Dinex IDP Service Manual

China Pl a te

Di s p e n s e r

Models IDP,I D P H , I D P D S , IDPDU & IDPHD

DINEX INTERNATIONAL, INC. • 628-2 HEBRON AVENUE, GLASTONBURY CT 06033 • WWW.DINEX.COM

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Parts Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dinex® Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

For Equipment with Serial 040001N & Newer

For Service Information, call 1-888-673-4639

Please provide following information:

• Model number

• Serial number

• Part Description and number as shown in parts list.

Manual No. CPD-2 Rev-06/05

Se r v i c e Ma n u a l

Printed in the USA

Congratulations:You have just purchased one of the finest

pieces of equipment on the market today.Before installing

or operating our new Dinex® Products equipment you

should read through this material. This manual should be

retained for further reference as it contains installation and

operating instructions, service tips, part list and warranty

information. Should you have any questions concerning

the Equipment, please call the Dinex Hotline at 1-888-6734639 (Monday through Friday from 8 am to 5 pm, Eastern

Standard Time).

IMPORTANT: For your safety, read and follow all cautions,

information and warnings

FREIGHT DAMAGE CLAIMS

Your Dinex® Products equipment was carefully inspected

and packed before leaving our factory.The transportation

company assumes full responsibility for safe delivery of

this equipment. Dinex® Products cannot assume responsibility for damage or loss incurred in transit. Visible damage

or loss should be noted on freight bill and signed by

person making delivery.

A freight claim should be filed immediately with the transportation company.If damage is unnoticed or concealed

until equipment is unpacked, notify the transportation

company immediately and tell them you want to file a

concealed damage claim.This must be done within fifteen

(15) days after delivery was made. Be sure to retain all

packing material and cartons.

WARNING:Installation of this equipment should be

performed only by persons qualified or licensed to install

electrical equipment.

• Service work should be performed only by a qualified

service technician. Service is available through

Authorized Dinex® Products Parts & Service Distributors

throughout the United States. For a complete listing of

these consult your distributor listing or write Dinex®

Products for the name of the nearest distributor.

• This equipment in intended for commercial use only.

Not for household use.

• Use of other than genuine Dinex® Products replacements parts or service work performed by other than

authorized Dinex® Products service agents will void the

warranty.

• Do not use any corrosive cleaners. Use only cleaners

approved for stainless steel.

Page 2

Introduction

Installation

SPRING ADJUSTMENT

NOTE: Spring adjustment is not covered under warranty.

Please note that china plates vary in weight. The following

is a guide to determine approximately how many springs

to use:

