Page 1

Service Manual

Mini Brockton

Model Number:

CFP4949BW

UL Part Number

6903570300

IMPORTANT SAFETY INFORMATION: Always read this manual rst before attempting to service this

replace. For your safety, always comply with all warnings and safety instructions contained in this

manual to prevent personal injury or property damage.

Dimplex North America Limited

1367 Industrial Road

1-888-346-7539 www.dimplex.com

In keeping with our policy of continuous product development, we reserve the right to make changes without notice.

© 2012 Dimplex North America Limited

Cambridge ON Canada N1R 7G8

REV PCN DATE

00 - 20-JAN-12

7400550000R00

Page 2

TABLE OF CONTENTS

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

EXPLODED PARTS DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

WIRING DIAGRAM ....................................................6

FLICKER ROD/MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3-POSITION AND HEATER SWITCH REPLACEMENT ........................7

HEATER ASSEMBLY REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

POWER CORD REPLACEMENT .........................................9

REMOTE CONTROL RECEIVER REPLACEMENT ...........................9

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Always use a qualied technician or service agency to repair this replace.

!

NOTE: Procedures and techniques that are considered important enough to emphasize.

CAUTION: Procedures and techniques which, if not carefully followed, will result in damage to the

equipment.

WARNING: Procedures and techniques which, if not carefully followed, will expose the user to the

risk of re, serious injury, or death.

