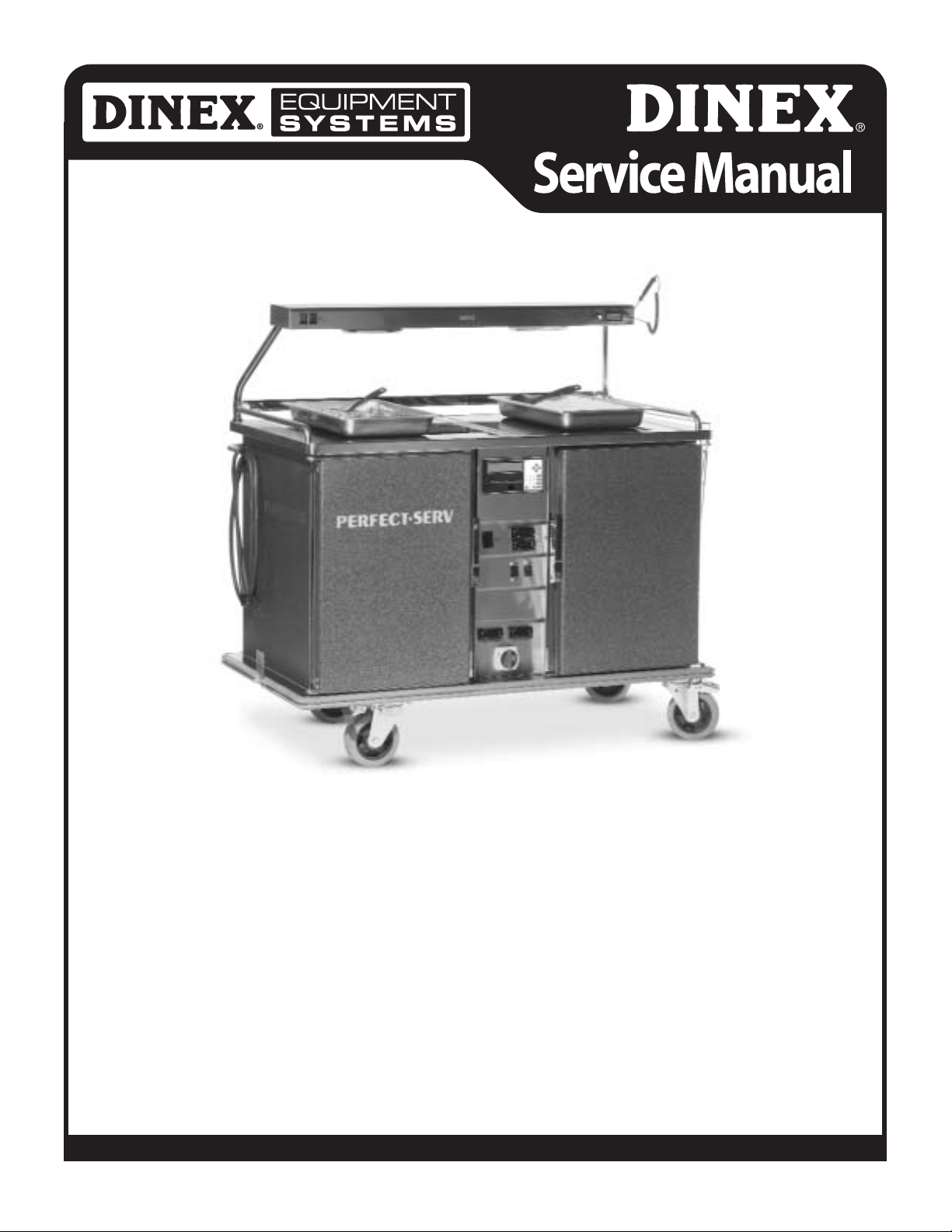

Dinex PSJR1G Service Manual

Perfect•Serv

™

DINEX INTERNATIONAL,INC. • 628-2 HEBRON AVENUE,GLASTONBURY CT 06033 • WWW.DINEX.COM

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation & Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Appendix 1 Cart Model Specifications & Parts Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dinex® Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

For Service Information,call 1-888-673-4639

Please provide following information:

• Model number

• Stamped-in code

• Part Description and number as shown in parts list.

Manual PSRV Rev-04/05

PSJR /PSSR Models

NOTE:The document is to be used in conjunction with the

Dinex’s Perfect•Serv™ Operation Manual

Page 2

Introduction:

ELECTRICAL

1.Check that all packaging and protective materials are

removed.

2.Prior to connection,check that the power supply is in

accordance with the product Data Plate details.

3.All units are provided with a NEMA 615-30 plug. Dual

supply units are fitted with a NEMA 5-15 plug on the

120 V AC line.

NOTE:Reference Appendix #1 for additional electrical

information

4.Dual supply units are fitted with a rotary isolator,which

must be turned to the ‘on’position after plugging the

unit in. The isolator is located on the control panel.

5.Should there be any doubt concerning electrical specifications or hardware,seek advice from a competent electrician.

WARNING:This appliance MUST be grounded. If in doubt,

seek the advice of a competent electrician.

DO NOTattempt to change the type of plug fitted or connect to any power supply,which differs from Data Plate.

DO NOTattempt to disconnect the unit while running.

ALL MODELS

A.Regeneration cook/chill,cook/freeze

B.Chillogen hold regeneration,cook/chill

C.Hotline only.

MODEL VARIATIONS

Hotline Keep-Hot Compartments

Keep-hot compartments are heated by fan assisted

elements. The temperature is controlled by digital thermostat with temperature display.

NOTE: All keep-hot compartments are factory pre-set to

maintain a temperature of 185˚F (85˚C).

Congratulations! You have just purchased one of the finest

pieces of equipment on the market today.Before installing

or operating your new Dinex Products equipment you

should read through this material.This manual should be

retained for further reference as it contains installation

instructions,service tips,par t list and warrant y information.

Should you have any questions concerning the Equipment,

please call the Dinex Hotline at 1-888-673-4639 (Monday

through Friday from 8 am to 5 pm,Eastern Standard Time).

IMPORTANT: For your safety,read and follow all cautions,

information and warnings

FREIGHT DAMAGE CLAIMS

Your Dinex Products equipment was carefully inspected

and packed before leaving our factory. The transpor tation

company assumes full responsibility for safe delivery of

this equipment.Dinex Products cannot assume responsibility for damage or loss incurred in transit.Visible damage

or loss should be noted on freight bill and signed by

person making delivery.

A freight claim should be filed immediately with the transportation company.If damage is unnoticed or concealed

until equipment is unpacked,notify the transpor tation

company immediately and tell them you want to file a

concealed damage claim.This must be done within fifteen

(15) days after delivery was made.Be sure to retain all

packing material and cartons.

WARNING:Installation of this equipment should be

performed only by persons qualified or licensed to install

electrical equipment.

• Adjustments and service work should be performed

only by a qualified service technician.S er vice is available through Authorized Dinex Products Parts & Service

Distributors throughout the United States.For a

complete listing of these consult your distributor listing

or write Dinex Products for the name of the nearest

distributor.

• This equipment in intended for commercial use only.

Not for household use.

• Use of other than genuine Dinex Products replacements

parts or service work performed by other than authorized

Dinex Products service agents will void the warranty.

• Do not use any corrosive cleaners.Use only cleaners

approved for stainless steel.

!

!

!

!

Assembly Instructions:

Installation:

!

3.The interiors of all compartments are formed into a onepiece unit and the cassette can be easily removed.

4.The interior of all compartments can be cleaned using a

water and stainless steel compatible disinfectant

applied using a spray bottle. The interior should be

completely dry prior to use.

WARNING:NEVER steam clean this equipment!

NEVER spray water into the control compartment or onto

the control panel.

5.The top,external and internal surfaces should be

cleaned with a hot soapy damp cloth.

6.Scouring pads should not be used to clean glass,hot

plates and sneeze guard glass. A glass cleaner should

be used.

7.After cleaning,the cart should be carefully dried.

WARNING:DO NOT use chemicals such as bleach or

undiluted cleaning agents.

DO NOTuse steel wool pads on ANY surface,this will cause

rusting and/or scratching.

DO NOTtouch quartz sneeze guard lamps during cleaning.

Page 3

Refrigerated Compartments Complete With Ice-Cream

Hold Facility

Refrigerated compartments are cooled by a side mounted

forced air system and controlled by digital thermostat

with temperature display.Ice cream section operates

automatically in conjunction with refrigerated section

(no display).

NOTE: Refrigerated section is factory pre-set for 36˚F (2˚C)

to 41˚F (5˚C).Ice cream section is factor y pre-set for 23˚F

(–5˚C) to 81˚F (–8˚C).

Additional Feature:The ice cream section can be removed

to utilize compartment as refrigerated compartment.

ICE CREAM SECTION REMOVAL

1.Slide cassette out of the compartment and place on a

level surface.

2.Lift ice cream coverflap and continue to slide the cover

forward until it completely clears the cassette.

3.The left and right side panels are removed by lifting them

upward. Lift carefully until the locating angles clear the

runners then move sideways and remove from cassette.

