Page 1

Installation and Operating Instructions

DTR Towel Rails

Models : DTR175W, DTR175C, DTR350W & DTR350C

Dimensions

(millimetres)

IMPORTANT : THESE INSTRUCTIONS SHOULD BE READ CAREFULL Y AND RET AINED FOR FUTURE REFERENCE

Table1

Model Rails Watts Weight (kg)

DTR175 W/C 12 175 4.4

DTR350 W/C 18 350 7.9

Important Safety Advice

WARNING - THE SURF ACE OF THIS RADIA TOR CAN BE HOT.

In order to be effective the towel rail will get hot, however

momentary contact with any part of it should not cause

injury.

CAUTION - This appliance is not intended for use by

chidren or other persons without assistance or

supervision if their physical, sensory or mental

capabilities prevent them from using it safely. Children

should be supervised to ensure that they do not play

with the appliance.

Precautions should be taken to ensure that prolonged

contact with the towel rail cannot occur. Particular care

should be taken in confined areas where accidental

prolonged contact with the rail could be more likely to

occur.

This appliance should only be used to dry fabrics washed

in water using commonly available detergents.

IMPORTANT - If the towel rail is to be installed in a place

used by the public, a warning notice should be placed

adjacent to the rail advising that the surface can be hot.

WARNING - In order to avoid a hazard for very young

children, this appliance should be installed so that the

lowest heated rail is at least 600mm above the floor.

General

The DTR towel rail is designed to provide an all year round service

for airing towels and articles of clothing. It is not intended to provide

a sole heating service, but the larger model will take the chill off an

average size bathroom, lavatory or en suite. Your rail will be in one

of two sizes and will have either silver chromium plated or white

stove-enamel finish.

No routine maintenance is necessary apart from occasional cleaning.

Both models are splashproof to IPX4 standard.

Electrical

The electrical installation of this towel rail must be carried out by a

competent electrician in accordance with the current I.E.E Regulations

for Electrical Equipment. The towel rail is suitable for use on an A.C.~

electrical supply. Before installation check that the supply voltage

corresponds with that marked on the rail.

IMPORTANT - The wires in the mains lead are coloured in

accordance with the following code:

BLUE - NEUTRAL

BROWN - LIVE

This appliance must only be used on A.C. mains supply of 230/240

Volts~.

Installation

If fitted in a room containing a bath or shower, to comply with the

current I.E.E. Regulations, a cable outlet will be

necessary with the supply to the heater controlled by a

double-pole pull-cord switch having a contact separation of 3mm in

each pole. The body of the switch should be situated as to be

normally inaccessible to a person using a bath or shower. Should

Equipotential Earth Bonding be required the earthing conductor in the

supply cord is deemed to provide the supplementary bonding

connection (see Regulation 547-03-0, ’16th’ Edition I.E.E. Wiring

Regulations.

IMPORTANT - Protect the electrical connection whilst

handling the towel rail.

The towel rail must be permanently fixed to the wall using the wall

brackets supplied. The rail must be mounted vertically as shown

observing the minimum clearances stated.

WARNING - The towel rail is heavy. Care must be taken when lifting

and fitting the towel rail.

Wall mounting

The wall mounting accessory pack contains:

(a ) 4 mounting brackets

(b) 1 allen key

(c ) 4 wall mounting screws, washers and wall plugs

(d) 4 hex. stud screws

100 min.

843

08/50116/1 (UK) Issue 1

DTR 350

shelf

602

Fig. 1

Page 2

Procedure for wall mounting

Step 1

A

B

A B

DTR 175 250 390

DTR 350 380 625

Mark suitable hole positions for the four fixing brackets (ensuring

they are horizontal) - see Fig. 2, and allow enough room above and

below for the clearance stated.

Drill and plug the wall to suit - see Fig. 3.

Fig. 2

W

Step 4

Lift the towel rail now with the inner sleeve assembly in position, and

align with the outer sleeve previously fixed to the wall. When all four

inner sleeves are inserted correctly into the outer sleeves of the

brackets tighten each nut fully . Replace the cap ‘Y’ and the hex. stud

screw. The distance the towel rail can be positioned from the wall

can be varied by adjusting the hex. stud screws. When in the desired

location, tighten fully to secure the towel rail to the wall.

