Dinex MOC20 Service Manual

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cleaning Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical & Refrigeration Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Accessing & Cleaning of Compressor Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Simplicool Refrigeration Unit Change Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement of Danfoss Cold Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Danfoss Control Location & setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Return Air Vents (Hot & Cold) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Removal of the Hot Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dinex® Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

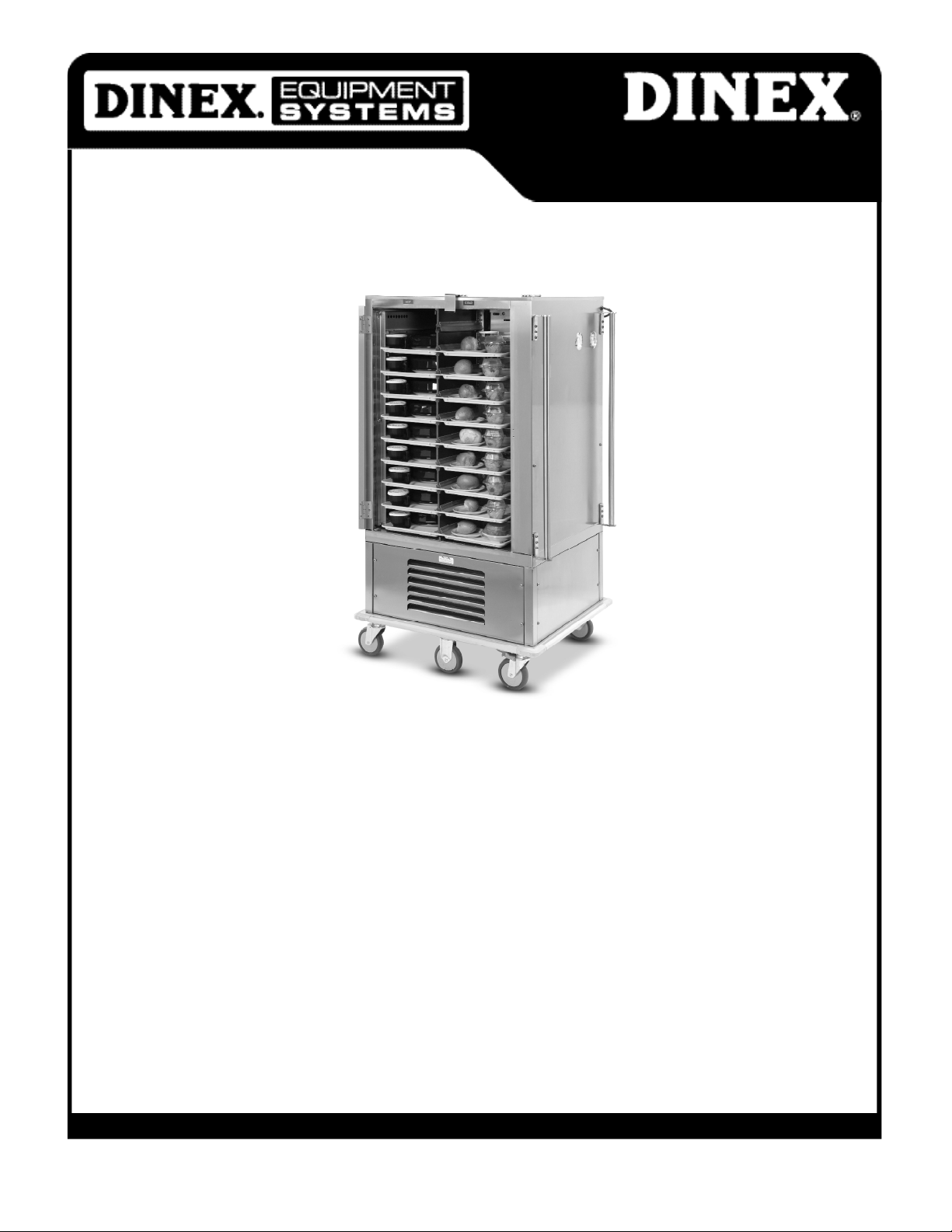

MOC20

H OT / COLD CA R T Se r v i c e Ma n u a l

DINEX INTERNATIONAL, INC. • 628-2 HEBRON AVENUE, GLASTONBURY CT 06033 • WWW.DINEX.COM

For Service Information, call 1-888-673-4639

Please provide following information:

• Model number

• Serial number

• Part Description and number as shown in parts list.