2 www.dimplex.com

Page 3

OPERATION

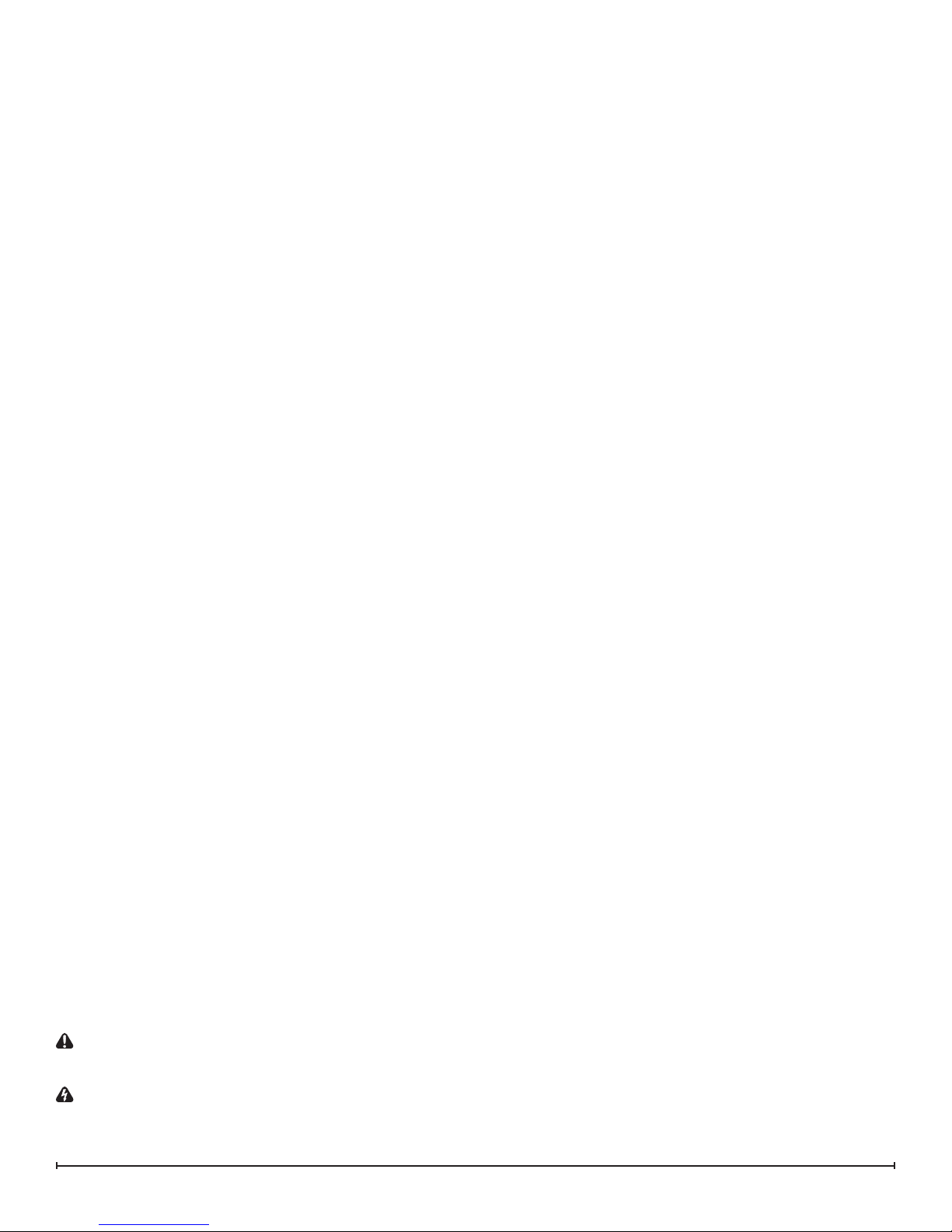

Figure 1

A

B

MANUAL CONTROLS

A. 3-Position Switch

The switch has two On positions marked with “ I ” and “ II ”.

The “ I ” position is for manual operation. In this position the

built-in remote control is bypassed. The “ II ” position is for

operating the unit with the provided remote control. When

in “ II ” position the unit is operated with the ON and OFF

buttons of the remote control. When the switch is in the

center “ O ” position the unit is off.

B. Heater Switch

The Heater Switch supplies power to the heating unit when

the 3-Position Switch (Figure 1A) is On (“I” or “II” positions).

Resetting the Temperature Cutoff Switch

Should the heater overheat, an automatic cut out will turn

the replace off and it will not come back on without being

reset. It can be reset by switching the 3-Position Switch to

Off and waiting ve (5) minutes before switching the unit

back on.

!

NOTE: If operating the unit with a remote control, the

remote control may require re-initializing after turning the

power off.

CAUTION: If you need to continuously reset the heater,

disconnect power and call Dimplex customer service at

1-888-DIMPLEX (1-888-346-7539).

Remote Control

The replace is supplied with a radio frequency integral

ON/OFF remote control (Figure 2). This remote control

has a range of approximately 50 feet (15.25 m), it does not

have to be pointed at the replace and can pass through

most obstacles (including walls). It is supplied with

one of hundreds of independent frequencies to prevent

interference with other units.

!

NOTE: Before attempting any operation with the

remote control, pull the plastic insulator strip out from

between the remote casing and battery cover (Figure 2).

!

NOTE: The remote control is an EEPROM system;

therefore if power is interrupted for whatever reason,

the built-in remote control receiver will hold the memory

of the remote’s radio frequency for up to 24 hours. The

remote should continue to operate the replace as

normal once unit is re-powered. Re-initialization of the

remote control to the replace should only be required

if there is a loss of power to the receiver for longer than

24 hours. (i.e. power failure, main power switch is turned

off).

!

NOTE: Ensure that the replace 3-Position Switch is

set to the remote control setting (I.E.. II).

To operate: push the ON button to turn replace on; push

the OFF button to turn replace off.

!

NOTE: Remote control only operates the main power

supply. Heat must still be controlled by switches on

replace.

Remote Control Initialization/Reprogramming

If the remote control or remote control receiver has been

replaced, follow these steps to initialize the remote control

and receiver:

Turn off power to replace.1.

Locate manual controls (Figure 1).2.

Set the 3-Position Switch to the remote position “II”.3.

Wait a minimum of ve (5) seconds and then re-acquire 4.

power to replace.

Within 10 seconds of re-acquiring power, press the ON 5.

button located on the remote control.

!

NOTE: You will have only 10 seconds to perform this

last step. Failure to do so will result in these steps

needing to be followed again.

This will synchronize the remote control and remote control

receiver.

Battery Replacement

To replace the battery:

Slide battery cover open on the remote control 1.

(Figure 3).

Install one (1) 12-Volt (A23) battery in the battery 2.

holder.

Close the battery cover3.

Battery must be recycled or disposed of properly.

Check with your Local Authority or Retailer for

recycling advice in your area.

Figure 2

On

Button

Off Button

Plastic

Strip

Battery

Cover

3

Page 4

MAINTENANCE

WARNING: Disconnect power before attempting

any maintenance or cleaning to reduce the risk of re,

electric shock or damage to persons.

