Dinex IREBC-35 Service Manual

Blast Chillers

DINEX INTERNATIONAL,INC. • 628-2 HEBRON AVENUE,GLASTONBURY CT 06033 • WWW.DINEX.COM

For Service Information,call 1-888-673-4639

Please provide following information:

• Model number

• Stamped-in code

• Part Description and number as shown in parts list.

Models:

IREBC-35,IREBC-75,IREBC-100

INSTALLATION,OPERATION

AND SERVICE MANUAL

Manual No.BC35/75/100 Rev-06/02

Dinex International, Inc. (“Dinex”) warrants that its TMP Equipment (“Equipment”) shall be free

from defects in materials and workmanship for a period of one (1) year from the date of delivery

to the initial end user (“End User”) (the “Warranty Period”). Dinex shall be notified of all

Equipment claimed to be defective and covered by this warranty. The End User shall include in

this notification the serial number and a copy of the Bill of Lading (showing delivery date) for the

Equipment. If Dinex’s investigation establishes the existence of the alleged defects, then Dinex

shall, at Dinex’s choice and expense, repair or replace the affected Equipment (provided that the

costs of labor on such repairs shall only be included for proper warranty claims asserted in

writing within ninety (90) days of the delivery date) and reimburse End User for the reasonable

shipping costs for returning the Equipment to Dinex, if any.

This warranty does not apply to defects in any Equipment caused by: (1) normal wear and tear;

(2) failure to comply with any Dinex-provided operation or maintenance instructions; (3) alteration

or modification by parties other than Dinex or (4) misuse, neglect, accident, Acts of God or other

causes beyond the control of Dinex after delivery of the Equipment by Dinex to its authorized

distributor.

Repaired or replacement Equipment under this warranty shall be warranted for the unexpired

portion of the original Warranty Period applicable thereto plus the period from notice to Dinex of

such defect until completion of repair or return to the point of original delivery to Buyer.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHETHER

ARISING BY LAW, CUSTOM, CONDUCT OR USAGE OF TRADE, AND THE RIGHTS AND

REMEDIES PROVIDED HEREIN ARE EXCLUSIVE AND PROVIDED IN LIEU OF ANY OTHER

RIGHTS AND REMEDIES. DINEX SHALL HAVE NO LIABILITY OTHER THAN AS PROVIDED

IN THIS WARRANTY, WHETHER CLAIMED IN CONTRACT, EQUITY, TORT OR OTHERWISE,

FOR OR RESULTING FROM DEFECTS IN MATERIALS OR WORKMANSHIP OR

OTHERWISE.

IN NO EVENT SHALL DINEX BE LIABLE FOR ANY SPECIAL, INCIDENTAL, INDIRECT OR

CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE

EQUIPMENT, REAGRDLESS WHETHER SUCH LIABILITY SHALL BE CLAIMED IN

CONTRACT, TORT, EQUITY OR OTHERWISE.

DINEX INTERNATIONAL,INC. 628-2 HEBRON AVENUE,GLASTONBURY CT 06033 | www.dinex.com

DINEX SERVICE HOTLINE 1.888.673.4639

®

WARRANTY

SUPPLEMENTAL WARRANTY AFTER 20 MONTH WARRANTY

FROM 21 MONTHS TO 5 YEARS

Dinex agrees to reimburse the original purchaser, for five (5) years after the date of

shipment for the net exchange cost of the replacement motor-compressor less any labor,

freight, taxes and handling charges.

The term “original purchaser-user” as used herein shall be deemed to mean that person,

firm, associa tion, or cor poration for whom the equipment was originally installed.

The term “motor-compressor” as used herein does not include unit base, air or wa ter

cooled condenser, receiver, electrical accessories such as relay, ca pacitors, pressure

control, or condenser fan motor assembly, etc. This war ranty fur ther does not include any

equipment to which said motor-compressor is connected, such as cooling coils,

temperature controls, refrigerant metering devices, refrigerant, etc. This war ranty shall be

void if said motor-compressor in our judgment has been subjected to misuse, negligence,

accident or operated contrary to the recommendations specified by the manufacturer or if

the serial number has been altered, defaced or removed.