4.Reverse procedure to re-insert

Plate Warmer Compartments

Units with a plate warmer will accept 40 plates in the upper section and 4 full size 2”deep pans in lower section at ambient temperature or separate refrigerated temperature depending on

model.

NOTE: All plate warmer units are factory pre-set and

regulate automatically to ensure plates are maintained

at serving temperature (no temperature display).

CLEANING

1.Before attempting to clean the unit, make sure that the

unit is switched off and disconnected from the power

supply and allowed to cool down completely.

2.Check that all plates and containers and any loose items

are removed from the unit.

!

!

Maintenance:

!

!

1.Tighten as required

2.Replace if worn

3.Replace wheel

4.Remove obstruction

(string,etc)

1.Loose axle bolt & nut

2.Abnormal play in swivel

head in caster

3.Tire tread wear

4.Wheel operation obstruction

PROBLEM SOLUTION

CASTERS

All wheel bearings are sealed for life and will not require

maintenance.

DOOR HINGES/HANDLES/CATCHES

Incorrect adjustment of door hinges,handles and catch

strike plates will cause an incorrect seal of the door

gasket. This will cause poor performance,hot spots and

gasket failure.

It is recommended that monthly inspections of hinges,

handles/catches be performed

Page 4

NOTE:Hinges,handles and door catches found to be

faulty due to abuse are not covered under warranty.

Monthly inspections are the customer's responsibility and

are NOT covered under warranty.

DOOR GASKET REPLACEMENT

Door gaskets should be inspected monthly for damage.

Damaged gaskets must be replaced immediately following the instruction below.

NOTE:Inspections are NOT covered under warranty.

1.Open door fully.

2.Firmly hold the gasket at one corner and pull out (this

will require some force).Continue to pull the gasket out

until it is fully removed.

3.Starting at one corner place the tongue of the gasket

into the slot and push hard to set gasket fully into place.

Continue to press gasket fully into place all around the

door.

4.Close door and check for correct fit and operation.

5.To check for positive gasket seal,place a piece of paper

between the oven door and the cabinet body and close

door.Some resistance should be experienced when

pulling paper out. Check seal all the way round and

adjust the door as necessary to obtain proper fit.

NOTE:Gaskets found to be damaged due to abuse are NOT

covered under warranty.

PLATE-WARMERS

To remove plate-warmers:

1.Remove all plates.

2.Pull the rack out until it stops.

3.Lift up and continue to pull out until the rack rollers

clear the runner.

4.Reverse the procedure to re-insert.

The only maintenance requirement on plate-warmers is

light lubrication of the rollers.

NOTE: Only approved non-toxic lubricant specifically

designed for use in the proximity of food must be used.

FAN HOUSING COVER

In the event that access is required behind the Fan

Housing Cover:

1.Remove the internal cassette.

2.The cover can be removed by unscrewing thumbscrew.

Slide the cover off of the locating pins then lift the cover

to the right to clear the compartment.

3.Reverse the procedure to re-insert.

IMPORTANT:Extreme care must be exercised during this

operation to ensure that the cover does not come into

contact with the fan blades and result in possible damage.

QUARTZ LAMP REPLACEMENT

1.Replacement quartz lamps must not exceed the

wattage specified on the “Maximum Wattage Label”on

the sneeze guard.

2.Switch off the unit,disconnect from the power

supply and allow it to cool.

3.Carefully slide mesh guard to one side until it clears the

bulb area.

4.Remove faulty lamp by pushing to one side then pull

down.

5.Reverse of steps 1- 4 to install the new lamp.

NOTE:It is recommended that bulb be installed using a

non lubricated tissue.

IMPORTANT:Lamps should not be touched with bare

hands or any type of towel with contamination,as this will

cause premature failure. If lamp is touched,wipe clean

with a cloth and alcohol prior to use.

1.Remove cover/tighten

screws

2.Replace hinge

3.Tighten as required

4.Replace door handle

5.Adjust using M3 Allan

key

6.Replace strike plate

1.Loose hinge

2.Abnormal play in hinge

3.Loose door handle

4.Door handle for proper

closing

5.Improper door closing at

the catch strike plate

6.Excessive wear at door

catch strike plate

PROBLEM SOLUTION

!

!

!

!

!

!

!

Page 5

REFRIGERATION SYSTEM

The condenser and compressor are located behind a tamperproof,sealed,fixed control panel. This panel can be

opened by removing (2) tamperproof screws from the

upper flange and folding the panel down.

Depending upon the model,it may be easier to access the

refrigeration system by removing the louvered front panel.

To remove the front panel perform the following:

1.Lift up the tray rail to the serving position.

2.Remove (2) bolts located on the underside of the bottom

panel structure.

3.Remove the louvered front panel by pulling the bottom

of the panel out first and letting it drop off of the upper

support locating pins.

4.Perform required refrigeration maintenance and repairs.

(i.e.cleaning of condenser)

5.Reinstall the front louvered panel in reverse of the

removal process.

ELECTRONIC COMPONENTS

The electronic components and compressor are located

behind a tamperproof,sealed,fixed control panel.

Access to this compartment is provided by hinging the

control panel down and by removing the body panel on

the opposite side of the cart. Only an authorized service

agent should access this compartment.

