Page 1

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

Description

The AH5794 is a single chip solution for driving single-coil

brushless direct current (BLDC) fans and motors. The

integrated full-bridge driver output stage uses soft switching to

minimize audible switching noise and electromagnetic

interference (EMI) providing a low noise solution.

Low operating voltage down to 1.8V allows motor speed to be

controlled by varying the supply voltage.

To help protect the motor coil, the AH5794 provides Rotor

Lock Protection which shuts down the output drive if rotor lock

is detected. The device automatically re-starts when the rotor

lock is removed. Over temperature shutdown provides

thermal protection for the device.

A Tachometer output is provided by open-drain Frequency

NEW PRODUCT

Generator (FG) Pin which allows external interface to monitor

motor rotation or speed. The FG output is the magnetic

change frequency.

The AH5794 is available in space saving and low profile

TSOT26 and U-DFN2020C-6 packages.

Features

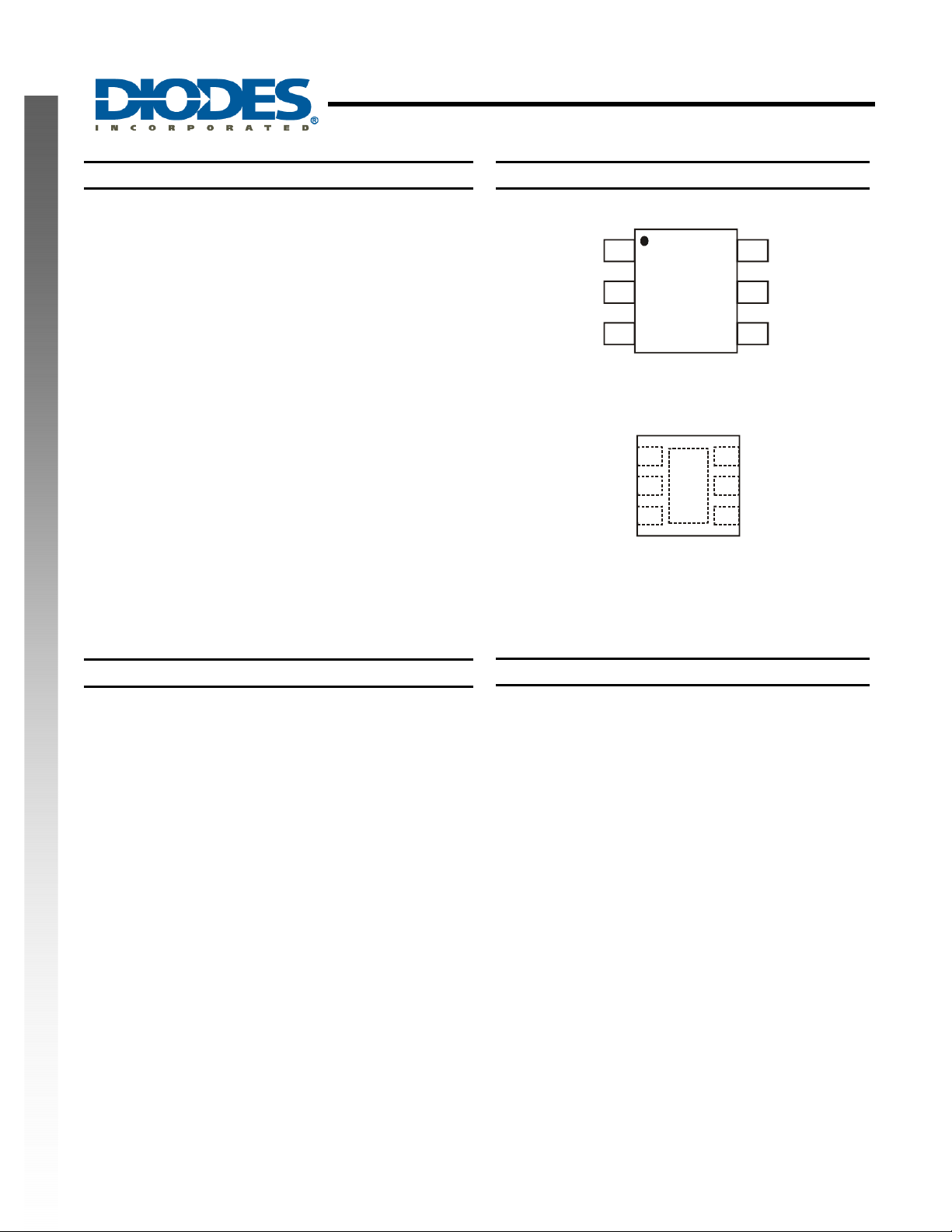

Pin Assignments

1

2

V

SS

3

O2

NC

V

DD

O1

U-DFN2020C-6

Applications

(Top View)

