Dinex DBC30 Installation Manual

DINEX INTERNATIONAL, INC. • 628-2 HEBRON AVENUE, GLASTONBURY CT 06033 • WWW.DINEX.COM

For Service Information, call 1-888-673-4639

Please provide following information:

• Model number

• Serial number

• Part Description and number as shown in parts list.

Manual No. DBC30 Rev-03/08

Printed in the USA

Model DBC30

BLAST CHILLER/SHOCK FREEZER

User’s Manual

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Controller Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Automatic Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Manual Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Cycles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Using the DBC30 Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Blast Chilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shock Freezing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Soft Chill Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Hard Chill Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Shock Freeze Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Panel for Blast Chiller for Model DBC30 Blast Chiller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Keyboard Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Key Combinations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1. Initial Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Programming the Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Automatic Cycle Parameters Programming (Blast Chiller Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Manual Cycle Parameters Programming (Blast Chiller Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Programming the Unit as a Shock Freezer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Automatic Cycle Parameters Programming (Shock Freezer Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Manual Cycle Parameters Programming (Shock Freezer Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1. Automatic Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Manual Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Defrost Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning the Condenser. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning the Storage Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Dinex® Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

INDEX

Page 2

OPERATING CYCLES

The operator can choose from the following 2 operating

cycles:

NOTE: All Chill Cycles automatically go into HOLDING

MODE when the selected food core temperature is reached

and remain there until the operator stops the cycle.

ADDITIONAL CYCLES

WARNING: Read and carefully follow all of the instructions in

this manual before you attempt to install this equipment.

NOTE: Any changes made to the equipment without

authorization from the factory will void the warranty.

PREPARATION

• Check the integrity of the unit once it is unpacked

• Check to make sure the floor is level

• Check that the available power supply (Voltage, # of

phases, Hz,Amps, max.fuse size) corresponds to the

ratings on the nameplate and that correctly rated

electrical protection is provided (VOLTAGE MUST BE

WITHIN ± 5% FROM THE NAMEPLATE VALUE).

INSTALLATION

Dimensions

Overall dimensions are 25 1/4" left to right, 25 7/8" front to

back, 34" height.With the door open 90° the front to back,

distance is 48 3/4".

Location

Ambient air temperature should be no greater than 90°F

to ensure the rated performance.

