Page 1

BLOWER ASSEMBLY

CABINET

SCREW "A"

SLOT

FILTER

Electric Cabinet Blower Heater

CH Series

IMPORTANT INSTRUCTIONS

When using electrical appliances, basic precautions should

always be followed to reduce the risk of re, electric shock

and injury to person, including the following:

Read all instructions before using this heater.1.

A heater has hot and arcing or sparking parts inside. Do 2.

not use it in areas where gasoline, paint or ammable

liquids are used or stored.

This heater is hot when in use. To avoid burns, do not let 3.

bare skin touch hot surfaces. If provided, use handles

when moving this heater. Keep combustible materials

such as: furniture, pillows, bedding, papers, clothes and

curtains away from heater.

To prevent a possible re, do not block air intakes or 4.

exhaust in any manner. Do not use on soft surfaces like

a bed where openings may become blocked.

Do not insert or allow foreign objects to enter any venti-5.

lation or exhaust opening as this may cause an electric

shock or re, or damage the heater.

SAVE THESE INSTRUCTIONS

Installation Instructions

Designed for high capacity, forced-air applications in

commercial, industrial or institutional buildings. Installs easily

on oors, walls or ceilings, surface or recess mount.

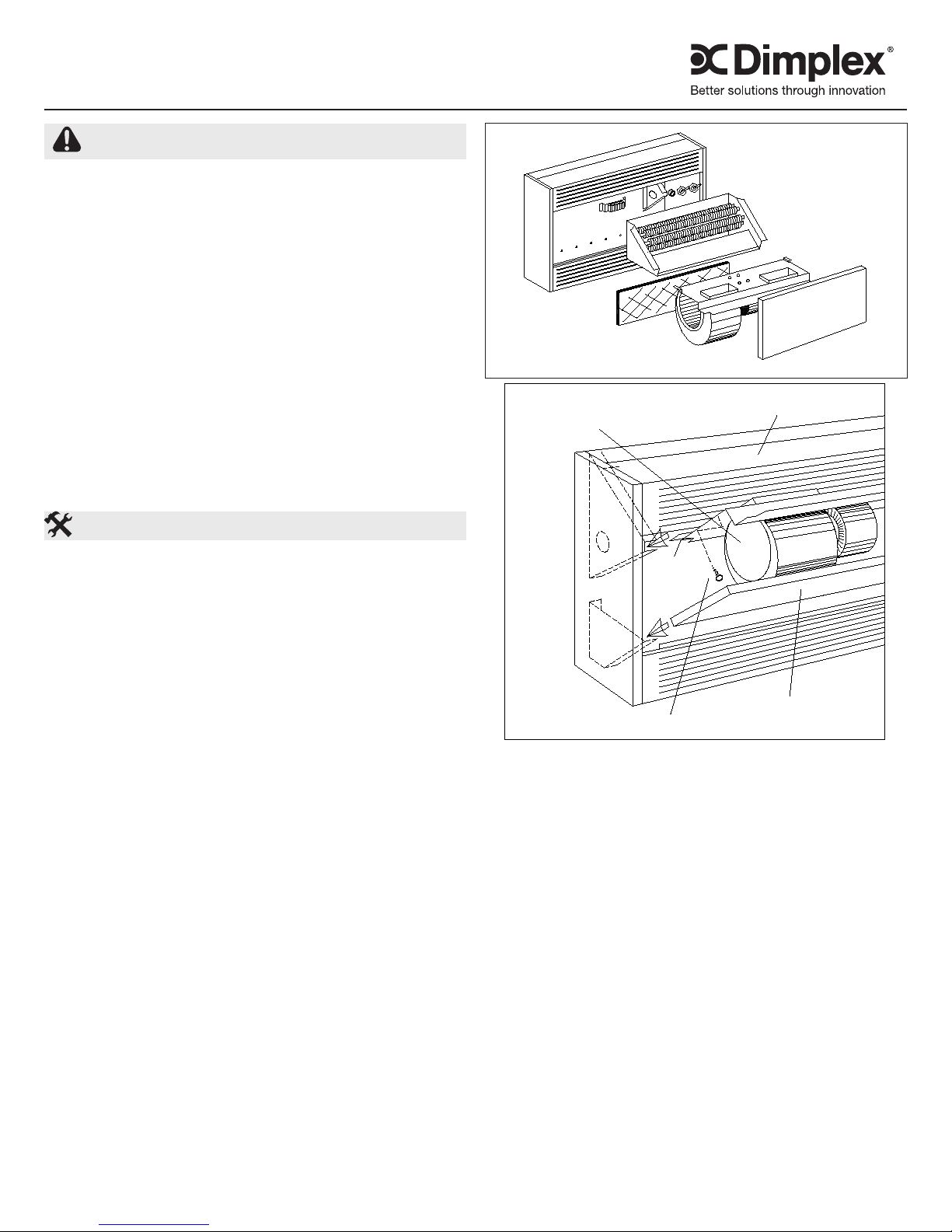

An exploded view of the major components of the CH

Cabinet Heater is shown in Figure 1. The heater is

completely assembled when shipped and must be partially

dismantled for installation.

