Dinex DHC2 Installation Manual

Hot/Cold Food Counter

Operating & Maintenance Manual

Models: DHC2

DHC3

DHC4

DHC5

DHC6

DineXpress Hot/Cold Food Counter:

SECTION 1: INTRODUCTION

Introduction ..............................................................................2

Freight Damage Claims...........................................................2

Application and Use ................................................................2

Safety ......................................................................................2

SECTION 2: INFORMATION

Information...............................................................................2

Identification Plate ...................................................................2

SECTION 3: INSTALLATION

Installation ...............................................................................2

For Service Information call 1.888.673.4639

Please provide following information:

• Model number

• Serial number

© 2011 DINEX | CARLISLE • 4711 EAST HEFNER ROAD, OKLAHOMA CITY, OK 73131 • WWW.DINEX.COM

DO NOT DISCARD

SECTION 4: OPERATING INSTRUCTION

Hot Operations ........................................................................3

Cold Operations ......................................................................3

SECTION 5: CLEANING INSTRUCTIONS

Cleaning ..................................................................................3

SECTION 6: MAINTENANCE

Maintenance ............................................................................4

SECTION 7: PARTS LIST

Parts List .................................................................................4

ELECTRICAL WIRING SCHEMATIC ......................................5

WARRANTY ............................................................................6

Manual No. DineXpress Hot Cold Manual

DineXpress Hot/Cold Food Counter | 2

INTRODUCTION

Congratulations! You have just purchased one of the nest pieces of

equipment on the market today. Before installing or operating your

new Dinex equipment you should read through this material. This

manual should be retained for further reference as it contains operation

instructions and warranty information. Should you have any questions

concerning the Equipment, please call the Dinex Hotline at 1-888-6734639 (Monday through Friday from 7 am to 6 pm, Central Standard

Time).

IMPORTANT: For your safety, read and follow all cautions,

information, and warnings.

!

FREIGHT DAMAGE CLAIMS

Your DineXpress Hot/Cold Food Counter was carefully inspected and

packed before leaving our factory. The transportation company assumes

full responsibility for the safe delivery of this equipment. Dinex cannot

assume responsibility for damage or loss incurred during transit. Visible

damage or loss should be noted on the freight bill and signed by

the person making the delivery.

A freight claim should be led immediately with the transportation

company. If damage is unnoticed or concealed until the equipment is

unpacked, notify the transportation company immediately and tell them

you want to le a concealed damage claim. This must be done within

fteen (15) days after delivery was made. Be sure to retain all packing

materials and cartons.

IMPORTANT: All packing materials should be retained for return

shipment.

!

APPLICATION AND USE

The Equipment is for commercial use in the food service industry. It

provides storage of dishes and is operated with a heating system.

ATTENTION: Installation of this equipment should be performed

only by persons qualied or licensed to install electrical equipment.

!

• Adjustments and service work should be performed only by

qualied service technicians.

• This equipment is intended for commercial use only. Not for

household use.

• Use of other than genuine Dinex replacement parts or service

work performed by those other than authorized Dinex service

agents will void the warranty.

• Do not use corrosive cleaners on the equipment. Use

only mild detergents.

INFORMATION

INFORMATION ON THIS SECTION

When contacting customer service please provide the following

information located on the product identication plate:

• Model number

• Serial number of the equipment (identication plate)

