Dinex Perfect Temp User Manual

Perfect•Temp

Users Guide

Revised July, 2007

INTERNATIONAL, INC. 628-2 HEBRON AVE, GLASTONBURY, CT 06033

WWW.DINEX.COM 800-523-9752

Perfect•Temp User’s Guide

Thank you for purchasing the

Dinex Perfect•Temp System.

For more than 35 years, Dinex has been the leader in contemporary,

innovative products for healthcare foodservice.

Today, Dinex is the industry standard for healthcare systems,

equipment and tray-top products throughou t the United States and

Canada.

The Dinex range of products extends from basic traytop ware and

disposables to high-tech induction heating and cook-chill

rethermalization s ystems.

We appreciate your business.

1

Table of Contents

Introduction

Perfect•Temp System Overview........................................................................... 3

Perfect•Temp Principles of Operation................................................................... 3

Advantages of Cook-Chill .................................................................................... 4

Equipment

Perfect•Temp Cart................................................................................................ 6

Perfect•Temp Main Controller ............................................................................ 10

Operation and Programming ……………………………………………………… 11

Perfect•Temp Trays and Dishware

Overview............................................................................................................ 24

Classic ................................................................................................................ 25

Classic II………………………………………………………………………….. 29

Menus and Plating Recommendations

Menus ................................................................................................................ 34

Garnishes and Sauces ......................................................................................... 35

Plating Recommendations .................................................................................. 37

General Plating Guidelines and Procedures......................................................... 38

Production Specifics........................................................................................... 39

Plating Diagrams (Food Placement).................................................................... 42

Meal Assembly and Delivery

Tray Assembly................................................................................................... 47

Rethermalization ................................................................................................ 50

Sanitation........................................................................................................... 51

Satelliting........................................................................................................... 54

System Troubleshooting......................................................................................... 57

Product Warranties................................................................................................ 59

