Dinex IDRE Service Manual

Open & Enclosed

Tray & Rack Dispensers

Models IDT2S,IDTS2S,IDT1E,IDT1S,IDT S1S,IDRE ,IDRS

DINEX INTERNATIONAL,INC. • 628-2 HEBRON AVENUE,GLASTONBURY CT 06033 • WWW.DINEX.COM

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Unpack & Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Spring Calibration - Trays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Spring Calibration - Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dinex® Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

For Service Information,call 1-888-673-4639

Please provide following information:

• Model number

• Serial number

• Part Description and number as shown in parts list.

Manual No. TRD-2 Rev-07/05

Service Manual

Printed in the USA

For Equipment with Serial 040001N & Newer

UNPACKING & SET-UP

While unpacking your dispenser,carefully inspect for any

damage.Remove all tape & packing material.Push down

on the carrier plate to make sure it travels smoothly.

Start loading trays.As you are loading,observe the tray

level.The top of the the stack should be maintained at a

comfortable height.If the level is too high or too low,

springs will have to be added or removed to attain the

proper height.

SPRING CALIBRATION - TRAYS

Tray size,design and weight determine how many springs

should support your trays. Self-leveling units are shipped

with all springs attached to prevent loss of springs;therefore,some springs will have to be disconnected for proper

operations. To insure smooth operation,use similar number of springs on both sides. Always unhook lower end of

springs only. Leave unused springs hanging for future use.

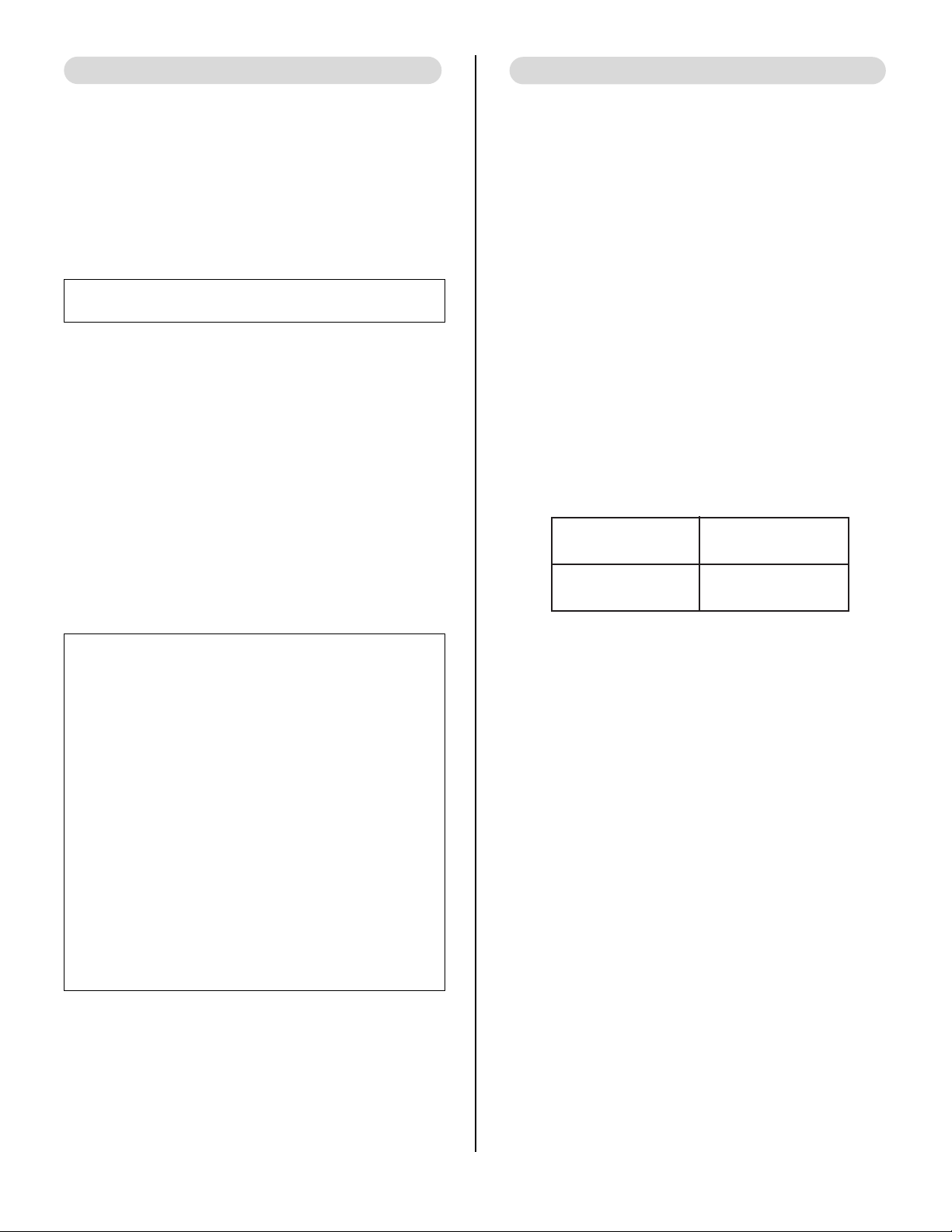

Use the following chart as a guide to determine approximately how many springs to use.