• Description of the part

• See Manual for item number

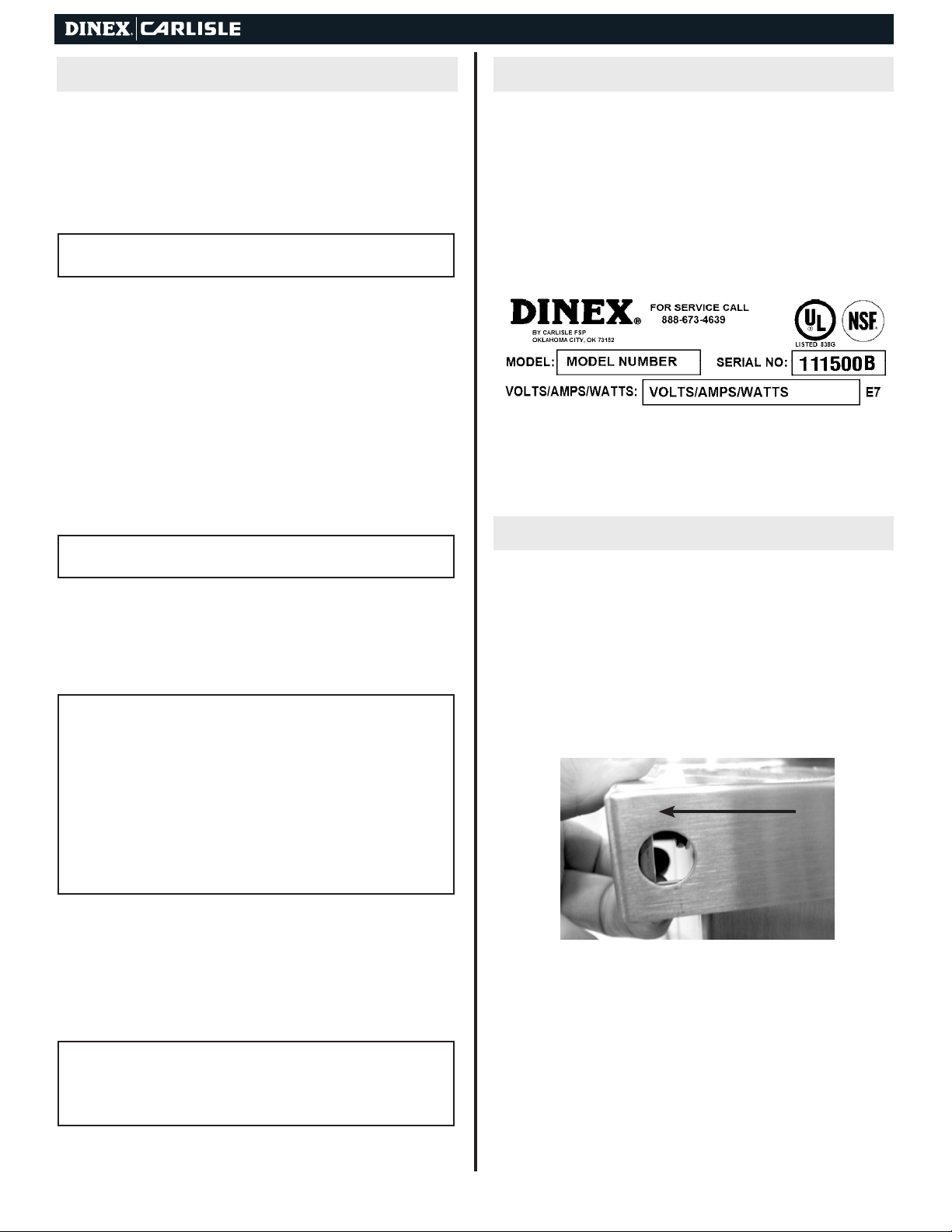

IDENTIFICATION PLATE

Different serial numbers for each unit.

Check the compatibility of machine voltage and amperage with electrical

connections

INSTALLATION

INHOUSE EQUIPMENT TRANSPORTATION AND INSTALLATION

To avoid equipment damage, carefully uncrated the equipment. Use

caution when setting the equipment into place. All units on casters

can be carefully rolled into position. Units equipped with legs must

be transported on dollies. NEVER lift units with a fork truck. Lifting

and transporting with a fork truck will damage the unit’s structure and

invalidate the warranty.

