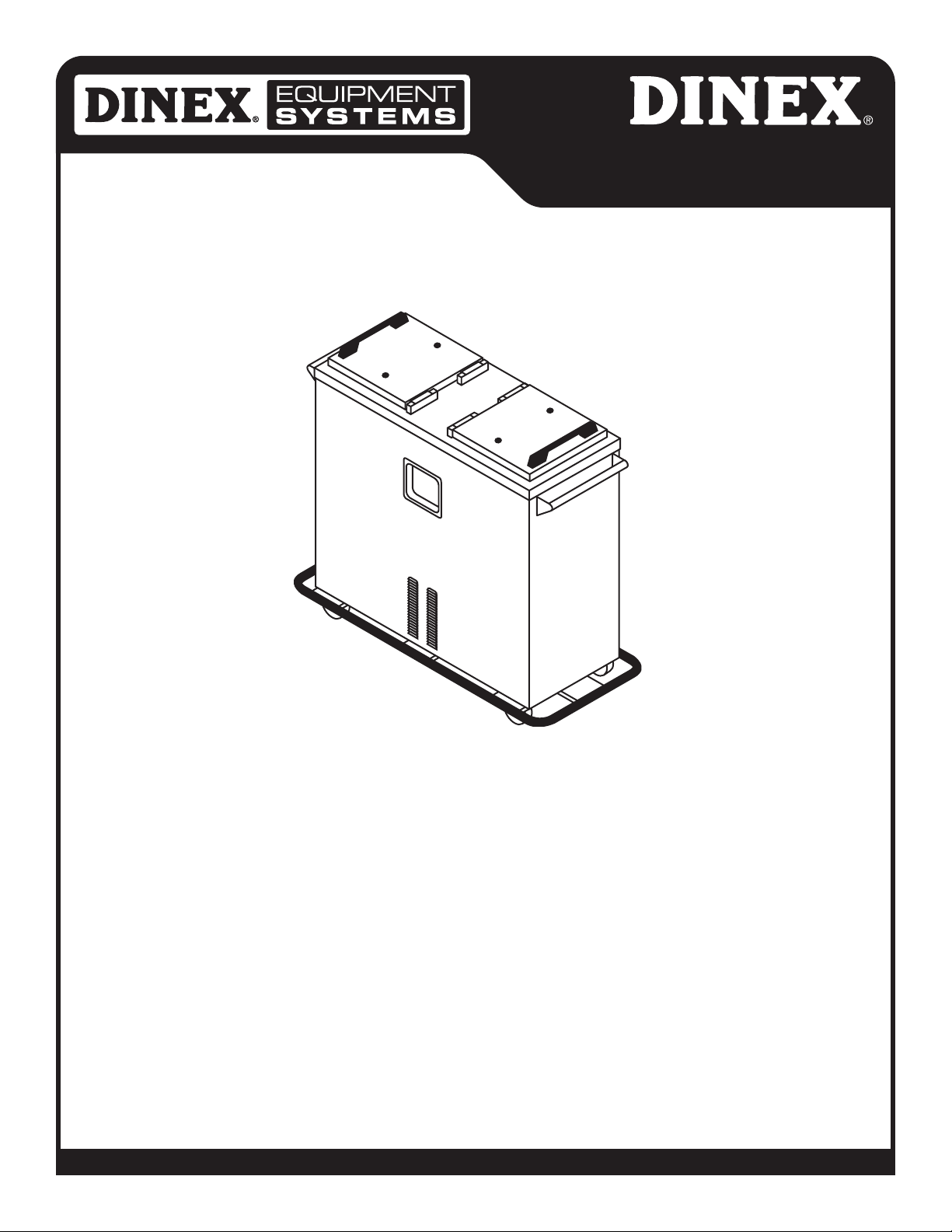

Dinex IDWB2-0775 Service Manual

Wax Base

Heater & Dispenser

DINEX INTERNATIONAL,INC. • 628-2 HEBRON AVENUE,GLASTONBURY CT 06033 • WWW.DINEX.COM

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpack & Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation & Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dinex® Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

For Service Information,call 1-888-673-4639

Please provide following information:

• Model number

• Serial number

• Part Description and number as shown in parts list.