TSOT26

(Top View)

1

2

3

AH5794

6

NCFG

V

5

DD

O1

4

FG

6

O2

5

V

4

SS

• Supports single-coil full-wave BLDC fan drivers

• Built-in Hall sensor and input amplifier

• Operating voltage: 1.8V to 6V

• VDD voltage speed control

• Soft switching for low noise DC fan motor applications

• Rotor Lock Protection (Lock detection, output shutdown

and automatic re-start)

• Thermal protection

• Tachometer (FG) output

• No external timing capacitor - Reduces the numbers of

external components required

• Low profile package: TSOT26 and U-DFN2020C-6

• Halogen and Antimony free “Green” packages.

• Lead Free Finish/ RoHS Compliant

AH5794

Document number: DS35809 Rev. 1 - 2

www.diodes.com

• 3V/ 3.3V/ 5V BLDC Cooling Fans

• Netbook/ Notebook BLDC fans

• Instruments cooling fans

• Low Voltage/ Low Power BLDC Motors

1 of 13

March 2012

© Diodes Incorporated

Page 2

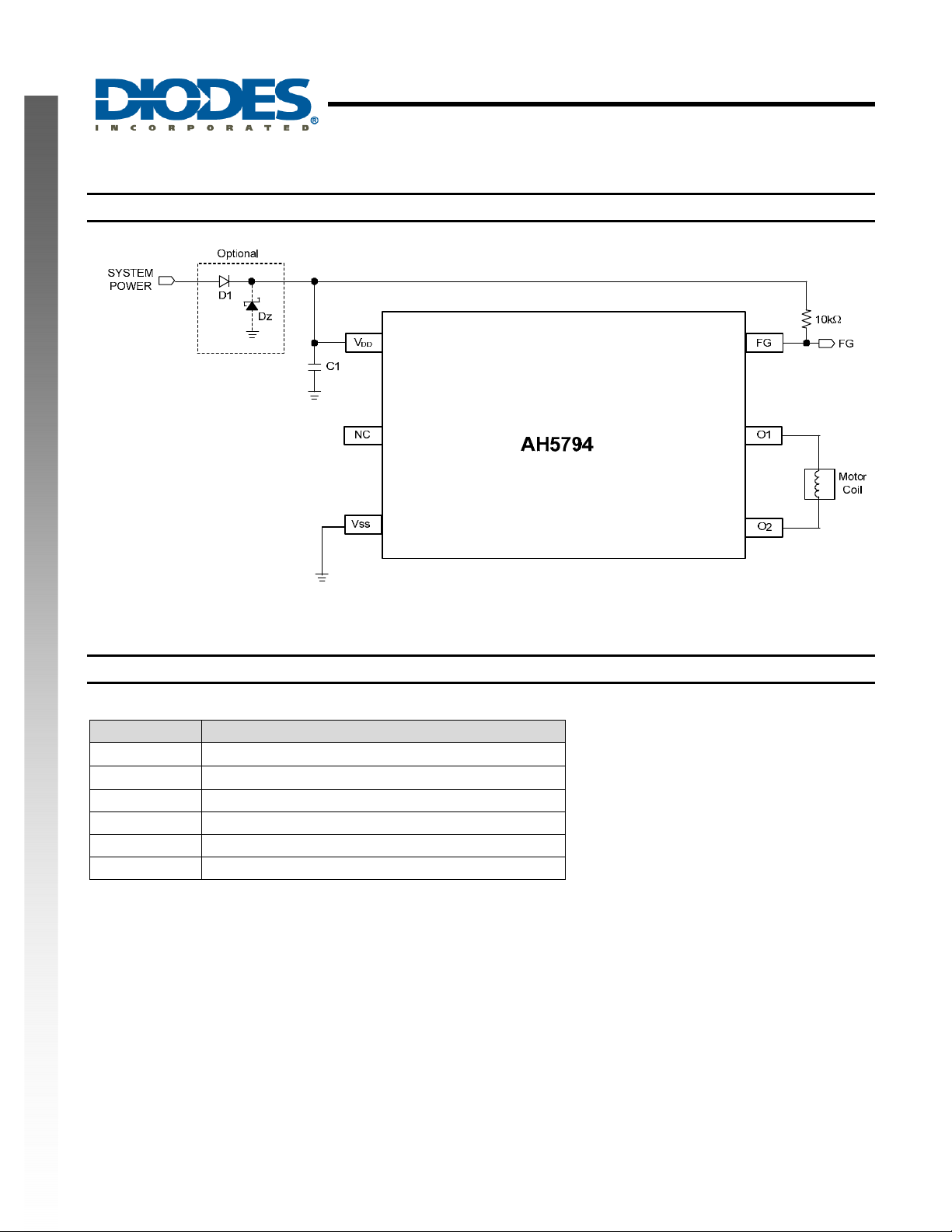

Typical Application Circuit

NEW PRODUCT

AH5794

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

Pin Descriptions

Pin Name Description

VDD

V

SS

O1 Output driving & sinking pin

O2 Output driving & sinking pin

NC No connection

FG Frequency generator (Note 1)

Notes: 1. The FG output is the same as the magnetic change frequency.

AH5794

Document number: DS35809 Rev. 1 - 2

Power supply pin

Ground pin

www.diodes.com

2 of 13

March 2012

© Diodes Incorporated

Page 3

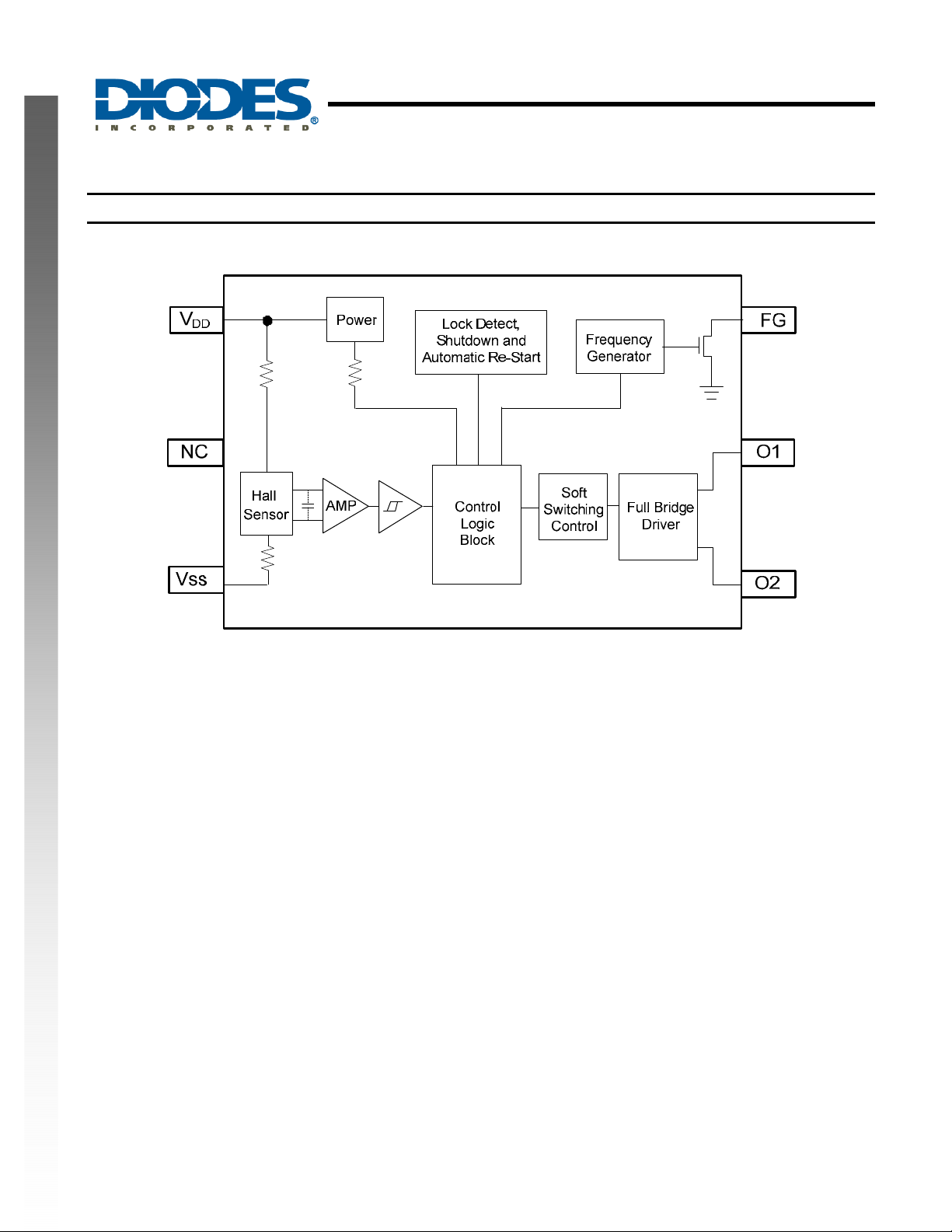

Functional Block Diagram (Note 2)