GENERAL CONDITIONS

Performance under this warranty is contingent upon causes beyond our control and we

shall not be liable for any default or delay in performance thereunder caused by any

contingency beyond our control including war, governmental restrictions or restraints,

strikes, fire, floods, short or reduced supply or raw material or discontinuance of the par ts

or motor compressor assembly by our suppliers.

This warranty applies only to the motor-compressor installed within the continental limits

of the United States.

This warranty does not give the owner of the refrigerator the rights to purchase a

complete replacement condensing unit of the same make or another make. It further does

not permit the replacement to be made with a motor-compressor of another make unless

written approval is authorized.

Expressly excluded from this warranty are damages resulting from spoilage of goods or

any other incidental damages inasmuch as this warranty applies only to the replacement

of defective motor-compressor.

ii

Changes in engineering standards cause variations in compressor

specifications. These changes are brought about by our upgrading programs

and our suppliers engineering product changes. It is impractical for the

customer to go to the manufacturer for the replacement compressor.

Suppliers have set up wholesaler organizations to handle replacements on a

local basis.

The standard O.E.M. (original equipment manufacturers) warranties are for an

unconditional 20 months from date of manufacture at their factor y. This

allows several months for Dinex to install a compressor and get the cabinet

into the field.

A defective compressor must be taken to a local wholesaler and exchanged

for a new one. If the first three digits of the defective compressor serial

number shows that it is less than 20 months old, the wholesaler is obligated

to give an even exchange.

The additional four year warranty is available from Dinex, 628-2 Hebron

Avenue, Glastonbur y, CT 06033-5006.

If the defective compressor is past 20 months of age, it must be exchanged

with the local wholesaler and the service company, dealer, or the customer

must temporarily pay for a new compressor, *less any salvage value of the

original. A copy of the original wholesale invoice and salvage credit memo,

must then be sent to Dinex, with the model and serial number of our ca binet.

Dinex will reimburse them for the net exchange price, less any labor, freight,

tax, or handling charges. Reimbursements are not prorated over the five year

warranty.

(*Note: Salvage credit applies to Copelamatic units only)

If any difficulties arise bey ond those mentioned, please call us directly at (888) 673-4639