2

Introduction

Perfect•Temp System Overview

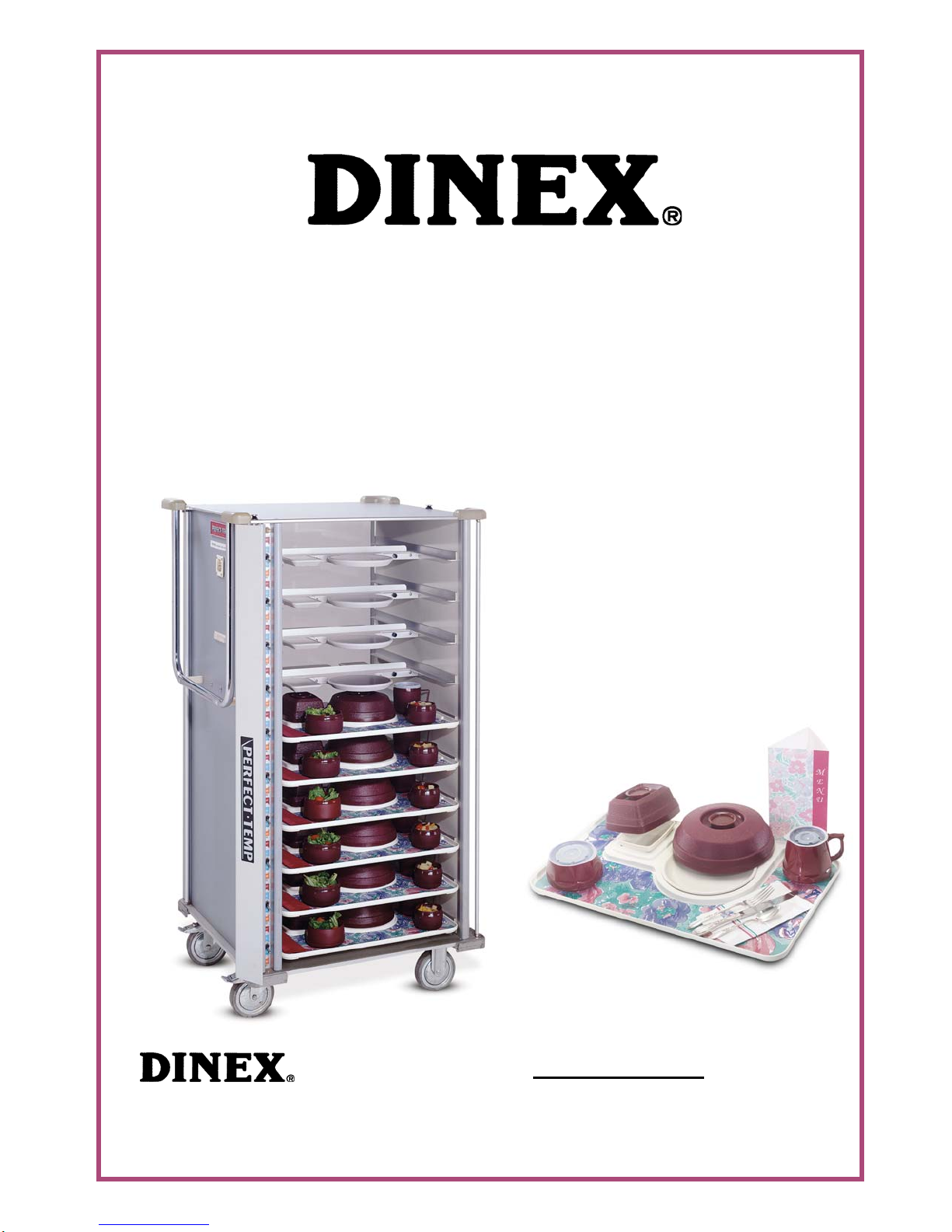

The Perfect•Temp system consists of a walk-in or roll- in refr igerator , a Perfect •Temp

rethermalization cart, an electronic controller, a set of serving trays with insulated covers,

and an assortment of reusable and disposable dishware.

The purpose of this system is to permit cold plating of patient meals in advance so as to

achieve maximum productivity from the kitchen staff. The cold plating of the meals enables

the staff to prepare three meals per standard eight-hour shift, thus eliminating the evening

shift that previously prepared the dinner meal. Plating the meals in advance allows the staff

to prepare the next day’s breakfast meal the day before, eliminating the need for the work

shift to start at 5:30 or 6:00 a.m. Normal 7:00 to 3:30 work shifts are possible.