CAUTION: Allow at least ve (5) minutes for the light

bulbs to cool before touching them to avoid accidental

burning of the skin.

The light bulbs need to be replaced when you notice a dark

section of the ame or when the clarity and detail of the log

ember bed exterior reduces. There are two (2) bulbs under

the ember bed, which generate the ames and embers.

Light Bulb Requirements

Quantity of two (2) clear chandelier or candelabra bulbs

with an E-12 (small) socket base, 60 Watt rating. Example:

GE 60BC or Philips 60 CTC.

Do not exceed 60 Watts per bulb

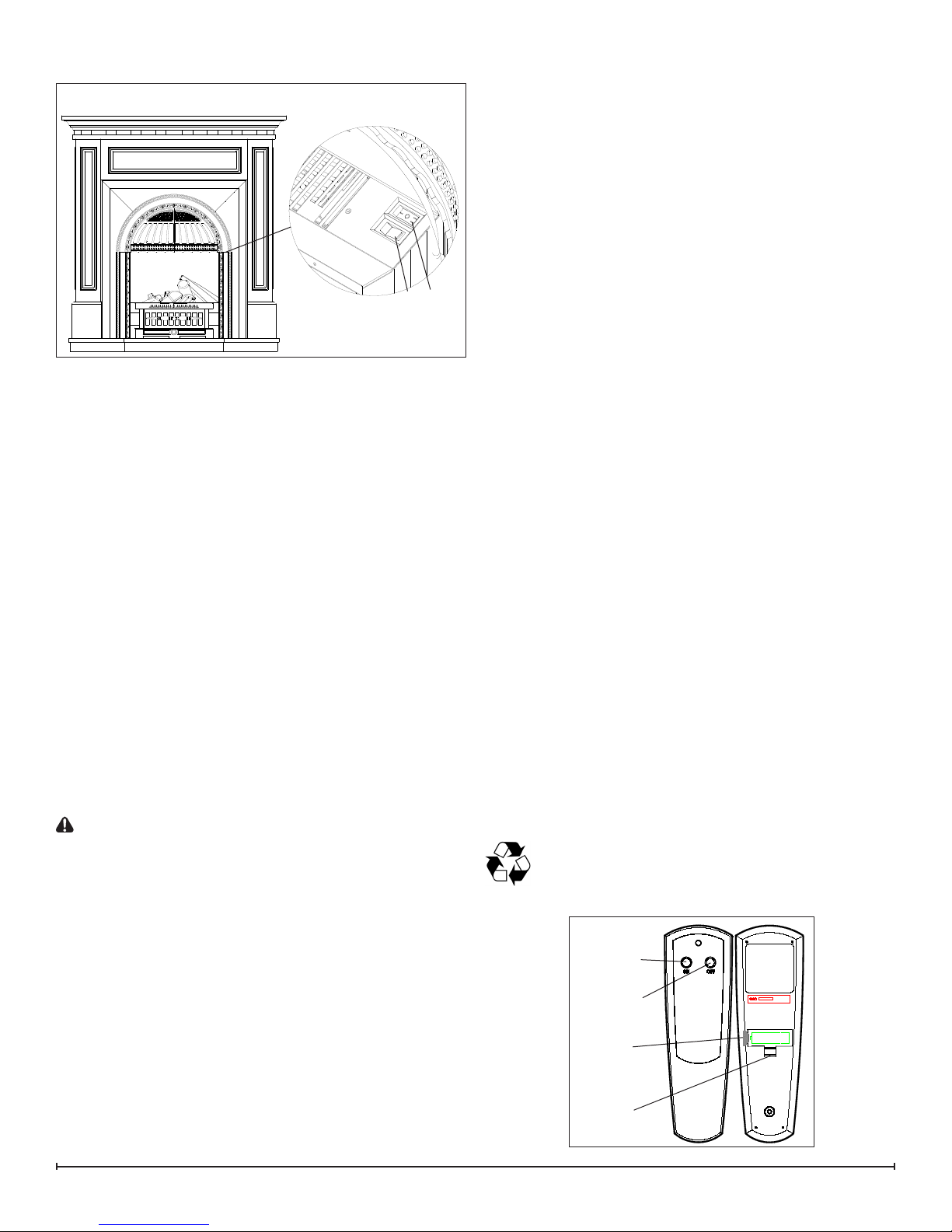

Bulb Replacement

The bulbs are located under the Ember Bed.