iii

RETAIN THIS MANUAL FOR FUTURE REFERENCE

SECTION 1

DESCRIPTION

Chill Processing Undercounter, Reach-In & Roll-In Refriger ator/Storage Cabinets

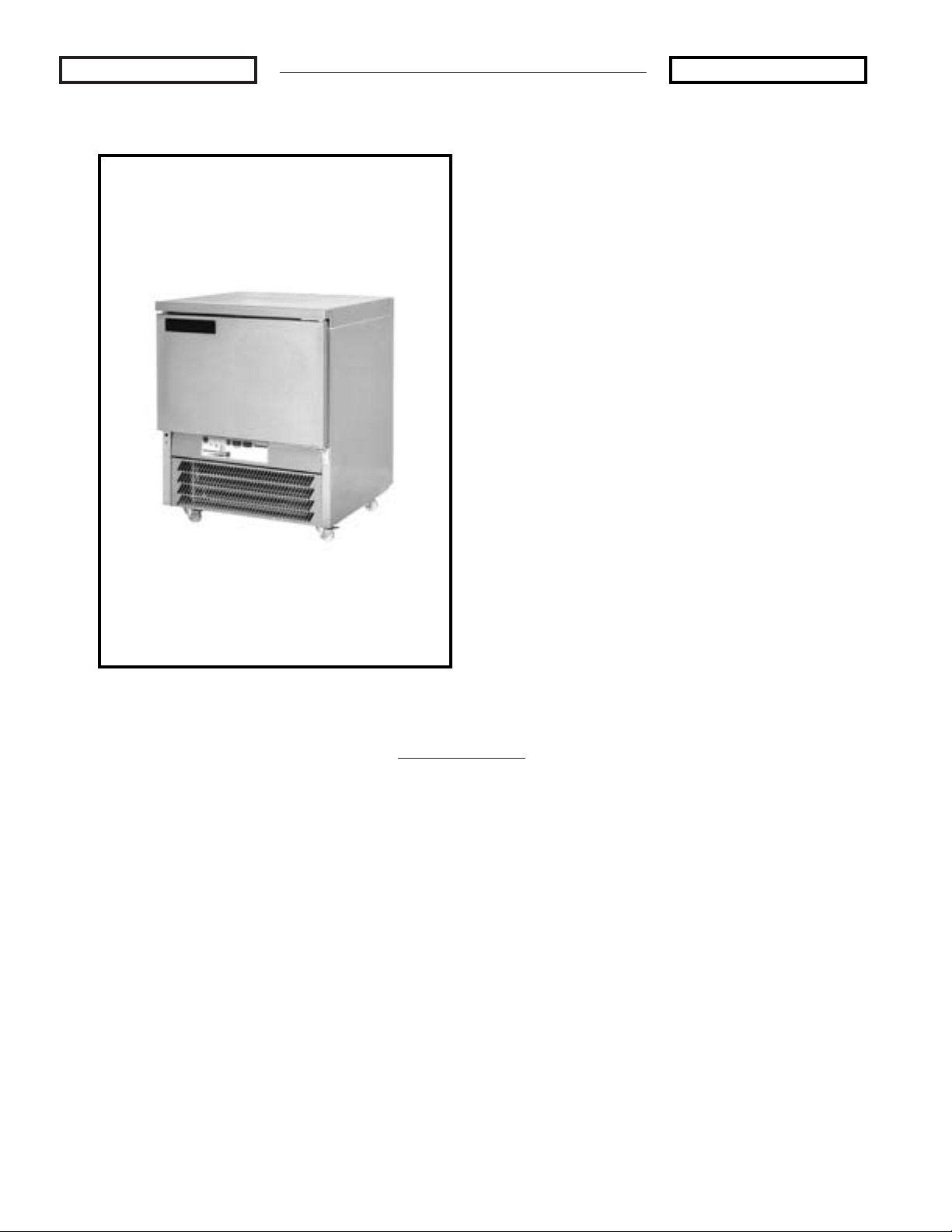

• IREBC-35: The IREBC-35 Reach-In Cabinet is ideal for foodservice operations which

require a small volume blast chiller. This model is capable of chilling 35 lbs of food

product to +38°F in approximately 90 minutes.

The comprehensive control panel features built in-alarms and can control the

chilling process with the food core temperature probe or the digital timer.

At the end of the blast chill cycle the cabinet automatically reverts to a +38°F

storage refrigerator.

