Dinex DCF-2 Service Manual

DINEX INTERNATIONAL, INC. • 628-2 HEBRON AVENUE, GLASTONBURY CT 06033 • WWW.DINEX.COM

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Start-up & Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Proper Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Parts List DCF Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts List Frost Top Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Parts List Refrigerated Base Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Wiring Schematics All Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6, 7 & 8

Dinex® Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DCF & DFT Cold Food & Frost Top Counters

RB/1D (One Door) and RB/2D (Two Door) Refrigerated Bases

For Service Information, call 1-888-673-4639

Please provide following information:

• Model number

• Serial number

• Part Description and number as shown in parts list.

DineXpress Cold Counters Rev-05/08

Printed in the USA

Cold Food Co u nte r s

Se r v i c e Ma n u a l

Page 2

Introduction:

You have purchased the new DineXpress® Equipment.

Please read this manual for helpful guidelines on how to

use your Equipment. Should you have any questions

concerning the Equipment, please call the Dinex Hotline

at 1-888-673-4639 (Monday through Friday from 8 am to 5

pm, Eastern Standard Time).

IMPORTANT: For your safety,read and follow all cautions,

information and warnings.

FREIGHT DAMAGE CLAIMS

Your Dinex Equipment was carefully inspected and packed

before leaving our plant. The transportation company

assumes full responsibility for the safe delivery of the

Equipment. Dinex does not assume any responsibility for

damage or loss incurred in transit. Please note any visible

damage or loss on the freight bill and have delivery personnel sign.

A freight claim should be filed immediately with the

t r a n s po r t ation co m p a n y. If co n cealed damage is discove re d

after unpacking the Equipment, please file a concealed

damage claim with the transport company within 10 days

after receipt of the goods.

IMPORTANT: All packing materials should be retained for

return shipment.

APPLICATION AND USE

The Equipment is for commercial use in the food service

industry. It provides storage of dishes and is operated

with a heating system.

SAFETY

The instru ctions co n tained in this manual provide impo rt a nt

guidelines for the Equipment user regarding a correct and

safe installation. Particular attention should be paid to the

warnings given in various parts of this manual. Never dismantle and/or repair the appliance with the power supply

in place. Especially, do not repair electrical elements if you

are not qualified for such work.

INFO: Please note that this appliance is for commercial

use only and must be used exclusively for the purposes

prescribed.

!

!

!

SECTION I: INHOUSE EQUIPMENT

TRANSPORTATION AND INSTALLATION

To avoid equipment damage, carefully uncrated the

equipment. Use caution when setting the equipment into

place. All units on casters can be carefully rolled into

position. Units equipped with legs must be transported

on dollies. NEVER lift units with a fork truck. Lifting and

transporting with a fork truck will damage the unit’s

structure and invalidate the warranty.