Principles of Operation

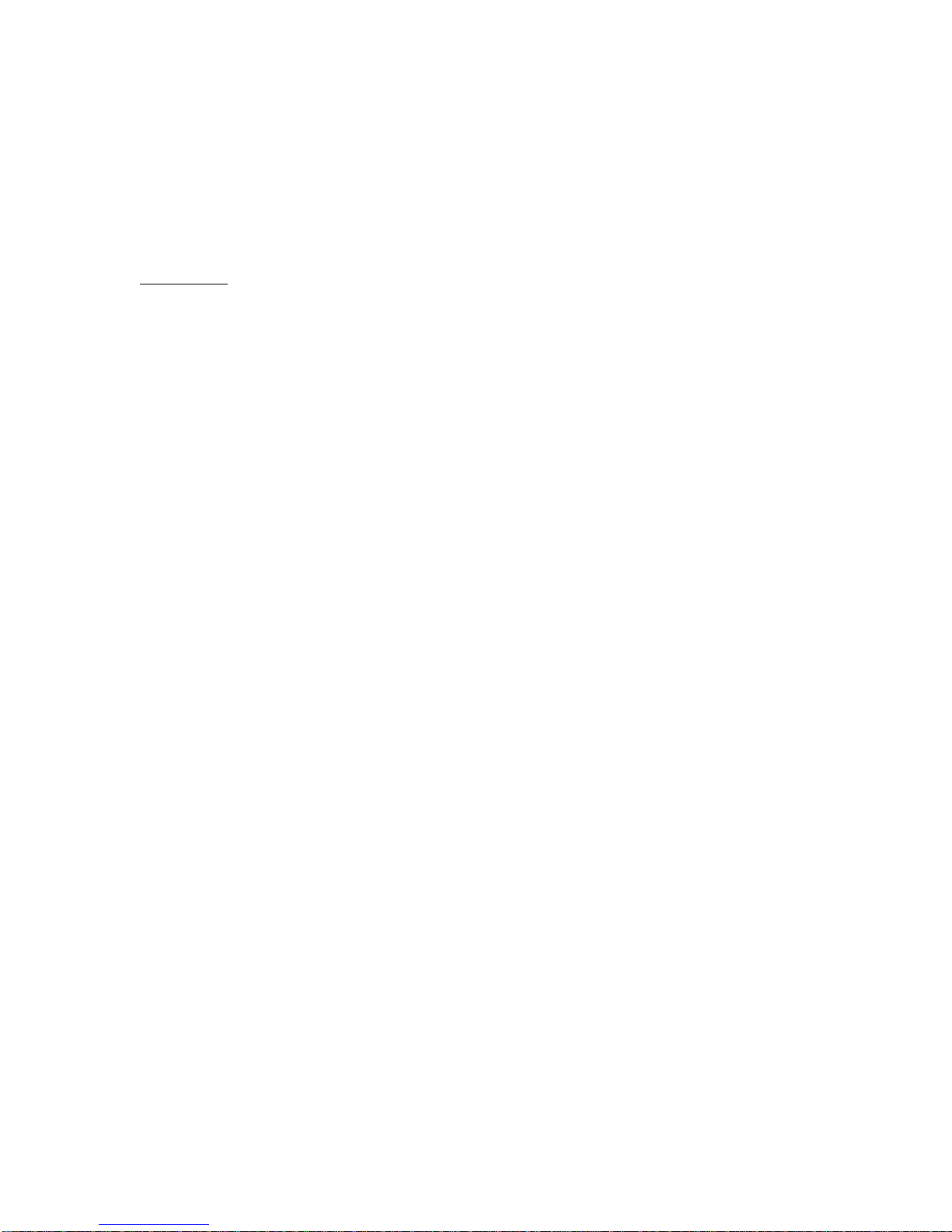

The front of the serving tray has two open compartments (“Classic or Classic II”

server) into which a ceramic, reusable plastic or disposable dish is placed. The rear of the

serving tray has a large cold compartment. These compartments are enclosed and separated

from each other by either insulated tray covers or insulated domes, so no temperature transfer

occurs. The open wing of the tray is used for silverware, condiments, and a frozen dessert or

a hot beverage. The Classic tray style incorporates individual dome covers for the entrée

dish and soup/cereal bowl and the Classic II uses insulated tray covers.

The ceramic, reusable plastic or disposable dishes protrude below the bottom of the

serving tray. When the tray assembly is completed, an insulated cover is placed on the tray

or domes on the soup and entree, and the whole assembly is then inserted into the

Perfect•Temp cart. The dishes protruding from the tray automaticall y align with the

individual heating pads.

When the Perfect•Temp cart has been filled with the desired number of trays, the cart is

placed into a refrigerator to keep all the food on each tray at a safe temperature.

Approximately thirty-five minutes before the meal is to be served, the rethermalization

cycle begins, activated either manual ly or automatically. During this cycle, the heater pads

warm up and transfer their heat to the dishes. By the end of the cycle, the food in each dish

will have reached 170°F. or higher.

The insulated cover (or dome) confines the transfer of heat to the entrée and soup,

while the cold foods on the tray stay cold. The residual heat in the heater pads helps to

maintain food temperatures during meal delivery.

3

Advantages of Cook-Chill

The Perfect•Temp meal delivery system is based upon cook-chill technology, which

allows food to be prepared in advance of service, rapidly chilled, and held in chilled

inventory (food bank). Patient meals are plated chilled and held under refrigeration. Just

prior to service, foods to be served hot are rethermalized.

Advantages

:

1. Rapid chilling and chilled storage techniques simplify handling to such an extent that

fluctuations in daily workloads can be virtually eliminated.

2. Since all meals are prepared in advance, production can be scheduled to make the best

use of equipment, space and staff. “Cook to order” is eliminated.

3. Chilled food’s nutritional value, appearance and texture is better than that of food

produced conventionally and held hot for long periods prior to service; and compared to

frozen food, chilled food suffers only minimal storage effects.

4. Food can be purchased in bulk, resulting in lower food costs.

5. Waste decreases due to flexible stock control, recipe standardization, increased menu

variety, and greater ability to respond to population fluctuations.

6. Staff working conditions are improved due to less peak mealtime tension. Daily tasks

proceed at a more even pace and the staff can focus on the quality and appetizing

appearance of food presented.

7. Labor costs are reduced. The success of cook-chill relies on the improved use of both

skilled and unskilled labor. By concentrating food production, meal assembly, and meal

delivery into self-sufficient, centr al uni ts, each unit can operate at maximum efficiency.

Production can occur on a five-day schedule, and meal assembly for breakfast, lunch and

dinner can be done during a single, eight-hour shift. All of this means reduced labor

costs.

8. Consolidation of production and assembly for several patient units into a single operation

can further enhance the benefits of cook-chill.

9. Savings also can be achieved in costs associated with space.

4

Equipment

5

Equipment

The Perfect• Temp Cart

The Perfect•Temp rethermalization cart is the culmination of many years of

development and testing. Its design has addressed the deficiencies of similar

rethermalization systems on the market and has produced a rethermalization cart that

surpasses the competition in appearance, flexibility, durability—and most importantly,

performance.

Feature Highlights:

• Solid 3/8” aluminum top and bottom surfaces provide exceptional wear resistance and

caster support.

• Aluminum extrusions provide maximum strength and durability while offering a

clean, efficient appear ance.

• Individual heater pad design eliminates sagging of the heater shelf and reduces costs

and downtime when replacing heater pads.

• Nonstick heater pad surfaces improve sanitation and reduce cleaning time.