To assist with the alignment of the outer ‘W’ and inner ‘Z’ sleeves the

outer sleeve may be adjusted using the slot provided, refer to Note in

step 2.

Drying and Airing Towels

It is recommended that for efficient drying, no more than two layers

of towels or similar fabric should be draped over the rail. Items

should be placed evenly over the whole surface of the rail where

possible.

It is not advisable to leave very damp towels or clothes on the towel

rail when not in use, as this may in time, affect the paint finish.

The rail, although hot to the touch is not hot enough to scorch or burn

fabrics. However, soap and detergents remaining in articles after

washing can cause discoloration. Therefore care should be taken

to thoroughly rinse articles before airing.

Wiring

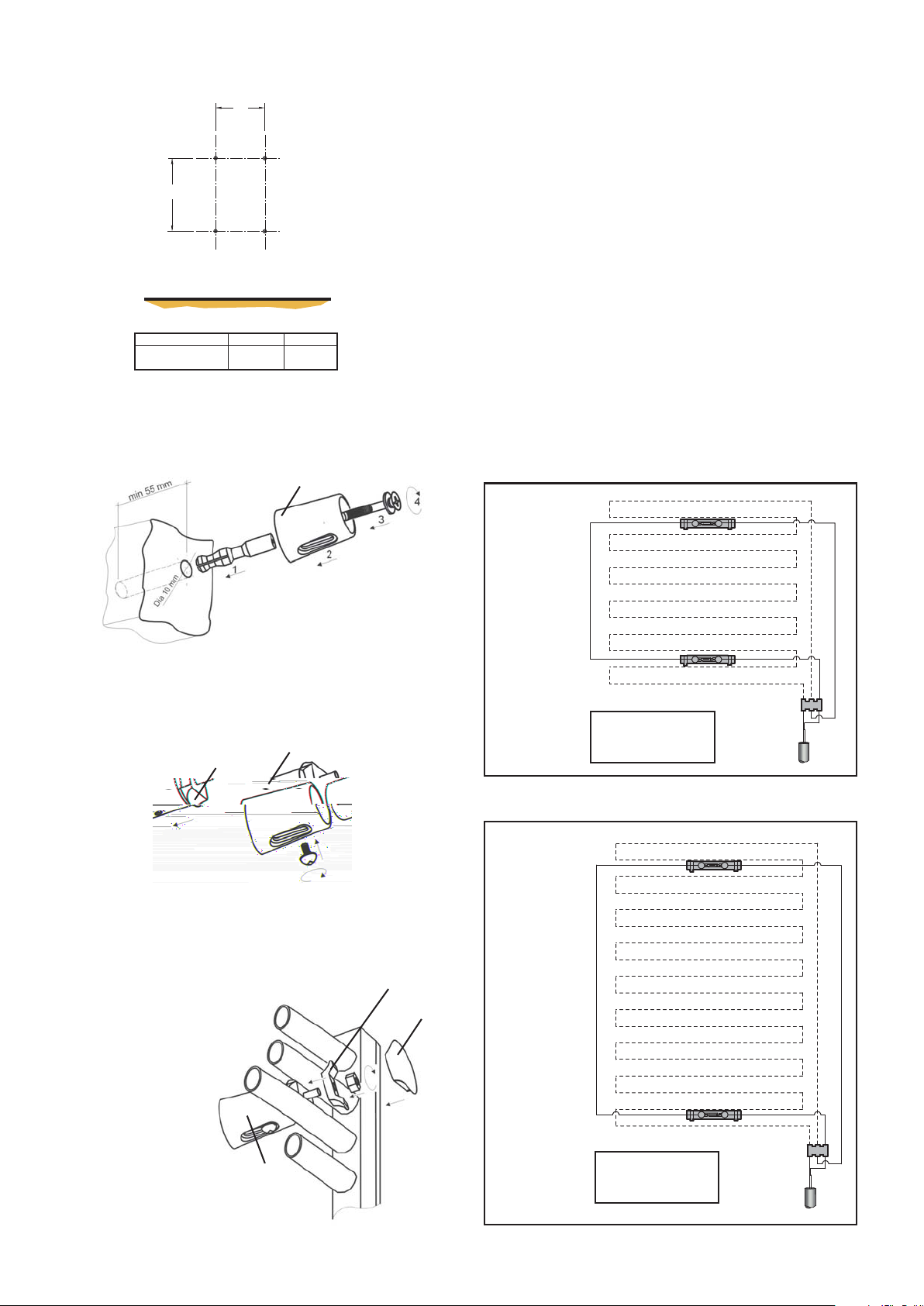

Wiring Diagrams : for DTR175 see Fig. 6, and DTR350 see Fig. 7.

Fig. 3

Step 2

The hex. stud screw in the slot has to be removed using the allen key

provided first, to separate the inner ‘Z’ and outer ‘W’ sleeves of the

wall brackets - see Fig. 4.

Z

W

Fig. 4

Mount the four outer sleeve wall brackets in line with the drilled out

holes using the screws provided - see steps 1 - 4 in Fig. 3.

Note: the brackets have slot holes to allow for possible adjustment

later.

Step 3

Remove the cap ‘Y’ from

the inner sleeve

assembly, unscrew the

nut and remove the rail

support ‘X’ - see Fig. 5.

On the inner side (wall)

of the towel rail position

the inner sleeve

between the cross rails

as indicated in Fig. 1.

Position the rail support

to receive the bolt on the

inner sleeve and hand

tighten with the nut - see

Fig. 3.

Slide into position (see

suggested positions in

Fig. 1).

W

X

Y

Fig. 5

DTR 175

DTR 350

A - Terminal Block

C1 - Cut-out 1

C2 - Cut-out 2

A - Terminal Block

C1 - Cut-out 1

C2 - Cut-out 2

C1

C2

C1

C2

A

L

N

N

L

Fig. 6

A

L

N

L

N

Fig. 7

Page 3

Operation (Electrical)

Heat will be distributed along each of the rails.

Some variation in the temperature across the surface of the rail is

also normal. When the appliance is covered the heating pattern of

the rails may alter slightly.

Cleaning

The finish on your towel rail can be maintained by occasionally