To gain access to the bulbs:

Remove the nut and washer as indicated in Figure 3 1.

and pull the front trim away from the replace (Figure

4).

Remove three (3) screws holding Ember Bed in place 2.

(Figure 4).

Release left side of Flicker Rod by turning rod and 3.

plastic bushing to match key slot of bracket. Pull

forward to clear bracket.

Remove the defective lamp(s) by unscrewing counter 4.

clockwise.

Figure 3

Figure 4

Flicker Rod

Ember Bed

Screws

Front Trim

Replace with a 60 Watt E12 clear chandelier or 5.

candelabra. Take care not to over-tighten the bulb.

Ret the Flicker Rod and Ember Bed, and secure with 6.

the screws removed in step 2.

Refit front trim and secure with washer and nut.7.

!

NOTE: To remove the rebox insert prior to repair,

remove the nine (9) black screws at the back of the

rebox as shown in Figure 3 and slide it out to the back.

Helpful Hints

It is a good idea to replace all light bulbs at one time if they

are close to the end of their rated life. Group replacement

will reduce the number of times you need to open the unit

to replace light bulbs.

4 www.dimplex.com

Washer

& Nut

Screws to

remove: 3 per

side and 3

along top edge

Cleaning

WARNING: Always disconnect from the power supply

before cleaning the replace.

For general cleaning use a soft clean duster – never use

abrasive cleaners. The glass viewing screen should be

cleaned carefully with a soft cloth. DO NOT use glass

cleaners.

To remove any accumulation of dust or uff, the soft brush

attachment of a vacuum cleaner should occasionally be

used to clean the outlet grill of the fan heater.

Page 5

EXPLODED PARTS DIAGRAM

6

8

7

9

4

3

14

1

13

2

Replacement Parts List

POWER CORD 1. . . . . . . . . . . . . . . . . . . 4100090104RP

FLICKER MOTOR2. . . . . . . . . . . . . . . . . . 2000210200RP

LIGHT HARNESS/ SOCKET3. . . . . . . . . 4200121000RP

PARTIALLY REFLECTIVE GLASS4. . . . . 5900860100RP

REMOTE CONTROL RECEIVER5. . . . . . 3000380200RP

REMOTE CONTROL6. . . . . . . . . . . . . . . 3000370500RP

3-POSITION SWITCH7. . . . . . . . . . . . . . 2800071100RP

HEATER SWITCH8. . . . . . . . . . . . . . . . . . 2800070900RP

10

5

11

12

HEATER ASSEMBLY9. . . . . . . . . . . . . . . 2200491200RP

MINI-BROCKTON TRIM10. . . . . . . . . . . . . 6905840184RP

CAPACITOR11. . . . . . . . . . . . . . . . . . . . . . 2300030100RP

TERMINAL BLOCK12. . . . . . . . . . . . . . . . . 4000070100RP

FLICKER ROD CONNECTOR13. . . . . . . . 8500680100RP

FLICKER ROD14. . . . . . . . . . . . . . . . . . . . 5900890100RP

LOG SET15. . . . . . . . . . . . . . . . . . . . . . . . . 0440090100RP

5

Page 6

WIRING DIAGRAM

6 www.dimplex.com

Page 7

FLICKER ROD/MOTOR REPLACEMENT

Tools Required: Phillips head Screwdriver

WARNING: If the replace was operating prior to

servicing allow at least 10 minutes for light bulbs and

heating elements to cool off to avoid accidental burning

of skin.

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Remove the nut and washer which secure the front trim 1.

to the mantel from behind (Figure 3).

Remove the front trim by pulling it away from the front 2.

of the mantel.

Remove the mesh curtains & rod from the mantel by 3.

pulling them away from the mantel, and set them aside

(Figure 5).

Remove 2 screws from the front of the replace which 4.

secure the rebox to the mantel base. These 2 screws

are in the bottom front of the rebox to the left and right

side (Figure 2).

From behind the mantel, remove 11 screws which se-5.

cure the rebox to the mantel (Figure 3).

Remove the rebox from behind the mantel and lay it 6.

on its back.

Remove the logset and front cover of the rebox by 7.

removing the 4 screws: 2 left and 2 right. They are

located on the lower, side panels of the rebox.

