Page 1

Service Manual

Model Number:

PF2325

PF3033

UL Part Number

690932XXXX

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to service this replace. For your

safety, always comply with all warnings and safety instructions contained in this manual to prevent personal injury or property damage.

REV PCN DATE

Dimplex North America Limited

1367 Industrial Road Cambridge ON Canada N3H 4W3

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product development, we reserve the right to make changes without notice.

© 2016 Dimplex North America Limited

00 - 2-OCT-14

01 - 23-FEB-15

02 4-JAN-16

7400790100R02

Page 2

TABLE OF CONTENTS

Operation ...........................................................3

Maintenance .........................................................5

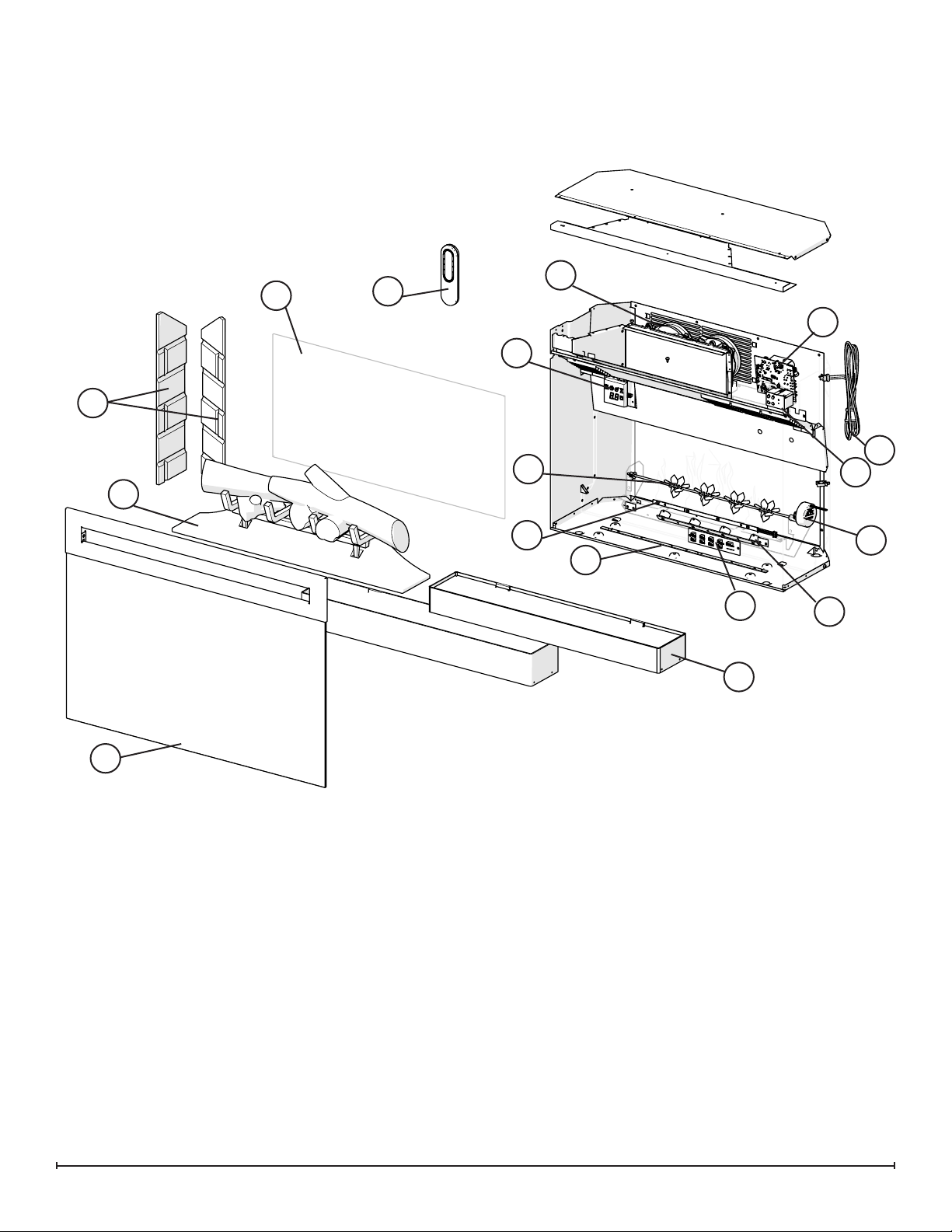

Exploded Parts Diagram - PF2325 Mod 0-A ...............................6

Exploded Parts Diagram - PF2325 Mod B .................................7

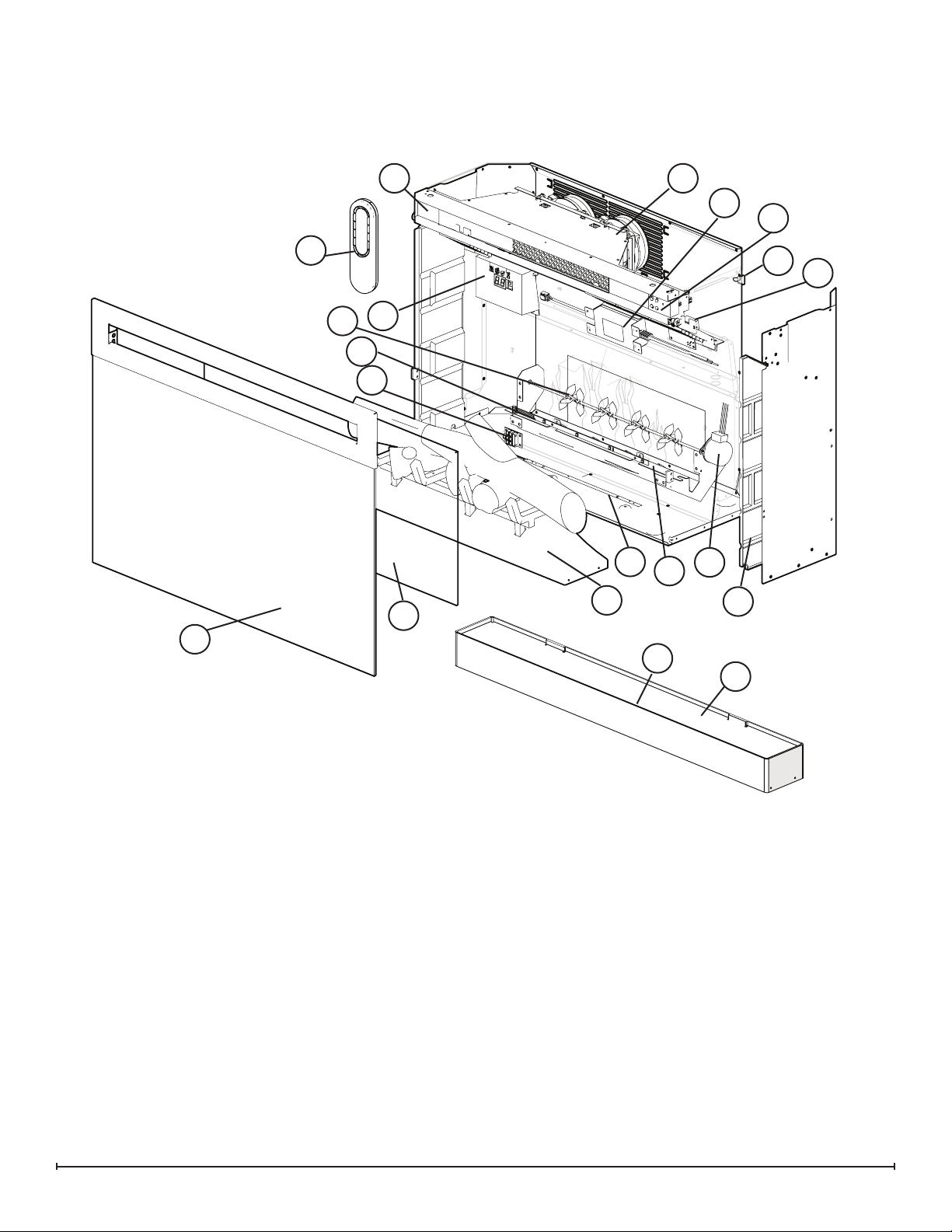

Exploded Parts Diagram - PF3033 Mod 0-A ...............................8

Exploded Parts Diagram - PF3033 Mod B .................................9

Wiring Diagram .....................................................10

Main Control Board Replacement

(Mod 0-A units Only) ............................ 12

Flame LED Light and Media Light Assembly Replacement .................12

Floating Display Assembly / Main Control Board Replacement ..............13

Top Light

Heater Assembly

Power Cord

Replacement ..................................................13

Replacement ...........................................14

Replacement ................................................14

Flicker Motor & Rod Replacement ......................................14

gWaveTM Assembly

Relay Board Replacement

Power Supply Replacement

Log set

Replacement ....................................................16