wiping over with a damp cloth and lightly finishing with a soft dry

cloth. This should only be carried out when the rail is cold. Do not

use abrasive cleaning powders as this could damage the surface

finish.

Page 4

Recycling

For electrical products sold within the European Community.

At the end of the electrical products useful life it should not

be disposed of with household waste. Please recycle

where facilities exist. Check with your Local Authority or

retailer for recycling advice in your country.

After Sales Service

Your product is guaranteed for two years from the date of purchase.

Within this period, we undertake to repair or exchange this product

free of charge (subject to availabilitiy) provided it has been installed

and operated in accordance with these instructions.

Your rights under this guarantee are additional to your statutory

rights, which in turn are not affected by this guarantee.

Should you require after sales service you should contact our

customer services help desk on 0845 600 5111. It would assist us if

you can quote the model number, series, date of purchase, and

nature of the fault at the time of your call. The customer services

help desk will also be able to advise you should you need to purchase

any spares.

Please do not return a faulty product to us in the first instance as this

may result in loss or damage and delay in providing you with a

satisfactory service.

Please retain your receipt as proof of purchase.

Dimplex UK Limited

Millbrook House

Grange Drive

Hedge End

Southampton

Hampshire. SO30 2DF

[c] Dimplex UK Limited

All rights reserved. Material contained in this publication may not be reproduced in whole or in part, without prior permission in writing of Dimplex UK Limited.

The product complies with the European Safety Standards EN60335-2-30 and the European Standard Electromagnetic Compatibility

(EMC) EN55014, EN60555-2 and EN60555-3 which cover the essential requirements of EEC Directives 73/23 and 89/336

UK customer help line 8.00am–5.00pm Mon-Fri and 8:30am-1.00pm Sat (October-March)

Technical Services: Tel. 0845 600 5111

Fax. 01489 773053

e-mail technical.services@dimplex.co.uk

Republic of Ireland Tel. 01 8424833

Loading...

Loading...