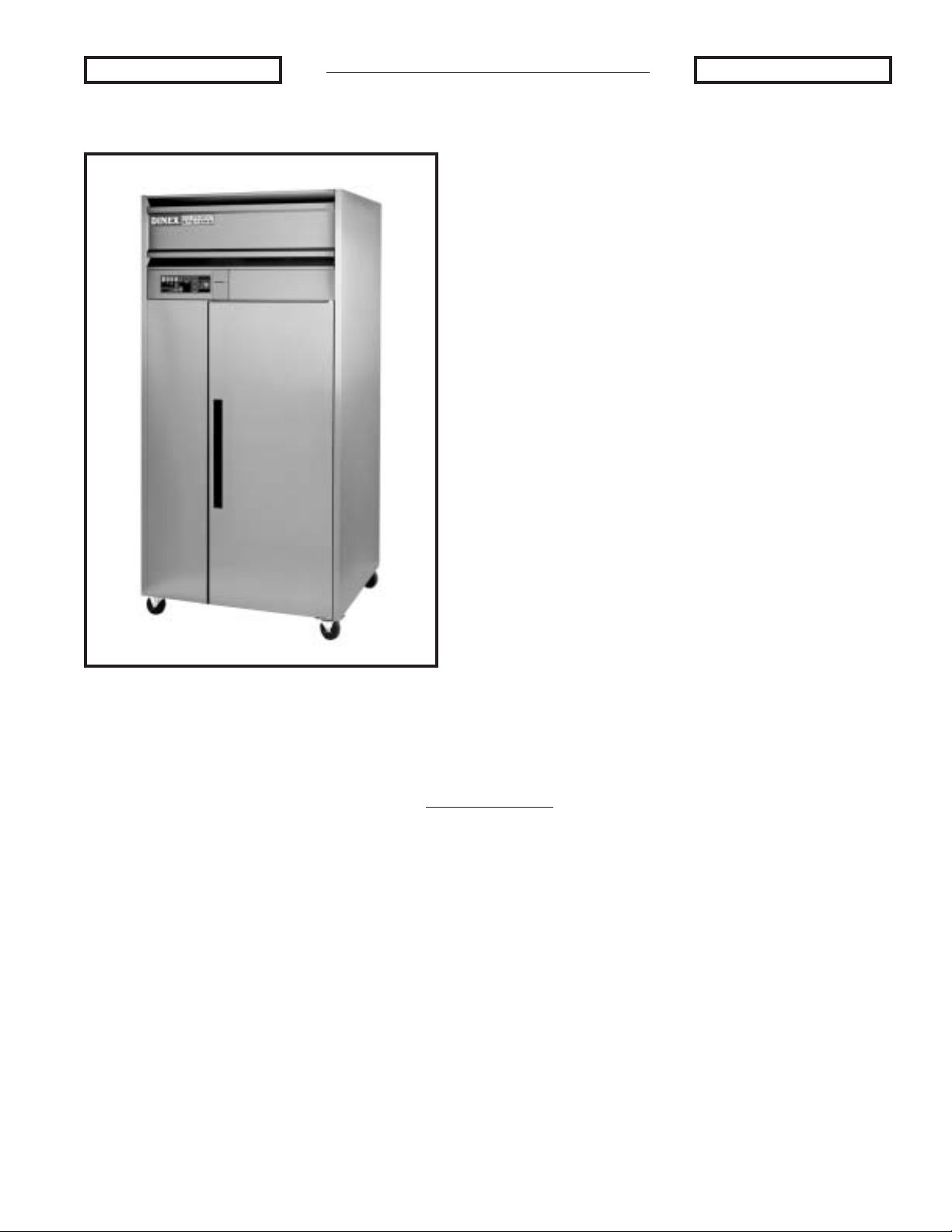

• IREBC-75:

The IREBC-75 Reach-In Cabinet is ideal for small to medium size

foodservice operations which require a blast chilling capability. This model is

capable of chilling 75 lbs of food product to +38°F in approximately 90

minutes. Daily capacity is over 900 lbs of processed product.

The comprehensive microprocessor is controlled by a digital timer.

Core temperatures can be determined quickly and accurately with the food probe.

At the end of the chill cycle the cabinet automatically defrosts and reverts to a

+38°F storage refrigerator.

• IREBC-100:

The IREBC-100 Reach-In Cabinet is ideal for small to medium size

foodservice operations which require blast chilling capability. This model is

capable of chilling 100 lbs of food product to +38°F in approximately 90 minutes.

Daily capacity is over 1200 lbs of processed product.

The comprehensive microprocessor is controlled by a digital timer.

Core temperatures can be determined quickly and accurately with the food probe.

At the end of the chill cycle the cabinet automatically reverts to a +38°F

storage refrigerator.

Section 1-Description Section 1-Description

1

The IREBC-35 Undercounter Blast Chiller

Standard Features:

Two Operational Features:

- Blast Chill Processing Refrigerator

- +38°F Storage Refrigerator

Operational Indicator Panel with Microprocessor:

- Blast Chill Cycle Controlled Automatically by

Either a Food Probe or Digital Timer

- Four (4) Preset Chilling Times: 30,60,90,240

Mins.

- Cabinet Temperature Digital Display

- Food Temperature Digital Display

- Defrost Mode Indicator

- On/Off, Blast Chill Cycle and Cancel Buttons

- Power Failure Alarm

Stainless Steel Top, Front, Sides, Door and

Interior

Flush Mounted Doors, Anti-Condensation

Heaters and Removable Magnetic Door Gaskets

Five (5) Pairs of Adjustable Pan Slides for 12” x

20” x 2-1/2” Pans

Heavy Duty Swivel Casters with Brakes on the

Front

Hot Gas Condensate Vaporization

Large Surface Area Evaporator and High Velocity

Fan

CFC Free R-134a Refrigerant

Specifications

Dimensions Electrical Date

Capacity (lbs/90 mins) 35 lbs Voltage 208/60/1

Width 28” Amperage 7.0

Depth 32” Feed Wires & Ground 2

Open Door Depth 58-3/4” 10 FT Cord Installed, No Plug

Height 35”

Clear Door Width 21”

Clear Door Height 15”

Number of Tray Slides 5 pairs (10)

Refrigeration Data Crated Dimensions

Compressor HP 3/4 Width 31”

BTU/HR 4,827 Depth 34”

90°F Ambient, 14°F Evaporator Height 39”

Weight Data (lbs)

Crated 414

Uncrated 269

Section 1-Description

2

Section 1-Description

The IREBC-75 Reach-In Blast Chiller

Standard Features:

Two Operational Features:

- Blast Chill Processing Refrigerator

- +38°F Storage Refrigerator

Operational Indicator Panel with Microprocessor:

- Blast Chill Cycle Controlled Automatically by Either a

Food Probe or Digital Timer

- Four (4) Preset Chilling Times: 30,60,90,240 Mins.