Page 6

APPENDIX NO.1

Cart Model Specification & Part Numbers

Page 7

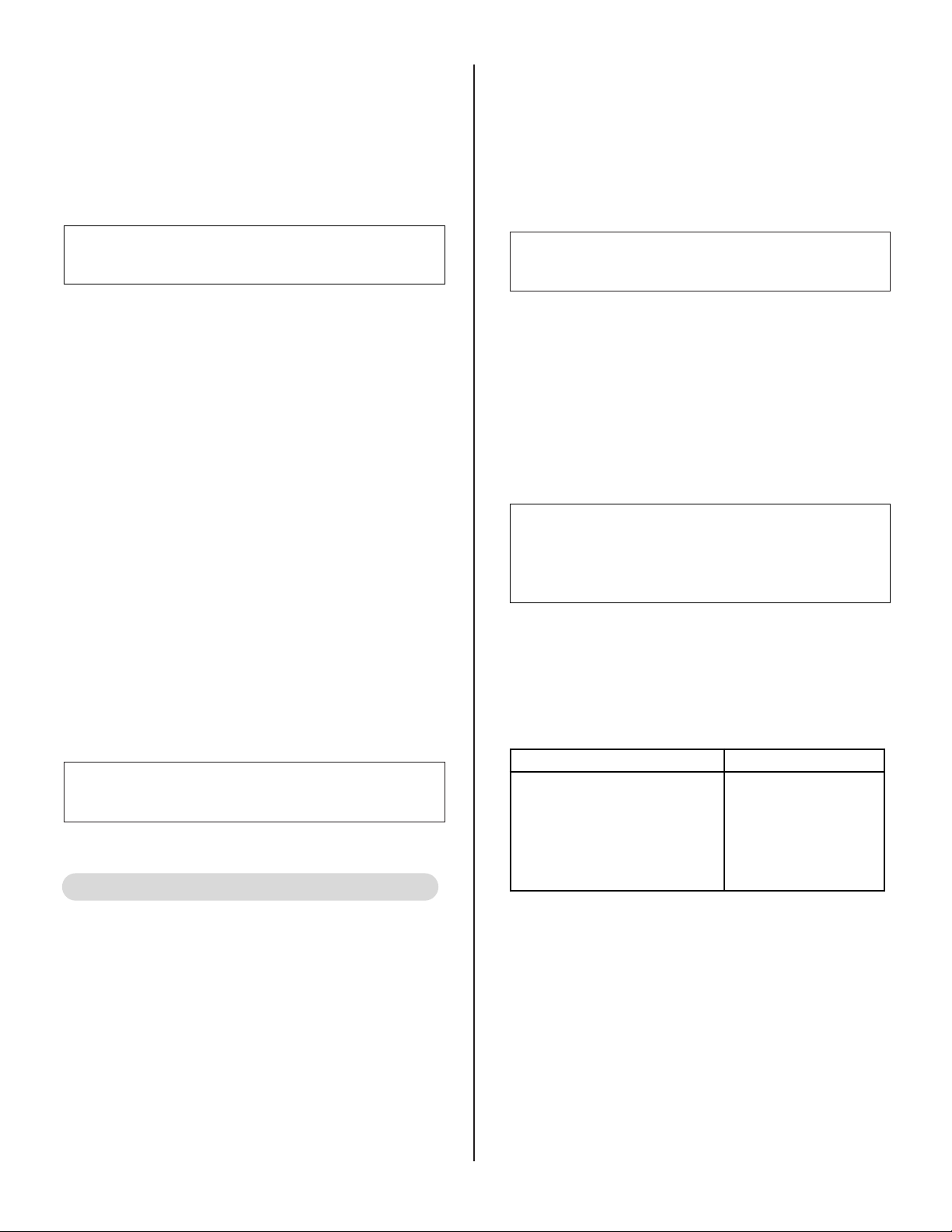

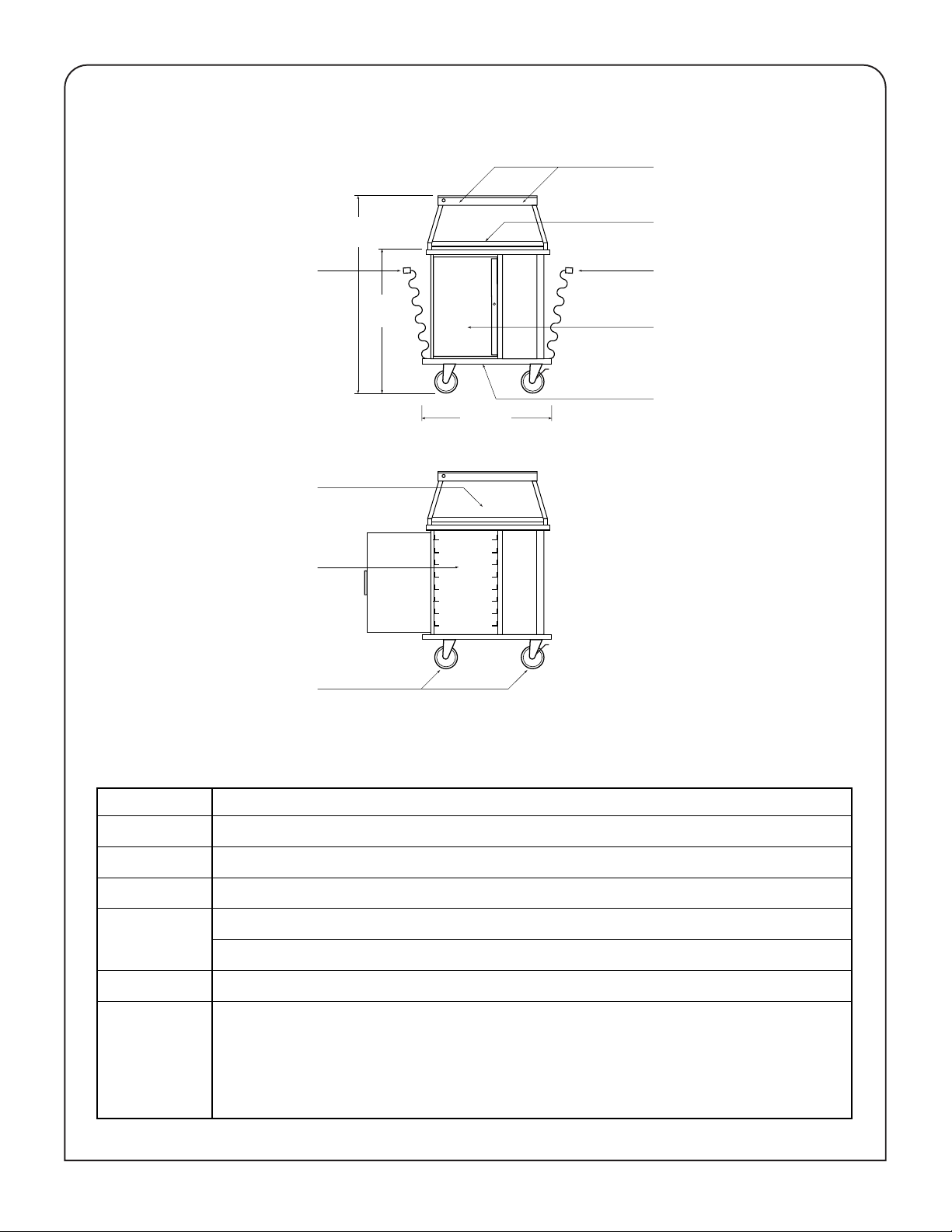

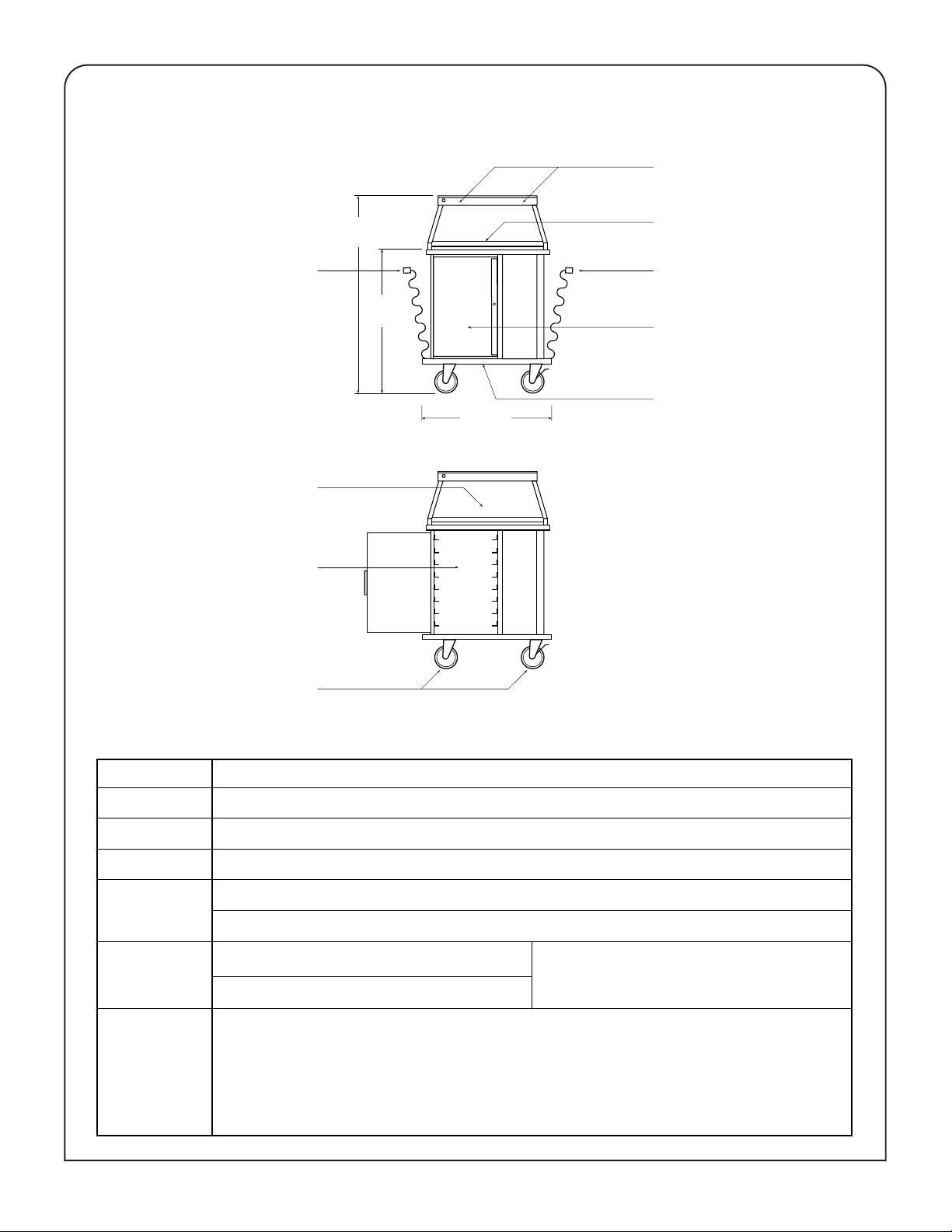

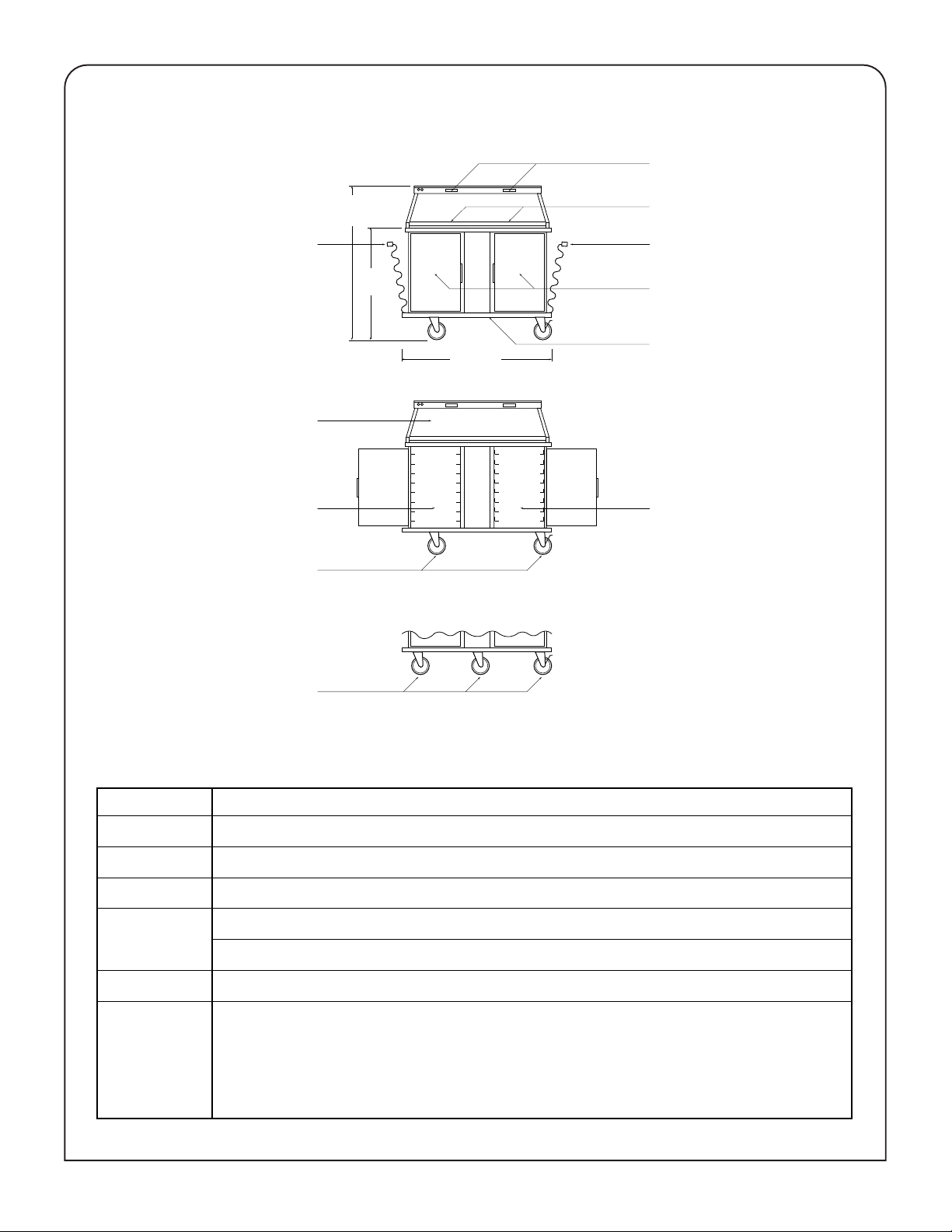

MODEL

DESCRIPTION

DINENSIONS

WEIGHT

ELECTRICAL

REFRIGERATION

ADDITIONAL

INFORMATION

PSJR1G

220 lbs.

N/A

MAX LOAD:5000 Watts (Via Inhibit Relay)

MAXIMUM LOAD AMPS:13.9 Per Phase

1 x 120 Volt 60Hz 15 Amp Plug

1 x 300 Watt 110 Volt Quartz Lamp

1 x 300 Watt 110 Volt Black

Thermo Panel

1 x 3 Phase 208 Volt 60Hz

30 Amp Plug

5000 Watt Thermalization Oven

(1x 1000 Watt And 2 x 2000 Watt

Elements)

Bracket Attachment Prepared

To Accept Anti Static Strip

Full Depth Plexiglas Sneeze Screen

8 Pan Thermalization Oven

c/w Cassette

Standard 4 Castor Arrangement

2x 16cm

Fixed

Casters

2x 16cm

Swivel Braked

Casters

8 Pan Thermalization Compartment.

39.5”W (100cm) x 30”D (75cm) x 37.5”H (95cm) To Work Surface x 51.5”(131cm) To Top Of Gantry

1.For electrical wiring see drawing No.PSJR1G.

2.When optional extra PSAVDL Data Logger System or PSAVOBP on board food probe with pass /

fail are fitted,please refer to drawing No.PSAEOE for electrical wiring integration.

A.Anti static bracket fitted as standard from August 04’.

Perfect•Serv Specification Char t

PSJR1G

39.5”

(100cm)

37.5”

(95cm)

51.5”

(131cm)