• The simple, effective selector switch to activate heater pads is not sensitive to tray

motion during transit and does not require tray reversal for cold meals.

• The selector switch is available in two or three position versions so that any tray can

hold a cold entrée (sandwich) but still hold hot soup and a side dish.

• Selector switch positioning makes it possible to change the heat program for any tray

without removing the cart from the refrigerator.

• The “quick disconnect” electrical connection is at eye level, eliminating doubt about

power connection to the cart and the need to run test sequences.

• A multi-function power controller provides maximum flexibility on rethermalization

times, rethermalization duration, and hold cycles.

• Switch shields prevent tray slippage and eliminate accidental contact with selector

switches.

6

The Perfect• Temp Cart Stru ct u re

The Perfect•Temp cart has a solid aluminum base, 3/8” thick, which has been machined

to accept the aluminum corner extrusions. The top of the cart is the mirror image of the

bottom, which securely locks the vertical corner extrusions into place.

The side panels of the cart incorporate a sandwich design consisting of an aluminum

outer panel, a 3/8” thick, honeycomb panel, and another aluminum inner panel. All three

components are bonded together, then secured in the channel raceway of the corner

extrusion.

The side wall, which includes the tubular aluminum handle, is actually two walls with a

hollow core. This core is used as a raceway to run the electrical wiring harness and to

enclose the panel-mounted main electrical connection.

Along the side walls are track angles that support the trays when they are inserted into

the Perfect•Temp cart. Each tray is slid along the tracks until it travels over the heater pads.

A tray stop prevents misalignment of the tray, which would cause improper rethermalization.

Along the two open sides of the Perfect•Temp cart are large numerals that designate the

number of the tray level. This serves as an aid when determining which tray levels are to be

activated or deactivated by the selector switches.

At the top of the cart, centered between the tubular handles, is the electrical connection

to the main controller. The main controller is supplied with a cable assembly that includes a

4- or 5-pin, quick disconnect bayonet plug. The plug connects directly to the receptacle on

the cart to ensure a positive electrical connection. This connection must be made whenever

the cart is to be used to rethermalize meals.

All vertical edges of the Perfect•Temp cart are capped with high-strength aluminum

alloy extrusions. Each extrusion (6 total) includes an integral, replaceable PVC vinyl

bumper, which runs the entire height of the cart for optimum performance.

Adjacent to the selector switch location, pivoting between the top and bottom plate, is

the aluminum switch shield extrusion. When rotated to the “open” position, full access to the

selector switches is possible. When “closed,” the switch shield hides the selector switches

from view, preventing accidental contact or tampering.

The switch shield also acts as a tray stop to prevent serving trays from sliding out of the

cart during transport.

The Perfect•Temp insulated tray cover featur es the patented “cold cone, ” which

promotes superior cold food temperatures, yet works to retain food temperature integrity

when the tray is in transit. Since food trays will be delivered and served from the

Perfect•Temp cart, hot food will actually stay hotter longer, since the heater pads are

insulated and help reduce cool-down from below the dishes.

Tray presentation to patients is enhanced by the availability of insulated covers in a

variety of colors with matching mugs, placemats and china dishware. The full cover in the

7

Classic II system permits the placing of salads, desserts, and so on, directly on the tray

without cumbersome and unattractive plastic over-wraps. Patient perception is enhanced;

convenience is improved for both patients and dietary staff; and clean-up is reduced. The

ability to use disposable, reusable plastic, or china dishware interchangeably is helpful in

fulfilling specific patient needs.

The limits of dietary staffing require staggering the delivery of Perfect•Temp carts to

patient areas. The “Station Commander” controller enables the system to stagger completion

times as needed, preset the frequency and duration of holding cycles, and run automatically

or manually. An indicator on each controller verifies that the cart has been placed in the

refrigerator, has been electricall y connected, and is ready for the rethermalization cycle to

begin. Once started, other indicators on the controller indicate rethermalization, holding, or

ready status. A 10-second buzzer sounds at the end of every heating or hold cycle.

Perfect•Temp Cart Heater Pad Design

Each tray level on the Perfect•Temp cart is equipped with two heater pads. The small

pad is primarily for the rethermalization of hot cereals and soups. The larger pad is for the

entrée.

The heater pad assembly consists of an engineered resin casting, a computer-designed

heating grid, a layer of insulation, thermostat and thermal fuse. The entire assembly is

permanently sealed to prevent water penetration and eliminate potential residue build-up. .

The heater pad fixture serves a dual purpose. First, it provides a protective shell into

which the heater pad is assembled. Second, the casting is designed to be fastened

mechanically in the cart, offering superior strength and durability.

