Page 1

The product complies with the European Safety Standards EN13229 for Room heaters red by solid fuel.

Bellingham 4.7kW Multifuel Inset Stove

For Standard 16” Fireplace Opening

Please hand these instructions to the stove user when installation is complete.

Leave the system ready for operation and instruct the user in the correct use of the

appliance and operation of controls.

Installation should only be carried out by a suitably qualied installer.

Dimplex recommend using an installer who is registered with HETAS (UK) or with INFO

(Republic of Ireland). Installation must comply with all current Building Regulations.

08/52386/0 - Issue 4

25 Nov 2014

Page 2

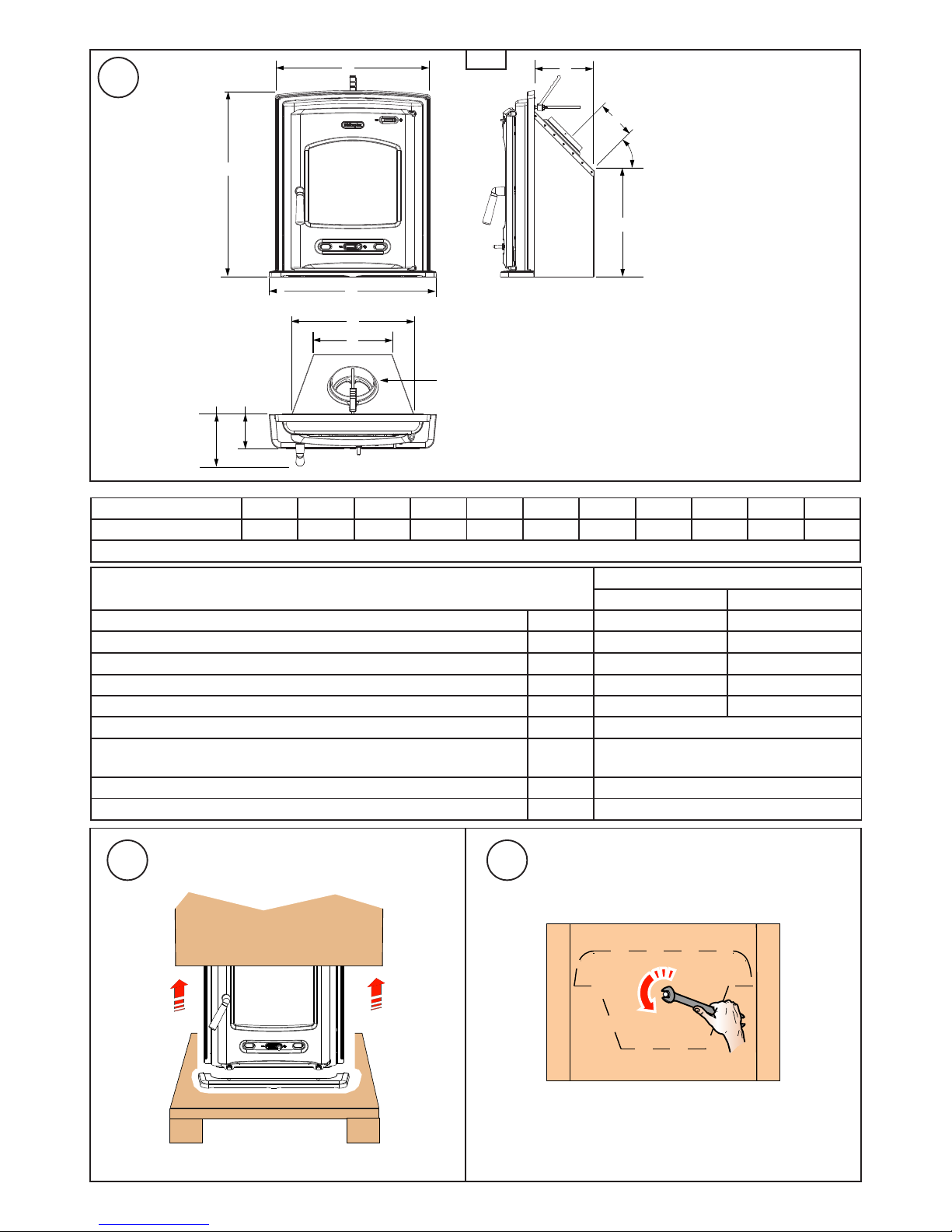

1

2 3

Table 1 - Dimensions A B C D E F G H J K L

Bellingham Inset 4.7kw 600 500 540 250 393 111 167 192 150 340 152

Note: All Dimensions in mm. Dimensions stated may be subject to a slight ± variation. ( 25.4mm = 1”)