Page 8

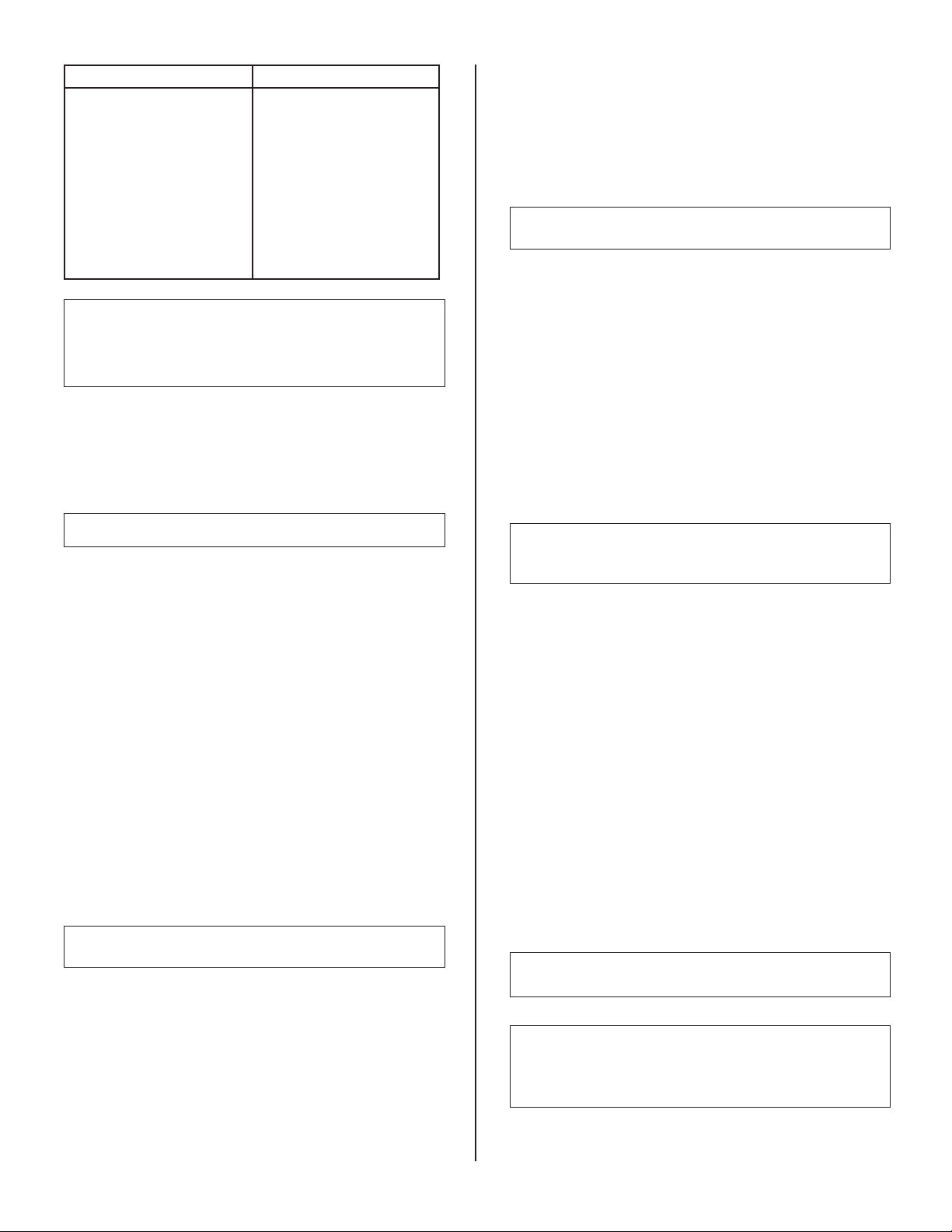

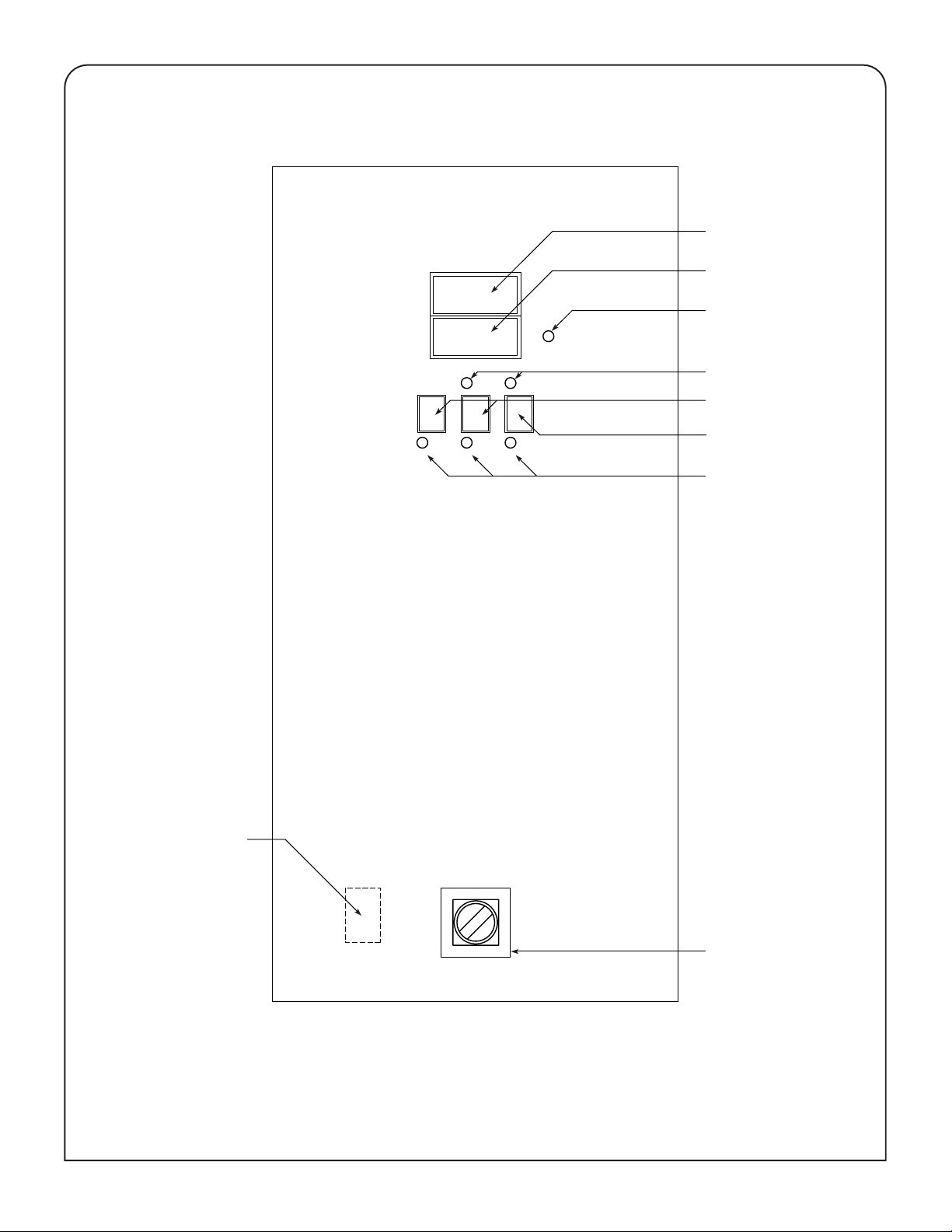

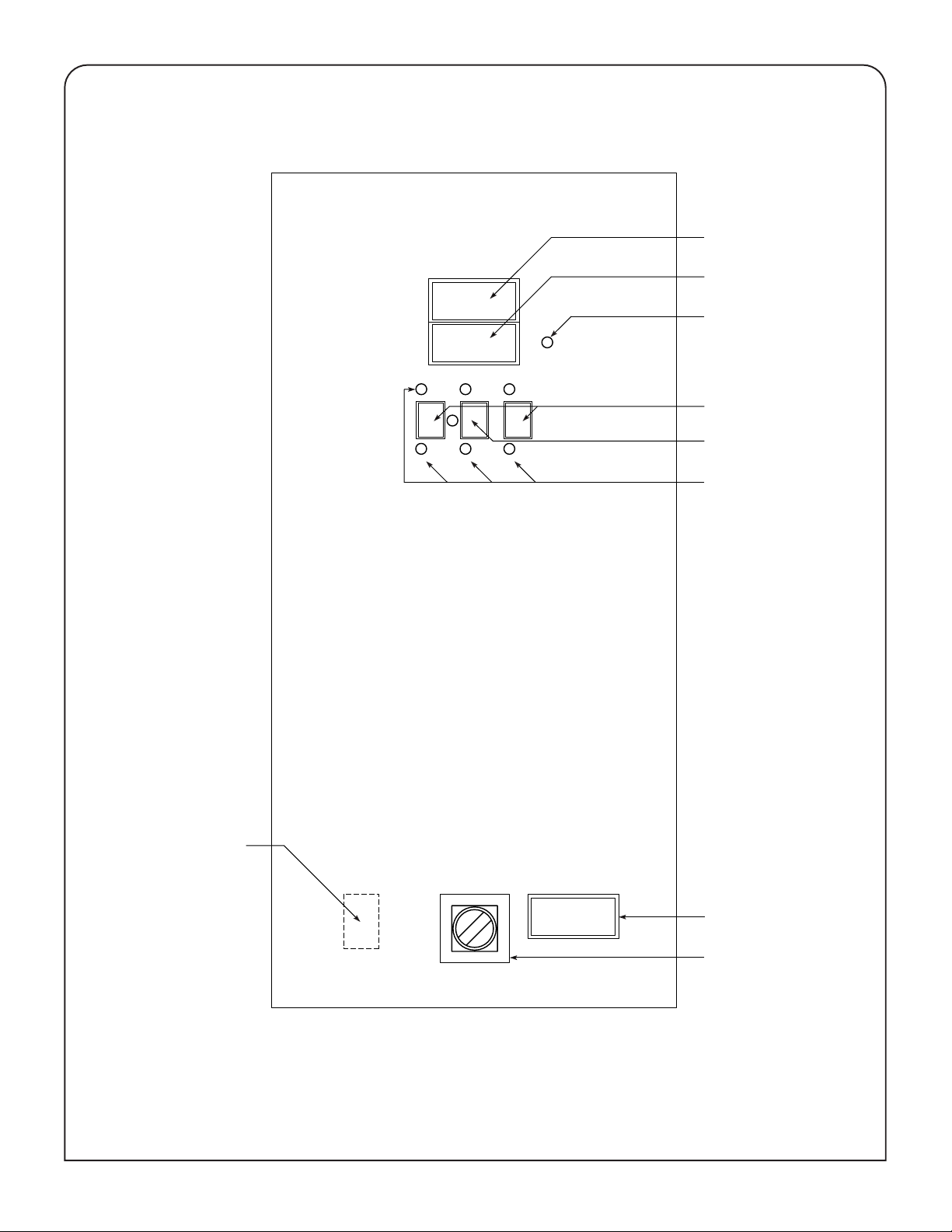

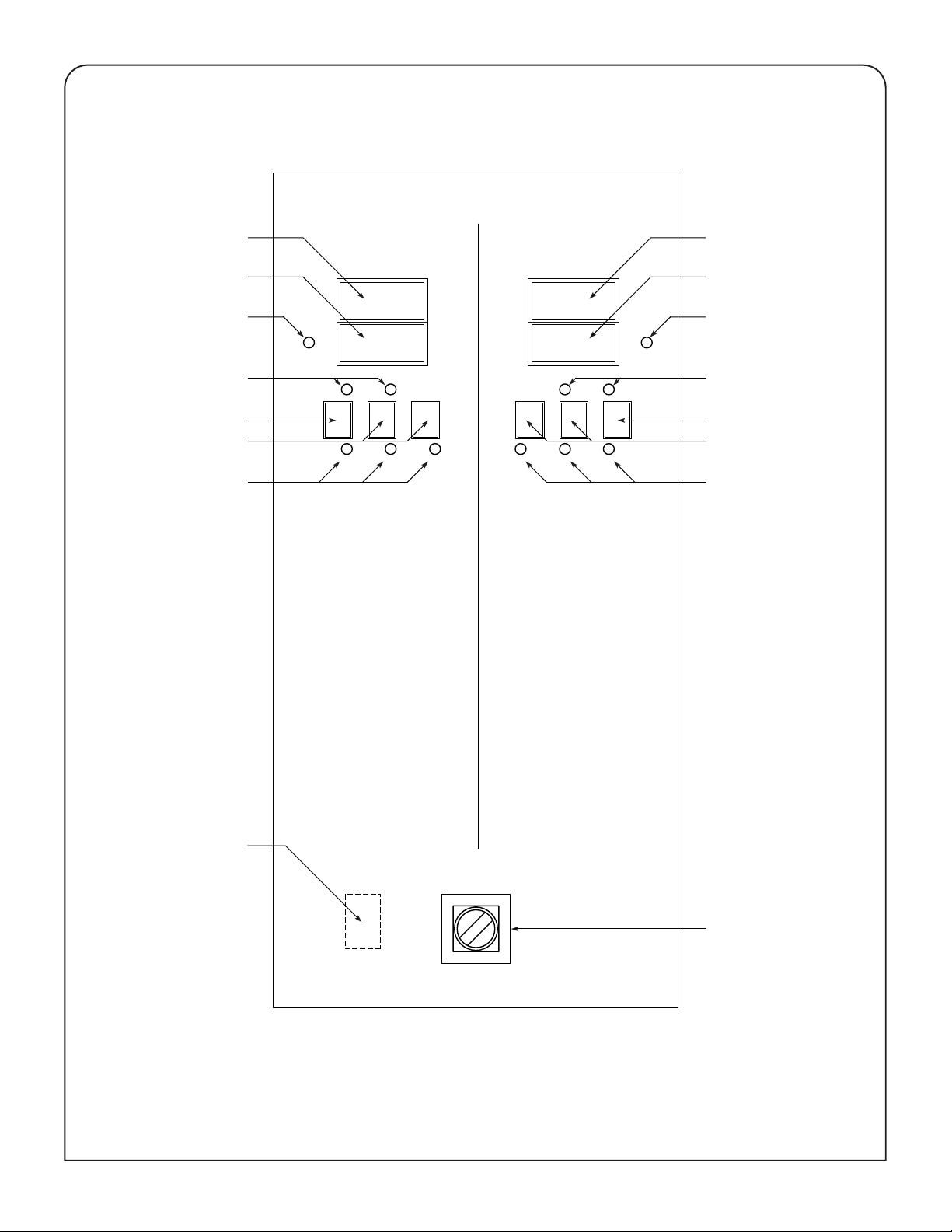

MAIN ISOLATOR

READY

OVEN TEMPERATURE

OVEN TIME

PART

LOAD

PART

LOAD

REGEN

OFF

KEEP

HOT

BOOST

Perfect•Serv Specification

PSJR1G Control Panel

Digital Temper ature

Controller (Display) (2460)