Adjustment Instructions

1.Disconnect enough springs at bottom loop so that 13

springs on each side are left connected for 14”x 18”

trays. For 15”x 20”trays,the amount of springs connected

on each side should be 16.

2.Place 12 trays in unit. The top tray should self-level one

or two trays above the top edge.

3.If the top tray is below the top edge,remove all the

trays. Attach one or more silver springs to the carriage

(bottom of spring). If two springs are attached,be sure

to attach one to each side. Replace the trays and check

tray level. Repeat above operation if needed.

4.If the top tray is more than two trays above the top

edge,remove trays,and detach one or two springs from

the carriage. If two springs are detached,be sure to

detach one from each side. Replace the trays,and check

tray level. Repeat above operation if needed.

5.Repeat the above with more trays and with fewer trays.

6.When dispenser is fully loaded with trays,the top tray

will be several inches above the top edge of the dispenser. When dispenser has only a few trays left,the

top tray will be about even with the top edge of the

dispenser.

23 to 27

30 to 34

14”x 18”

15”x 20”

Tra y S iz e

Springs Required

Page 2

Introduction

Installation

Congratulations:You have just purchased one of the finest

pieces of equipment on the market today.Before installing

or operating our new Dinex® Products equipment you

should read through this material.This manual should be

retained for further reference as it contains installation and

operating instructions,service tips,part list and warranty

information.Should you have any questions concerning

the Equipment,please call the Dinex Hotline at 1-888-6734639 (Monday through Friday from 8 am to 5 pm,Eastern

Standard Time).

IMPORTANT: For your safety,read and follow all cautions,

information and warnings

FREIGHT DAMAGE CLAIMS

Your Dinex® Products equipment was carefully inspected

and packed before leaving our factory. The transpor tation

company assumes full responsibility for safe delivery of

this equipment.Dinex® Products cannot assume responsibility for damage or loss incurred in transit.Visible damage

or loss should be noted on freight bill and signed by

person making delivery.

A freight claim should be filed immediately with the transportation company.If damage is unnoticed or concealed

until equipment is unpacked,notify the transpor tation

company immediately and tell them you want to file a

concealed damage claim.This must be done within fifteen

(15) days after delivery was made.Be sure to retain all

packing material and cartons.

WARNING:Installation of this equipment should be

performed only by persons qualified or licensed to install

electrical equipment.

• Adjustments and service work should be performed

only by a qualified service technician.S er vice is available

through Authorized Dinex® Products Parts & Service

Distributors throughout the United States.For a

complete listing of these consult your distributor listing

or write Dinex® Products for the name of the nearest

distributor.

• This equipment in intended for commercial use only.

Not for household use.

• Use of other than genuine Dinex® Products replacements parts or service work performed by other than

authorized Dinex® Products service agents will void the

warranty.

• Do not use any corrosive cleaners.Use only cleaners

approved for stainless steel.

!

!

SPRING CALIBRATION - RACKS

Rack size,design and weight contents determine how

many springs should support your racks. Self-leveling

units are shipped with all springs attached to prevent loss

of springs;therefore,some springs will have to be disconnected for proper operations. To insure smooth operation,

use similar number of springs on both sides. Always

unhook lower end of springs only. Leave unused springs

hanging for future use.