Do NOT install the unit near a heat source, in an area

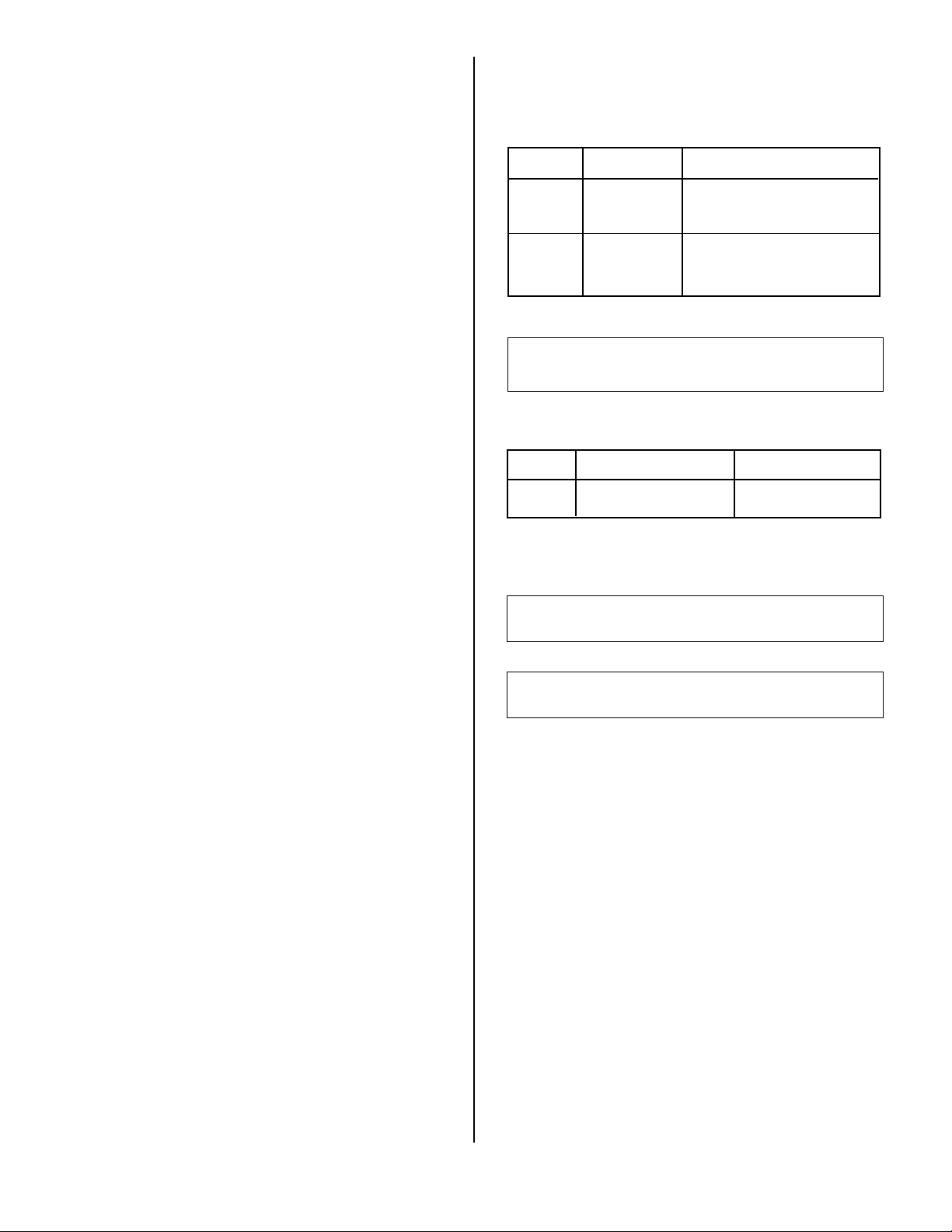

MODE

USES

NOTES

Defrost

To defrost the

evaporator, not the food.

Use when necessary.

You have just purchased the new Dinex Equipment. Please

read this manual for helpful guidelines on how to use your

Equipment. Should you have any questions concerning

the Equipment, please call the Dinex Hotline at 1-888-6734639 (Monday through Friday from 8 am to 5 pm, Eastern

Standard Time).

The Model DBC30 Blast Chiller/Shock Freezer is used to rapidly chill cooked foods to temperatures suitable for refrigerated or frozen storage. It has a capacity of (3) 12" x 20" x 21/2" pans (not included). Model DBC30, in Chiller mode, is

capable of lowering the core temperature of up to 30 lbs. of

food from 160° F to 40° F within 90 minutes. In Shock Freeze

mode it is capable of lowering the core temperature of up

to 18 lbs. of food from 160° F to 0° F within 4 hours. Model

DBC30 employs a high velocity flow of cooled air to assure

even cooling of the entire load of food, and to quickly bring

the food temperature through the danger zone in which

bacteria multiply rapidly.This is done in accordance with

HACCP, FDA and all state regulations.

CONTROLLER FEATURES

The electronic control system is solid state and is based on

the latest microprocessor technology.The display is VFD

Industrial Type. It displays 2 lines of 20 characters each and

allows operator viewing from any angle. The display is programmed to show clear step-by-step instructions and

operating data. The unit has built-in safety and self-diagnostic systems. The controller notifies the operator if various faults, as listed below,should occur:

• Faulty air temperature probe

• Faulty food temperature probe

• High air temperature (above 140° F)

• Low air temperature (below -35° F)

• High food temperature (above 180° F)

• Low food temperature (below 35° F)

• Excessively high pressure.

OPERATING MODES

The operator can choose from the following modes:

Automatic Mode

This is the preferred mode, in which the food probe is

active and takes part in controlling the chilling or freezing

processes.The cycle will never proceed to its next step

until the food probe has reached its set breaking temperature.The operator needs only to insert the probe into the

food. It is recommended that the operator remove the

food when its temperature starts to flash and the display

shows “Ready”. The unit will automatically switch into

holding mode (cavity air temperature between 35° F

and 42° F) when the food has reached the end cycle

programmed temperature.

Manual Mode

Operating time is set manually, by the operator, for the

meal that has been chosen. Air temperature is controlled

by the air probe. If the food probe has been inserted into

the food it will provide temperature readouts only.The

unit will automatically switch into the holding mode at the

end of the cycle.

Page 3

!

!

!