Electronics Junction Board

Lower & Media LED Light Assembly

Replacement .........................................15

(Mod B units Only) .................................... 15

(Mod B units Only) .................................. 16

Replacement ..................................16

Replacement ..........................17

Partially Reective Glass

Replacement ....................................17

Power Regulator Board Installation (Mod 0 units Only) ....................17

Troubleshooting Guide ...............................................18

Always use a qualied technician or service agency to repair this replace.

!

NOTE: Procedures and techniques that are considered important enough to emphasize.

CAUTION: Procedures and techniques which, if not carefully followed, will result in damage to the equipment.

WARNING: Procedures and techniques which, if not carefully followed, will expose the user to the risk of re, serious

injury, or death.

2 www.dimplex.com

Page 3

OPERATION

WARNING: This electric rebox must be properly in-

stalled before it is used.

This rebox operates with Comfort$averTM technology, which

automatically adjusts the fan speed and heater wattage to

safely and precisely match the requirements of the room

based on the thermostat setting. The heater operates such

that once the room reaches the set point, the fan and heater

will continuously run at a low level, to maintain the desired

room temperature. If the temperature in the room rises signicantly, i.e. sun coming through a window or a central furnace

turns on, the heater and fan will turn off and periodically turn

back on to circulate the air around the unit, until the room

temperature drops and requires the heater to be constantly

on again.

!

NOTE:

tinuously while the heater is on.

!

NOTE:

is a built in cool down period of 1 minute before the fan shuts

off completely.