Digital Countdown

Timer (Display) (2463)

Ready Light

Green Mini Neon (1112)

Function Selected Lights

Amber Mini Neon (1117)

Function Selected Lights

Green Mini Neon (1112)

6 Pole Isolatator (1980)

3 Way Switch (1003D)

2 Way Switches (1003E)

Dotted Outline Shows

Position Of Data Transfer

Point (Window) When

PSAVDL Option Is Fitted

Page 9

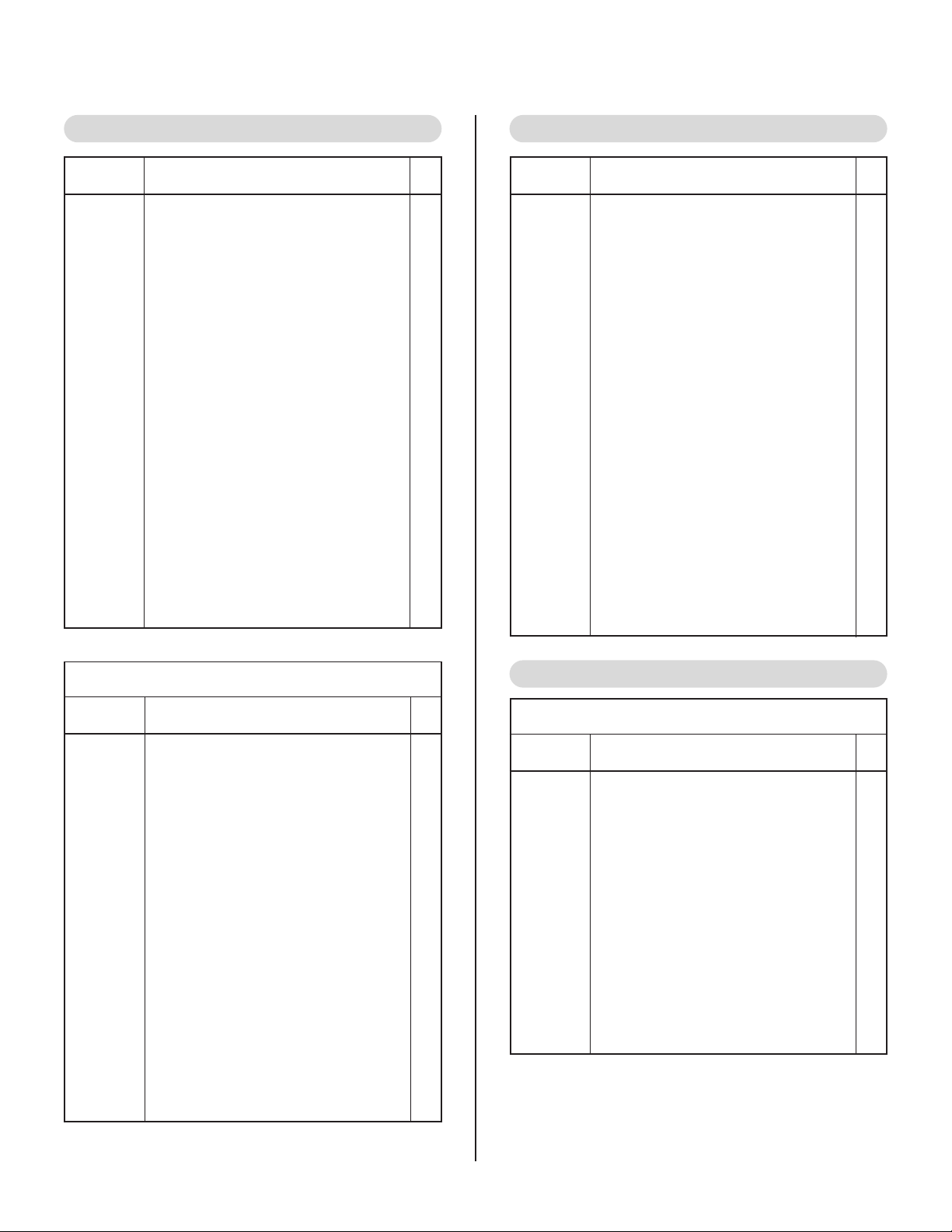

2001

2003

0638A

1964B

2670

2239DA

2238

2237DA

2253A

1003E

3132D

0490

0491

2086

1383

2

2

3M

1

1

1

1

1

1

1

1

4

4

2

1

CHASSIS

160”Swivel Braked Caster

160”Fixed Caster

Rubber Bumper (Per Unit)

DOORS

Lockable Handle c/w Catch

Full Size Door Gasket

TOP

110V x 300 Watt Black Thermo Panel

GANTRY

Quartz Lamp Holder

110V x 300 Watt Quartz Lamp

Quartz Lamp Guard (Mesh)

Gantry On / Off Switch (2 Way)

Full Depth Plexiglas Sneeze Screen

CASSETTES

S/S Wheels

S/S Pins

FAN GUARD

Anti Tilt Pin

M5X12 S/S Thumbscrew

Parts

Number

Description Qty Qty

1990

1011A

1039B

1040B

2460

2463

1003E

1003D

1112

1117

1980

1935

1945

2311

3060

2461

1138

2675

0353

1110

1992A

0378

0383

3

3

1

2

1

1

2

1

4

2

1

2

1

2

1

1

1

1

1

1

2

3

1

THERMALIZATION COMPARTMENTS

Fan Motors

Fan Blade

Rapid Heat Element 1000 Watt

Rapid Heat Element 2000 Watt

Digital Temperature Controller (Display)

Digital Countdown Timer (Display)

2 Way Switch

3 Way Switch

Green Mini Neon

Amber Mini Neon

6 Pole Isolator

16 Amp 1 Pole MCB

20 Amp 3 Pole MCB

Change Over Relay

4 Pole Relay

Inhibit Relay

230V Transformer

Delay Timer

5-5 Contacter

K Thermocouple

Auto High Limit Stat

5 Amp Fuse

16 Amp Fuse

Parts

Number

Description

2900

2906

2902

2905

2904

2903

1110

2918

1138

3064

3062

0348

2460

1113

1112

2905

2904

1138

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

PSAVDL DATA LOGGING SYSTEM

Data Logger PCB Board (Panel)

Data Logger Push Button (Yellow)

Data Logger Temp Display Screen

Food Probe

Food Probe Socket

Data Transfer Point Window (Panel)

K Thermocouple

Resistor

230V Transformer

110V Transformer

110V Relay

2 Amp Fuse

PSAVOBP ON BOARD PROBE WITH

PASS / FAIL

Digital Temperature Controller (Display)

Red Mini Neon

Green Mini Neon

Food Probe

Food Probe Socket

230V Transformer

Parts

Number

Description

Optional Extras

This section refers to electrical optional extras and is only

vaild when ordered and fitted.

1964B

1990

1039B

1040B

2460

2463

1110

1992A

1112

2311

2675

2237DA

2239DA

0378

0383

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Lockable Handle c/w Catch

Fan Motor

Rapid Heat Element 1000 Watt

Rapid Heat Element 2000 Watt

Digital Temperature Controller (Display)

Digital Countdown Timer Display

K Thermocouple

High Limit Stat

Green Mini Neon

Change Over Relay

Delay Timer

110V x 300 Watt Quartz Lamp

110V v 300 Watt Black Thermo Panel

5 Amp Fuse

16 Amp Fuse

Parts

Number

Description

PSSK1 – PSSR2GG

This recommended spare parts kit is for PSJR1G only and to order please quote PSSPK1-PSJR1G

Parts Chart Parts Chart

Recommended Spare Parts Kit

Qty

Qty

PSJR1G

Page 10

1 x 120 Volt 60Hz 15 Amp Plug

1 x 300 Watt 110 Volt Quartz Lamp

1 x 300 Watt 110 Volt Black

Thermo Panel

1 x 3 Phase 208 Volt 60Hz

30 Amp Plug

5000 Watt Thermalization Oven

(1x 1000 Watt And 2 x 2000 Watt

Elements)

Bracket Attachment Prepared

To Accept Anti Static Strip

Full Depth Plexiglas Sneeze Screen

8 Pan Chillotherm Oven / Fridge

c/w Cassette

Standard 4 Castor Arrangement

2x 16cm

Fixed

Casters

2x 16cm

Swivel Braked

Casters

Perfect•Serv Specification Char t

PSJR1C

39.5”

(100cm)

37.5”

(95cm)

51.5”

(131cm)

MODEL

DESCRIPTION

DINENSIONS

WEIGHT

ELECTRICAL

REFRIGERATION

ADDITIONAL

INFORMATION

REFRIGERANT GAS:R404A

DESIGN PRESSURES

HIGH = 17 - 19 BAR

LOW = 1.5 - 2 BAR

REFRIGERANT CHARGE:500 GRAMS

1.For electrical wiring see drawing No.PSJR1C.

