Page 1

Ceiling Heater (with ConnexTM)

CMH Series

IMPORTANT INSTRUCTIONS

When using electrical appliances, basic precautions should always

be followed to reduce the risk of re, electric shock and injury to person, including the following:

1. Read all instructions before using this heater.

2. The heater is hot when in use. To avoid burns, do not let bare

skin touch hot surfaces. Keep combustible materials, such as

furniture, pillows, bedding, papers, clothes, and curtains at least

a 3.3 ft (1 m) from the front of the heater and keep them away

from the sides and rear.

3. Wiring procedures and connections should be in accordance

with the National Electric Code (NEC & CEC) and local codes.

4. Extreme caution is necessary when any heater is used by or

near children or invalids and whenever the unit is left operating

and unattended.

5. Do not operate any heater after it malfunctions. Disconnect

power at service panel and have heater inspected by a certied

electrician before reusing.

6. To disconnect heater, turn off power to heater circuit at main dis-

connect panel.

7. Do not use outdoors.

8. Use this heater only as described in this manual. Any other use

not recommended by the manufacturer may cause re, electric

shock, or injury to persons.

9. A heater has hot and arcing or sparking parts inside. Do not use

it in areas where gasoline, paint or ammable liquids are used

or stored.

10. This heater is hot when in use. To avoid burns, do not let bare

skin touch hot surfaces. Keep combustible materials such as:

furniture, pillows, bedding, papers, clothes and curtains away

from heater.

11. Do not insert or allow foreign objects to enter any ventilation or

exhaust opening as this may cause an electric shock or re, or

damage the heater.

12. To prevent a possible re, do not block air intake or exhaust in

any manner.

!

NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment on a circuit different from that to which the

receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

FCC CAUTION: Any changes or modications not expressly approved by

the party responsible for compliance could void the user’s authority to operate

this equipment.

This device complies with Industry Canada licence-exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

