Dinex DBC175 User Manual

JOB _____________

ITEM # _____________

BLAST CHILLER / SHOCK FREEZER

Item Number: DXDBC175

Application

This compact unit has a self-contained,

air-cooled refrigeration system and is

complete with all required controls and

accessories. The microprocessor control

system provides a choice of operating

cycles: soft chilling, hard chilling, shock

freezing, holding, and sterilizing. A heated

core temperature probe is provided for

accurate control of temperature within

the product. The cabinet is sized to

accommodate one mobile rack (not

included) to hold 12” x 20” x 2-1/2” deep

food pans or 18” x 26” sheet pans. (not

included)

Construction

The chilling/freezing cabinet is constructed

of polished type 304 stainless steel, with

2” of CFC-free, high density polyurethane

insulation. The interior corners are fully

rounded. The door is equipped with a

removable magnetic gasket. All motors

are sealed ball bearing wash-down

type. The cabinet floor is insulated (1/2”

CFC-free high density polyurethane)

and is provided with an integral 3” long

ramp to facilitate access. A minimum 6”

clear space is required on the control

panel side of the cabinet for service. A

minimum 12” clear space is required on

the hinge side of the cabinet for door

opening. The door is hinged on

operator’s left.

Refrigeration System

The self-contained refrigeration system

which is mounted on the top of the cabinet,

includes a condensing unit using R-404A

refrigerant. The evaporator temperature

range is +25ºF to – 40ºF.The compressor

is a semi-hermetic type with inherent

overload protection.

Performance

Blast chilling (soft or hard) lowers the

food core temperature from 160°F to

38°F in less than 2 hours. Shock freezing

lowers the food core temperature from

160°F to 0°F within 4 hours. Chilling

and freezing times will vary somewhat,

depending on the food quantity, initial

temperature, density, moisture content,

specific heat, and type of container.

The airflow has a high velocity, indirect

pattern designed to cool all levels at

identical rates. Time/temperature chilling

and freezing rates meet or exceed all

FDA and state regulations.

Microprocessor Control System

The solid state electronic control panel

is user friendly, easy to reach and can be

set for automatic or manual operation.

The heated core probe continuously

measures the product temperature

during the chilling or freezing cycles. At

the end of freezing cycle the probe can

be heated for ease of removal from the

Item Number

q DXDBC175

frozen product. Easy to read VFD display

and buzzer alarm are standard features.

All settings are programmable by the

operator. The standard operating cycles

include the following:

• Soft Chilling: The air temperature is

held in the range of 28°F to 35°F, ideal

for delicate food items. The chilling

cycle is completed when the food core

temperature reaches 38°F to 40°F.

• Hard Chilling: The air temperature is

lowered to 0°F. When the food core

temperature reaches 60°F, the air

temperature rises to a range of 28°F

to 35°F. The chilling cycle is completed

when the food core temperature

reaches 38°F to 40°F.

• Shock Freezing: This cycle is designed

to avoid damage to the food structure,

keeping the food free of large ice

crystals. The air temperature is lowered

to and held at -25°F. The freezing cycle

is completed when the food core

temperature reaches 0°F.

• Holding: At the end of any cycle (soft

chilling, hard chilling or shock freezing),

the unit will automatically switch to a

holding mode which will keep the food

at 38°F (chilled) or at 0°F (frozen) until

START/STOP button is pressed to end

the cycle. If the door is opened before

pressing START/STOP button, the

holding mode will resume when the

door is closed and continue until

START/STOP button is pressed.

Options

6” high s/s legs are standard extra heavy

duty 4” diameter casters

2-w/brakes are optional.

Warranty

One year parts and labor.

