Page 1

CFH60, CFH90 & CFH120

Tel:

+44

(0)191 490 1547

Fax:

+44 (0)191 477 5371

Email:

northernsales@thorneandderrick.co.uk

Website: www.heattracing.co.uk

www.thorneanderrick.co.uk

Electronic Wall Mounted Fan Heater

The product complies with the European Safety Standards EN60335-2-30 and the European Standard Electromagnetic Compatibility (EMC) EN55014,

EN60555-2 and EN60555-3. These cover the essential requirements of EEC Directives 2006/95/EC and 2004/108/EC

08/19511/1 (UK) Issue 1

Page 2

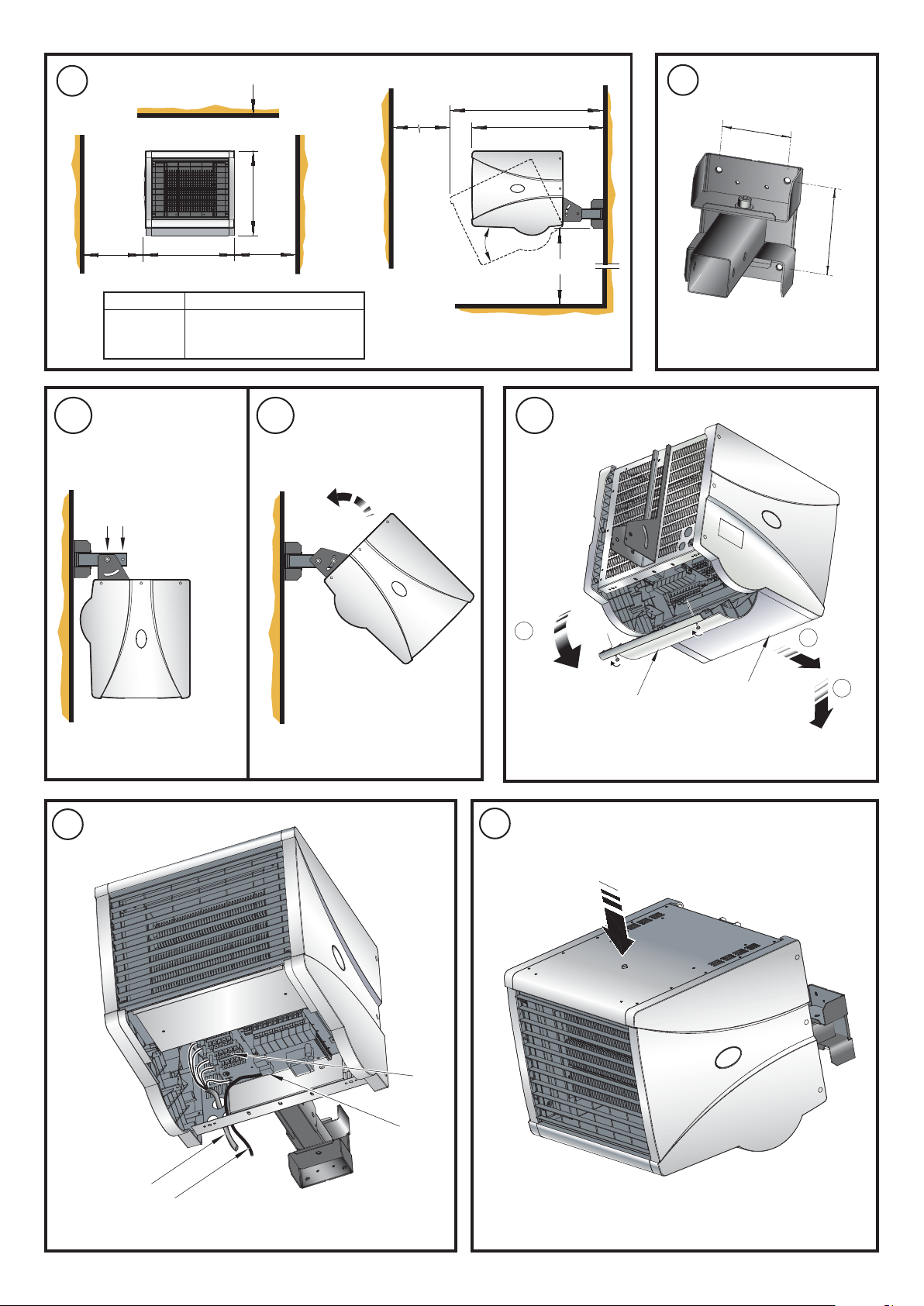

1

D2

D1

100mm

Min.

H

1000mm

Min.

2

70mm

500mm

Min.

CFH60 386 360 565 630

CFH90 386 360 565 630

CFH120 386 360 565 630

L

500mm

Min.

L H D1D2

3a 3b

1 2

o

45

Max.

2.0m MIN

70mm

4

1

2

x

3

y

5

6

z

w

x

y

Page 3

7

MLC MLC

CPC

L1 N L1 N

L3 L2

380 - 415V

3PN + E

380 - 415V

3PN + E

M

C

D

E

B

L3 L2

B

E

D

C

M

ECP

SU SU

MU

L1 N

L3 L2

380 - 415V

3PN + E

M

C

D

E

B

POWER IN

HEATER

B

US OU

T

B

US I

N

LED

PO

WER I

N

HEATER

B

US OUT

B

US I

N

LED

POWER IN

HEATER

B

US OU

T

B

US I

N

LED

380 - 415V

3PN + E

L3 L2

CFH60, CFH90 & CFH120

B

L1 N

E

M

POWER IN

HEATER

3 min

BUS OUT

BUS IN

LED

45 min

8

220 - 240V ~1PN + E 380 - 415V ~3PN + E

(FACTORY SUPPLIED)

BLUE

PINK

PINK

BLUE

BLUE

VIOLET

VIOLET

BROWN

BROWN

ORANGE

ORANGE

WHITE

WHITE

N

L1

L2

BLUE

PINK

PINK

BLUE

BLUE

VIOLET

VIOLET

BROWN

BROWN

WHITE

WHITE

N

L1

L2

9

L3

= CFH90 & CFH120

ORANGE

ORANGE

L3

Page 4

Dimplex Industrial Fan Heater

Models : CFH60, CFH90 & CFH120

IMPORTANT: THESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND RETAINED FOR FUTURE REFERENCE

IMPORTANT SAFETY ADVICE

DO NOT COVER OR OBSTRUCT the air inlet or outlet grille.