Manual No. WBHD Rev-03/03

Printed in the USA

Service Manual

Models:

IDWB2/0900,IDWB2/0775,IDWB3/0900,

IDWB3/0775,ID WB4/0900,IDWB4/0775

Congratulations! You have just purchased one of the finest

pieces of equipment on the market today.Before installing

or operating our new Dinex® Products equipment you

should read through this material.This manual should be

retained for further reference as it contains installation and

operating instructions,service tips,par t list and warranty

information.Should you have any questions concerning

the Equipment,please call the Dinex Hotline at 1-888-6734639 (Monday through Friday from 8 am to 5 pm,Eastern

Standard Time).

IMPORTANT: For your safety,read and follow all cautions,

information and warnings

FREIGHT DAMAGE CLAIMS

Your Dinex® Products equipment was carefully inspected

and packed before leaving our factory. The transpor tation

company assumes full responsibility for safe delivery of

this equipment.Dinex® Products cannot assume responsibility for damage or loss incurred in transit.Visible damage

or loss should be noted on freight bill and signed by

person making delivery.

A freight claim should be filed immediately with the transportation company.If damage is unnoticed or concealed

until equipment is unpacked,notify the transpor tation

company immediately and tell them you want to file a

concealed damage claim.This must be done within fifteen

(15) days after delivery was made.B e sure to retain all

packing material and cartons.

WARNING:Installation of this equipment should be

performed only by persons qualified or licensed to install

electrical equipment.

• Adjustments and service work should be performed

only by a qualified service technician.Service is available

through Authorized Dinex® Products Parts & Service

Distributors throughout the United States.For a

complete listing of these consult your distributor listing

or write Dinex® Products for the name of the nearest

distributor.

• This equipment in intended for commercial use only.

Not for household use.

• Use of other than genuine Dinex® Products replacements parts or service work performed by other than

authorized Dinex® Products service agents will void the

warranty.

• Do not use any corrosive cleaners.Use only cleaners

approved for stainless steel.

1.Carefully remove carton or crate from unit Remove all

loose packing material,making sure that no small parts

or accessories are lost Inspect unit for concealed damage before discarding packing material.

Page 2

Introduction:

Installation:

NOTE:It is the responsibility of the installer to comply with

all local codes.

2.M ake sure that the master switch is in the OFF position.

Turn thermostat control knob to the off position.

3.Connect unit to proper elec trical ser vice- Unit can

operate on 208 or 240 V.A.C.,single phase.

Receptacles required are:

a.Models: IDWB2/0900 81 IDWB2/0775 6-20R (20 Amp)

Receptacle

b.Models:IDWB3/0900,IDWB3/0775.IDWB4/0900 &

IDWB4/0775 = 6-30R (30 Amp) Receptacle

4.Turn master switch “ON”,power “ON”pilot light will glow

and blower motor will start to run.

CAUTION:If excessive noise or vibration is noticed,turn

master switch “OFF” and check blower wheel for freight

damage or loose objects.

THEORY OF OPERATION

1.The Dinex Unitized Base Dispenser is designed to heat 7-

3/4”or 9”Dinex Wax Bases.

2.The unitized base silo is designed to heat the unitized

bases thoroughly and efficiently,by circulating hot air

over the electric heating elements and around the bases

using a high efficiency blower system.

3.Once the bases have been heated,the dispenser can be

electrically disconnected and moved to the tray makeup line.Due to the high quality insulation characteristics,it is not necessar y to electrically reconnect the dispenser during the serving period.

WARNING:Unit should not be operated continuously

twenty-four (24) hours a day.The master switch should

be turned “OFF” af ter ser ving the last meal of the day.

LOADING OF BASES

WARNING:Over filling dispenser silos or use of other than

Dinex brand bases may cause injury to the operator or

damage to the dispenser,thus voiding the warranty.

1.Each silo is designed for use with Dinex unitized bases,

depending on the model purchased.

2.There is an easy way to determine when the correct

number of unitized bases have been loaded into a silo.

Fill the silo until the bases are flush with the top of the

unit,then remove one base.You should now have the

proper number of bases in the silo.

NOTE: Never drop stacks of bases into the silo assembly.

This can damage the silo components and void the

warranty.Place three to four bases at a time into the silo.

!

!

!

!

!

!

!