Building 2, Suite 106

628 Hebron Avenue

Glastonbury, CT 06033

800.523.9752 Fax: 860.652.3135

www.dinex.com

154-REV 10/09

BLAST CHILLER / SHOCK FREEZER

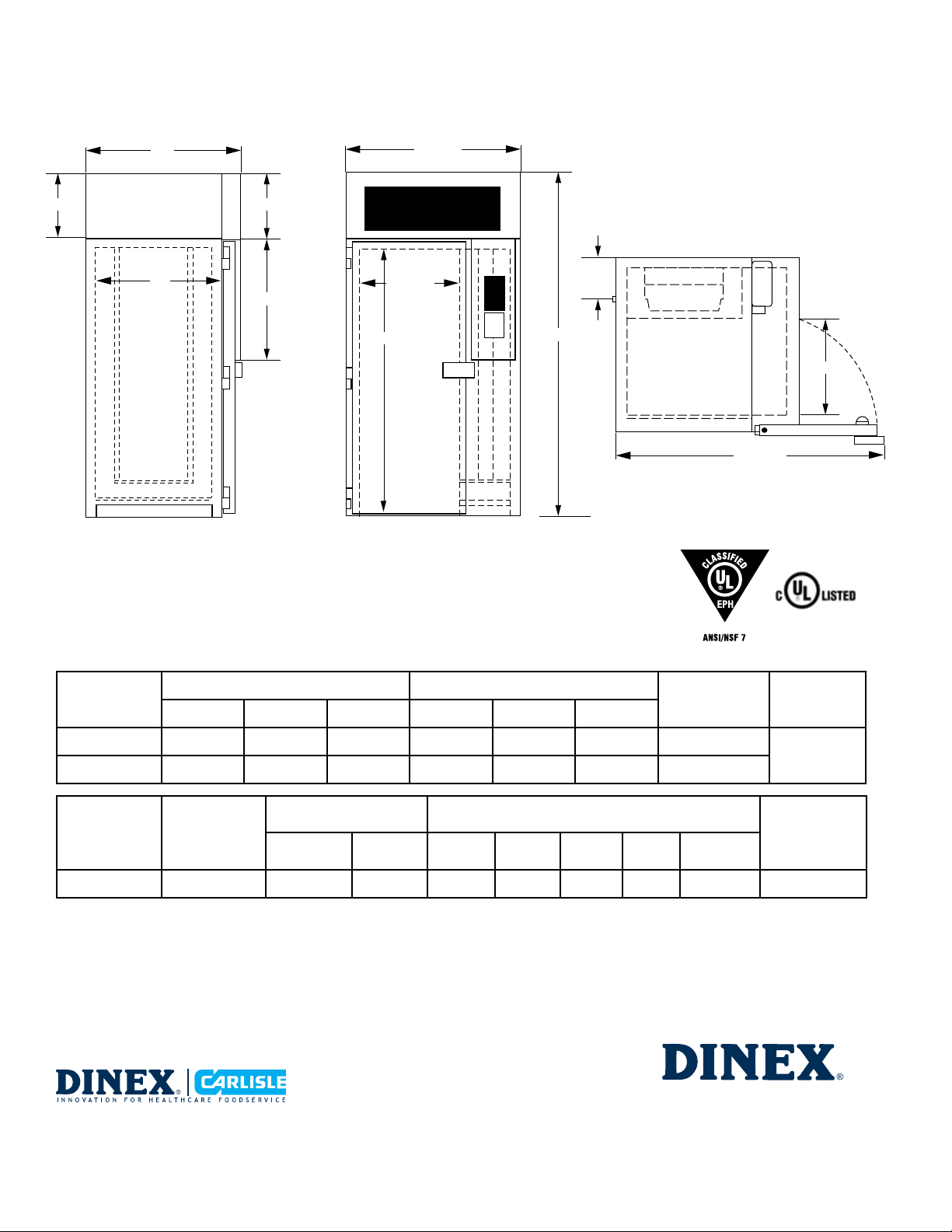

17-3/8”

42”

34”

18”

32-1/4”

72-1/4”

27-1/8”

Front ViewLateral View

47-1/4”

11”

93”

27-1/8”

72-1/2”

Top View

Items and Dimensions

OUTSIDE INSIDE

LENGTH DEPTH HEIGHT LENGTH DEPTH HEIGHT

English 47.25” 42” 93” 27.125” 34” 72.25” 66.125”

Metric (cm) 120.0 106.7 236.2 69.0 86.4 183.5 174.3

ITEM

NUMBER

MODEL

NUMBER

MAXIMUM LOAD PER

CYCLE (LBS)

CHILL FREEZE VOLTS PH. HZ. AMPS

ELECTRICAL TOTAL

DXDBC175 DBC175 200 lb. 120 lb. 208 3 60 19.5 30 1.0

Please confirm that you have the most current specification sheet by visiting www.dinex.com.

Dinex® reserves the right to change specifications and product design without notice.

Such revisions do not entitle the buyer to corresponding changes, improvements,

additions or replacements for previously purchased equipment.

Printed in USA

DEPTH WITH

DOOR OPENED

REQUIRED

CIRCUIT (A)

Building 2, Suite 106

628 Hebron Avenue

Glastonbury, CT 06033

800.523.9752 Fax: 860.652.3135

www.dinex.com

SHIP

WEIGHT

915 lb.

(415kg)

COMPRESSOR

HP

154-REV 10/09

Loading...

Loading...