NEW PRODUCT

AH5794

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

Notes: 2.The AH5794 has an open-drain tachometer FG output that follows the magnetic change frequency. Typically a pull-up resistor of 10k is

recommended from FG pin to the supply voltage.

AH5794

Document number: DS35809 Rev. 1 - 2

3 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Page 4

AH5794

Absolute Maximum Ratings (T

Symbol Characteristics Values Unit

VDD

I

O(PEAK)

PD

TST

ESD HBM Human Body Model ESD Protection 4 kV

Notes: 3. Stresses greater than the 'Absolute Maximum Ratings' specified above, may cause permanent damage to the device. These are stress ratings only;

functional operation of the device at these or any other conditions exceeding those indicated in this specification is not implied. Device reliability

may be affected by exposure to absolute maximum rating conditions for extended periods of time

4. U-DFN2020C-6 exposed pad soldered to minimum recommended landing pads (see Package Outline Dimension section) on a two-layer 2oz.

copper FR4 PCB (1.6mm thickness) with no thermal vias in exposed PADs or any copper flood connecting to the landing pattern of the

exposed pad.

Recommended Operating Conditions (T

NEW PRODUCT

Symbol Parameter Conditions Min Max Unit

VDD Supply Voltage at VDD pin

TA

Electrical Characteristics (T

Symbol Characteristics Conditions Min Typ. Max Unit

IDD

VOH

VOL

VOH +VOL

TSW

I

LEAK

V

FGOL

TON

RDR

TJ_

SDN_TH

TJ_

SDN_HYST

AH5794

Document number: DS35809 Rev. 1 - 2

Supply Voltage 7 V

Maximum Output Current (Peak) 1000 mA

Power Dissipation

Storage Temperature Range -65 ~ +150

Operating Ambient Temperature Range Operating -40 +105

Supply Current No Load - 2.2 - mA

Output Voltage High

Output Voltage Low

Output voltage of N- and PMOS

combined

Output Switching Slope Duration 17 load on O1/O2 - 200 - s

FG Output Leakage Current - - 5 A

FG Output Voltage Low

On Time 350 500 650 ms

Duty Ratio

IC junction temperature thermal

shutdown threshold

IC junction temperature thermal

shutdown hysteresis

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

= 25°C, unless otherwise noted, Note 3)

A

TSOT26 650

U-DFN2020C-6 750 (Note 4)

= 25°C)

A

DC supply speed control mode 1.8 6.0 V

= 25°C, V

A

= 5V)

DD

I

OUT

I

OUT

I

OUT

I

OUT

I

OUT

I

OUT

I

FG

T

OFF

= 300mA

= 500mA

= 300mA

= 500mA

= 300mA

= 500mA

= 5mA

/ TON

4.70 4.88 - V

4.5 4.8 - V

- 0.12 0.3 V

- 0.2 0.5 V

0.3 0.5 V

0.5 V

- - 0.4 V

- 10 -

175

25

4 of 13

www.diodes.com

© Diodes Incorporated

mW

o

C

o

C

o

C

o

C

March 2012

Page 5

AH5794

Magnetic Characteristics (T

Symbol Parameter Min Typ. Max Unit

BOP

BRP

Bhy

Notes: 5. Magnetic characteristics may vary with supply voltage, operating temperature and after soldering.

Operating Characteristics

Operate Point 10 25 50

Release Point -50 -25 -10

Hysteresis - 50 -

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

= 25°C, VDD = 1.8V to 6V, Note 5)

A

(1mT = 10 G)

Gauss

NEW PRODUCT

O1

V

OH

RP

ON

Output Voltage in Volts

OFF

OP

OFF

RP

Output Voltage in Volts

V

OL

V

OL

Magnetic Flux Density in GaussMagnetic Flux Density in Gauss

O2

V

OH

OP

ON

BopBrp 0BopBrp 0

S

Marking side

N

Marking side

N

(U-DFN2020C-6)

AH5794

Document number: DS35809 Rev. 1 - 2

S

(TSOT26)

5 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Page 6

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

Operating Characteristics (Note 6, 7, 8 and 9)

AH5794

O2

O1

FG

S

N

Ton

Normal spinning

motor locked detected

Toff

Mechanical lock

Magentic

NEW PRODUCT

Truth Table

O1 O2 FG

L H L

H L H

L L

Notes: 6. In “Normal spinning, the FG changes its state at each edge of O1.