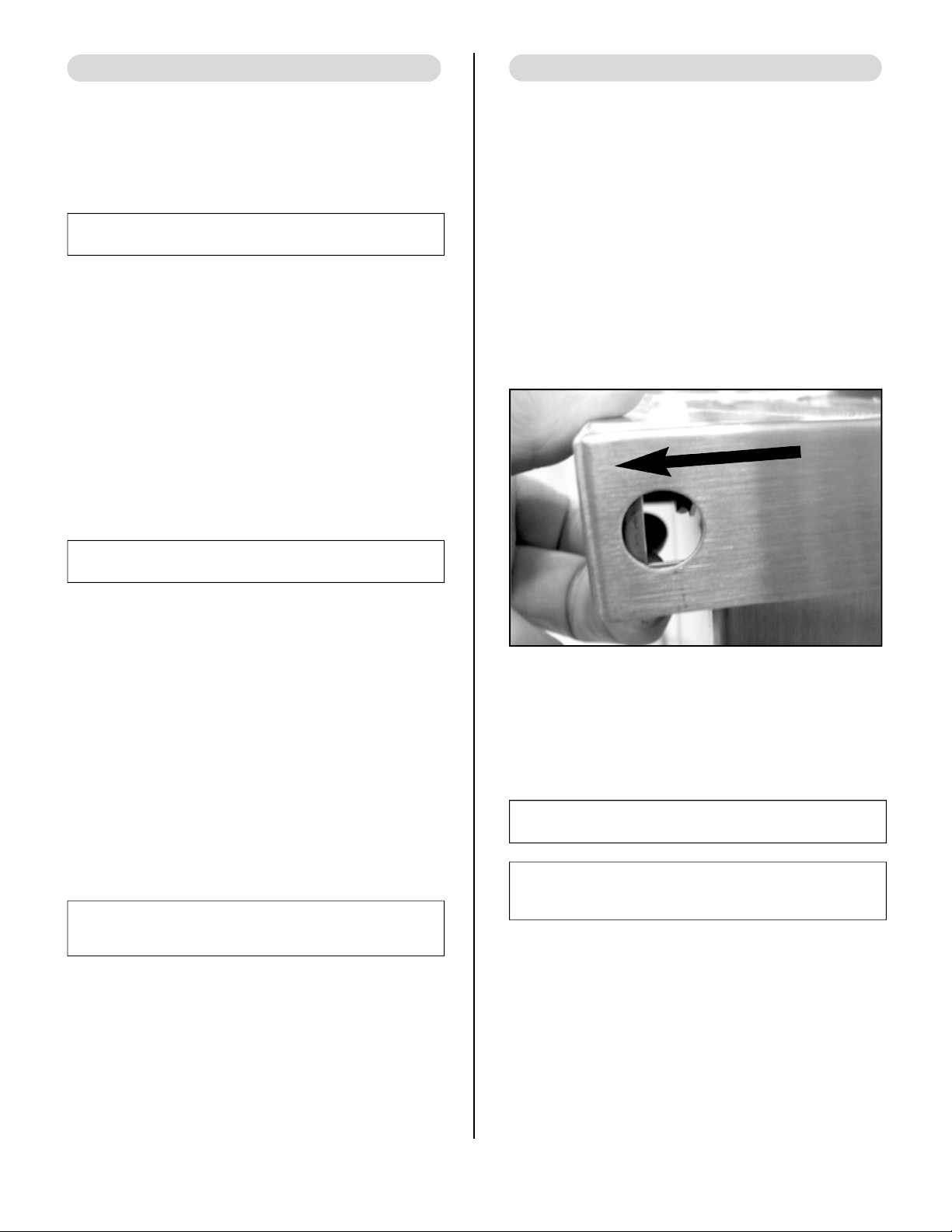

To interconnect the equipment into a line-up, see ( Fi g . 1 ) .

Grasp the locking device. Pull outward and hold while the

adjacent unit is pushed into place. Once the adjacent unit

is in place, release the locking device and it will lock into

the adjacent slotted stud.

Installation:

COLD FOOD, FROST TOP &

UNDERCOUNTER REFRIGERATED TABLES

START-UP & OPERATION

IMPORTANT: It is the re s po n s i b i l i ty of the installer to co m p ly

with all State & Local elect ri c al cod e s.

CAUTION: Co n n e cting the unit to the impro per powe r

s o u r ce can cause damage to the unit and i n va l i d a t e the

wa r ra n t y.

Figure 1

!

!

Page 3

Connect the unit to a proper power source.The following

are the electrical requirements for standard units without

any electrical options. Should your unit have electrical

options such as a duplex receptacle, overhead lights,

refrigerated base, etc, please check the rating tag on the

unit to determine the proper 120 VAC electrical power

requirements!

1. Models DCF/27, DCF/37, DCF/47, DCF/2, DCF/3, DCF/4,

DFT/2, DFT/3 & DFT/4:

Electrical: 120 VAC, 15 AMP (NEMA 5-15R Receptacle).

These units are equipped with a1/3 H.P Compressor.

2. Models DCF/57, DCF/67, DCF/5, DCF/6,DFT/5 & DFT/6:

120 VAC 20 AMP Service (NEMA 5-20R Receptacle).

These units are equipped with a 1/2 H.P. Compressor.

The drain valve must be closed prior to use. Turn the unit

on by turning the master switch to the “On”position. Let

unit operate for at least 45 minutes prior to use. Please

note that these units are designed to maintain cold food

temperatures.Thus pans of food product must be

prechilled prior to being placed into the unit. Never place

food directly into the

refrigerated wells of refrigerated base.