Table 2 - Technical Specication

Bellingham Inset BLM4iSE

Wood Solid Fuel

Nominal heat output kW 4.7 4.7

Efciency % 81.8 72.8

CO Emission (@13% O2) % 0.24 0.24

Flue Gas Temp °C 233 258

Flue Gas Mass Flow g/s 3.9 4.4

Refuel Period hr 1

Safe Distance to Combustible Materials mm

Top 350mm

Sides 150mm

Flue Outlet Size mm/inch 152 / 6

Product Weight kg 70

A

B

H

C

F

E

D

G

K

J

L (Dia)

45˚

- 2 -

Page 3

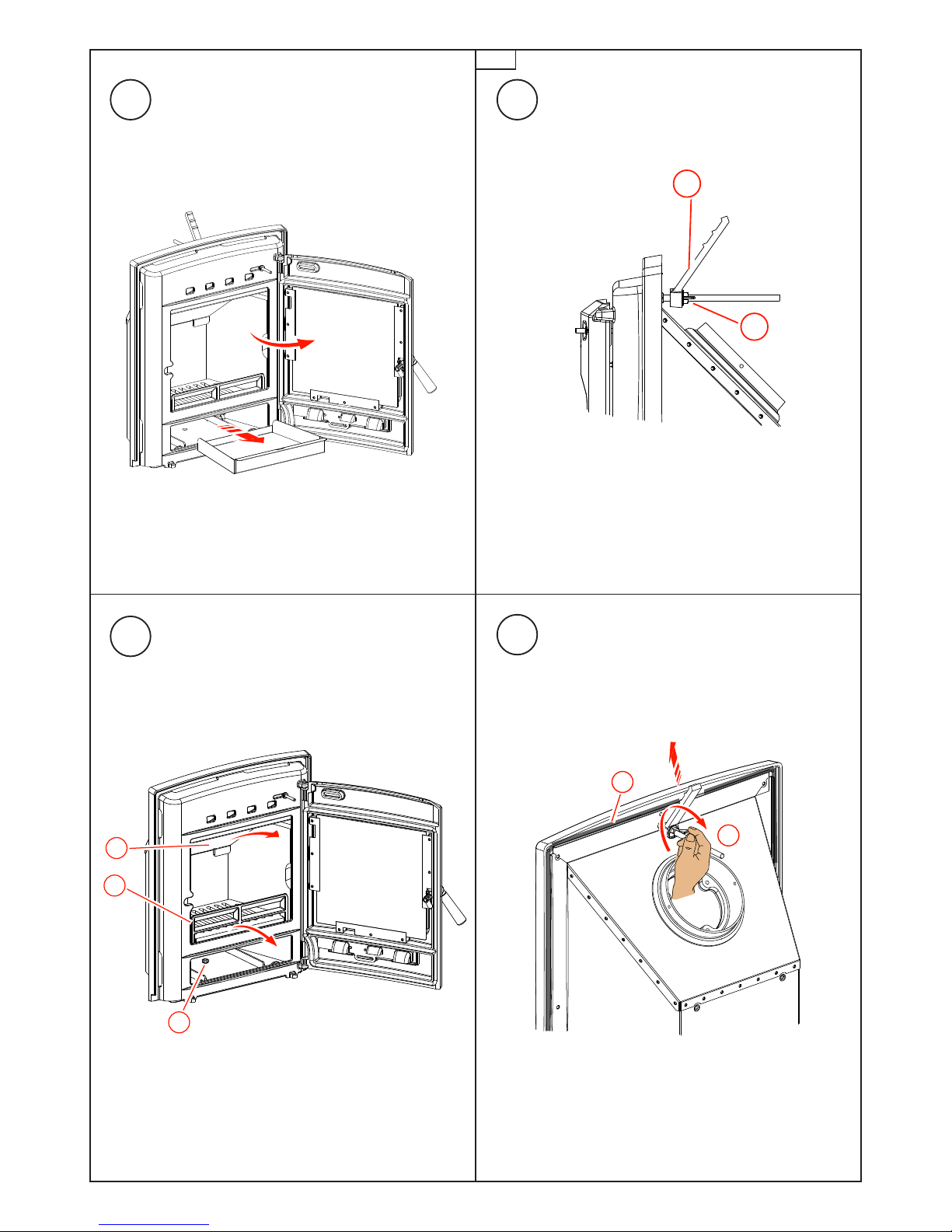

4 5

6

7

- 3 -

1

2

6

7

5

4

3

Page 4

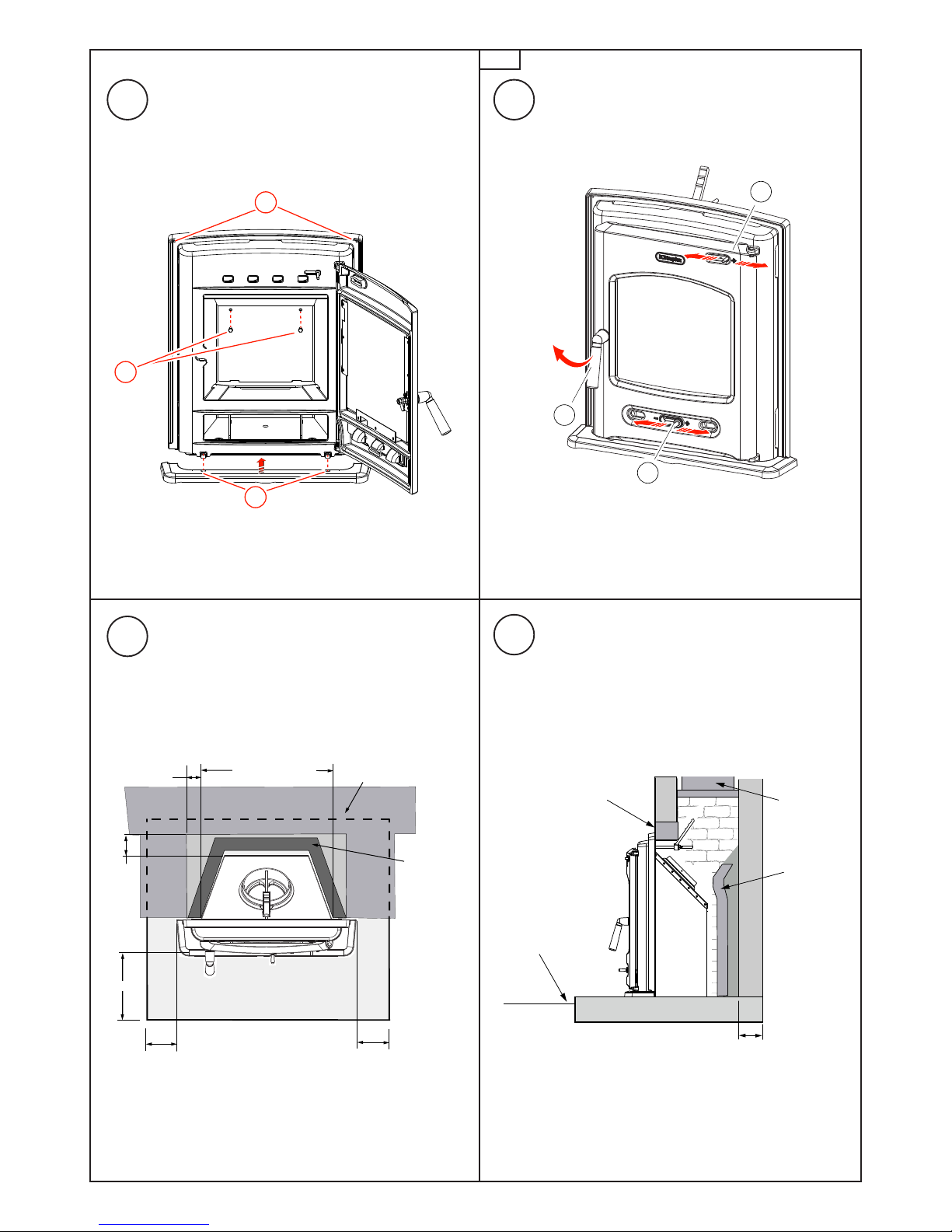

9

8

10

8 9

10

11

- 4 -

Fireback to

BS1251

Lintel or

Gather

Constructional Hearth

min 125mm thick

min 75mm

Change in flooring

level to distinguish

hearth

Clay Flue pipe

Z

CONSTRUCTIONAL HEARTH

NON COMBUSTIBLE

125mm THICK MINIMUM

Z = At least 150mm or to a

suitably heat resistant wall

min 225mm

Z

non combustible wall

min thick Y

fireback and

insulated infill

Fireplace Opening

400mm (16”)

X

X

Typical installation

C

A

B

Page 5

Important Safety Advice

Please read these instructions carefully before installing

or using this appliance. Failure to do so may result in

damage to persons and property.