UNHEATED MODELS

Dish Diameter Springs Required

Up To 5” 4 Silver

5 1/8”To 5 3/4” 4 Silver

5 7/8”To 6 1/2” 4 Silver

6 9/16”To 7 1/4” 7 To 9 Silver

7 3/8”To 8 1/8” 9 To 11Silver

8 1/4”To 9 1/8” 10 To 13 Silver

9 1/4”To 10 1/8” 12 To 16 Silver

10 1/4”To 12 1/4” 16 To 22 Silver

HEATED MODELS

Dish Diameter Springs Required

6”To 7” 7 To 9 Brown

7”To 8” 9 To 11 Brown

8”To 9” 10 To 13 Brown

9”To 10” 12 To 16 Brown

10”To 11” 16 To 19 Brown

11”To 12” 19 To 22 Brown

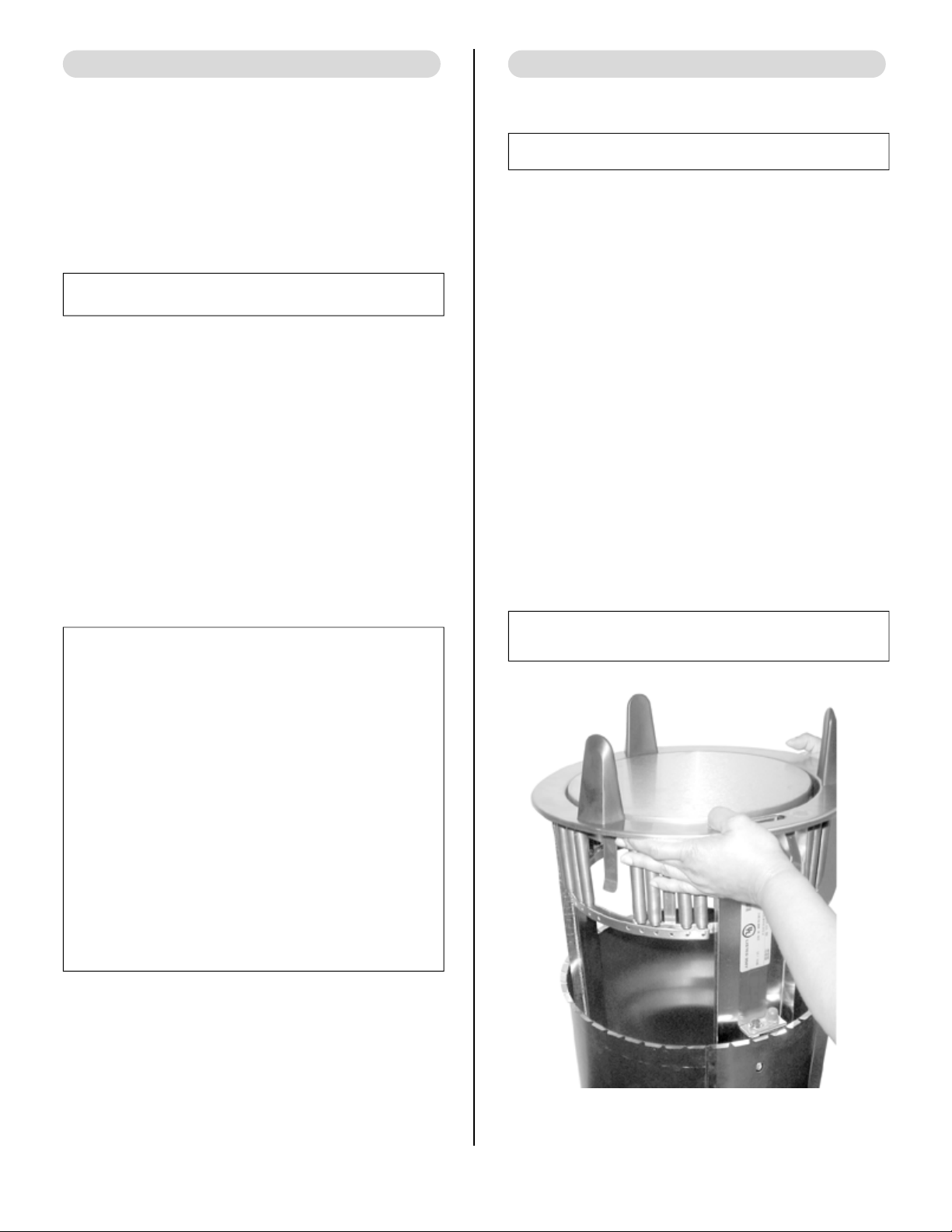

TO ACCESS SPRINGS

CAUTION: Allow heated dispensers to cool down to room

temperature.Lift self-leveling mechanism out of the

cabinet (See Fig.1) and set it onto the floor.

!

!

!

!

Figure 1

CLEANING

WARNING: Never submerge or saturate electrical components in water.

IMPORTANT: Always disconnect the electrical power to

the equipment and allow equipment to cool down prior to

cleaning.

Clean outside of cabinet/cart with mild soap & water or a

cleaner approved for stainless steel. Never use cleaners

containing chlorine.

The self-leveling mechanism can be removed and cleaned

with mild soap and water or a cleaner approved for stainless steel. Once the self-leveling mechanism has been

removed,the Heat Tube can be cleaned. NEVER submerge

the heating element, electrical controls and electrical

cord/plug in water.

REMOVAL OF HEATED TUBES FROM

CART/CABINET

1. Unplug cart from electrical source.

NOTE: Always start by removing the heated tube from the

cart which is the closest to the electrical source cord (Fig.4).

2. Lift self-leveling mechanism out of tube and place on

floor (Fig. 1).