IMPORTANT:Th e re are louve r ed panels loca ted on the

f r ont and back of the unit. A constant air flow must always

be maintained thru these louve red panels.Th u s , t h ey must

n e ver be bloc k ed or the airf l o w obstru cted in any manner. If

this is allowed to oc c u r,the cooling efficiency of the unit will

be affe cte d. Bl oc k ed or obstru cted louver panels can also

cause damage to the co m p r essor thus invalidating the

wa r ra n ty.Never allow for napkins or other paper prod u cts to

o b s t ru ct the air flow thru the louve r ed panels.

!

REQUIREMENTS

To maintain proper cooling and to prevent compressor

damage, the compressor coils must be cleaned, at a

minimum every 4 months. To do this, disconnect the

electrical power to the unit, remove the two louvered

panels and clean the coils by vacuuming out the dust and

dirt. Blowing the coils out with air pressure is the most

efficient way to clean the coils. However, if air pressure is

used, the unit must me relocated to a controlled

environment away from food product and away from all

non-experienced personal. Failure to properly clean the

compressor coils on a regular basis will reduce the

cooling efficiency of the unit. This situation can also

cause damage to the compressor thus invalidating the

warranty.The cleaning of the refrigeration coils is the

responsibility of the facility. This procedure is not a

warranty issue.

PROPER CLEANING

Counters must be cleaned after use or at least once daily.

All food spillage must be removed.

For long equipment life:

1. NEVER use chlorinated or other harsh cleaners. Contrary

to popular belief, stainless steel is not totally impervious.

Ch l o rine and other harsh cleaners can cause the stainless

steel units to rust, pit and corrode.

2. NEVER use commercial steel wool or steel wool type

scouring pads. The fibers from these pads c an become

impregnated into the stainless steel foodwells and

cause/expedite rusting, pitting & corrosion of the

foodwells.

3. ALWAYS clean foodwells after each use or at a minimum

daily with non-chlori n ated cleaners approved for stainless

s t e e l. Scour each foodwell to remove all food buildup

with a plastic or pure stainless steel scouring pad. Follow

by a through rinsing and wipe dry with a soft cloth.

ELECTRICAL & REFRIGERATION

SPECIFICATIONS

1. 1/3 H.P. Compressors: Refrigeration Type: 134A,

Refrigeration Charge=25 Ounces

Pressure settings: 150 psi Low Pressure & 350 psi High

Pressure

Electrical Rating: 120 VAC,7.2 R.L.A Amps & 9.5 Start-up

Amps.

2. 1/2 H.P. Compressors: Refrigeration Type 134A,

Refrigeration Charge 30 Ounces.

Pressure Settings: 150 psi Low pressure & 235 psi High

Pressure

Electrical Rating: 120 VAC, 8.8 R.L.A & 11.5 Start-up

Amps.