2.When optional extra PSAVDL Data Logger System or PSAVOBP on board food probe with pass /

fail or PSAV7DT 7 day programmable timer are fitted please refer to drawing No.PSAEOE for

electrical wiring integration.

A.Anti static bracket fitted as standard from August 04’.

PSJR1C

242 lbs.

MAX LOAD:5000 Watts (Via Inhibit Relay)

MAXIMUM LOAD AMPS:13.9 Per Phase

8 Pan Chillotherm Combined Oven / Fridge Compartment.

39.5”W (100cm) x 30”D (75cm) x 37.5”H (95cm) To Work Surface x 51.5”(131cm) To Top Of Gantry

Page 11

MAIN ISOLATOR

READY

OVEN TEMPERATURE

OVEN TIME

PART

LOAD

CHILOGEN

ON

PART

LOAD

REGEN

OFF

S

KEEP

HOT

BOOST

FRIDGE TEMPERATURE

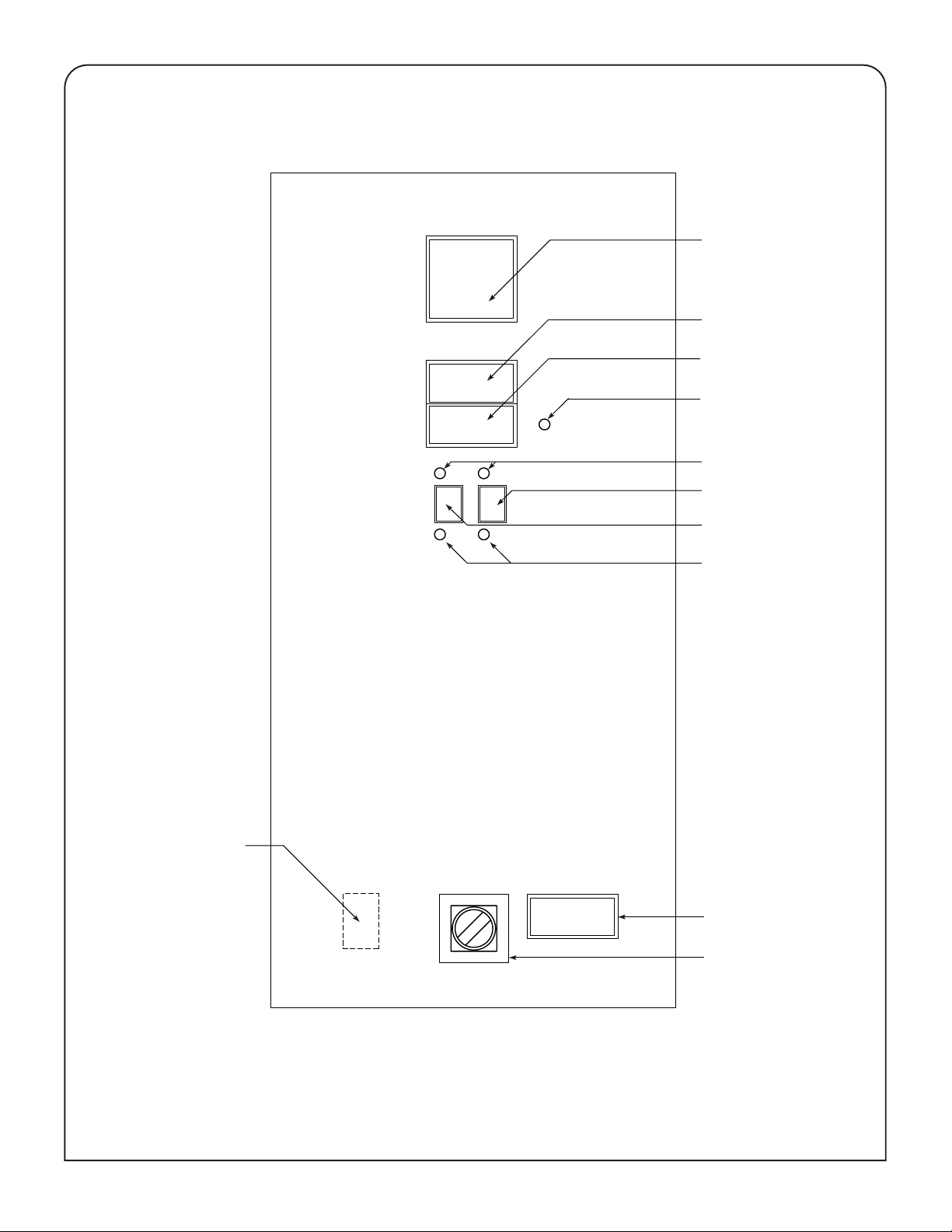

Perfect•Serv Specification

PSJR1C Control Panel

(This Control Panel Represents The Manual Operated Version)

Digital Temper ature

Controller (Display) (2460)

Digital Countdown

Timer (Display) (2463)

Ready Light

Green Mini Neon (1112)

Function Selected Lights

Amber Mini Neon (1117)

Function Selected Lights

Green Mini Neon (1112)

6 Pole Isolatator (1980)

3 Way Switch (1003D)

2 Way Switches (1003E)

Dotted Outline Shows

Position Of Data Transfer

Point (Window) When

PSAVDL Option Is Fitted

Digital Temper ature

Controller (Display) (2460)

Operates In Chillotherm

Mode Showing Cold

Temperature

Page 12

MAIN ISOLATOR

FRIDGE TEMPERATURE

OVEN TIME

PART

LOAD

PART

LOAD

KEEP

HOT

BOOST

READY

OVEN TEMPERATURE

7 Day Timer

Perfect•Serv Specification

PSJR1C Control Panel

(This Control Panel Represents The Automated Version With 7 Day Timer)

Digital Temper ature

Controller (Display) (2460)

PSAV7DT 7 Day

Programmable Timer

(0414)

Digital Countdown

Timer (Display) (2463)

Ready Light

Green Mini Neon (1112)

Function Selected Lights

Amber Mini Neon (1117)

Function Selected Lights

Green Mini Neon (1112)

6 Pole Isolatator (1980)

3 Way Switch (1003D)

2 Way Switches (1003E)

Dotted Outline Shows

Position Of Data Transfer

Point (Window) When

PSAVDL Option Is Fitted

Digital Temper ature

Controller (Display) (2460)

Operates In Chillotherm

Mode Showing Cold

Temperature

Page 13

2001

2003

0638A

1964B

2670

2239DA

2238

2237DA

2253A

1003E

3132D

0490

0491

2086

1383

2

2

3M

1

1

1

1

1

1

1

4

4

2

1

CHASSIS

160”Swivel Braked Caster

160”Fixed Caster

Rubber Bumper (Per Unit)

DOORS

Lockable Handle c/w Catch

Full Size Door Gasket

TOP

110V x 300 Watt Black Thermo Panel

GANTRY

Quartz Lamp Holder

110V x 300 Watt Quartz Lamp

Quartz Lamp Guard (Mesh)

Gantry On / Off Switch (2 Way)

Full Depth Plexiglas Sneeze Screen

CASSETTES

S/S Wheels

S/S Pins

FAN GUARD

Anti Tilt Pin

M5X12 S/S Thumbscrew

Parts

Number

Description Qty Qty

1990

1011A

1039B

1040B

2460

2463

1003E

1003D

1112

1117

1980

1935

1945

2311

3060

2461

1138

2675

0353

1110

1992A

0378

0383

2605D

1123

3275A

0308D

0420

0054

2460

3

3

1

2

1

1

1

1

5

2

1

2

1

3

1

1

1

1

1

1

3

3

1

1

1

1

1

1

1

2M

THERMALIZATION COMPARTMENTS

Fan Motors

Fan Blade

Rapid Heat Element 1000 Watt

Rapid Heat Element 2000 Watt

Digital Temperature Controller (Display)

Digital Countdown Timer (Display)

2 Way Switch

3 Way Switch

Green Mini Neon

Amber Mini Neon

6 Pole Isolator

16 Amp 1 Pole MCB

20 Amp 3 Pole MCB

Change Over Relay

4 Pole Relay

Inhibit Relay

230V Transformer

Delay Timer

5-5 Contacter

K Thermocouple

Auto High Limit Stat

5 Amp Fuse

16 Amp Fuse

CHILLOTHERM FUNCTION TO OVEN

Dinex U.L.Compressor (12)

Lu-Ve Condenser Coil

High Speed Condenser Fan

High Pressure Cut Out Switch

1/4”Filter Drier

0.52 Capillary Tube

Digital Temperature Controller (Display)

Parts

Number

Description

2900

2906

2902

2905

2904

2903

1110

2918

1138

3064

3062

0348

2460

1113

1112

2905

2904

1138

0414

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

PSAVDL DATA LOGGING SYSTEM

Data Logger PCB Board (Panel)

Data Logger Push Button (Yellow)

Data Logger Temp Display Screen

Food Probe

Food Probe Socket

Data Transfer Point Window (Panel)

K Thermocouple

Resistor

230V Transformer

110V Transformer

110V Relay

2 Amp Fuse

PSAVOBP ON BOARD PROBE WITH

PASS / FAIL

Digital Temperature Controller (Display)

Red Mini Neon

Green Mini Neon

Food Probe

Food Probe Socket

230V Transformer

PSAV7DT 7 DAY PROGRAMMABLE

TIMER

Le-Grand 7 Day Timer

Parts

Number

Description

Optional Extras

This section refers to electrical optional extras and is only

vaild when ordered and fitted.