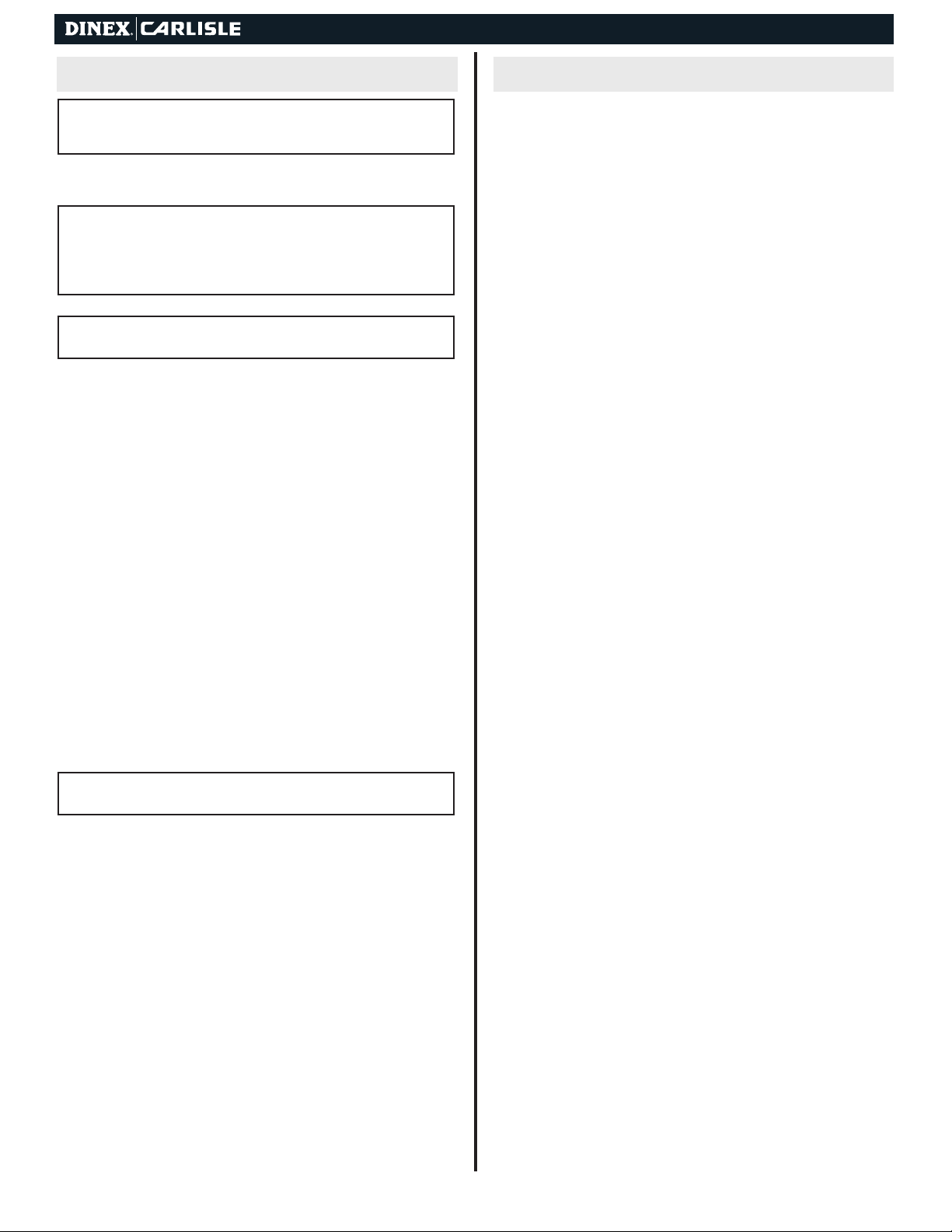

To interconnect the equipment into a line-up, see ( Fig. 1). Grasp the

locking device. Pull outward and hold while the adjacent unit is pushed

into place. Once the adjacent unit is in place, release the locking device

and it will lock into the adjacent slotted stud.