3. Lift heated tube out of cart and rest on top of cart (Fig.

4). Reach inside cart following flexible conduit to twistloc plug.Twist plug counterclockwise and remove from

receptacle. Heated tube may now be placed on floor.

4. Duplicate above steps for other tube or tubes.

5. To install tubes reverse above procedure. Always install

the heated tube that is the farthest from the electrical

source cord first. Pick up heated tube, place on top of

cart, connect twist-loc plug to receptacle inside cart

with a clockwise motion, lower tube into cart. Now

install the next farthest tube from the electrical source

Page 3

!

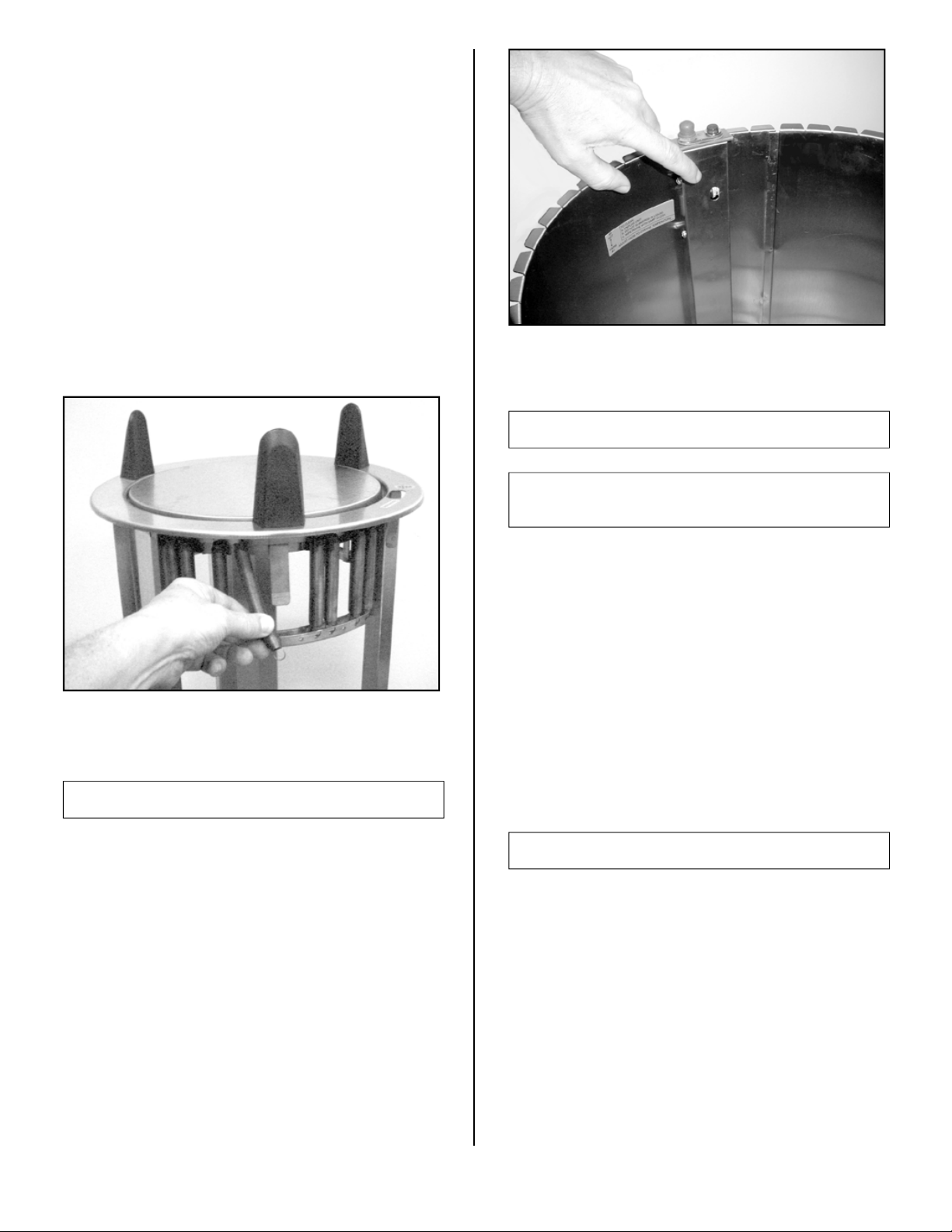

TO ADJUST SPRINGS

1. Place ten (10) dishes into the silo.

2. If the dishes are above the top of the plastic dish guides,

one or more of the springs must be unhooked. Always

unhook the lower end of the spring only (Fig. 2). Leave

the unhooked springs hanging for future use. Note, to

insure a smooth operation, maintain, as much as possible, an even amount of springs in each spring section.

3. If after adjustment, the dishes are too low, remove the

dishes & reconnect springs making sure that an equal

amount of springs are connected in each section.

Repeat this procedure until plates are at the proper

height.

Once proper adjustment has been acquired, place

self-leveling mechanism back into the cart/cabinet.

THERMOSTAT ADJUSTMENT

NOTE: Thermostat adjustment is not covered under

warranty.

The thermostats are factory set at approximately 150° F.

This is the temperature at the thermostat and is not necessarily the actual plate temperature. The thermostat range

is from 100 to 200 degrees F.

To adjust the thermostat, remove self-leveling mechanism

(Fig.1).

The thermostat is located inside the Heated Tube (Fig.3).

To increase the temperature, turn the thermostat dial to a

higher number.To lower the temperature, turn to a lower

number.Select desires setting. Place self-leveling mechanism back into the cabinet.

!

!

!

Figure 3

Figure 2

cord following same directions. After all tubes are

installed, place self-leveling mechanisms into tubes.