ENSURE THE APPLIANCE IS EARTHED.

Always disconnect supply before working on the product.

Do not use this heater in areas where excessive dust

exists.

This heater must not be located immediately above or

below a fixed socket outlet or connection box.

This product should be mounted safely to a solid wall.

Ensure the supply cables are of adequate current carrying

capacity and are protected by a suitable fuse.

This appliance should only be connected to the fixed wiring

of the premises by means of conduit.

This product must not be subjected to water spray or

immersion.

If the appliance is mounted in a toilet or washroom, the

appliance should be mounted such that no part of it can

be touched by a person using a fixed bath or shower.

If the appliance is mounted in a toilet or washroom an

isolating switch must be provided outside the washroom

adjacent to the entrance door.

WARNING: Isolate electrical supply to ALL modular linked

units when carrying out maintenance.

Wall Mounting

Remove the wall mounting bracket from the back of the heater

and using it as a guide (see Fig. 2) mark off the hole positions on

a suitable wall (a minimum height of 2 meters is required from

the floor level to the bottom of the bracket). Solid brick or concrete

block walls must be drilled and plugged. Fix the wall mounting

bracket to the wall and assemble the heater to the extension

tube using a bolt and wing nut fitted into hole 1 shown in Fig. 3a.

Rotate the heater as shown in Fig. 3b, and fix the heater into

position using the remaining bolt and wing nut in hole 2. Pivot

and rotate the heater into the desired position and tighten all

three wing nuts. A 6mm Allen key can be used as an aid to

tightening the bolts.