Grasp the rubber gasket connecting the icker rod and 8.

icker motor shaft on the right. Simultaneously pull and

twist the gasket (with the icker rod attached) away

from the motor. Once the rod and gasket are detached,

slide them to the right, guiding the rod out of the left

mounting bracket.

Figure 5

!

NOTE: When removing the Flicker Rod, damage may

occur if bent excessively or handled improperly. Ensure that

the Flicker Rod is straight and not crushed before reinstalling.

Turn the rebox and lay it on its right side, with the 9.

switch side towards the ceiling.

Remove only the 3 screws, closest to the icker motor, 10.

that secure the retaining bracket to the back panel (the

one that both the icker motor and the light sockets are

attached to). Also remove the 2 screws directly above

the rear left foot as well as the screw above and to the

right of those screws.

!

NOTE: Removing these should partially release the

mounting bracket, just enough to gently pull the motor

forward from the front and access the 2 motor mounting

screws.

Remove the two mounting screws on the icker motor.11.

Remove the lower Partially Reective Glass retaining 12.

bracket by removing the 2 mounting screws.

Slide the Partially Reective Glass down and place it 13.

in a safe place. This will give access to the terminal

block.

Loosen the screws that hold the old icker motor wires 14.

and replace with the wires for the new icker motor on

the terminal block.

Orient the new icker motor and mount to the mounting 15.

bracket.

Reassemble in the reverse order.16.

3-POSITION AND HEATER SWITCH

REPLACEMENT

Tools Required: Phillips head Screwdriver

Flat Head Screwdriver

WARNING: If the replace was operating prior to

servicing allow at least 10 minutes for light bulbs and

heating elements to cool off to avoid accidental burning

of skin.

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Remove the nut and washer which secure the front trim 1.

to the mantel from behind (Figure 3).

Remove the front trim by pulling it away from the front 2.

of the mantel.

Remove the mesh curtains & rod from the mantel by 3.

pulling them away from the mantel, and set them aside

(Figure 5).

Remove 2 screws from the front of the replace which 4.

secure the rebox to the mantel base. These 2 screws

are in the bottom front of the rebox to the left and right

side (Figure 2).

From behind the mantel, remove 11 screws which se-5.

cure the rebox to the mantel (Figure 3).

Remove the rebox from behind the mantel and lay it 6.