MODE

END FOOD

TEMPERATURE

NOTES

Automatic

Manual

38° F To 40° F

38° F To 40° F

Air temp.starts at 0°F, rises to 28°F

to 35° F when food core temp.

reaches 60°F

For 1 hour air temperature is

maintained between 0°F and10°F

and for another hour is maintained between 28°F and 35°F

INTRODUCTION

INSTALLATION

exposed to direct sunlight, or in a closed area with high

temperatures and insufficient air change.

Level the unit by rotating its adjustable feet, ensuring that

the weight of the unit is off the legs when doing so.

Make certain that the unit is correctly leveled - correct

functioning may be compromised if it is not.

Mount the rails for the drain pan, using the screws sent

with the unit. The mounting inserts are already in place

under the unit. Slide the drain pan on the rails.

Plug the power supply cord into a proper outlet in accordance with the chart below.

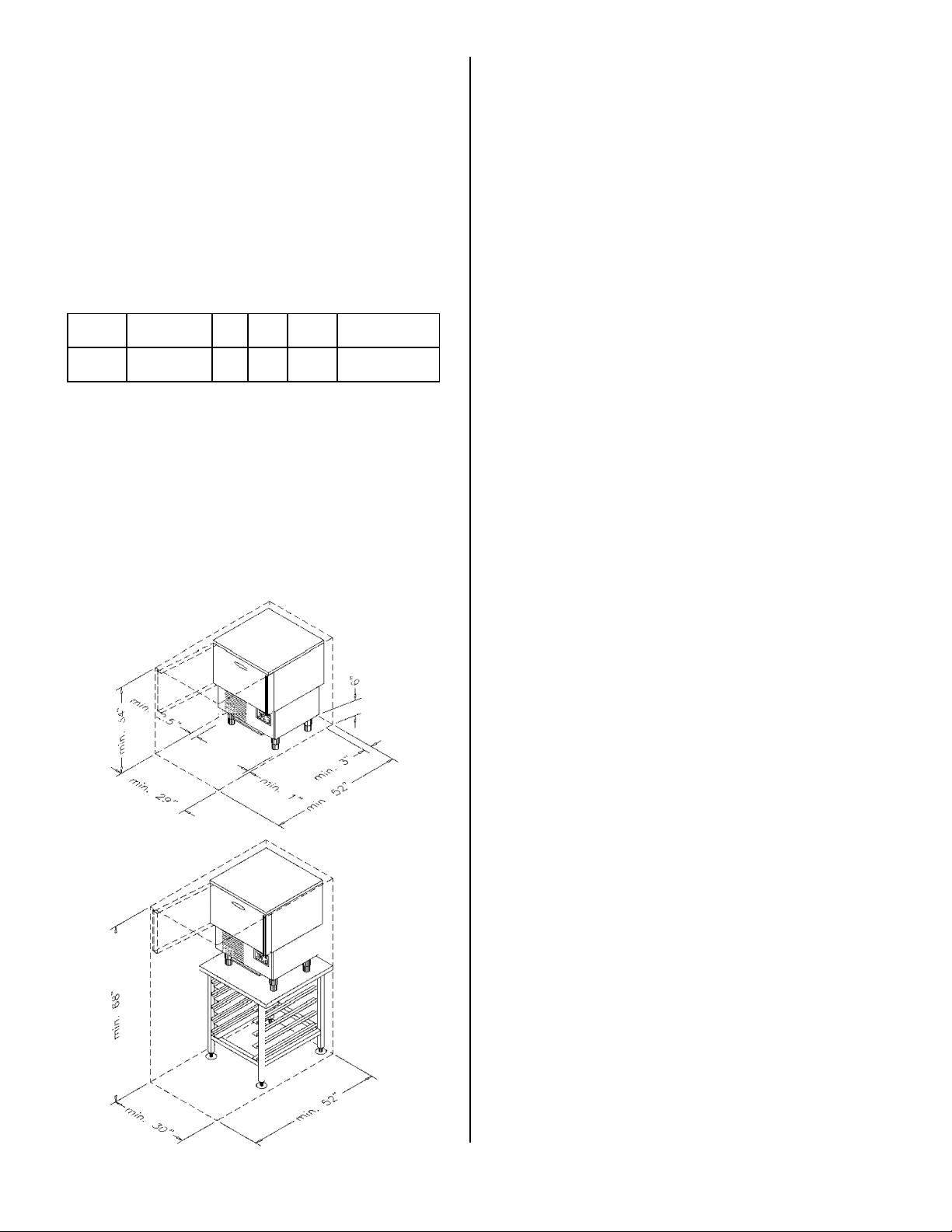

Spaces Around The Cabinet

• At least 1" clear space is required on the right side of the

cabinet for air flow and service.