The heater pad fixture is fabricated with a flanged end that mates to a box channel

running the width of the cart at each tray level. All electrical wires run inside the box channel

and connect to each heater pad. The heater pad casting is then secured with two screws that

pass through the flange of the casting into the box channel.

The top surface of the heater pad is a layer of coated (nonstick) aluminum. A

computer-designed heater grid is vulcanized to the underside of the aluminum. The design of

the heater grid is specific to the heating requirements, which means that the grid pattern for

each of the pads is different. The purpose of changing the grid pattern is to develop the

thermal patterns necessary for each application. The needs of the soup or hot cereal heating

pad are not the same as the needs for the entrée heating pad. Three different grid patterns

resulted.

Beneath the top layer of aluminum and its bonded heater grid is fiberglass insulation to

help direct the transfer of heat toward the dish and to shield the tray and cover below from

unnecessary thermal conductivity.

The insulation is protected from moisture by the bottom of the heater pad fixture. The

resulting assembly is then completely sealed with silicone sealant.

8

The design of the heater pad assembly offers the advantage of being field replaceable

without affecting the adjoining heater pads. Separate pads also minimize heat conductivity to

the Perfect•Temp cart body, reducing electrical loads and improving efficiency.

Heater Pad Control (On-Off)

Depending upon the cart model, each Perfect•Temp cart will have 16, 20 or 24 tray

levels. Each tray level consists of two heater pads. Each level is controlled by one or two

selector sw i t c h es.

On the outside of the Perfect•Temp cart, along the vertical extrusion closest to the

handles, are the selector switches. The toggle switches have three positions: all pads hot, all

pads cold, or side dish pads hot. An optional two-position , two switch per server is

available. This allows individual control of each heater pad.

Cart Lexan Door Option

An optional set of Lexan doors is available for the Perfect•Temp rethermalization cart.

The purpose of these doors is to enclose the tray areas of the cart to reduce or eliminate the

need to over-wrap exposed plated foods. The doors also restrict incidental contact from

unauthorized personnel or patients, reducing pilferage of food products from the patient

trays.

Each Lexan door is secured along one vertical edge by an aluminum extrusion which

provides rigidity and acts as the hinge. The remaining three edges of the door are chamfered

to provide a smooth appearance and eliminate sharp edges.

When closed, the doors are held in place by the switch shield extrusion that encloses

the switches, as well as the edge of the door. To rotate the switch shield, lift the plunger pin

which is secured to the top plate of the cart.

When fully open, the two doors are nested, one in front of the other, against the front

wall of the cart opposite the handle. Once again, release the plunger pin to nest or de-nest the

doors.

9

Perfect•Temp Main Controller

The primary purpose of the main controller is to deliver consistent, precisely controlled

electrical voltage to the heater pads. The controller accepts 200 to 240 VAC input and

delivers the necessary output voltage and current to the pads.

The second function of the main controller is to time there rethermalization cycle.

Once the cycle has started, a red digital display begins counting down from the programmed

time. When the programmed time has elapsed, a signal will sound for 10 seconds.

If the main controller is not turned off at the completion of the rethermalization cycle, a

hold cycle will begin which will apply heat to the food for two minutes. At the end of the

two-minute heat cycle, the alarm will once again sound for 10 seconds. This sequence will

repeat indefinitely until the main controller is turned off.

The last feature, which is standard on the model Station Commander controller, is a

three-event, 24-hour, automatic timer. Once set for the start times of all three meals, the

automatic timer will automatically start there rethermalization cycle at each mealtime. This

feature eliminates the need for each rethermalization cycle to be started manually. This

feature is especially suited to applications where multiple Perfect•Temp carts are in use and

are to be started sequentially according to the serving schedule.

A safety system automatically disconnects power from the Perfect•T emp car t whenever

the roll-in refrigerator door is opened.

The controllers also include a standard indicator light which illuminates whenever the

rethermalization cycle i s in process, as well as a “ready” light that lights whenever the car t

has been plugged in and is ready to be activated.

Summary of Perfect•Tem p Control ler

Station Commander

• Flush mounted above door of roll-in refrigerators

• Input and output cables terminated in junction boxes mounted on top of refrigerator

• UL approved

10

PERFECT-TEMP STATION COMMANDER CONTROLLER –

MODEL PT-SC SERIES OPERATION INSTRUCTIONS

Introduction

The PT-SC controller (Station Commander) is configured into two independent modules, the

Operator Module and the Power Module which are linked together by an interconnecting,

low-voltage cable.

The software, or programming information, is entered and stored in the operator module

which may be wall mounted or installed in a roll-in refrigerator bezel.