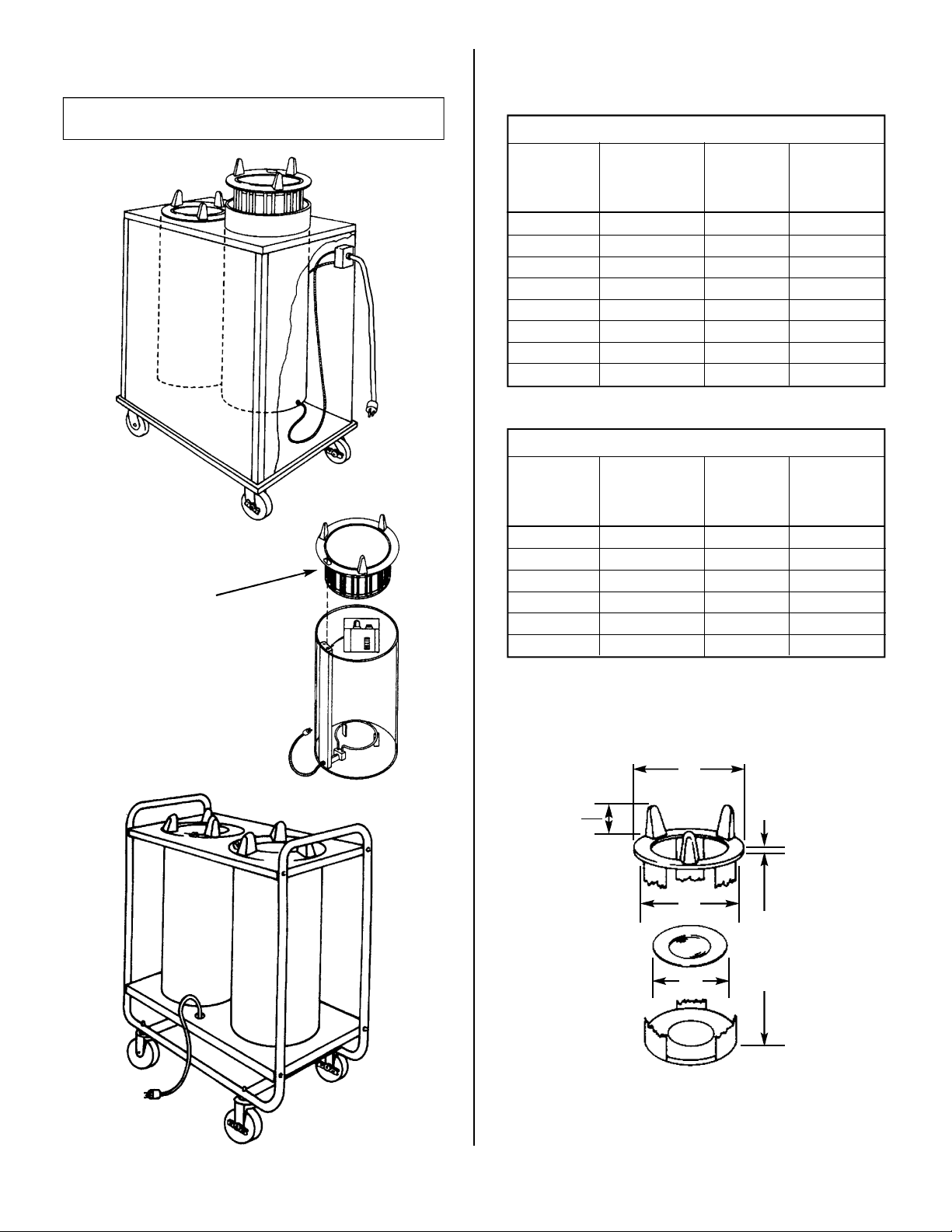

NOTE: Tubes in tubular style not removable (Fig.6).

Page 4

!

Tubular Style

Cabinet Style

Figure 4

Self-leveling

Mechanism

Figure 5

Figure 6

HEATED &NON-HEATED DROP-IN

INSTALLATION INSTRUCTIONS

NON-HEATED SILO

Mod e l

Nu m be r

No n - He a te d /

Sh i e l d e d

Ac co m m o d a te s

Dish Di a m e te r

( A D )

Ove rall

Si ze Ri n g

Di a m e ter (R)

Di a m e ter Of

Hole Cu to u t

In Co u n ter (H)

Cu tout Di m e n s i o n s - C hina Pl a te Dro p i n s

I D P D S / 0 5 0 0 Up To 5" 8 1/4" 7 11/64"

I D P D S / 0 5 7 5 5 1/8" to 5 3/4" 9 " 8 3/16"

I D P D S / 0 6 5 0 5 7/8" to 6 1/2" 9 3/4" 8 15/16"

I D P D S / 0 7 2 5 6 5/8" to 7 1/4" 10 1/2" 9 11/16"

I D P D S / 0 8 1 2 7 3/8" to 8 1/8" 11 3/8" 10 9/16"

I D P D S / 0 9 1 2 8 1/4" to 9 1/8" 12 3/8" 11 9/16"