Installation Instructions

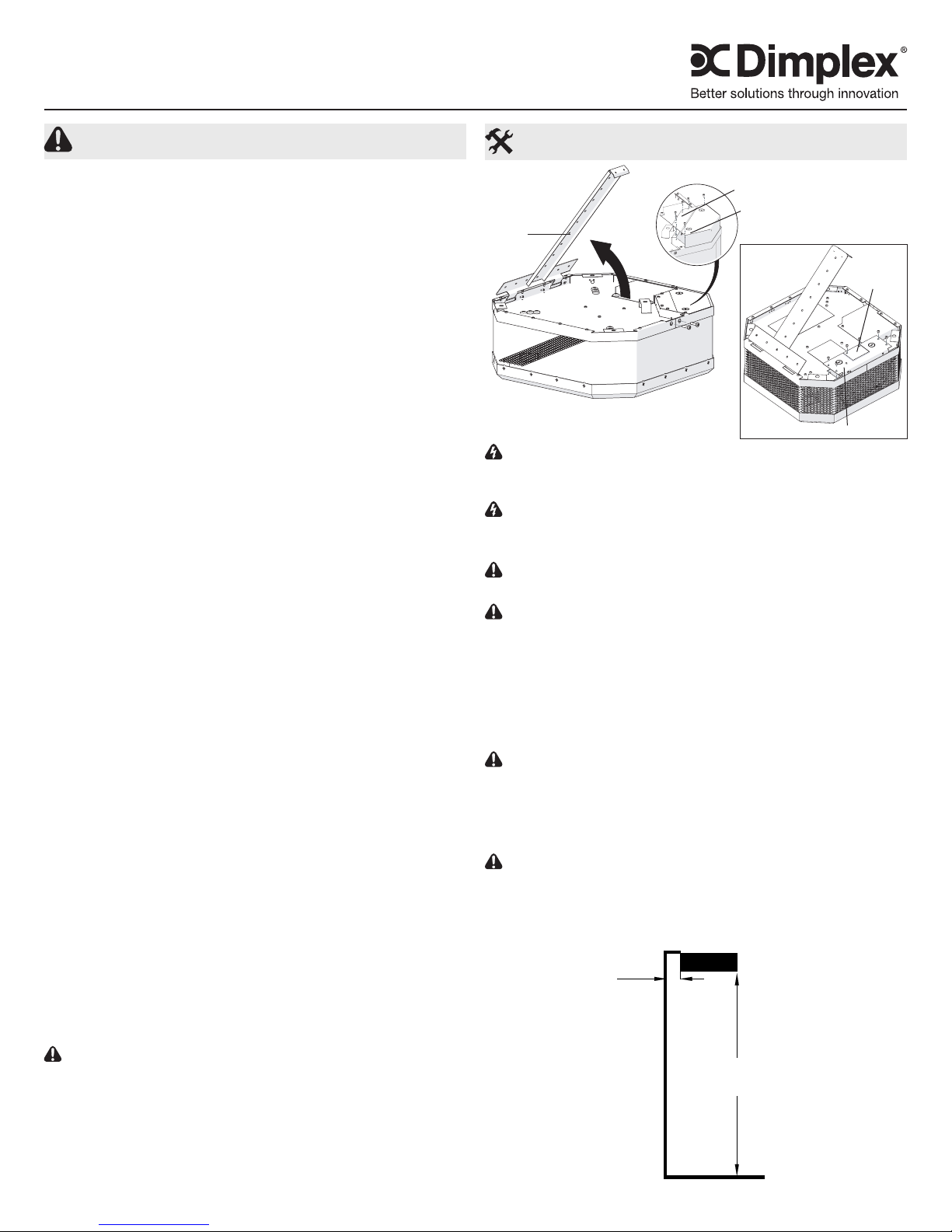

Figure 1

7.5 - 10 kW

Mounting

Bracket

WARNING: Wiring procedures and connections should be

in accordance with the National Electric code (NEC) and local

codes.

WARNING: To reduce the risk of re, do not store or use

gasoline or other ammable vapors and liquids in the vicinity

of the heater.

CAUTION: It is recommended that two people install the

unit.

CAUTION: The heater should be mounted for DOWNWARD discharge only.

Surface Mount

1. Unpack the heater from the carton and remove the two

screws securing the bracket to the unit, to remove the

mounting bracket, and remove the terminal box covers.

(Figure 1)

CAUTION: Care should be taken when removing the terminal box cover, as the electrical connections are attached to it.

2. Determine the desired location for the heater and secure

the mounting bracket to the ceiling (hardware not includ-

ed).

CAUTION: The ceiling and mounting hardware must have

adequate strength to support the heater. Attachment to a rm

support is a necessity.

!

NOTE: See Figure 2 for minimum clearances for the unit.

Figure 2

MINIMUM

2-5kW - 10" (250mm)

7.5-10kW - 16" (410mm)

Inspection Cover

Terminal

Box Cover

2 - 5 kW

2-5 kW - 6' (152 cm)

8 ft (244 cm)

7.5-10 kW - 8' (213 cm)

Inspection

Cover

Terminal Box Cover

SAVE THESE INSTRUCTIONS

7213180100R04

Page 2

3. Remove the desired knockout from the terminal box.

!

NOTE: It is only necessary to remove the knockout(s) that

will feed the power supply wiring, keeping in mind the heater

mounting location and supply wire location.

4. Hang the heater from the hooked edge of the mounting

bracket and proceed to the wiring instructions.

Hanging Mount (Threaded Rod)

1. Unpack the heater from the carton, remove the two screws

securing the bracket to the unit and remove the screws

securing the terminal box cover. (Figure 1)

CAUTION: Care should be taken when removing the termi-

nal box cover, as the electrical connections are attached to it.

!

NOTE: See Figure 2 for minimum clearances for the unit.