Manual No. MOCMANUAL Rev-06/07Printed in the USA

SET UP

Carefully uncrate the unit.Re m o ve all loose packing

m a te r i a l , m a k ing sure that no small parts or acce s s o ries

a re lost. I n s pe c t the unit for co n cealed damage be fo re

d i s c a rding the packing mate ri a l .

NOTE: It is the responsibility of the installer to comply with

all local codes.

IMPORTANT: The hot and cold controls are factory set.

Never attempt to change these settings. All control setting

changes must be performed by a qualified technician.

The unit is now re a dy for use. It is impo rt a n t that at

l e a s t

1 2 ” of open airspace be maintained at the louve red panels.

I m p r o per air flow thru

the re f ri g e ration co m p res sor ca n

lead to inadequate coo l i n g , ove rh e a ting and damage to the

co m p re s s o r. Such a condition will void the wa rra nty.

The basic operation of the MOC20 is a dual compartment

cart that holds pre-plated meals on hot and cold trays.

This unit is designed for hospital/health care food service

operations that use cook-serve meal preparation. The

MOC20 is independently powered, meaning that it is not a

static cart and plugs in to any 120vac single phase, 20 amp

(NEMA 5-20R) dedicated receptacle. The MOC20 uses separate sides to maintain hot and cold food temperatures via

gentle convection heating and a built in refrigeration system. It accomplishes this by using heated forced air via a

blower/heated coil system and forced cool air via the

Simplicool/Danfoss refrigeration system.

1. To start the unit, simply plug it into a 120 VAC 20 amp

dedicated receptacle. Since the unit draws 15.5 amps at

startup, a dedicated receptacle is required.

2. Close the doors and allow the unit to precool and

preheat for 20 minutes. Next,load the trays of food into

the cart. Keep the doors closed as much as possible.

Door(s) left open for extended periods of time will

greatly affect food temperatures.

3 . The refrigeration system is design to operate for 30

minutes and then automatically go into a 5 minute

defrost. During the 5 minute defrost cycle, the compressor

shuts down. Thus when looking at the thermometers

located on the side of the unit, temperatures will rise to

approximately 210/215 degrees F. on the hot side and

up to approximately 55 degrees F. on the cold side. Once

the defrost ends, the temperatures will level out in

approximately 10 minutes.This fluctuation does not

affect food temperatures.

You have just purchased the new Dinex Equipment. Please

read this manual for helpful guidelines on how to use your

Equipment. Should you have any questions concerning

the Equipment, please call the Dinex Hotline at 1-888-6734639 (Monday through Friday from 8 am to 5 pm, Eastern

Standard Time).

IMPORTANT: For your safety,read and follow all cautions,

information and warnings

FREIGHT DAMAGE CLAIMS

Your Dinex Equipment was carefully inspected and packed

before leaving our plant.The transportation company

assumes full responsibility for the safe delivery of the

Equipment. Dinex does not assume any responsibility for

damage or loss incurred in transit. Please note any visible

damage or loss on the freight bill and have delivery personnel sign.

A freight claim should be filed immediately with the transportation company.If concealed damage is discovered

after unpacking the Equipment, please file a concealed

damage claim with the transport company within 10 days

after receipt of the goods.

IMPORTANT: All packing materials should be retained for

return shipment.

SAFETY

The instructions contained in this manual provide important guidelines for the Equipment user regarding a correct

and safe installation. Particular attention should be paid to

the warnings given in various parts of this manual. Never

dismantle and/or repair the appliance with the power supply in place. Service work must be performed by qualified

personal.

INFO: Please note that this appliance is for commercial

use only and must be used exclusively for the purposes

prescribed.

Page 2

Introduction

Operation

!

!

!

!

!

CLEANING INSTRUCTIONS

WARNING: Never spray or pressure wash this equipment.

Such action can cause damage to the electrical component, could cause serious electrical shock and will

completely void the equipment warranty.