!

NOTE: This heater is shipped with the outlets in

the front/front (D) conguration, see Figure 7. If another

conguration is required it will be necessary to rearrange the

outlets (See notation REMOVING FRONT PANEL).

REMOVING FRONT PANEL

Remove the cover screws located at top of panel. After

panel is swung open, pull the spring-loaded hinge (located

at one end of panel) towards the centre of the panel. Units

are shipped with doors for upow application. If unit is to

be installed as downow, the panel can be removed and

installed in reverse position. Before mounting the heater

determine the inlet/outlet panel arrangement. Remove the

screws holding the panel(s) in place at the back and at the

front. Reverse the panel(s) and secure back in place.

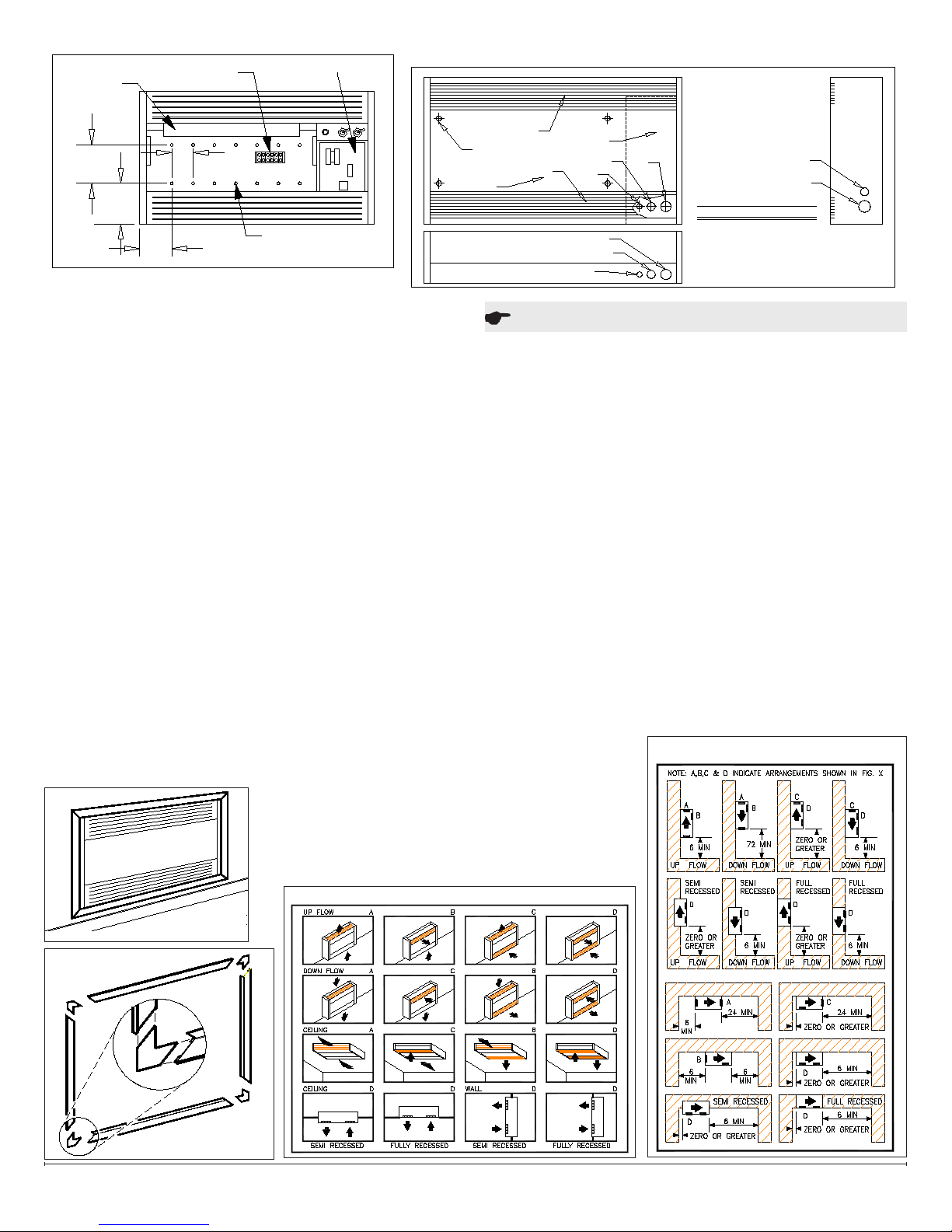

FASTENING TO WALL

For oor mounted units it is necessary to use only the holes

marked “A” in Figure 3 in order to secure unit to the wall. The

Motor and Blower Assembly need not be removed. The lter

may be removed to assist in installation.