Electrical and Control connections

Note: The installation of this appliance should be carried out

by a competent electrician and be in accordance with the

current IEE wiring regulations.

All products are fitted with a microprocessor control. Electrical

power and control connections for all CFH models are made by

removing the control housing and bottom panel. The control

housing (‘y’ in Fig. 4) is detached by removing the two quick

release fasteners and hinging the housing as shown (see step

1 in Fig. 4). The bottom panel (‘x’ in Fig. 4) is detached by removing

two screws and lifting off as shown (see steps 2 & 3 in Fig. 4).

Note: A suitable local isolating switch must be provided in the

electrical supply circuit as close as possible to the heater with at

least 3mm clearance on each pole.

General

A range of robust, high power wall mounting fan heaters

designed to coordinate with the Dimplex range of Air Curtains,

providing environmental heating in commercial and light

industrial environments.

The heaters work by gradually raising the air temperature in the

building and should be positioned so as best to achieve an

even temperature distribution.

The product range has outputs of 6kW, 9kW and 12kW, and each

product contains on-board electronics that enables ‘daisy-chain’

linking to an electronic control panel (CFCH) or building energy

management system.

Connectivity between heater and control panel is achieved using

LAN (Local Area Network) cable i.e. CAT5, CAT5E or CAT6, pin

configuration is straight through 1 to 1.

The electronic controller has a number of features including

thermostatic control. For more details on these refer to the CFCH

instruction leaflet.

Model Heat Electrical Electrical Weight Min

Output Supply Load installed

(per phase) height

kW A kg m

220-240V~ 1PN 26.0

CFH60 3 / 6 13 2

380-415V~ 3PN 9.0

220-240V~ 1PN 38.8

CFH90 6 / 9 14 2

380-415V~ 3PN 13.3

220-240V~ 1PN 51.6

CFH120 6 / 12 14 2

380-415V~ 3PN 17.5

Wiring Diagrams - see Fig. 7

A - PCB

B - Mains in terminal blocks

C - Cut-out circuit

D - LAN Sockets

E - Elements

M - Motor

Remove the large knock-out from back panel of heater and feed

appropriate supply cable (see ‘x’ in Fig. 5) to terminal blocks ‘z’.

Make electrical connections as shown in Fig. 7 and fix the cable

in back panel using suitable cable gland (not supplied). By

removing one of the smaller knock-outs and using LAN cable

(see ‘y’ in Fig. 5) make the control connection to the BUS IN

socket ‘w’ also shown in Fig. 5. Fix this cable in the back panel

using a suitable cable gland (not supplied) and feed back to the

electronic control panel (CFCH) using suitable conduit if required.

Refer to CFCH Instructions for installation and connections of

electronic control panel. Replace the bottom panel and control

housing and switch on power to heater and installed electronic

control panel. Ensure that all control settings function correctly.

Note: The factory supplied unit can accept three phase voltage

of ~380-415V. For single phase ~220-240V refer to the electrical

wiring label (see Fig. 8) fixed to the underside of the bottom

panel. To change between different voltage systems, rearrange

the push on connections as per the required wiring diagram.

Page 5

Operation using Control Panel - CFCH

Tel:

+44

(0)191 490 1547

Fax:

+44 (0)191 477 5371

Email:

northernsales@thorneandderrick.co.uk

Website: www.heattracing.co.uk

www.thorneanderrick.co.uk

Maintenance

Switch on electrical supply to the fan heater and the electronic

control panel. When all units are powered up and there is a

connection between the controller and the master unit, an LED

will turn on in the controller to indicate the units are functioning.

Refer to the CFCH instruction leaflet on the operation of the

electronic control panel.

Delayed Shutdown

Door Switch (3min Runback): By wiring in a normally open contact

to the door switch connections shown in Fig. 7, the folowing

operation is achieved:

• Up to 1 minute after contact closed, unit runs at set

condition.