2. There are four brackets on the top surface of the unit with

1/2 in. (13 mm) holes which can be used to suspend the

unit from an open ceiling using 3/8” (9.5 mm) threaded

rod.

3. Remove the desired knockout from the terminal box.

!

NOTE: It is only necessary to remove the knockout(s) that

will feed the power supply wiring, keeping in mind the heater

mounting location and supply wire location.

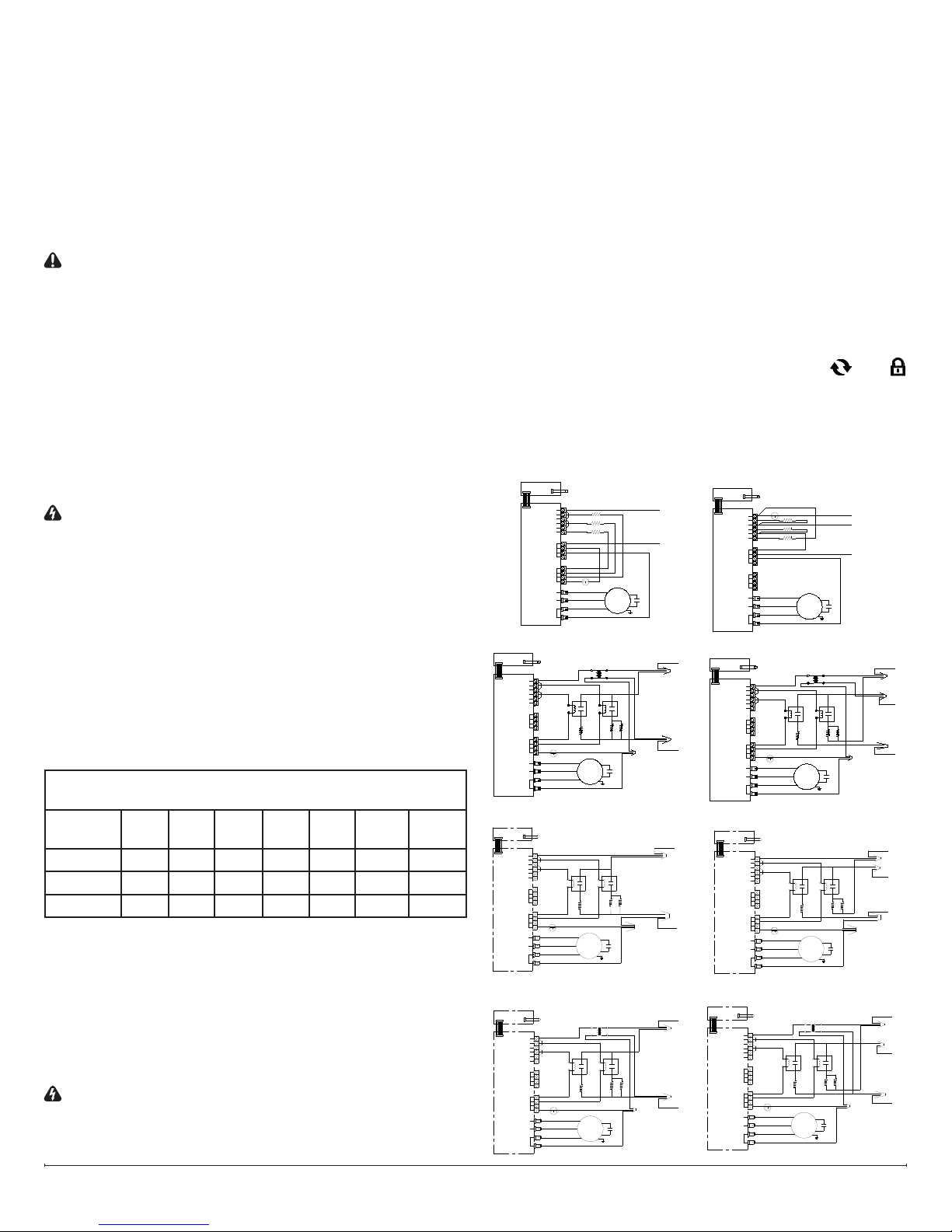

Wiring

WARNING: Wiring procedures and connections should be

in accordance with the National Electric Code (NEC) and local

codes.