The electrical connection from the building electrical supply and the output to the PerfectTemp cart(s) are done within the power module which is available as either a single cart

version (Single Power Module) or a eight (8) cart version (Quad Power Module).

Programming Overview

The Station Commander Operator Module is capable of being programmed to facilitate the

following:

• Program for up to eight (8) Perfect-Temp carts.

• Automatic rethermalization start for breakfast, lunch and dinner.

• Ability to accept a second start time for a second cart at breakfast, lunch and dinner.

• Independent rethermalization cycle times for each meal.

• Automatic “hold” cycle at the completion of the rethermalization cycle. “Hold” cycles

can be customized for each meal, by selecting “hold” cycle duration, heat, and no-heat

sequencing.

• Keypad entered pass codes for entry into the programming menu or for manual starting of

the rethermalizati on cycle.

• Programmable pass codes (2 levels).

11

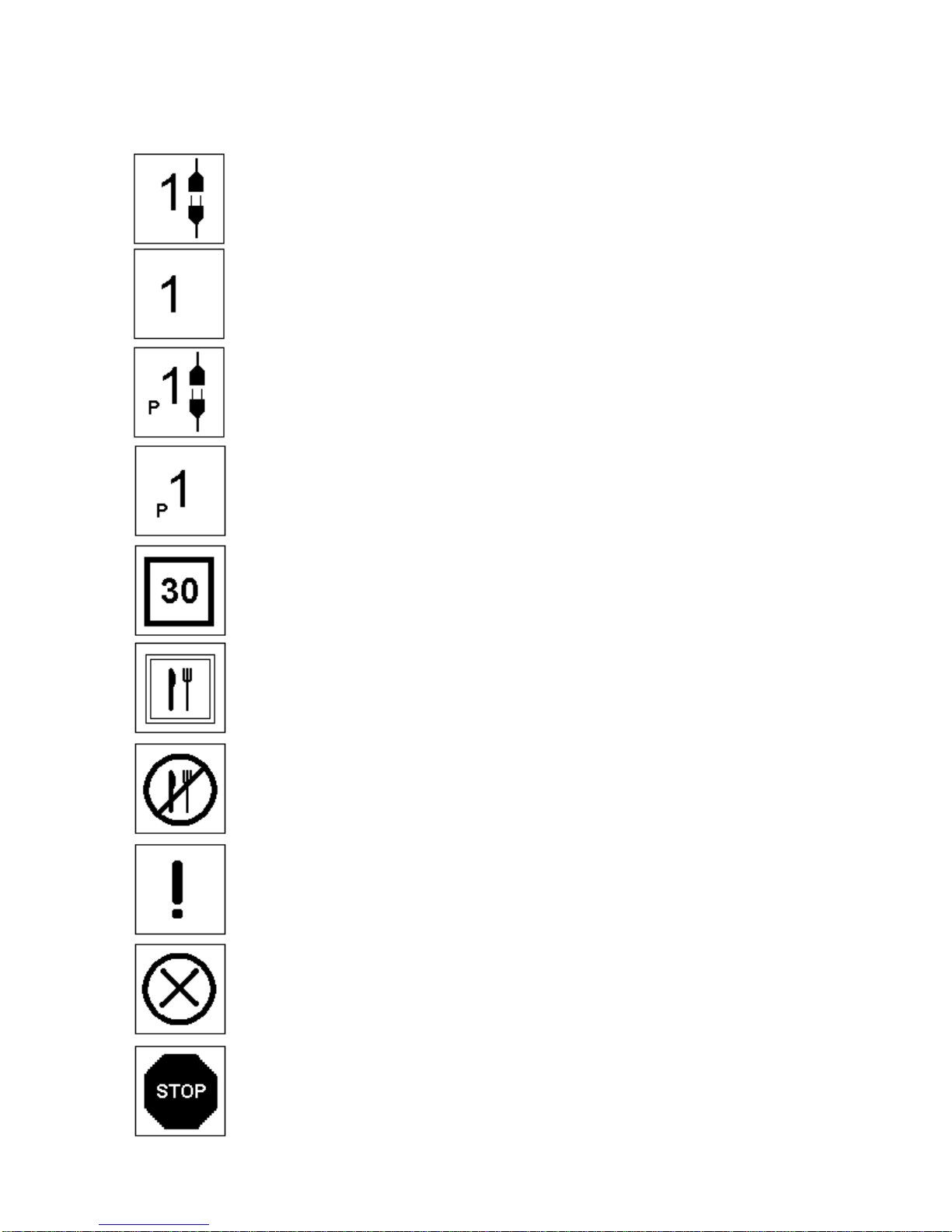

No meals programmed for this cart. This cart is unplugged.