7. When the motor locks with South pole at the Hall element, O2 is kept on “L” and O1 is a clock with Ton/Toff ratio.

When motor locks with North pole at the Hall element, O1 is kept on “L”, O2 is a clock with Ton/Toff ratio.

8. When “Re-start spinning” occurs, the motor speed ramps up to the “Normal Spinning” speed from zero.

Speed ramp-up profile depends on motor characteristics.

9. X: H or L depends on magnetic pole North or South

AH5794

Document number: DS35809 Rev. 1 - 2

X

(Note 9)

6 of 13

www.diodes.com

“Re-start spinning”

motor locked cleared

March 2012

© Diodes Incorporated

Page 7

AH5794

Application Note

Motor Speed Control

DC Supply Voltage (VDD) Speed Control

Motor speed can be controlled by varying the VDD supply voltage between 1.8V to 6V.

With 5V nominal motor, changing V

Soft Switching

AH5794 uses soft switching of the motor coil current during commutation for to minimize audible switching noise and

electromagnetic interference (EMI) to provide a low noise solution.

Vdd

Vout 1

NEW PRODUCT

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

voltage between 5V to 1.8V, speed can be controlled from 100% to 36% typically.

DD

Vout 2

Vss

200µs typ.

AH5794

Document number: DS35809 Rev. 1 - 2

7 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Page 8

P

OWER

PATIO

Thermal Performance Characteristics

(1) Package type: TSOT26

TA (°C) 25 50 60 70 75 80 85 90 95 100

PD (mW)

TA (°C)

PD (mW)

NEW PRODUCT

651 521 469 417 391 365 339 313 286 260

105 110 115 120 125 130 135 140 145 150

234 208 182 156 130 104 78 52 26 0

700

650

600

500

N (mW)

400

300

DISSI

AH5794

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

200

100

0

-40 25 50 75 100 125 150

TEMPERATURE (°C)

Power Dissipation Curve

105

AH5794

Document number: DS35809 Rev. 1 - 2

8 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Page 9

AH5794

P

OWER

PATIO

N

Thermal Performance Characteristics (cont.)

(2) Package type: U-DFN2020C-6 (Note 10)

TA (°C) 25 50 60 70 75 80 85 90 95 100

PD (mW) 781 625 563 500 469 438 406 375 344 313

TA (°C) 105 110 115 120 125 130 135 140 145 150

PD (mW) 281 250 219 188 156 125 94 63 31 0

900

800

700

(mW)

600

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

NEW PRODUCT

500

400

DISSI

300

200

100

0

-40 25 50 75 100 125 150

TEMPERATURE (°C)

Power Dissipation Curve

105

Notes: 10. U-DFN2020C-6 exposed pad soldered to minimum recommended landing pads (see Package Outline Dimension section) on a two-layer 2oz.

copper FR4 PCB (1.6mm thickness) with no thermal vias in exposed PADs or any copper flood connecting to the landing pattern of the

exposed pad.

AH5794

Document number: DS35809 Rev. 1 - 2

9 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Page 10

X

Ordering Information

AH5794

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

A 5794 - - H

XX 7

PackingPackage

WU : TSOT26

FDC : U-DFN2020C-6

7 : Tape & Reel

Device

AH5794-WU-7 WU TSOT26 3000/Tape & Reel -7

AH5794-FDC-7 FDC U-DFN2020C-6 3000/Tape & Reel -7

Notes: 11. Pad layout as shown on Diodes Inc. suggested pad layout document AP02001, which can be found on our website at

http://www.diodes.com/datasheets/ap02001.pdf

12. EU Directive 2002/95/EC (RoHS) & 2011/65/EU (RoHS 2) compliant. No purposely added lead. Halogen and Antimony free.

NEW PRODUCT

Please visit our website at http://www.diodes.com/products/lead_free.html

Package

Code

Packaging

(Note 11 & 12)

