Dinex DXIDPHD Installation Manual

China Plate Dispenser

Operating & Maintenance Manual

Models: DXIDP

DXIDPH

DXIDPDS

Drop-in, Heated

Open-Style

DXIDPHD

Enclosed-Style

Drop-in, Unheated

China Plate Dispenser:

SECTION 1: INTRODUCTION

Introduction ..............................................................................3

Freight Damage Claims...........................................................3

Application and Use ................................................................3

Safety ......................................................................................3

SECTION 2: INFORMATION

Information...............................................................................3

Identification Plate ...................................................................3

For Service Information call 1.888.673.4639

Please provide following information:

• Model number

• Serial number

© 2011 DINEX | CARLISLE • 4711 EAST HEFNER ROAD, OKLAHOMA CITY, OK 73131 • WWW.DINEX.COM

SECTION 3: INSTALLATION

Spring Adjustment ...................................................................3

Thermostat Adjustment ...........................................................4

Operating Suggestions ............................................................4

Cleaning ..................................................................................4

Removal of Heated Tubes ......................................................4

Drop-in Installation ..................................................................5

APPENDIX ..............................................................................7

WARRANTY ..........................................................................13

Manual No. China Plate Dispenser Manual

DO NOT DISCARD

China Plate Dispenser | 3

INTRODUCTION

Congratulations! You have just purchased one of the nest pieces of

equipment on the market today. Before installing or operating your

new Dinex equipment you should read through this material. This

manual should be retained for further reference as it contains operation

instructions and warranty information. Should you have any questions

concerning the Equipment, please call the 24/7 Dinex Hotline at 1-888673-4639.

IMPORTANT: For your safety, read and follow all cautions,

information, and warnings.

!

FREIGHT DAMAGE CLAIMS

Your China Plate Dispenser was carefully inspected and packed

before leaving our factory. The transportation company assumes full

responsibility for the safe delivery of this equipment. Dinex cannot

assume responsibility for damage or loss incurred during transit. Visible

damage or loss should be noted on the freight bill and signed by

the person making the delivery.

A freight claim should be led immediately with the transportation

company. If damage is unnoticed or concealed until the equipment is

unpacked, notify the transportation company immediately and tell them

you want to le a concealed damage claim. This must be done within

fteen (15) days after delivery was made. Be sure to retain all packing

materials and cartons.

IMPORTANT: All packing materials should be retained for return

shipment.

!

INFORMATION

INFORMATION ON THIS SECTION

When contacting customer service please provide the following

information located on the product identication plate:

• Model number

• Serial number of the equipment (identication plate)

• Description of the part

• See Manual for item number

IDENTIFICATION PLATE

BY CA RLI SL E F SP

OKL AH OMA C ITY , O K 731 52

Different serial numbers for each unit.

Check the compatibility of machine voltage and amperage with electrical

connections

INSTALLATION

APPLICATION AND USE

The Equipment is for commercial use in the food service industry.

ATTENTION: Installation of this equipment should be performed

only by persons qualied or licensed to install electrical equipment.

!

• Adjustments and service work should be performed only by

qualied service technicians.

• This equipment is intended for commercial use only. Not for

household use.

• Use of other than genuine Dinex replacement parts or service

work performed by those other than authorized Dinex service

agents will void the warranty.

• Do not use corrosive cleaners on the equipment. Use

only mild detergents.

SAFETY

The instructions contained in this manual provide important guidelines

for the Equipment user regarding a correct and safe installation.

Particular attention should be paid to the warnings given in various parts

of this manual. Never dismantle and/or repair the appliance with the

power supply in place. Especially, do not repair electrical elements if

you are not qualied for such work.

IMPORTANT:

!

• Please note that the China Plate Dispenser is for commercial use

only and must be used exclusively for the purposes prescribed.

SPRING ADJUSTMENT

NOTE: Spring adjustment is not covered under warranty.

!

Please note that china plates vary in weight. The following is a guide to

determine approximately how many springs to use:

UNHEATED MODELS

Dish Diameter Springs Required

8 1/4" to 9 1/8" 8 to 12 Silver

9 1/4" to 10 1/8" 8 to 16 Silver

10 1/4" to 12 1/4" 8 to 20 Silver

HEATED MODELS

Dish Diameter Springs Required

8 1/4" to 9 1/8" 8 to 12 Brown

9 1/4" to 10 1/8" 8 to 12 Brown

10 1/4" to 12 1/4" 8 to 20 Brown

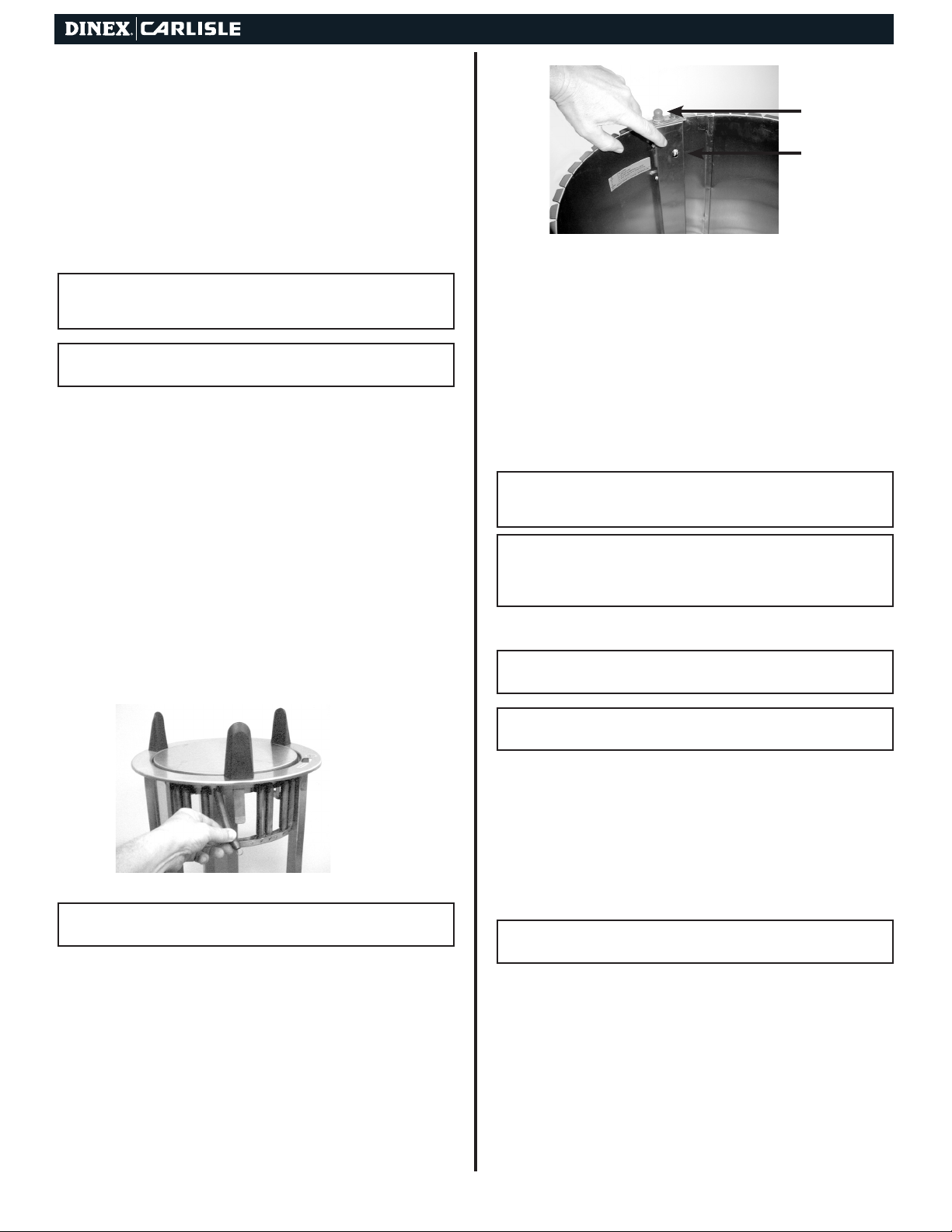

TO ACCESS SPRING

CAUTION:

• Allow heated dispensers to cool down to room temperature. Lift

!

self-leveling mechanism out of the cabinet (see g. 1) and set it

onto the oor.

Caution: Exposed surfaces of heated dispensers can be hot to the

touch and may cause burns.

!

• Disconnect dispenser from electrical power and allow to cool

before removing open tube assembly from shield.

Figure 1

Tension on the carriage is adjustable for differing types of dinner ware

by connecting, disconnecting or substituting carriage springs:

1. Remove the open tube assembly of shielded dispensers from the

shield. Stand the open tube assembly upright and secure it to

prevent tipping.

2. Test the spring tension by stacking 10 pieces of dinnerware on the

carriage and noting the position of the top piece.

3. Disconnect or substitute carriage springs until the right

combination is found to allow the top piece of dinnerware to be

raised just high enough to be easily picked from the dispenser. In

order to allow the carriage to stay level and operate smoothly, be

sure to make the same changes to all four sections of carriage

springs.

NOTE: There are two different tension springs. Coarse and ne

springs are visually nearly identical, but the difference in tension can

!

be felt by carefully stretching them.