1. Run supply wiring of proper voltage and wire size to the

location of the terminal box of the heater. (See Table 2)

Supply wiring should be enclosed in 1/2 in. (13 mm) con-

duit.

2. Wire all heaters and controls in accordance with the ap-

propriate wiring diagram.

!

NOTE: The wiring diagram for specic unit is located on

top of the heater.

Table 2 - Recommended minimum supply wire sizes are

listed in the table below:

MAXIMUM WATTS PER CIRCUIT USING 75 °C WIRE

(COPPER WIRE)

Rough in

Wire Size

14 1440 2496 2880 3324 4164 5760 7200

12 1920 3328 3840 4432 5552 7680 9600

10 2880 4992 5760 6648 8328 11520 14400

!

NOTE: Supply wire entry is commonly made into one

heater. Though wiring (factory furnished) can be used for connection to adjacent heaters.

3. Wrap the supply ground wire around the green ground

screw and tighten.

4. Do a nal and complete check of all wiring then replace the

terminal box covers being careful not to pinch any wires.

5. The terminal box covers may now be reinstalled.

WARNING: TO PREVENT THE RISK OF FIRE OR IN-

JURY, DO NOT OPERATE THE HEATER UNLESS IT IS

FULLY ASSEMBLED.

120V 208V 240V 277V 347V 480V 600V

!

NOTE: The inspection cover is intended to provide access

for electrical inspections.

6. Swing the heater upwards to secure the opposite side of

the heater to the bracket and secure with previously removed screws.

Initial Set Up

After the unit has been installed, calibration of the unit to the

area will be required. This can be done by closing all doors

and windows to the room and turning the unit ON. When the

unit is initially turned on there is a 28 minute period of calibra-

tion of the unit where the software runs at full power for 20

minutes, then runs for 8 minutes to cool the heater down.

If the unit is relocated or the size of the area that it is installed

in changes, it is recommended that the unit be reset to the factory default to allow the unit to recalibrate.

Factory Default

1. Press and hold the V for 3 seconds. Both the and

icons will begin to ash.

2. Within 5 seconds press ✚, then ✚, then –, then –, then

V, then –.