- Cabinet Temperature Digital Display

- Food Temperature Digital Display

- Defrost Mode Indicator

- Power Failure Alarm

- Three (3) Food Probes with Digital Temperature

Indication

Seven (7) Day Temperature Recorder with Printout

Demand

Stainless Steel Top, Front, Sides, Door and Interior

Flush Mounted Doors, Anti-Condensation Heaters and

Removable Magnetic Door Gaskets

Twelve (12) Pairs of Adjustable Pan Slides on 3-1/2”

Centers for 18” x 26” Sheet Pans & 12” x 20” hotel pans.

Heavy Duty Swivel Casters with Brakes on the Front

Condensate Disposed of Automatically

Large Surface Area Evaporator and High Velocity Fan

Contained in a Separate Service Compartment

Condensate Disposed of Automatically

Automatic Defrost

CFC Free R-134a Refrigerant

Specifications

Dimensions Electrical Date Refrigeration Data

Capacity (lbs/90 mins) 75 lbs Voltage 208/60/1 Compressor HP 1-1/2

Width 35-1/2” Amperage 15.0 BTU/HR 1,211

Depth 36” Feed Wires & Ground 2 90°F Ambient, +14°F Evaporator

Open Door Depth 58-1/4” 10 FT Cord Installed, No Plug

Height 77-1/2”

Clear Door Width 18”

Clear Door Height 48-1/2”

Number of Tray Slides 12 pairs (24)

Crated Dimensions Weight Data (lbs)

Width 37-1/2” Crated 618

Depth 38” Uncrated 548

Height 79”

3

Section 1-Description Section 1-Description

The IREBC-100 Reach-In Blast Chiller

Standard Features:

Two Operational Features:

- Blast Chill Processing Refrigerator

- +38°F Storage Refrigerator

Operational Indicator Panel with Microprocessor:

- Blast Chill Cycle Controlled Automatically by Either a

Food Probe or Digital Timer

- Four (4) Preset Chilling Times: 30,60,90,240 Mins.

- Cabinet Temperature Digital Display

- Food Temperature Digital Display

- Defrost Mode Indicator

- Power Failure Alarm

-Three (3) Food Probes with Digital Temperature

Indication

Seven (7) Day Temperature Recorder with Printout

Demand

Stainless Steel Top, Front, Sides, Door and Interior

Flush Mounted Doors, Anti-Condensation Heaters and

Removable Magnetic Door Gaskets

Twelve (12) universal tray/hotel pan slide.

Heavy Duty Swivel Casters with Brakes on the Front

Condensate Disposed of Automatically

Large Surface Area Evaporator and High Velocity Fan

Contained in a Separate Service Compartment

Automatic Defrost

CFC Free R-404A Refrigerant

Specifications

Dimensions Electrical Date Refrigeration Data

Capacity (lbs/90 mins) 100 lbs Voltage 208/60/3 Compressor HP 2

Width 43-3/8” Amperage 8.6 BTU/HR 12,098

Depth 40-5/8” Feed Wires & Ground 3 90°F Ambient, +14°F Evaporator

Open Door Depth 66” Hard-Wired

Height 81”

Clear Door Width 21-3/8”

Clear Door Height 51-3/8”

Number of Shelves 12

Crated Dimensions Weight Data (lbs)

Width 46-1/2” Crated 659

Depth 43-1/2” Uncrated 648

Height 84”

4

SECTION 2

INSTALLATION

Reach-In Models:

IMPORTANT:

It is highly recommended that your

refrigerator or freezer be installed by an

Authorized Dinex Installer.

A. Receiving Shipment

Upon arrival, examine the exterior of the shipment

packaging for any signs of rough handling.

If the cabinet is damaged, it should be noted on the

delivery slip or bill of lading and signed to that effect. A

claim must be filed immediately against the carrier

indicating the extent and estimated cost of damage

incurred.