No meals programmed for this cart. Cart is plugged in.

Meals are programmed for this cart. This cart is unplugged.

Meals are programmed for this cart. Cart is plugged in.

Cart is rethermalizing meal. Remaining time is shown in center of icon.

Meal is ready. Outer box area will blink.

Hold time is exceeded. Rethermalization has stopped.

Warning or informational message. This icon does not appear on the main

screen, but accompanies message displayed as a result of main screen

interactions.

Error. Indicates that there has been a user entry error or that the requested

operation can not be performed at this time. This icon does not appear on the

main screen, but accompanies message displayed as a result of main screen

interactions.

Cart is being Stopped. This icon appears temporarily when a cart is manually

stopped. This icon will remain for approximately one minute after

disconnecting cart.

12

Programming Number of Carts Displayed and Speaker

1) Press the “PROGRAM” key

2) Display will prompt:

Select:

Program Meal Times

Configure Unit

3) Use the “ “ keys to highlight “Configure Unit”.

4) Press the “YES” key to select.

5) Enter pass code “15037” on the keypad.

6) Display will prompt:

Select:

System Setup

Set Meal Parameters

Set Pass co d e s

Set Time of Day

Reset

7) Use the “ “ keys to highlight “System Setup”.

8) Press the “YES” key to select.

9) Display will prompt:

System Setup

Number of Carts: 8

Alarm : ON/OFF

Key Click: ON/OFF

10) Use the keypad to enter the number of carts to be displayed (1-8).

11) Use the “ “ keys to change the Alarm to ON/OFF setting.

12) Pr ess the “SAVE ” key t o store the change(s).

13) Press the “CANCEL” key to exit programming.

13

Meal Parameters

The Station Commander operator module has the capability of programming the carts under

its control for different rethermali zati on cycle lengths for each meal. This means that the

breakfast meal rethermalization cycle could be less than the dinner and lunch cycles, should

this be desirable.

In addition, an automatic hold cycle can be programmed to supply intermittent heating after

the normal rethermalization cycle is complete. This allows carts to be held for a

programmable period of time without significant loss of heat to hot food items.

The hold cycle is comprised of two parts, the “ready” time and “maintain” time. At the

completion of the rethermal izat ion cycle, the electrical power t o the Perfect- T em p cart is

switched “off”. The duration of time that the power remains “off” is known as “ready” time.

When the “ready” time duration expires, electrical power to the Perfect-Temp cart is

switched “on”. The duration of time that the power remains “on” is known as “maintain”

time. At the expiration of the “maintain” time, the power again is switched “off” for another

“ready” time. This sequence continues until the total elapsed time of both the “ready” and

“maintain” time exceeds the programmed “hold” time.

When the duration of the programmed “hold time” is exceeded, the Station Commander

automatically discontinues further activity with that particular cart and displays the “Hold

Time Exceeded” symbol.

Programming Meal Parameters

1) Press the “PROGRAM” key

2) Display will prompt:

Select:

Program Meal Times

Configure Unit

3) Use the “ “ keys to highlight “Configure Unit”.

4) Press the “YES” key to select.

5) Enter pass code “15037” on the keypad.

6) Display will prompt:

Select: System Setup

Set Meal Parameters

Set Pass co d e s

Set Time of Day

Reset

7) Use the “ “ keys to highlight “Set Meal Parameters”.

14

8) Press the “YES” key to select.

9) Display will prompt:

Retherm Hold Maintain(on) Ready(off)

Breakfast 35 30 01 02

Lunch 37 30 01 02

Dinner 37 30 01 02

The retherm times depend on the type of dishes used. Fro example: HH Disposables average

37 minutes; HH Resuables average 38 minutes; china averages 40 minutes.

10) Use the “ “ keys to highlight the parameter you would like to change.

11) Use the keypad to enter the new parameters.

12) Repeat steps 26-27 to update additional parameters

13) Press the “SAVE” key to store the change(s).

14) Press the “CANCEL” key to exit programming

Pass Cod es

Each operator module is equipped with three levels of pass codes to provide security and

prevent tampering with cart rethermalization programming or initiation.

1) The Maste r p a ss co d e al l o w s e n t r y i n to the system. T h e Maste r p a ss co d e n umber is

15037.

2) The Supervisor pass code is a 4-digit pass code that permits access to mealtime

programming. This code can be selected and changed at any time. See Programming

Pass Codes section.

3) The User pass code is a 3-digit pass code and permits access to the manual start

function. As with the Supervisor code, this code can be selected and changed at any

time. See Programming Pass Codes section.

Progra m ming Pass Cod e s

1) Press the “PROGRAM” key

2) Display will prompt:

Select:

Program Meal Times

Configure Unit

15

3) Use the “ “ keys to highlight “Configure Unit”.