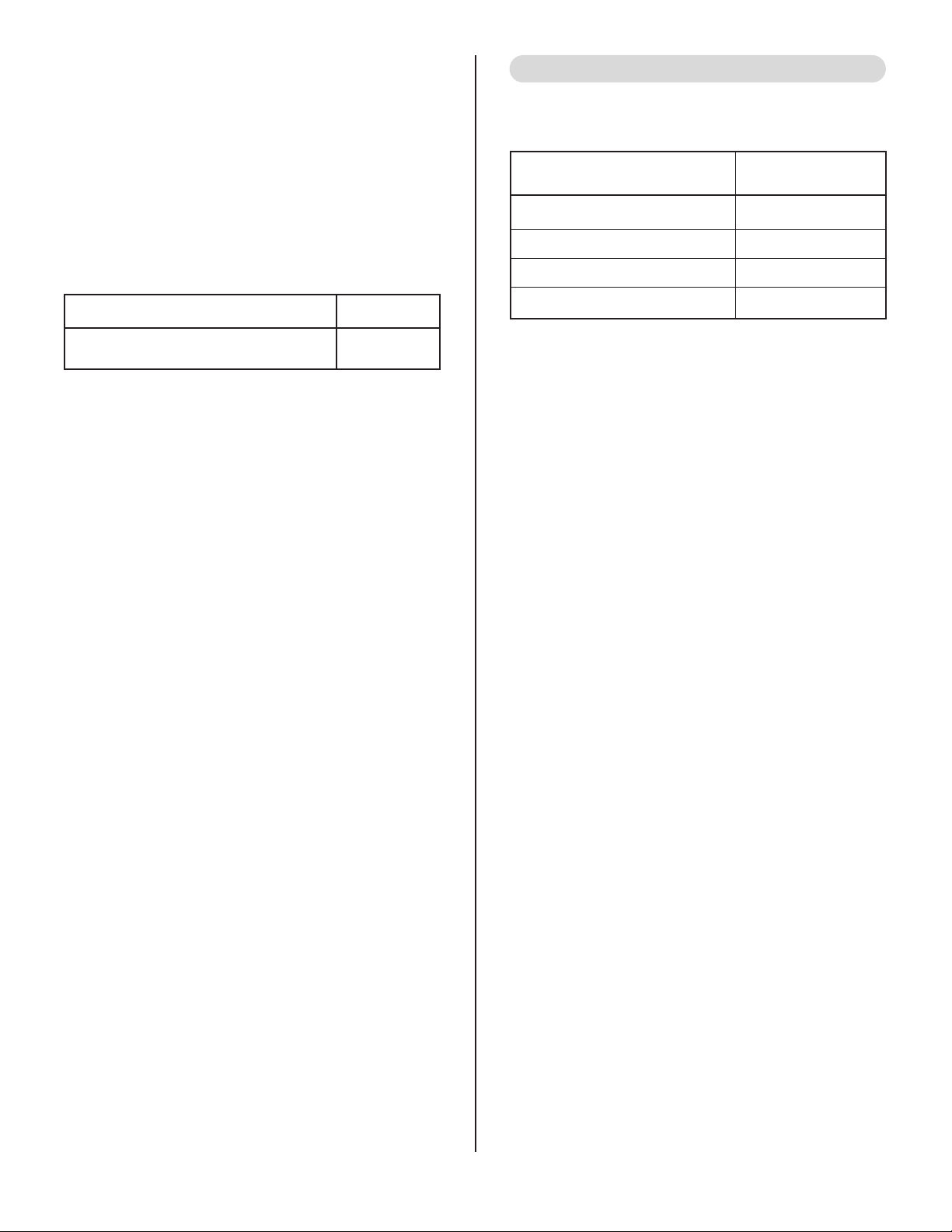

Use the following chart as a guide to determine approximately how many springs to use.

Adjustment Instructions

1.Disconnect enough springs from the carriage so that 7

springs are left connected on each side for glass racks.

For cup racks,the amount of springs connected on each

side should be 9.

2.Place one loaded rack in unit. The top edge of the rack

should self-level just above the top edge.

3.If the rack is below the top edge,remove it. Attach one

or more springs to the carriage (bottom of spring). If

two springs are attached,be sure to attach one to each

side. Replace the rack and check level. Repeat above

operation if needed.

4.If the rack is to far above the top edge,remove it,and

detach one or two springs from the carriage. If two

springs are detached,be sure to detach one from each

side. Replace the rack,and check level. Repeat above

operation if needed.

5.Repeat the above with more racks.

6.When dispenser is fully loaded,the top rack will be several inches above the top edge of the dispenser. When

dispenser has only one rack left,it will be about even

with the top edge of the dispenser.

CLEANING

1.Self-leveling mechanism may be cleaned with soap and

water or stainless steel polish.

2.Springs may be removed for cleaning if desired.

Removal of springs can be done by hand without the

use of tools.

3.Wash stainless steel on mobile unit with soap and water

or stainless steel polish. Stainless steel sur faces must be

thoroughly rinsed and dried,or corrosion may result.

Page 3

PARTS LIST ENCLOSED TRAY & RACK DISPENSERS

12 to 16

16 to 20

1 - 20”x 20”or 2 - 10”x 20” Glass Rack

1 - 20”x 20”or 2 - 10”x 20” Cup Rack

Racks Size

Springs

Required

PARTS NUMBER

Caster,Swivel No Brake 111847

Caster,With Brake 111848

Spring 09906

Bumper,Corner 09405

DESCRIPTION

Replacement Parts

(10” x 20” racks must be placed side by side on the

self-leveling carriage.)

Loading...

Loading...