Installation of this appliance must be carried out by a

suitably qualied competent person in accordance with

all Building Regulations, including those referring to Local

Authority Bye-Laws, National and European Standards

and Codes of Practice.

Do not install this appliance on a shared ue.

Do not t an extractor fan in the same room as this

appliance.

Ensure that there is adequate ventilation in the room in

accordance with building standards. Do not obstruct any

of the air inlets or outlets on the appliance.

A ue damper should not be tted when burning solid

fuels other than wood.

This appliance operates at very high temperatures and

retains its heat for a period after use. Do not touch any

surfaces while in use. All persons including children and

the inrm should be warned of this and not allowed to

touch any surfaces while in use. Please use a suitable

reguard to prevent contact when in use.

Do not place any photographs, paintings, TV’s or other

combustible items near the appliance as exposure to

hot surfaces will cause damage. Maintain safe distances

from combustible materials in accordance with these

instructions.

The operator must use the tools provided. The glove

provided is a tool.

This appliance is for domestic heating use only in

accordance with these operating instructions. Do not

make any unauthorised changes to the appliance.

Do not burn petroleum coke fuels, bituminous (smokey)

coal,household waste or plastic in this appliance.

Burn only fuels with a low moisture content, such as

smokeless fuel or properly seasoned wood. Burning soft

or wet fuels such as unseasoned timber or peat will only

result in a build up of tar in the stove and the chimney

and will cause staining of the glass.

Do not use ammable liquids to ignite the re.

Avoid the use of aerosols in the vicinity of the stove when

it is in operation.

Clean your chimney at least twice a year and check the

bafe plate monthly to ensure there are no blockages. Do

not allow a build up of ash to occur in the ash pan as this

will cause the grate to burn out prematurely.

Regular maintenance should be carried out by a suitably

qualied engineer.

IMPORTANT: THESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND RETAINED FOR FUTURE REFERENCE

Health and Safety Precautions

Handling: This product is heavy and should be handled with care

to avoid the possibility of personal injury when moving or servicing.

Adequate facilities must be available for the unloading and handling

of this appliance. Use protective clothing.

Fire Cement/Glue: Some types of re cement/glue are caustic

and should not be allowed to come into contact with the skin. Use

suitable protective gloves when handling. In case of contact, wash

immediately with plenty of water.

Asbestos: This appliance contains no asbestos. If there is a

possibility of disturbing asbestos as a result of installation then

specialist guidance must be sought prior to installing.

Please Note: Any white deposits on the stove joints are caused

by humidity reacting with the joint sealant. These deposits are

not cause for alarm and may be brushed off using a soft cloth.

If required the joints may be blackened again with a proprietary

stove polish.

Installation Instructions

General

These instructions give a guide for the installation of the stove but

in no way absolves the installer from responsibilities to conform

to all relevant standards relating to the installation of solid fuel

appliances.

This stove is designed to be recessed in a standard 16” sized

replace opening. The stove is only suitable for use on a replace

and chimney that has been tted for use with solid fuel. The

replace backpanel and hearth must have the necessary expansion

joints and the backlling suitable for solid fuel use.

We recommend that for UK installations a HETAS registered

installer should be used, who will be able to give a Certicate of

Compliance that installation complies with Building Regulations.

In Ireland a registered installer from the Irish Nationwide Fireplace

Organisation should be used.

Please note that to the best of our abilities these instructions are

correct at time of printing, however we cannot be held responsible

for any differences in legislation which may occur in the future.

Assembly of the stove

1. Unscrew the wooden crate and lift off the upper box (Fig 2).

2. The stove is bolted to the crate through the base of the stove

to prevent damage during transportation. Unscrew the xing

bolt (Fig 3) to release the crate before installing the stove.

Unscrew the fascia plinth and set aside for xing later.