Sample Wiring Diagrams

240V 2/3/4/5KW 1PH

SENSOR

DISPLAY BOARD

14

13

12

H1

11

10

H2

9

H3

TB1

8

7

6

5

POWER BOARD

TB3

4

3

2

1

TB2

CUTOUT

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

347/600V 3/4/5KW 1PH

SENSOR

DISPLAY BOARD

14

13

12

11

10

9

20A

TB1

CONTACTOR

8

7

6

5

POWER BOARD

TB3

4

3

2

1

TB2

CUTOUT

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

208V/240V 7.5/10KW 1PH

SENSOR

DISPLAY BOARD

14

13

12

11

10

9

30A

TB1

CONTACTOR

8

7

6

5

POWER BOARD

TB3

4

3

2

1

TB2

CUTOUT

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

L1

T1

H1

L1

T1

H1

TRANSFOMER

FAN

MOTOR

FAN

MOTOR

MOTOR

347/600V240V

L1

T1

H2

G

L1

T1

H2

G

480V/600V 7.5/10KW 1PH

SENSOR

DISPLAY BOARD

POWER BOARD

14

13

12

11

10

9

TB1

8

7

6

5

TB3

4

3

2

1

TB2

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

20A

CONTACTOR

CUTOUT

L1

T1

H1

TRANSFOMER

240V

FAN

MOTOR

480V/600V

H2

G

L1

T1

FAN

CONTACTOR

CONTACTOR

CONTACTOR

L1

L2

G

L1

20A

H3

L2

L1

40A

H3

L2

L1

20A

H3

L2

240V 3/4/5KW 3PH

SENSOR

DISPLAY BOARD

CUTOUT

14

13

12

H1

11

10

H2

9

H3

TB1

8

7

6

5

POWER BOARD

TB3

4

3

2

1

TB2

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

600V 3/4/5KW 3PH

SENSOR

DISPLAY BOARD

14

13

12

11

10

9

8

7

6

5

POWER BOARD

208V 7.5/10KW 3PH

DISPLAY BOARD

POWER BOARD

TB1

CONTACTOR

TB3

4

3

2

1

TB2

CUTOUT

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

SENSOR

14

13

12

11

10

9

TB1

CONTACTOR

8

7

6

5

TB3

4

3

2

1

TB2

CUTOUT

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

L1

20A

T1

H1

30A

H1

FAN

MOTOR

TRANSFOMER

240V 347/600V

FAN

MOTOR

T1

FAN

MOTOR

G

L1

T1

H2 H3

G

H2

G

L1L1

T1

L1

L2

L3

20A

CONTACTOR

CONTACTOR

H3

L2

L1

40A

L3

277V/347V/480V/600V 7.5/10KW 3PH

SENSOR

DISPLAY BOARD

POWER BOARD

14

13

12

11

10

9

TB1

8

7

6

5

TB3

4

3

2

1

TB2

T1/FAN LOW

T3/FAN HIGH

T2/FAN NEUTRAL

T4/L2

20A

CONTACTOR

CUTOUT

L1

T1

H1

TRANSFOMER

240V

FAN

MOTOR

277V/347V/480V/600V

L1

CONTACTOR

T1

H2

G

L2

L1

30A

H3

L2

L1

L3

L3

www.dimplex.com2

Page 3

Operation

Figure 3

A - Setting/Temperature Display

B - Comfort Setting Icon

C - Economy Setting Icon

D - Set Back Temperature Setting

E - Synchronized Icon

F - Lock Icon

G - Decrease Button

H - Increase Button

I - Menu Button

icon ashing. After the Set Back Temperature has been set,

the icon will become solid after three seconds and the Set

Back Temperature will be enabled.

To return back to the Comfort Setting press the V button. The

icon will disappear and the icon will appear.

D. Set Back Temperature Setting

The Set Back Temperature Setting is used during periods

when the Economy setting feature is active. This temperature

adjustment can be set by pressing the V followed by the ✚ or

–.

A

D

C

B

F

E

H

G

I

WARNING: This heater is factory prewired for operation

with the built-in thermostat. THIS HEATER IS NOT TO BE

USED WITH A REGULAR WALL THERMOSTAT.

CAUTION: This heater must be properly installed before

it is used.

The CMH is designed with a two stage heating element that

will turn on and off based on the built-in temperature sensor to

maintain a constant room temperature.

!

NOTE: The element retains heat after shutdown, there is

a built in cool down period of 5 minutes before the fan shuts

off completely.

Manual Controls

(See Figure 3 for display reference)

When power is rst supplied to the CMH the Setpoint Tem-

perature will ash in the temperature display area. At any time

either the ✚ or – button can be pressed to have the tempera-

ture setpoint displayed again.

A. Setting/Temperature Display

The CMH is designed to control the temperature of a room

from 41-104°F (5-40 °C). By pressing the ✚ or – will increase

or decrease the desired temperature for the room to be heated

by 0.5° (in either °C or °F).

When adjusting the Setpoint Temperature the display will

switch back to display the ambient temperature after 5 sec-

onds.

!

NOTE: The unit can be set to run continuously as a fan by

setting the temperature at 41 °F (5 °C). At this temperature

the heater will not turn on.

!

NOTE: Pressing the ✚ and – at the same time will toggle

between °C and °F.

B. Comfort Setting

The Comfort Setting icon will be displayed when the heater

is in normal operation based on the Setpoint Temperature for

the room.