7

Page 8

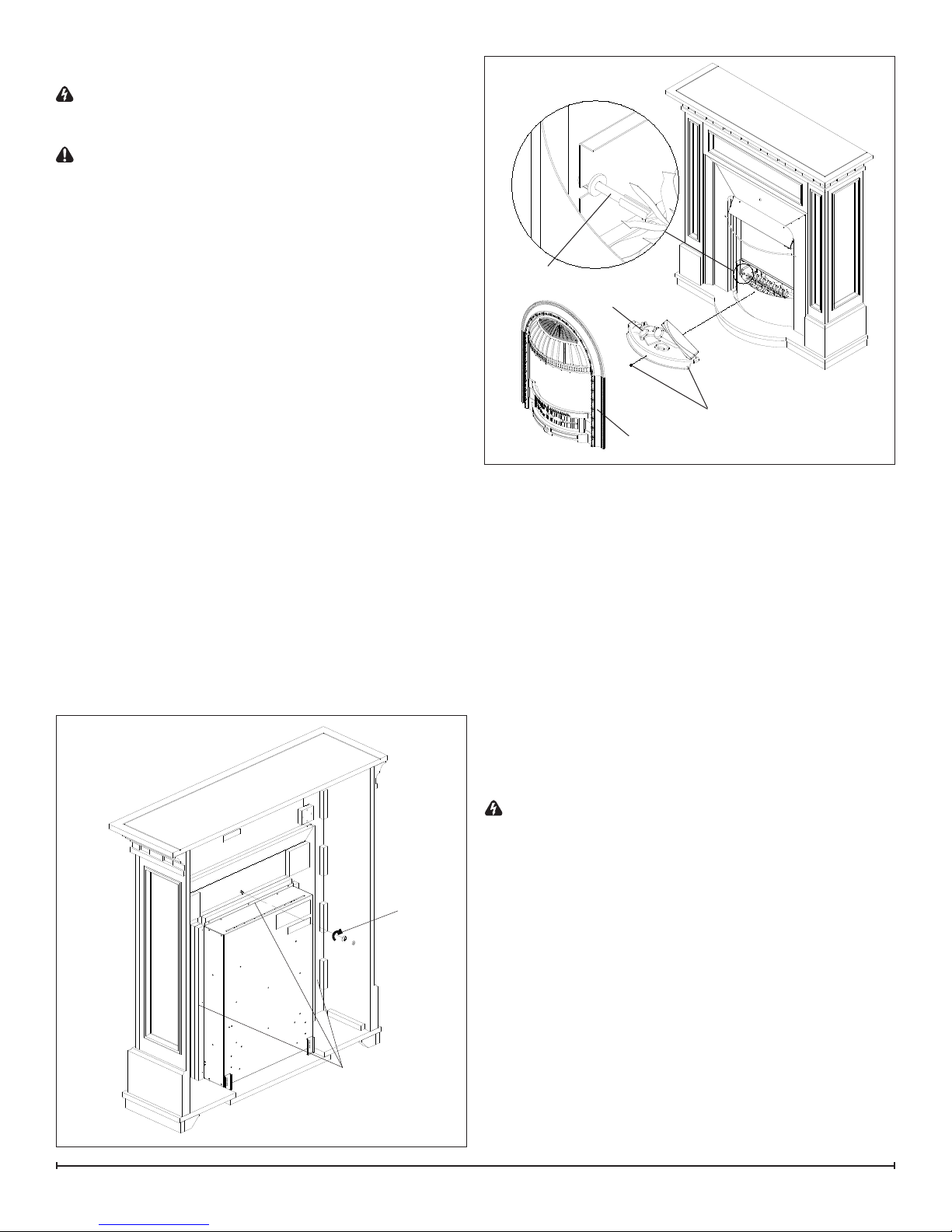

Figure 6

Heater Housing

Switches

on its right side (with the switches at the bottom).

Remove the 2 screws from the upper back panel, 7.

located approximately 5 ½ inches down from the top of

the insert, (This is on your left side if facing the back of

the unit while on its side). These screws hold the back

part of the heater housing to the insert.

While carefully holding the heater housing from the 8.

front, remove the 2 screws from the top panel of the

insert which hold the top of the heater housing to the

insert.

!

NOTE: There are wires still attached to the heater

housing once the screws are removed.

Carefully lay the rebox insert on its back and pull the 9.

heater housing, with the heater assembly still attached,

out from the front of the rebox.

Move the heater housing 45 degrees and rest it on the 10.

work surface just beside the rebox.

Remove the 4 screws which mount the heater assem-11.

bly to the housing. This will allow you to remove the

heater assembly out of the housing so that you can

access the switches inside. (Figure 6)

Locate the defective switch mounted to the heater 12.

housing and disconnect the wiring clips and connections noting their original locations.

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the switch to

release the wires.

Depress the retainer clips on the rear of the switch and 13.

push the switch out of the heater housing.

Properly orient the new switch and reconnect all of the 14.

wiring clips and connections.

Reassemble in the reverse order as above15.

Heater Assembly

HEATER ASSEMBLY REPLACEMENT

Tools Required: Phillips head Screwdriver

Flat Head Screwdriver

WARNING: If the replace was operating prior to

servicing allow at least 10 minutes for light bulbs and

heating elements to cool off to avoid accidental burning

of skin.

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Remove the nut and washer which secure the front trim 1.

to the mantel from behind (Figure 3).

Remove the front trim by pulling it away from the front 2.

of the mantel.

Remove the mesh curtains & rod from the mantel by 3.

pulling them away from the mantel, and set them aside

(Figure 5).

Remove 2 screws from the front of the replace which 4.

secure the rebox to the mantel base. These 2 screws

are in the bottom front of the rebox to the left and right

side (Figure 2).

From behind the mantel, remove 11 screws which se-5.

cure the rebox to the mantel (Figure 3).

Remove the rebox from behind the mantel and lay it 6.

on its right side (with the switches at the bottom).

Remove the 2 screws from the upper back panel, 7.

located approximately 5 ½ inches down from the top of

the insert, (This is on your left side if facing the back of

the unit while on its side). These screws hold the back

part of the heater housing to the insert.