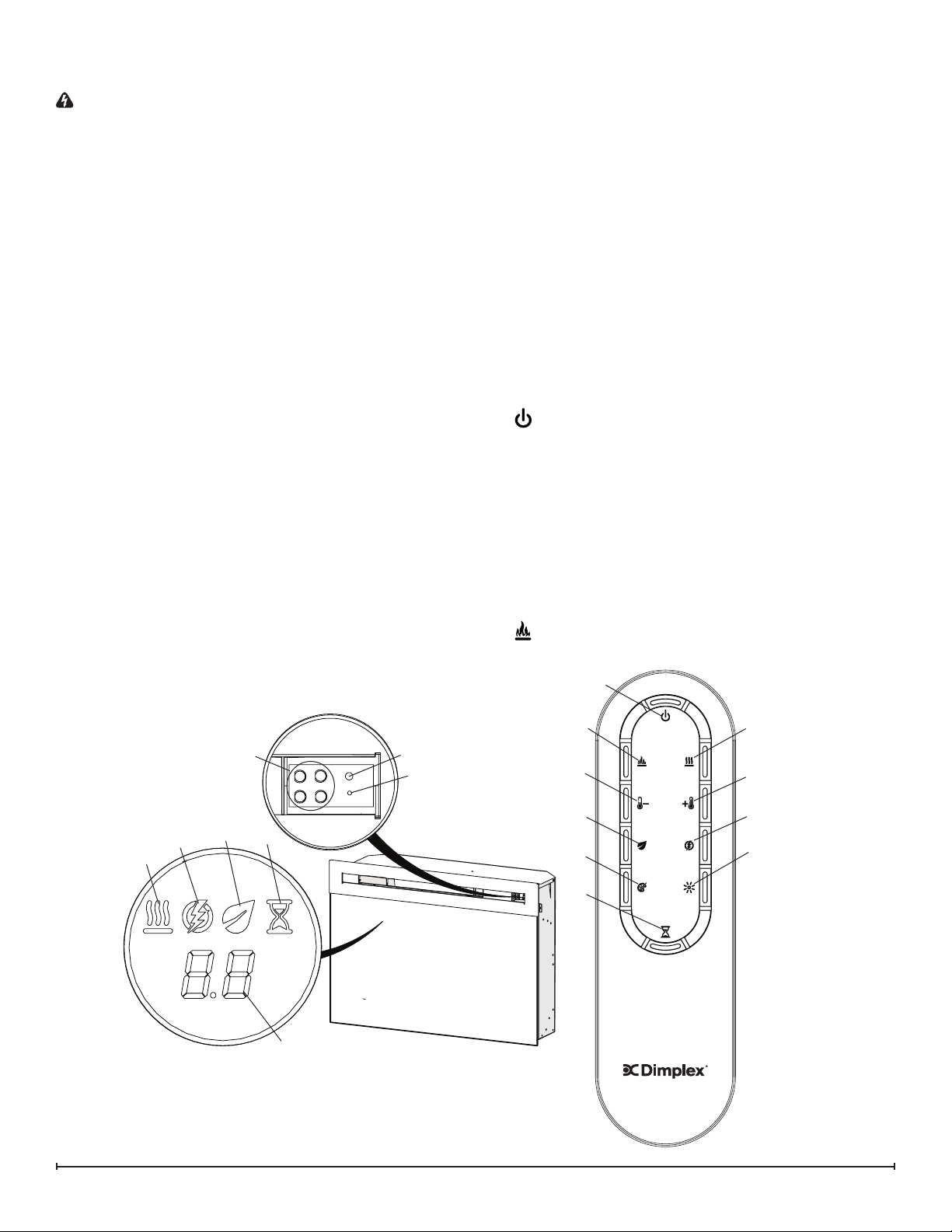

gWaveTM Controls

The replace can be operated by a simple “wave” in-front of

the unit. By waving your hand vertically approximately 4 in.

(102 mm) in-front of the gWaveTM sensor in the upper right

hand corner of the unit, the unit and different control functions

can be activated. This is also indicated by the LED light turning

green.

There is a Gesture On/Off button located below the LED

pilot light which can be used to turn this feature On or Off.

The unit is designed so that the fan will run con-

The element retains heat after shutdown, there

It is recommended that a straightened paperclip be used to

press the button through the small hole. When the gWave

controls are turned off, the green light will ash 4 times

before turning off and it will remain solid green when the

gWave

stration mode to exhibit all of the functions of the unit in a 95

second period of time. This can be activated by holding your

hand in front of the gWaveTM sensor for 7 seconds. When the

unit has gone through the demonstration mode once it will

return to the previous operation.

!

NOTE:

TM

controls are active.

The unit is programmed to have a built in demon-

TM

Remote Operation

The replace is supplied with an IR multifunction remote

control.

!

NOTE: To operate correctly, the remote control must

be pointed towards the front of the unit.

Controls

1. Standby: Turns unit On or Off.

→ Activated by pressing the corresponding button on the

remote or “waving” in-front of the gWaveTM. “Waving” up will

turn the unit On and “Waving” down will turn the unit Off.

• The unit will turn on with the same functions that it was set

to when it was turned Off and the intake temperature will be

indicated on the On Screen Display.

!

NOTE: When any button is pressed the intake temperature will be displayed on the On Screen Display for 5

seconds.

2. Flame On/Off: Turns the ame effect On or Off.

Figure 1

⑦

③

gWave

Controls

⑥

TM

⑩

⑪

LED Pilot Light

Gesture On/Off

②

④

⑥

⑧

⑩

①

③

⑤

⑦

⑨

3

Page 4

→ Activated by pressing the corresponding button on the

remote or “waving” in-front of the gWaveTM - wave up to

turn on and wave down to turn off.

• When On the ame effect is visible in the unit.