• Between 1 & 2 minutes. unit runs half & half settings.

• Between 2 & 3 minutes. unit runs fan only settings.

• Over 3 minutes. unit enters stand-by mode.

PIR Sensor (45min Runback): By changing the PCB mounted

links shown in Fig. 7 the runback timer will operate as follows:

• Up to 15 minutes after contact closed, unit runs at set

condition.

• Between 15 & 30 minutes. unit runs half & half settings.

• Between 30 & 45 minutes. unit runs fan only settings.

• Over 45 minutes. unit enters stand-by mode.

Modular Linking

A number of fan heaters can be connected together in a ‘daisy

chain’ fashion. A total of ten units can be controlled from a single

electronic control panel. The required connections can be made

in a daisy chain fashion as shown in Fig. 9. (References shown

below).

ECP - Electronic Control Panel

MU - Master Unit

SU - Slave Unit

MLC - Modular Linking Cable

CPC - Control Panel Cable

To make these connections remove one of the small knock-outs

and feed an appropriate LAN cable (not supplied) to the BUS

OUT control socket (‘D’ in Fig. 9) of the Master Unit. Fix this cable

in the back panel using suitable cable gland (not supplied).

Continue this process for all linked heaters. Replace the control

housing of each heater and power up all units. Ensure that all

control settings function correctly.

Thermal Safety Cut-out

The power supply to the heating elements will be interrupted if

one or a combination of the following abnormal events occurs:

1. Air inlet or outlet grilles are obstructed.

2. Internal ventilation is impaired due to build up of dust and

fluff.

3. Blower unit stalls.

Note: Before re-setting the cut-out, the reason for activation must

be determined and corrective action taken.

To reset the thermal safety cut-out, access reset button as shown

in Fig. 6 and push in direction of arrow.

WARNING: Disconnect electrical supply to all connected units

prior to carrying out maintenance.

Optimum performance and long service from this product will

only be realised if regular maintenance is carried out. Dimplex

recommends regular checks dependant on normal use or more

frequent checks where the unit is installed in arduous conditions

or used continually for more than 10 hours per day.

Standard Maintenance

Where the product is subject to use not exceeding 10 hours

per day:

Every 3 months the fan wheels, impellors, heating elements, air

inlet and outlet grilles should be cleaned, removing dust and

debris with a suitable soft brush.

Every 12 months all moving parts should be checked for free

running with appropriate remedy/adjustment made where

necessary.

Extended Maintenance

Where the product is subject to arduous conditions or is used

continually for more than 10 hours per day:

Each month the fan wheels, impellors, heating elements and

air inlet and outlet grilles should be checked and cleaned,

removing dust and debris with a suitable soft brush.

Every 6 months all moving parts should be checked for free

running with appropriate remedy/adjustment made where

necessary.

Recycling

For electrical products sold within the European Community.

At the end of the electrical products useful life it should

not be disposed of with household waste. Please

recycle where facilities exist. Check with your Local

Authority or retailer for recycling advice in your country.

Cleaning

WARNING: DISCONNECT SUPPLY before carrying out

maintenance.

External appearance can be maintained by wiping occasionally

with a damp cloth. For stain removal, a weak soap solution can

be applied with a cloth and the surface wiped dry. Care must be

taken to avoid any moisture ingress into the product.

After Sales Service

Your product is guaranteed for one year from the date of purchase.

Within this period, we undertake to repair or exchange this product

free of charge (excluding element & subject to availability)

provided it has been installed and operated in accordance with

these instructions.

Your rights under this guarantee are additional to your statutory

rights, which in turn are not affected by this guarantee.

Should you require after sales information or assistance with

this product please go to

find our self help guide by clicking on “After Sales” or ring our

helpdesk on 0845 600 5111 (UK) or 01 842 4833 (R.O.I.) .

Spare parts are also available on the website

www.dimplex.co.uk

Please retain your receipt as proof of purchase.

www.dimplex.co.uk where you will

Loading...

Loading...