Resistance, Junction to Ambient Air (Note 7) @ T

Notes: 5. Device mounted on FR-4 PCB, 2oz with minimum recommended pad layout.

6. Device mounted on 25mm x 25mm 2oz copper board.

7. Device mounted on 50mm x 50mm 2oz copper board.

NEW PRODUCT

= +25°C

A

= +25°C

A

R

θJA

0.37

0.87

1

335

143

120

W

°C/W

Recommended Operating Conditions

Symbol Parameter Min Max Unit

V

BIAS

V

ADVANCE INFORMATION

I

OUT

LED

TA

Note: 8. Subject to ambient temperature, power dissipation and PCB.

Electrical Characteristics – NPN Transistor – Q1 (@T

Symbol Characteristic Test Condition Min Typ Max Unit

V

V

I

V

CE(SAT

V

BE(SAT

CEX

IBL

hFE

Collector-Emitter Breakdown Voltage (Note 9)

CEO

Emitter-Base Breakdown Voltage

EBO

Collector Cutoff Current

Base Cutoff Current

DC Current Gain

Collector-Emitter Saturation Voltage (Note 9)

Base-Emitter Saturation Voltage

Electrical Characteristics – NPN Pre-biased Transistor – Q2 (@T

Symbol Characteristic Test Condition Min Typ Max Unit

V

V

V

I

CBO

I

EBO

V

CE(SAT

hFE

R1

*Characteristics of transistor only.

Note: 9. Short duration pulse test used to minimize self-heating effect.

AL5802

Document number: DS35516 Rev. 9 - 2

Collector-Base Breakdown Voltage

CBO

Collector-Emitter Breakdown Voltage (Note 9)

CEO

Emitter-Base Breakdown Voltage

EBO

Collector Cut-Off Current

Emitter Cut-Off Current

Collector-Emitter Saturation Voltage (Note 9)

DC Current Gain (Note 9)

Input Resistance — 7 10 13 kΩ

Supply voltage range 4.5 30

OUT voltage range 0.8 30

V

LED pin current (Note 8) 10 120 mA

Operating ambient temperature range -40 +125 °C

= +25°C, unless otherwise specified.)

A

IC = 1.0mA, IB = 0

IE = 10µA, IC = 0

VCE = 30V, V

VCE = 30V, V

= 100µA, VCE = 1.0V

I

C

= 1.0mA, VCE = 1.0V

I

C

I

= 10mA, VCE = 1.0V

C

IC = 10mA, IB = 1.0mA

IC = 10mA, IB = 1.0mA

IC = 50μA, IE = 0

IC = 1mA, IB = 0

IE = 50μA, IC = 0

VCB = 30V, IE = 0

V

= 4V, IC = 0

EB

IC = 10mA, IB = 1mA

VCE = 5V, IC = 150mA

3 of 11

www.diodes.com

EB(OFF)

EB(OFF)

= 3.0V

= 3.0V

= +25°C, unless otherwise specified.)

A

40 — — V

6.0 — — V

— — 50 nA

— — 50 nA

40

70

100

—

—

—

—

—

300

— — 0.20 V

0.65 — 0.85 V

30 — — V

30 — — V

5.0 — — V

— — 0.5 µA

— — 0.5 µA

— — 0.3 V

100 — — —

March 2014

© Diodes Incorporated

—

Page 4

A

Thermal Characteristics

NEW PRODUCT

ADVANCE INFORMATION

AMBIENT TEMPERAURE (°C)

Fig. 2 Derating Curve

L5802

Fig. 3 Max Power vs. Area

Fig. 4 Thermal Resistance vs. Area

AL5802

Document number: DS35516 Rev. 9 - 2

4 of 11

www.diodes.com

March 2014

© Diodes Incorporated

Page 5

A

Typical Performance Characteristics

NEW PRODUCT

L5802

Fig. 5 Output Current vs. V

Fig. 6 Output Current vs. R

out

EXT

ADVANCE INFORMATION

Fig. 7 Output Current vs. V

out

Fig. 8 Output Current vs. V

out

Fig. 9 Output Current vs. V

Note: 10. V

in the “Output current Vs V

out

AL5802

Document number: DS35516 Rev. 9 - 2

Fig. 10 Output Current vs. V

out

” graphs limited by power dissipation in the device.