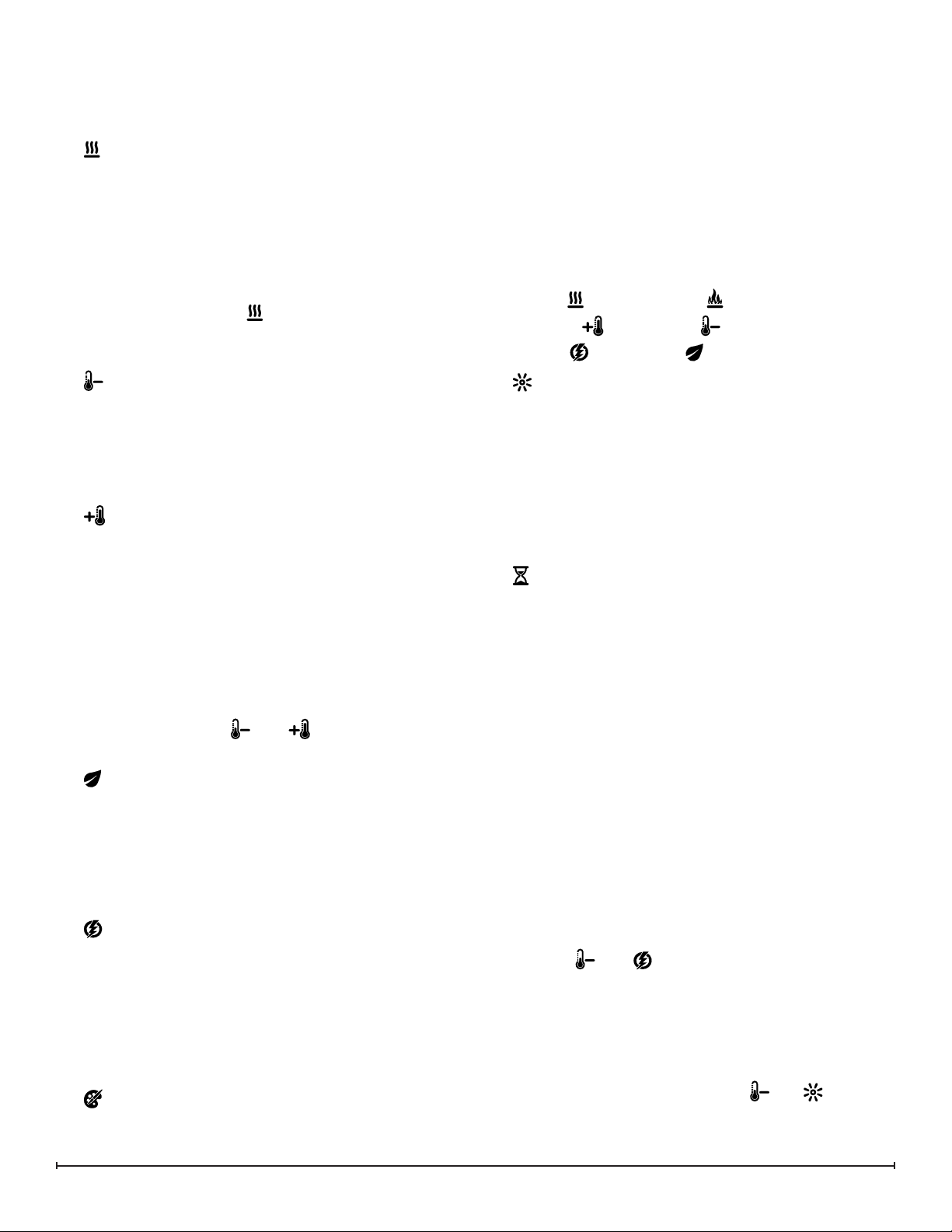

3. Heat On/Off: Turns the heater On or Off.

→ Activated by pressing the corresponding button on the

remote or holding your hand in-front of the gWaveTM for 3

seconds.

• Indicated by the icon and intake temperature being illuminated on the Floating Display™ and the heater turning On

or Off.

!

NOTE: The heater can be operated when the ame is

not visible. In this case the icon will remain on the Float-

ing Display™ until the heater is turned off or the ames are

turned back on.

→ Changed by repeatedly pressing the corresponding button on the remote.

• Cycles through the different preset ambient lighting settings of the unit, this includes different combinations of

colors of the top lighting, ame base and media lighting (if

applicable).

!

NOTE: The last option is a personalized color setting

(“P”), where using the buttons on the remote the lighting

of the unit can be adjusted to any shade of any color. The

initial setting is no light (Red=0, Blue=0, Green=0) and can

be adjusted, while the display is ashing, by pressing the

outlined buttons (below) to adjust the tones.

Red Tones: increase and the decrease.

Green Tones: increase and decrease.

Blue Tones: increase and decrease.

4. Temperature Down: Decreases the heat output.

→ Adjusted by repeatedly pressing the corresponding button on the remote.*

• Indicated by set point temperature on the Floating Display™ decreasing and the speed of the fan decreasing to

reduce the amount of heat being projected into the room.**

5. Temperature Up: Increases the heat output.

→ Adjusted by repeatedly pressing the corresponding button on the remote.*

• Indicated by the set point on the Floating Display™

increasing and the speed of the fan increasing to increase

the amount of heat being projected into the room.

* The rst time the button is pressed the current tempera-

ture set point will be displayed for 5 seconds.

** The temperature can be adjusted from 5 °C to 30 °C (41

°F to 86 °F).

!

NOTE: Pressing the then will toggle between °C

and °F.

6. Eco: Runs the heater in a reduced wattage range

when activated.

→ Adjusted by pressing the corresponding button on the

remote when the heater is on.

• Indicated by the icon being illuminated on the Floating

Display™ and the speed of the fan will decrease proportionally.

7. Boost: Turns On/Off the heater boost function.

Runs the unit at the full rated wattage.

→ Activated and adjusted by repeatedly pressing the corresponding button on the remote.

• Indicated by the heater running at full heat, for a predetermined amount of time, to quickly heat up a cold room/

space. The Boost can be set for a maximum of 20 minutes,

in 5 minute increments.

8. Multi-Fire XD™: Scrolls through the different

media theme color presets for the media, ame base

and top lights.

9. Brightness: Changes the brightness of the lights

in the unit.

→ Adjusted by repeatedly pressing the corresponding button on the remote.

• Indicated by the second digit on the Floating Display™

changing to show: “A” (high), “b” (low), “C” (high with media

icker) and “d” (low with media icker).

!

NOTE: Media icker is not an option on the Multi-Fire

XD™ levels 5, 6 or P.

10. Sleep timer: Turns the unit off after a preset

duration (from 30 minutes (0.5h) to 8 hours, in ½ hour

increments).

→ Activated and adjusted by repeatedly pressing the corresponding button on the remote.

• Indicated by the Floating Display™ changing to indicate

30 minutes (0.5 h) through 8 hours. The replace will

automatically turn off when the sleep timer reaches zero

minutes. The sleep timer can be cancelled at any time by

pressing the sleep timer button repeatedly until the sleep

timer will no longer be visible.

11. Numerical Display

→ Default display will be the heater air intake temperature

or settings (e.g. Multifire XD, Brightness, etc.)

Disable Heat

If desired, depending on the season, the heater on the unit

can be disabled. The unit will operate in the same fashion,

with remainder of the controls.

Pressing the then will enable or disable the heater.

When in the heat disable mode, the temperature reading/

setting on the On Screen DisplayTM displays nothing (“--”).

!

NOTE: The heater will not work when the unit is con-

trolled with gWaveTM either.

Checking Software Level

The revision can be checked by press and at the

same time.

4 www.dimplex.com

Page 5

Resetting the Temperature Cutoff Switch

Should the heater overheat, an automatic cut out will turn

the replace off and it will not come back on without being

reset. It can be reset by unplugging the unit and waiting 15

minutes before plugging the unit back in.

Once power is restored the unit will start to reset itself.

During this process you will hear repeated beeps and the

Floating Display™ may turn on and off.

CAUTION: If you need to continuously reset the heater,

disconnect power and call Dimplex customer service at

1-888-DIMPLEX (1-888-346-7539).

Battery Replacement (Figure 3)

To replace the battery:

1. Slide battery cover open on the back of the remote

control.

2. Install one 3V (CR 2032) battery in the battery holder.

3. Close the battery cover.

Battery must be recycled or disposed of properly.

Check with your Local Authority or Retailer for recy-

cling advice in your area.

MAINTENANCE

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of re, electric

shock or damage to persons.

CAUTION: Allow adequate time for the element and

body casing to cool before attempting to clean the unit.

It is suggested that the heater be inspected regularly, for

cleanliness of the fan exhaust and intake grille, to ensure

optimal performance is maintained. The grille can be

cleaned by vacuuming off all dust and dirt.