3. Remove the plastic bag, To make the product easier for

handling on installation, open the stove door and remove

the liner bricks, bafe plate, grate bars and ashpan (Fig 4).

Place these in a secure place to avoid damage. These must

be retted after installation.

4. Unscrew the wingnut to loosen the clamp on the xing bar.

(1 & 2, Fig 5).

5. Place the inset stove into position in the replace and mark

the intended position of the xing screw through the hole in

the bottom of the appliance (5, Fig 6). Remove the stove

and drill a hole then insert a M8 expanding wall rawl bolt to

secure base in position. Re-position the stove and screw into

place. The xing hole should then be sealed with re cement

to avoid air leakage.

6. Create a seal with the fascia of the replace making sure

the rope seal (6, Fig 7) on the back of the stove comes into

Bellingham 4.7kW Multifuel Inset Stove (BLM4iSE)

- 5 -

Page 6

- 6 -

contact with the fascia. Place hand through the stove collar

and tighten the wingnut on the clamping bar (7, Fig 7). The

clamp creates pressure when it contacts the chimney/lintel.

The stove should be tightly sealed to the replace fascia.

7. If required the stove may be secured directly to the fascia

using the xing screw holes (8, Fig 9). Alternatively as a last

resort xing option, the stove may be screwed through the

appliance and directly into the reback. To do this remove the

wrap xing bolts (9, Fig 9) and bolt directly into the reback

using stainless steel M5 expanding wall bolts. In all cases,

only high temperature metal wall xings may be used and all

xings through the appliance must be made air tight so there

is no smoke leakage.

8. Position the fascia plinth in front of the appliance lining up

the screw holes with the xing bosses and screw in position

using the 2 x M6 countersunk screws provided (10, Fig 8).

Chimney & Flue Connections

Before installing, check that the chimney is in good condition; dry

and free from cracks and obstructions. The diameter of the chimney

ue or any joiner sections should not be less than 150mm and not

more than 230mm. If these requirements are not met, the chimney

should be relined by a suitable method by a qualied person.

The chimney height and the position of the chimney terminal should

conform to Building Regulations. If you have any doubts about the

suitability of your chimney, consult your local dealer or stockist.

The chimney must be swept thoroughly before connection to the

stove and swept every six months thereafter.

If there is no existing chimney then a prefabricated block chimney

or a twin walled insulated stainless steel ue to BS4543 can be

used. These must be tted in accordance with the manufacturers

instructions and in compliance with Building Regulations.

If using a joiner ue, connect the ue pipe to the stove making sure

that it ts snugly into the base of the ue collar . Seal the collar

and ue connection with re cement or with other suitable high

temperature sealant. Add ue sections as required; note that all

ue sockets must face upwards. Ensure that the ue pipe end is

no closer than 76mm to the side or rear of the chimney walls. It is

essential that all connections between the stove and the chimney

ue are sealed and made airtight.

This product must not be installed on a shared ue.

Flue Deposits

If the chimney was previously used as an open re, it is possible

that the higher ue gas temperatures generated by the stove may

loosen deposits that were previously adhered to the inner surface

of the ue pipe which could cause a blockage. We recommend

that in this situation a second sweeping of the chimney should be

carried out within one month of initial stove use after installation.

Floor Protection & Installation Clearances

In all instances the stove must be positioned on a non-combustible

hearth that conforms to Building Regulations and is rm, secure

and capable of supporting the stove. Care should be taken to

ensure the stove is level.

Building Regulations require that a solid constructional hearth of

minimum 125mm must be used, including the thickness of the oor

and any decorative top surface (e.g. tiling). The Constructional

hearth must extend minimum 225mm in front of the appliance

and at least 150mm from either side and the rear of the appliance.

(Fig 10).

All walls adjacent to the hearth should be made from solid non

combustible material with minimum thickness as per table 3:

Table 3

Stove distance X

from wall

Min Wall

Thickness Y

Min solid wall height

300mm above the

appliance and 1.2m

above the hearth

less than 50mm 200mm

50mm and over 75mm

Table 4 shows the minimum safe distances to combustable

materials which must be observed in all installations. Any

surrounding combustible material should not exceed 80°C.