For wall-mounted units, in order to ensure adequate support,

a greater number of mounting holes may be used. To gain

access to them the Motor and Blower Assembly the Filter

must rst be removed. Remove screws at each end of the

Assembly as shown in Figure 2, then pull out Assembly. Be

sure to disconnect plug at the Blower deck before removing

the Assembly. Slide out Filter as shown. The unit is now

ready for securing to the wall.

With ceiling mounted units, use the four (4) 9/16” (14.29 mm)

Figure 1

Filter

Figure 2

diameter knockouts provided on back of unit, use the same

procedure as in the wall-mounted units. Please make sure

that installation is strong enough to support the weight of the

heater.

SEMI/FULL-RECESSED APPLICATIONS

For either semi- or full-recessed applications care must be

taken to provide the proper size of opening in the wall or

ceiling. See Figure 4 for dimensioning details. On the length

and width dimensions, 1/4” (6.35 mm) must be allowed to

insert the trim frame. In a semi-recessed application the unit

can be recessed to any depth except when the inlet and/

or discharge (outlet) are on the top or bottom of the heater

as opposed to the front. Please see Figure 5 for a typical

installation.

ACCESSORY TRIM FRAME ASSEMBLY

Refer to Figure 6 for assembly. Assemble heater frame on

a at surface. Insert “L” shaped splices into each corner

as shown. Use a carpenter’s square to be sure of exact 90

degree angle at corners. Square up one corner at a time,

then centre punch one at a time to crimp down inside ange

onto “L” shaped splice. Trim frame can be secured to wall

with screws (not provided), cement or adhesive.

Cabinet

Heater

Section

Blower

Assembly

Front

Panel

7203510000R03

Page 2

.562 DIA. KNOCKOUTS

FOR CEILING MOUNT

(SEE NOTE BELOW)

FRONT PANEL

"A"

11.375 DIA.

"E"

"C"

1.375 - 2.000 DIA.

KNOCKOUT SCHEDULE

.875 DIA.

1.750 - 2.000 DIA.

1.750 DIA.

CEILING MOUNTING HOLES ARE

OF HEATER.

SHOWN AS VIEWED FROM FRONT

"B"

INLET

"C"

"A"

"C"

"D"

"B"

ITEM

"A"

"B"

CONTROL SECTION

OUTLET

NOTE:

SIZE (INCHES)

1

2

2

QTY.

2

"D"

"E"

Figure 3

5.875

(149mm)

4.000

(102mm)

7.750

(198mm)

8.000

(203mm)

HEATER

TERMINAL BLOCK

CONTROL PANEL

MOUNTING HOLES

4" (102mm) CENTRES

SECTION

A A

Figure 4

MOUNTING CLEARANCES

In order for this heater to operate properly the clearances

shown in Figure 8 will have to be maintained. Failing to

do so may result in a poor performance from the heater.

Dimensions are shown in inches (millimetres).

DUCT COLLAR MOUNTING

An 18” (457 mm) section of duct work with 90 degrees bends

may be added to the inlet and outlet of the heater with 8”

(203 mm) clearance to combustible surfaces. Inlet and outlet

grilles placed on the end of the must have a minium of 65%

open area. Refer to Figure 9 for cross-sectional dimensions

of duct. Duct collar inlet/outlets can be as per Figure 7.

Secure the duct to the anges provided.

!

NOTE: External static pressure exceeding 0.15”wg is not

recommended.

WIRING INFORMATION

For service entrance refer to Figure 04 for knockout sizes 1.

available and their locations.

!

NOTE: For upow application, control section and knock-

outs are located on lower right side of unit and for downow

application they will be on upper left hand side of unit.

All external wiring to the heater shall be in accordance 2.

to the Local and National Building codes. It is

recommended that only qualied electrical personnel

shall perform any service on this unit.

Figure 5

Refer to data plate and 3.

wiring diagram for correct

voltage and amperage

rating. These must be

considered in the size of

eld wiring.

Figure 7

Operation

The CH Cabinet Heater is available with a choice of control

options to provide exibly of operation in various applications.

The type of control option is reected in the Catalogue

Number as the eighth digit. Please check one of the following

options to ensure that is what has been ordered or required.

-3: The unit is automatically controlled by it’s own built-in

thermostat with a range of 45 degrees F (7 C) to 90 degrees

F (32 C). In addition to the toggle switch (“Heat & Fan”,

“OFF” and “Fan Only”) this option has a two position toggle

switch for High/Low Heat Selection and High/Low Blower

Speed. HIGH and LOW Heat give 100% for HIGH and

approximately 50% Low heat. Correspondingly the blower

speeds are approximately 1050 and 800 R.P.M. The Fan

Delay is effective only on the “OFF” cycle, as the fan comes

on at the same time the heat comes on, during the “Heat &

Fan” cycle.