Glass Cleaning

The front glass is cleaned in the factory during the assembly operation. During shipment, installation, handling,

etc., the front glass may collect dust particles, these can be

removed by dusting lightly with a clean dry cloth.

To remove ngerprints or other marks, the glass can be

cleaned with a damp cloth. The glass should be completely dried with a lint free cloth to prevent water spots. To

prevent scratching, do not use abrasive cleaners or spray

liquids on the glass surface.

Fireplace Surface Cleaning

To remove ngerprints or other marks, the exterior nish

can be cleaned with a damp cloth with a mild detergent.

The surface should be completely dried with a lint free cloth

to prevent water spots.

Servicing

Except for installation and cleaning described in this manual, an authorized service representative should perform any

other servicing.

5

Page 6

EXPLODED PARTS DIAGRAM - PF2325 Mod 0-A

13

12

4

5

7

3

2

14

6

9

17

1

16

8

15

10

11

Replacement Parts - PF2325 Mod 0-A:

1. Flicker Motor .......................... 2000480100RP

2. Heater Assembly (with cutouts) ...........2203650100RP*

*For MOD 0 units send Power Regulator Board as well

3. Cord Set ............................. 4100090204RP

4. Remote Control ....................... 3001250100RP

5. Main Control Board ....................3001260100RP

6. gWaveTM Assembly .................... 3001400100RP

7. Floating Display™ Assembly .............3001470100RP

8. Electronics Junction Board ............... 3001460100RP

9. Log set .............................. 0441690100RP

10. Media Tray - Flat ......................0441580100RP

Curved .................... 0441580300RP

6 www.dimplex.com

11. Front Glass - Flat ...................... 1026770100RP

Curved ................... 1026770300RP

12. Partially Reective Glass ................ 5902750100RP

13. Brick Panel Set ........................ 0441600100RP

14. Flicker Assembly ...................... 5902830100RP

15. Lower Light Assembly ..................3001310100RP

16. Media LED Light Assembly ..............3001330300RP

17. Flame LED Light Assembly .............. 3001330100RP

18. Glass Media .......................... 1400070200RP

19. Acrylic (Ice) Media .....................1400130200RP

20. Power Regulator Board .............

PFRESISTORPCBRP

Page 7

EXPLODED PARTS DIAGRAM - PF2325 Mod B

13

10

2

8

6

4

3

7

5

16

18

9

19

11

20

1

15

14

17

12

Replacement Parts - PF2325 Mod B:

1. Flicker Motor .......................... 2000480100RP

2. Heater Assembly (with cutouts) ........... 2203650100RP

3. Cord Set ............................. 4100190400RP

4. Remote Control ....................... 3001250100RP

5. Main Control Board ....................3001530100RP

6. gWaveTM Assembly .................... 3001620100RP

7. Relay Board .......................... 3001540100RP

8. Power Supply ......................... 2100250300RP

9. Log set Junction Board. . . . . . . . . . . . . . . . . . 3001600100RP

10. Top Light Assembly .................... 3001290100RP

11. Log set .............................. 0441690200RP

12. Media Tray - Flat ......................0441580100RP

Curved .................... 0441580300RP

13. Front Glass - Flat ...................... 1026770400RP

Curved ................... 1026770700RP

14. Partially Reective Glass ................ 5902750100RP

15. Brick Panel Set ........................ 0441600100RP

16. Flicker Assembly ...................... 5902830100RP

17. Media LED Light Assembly ..............3001330700RP

18. Ember LED Light Assembly .............. 3001330100RP

19. Flame LED Light Assembly .............. 3001310100RP

20. Flame Bed LED Light Assembly ........... 3001330200RP

21. Small Acrylic Media ....................1400150300RP

22. Large Acrylic Media (Ice Chunks). . . . . . . . . . 1400130200RP

7

Page 8

EXPLODED PARTS DIAGRAM - PF3033 Mod 0-A

13

11

12

4

2

6

5

7

14

3

9

17

16

8

1

15

10

Replacement Parts - PF3033 Mod 0-A:

1. Flicker Motor .......................... 2000480100RP

2. Heater Assembly (with cutouts) ........... 2203650100RP

*For MOD 0 units send Power Regulator Board as well

3. Cord Set ............................. 4100090204RP

4. Remote Control ....................... 3001250100RP

5. Main Control Board ....................3001260100RP

6. gWaveTM Assembly .................... 3001400100RP

7. Floating Display™ Assembly .............3001470100RP

8. Electronics Junction Board ............... 3001460100RP

9. Log set .............................. 0441540100RP

10. Media Tray ........................... 0441580200RP

8 www.dimplex.com

11. Front Glass .......................... 1026770200RP

12. Partially Reective Glass ................ 5902750400RP

13. Brick Panel Set ........................ 0441600300RP

14. Flicker Assembly ...................... 5902830200RP

15. Lower Light Assembly ..................3001310300RP

16. Media LED Light Assembly ..............3001330500RP

17. Flame LED Light Assembly .............. 3001330300RP

18. Glass Media .......................... 1400070200RP

19. Acrylic (Ice) Media .....................1400130200RP

20. Power Regulator Board .............

PFRESISTORPCBRP

Page 9

EXPLODED PARTS DIAGRAM - PF3033 Mod B

2

8

10

4

5

6

3

7

15

9

16

11

19

18

1

20

17

12

13

Replacement Parts - PF3033 Mod B:

1. Flicker Motor .......................... 2000480100RP

2. Heater Assembly (with cutouts) ........... 2203650100RP

3. Cord Set ............................. 4100190400RP

4. Remote Control ....................... 3001250100RP

5. Floating Display™ Assembly/Main Control Board 3001530100RP

6. gWaveTM Assembly .................... 3001620100RP

7. Relay Board .......................... 3001540100RP

8. Power Supply ......................... 2100250300RP

9. Log set Junction Board. . . . . . . . . . . . . . . . . . 3001600100RP

10. Top Light Assembly .................... 3001290100RP

11. Log set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0441540200RP

14

12. Media Tray ........................... 0441580200RP

13. Front Glass ..........................1026770600RP

14. Partially Reective Glass ................ 5902750400RP

15. Brick Panel Set ........................ 0441600300RP

16. Flicker Assembly ...................... 5902830200RP

17. Media LED Light Assembly ..............3001330600RP

18. Ember LED Light Assembly .............. 3001300200RP

19. Flame LED Light Assembly .............. 3001310300RP

20. Flame Bed LED Assembly ............... 3001330400RP

21. Small Acrylic Media ....................1400150300RP

22. Large Acrylic Media (Ice Chunks) (2 req’d) .. 1400130200RP

9

Page 10

WIRING DIAGRAM

MOD -

ONLY USED ON MEDIA MODELS

LOG / MEDIA JUNCTION BOARD

NUMBER OF CONNECTIONS

IS BASED ON TYPE OF FIREBOX

GESTURE ASSY

FLAME LED ASSY

TYPE OF CONNECTIONS

IS BASED ON TYPE OF FIREBOX

LED STRIP, RBG

TOP LIGHT ASSY

TOP LIGHT ASSY

MAIN TO GESTURE HARNESS

F1400 MAIN BOARD 3001260100

LINE T4

J1 LOG / MEDIA

NEUTRAL T5

NEUTRAL T6

J2 FLAME COLOUR

HEATER T1

FAN J9

J3 TOP LIGHT

FAN J10

J4 TOP LIGHT

NTC J11

MOTOR T2

J7 GESTURE

NEUTRAL T7

J5 FLAME 1W

DISPLAY J8

THERMAL

CUT OUT

THERMAL

CUT OUT

HEATER ELEMENT

FLICKER MOTOR

LINE IN

NEUTRAL

HEATER ASSEMBLY

MOD A

LOG / MEDIA JUNCTION BOARD

NUMBER OF CONNECTIONS

IS BASED ON TYPE OF FIREBOX

GESTURE ASSY

FLAME LED ASSY

TYPE OF CONNECTIONS

IS BASED ON TYPE OF FIREBOX

LED STRIP, RBG

TOP LIGHT ASSY

TOP LIGHT ASSY

MAIN TO GESTURE HARNESS

ONLY USED ON MEDIA MODELS

F1400 MAIN BOARD 3001260100

J1 LOG / MEDIA

J2 FLAME COLOUR

J3 TOP LIGHT

J4 TOP LIGHT

J7 GESTURE

J5 FLAME 1W

LINE T4

NEUTRAL T5

NEUTRAL T6

HEATER T1

FAN J9

FAN J10

NTC J11

MOTOR T2

NEUTRAL T7

DISPLAY J8

THERMAL

CUT OUT

DISPLAY BOARD ASSY

THERMAL

CUT OUT

HEATER ELEMENT

FLICKER MOTOR

LINE IN

NEUTRAL

HEATER ASSEMBLY

10 www.dimplex.com

Page 11

MOD B

L

G

MAIN BOARD

OR

FLAME BED LED ASSEMBLY (RGB)

OR

LOGSET JUNCTION BOARD

MEDIA LED LIGHT ASSEMBLY

GESTURE

ASSY

FLAME LED LIGHT ASSEMBLY (1W)

OR

TOP LIGHT ASSY

TOP LIGHT ASSY

POWER SUPPLY

HEATER ASSEMBLY

NTC

THERMAL

CUT OUT

RELAY BOARD

FLICKER MOTOR

11

Page 12

MAIN CONTROL BOARD REPLACEMENT

(Mod 0-A units Only)

Tools Required: Phillips Head Screwdriver

Flat Head Screwdriver

Needle Nose Pliers

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and the 3 along the middle of the panel (Figure

3).

5. Locate the main control board and transfer the wir-

ing connections from the old board to the new board.

(Figure 4)

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the main control

board to release the wires.

6. Release the main control board from the unit by using

needle nose pliers to depress the tab on the mounting

standoffs and gently lift the driver board off.

7. Properly orient and insert the new main control board.

8. Reassemble in the reverse order as above.

Figure 3

Top Panel

FLAME LED LIGHT AND MEDIA LIGHT ASSEMBLY REPLACEMENT

Tools Required: Phillips Head Screwdriver

Small Adjustable Wrench

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

Figure 4

Mod 0-A

gWaveTM Assembly

Flicker Motor

Flame LED Light Assembly

Mod B

gWaveTM Assembly

Heater Assembly

Main Control Board

Heater Assembly

Top LED Light

Floating Display

Assembly

Top LED Light

Back Panel

Flicker Motor

Media LED Light Assembly

Relay Board

Power Board

Floating Display

Assembly

12 www.dimplex.com

Page 13

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and the 3 along the middle of the panel (Figure

3).

5. Locate the ame LED light assembly, at the bottom of

the unit. (Figure 4)

6. Locate and remove the two screws on either end secur-

ing the bracket, that the light assembly and the icker

rod are attached to, and remove assembly (Figure 5).

7. Using the small adjustable wrench remove the 3 nuts

or plastic standoffs, by pressing the center pin out to

release the board, to remove the LED light assembly.

8. Follow the wiring to the main control board and replace

with new connection.

9. Properly orient and insert the new LED light assembly.

10. Reassemble in the reverse order as above.

FLOATING DISPLAY ASSEMBLY / MAIN CONTROL BOARD REPLACEMENT

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

with new connection.

8. Properly orient and insert the new oating display as-

sembly.

9. Reassemble in the reverse order as above.

MOD B

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and one in the middle of the panel (Figure 3).

5. Locate the oating display assembly. (Figure 4)

6. Transfer the connections from the existing board to the

new display/control board.

7. Remove the 4 screws securing the board to the assem-

bly.

8. Properly orient and insert the new oating display as-

sembly.

9. Reassemble in the reverse order as above.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

MOD 0-A

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and the 3 along the middle of the panel (Figure

3).

5. Locate the oating display assembly. (Figure 4)

6. Remove the 2 screws located at the top of the assem-

bly, gently remove the board and surrounding bracket.

7. Follow the wiring to the main control board and replace

Figure 5

Mounting Screws

TOP LIGHT

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and the 3 along the middle of the panel (Figure

3).

Figure 6

REPLACEMENT

Needle Nose Pliers

Top Mounting Screws

Securing Nuts

Flame LED Light

Media LED Light

Bottom Mounting Screws

13

Page 14

5. Locate the top light that requires to be replaced. (Figure 4)

6. Release door that houses the LED light board by pressing the tab to the left and opening the door.

7. Release the LED light board from the top panel by using needle nose pliers to depress the tab on the mounting standoffs and gently lift the board off.