WARNING: Cleansers,detergents,sanitizers or bleaching

agents that contain chlorides or phosphates will cause

permanent damage to stainless steel and aluminum

products.The damage can appear as pits, severe discoloration, dulling of the finish and rust on stainless steel.This

damage is permanent and will void the equipment warranty.

Prior to cleaning, unplug the cabinet from the electrical

power source. Using a mild soap and water,or other

cleaners or sanitizers approved for stainless steel, wipe

down the interior and exterior of the unit.This mild

solution can be used as well on the center wall silicone

rubber air dams/wipers. Do not use excessive water.

Once clean, wipe dry with a soft cloth.

IMPORTANT: There are hot and cold air discharge open-

ings located in the center of the inter compartments.There

are also return air holes located on each side of the inter

compartment. Never allow water and cleaning solutions

to enter these openings. If this occurs, the moisture will

damage the internal electrical components and void

the warranty.

ELECTRICAL AND REFRIGERATION SPECIFICATIONS

Electrical: 120 VAC 1 phase 15.5 amps. Dedicated receptacle

required. Refrigeration: R134A Freon, charge is 10.5 ounces,

high side pressure is 197 psig & low side pressure is 104 psig.

Mo nt h l y , check the condition of the co m p res sor filter and

clean as needed.No te that a dirty filter will affe c t the pe rfo rm a n ce of the re f ri g e r ation sys te m , cause damage to the

co m p ressor and may void the equipment wa rra nty. For

f i l ter access and cleaning instru c t i o n s , re f er to the

“Ac cessing and cleaning of the Fi l te r”s e ction in this manual.

IMPORTANT:

This procedure is not covered under warranty

and is the responsibility of the facilities maintenance/

engineering department. Such procedure must be

performed by a qualified technician.

!

1. General Safety and trouble shooting tips:

a. Safety: When troubleshooting unit, make sure to

disconnect the unit from the electrical power

source. Do this by unplugging the unit from the 120

Volts, AC power source. Once the panels have been

removed,a qualified & trained technician can electrically energize the unit for troubleshooting purposes.

b. Also, at the terminal block, check for intermittent

contact that occurs when a wire of a thicker gauge

contacts an adjoining wire that is on a different

circuit. Check for integrity of electrical wiring and

connections. Check to see that all fork or ring terminals are tight on terminal board, heater and relay.

Also check for intermittent contact made if a wire of

thicker gauge is next to the wire in question. Check

for tightness of wire nuts and all other electrical connections. Check electrical wiring for chafing and

insulation tears.

2. Unit is not Heating:

NOTE: If the unit is heating, but not at its maximum

performance level, check the return vent holes located

on the inside side panels. The five (5) return holes located

toward the center of the cabinet must be plugged. See

“RETURN AIR VENTS (HOT & COLD)” on page 7 of

this manual.

a. If unit is not heating and all wiring is determined to

be in good order: First,note whether the unit is

heating up to 160° F. This should take about 30

minutes and can be verified by placing a thermocouple or thermometer in the bottom of the heated

compartment. The thermometer or thermocouples

should read 140° F -160° F. If not:

b.

Check to see if the 3300 Cal controller is reading 160° F

.

If not, reprogram the controller. This controller is

located inside a lower access panel. Note that when

the controller is operating properly, the temperature

display will read 157° to 167° F. Also, there will be a

flashing LED apparent on the left hand corner of the

controller. If programmed properly:

c. Check to see if relay is energized. If so, go to next

step. Check for mechanical binding or chattering

(usually repetitive). If so then replace relay. Please

note that the controller circuitry has a certain amount

of capacitance, meaning that there is enough charge

to hold the NO (normally open) set of contacts on the

relay closed until such time that the controller

de-energizes (approximately 160° F).Thus, if checking

the relay with an ohm meter, the contacts should

show continuity,or if checking while electrically

energized,there should be 120 volts across the

terminals.This will hold true until the Cal 3300

controller senses a temperature of approximately

160° F. However, since the unit has a heating issue, at

this point in the troubleshooting process, the Cal

3300 controller should not be showing this reading.

!

!

!

Page 3

Maintenance

!