!

NOTE: Either the or icon will always be visible, de-

pendent on the setting being used.

C. Economy Setting

The Economy Setting can be used to change the Setpoint

Temperature for a user determined period of time. By pressing

the V the Economy Setting will be enabled - signied by the

E. Synchronized Icon

The CMH features CONNEXTM, a wireless technology that

works with Dimplex single and multi-zone CONNEXTM controllers to provide simple whole home connectivity and comfort.

CONNEXTM controllers are available to control one or multiple

CONNEX

TM

series heaters within a 50’ (15 m) radius. In order

for the controller to have this function the CMH and the controller will need to be synchronized. To do this:

1. On the CMH press and hold the V button for 3 seconds,

both the and icons will begin to ash.

2. Press the – , ✚ and then V, on the CMH.

3. Within 10 seconds press any button once on the

CONNEXTM Controller.

!

NOTE: There is a 3 second delay between pressing the last

button on the controller and the CMH.

!

NOTE: To desynchronize a CMH from the synchronized

CONNEXTM Controller; on either the CMH or the controller:

1. Press and hold the V for 3 seconds.

2. Press the V, ✚ and then –.

Nothing will need to be done to the other component.

Dimplex single and multi-zone CONNEXTM controllers are sold

separately and are available for purchase from your authorized Dimplex dealer.

To nd your local Dimplex dealer, visit www.dimplex.com.

F. Lock Icon

The CMH has a Lock feature to prevent settings from accidentally being changed.

1. Press and hold the V for 3 seconds. Both the and

Icons will begin to ash.

2. To Enable: Within 5 seconds press ✚, then –, then ✚,

then –. The icon will appear

To Disable: Within 5 seconds press –, then ✚, then –,

then ✚. The icon will disappear.

!

NOTE: The CMH can be locked in either the Comfort or

Economy Setting. Ensure that the desired icons are present

when locking is complete.

Boost Function

The CMH is also equipped with a “Boost Function” which allows the user to run the unit at full heat, for a predetermined

amount of time, to quickly heat up a cold room/space. The

Boost can be set for a maximum of 20 minutes, in 5 minute

increments.

To enable Boost:

1. Press and hold ✚ for 5 seconds. The area where the tem-

perature normally displays will begin to toggle between

3

Page 4

the display of “HI” and “20”.

!

NOTE: The “20” indicates the time (in minutes) remaining

in Boost function. The timer is updated as the time counts

down 19, 18, 17, etc.

2. The length of time that Boost is enabled for can be ad-

justed by pressing the ✚ or – buttons. Every time the

✚ or – button is pressed the timer will be adjusted by 5

minutes and will cycle back to 20 minutes.

3. When the timer times out the heater will return to the programmed settings.

!

NOTE: At any time you can hold down the – button for 5

seconds and exit the Boost function.

Replacement Parts

2-5 kW Units (Small)

Cutout ............................... 00009112RP

Fan Blade ..........................5300020200RP

Motor ..............................2000470100RP

Capacitor ...........................3200070100RP

Housing Cover ................. CMH-COVER-S-W-RP

ConnexTM Components

Display Board ................CMH-DISPLAYPCB-RP

Power Board ................. CMH-POWERPCB-RP

Temperature Sensor .................2500670100RP

Item #

CMH35A34CX

CMH02A31CX Not required DMP-26B-RP

CMH35A51CX 110XE-

CMH35A84CX DMP-26J-RP DMP-26K-RP 2100120500RP

Contactor

(2 per Unit)

N/A

BA00100000-

01RP

(Top Element)

DMP-26B-RP DMP-26C-RP

DMP-26F-RP DMP-26G-RP 2100120200RP

7.5 - 10 kW Units (Large)