• At least 2.5" clear space is required on the left side of the

cabinet for door opening and air flow.

• At least 3" clear space is required on the rear of the

cabinet for optimum air flow.

• Enough space should be provided in front of the cabinet

to fully open the door.

Optional Stand

BLAST CHILLING

All cooked food rapidly loses its quality and aroma if it is

not served promptly. Natural bacteria growth, the main

reason why food becomes stale, takes place at an exponential rate between 140°F and 40°F. However lower temperatures have a hibernating effect that increases as the

temperature drops, thereby gradually reducing bacterial

activity until it stops altogether.Only fast reduction of the

temperature at the product's core allows its initial characteristics to be maintained intact.The DBC30 blast chiller

gets food through this high-risk temperature band rapidly,

cooling the core of the product to 40°F within 90 minutes.

This conserves food quality, color and aroma while increasing its storage life. After blast chilling, the food can be preserved at 38°F for up to 5 days.

SHOCK FREEZING

For storage over the medium-long term, food has to be

shock frozen (to 0°F or below). Freezing means converting

the water contained in food into crystals. Thanks to the

high speed at which low temperature penetrates the food,

the DBC30 shock freezer assures the formation of small

crystals (micro-crystals) that do not damage the product in

any way.Uncooked raw materials, semi-processed food

and cooked food can be treated safely.When the food is

thawed, no liquids, consistency,weight or aroma will be

lost, and all its initial qualities will remain unchanged.

SOFT CHILL CYCLE

(160°F to 40°F)

This cycle is recommended for "delicate", light, thin products or small piece sizes, such as vegetables,creams,

sweets, fish products and fried foods. Soft chilling lowers

the food temperature quickly, but extremely delicately so

as not to damage the outside of the food.This is the ideal

cycle to chill any food quickly but delicately, even in haute

cuisine.

HARD CHILL CYCLE

(160°F TO 40°F)

Hard chilling is suited for "dense" products and products

with a high fat content, in large pieces or those products

typically more difficult to chill. Careful chilling control

ensures that the end temperature of 40°F is reached at the

core of the product, with no danger of freezing and

damaging the product, not even on its surface.

SHOCK FREEZE CYCLE

(160°F TO 0°F)

This cycle is recommended when you want to store food

for several weeks or months, at temperatures below 0°F.

Freezers are suited for storing ready frozen foods, but not

for freezing them. During shock freezing, the liquids contained in the food are transformed into micro-crystals that

do not harm the tissue structure. When the food is used

and thawed, its quality will be excellent. It is especially

suited for all semi-processed food and raw products.

Page 4

MODEL

VOLTAGE

NOTES

5-15P

HZ

60HP1

AMPS

10

DBC30

120, 1 PH

USING THE DBC30

TECHNOLOGY

Page 5

KEYBOARD KEYS

ON/OFF

START/STOP

A – automatic cycle

M – manual cycle

UP, DOWN, SELECT, ENTER – programming keys

KEY COMBINATIONS

• Initial Programming state – to initially set the device

Press and hold “START/STOP” for 5 seconds

• Cycles programming state – to initially set A and M cycles

Press “ENTER” for 1 second

• Load default values

Press “DOWN” for 10 seconds

• Ready To Go state in order to start a cycle

Press “ON/OFF”

• Defrost

Press UP for 5 sec.