While carefully holding the heater housing from the 8.

front, remove the 2 screws from the top panel of the

insert which hold the top of the heater housing to the

insert.

!

NOTE: There are wires still attached to the heater

housing once the screws are removed.

Carefully lay the rebox insert on its back and pull the 9.

heater housing, with the heater assembly still attached,

out from the front of the rebox.

Move the heater housing 45 degrees and rest it on the 10.

work surface just beside the rebox.

Remove the 4 screws which mount the heater assem-11.

Figure 7

8 www.dimplex.com

Page 9

bly to the housing. This will allow you to remove the

heater assembly out of the housing so that you can

access the switches inside. (Figure 6)

Disconnect wiring connections and connect to replace-12.

ment heater assembly noting their original locations.

Reassemble in the reverse order as above.13.

POWER CORD REPLACEMENT

Tools Required: Phillips head Screwdriver

Slip Joint Pliers

Flat Head Screwdriver

WARNING: If the replace was operating prior to

servicing allow at least 10 minutes for light bulbs and

heating elements to cool off to avoid accidental burning

of skin.

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Remove the nut and washer which secure the front trim 1.

to the mantel from behind (Figure 3).

Remove the front trim by pulling it away from the front 2.

of the mantel.

Remove the mesh curtains & rod from the mantel by 3.

pulling them away from the mantel, and set them aside

(Figure 5).

Remove 2 screws from the front of the replace which 4.

secure the rebox to the mantel base. These 2 screws

are in the bottom front of the rebox to the left and right

side (Figure 2).

From behind the mantel, remove 11 screws which se-5.

cure the rebox to the mantel (Figure 3).

Remove the rebox from behind the mantel and lay it 6.

on its back.

Remove the logset and front cover of the rebox by 7.

removing the 4 screws: 2 left and 2 right. They are

located on the lower, side panels of the rebox.

Grasp the rubber gasket connecting the icker rod and 8.

icker motor shaft on the right. Simultaneously pull and

twist the gasket (with the icker rod attached) away

from the motor. Once the rod and gasket are detached,

slide them to the right, guiding the rod out of the left

mounting bracket.

!

NOTE: When removing the Flicker Rod, damage may

occur if bent excessively or handled improperly. Ensure that

the Flicker Rod is straight and not crushed before reinstalling.

From beneath the rebox, remove the 2 screws that 9.

secure the power cord internal housing to the outer

frame. (Figure 7)

Disconnect wiring connections in the terminal block.10.

With needle nosed pliers, squeeze and push the grom-11.

met securing the power cord out of the casing.

Connect the new power cord into the same location.12.

Reassemble in the reverse order as above.13.

REMOTE CONTROL RECEIVER

REPLACEMENT

Tools Required: Phillips head Screwdriver

Slip Joint Pliers

Flat Head Screwdriver

WARNING: If the replace was operating prior to

servicing allow at least 10 minutes for light bulbs and

heating elements to cool off to avoid accidental burning

of skin.

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

Remove the nut and washer which secure the front trim 1.

to the mantel from behind (Figure 3).

Remove the front trim by pulling it away from the front 2.

of the mantel.

Remove the mesh curtains & rod from the mantel by 3.

pulling them away from the mantel, and set them aside

(Figure 5).

Remove 2 screws from the front of the replace which 4.

secure the rebox to the mantel base. These 2 screws

are in the bottom front of the rebox to the left and right

side (Figure 2).

From behind the mantel, remove 11 screws which se-5.

cure the rebox to the mantel (Figure 3).

Remove the rebox from behind the mantel and lay it 6.

on its back.

Remove the logset and front cover of the rebox by 7.

removing the 4 screws: 2 left and 2 right. They are

located on the lower, side panels of the rebox.

Remove the lower Partially Reective Glass retaining 8.

bracket by removing the 2 mounting screws.

Slide the Partially Reective Glass down and place it 9.

in a safe place. This will give access to the Remote

Control Receiver.

Disconnect the wires noting their original location.10.

!

NOTE: A at head screwdriver can be used to gently

pry between the end of the connector and the receiver to

release the wires.

Remove the original remote control receiver from the 11.

mounting tabs located on the 4 corners of the receiver.

This can be done by cutting the tips of the tabs with

wire snips, or breaking the tips with pliers, then pulling

the receiver off the remainder of the tabs.