8. Follow the wiring to the main control board and replace

with new connection.

9. Properly orient and insert the new board.

10. Reassemble in the reverse order as above.

HEATER ASSEMBLY

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and the 3 along the middle of the panel (Figure

3).

5. Locate the heater assembly and disconnect the wiring

connections noting their original locations.

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

6. Remove the 4 screws that secure the heater assembly

to the unit (2 on the top and 2 on the bottom). (Figure

6)

7. Properly orient and install the new heater assembly

and connect all of the wiring.

!

NOTE: In order to disconnect the heater assembly

from the power cord the shrink wrap that connects the red

and black wire will have to be removed. To reconnect the

black wire from the power cord and the new wire from the

heater a wire connector will have to be used.

WARNING: Ensure wires do not come in contact with

moving parts by securing wires in wiring tie wraps.

8. Reassemble in the reverse order as above.

REPLACEMENT

POWER CORD

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and the 3 along the middle of the panel (Figure

3).

5. Locate the power cord and disconnect the wiring con-

nections noting their original locations.

!

NOTE: In order to disconnect the heater assembly

from the power cord the shrink wrap that connects the red

and black wire will have to be removed. To reconnect the

black wire from the power cord and the new wire from the

heater a wire connector will have to be used.

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

6. With needle nose pliers, grasp the power cord strain

relief grommet from inside the back of the bottom panel

and push while twisting to remove.

7. Install the new power cord.

8. Reassemble in the reverse order as above.

REPLACEMENT

Needle Nose Pliers

FLICKER MOTOR & ROD REPLACEMENT

Tools Required: Phillips Head Screwdriver

Flat Head Screwdriver

Needle Nose Pliers

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

14 www.dimplex.com

Page 15

Figure 7

Log set

Mirror Bracket

Lower Light

Assembly

rebox and the 3 along the middle of the panel (Figure

3).

5. Locate the icker motor and icker rod.

6. Remove the 2 screws that secure the icker rod mount-

ing bracket to the unit.

7. Locate and disconnect the 2 motor assembly wires going to the main control board.

8. Remove the 2 motor mounting screws.

9. Remove the tie wrap from the connector, separate the

motor from the icker connector and remove.

!

NOTE: The tie wrap is included for shipping purposes

and does not need to be reinstalled on the unit.

10. Slide the icker rod out of the snap-in bushing and

remove.

11. Reassemble in the reverse order as above.

GWAVETM ASSEMBLY

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

MOD 0-A

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

Electronics Junction Board

REPLACEMENT

Flat Head Screwdriver

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. To loosen the back panel to allow removal of the top

pane, remove the 4 screws along the top of the back

panel and the rst screw along either side of the back

of the unit.

5. Remove the 12 screws around the top panel of the rebox and the 2 along the middle of the panel (Figure 3).

6. Remove the front portion of the panel, as well, by removing the 5 screws along the top.

7. Locate the gWaveTM assembly (Figure 4).

8. Release the gWaveTM assembly from the top panel by

gently depressing the tab on the top of the assembly

with the at head screwdriver and gently remove.

9. Properly orient and connect the new assembly.

10. Reassemble in the reverse order as above.

MOD B

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and the 3 along the middle of the panel (Figure

3).

5. Locate and remove the two screws, recessed in the

top assembly, this will allow you to gently push the

gWaveTM assembly out the front of the unit, through the

opening in the back.

6. Disconnect the old assembly and connect the new as-

sembly.

7. Slide the assembly back into the unit.

8. Reassemble in the reverse order as above.

RELAY BOARD REPLACEMENT

(Mod B units Only)

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

15

Page 16

4. Remove the 14 screws around the back panel of the

rebox and one in the middle of the panel (Figure 3).

5. Locate the relay board assembly. (Figure 4)

6. Transfer the connections from the existing board to the

new display/control board.

7. Remove the 4 screws securing the board to the assembly.

8. Properly orient and insert the new oating display assembly.

9. Reassemble in the reverse order as above.

POWER SUPPLY REPLACEMENT

(Mod B units Only)

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the

rebox and one in the middle of the panel (Figure 3).

5. Locate the power supply assembly. (Figure 4)

6. Disconnect the power supply from the relay board and

the display/control board and install the new power

supply in their place.

7. Remove the 4 screws securing the assembly to the

unit.

8. Properly orient and insert the new power supply as-

sembly.

9. Reassemble in the reverse order as above.

LOG SET

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

REPLACEMENT

taken when handling the glass.

3. Remove the brick panels from either side of the unit,

they are attached using magnets.

4. Gently place the unit its back to expose the bottom

of the unit. Remove the 4 screws from bottom and 2

screw form either side that secure the log set.

5. Lift the log set out of the unit, being careful not to strain

the electronic cords.

6. Remove the electrical connections from the electronics

junction board, replace with new log set connections.

7. Reassemble in the reverse order as above.

ELECTRONICS JUNCTION BOARD REPLACEMENT

Tools Required: Phillips Head Screwdriver

Needle Nose Pliers

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the brick panels from either side of the unit,

they are attached using magnets.

4. Gently place the unit its back to expose the bottom

of the unit. Remove the 4 screws from bottom and 2

screw form either side that secure the log set.

5. Lift the log set out of the unit, being careful not to strain

the electronic cords.

6. Locate the electronics junction board and disconnect

the wiring connections noting their original locations.

(Figure 7)

7. Release the junction board from the bottom panel by

using needle nose pliers to depress the tab on the

mounting standoffs and gently lift the driver board off.

8. Properly orient and install the new electronics junction

board and connect all of the wiring.

9. Reassemble in the reverse order as above.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

16 www.dimplex.com

Page 17

LOWER & MEDIA LED LIGHT

ASSEMBLY

Tools Required: Phillips Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the brick panels from either side of the unit,

they are attached using magnets (if applicable).

4. Gently place the unit its back to expose the bottom

of the unit. Remove the 4 screws from bottom and 2

screw form either side that secure the log set.

5. Lift the log set out of the unit, being careful not to strain

the electronic cords.

6. Locate the lower light assembly and disconnect the

wiring connection from the electronics junction board

noting the original location. (Figure 7)

7. Release the light assembly from the bottom panel by

using needle nose pliers to depress the tab on the

mounting standoffs and gently lift the light assembly off.