SAFETY

The instructions contained in this manual provide important guidelines

for the Equipment user regarding a correct and safe installation.

Particular attention should be paid to the warnings given in various parts

of this manual. Never dismantle and/or repair the appliance with the

power supply in place. Especially, do not repair electrical elements if

you are not qualied for such work.

IMPORTANT:

!

• Please note that the DineXpress Hot/Cold Food Counter is

for commercial use only and must be used exclusively for the

purposes prescribed.

Figure 1

DineXpress Hot/Cold Food Counter | 3

OPERATING INSTRUCTIONS

IMPORTANT: Prior to switching from Hot to Cold or Cold to Hot

operation, allow for the temperature of the unit to stabilize to room

!

temperature.

HOT OPERATIONS

IMPORTANT: It is the responsibility of the installer to comply with

all State & Local electrical codes. Connect the unit to the proper

!

electrical power source. Check the rating tag on the unit to insure

that the unit is being connected to the proper electrical power

source.

CAUTION: Connecting the unit to the improper power source can

cause damage to the unit and invalidate the warranty

!

Turn the master switch to the “Hot” (heated) mode.

1. Wet & Dry Operations: For wet operations, make sure that the

drain is closed. For wet applications, do not add more that one (1)

inch of water to the foodwell. Please note that the wet operation

will provide the most efcient temperature holding of the food

product.

2. For wet & dry operation, cover the well with a cover, or place an

empty pan in the well. Turn the thermostats to the highest setting

and preheat the wells for a minimum of 45 minutes.

3. Next, place pans of preheated food into the foodwells. It is

important to note that the unit is designed to maintain food

temperatures. The unit is not designed to raise the food

temperatures. To avoid the loss of the food temperatures, keep

the pans of food covered when not serving. Also, during the

serving period, keep any empty foodwells covered with a cover or

empty food pan when not in use. Due to the density and unknown

preheated temperatures of food product going into the unit, there

is no established formula for specic food temperatures of specic

foods.

4. Once pans of food have been placed into the unit, adjust the

thermostat to the desired temperature setting.

CLEANING INSTRUCTIONS

PROPER CLEANING OF FOODWELLS

Foodwells must be cleaned after use or at least once daily. All food

spillage, calcium build-up and chlorides (from the water supply) must be

removed. Please note that foodwells will discolor (turn brown) with use!

For long foodwell life and to avoid invalidation of warranty:

1. NEVER use chlorinated or other harsh cleaners. Contrary to

popular belief, stainless steel is not totally impervious. Chlorine

and other harsh cleaners can cause the stainless steel foodwells

to rust, pit and corrode. This reaction is expedited due to heat.

Should chlorine be present in the facilities water system or

from chlorinated cleaners and calcium is allowed to build up, a

chemical reaction will occur. This reaction will cause the foodwells

will pit, rust and/or corrode in a short period of time.

2. NEVER use commercial steel wool or steel wool type scouring

pads. The bers from these pads can become impregnated into

the stainless steel foodwells and cause/expedite rusting, pitting &

corrosion of the foodwells.

3. ALWAYS clean foodwells after each use or at a minimum daily

with non-chlorinated cleaners approved for stainless steel. Scour

each foodwell to remove all calcium & food buildup with a plastic

or pure stainless steel scouring pad. Follow by a through rinsing

of each foodwell and wipe dry with a soft cloth. Through cleaning

is imperative to remove food spillage as well as calcium buildup

and chlorides that are present in most water systems.

COLD OPERATIONS

IMPORTANT: If switching from Hot to the Cold mode, allow for the

unit to cool to room temperature.

!

Turn the master switch to the “Refrigeration” (cold) mode.

The compressor will energize and the unit will start cooling. Cover the

well with empty pans or pan covers and allow for the unit to cool for 45

minutes. Remove the covers and places pans of precooled food into the

well. Note that this unit is designed to hold cold temperatures. It is not

designed to lower food temperatures.

Loading...

Loading...