NOTE: Springs for heated and non-heated units are different and

should not be mixed in the same dispenser.

!

4. Disconnect unused springs from the lower retaining bracket

and allow them to dangle. They will remain out of the way, but

available if adjustments are later required.

TO ADJUST SPRING

1. Place ten (10) dishes into the silo. Approximately 6" Height.

2. If the dishes are above the top of the plastic dish guide, one or

more of the springs must be unhooked. Always unhook the lower

end of the spring only (see g. 2). Leave the unhooked springs

hanging for future use. Note, to insure a smooth operation,

maintain, as much as possible, an even amount of springs in

spring section

3. If after adjustment, the dishes are too low, remove the dishes &

reconnect springs making sure that an equal amount of springs

are connected in each section.

4. Repeat this procedure until plates are at the proper height.

Once proper adjustment has been acquired, place self-leveling

mechanism back into the cart/cabinet.

Figure 2

China Plate Dispenser | 4

Power Switch

Figure 3

OPERATING SUGGESTIONS

1. Load the dispenser with the appropriate size dinnerware.

• Dinnerware which is too large may be broken or may jam the

carriage.

• Dinnerware which is too small cannot be safely dispensed, and

may be broken or may jam the carriage

2. Load no more than a 6" stack of dinnerware at a time.

3. Dispensers are designed for EMPTY dinnerware only.

4. For heated dispensers, turn the power switch to ON. When the

switch is ON the indicator light will glow.

5. Unused dispensers should be covered with the optional silo cover

(DXIACPH0912, DXIACPH1012, DXIACPH1012)

CAUTION: Hot Surface

• Exposed surfaces of heated dispenser can be hot to the touch

!

and may cause burns.

CAUTION: Pinch Hazard

• Hold dinnerware by the sides when loading the dispenser.

!

• Holding dinnerware by the bottom can allow ngers to become

trapped between the plates and the dispenser wall.

CLEANING

WARNING: Never submerge or saturate electrical components in

water.

!

INFORMATION: Always disconnect the electrical power to the

equipment and allow equipment to cool down prior to cleaning.

!

Cleaning outside of cabinet cart with damp cloth only.

The self-leveling mechanism can be removed and cleaned with mild

soap and water or a cleaner approved for stainless steel. Once the selfleveling mechanism has been removed, the Heat Tube can be cleaned.

Never submerge the heating element, electrical controls, electrical cord/

plug in water.

Temperature

Adjustment

THERMOSTAT ADJUSTMENT

NOTE: Thermostat adjustment is not covered under warranty

!

Heated dispensers are factory set on high. The temperature may be

changed by turning the temperature adjustment dial (see g. 3):

• Clockwise to increase temperature

• Counter-clockwise to decrease temperature

For unshielded dispensers, carefully slide open tube into the cutout in

the counter.

For shielded and heated dispensers, carefully slide the shield into the

cutout in the counter and attach with the supplied mounting hardware.

Carefully slide the open tube into the shield.

REMOVAL OF HEATED TUBES FROM CART/CABINET

1. Unplug cart from electrical source.

NOTE: Always start by removing the heated tube from the cart

which is the closest to the electrical source cord (see g. 4).

!

2. Lift self-leveling mechanism out of tube and place on oor (see

g. 1).

3. Lift heated tube out of cart and rest on top of cart (see g. 4).

Reach inside cart following exible conduit to twist-loc plug. Twist

plug counter-clockwise and remove from receptacle. Heated tube

may now be placed on oor.

4. Duplicate above steps for other tube or tubes.

5. To install tubes reverse above procedure. Always install the

heated tube that is the farthest from the electrical source cord

rst. Pick up heated tube, place on top of cart, connect twist-loc

plug to receptacle inside cart with a clockwise motion, lower tube

China Plate Dispenser | 5

into cart. Now install the next farthest tube from the electrical source

cord following same directions. After all tubes are installed, place

self-leveling mechanisms into tubes.

NOTE: Tubes in tubular style not removable (see g. 6).

!