Quantity Part Number Suffix

7” Tape and Reel

Marking Information

(1) Package type: TSOT26

Part Number Package Identification Code

AH5794-WU-7 TSOT26 J4

(2) Package type: U-DFN2020C-6

( Top View )

: Identification C o de

XX

XX

Y W X

Part Number Package Identification Code

AH5794-FDC-7 U-DFN2020C-6 J4

AH5794

Document number: DS35809 Rev. 1 - 2

www.diodes.com

Y : Year : 0~9

: Week : A~ Z : 1~26 week;

W

a~z : 27~52 week; z repr es en ts

52 and 53 week

X

: A~Z : Internal c ode

10 of 13

March 2012

© Diodes Incorporated

Page 11

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

Package Outline Dimensions (All Dimensions in mm)

(1) Package type: TSOT26

NEW PRODUCT

AH5794

(2) Package Type: U-DFN2020C-6

0.57/0.63

0.05 C

0.08 C

Pin#1 ID

B

1.95/2.075

0.15 C

2x-

1.0±0.1

0.55±0.1

0/0.05

2x

R

0

.

1

0.86/1.06

R0.1

0.65nom.

Hall Sensor

C

0.15

1.95/2.075

1.55/1.75

5

Bottom View

Top Mark

0.43mon.

(Active area depth)

0.15max.

C

A

0.30/0.40

0.2/0.3

0.05

Seating plane

6x-0.37

0.57/0.63

0.30±0.1

Die

M C A B

6x-0.45

0.65

1.59

Land Pattern Recommendation

(Unit:mm)

0.9

Top View

AH5794

Document number: DS35809 Rev. 1 - 2

11 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Page 12

Taping Orientation

(1) Package Type: U-DFN2020C-6

NEW PRODUCT

AH5794

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

Notes: 11. The taping orientation of the other package type can be found on our website at http://www.diodes.com/datasheets/ap02007.pdf.

AH5794

Document number: DS35809 Rev. 1 - 2

12 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Page 13

NEW PRODUCT

AH5794

SINGLE PHASE HALL EFFECT LATCH FAN MOTOR DRIVER

IMPORTANT NOTICE

DIODES INCORPORATED MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARDS TO THIS

DOCUMENT, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION).

Diodes Incorporated and its subsidiaries reserve the right to make modifications, enhancements, improvements, corrections or other

changes without further notice to this document and any product described herein. Diodes Incorporated does not assume any liability

arising out of the application or use of this document or any product described herein; neither does Diodes Incorporated convey any

license under its patent or trademark rights, nor the rights of others. Any Customer or user of this document or products described

herein in such applications shall assume all risks of such use and will agree to hold Diodes Incorporated and all the companies

whose products are represented on Diodes Incorporated website, harmless against all damages.

Diodes Incorporated does not warrant or accept any liability whatsoever in respect of any products purchased through unauthorized

sales channel.

Should Customers purchase or use Diodes Incorporated products for any unintended or unauthorized application, Customers shall

indemnify and hold Diodes Incorporated and its representatives harmless against all claims, damages, expenses, and attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized application.

Products described herein may be covered by one or more United States, international or foreign patents pending. Product names

and markings noted herein may also be covered by one or more United States, international or foreign trademarks.

LIFE SUPPORT

Diodes Incorporated products are specifically not authorized for use as critical components in life support devices or systems without

the express written approval of the Chief Executive Officer of Diodes Incorporated. As used herein:

A. Life support devices or systems are devices or systems which:

1. are intended to implant into the body, or

2. support or sustain life and whose failure to perform when properly used in accordance with instructions for use provided

in the labeling can be reasonably expected to result in significant injury to the user.

B. A critical component is any component in a life support device or system whose failure to perform can be reasonably expected

to cause the failure of the life support device or to affect its safety or effectiveness.

Customers represent that they have all necessary expertise in the safety and regulatory ramifications of their life support devices or

systems, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements

concerning their products and any use of Diodes Incorporated products in such safety-critical, life support devices or systems,

notwithstanding any devices- or systems-related information or support that may be provided by Diodes Incorporated. Further,

Customers must fully indemnify Diodes Incorporated and its representatives against any damages arising out of the use of Diodes

Incorporated products in such safety-critical, life support devices or systems.

Copyright © 2012, Diodes Incorporated

www.diodes.com

AH5794

Document number: DS35809 Rev. 1 - 2

13 of 13

www.diodes.com

March 2012

© Diodes Incorporated

Loading...

Loading...