Parts Chart Parts Chart

Qty

PSJR1C

Page 14

1964B

1990

1039B

1040B

2460

2463

1110

1992A

1112

2311

2675

2237DA

2239DA

0378

0383

2605D

0054

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2M

Lockable Handle c/w Catch

Fan Motor

Rapid Heat Element 1000 Watt

Rapid Heat Element 2000 Watt

Digital Temperature Controller (Display)

Digital Countdown Timer Display

K Thermocouple

High Limit Stat

Green Mini Neon

Change Over Relay

Delay Timer

110V x 300 Watt Quartz Lamp

110V v 300 Watt Black Thermo Panel

5 Amp Fuse

16 Amp Fuse

Dinex U.L Compressor (12)

0.52 Capillary Tube

Parts

Number

Description

PSSK1 – PSJR1C

This recommended spare parts kit is for PSJR1G only and to order please quote PSSPK1-PSJR1C

Recommended Spare Parts Kit

Qty

Page 15

MODEL

DESCRIPTION

DINENSIONS

WEIGHT

ELECTRICAL

REFRIGERATION

ADDITIONAL

INFORMATION

PSSR2GG

361 lbs.

N/A

MAX LOAD:6000 Watts (Via Inhibit Relay)

MAXIMUM LOAD AMPS:16.6 Per Phase

1 x 120 Volt 60Hz 15 Amp Plug

2 x 300 Watt 110 Volt

Quartz Lamps

2 x 300 Watt 110 Volt

Black Thermo Panels

1 x 3 Phase 208 Volt 60Hz

30 Amp Plug

3000 Watt Thermalization Oven.

(3x 1000 Watt Elements)

Bracket Attachment Prepared To

Accept Anti Static Strip

8 Pan Thermalization Oven

c/w Cassette

Full Depth Plexiglas Sneeze Screen

8 Pan Ambient Compartment

c/w Cassette

Standard 4 Caster Arrangement

Alternative 6 Caster Arrangement

2x 16cm

Fixed Casters

2x 16cm

Fixed

Casters

2x 16cm

Swivel Braked

Casters

2x 16cm

Swivel

Casters

2x 16cm

Swivel Braked

Casters

Two 8 Pan Thermalization Oven

57.5”W (145cm) x 30”D (75cm) x 37.5”H (95cm) To Work Surface x 51.5”(131cm) To Top Of Gantry

1.For electrical wiring see drawing No.PSSR2GG.

2.When optional extra PSAVDL Data Logger System or PSAVOBP on board food probe with pass /

fail are fitted,please refer to drawing No.PSAEOE for electrical wiring integration.

A.All Perfect•Serv senior gantry switches operate 1 quartz lamp and 1 black thermo panel

together from May 04.

B.Anti static bracket fitted as standard from August 04’.

Perfect•Serv Specification Char t

PSSR2GG

57.5”

(145cm)

37.5”

(95cm)

51.5”

(131cm)

MAIN ISOLATOR

OVEN TEMPERATURE

OVEN TIME

PART

LOAD

READY READY

REGEN

OFF

PART

LOAD

REGEN

OFF

KEEP

HOT

BOOST

OVEN TEMPERATURE

OVEN TIME

PART

LOAD

REGEN

OFF

PART

LOAD

REGEN

OFF

KEEP

HOT

BOOST

Page 16

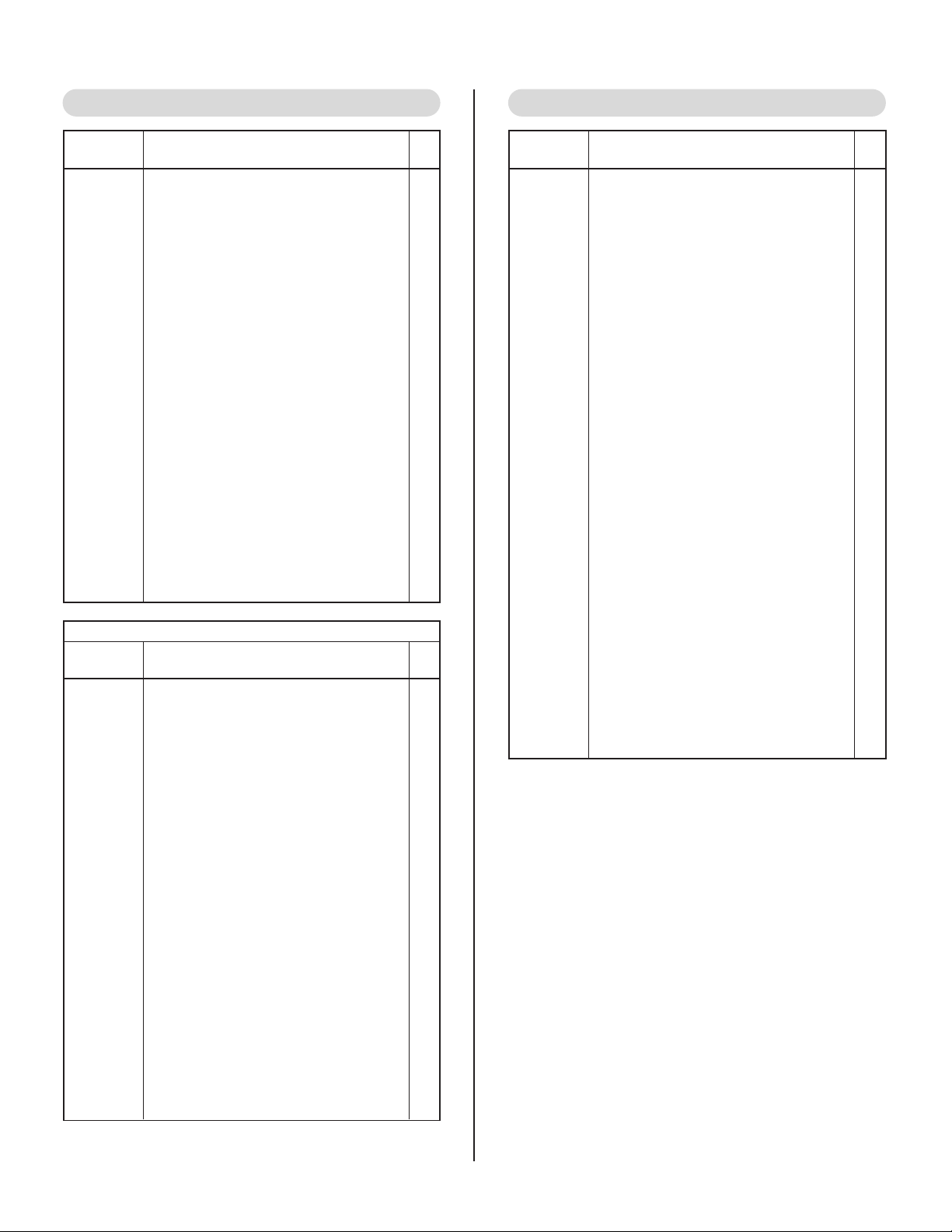

Perfect•Serv Specification

PSSR2GG Control Panel

Digital Temper ature

Controller (Display) (2460)

Digital Temper ature

Controller (Display) (2460)

Digital Countdown

Timer (Display) (2463)

Ready Light

Green Mini Neon (1112)

Function Selected Lights

Amber Mini Neon (1117)

Function Selected Lights

Green Mini Neon (1112)

6 Pole Isolatator (1980)

3 Way Switch (1003D)

2 Way Switches (1003E)

Digital Countdown

Timer (Display) (2463)

Ready Light

Green Mini Neon (1112)

Function Selected Lights

Amber Mini Neon (1117)

Function Selected Lights

Green Mini Neon (1112)

Dotted Outline Shows

Position Of Data Transfer

Point (Window) When

PSAVDL Option Is Fitted

3 Way Switch (1003D)

2 Way Switches (1003E)

Loading...

Loading...