out

5 of 11

www.diodes.com

bias

© Diodes Incorporated

March 2014

Page 6

NEW PRODUCT

A

L5802

ADVANCE INFORMATION

AL5802

Document number: DS35516 Rev. 9 - 2

Fig. 11 Output Current vs. V

Fig. 13 Output Current vs. V

bias

bias

6 of 11

www.diodes.com

Fig. 12 Output Current vs. V

bias

March 2014

© Diodes Incorporated

Page 7

A

Application Information

NEW PRODUCT

ADVANCE INFORMATION

Fig. 14 Typical Application Circuit for

Linear Mode Current Sink LED Driver

L5802

The AL5802 has been designed for driving low current LEDs with typical

LED current of 20mA to 100mA. It provides a cost effective way for

driving low current LEDs compared with more complex switching

regulator solutions. Furthermore, it reduces the PCB board area of the

solution as there is no need for external components like inductors,

capacitors and switching diodes.

Figure 14 shows a typical application circuit diagram for driving an LED

or string of LEDs. The NPN transistor Q1 measures the LED current by

sensing the voltage across an external resistor R

reference to set the voltage across R

and controls the base current

EXT

into Q2. Q2 operates in linear mode to regulate the LED current. The

LED current is

= V

I

LED

BE(Q1)

/ R

EXT

From this, for any required LED current the necessary external resistor

can be calculated from

R

EXT

= V

R

EXT

BE(Q1)

/ I

LED

Two or more AL5802 can be connected in parallel to construct higher

current LED strings as shown in Figure 15.

Consideration of the expected linear mode power dissipation must be

factored into the design, with respect to the AL5802's thermal

resistance. The maximum voltage across the device can be calculated

by taking the maximum supply voltage less the voltage across the LED

string.

V

P

CE(Q2)

= V

D

= VCC – V

* I

CE(Q2)

LED

+ ( VCC – V

LED

– V

BE(Q1)

BE(Q2)

– V

BE(Q1)

As the output current of AL5802 increases, it is necessary to provide

appropriate thermal relief to the device. The power dissipation

supported by the device is dependent upon the PCB board material, the

copper area and the ambient temperature. The maximum dissipation

the device can handle is given by:

P

= ( T

D

J(MAX)

- TA) /R

θJA

Refer to the thermal characteristic graphs on page 4 for selecting the

appropriate PCB copper area.

. Q1 uses its VBE as

EXT

)2 / R1

Fig. 15 Application Circuit for Increasing LED Current

AL5802

Document number: DS35516 Rev. 9 - 2

7 of 11

www.diodes.com

March 2014

© Diodes Incorporated

Page 8

A

PWM dimming can be achieved by driving the EN pin. An external open-collector NPN transistor or open-drain N-channel MOSFET can be used

to drive the EN pin as shown in Figure 16. Dimming is achieved by turning the LEDs ON and OFF for a portion of a single cycle. The PWM

signal can be provided by a micro-controller or analog circuitry. Figure 17 is a typical response of LED current vs. PWM duty cycle on the EN pin.

NEW PRODUCT

-or-

ADVANCE INFORMATION

L5802

AL5802

Document number: DS35516 Rev. 9 - 2

Fig. 16 Application Circuits for LED Driver with PWM Dimming Functionality

60

50

40

30

20

LED CURRENT (mA)

10

0

Fig. 17 Typical LED current response vs. PWM duty cycle for

200

PWM DUTY CYCLE (%)

= 13Ω at 400Hz PWM frequency

R

EXT

40 60 80 100

8 of 11

www.diodes.com

March 2014

© Diodes Incorporated

Page 9

NEW PRODUCT

A

A

A

ADVANCE INFORMATION

L5802

SDM10U45LP

V

S

L5802

R

S

Fig. 18 Application circuit for LED driver

with reverse polarity protection

V

S

BAS40BRW

L5802

To remove the potential of incorrect connection of the power supply

damaging the lamp’s LEDs, many systems use some form of

reverse polarity protection.

One solution for reverse input polarity protection is to simply use a

diode with a low V

increases the available voltage to the LED stack and dissipates

V

F

less power. A circuit example is presented in Fig. 18 using Diodes

Inc. SBR® (Super Barrier Rectifier) technology. An SDM10U45LP

(0.1A/45V) is shown, providing exceptionally low V

size of 1mm x 0.6mm, equivalent to an 0402 chip style package.