Operation Instructions:

Page 3

CONTROL SETTINGS

1.The master switch in the control panel on the front of

the unit controls the power to the unit.

2.The pilot light in the control panel will indicate power “ON”

when the master switch is turned to the “ON”position.

WAX BASE SILO THERMOSTAT SETTINGS

1.The heaters in the unitized base are controlled by an

adjustable thermostat located in the control panel.The

thermostat knob has an OFF position and is numbered 1

to 10.With the master switch “ON”and the thermostat

set to “OFF”,the blower motor will run but the heaters

will not operate.Thermostat must be turned to a setting

of 1 or higher to operate the heaters in the base silo.

2.Turn the thermostat knob clockwise to the number “7.5”

setting.The number “10”setting is the highest temperature setting for the dispenser.If you find that the bases

are too hot for your application,reduce the temperature

by turning the thermostat knob back to the 5, 6,or 7 setting.Since virtually all facilities operate differently,the

best way to determine your thermostat setting is to

start with the No.7.5 setting,and adjust up or down for

the next meal.Keep turning the knob until the proper

temperature is reached.

3.Once the proper temperature setting is determined,it is

not necessary to reset the thermostat at every meal.

Leave the thermostat at the desired setting and turn the

unit on and off using the master switch.

APPROXIMATE HEAT-UP TIMES

Cold bases (first meal of the day):1-1/2 to 2 hours.

Warm bases:1 to 1-1/2 hours

All times are approximate only and may vary depending

on each facilities operation,locations of units and supply

voltage.

Make sure that silo doors are closed during the heating cycle.

DISPENSING BASES

1.Turn master switch “OFF”and disconnect electrical plug

from receptacle.Move dispenser to start of the tray

make-up line.

WARNING:Severe burns may be caused if instructions are

not followed.Operator must wear heavy gloves when

dispensing bases.

2.Never touch bases with your bare hands,always use

heavy gloves and a suction lifter to handle bases.

3.I f,when using a suction lifter,a base comes loose,do not

try to catch the base...let it fall.

4.Never assume that a base is cool enough to handle with

your bare hands.Bases retain enough heat to cause

burns for several hours after being removed from the

dispenser.

5.I f a base becomes jammed in the silo,never reach into

the silo to free it.Use a long stick (such as a broom

handle) to free the base.

6.Dispense bases using the Dinex Suc tion Lif ter No.

TMP1097HNDLIFT.Hold the lifter in the palm of your

hand with your thumb over the release button.Use a

snap action of your wrist to attach the lifter to the base,

lift the base out of the silo and onto a waiting tray or

base underliner,press the release button with your

thumb to release base with the lifter.

Do not leave the suction lifter attached to a hot base.

This will greatly shorten the life of the suction lifter cup.

Dinex equipment is constructed with the best quality

material and is designed to provide you with durable

service when treated with ordinary care.To obtain the

best performance from your equipment,it should be

cleaned daily and maintained in good condition.

CAUTION:Prior to cleaning or maintenance,turn the

master switch “OFF” and disconnect the power cord

from the receptacle.

DAILY CLEANING

1.Cleaning and sanitizing agents for stainless steel and

aluminum should be used with a soft cloth and water.

CAUTION:Never use chlorinated cleaners,cleaners

containing QUARTENARY salts or other harsh chemicals.

2.The exterior of the dispenser should be cleaned daily

using a mild detergent suitable for stainless steel and

warm water.

3.Open the silo door and clean the inside of the door and

door gasket with detergent and warm water.

4.Wipe the cord and plug using a cloth with detergent

and warm water.

5.The thermostat knob should be removed by pulling it

straight out of the thermostat.The thermostat behind

the knob should be cleaned.

CAUTION:Do not use excessive water that could short out

the controls.

INTERIOR CLEANING

CAUTION:Prior to cleaning or maintenance,turn the master

switch,“OFF”and disconnect the power cord from the

receptacle and allow time for the dispenser to cool down.

1.The interior of the dispenser and silos should be cleaned

as required,at least once every three months.

2.Open silo door and unload unitized bases.

CAUTION:Bases may be hot so use gloves and lifter to

remove.

3.Using gloves,remove the silo by grasping the top of the silo

assembly and lifting straight up out of the dispenser.

Maintenance

!

!

!

!

!

!

Loading...

Loading...