Troubleshooting

c. Determine if unit is performing the proper 30 minutes

cool cycle, followed by a 5 minutes defrost cycle. After

every 30 minutes, the unit will go into an automatic 5

minute defrost. During the 5 minute defrost cycle, the

compressor shuts down. Thus, during this period,

when looking at the thermometers located on the

side of the unit, the hot temperature will rise to

approximately 210/215 degrees F. During this period,

the cold thermometer will rise to approximately 55° F.

Once the defrost cycle ends, the hot & cold temperatures will level out in approximately 10 minutes. If

cycling properly:

d. Check the continuity of the cold Side Thermistor at the

Danfoss control. If no continuity, replace the

Thermistor. To do this, the complete Simplicool

refrigeration unit will have to be removed from the

cabinet. See: Simplicool Refrigeration Unit Change

Our Instructions” on page 5 of this manual. Once the

Simplicool system has been removed, see section

“Replacemant of Danfoss Cold Thermistor” on Page 7

of this manual. If O.K.:

e. Check the Danfoss control to make sure that it is at

the proper setting. See “Danfoss Control Location

and Setting” section on page 7 of this manual. To

properly set the Danfoss control, turn the stem

clockwise as far as it will go. If O.K.:

f. Check the seal between the Simplicool refrigeration

unit and the cabinet. There must be a good seal

between the Simplicool unit and the cabinet bottom.

First make sure that the Simplicool refrigeration unit

is sitting properly on the support pedestals with Split

Washers and that the Rear Retainer bracket is in

place. See section “Simplicool Refrigeration Unit

Change Out Instructions” on page 5 and refer

specifically to figures 1, 2 & 5.

g. Check the operation of the Simplicool refrigeration

unit. If faulty, it can not be repaired. Contact Dinex for

a replacement unit. If under warranty,the faulty unit

can be exchanged for a new one. For out of warranty

units, a new unit can be purchased and a partial

credit given for the return of the failed unit.To

replace the unit, refer to the “Simplicool Refrigeration

Unit Change Out Instructions” on page 5 of this manual.

IMPORTANT:

The following troubleshooting steps may

require the removal of the “Hot Box Assembly”.

NOTE:

The Hi-Limit Thermostat, Hot Side Thermocouple and

the Blower Assembly are all located in this box.

See section “Removal of the Hot Box Assembly” on page 8

of this manual.

d. Next, check the heating element:First, energize the

unit and check the voltage across the heater terminals.

If no voltage reading, check internal electrical wiring to

the element. If there is 120 volts across the heater

terminals, clamp an amp meter around one of the

heating element lead wires. The heating element is

rated 120 VAC, 1100 watts, thus, the amp meter should

read approximately 9 amps. If not,replace the heating

element. If so,the heating element is O.K.:

e. Perform a continuity check on the hot side thermo-

couple.This thermocouple can be accessed at the Cal

3300 controller.If no continuity, replace the thermocouple. If O.K.

f. Check the hi-limit thermostat for continuity.Since the

unit is not heating, the hi-limit thermostat should be

closed. If not, replace it. Please note that this hi-limit

thermostat is set to open at 300 F. Its sole purpose is

to act as a safety device. If hi-limit is O.K.:

g. Check blower assembly.See if motor is running. There

should be some motor/blower wheel vibration. Also,

an air flow should be felt from inside the heated compartment. If not, check for 120 volts at the motor. If

there is not 120 volts, check internal wiring. If so, and

the air flow does not seem to be adequate, if available,

use an Anemometer to measure the air flow. To do

this, remove the air plentum from inside the cabinet

and check the air flow. The air flow should be from

700 to 900 FPM. If not, replace the blower assembly.

3. Unit Not Cooling:

a. Make sure that all of the electrical wiring is in order;

next make sure that there is approximately 12”of

open air space at the louvered panels located in the

lower portion of the cabinet. Improper air flow thru

the louvered panels can cause improper cooling. This

condition can also cause overheating of the compressor and void the equipment warranty. If there is proper

air space:

b. Check to see if the filter located behind one of the

louvered panels is dirty. To access the filter see section

“Accessing and Cleaning of the Compressor Filter”on

page 5 of this manual. Please note that the cleaning of

the air filter is not covered under warranty.

If filter is clean:

!

Page 4

!

Loading...

Loading...