Cutout ...............................00009112RP

Fan Blade ..........................5300020200RP

Motor ..............................2000470100RP

Capacitor ...........................3200070100RP

Contactor (2 per Unit) .................2400220100RP

Housing Cover ................... CMH-COVER-L-RP

ConnexTM Components

Display Board ............... CMH-DISPLAYPCB-RP

Power Board .................CMH-POWERPCB-RP

Temperature Sensor .................2500780100RP

Item #

CMH810A21CX DMP-24-01RP DMP-24-02-RP

CMH08A23CX DMP-24-02-RP

CMH10A23CX DMP-24-01-RP DMP-24-02-RP

CMH810A31CX DMP-24-03-RP DMP-24-04-RP

CMH810A41CX DMP-24-05-RP DMP-24-07-RP

CMH810A51CX DMP-24-08-RP DMP-24-09-RP

CMH810A71CX DMP-24-10-RP DMP-24-11-RP

CMH08A73CX DMP-24-10-RP

CMH10A73CX DMP-24-10-RP DMP-24-11-RP

CMH810A81CX DMP-24-12-RP DMP-24-14-RP

CMH08A83CX DMP-24-12-RP

CMH10A83CX DMP-24-12-RP DMP-24-14-RP

P/N NO.

(Top Element)

Elements

P/N NO.

Elements

P/N NO.

(2 Bottom

Elements)

P/N NO.

(2 Bottom

Elements)

Transformer

N/A

Transformer

N/A

2100240100RP

2100240200RP

Maintenance

WARNING: Always disconnect power at the circuit breaker

to the unit prior to performing any maintenance or service

operation.

CAUTION: Allow adequate time for the element and body

casing to cool before attempting to work on the heater.

It is suggested that the heater be inspected regularly, for cleanliness of the fan intake and exhaust grilles, to ensure optimal

performance is maintained. The grilles can be cleaned either

by vacuuming off all dust and dirt or, washing the lter in warm,

soapy water and allowing to dry thoroughly before reinstalling.

Once cleaning is complete replace the grille and restore pow-

er.

WARNING: TO PREVENT THE RISK OF FIRE OR IN-

JURY, DO NOT OPERATE THE HEATER UNLESS IT IS

FULLY ASSEMBLED.

At least at yearly intervals the wire connection condition should

be inspected to ensure full electrical continuity and optimal

performance is maintained.

WARNING: The user can perform cleaning ONLY. All other

servicing should be performed by qualied service person-

nel.

Warranty

The Manufacturer warrants the CMH series ceiling heaters and components of the enclosed product against any defect in material or

workmanship for a period of one year from the date of purchase,

with the exception of the elements which are warranted to be free

from defect in material and workmanship for ten years. In full satisfaction of any claims under this Warranty the Manufacturer will repair

or replace without charge, in its factory or in the eld as it alone may

decide, any parts which in its opinion are defective.

The Manufacturer shall not be responsible for any transportation or

shipping costs in relation to such repair or replacement except as

specically assumed by it. Misuse of this product or repairs by persons other than the Manufacturer’s authorized personnel without the

Manufacturer’s written approval, will void this Warranty.

This Warranty is in lieu of all other warranties or conditions whether

express or implied including but not limited to those of merchantability or tness for purpose and shall constitute the sole remedy of

the Purchaser and the sole liability of the Manufacturer in respect of

the sale of the product, whether in the nature of breach or breach of

fundamental term, or of negligence or otherwise.

The Manufacturer shall not be liable for any special, indirect or consequential damages or for any damages resulting from removal or

replacement of a heater subject to warranty claim without the Manufacturer’s authorization.

This Warranty is transferable by the original consumer purchaser

of the product. Any claims under this Warranty must be submitted

in writing to the Service Manager, Dimplex North America Ltd., 1367

Industrial Rd., Cambridge, Ontario N1R 7G8, Canada.

1367 Industrial Road Cambridge ON Canada N1R 7G8

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product improvement, we reserve the right to make changes without notice.

© 2014 Dimplex North America Limited

Loading...

Loading...