Table 4 Top Sides

Bellingham Inset 4.7kW 350mm 150mm

Room Ventilation

For safe operation this stove must be provided with permanently

open combustion air supply in addition to normal room ventilation,

in accordance with Building Regulations. Minimum ventilation

requirements vary by country and whether the dwelling is

considered to be of standard construction or of airtight construction,

or if a ue draught stabiliser has been tted. The required open air

vent sizes are as follows:

Table 5 - Additional Room Ventilation Required

Construction Flue UK Ireland

Standard build

{air permeability

>5.0m³ /(h.m²)}

No Flue Stabiliser None 65 cm²

With Flue Stabiliser 14 cm² 65 cm²

Airtight build

{air permeability

≤5.0m³ /(h.m²)}

No Flue Stabiliser 26 cm² 65 cm²

With Flue Stabiliser 40 cm² 79 cm²

Note: It is unlikely that dwellings built prior to 2008 would have

an air permeability of less than 5m3/(hr.m2), at 50 Pa unless

extensive airtightness measures have been carried out. If in

doubt assume value ≤5.0m³ /(h.m²) or seek specialist advise.

Flue Draught

The chimney should be checked before the stove is installed to

ensure that there is adequate ue pull. The draught can be checked

initially by using a smoke match close to the ue opening. If the

chimney doesn’t pull the smoke it may suggest that the chimney

needs further attention. Any remedial work to the chimney ue

should be carried out by a suitably qualied engineer.

A ue draught of minimum 12 Pascal to maximum 25 Pascal is

required for satisfactory appliance performance. The ue draught

should be checked under re at high output and if it exceeds the

recommended maximum a ue draught stabiliser (or ue damper

as it is also known) must be tted so the rate of burning can be

controlled and prevent overring.

An extractor fan must not be used in the same room as this

appliance.

Flue Damper (Not Supplied)

When burning wood, a ue damper may be tted to reduce the

draught through the stove if the draught is too high. When the

damper is set in the open position the chimney draws at full draught,

increasing the volume of air ow through the stove and ue.

Shutting the damper restricts the ow, slowing the rate of burning.

The damper should be tted to the stove ue and should be the

same size as the ue pipe. As a rule it should be tted no closer

than 700mm from the ue outlet of the appliance.

A ue damper should not be tted when burning solid fuels

other than wood.

Page 7

- 7 -

Commissioning

Upon completion of installation, the stove and ue system should

be tested by a suitably qualied person to make sure it is safe for

normal use. A smoke draw test should be completed to check for

soundness of joints and seals and also that all smoke and fumes

are taken from the appliance up the chimney and emitted safely.

First warm the ue with a blowlamp or similar for about 10 minutes.

Place a lit smoke pellet on the centre of the grate with the air

controls open. Close the door – the smoke should be drawn up the

ue and be seen to exit from the ue terminal. Complete the test

with all windows and doors shut in the room where the appliance

is tted.

If a ceiling fan is present it must be operated on max for the duration

of the test. If there are any extraction fans in adjacent rooms these

too must be operated on maximum setting during the test with the

interconnecting doors open. If any spillage occurs, recheck the

suitability of the ue system making sure there is adequate air

supply to the room (as per Building Regulations).

Light the appliance and slowly increase the temperature to

operating levels. Open the main re door when the appliance

reaches normal operating condition and carry out a spillage test

using a smoke match or pellet around the door opening. If any

spillage occurs, open all windows, allow the re to go out and

recheck the ue system and ventilation.

Operating Instructions

Please read fully these operating instructions and advise any

other users of the correct operating procedures for this stove.

Warning: This appliance and its operating handles become

hot when the stove is in use and the stove will remain hot for

some time afterwards. For your safety use the glove provided.

Initial Firing of Stove

We recommend that you have 3-4 small res before you operate

your stove to maximum heat output. This is to allow the paint to cure

and the castings to relax and consolidate location. We recommend

this ‘running in’ procedure after long idle periods to preserve the

life of the stove. During this you may notice an unpleasant smell

as paint and re cement cures. It is not toxic but for your own sake

we would suggest that during this period you leave all doors and

windows open.

Air Controls

Primary air is controlled via the sliding vent (Fig 9 A) in the bottom

of the door; this provides a conventional air draught to the bed of

the re. Moving the slider to the right increases the air intake, to

the left reduces the air intake.

Secondary air is controlled via the sliding vent (Fig 9 B) above the

door. It is this ‘Airwash’ that keeps a clean and uninterrupted view

of the re, also aiding in good secondary combustion of fuel and

reducing emissions into the chimney and environment.