All units are performance tested and thoroughly

inspected prior to shipment. Upon leaving the factory, all

units are in perfect condition and the carrier signs to this

effect.

B. Uncrating Procedure

WARNING:

DO NOT, Under Any Circumstances, Lay

Your New Equipment Down On Either The

Back, Front or Sides!!!!

1. See instructions printed on shipping carton.

2. Also see warranty registration card inside the

back cover of this manual.

3. Remove protective cardboard corners, sides and

top.

4. Next remove the shipping skid.

5. If any concealed damage is discovered at this

time, notify the carrier in writing

, and retain all

carton and packing materials until an inspection

has been made or waived by the carrier.

CAUTION:

Exercise extreme caution when removing

the wooden skid, especially when the last

bolt is removed, as the skid, if not properly

blocked, will fall to the floor with extreme

force.

C. Removing Plastic Film

Stainless steel surfaces are protected with plastic film

when shipped. The film is easily removed by grasping an

edge or corner of the film and pulling it off.

D. Locating Your New Blast Chill Unit

The cabinet should not be placed in the immediate

vicinity of ranges, ovens and other heat radiating

equipment. As a hot ambient will reduce the cooling

efficiency of the unit as well as increase operating cost.

Self-Contained refrigeration is standard on reach-in

chillers. Adequate air ventilation is mandatory for the

condensing units in order to operate efficiently and to

prevent excessive and damaging operating temperatures.

E. Leveling

The cabinet must be standing level on all four casters for

the self-closing doors to operate properly and for proper

drainage of condensation from the evaporator. Casters

are non-adjustable, therefore the floor must be level.