FOR MODEL DBC30 BLAST CHILLER

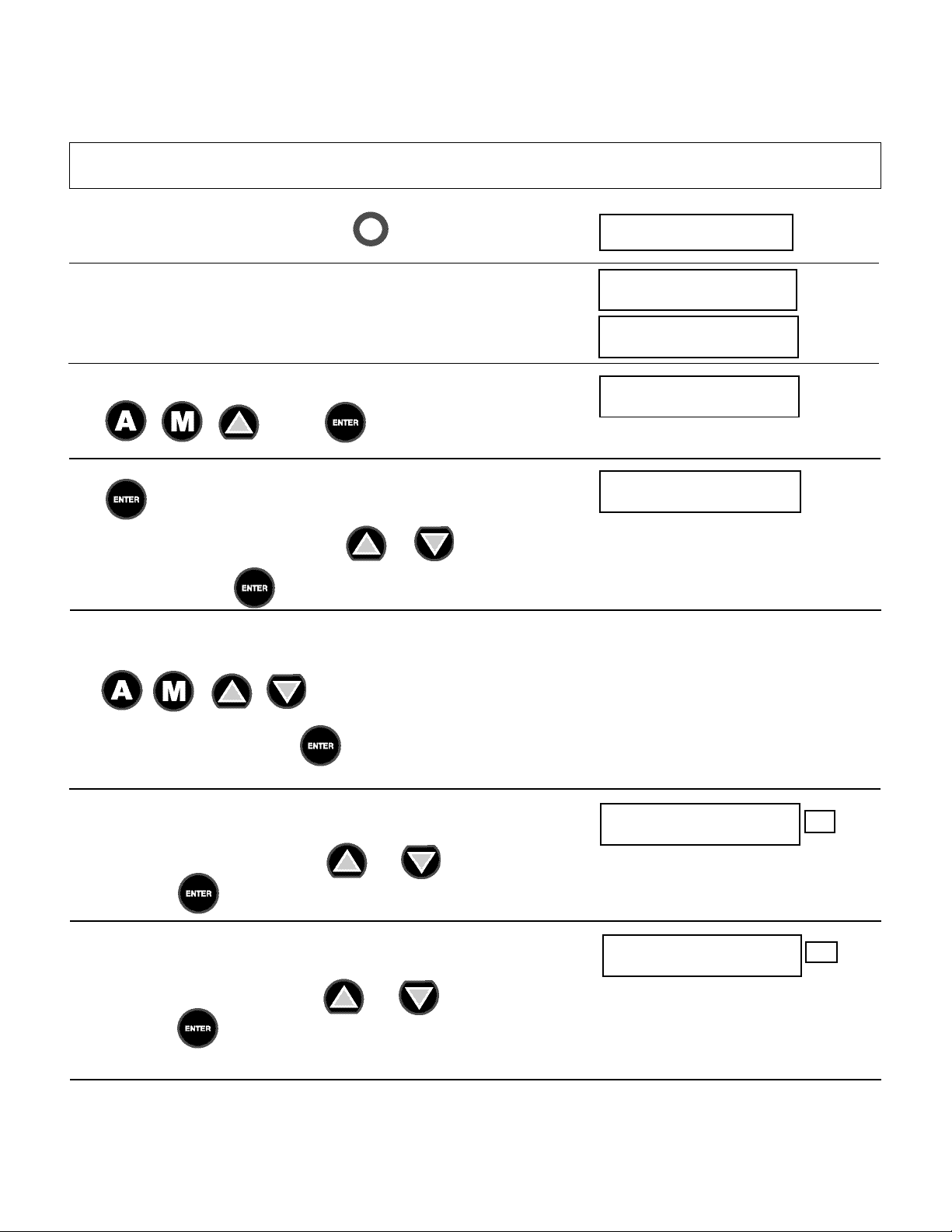

1. INITIAL PROGRAMMING

NOTE: Initial programming is preset at the factory (the unit is configured as a blast chiller). Use this section only if changes are

desired. If no changes are to be made, skip to Page 7.

(2. Programming the cycles).

a. With the display reading "OFF", press

("START/STOP") for 5 seconds.

b.When entering initial programming state, the display

will show for 3 seconds:

After 3 seconds – or if a key is pressed – the display will show:

c. Enter the default password by pressing, in order, the

and keys.

d. If you do not wish to change the password, press

.

To change the default password, press or

for "YES" then press .

The password will always be a combination of three of the four following keys:

("AUTO","MANUAL","UP","DOWN",).

Type the new password, then press

Be sure to remember the new password and keep a record of it in a safe place.

The high air alarm temperature should be left at

140 °F. However, if a change is desired:

e.To change the temperature, press or

then press .

The low air alarm temperature should be left at

-35°F. However,if a change is desired:

f. To change the temperature, press or

then press .

PROGRAMMING

Page 6

!

OFF

INITIAL PROGRAMMING

ENTER PASSWORD

ENTER PASSWORD

***

CHANGE PASSWORD?

NO

HIGH AIR ALARM

140°F

LOW AIR ALARM

-35°F

140

-35

Blinks

Blinks

Loading...

Loading...