Figure 4

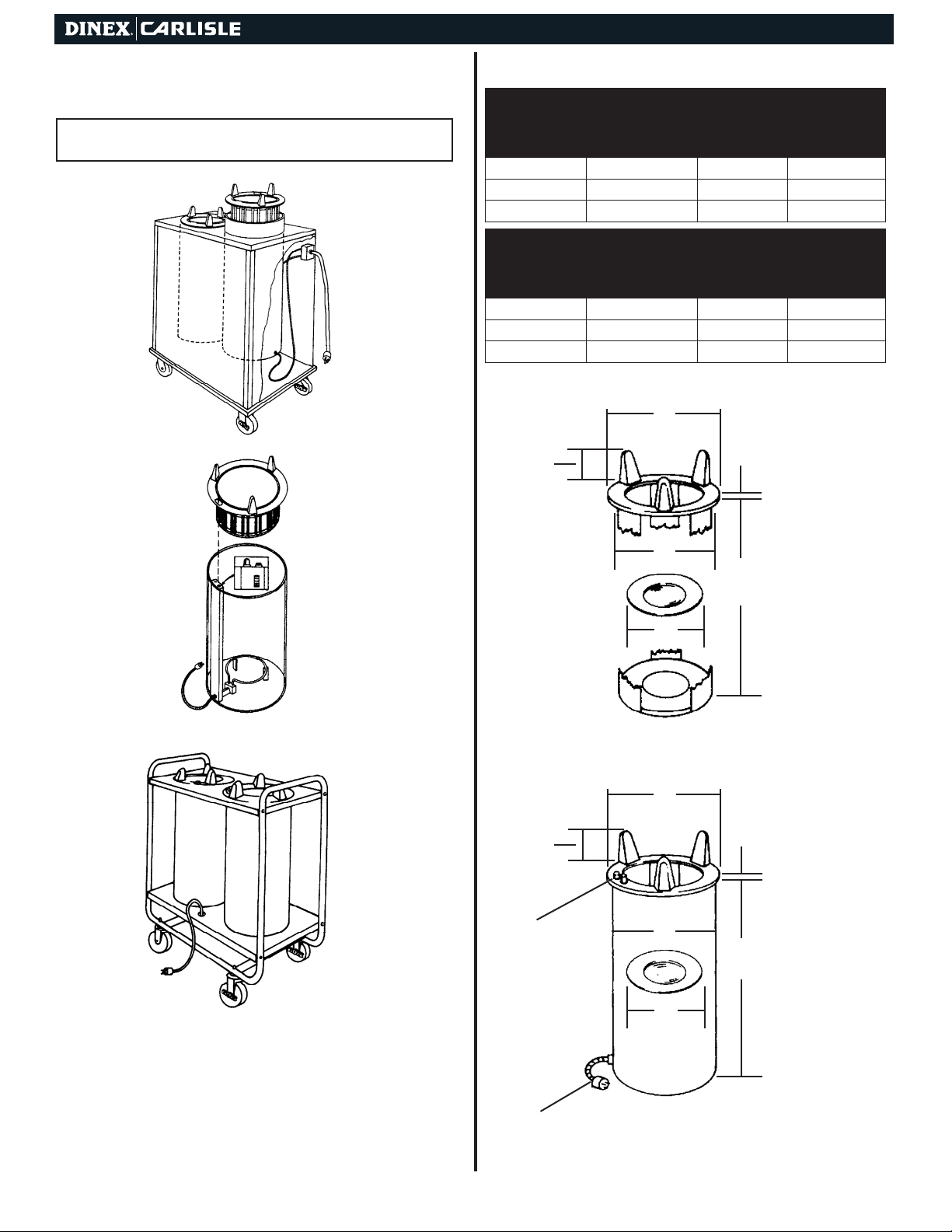

NON-HEATED & HEATED DROP-IN INSTALLATION INSTRUCTIONS

Cutout Dimensions - China Plate Drop-ins

Model #

Non-Heated /

Shielded

DXIDPDS0912 8 1/4" to 9 1/8" 12 3/8" 11 9/16"

DXIDPDS1012 9 1/4" to 10 1/8" 13 1/2" 12 9/16"

DXIDPDS1200 10 1/4" to 12 1/4" 15 1/4" 14 5/16"

Accommodates

Dish Diameter (AD)

Overall Size

Ring Diameter

(R)

Diameter of

Hole Cutout in

Counter (H)

Cutout Dimensions - China Plate Drop-ins

Model # Heated /

Shielded

DXIDPHD0912 8 1/4" to 9 1/8" 12 3/8" 11 9/16"

DXIDPHD1012 9 1/4" to 10 1/8" 13 1/2" 12 9/16"

DXIDPHD1200 10 1/4" to 12 1/4" 15 1/4" 14 5/16"

NON-HEATED SILO

3 1/2"

(9cm)

Accommodates

Dish Diameter (AD)

Overall Size

Ring Diameter

(R)

R

1/4"

(0.6cm)

Diameter of

Hole Cutout in

Counter (H)

Figure 5

Figure 6

HEATED SILO

3 1/2"

(9cm)

Switch & Pilot Light

(Heated Tubes)

H

28 5/8"

(72.7cm)

AD

R

1/4"

(0.6cm)

H

28 5/8"

(72.7cm)

AD

Flexible electrical conduit with twist-loc

(Heated Tubes)

Loading...

Loading...