Properly orient and install the new light assembly and connect all of the wiring.

8. Reassemble in the reverse order as above.

REPLACEMENT

Needle Nose Pliers

PARTIALLY REFLECTIVE GLASS REPLACEMENT

Tools Required: Phillips Head Screwdriver

Flat Head Screwdriver

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for heating elements and top panel to

cool off to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and

remove front glass assembly (glass lifts off).

CAUTION: Even though the glass is safety glass it

may break if bumped, struck of dropped. Care must be

taken when handling the glass.

3. Remove the brick panels from either side of the unit,

they are attached using magnets.

4. Gently place the unit its back to expose the bottom

of the unit. Remove the 4 screws from bottom and 2

screw form either side that secure the log set.

5. Lift the log set out of the unit, being careful not to strain

the electronic cords.

6. Locate and remove the 2 brackets that hold the partially

reective glass in the unit (along the bottom). (Figure 7)

7. Gently pry the glass forward using a at head screwdriver, being careful not to damage the corner tabs.

8. Transfer the rubber corner tabs from the old glass to

the new glass. Properly orient and install the new

glass.

9. Reassemble in the reverse order as above.

POWER REGULATOR BOARD INSTALLATION (Mod 0 units Only)

Tools Required: Phillips Head Screwdriver

Flat Head Screwdriver

CAUTION: If unit was operating prior to servicing allow at

least 10 minutes for heating elements and top panel to cool off

to avoid accidental burning of skin.

WARNING: Disconnect power before attempting any

maintenance to reduce the risk of electric shock or damage

to persons.

1. Unplug the unit from power outlet.

2. Remove the rebox from the front of the mantel and re-

move front glass assembly (glass lifts off). Carefully place

the glass assembly aside in a safe location.

CAUTION: Even though the glass is safety glass it may

break if bumped, struck or dropped. Care must be taken when

handling the glass.

3. Remove the loose media from the unit (if applicable).

4. Remove the 14 screws around the back panel of the re-

box and the 3 along the middle of the panel (Figure 3).

5. Locate the main control board. (Figure 4)

6. Remove the two wire connectors that lead to the heater

assembly (the receiver on the control board are labelled as

the “Fan” connections). (Figure 8)

7. Attach the two wire connectors to the power regulator

board.

8. Install the power regulator board to the left connector on

the main control board. (Figure 9)

9. Reassemble the unit.

Figure 8 Figure 9

Power Regulator Board

17

Page 18

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

General

Circuit breaker trips or fuse

blows when unit is turned on

Lights dim in room while the

unit is on

Power cord gets warm Normal Operation The power cord may get slightly warm to the touch

Fireplace shuts off/beeps when

heater comes on

Appearance

Fireplace does not turn on with

the gWaveTM controls

Fireplace turns on/off by itself gWaveTM sensor is being triggered by an

Fireplace does not turn on with

the Remote Control

Flame Frozen Loose wiring Check wiring connections

Flame is not visible Loose wiring Check wiring connections

Flame Shudder Defective Flicker Motor Replace Flicker Motor

Log set or Media bed does not

light up

Section of colored lights does

not light up or is a different

color

Log set or Media bed lighting

comes on by itself

Short in unit wiring. Trace wiring in unit.

Improper circuit current rating Additional appliances may exceed the current rating of

the circuit breaker or fuse. Plug unit into another outlet

or install unit on a dedicated 15 amp circuit.

Unit is drawing close to circuit current rating Move the unit to another outlet or install unit on a dedi-

cated 15 amp circuit

when the heater is on

Defective power cord Replace power cord if cord gets hot to the touch.

Power surge interference Unplug the unit for 15 minutes to allow the unit to de-

energize and reset the main control board

Install a power regulator board between the main control board and the heater assembly

Improper operation Refer to Operation Section

No incoming voltage from the electrical wall

socket

Loose wiring Check wiring connections

Defective gWaveTM assembly (green indica-

tor light, to right of sensor, maybe ashing)

external force

Improper operation Refer to Operation Section

The batteries in the remote control are

dead.

Defective remote control Replace the remote control

Defective oating display assembly

Defective Flicker Motor Replace Flicker Motor

Defective main control board Replace the main control board

Flame LED light assembly is not working Replace ame LED light assembly

Defective main control board Replace the main control board

Loose wiring Check wiring connections

Media LED light assembly or log set is not

working

Defective electronics junction board Replace electronics junction board

Defective main control board Replace the main control board

Media LED light assembly is not working Replace media LED light assembly

Defective main control board Replace the main control board

Check Fuse/Breaker Panel

Replace the gWaveTM assembly

Ensure sensor area is clear of objects and the unit is

not situated where direct beams/reections of light can

shine into sensor

Install new battery into the remote control.

Replace the oating display assembly

Replace media LED light assembly or log set

18 www.dimplex.com

Page 19

PROBLEM CAUSE SOLUTION

Heater

Heater is not turning on, but

ame effect is still functioning

Heater is turning off after a

couple of minutes of operation

Heater emits an odor Normal Operation Normal operation is when the heater emits an odor

Noise

Unit cycles through ‘Beeps”

and changing On screen Display when turned on

Buzzing noise coming from

heater assembly

Excessive noise with the

heater on

Grinding or excessive noise

with the heater off

Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective main control board Replace the main control board

Defective heater assembly Replace heater assembly

Improper operation Refer to Operation Section

Build up of dirt/dust in Heater Assembly Ensure that exterior intake louvers and rebox cavity

are free of dirt/dust.

Defective heater assembly Replace heater assembly

for a brief period after the heater is initially turned on.

The heater is burning off any dust accumulated during

manufacturing or operation.

Defective heater assembly Replace heater assembly

Improper initialization of electronics Unplug unit wait 20 minutes and plug back in

Defective heater assembly Replace heater assembly

There is a small current of electricity running through the motor

Dirty Heater Assembly Ensure that exterior intake louvers and rebox cavity

Defective heater assembly Replace heater assembly

Flicker rod hitting or rubbing against internal

components

Defective Flicker Motor Replace Flicker Motor

A small amount of noise is normal

Excessive buzzing noise can be minimized by use of

power regulator board installation

are free of dirt/dust.

Ensure rod is straight and mounted properly in the

bracket, spinning freely away from other components.

Replace if necessary.

19

Loading...

Loading...