Remove the remainder of the original mounting tabs by 12.

pushing them out through the back panel of the replace. Replace with the new mounting tabs provided

with the new remote control receiver into the same

location on the back panel .

Gently push the replacement receiver onto the new 13.

mounting tabs.

Replace the wires into their original conguration.14.

Re-assemble the replace in reverse order.15.

9

Page 10

TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

General

Circuit breaker trips or fuse

blows when unit is turned on

Unit turns on or off by itself Remote Control has a similar frequency

Lights dim in room while the unit

is on

Power cord gets warm Normal Operation The power cord may get slightly warm to the touch

Appearance

Fireplace does not turn on Manually

Fireplace does not turn on using

the Remote Control

Flame Frozen Defective Flicker Motor Replace Flicker Motor

Flame not bright or ame not

visible

Log set dim, not glowing Burnt light bulbs Replace light bulbs

Flame Shutter Defective icker motor Replace icker motor

Short in unit wiring. Trace wiring in unit.

Improper circuit current rating Additional appliances may exceed the current rating

of the circuit breaker or fuse. Plug unit into another

outlet or install unit on a dedicated 15 amp circuit.

Replace Remote Control

to other remotes in the area.

Radio frequency disturbance from outside sources.

Defective Remote Control Receiver Replace Remote Control Receiver. Initialize Remote

Unit is drawing close to circuit current

rating

Defective power cord Replace power cord if cord gets hot to the touch.

Improper operation Refer to Operation Section

No incoming voltage from the electrical

wall socket

Defective 3-Position Switch Replace 3-Position Switch

Loose wiring Check wiring connections

Defective Remote Control Receiver Replace Remote Control Receiver. Initialize with

Improper operation Refer to Operation Section

Remote control not initialized to replace Initialize the Remote Control

Remote Control not working Install new battery into the Remote Control. Initialize

Loose wiring Check wiring connections

Burnt light bulbs Replace light bulbs

Loose wiring Check wiring connections

Defective light harness Replace light harness

Replace Remote Control and Remote Control Receiver. Initialize Remote Control and Receiver.

Control and Receiver.

Move the unit to another outlet or install unit on a dedicated 15 amp circuit

when the heater is on

Check Fuse/Breaker Panel

Remote Control.

Remote Control to Remote Control Receiver.

Replace Remote Control Receiver. Initialize Remote

Control and Remote Control Receiver.

10 www.dimplex.com

Page 11

Light leaking around the log set Log set not positioned properly Check log set for proper t

PROBLEM CAUSE SOLUTION

Heater

Heater is not turning off Improper operation Refer to Operation Section

Defective Heater Switch Replace Heater Switch

Defective Remote Control Receiver Replace Remote Control Receiver

Defective Heater Assembly Replace Heater Assembly

Heater is not turning on Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective Heater Switch Replace Hater Switch

Defective Remote Control Receiver Replace Remote Control Receiver

Defective Heater Assembly Replace Heater Assembly

Heater is turning off after a

couple of minutes of operation

Heater emits an odor Normal Operation Normal operation is when the heater emits an odor

Heater fan turns on but heater

lacks heat

Heating element is glowing red Normal Operation Small glowing sections of the element are considered

Noise

Excessive noise with the heater onDirty Heater Assembly Ensure that exterior intake louvers and rebox cavity

Grinding or excessive noise with

the heater off

Build up of dirt/dust in Heater Assembly Ensure that exterior intake louvers and rebox cavity

are free of dirt/dust.

Defective Heater Assembly Replace Heater Assembly

for a brief period after the heater is initially turned on.

The heater is burning off any dust accumulated during

manufacturing or operation.

Defective Heater Assembly Replace Heater Assembly

Improper operation Refer to Operation Section

Loose wiring Trace wiring in unit

Defective Heater Assembly Replace Heater Assembly

normal.

Defective Heater Assembly If larger glowing sections are causing the heater to trip

the thermal cutout, unplug unit, discontinue use and

replace Heater Assembly.

are free of dirt/dust.

Defective Heater Assembly Replace Heater Assembly

Flicker rod hitting or rubbing against

internal components

Defective Flicker Motor Replace Flicker Motor

Ensure rod is straight and mounted properly in the

bracket, spinning freely away from other components.

Replace if necessary.

11

Loading...

Loading...