F. Cleaning (refer to section 4)

Section 2-Installation

Section 2-Installation

5

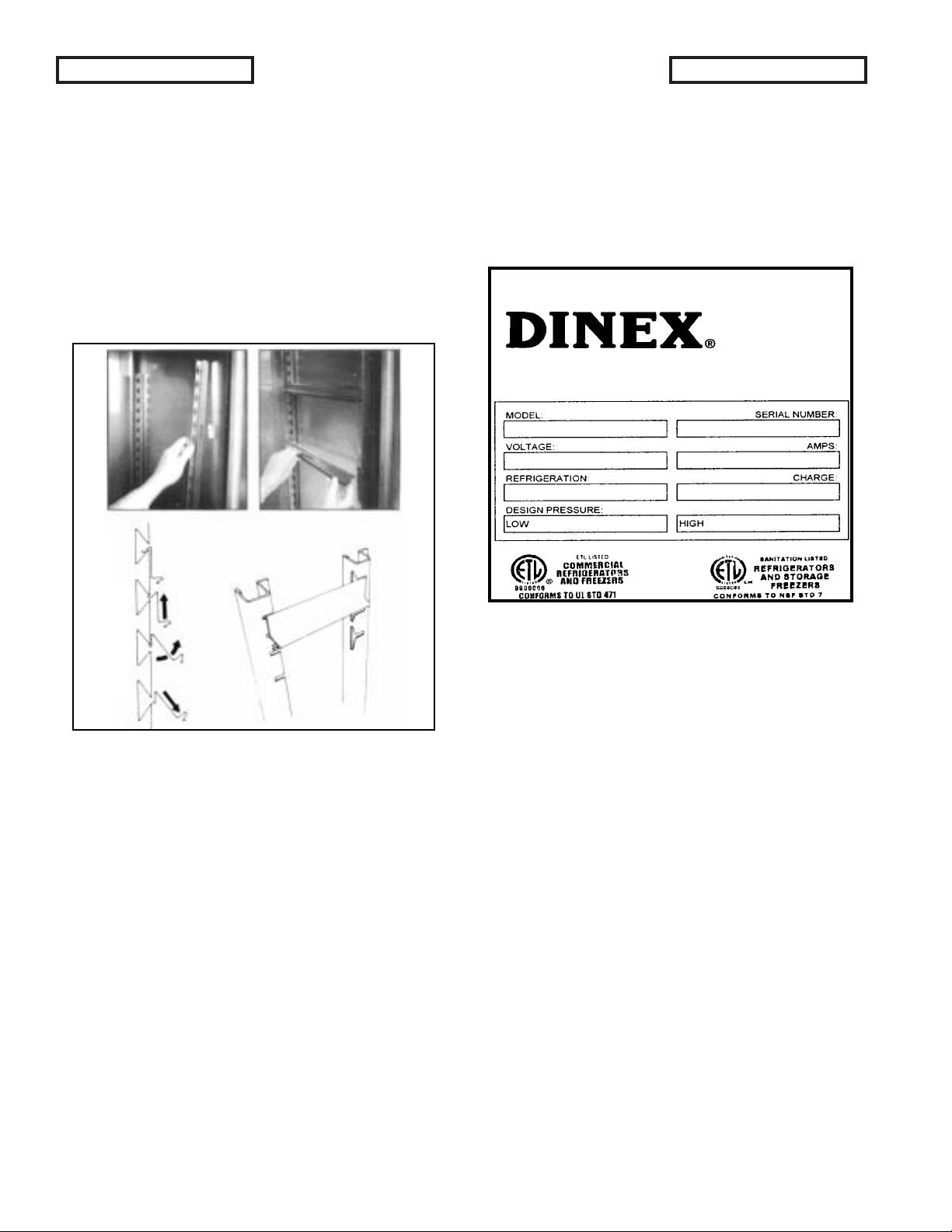

G. Installing Panslides (for Models IREBC-35 &

IREBC-75 only)

There are five (5) pairs of panslides for the IREBC-35

and twelve (12) pairs of panslides for the IREBC-75 that

are considered standard for these models. They are

shipped in a bundle fastened to the skid at the rear of the

cabinet and must be installed as seen in Figure 2-1.

Before installing the slides, remove the protective plastic

film. When installing, make sure the panslides are level

(from front to back) and are at the same height on each

side. Otherwise, the pans will not sit level and could fall.

Figure 2-1

Panslide Installation

H. Electrical Supply

The IREBC-35 and IREBC-75 are furnished with an

electrical power cord, plug and receptacle. The

appropriate NEMA receptacle must be available at the

installation location. Other models require a qualified

electrician to furnish and install wiring for the power

supply. This must be connected to the identified

terminals provided inside the control panel. Refer to the

appropriate wiring diagram furnished with the cabinet for

guidance.

Electrical power of the correct voltage, phase and

ampacity must be supplied to the Blast Chiller. The

chiller must have it’s own separate electrical circuit

breaker with no other equipment or appliance connected

to that breaker. For the electrical requirements see the

cabinet data plate located on the interior wall.

I. Location of Serial Number/Data Plate

The serial number/data plate is located on the interior

wall of the cabinet. Refer to Figure 2-2 to see what the

plate looks like.

Figure 2-2

Serial Number/Data Plate

J. Check List (with Power Turned Off)

Note: Examine The Following Before Start-UP!!!!

Caution!: Make sure electrical power is turned off prior

to making these checks to avoid the

possibility of unexpected injury.

1. Check that above installation recommendations have

been adhered to. Pay particular attention to

installation location for any potential excessive

heat sources (oven, range, etc.) or inadequate air

ventilation conditions which can cause compressor

overheating problems and/or failure. if any such

condition exists notify the owner to have the installer

correct.

2. Check refrigeration tubing for damage (or potential

for) such as kinks and not touching or rubbing

against anything.

3. Make sure cabinet is sitting level with four (4)

casters in contact with the floor.

4. If on casters, make sure front caster brakes are in

“locked” position.

Section 2-Installation

Section 2-Installation

6

110 Woodcrest Rd.

Cherry Hill, NJ 08003

800-523-9752

5. Check door operation. Make sure door self-closes

when opened to less than 90 degrees. Also make

sure it stays open when opened past 90 degrees.

6. Inspect magnetic door gasket to be sure it is

making contact on all four (4) sides and that it is not

cut, torn, twisted or otherwise deformed.

7. Check installation of shelves or pan slides

as appropriate.

8. Check electrical power source for correct voltage,

phase and ampacity. Refer to cabinet data plate for

requirements.

9. Make sure all circuit breakers are turned on.

10. Check all fan blades. They should turn freely

without touching anything.

11. Check electrical power supply cord and plug for any

damage.

12. Check condensate vaporizer (evaporator) tray at

rear of cabinet (IREBC-35 location is

inside compressor compartment) for any

damage and foreign debris (remove if present).

Section 2-Installation

Section 2-Installation

7

Loading...

Loading...