Lighting the Stove

Place re lighters or paper and 5-6 pieces of dry kindling on the

grate. Light the re at base and allow the kindling to light fully

across the grate. Build the re up gradually using small rells of

fuel until there is a good re bed and the re is well established.

When refuelling with wood, leave both air controls in the fully open

position to the right for 1-2 minutes until the new fuel is burning

brightly. Once the fuel is fully alight and ames are well established,

the primary air (undergrate air) should be closed fully and the

airwash reduced to adjust the stove to the desired heat output.

If refuelling with solid fuel then the airwash should be closed

and the primary air slide should be fully open until the fuel is well

alight. Once the fuel is well alight the primary air may be adjusted

to control the re to the desired heat setting.

Do not operate the stove with both air supplies open for

extended periods, as this will result in overring, causing

excessive running temperatures and premature burnout of

components.

Running the Stove

When your fuel is well alight you can start to restrict the air intake to

the desired setting. Your stove is burning with maximum efciency

when a bright re is achieved using minimum air inlet.

Never leave the stove unattended until the fuel is burning well and

the air supply has been adjusted down to desired level.

Note that refuelling onto a low rebed causes excessive smoke

to occur. Refuelling must be carried out onto a sufcient quantity

of glowing embers to ignite fuel in a reasonable period. If there

are too few embers add kindling rst to get re going again before

refuelling. The stove is not suitable for overnight burning.

For optimum performance the stove should not be overlled with

fuel above the height of the rear brick. To do so can cause poor

operation, excessive smoke to occur and possible damage to bafe

plate. The stove must not be operated with the door left open.

This stove is capable of intermittent operation.

Notes on Wood Burning

Burn only dry, well seasoned wood (< 20% moisture), which should

have been cut, split and stacked for a minimum of 12 months (24

months is better) with free air movement around all sides of the

stack to enable it to dry out. Burning wet or unseasoned wood will

create tar deposits in the stove and chimney and will not produce

a satisfactory heat output. When loading wood, make sure that the

end grain of the wood in the stove is pointing away from the glass

otherwise the moisture and gases coming from the end grain of

the wood will dirty the glass.

Table 6 - Maximum log lengths

Bellingham Inset 4.7kW 230mm (9”)

Notes on Solid Fuel burning (Other than Wood)

Always de-ash the stove before burning solid fuel and do not let the

ash build up to the underside of the grate bars. Solid fuel produces

ash, which if allowed to build up it will stie the air ow through the

grate and will eventually cause the re to die. Air passing through

the rebed cools the grate. Distortion or burning out of the grate

bars is nearly always caused by ash being allowed to build up

on the underside of the grate. With some solid fuels a residue of

burnt fuel or clinker will accumulate on the grate. It is important to

empty the ash pan and remove clinker after each ring of the stove.

We recommend the use of HETAS approved manufactured

smokeless fuels. Note that different types of fuel will give different

performances. Using the stove as an incinerator for household

waste invalidates the warranty is not recommended as fumes from

plastic, etc will cause pollution to the atmosphere and will cause

damage to the stove.

Petroleum coke fuels, bituminous (smokey) coal or household

waste should not be burned in this appliance.

Shutting Down

To shut down the stove, close the primary air controls and then

the secondary air controls by moving both sliders to the left. If the

controls are left in this position the re will be starved of air and will

go out. To revive the re if it has not already extinguished, open

the primary air controls rst, then the secondary air.

Page 8

- 8 -

De-Ashing

This insert stove is tted with a removable log bar and grate. It

is important to de-ash the stove regularly to prevent ash build up

which may impede the primary air input.

Where possible, it is best to wait until the stove and ash has cooled

fully before removing the ash pan. To remove, open the stove door

by turning the handle anti-clockwise (Fig 9 C) then using the hand

tool provided lift the ash pan out of the re (Fig 4). For efcient

burning, make sure the grate is clear of unburnt debris; e.g. nails,

etc. Dispose of the ash into a non combustible container until the

ash has cooled down completely to room temperature.

If shutting down the stove for long periods (e.g. for summer months)

make sure that all ash is removed from the stove and that the

chimney ue ways and bafe plate are brushed clean. When the

stove is cold a vacuum cleaner may be used to remove any residual

ash or soot. Close the door and leave all air inlets open fully. This

action will ensure air circulation through the appliance and will help

to avoid corrosion and condensation within the appliance during

this shut down period.