Other reverse voltage ratings are also available in Diodes’ website

such as the SBR02U100LP (0.2A/100V) or SBR0220LP (0.2A/20V).

Automotive applications commonly use this method for reverse

battery protection.

A second approach, shown in Fig. 19, improves upon the method

shown in Fig. 18. Whereas the method in Fig. 18 protects the light

engine, it will not function until the problem has been diagnosed and

corrected.

The method shown in Fig. 19 not only provides reverse polarity

protection, it also corrects the reversed polarity, allowing the light

engine to function.

The BAS40BRW incorporates four low V

single package and allows more voltage available for the LED stack

and dissipates less power that standard rectifier bridges.

in-line with the driver/LED combination. The low

F

for its package

F

, Schottky diodes into a

F

Fig. 19 Application circuit for LED driver with

assured operation regardless of polarity

AL5802

Document number: DS35516 Rev. 9 - 2

R

S

9 of 11

www.diodes.com

March 2014

© Diodes Incorporated

Page 10

A

Ordering Information (Note 11)

Device Qualification Packaging

AL5802 Commercial SOT26 3,000/Tape & Reel -7

AL5802 Commercial SOT26 10,000/Tape & Reel -13

Note: 11. For packaging details, go to our website at http://www.diodes.com/products/packages.html.

Marking Information

NEW PRODUCT

L102 = Product Type Marking Code

YM = Date Code Marking

Y = Year (ex: B = 2014)

M = Month (ex: 9 = September)

ADVANCE INFORMATION

L102

Date Code Key

Year 2011 2012 2013 2014 2015 2016 2017 2018 2019

Code Y Z A B C D E F G

Month Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Code 1 2 3 4 5 6 7 8 9 O N D

YM

Package Outline Dimensions

Please see AP02002 at http://www.diodes.com/datasheets/ap02002.pdf for latest version.

K

J

A

B C

H

M

D

L

Suggested Pad Layout

Please see AP02001 at http://www.diodes.com/datasheets/ap02001.pdf for the latest version.

G

Z

C2

C2

C1

AL5802

Document number: DS35516 Rev. 9 - 2

Y

X

10 of 11

www.diodes.com

Quantity Part Number Suffix

Tape and Reel

Dim Min Max Typ

Dimensions Value (in mm)

Z 3.20

G 1.60

X 0.55

Y 0.80

C1 2.40

C2 0.95

SOT26

A 0.35 0.50 0.38

B 1.50 1.70 1.60

C 2.70 3.00 2.80

D

H 2.90 3.10 3.00

J 0.013 0.10 0.05

K 1.00 1.30 1.10

L 0.35 0.55 0.40

M 0.10 0.20 0.15

0° 8°

All Dimensions in mm

0.95

L5802

March 2014

© Diodes Incorporated

Page 11

A

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS DOCUMENT,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

(AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other changes

without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability arising out of the

application or use of this document or any product described herein; neither does Diodes Incorporated convey any license under its patent or

trademark rights, nor the rights of others. Any Customer or user of this document or products described herein in such applications shall assume

all risks of such use and will agree to hold Diodes Incorporated and all the companies whose products are represented on Diodes Incorporated

website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized sales

NEW PRODUCT

channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall indemnify and

hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees arising out of, directly or

indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names and markings

noted herein may also be covered by one or more United States, international or foreign trademarks.

This document is written in English but may be translated into multiple languages for reference. Only the English version of this document is the

final and determinative format released by Diodes Incorporated.

ADVANCE INFORMATION

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without the express

written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected to cause the

failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or systems, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any

use of Diodes Incorporated products in such safety-critical, life support devices or systems, notwithstanding any devices- or systems-related

information or support that may be provided by Diodes Incorporated. Further, Customers must fully indemnify Diodes Incorporated and its

representatives against any damages arising out of the use of Diodes Incorporated products in such safety-critical, life support devices or

systems.

Copyright © 2014, Diodes Incorporated

www.diodes.com

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided in the

IMPORTANT NOTICE

LIFE SUPPORT

L5802

AL5802

Document number: DS35516 Rev. 9 - 2

11 of 11

www.diodes.com

March 2014

© Diodes Incorporated

Loading...

Loading...