I D P D S / 1 0 1 2 9 1/4" to 10 1/8” 13 3/8" 12 9/16"

I D P D S / 1 2 0 0 10 1/4" to 12 1/4" 15 15/16" 14 11/16"

Mod e l

Nu m be r

He ate d /

Sh i e l d e d

Ac co m m o d a te s

Dish Di a m e te r

( A D )

Ove rall

Si ze Ri n g

Di a m e ter (R)

Di a m e ter Of

Hole Cu to u t

In Co u n ter (H)

Cu tout Di m e n s i o n s - C hina Pl a te Dro p i n s

I D P H D / 0 6 5 0 5 7/8" to 6 1/2" 9 3/4" 8 15/16"

I D P H D / 0 7 2 5 6 5/8" to 7 1/4" 10 1/2" 9 11/16"

I D P H D / 0 8 1 2 7 3/8" to 8 1/8" 11 3/8" 10 9/16"

I D P H D / 0 9 1 2 8 1/4" to 9 1/8" 12 3/8" 11 9/16"

I D P H D / 1 0 1 2 9 1/4" to 10 1/8” 13 3/8" 12 9/16"

I D P H D / 1 2 0 0 10 1/4" to 12 1/4" 15 15/16" 14 11/16"

R

H

A D

3 1/2”

( 9 c m )

1 / 4 ”

( 0 . 6 c m )

27 1/4”

( 6 9 c m )

Sh i e l d e d

2 8 ” ( 7 1 c m )

Loading...

Loading...