-T: This option incorporates a two position toggle switch as

in option-3 above and functions the same way. In addition

a low voltage control relay complete with an integral

transformer is provided for connection to a remote 24 volt

thermostat. The fan delay works the same as in “-3” above

also.

-R: This option also

uses the two position

toggle switch as in

the above options.

Provision is provided

for a line voltage

thermostat. The fan

delay works the same

as in “-3” above.

Figure 8

Figure 6

www.dimplex.com2

Page 3

Maintenance

CONTROL SECTION

FRONT PANEL

OUTLET

INLET

NOTE:

ALTERNATE LOCATION OF DUCT

COLLAR WHEN LOCATED AT FRONT

NOTE:

ALTERNATE LOCATION

OF DUCT COLLAR WHEN

LOCATED AT FRONT

CABINET SIZE

32" (813)

45" (1143)

65" (1651)

78" (1982)

DUCT OPENING

4" (102) x 15" (381)

4" (102) x 28" (711)

4" (102) X 49" (1245)

4" (102) X 61 1/4" (1156)

AREA

.41 (.039)

.78 (.072)

1.37 (.127)

1.70 (.158)

SQ. FT. (METER)

If motors or blowers need servicing, or oiling they can 1.

easily be removed removing screws as illustrated in

Figure 2. The complete assembly then slides out, after

electrical plug connector is unplugged.

If heat sections need servicing, they can easily be 2.

removed by removing screws (“A”) in Figure 2. The

complete heat section assembly then slides out, after all

wires into the terminal block are removed. Care must be

taken to assure that all wires are replaced in the correct

terminal block as per wire numbering or coding. The limit

control and elements can be readily serviced when the

heat section is removed.

All controls are readily accessible through the inner 3.

control door. All controls can be serviced through this

door.

Filter is accessible after the front panel is opened. Slide 4.

lter out and clean or replace a minimum of twice per

heating season. Optional permanent type lter can be

cleaned with water and detergent or any available lter

cleaning solution.

Figure 9

Warranty

The Manufacturer warrants the heater and components of the enclosed product

against any defect in material or workmanship for a period of one year from

the date of purchase. In full satisfaction of any claims under this Warranty the

Manufacturer will repair or replace without charge, in its factory or in the eld as it

alone may decide, any parts which in its opinion are defective.

The Manufacturer shall not be responsible for any transportation or shipping

costs in relation to such repair or replacement except as specically assumed

by it. Misuse of this product or repairs by persons other than the Manufacturer’s

authorized personnel without the Manufacturer’s written approval, will void this

Warranty.

This Warranty is in lieu of all other warranties or conditions whether expressed or

implied including but not limited to those of merchantability or tness for purpose

and shall constitute the sole remedy of the Purchaser and the sole liability of the

Manufacturer in respect of the sale of the product, whether in the nature of breach

or breach of fundamental term, or of negligence or otherwise.

The Manufacturer shall not be liable for any special, indirect or consequential

damages or for any damages resulting from removal or replacement of the heater

subject to warranty claim without the Manufacturer’s authorization.

This Warranty is transferable by the original consumer purchaser of the product.

Any claims under this Warranty must be submitted in writing to the Service

Manager, Dimplex North America Ltd., 1367 Industrial Rd., Cambridge, Ontario

N1R 7G8, Canada.

Replacement Parts

Part No. Part No.

Motor 1/10HP 208/240V 1PH 08071101RP

1/20HP 208/240V 1PH 02024293RP

1/30HP 208/240V 1PH 02024101RP

1/20HP 208V 1PH 02024288RP

1/20HP 240V 1PH 02024290RP

1/30HP 277V 1PH 02024102RP

Capacitor 02007005RP

Element 208V 1000w 02030057RP 2000w 02030054RP

240V 1000w 02030058RP 2000w 02030055RP

277V 1000w 02030059RP 2000w 02030056RP

347V 1000w 02050036RP 2000w 02050037RP

480V 1000w 02032073RP 2000w 02032072RP

600V 1000w 02050038RP 2000w 02050039RP

Contactor 40A 208/240v 2400160300RP 277v 2400160400RP

50A 208/240v 2400160900RP

Cutout 02005317RP

Blower housing 30006858RP

Blower wheel 02000083RP

Thermostat 03005036RP

Thermostat knob 8800030200RP

Hi/Low switch 2800060100RP

On/Off switch 02005038RP

Relay 02005592RP

1367 Industrial Road Cambridge ON Canada N1R 7G8

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product improvement, we reserve the right to make changes without notice.

© 2011 Dimplex North America Limited

3

Loading...

Loading...