Maintenance

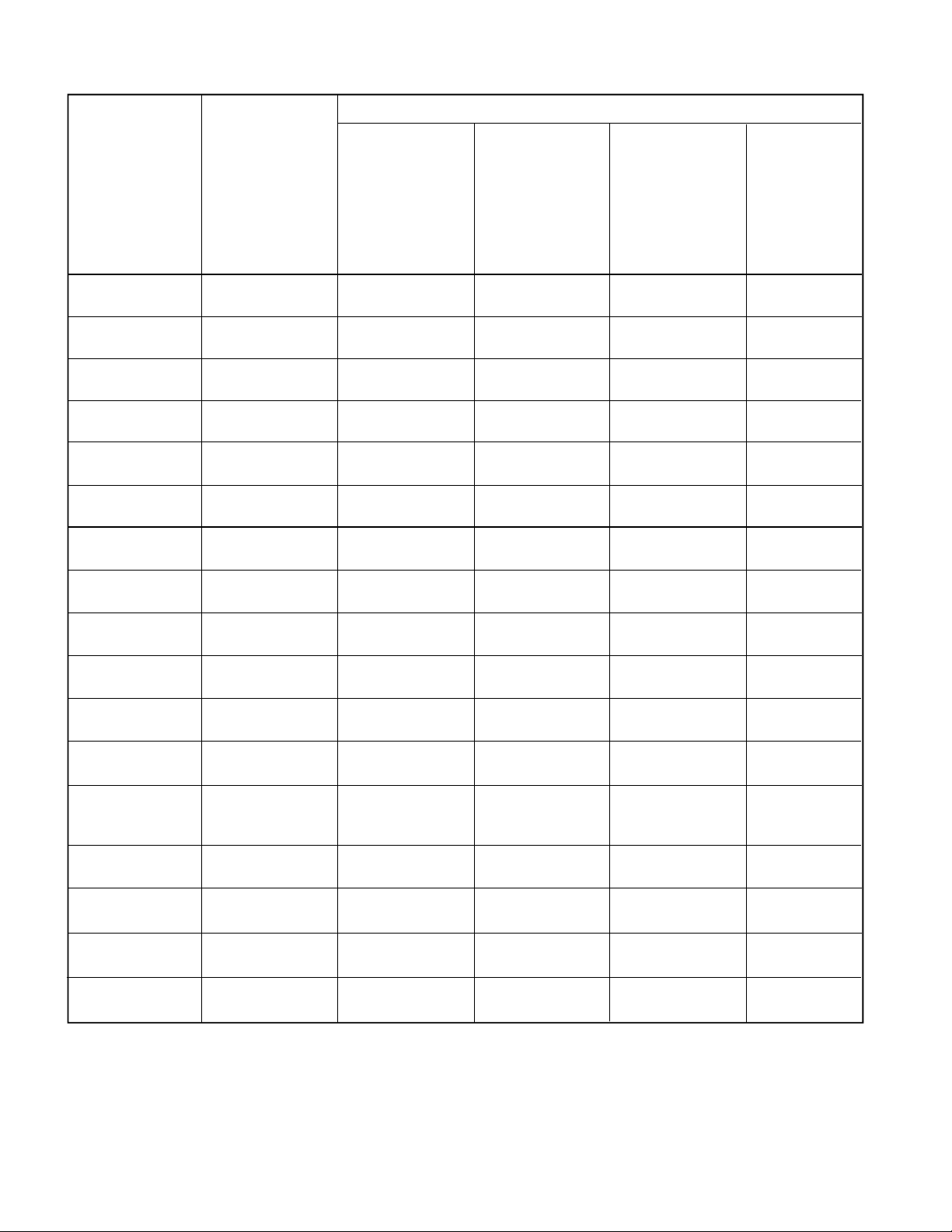

DCF/2

DCF/2NR

DCF/3

DCF/3NR

DCF/4

DCF/4NR

(Note: NR Signifies

Non-Refrigerated)

MODELS

Page 4

DESCRIPTION

PART

NUMBER

DCF/27

DCF/37

DCF/47

DCF/57

DCF/67

DCF/5

DCF/5NR

DCF/6

DCF/6NR

(Note: NR

Signifies Non-

Refrigerated)

Switch, "On-Off:"

with Light

DX186020055

X

X

X X

Pressure Control

DX186140010

X

X

X X

Drain Valve 1"

npt Ball

DX186150189

X

X

X X

X

Optional

Optional

Receptacle, Duplex

120 V. 15 Amp.

DX186060676

X X

X

Caster, Swivel

W/Brake

DIN-5S-BRK-BG X X

X

Caster, Swivel

No Brake

DIN-5S-BG

X X

X

Legs, Adjustable

DX183090050

X X

X

Interlock Stud

DX181000200

X X

X

Interlock Female

Assy.

Adapter Bar

Adjustable Height

Casters (Optional)

See Following:

Mounting Plate,

Adjustable Caster

Casters, Adjustable,

Swivel With Brake

Casters, Adjustable,

Swivel No Brake

Lock Nut,

Adjustable Caster

DX160952296

186110121

(No DX)

DX160952707

DX183015246

DX183015245

DX180600091

X

X

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

Optional

X

X

Optional

Optional

X

X

Optional

Optional

Compressor 1/2 HP,

120 VAC, Low Temp

DX186125050

X

X

Compressor 1/3 HP

120 VAC, Low Temp

DX186125030

X

X

Parts List Standard Cold/Mechanically Refrigerated Tables

Loading...

Loading...