4) Press the “YES” key to select.

5) Enter pass code “15037” on the keypad.

6) Display will prompt:

Select: System Setup

Set Meal Parameters

Set Pass co d e s

Set Time of Day

Reset

7) Use the “ “ keys to highlight “Pass codes”.

8) Press the “YES” key to select.

9) Display will prompt:

Change Pass codes

Supervisor: 4444

User 333

Note: These are the default factory settings.

10) Use the keypad to enter new pass codes.

11) Pr ess the “SAVE ” key t o store the changes.

12) Press the “CANCEL” key to exit programming.

Programming Time of Day

Notes: 1. All programming is done in military time (0 to 2400) to reduce the chance of

programming errors.

2. You must change the Station Commander manually for daylight savings time.

1) Press the “PROGRAM” key

2) Display will prompt:

Select:

Program Meal Times

Configure Unit

3) Use the “ “ keys to highlight “Configure Unit”.

4) Press the “YES” key to select.

16

5) Enter pass code “15037” on the keypad.

6) Display will prompt:

Select: System Setup

Set Meal Parameters

Set Pass co d e s

Set Time of Day

Reset

7) Use the “ “ keys to highlight “Set Time of Day”.

8) Press the “YES” key to select.

9) Use the keypad to enter a new time.

10) Pr ess the “SAVE ” key t o store the change(s).

11) Press the “CANCEL” key to exit programming

Resetting the Controller

Note: Resetting the controller will reset “Meal Parameters” to default factory settings and

remove all “Meal Times”

1) Press the “PROGRAM” key

2) Display will prompt:

Select:

Program Meal Times

Configure Unit

3) Use the “ “ keys to highlight “Configure Unit”.

4) Press the “YES” key to select.

5) Enter pass code “15037” on the keypad.

6) Display will prompt:

Select:

System Setup

Set Meal Parameters

Set Pass co d e s

Set Time of Day

Reset

17

7) Use the “ “ keys to highlight “Reset”.

8) Press the “YES” key to select.

9) Display will prompt:

Resetting the unit will

Destroy all programming information.

Do you wish to continue?

10) Press the “YES” key to complete the resetting process.

11) Press the “CANCEL” key to exit programming.

Meal Times

The meal times programmed are the actual meal times that the Perfect-Temp cart is expected

to be ready for meal service.

When mealtime is programmed, the Station Commander will automatically calculated the

correct rethermalization start time based upon the programmed length of there thermalization

cycle.

For example, if the Perfect-Tem p cart is to be ready for meal delivery at 11:00 a.m., and a

rethermalization cycle of 35 minutes is programmed. Then 11:00 is programmed as the

mealtime and the controller automatically starts the rethermalization cycle at 10:25 a.m.

(11:00 minus the 35 minute rethermalization cycle).

A second cart may be programmed for any cart location for breakfast, lunch or dinner. Some

consideration should be given to the programming of the second cart time. The

rethermalization time for the cart and the amount of time needed to change out the carts

needs to be considered.

For example, if the rethermalization time is 35 minutes and you need 5 minutes to get the

carts changed out, Then the second cart meal time should be at least 40 minutes after the first

(35 minute rethermalization cycle plus 5 minutes for changing carts).

Programming Meal Times

1) Press the “PROGRAM” key

2) Display will prompt:

Select:

Program Meal Times

Configure Unit

3) Use the “ “ keys to highlight “Program Meal Times”.

18

4) Press the “YES” key to select.

5) Enter pass code “4444” on the keypad.

6) Display will prompt:

Select:

Program Meals

Copy Meals

7) Use the “ “ keys to highlight “Program Meals”.

8) Press the “YES” key to select.

9) Display will prompt:

Select Cart:

1 2 3 4 5 6 7 8

10) Use the “ “ keys to highlight the cart you would like to program.

11) Pr ess the “YE S ” key to select.

12) Display will prompt:

Meal 2nd Cart

Breakfast --:-- --:- Lunch --:-- --:- Dinner --:-- --:--

13) Use the keyboard to enter meal times. The cursor will automatically jump from field to

field. Use the “ “ keys for extra mobility. The “NO” key may be used to

remove existing meal times.

14) Pr ess the “SAVE ” key t o store the change(s).

15) Press the “CANCEL” key to exit programming or repeat steps 6-14 for the next cart.

IMPORTANT: The Perfect Temp cart must be hooked up to the drop cord 15 minutes prior

to the start of the cycle. Failure to do so may cause the Station Commander to not recognize

that the cart is plugged in, and may not start.

19

Loading...

Loading...