Safety Notes for Your Guidance

FIRES CAN BE DANGEROUS.

Always use a re guard in the presence of children, the elderly

or the inrm. Inform all persons the dangers of high temperatures

during operation of the appliance including the stove pipe.

Use operating tools provided.

DO NOT OVER FIRE.

It is possible to re the stove beyond its design capacity. This could

damage the stove, so watch for signs of over ring. If any part of

the stove starts to glow red, the stove is in an over re situation

and the controls should be adjusted accordingly to reduce air

intake. Never leave the stove unattended for long periods without

adjusting the controls to a safe setting. Careful air supply control

should be exercised at all times.

Warning - Fume Emissions

Properly installed and operated, this appliance will not emit fumes.

Occasional fumes from de-ashing and refuelling may occur.

Persistent fume emission must not be tolerated. If fume emission

does persist, then the following immediate action must be taken:

1. Open doors and windows to ventilate the room.

2. Let the re out, or eject and safely dispose of fuel from the

appliance.

3. When the stove has cooled, check for chimney ue blockage

and clean if required.

4. Do not attempt to relight the re until the cause has been

identied. If necessary seek professional advice.

General Maintenance

Bafe Plate: This should be removed at least once a month to

prevent any build up of soot or ash, which could lead to blocked

ue ways and dangerous fume emission. This must be done when

the stove is cold. To remove, lift plate up and rotate to clear xings.

Make sure the plate is returned to correct position when placed

back in the stove.

Stove Body: The stove is nished with a heat resistant paint and

this can be cleaned with a soft brush. Do not clean while the stove

is hot, wait until it has cooled down. The nish can be renovated

with a suitable brand of stove paint.

Glass Panels: Clean the glass panels when cool with a proprietary

glass cleaner or some damp newspaper. Do not use abrasive

materials as these can scratch the glass and make subsequent

cleaning more difcult. Wet logs on heated glass, a badly aimed

poker or heavy slamming of the doors could crack the glass panel.

The glass should not fracture from heat.

Chimney: Check your chimney each year before starting to use

your stove for the winter. Birds may have nested in the chimney

or masonry may have cracked. Both chimney and ue pipe must

be swept at least once a year by a Qualied Chimney Sweep.

Troubleshooting

1. Poor heat output

a. Stove too small for room: Seek advice from a Qualied Heating

Engineer as to (kW) output required for the room size. As a

guideline the volume of the room in cubic feet divided by 500;

e.g. room 15’x15’x8’ would require 3.6kW approx.

b. Chimney and/or ue pipe restricted, room ventilation restricted:

On installation these should have been checked but regular

maintenance is necessary as conditions can change; e.g. soot

build up, birds nesting, masonry fall, dust build up or furniture

blocking vents.

c. Poor quality fuel: Only burn dry seasoned timber, soft woods

have a lower heat output than hard woods per hour. Solid

fuels vary in heat value; check with your coal merchant as to

suitability.

2. Dirty Glass Panel

a. Generally caused by poor fuel quality, damp fuel or burning

wood that has not been properly seasoned.

b. Airslide not in correct position for the fuel type, e.g. on solid fuel

setting when burning wood.

c. Fire burning too low, open air vents on stove to create hot re;

this may ‘burn’ glass clean.

d. If glass requires cleaning use glass cleaner recommended by

your supplier; only use glass cleaner on cold glass. DO NOT

USE any abrasives or scrapers as these will scratch glass and

increase future tar build up making it harder to clean.

3. Unburnt Fuel in Firebox

Insufcient air reaching fuel causing it to go out. Open the air

slide, this will supply combustion air to burn fuel fully (unless it

has insufcient heat to ignite or has already extinguished). Check

if the ash pan is full and empty if required. De-ash to make sure

the grate is not blocked and check for jammed clinker or nails

when the re is out and the stove has cooled. A small amount of

unburnt clinker is normal after the re has extinguished and the

amount left is dependent on fuel type.

4. Smoke and Fumes Entering Room

These are very dangerous and must NOT be tolerated. Open

window and allow re to burn out. Seek expert advice immediately.

DO NOT USE stove until the problem is solved.

5. Chimney Fire

Identied by loud roaring sounds, dense smoke and sparks emitting

from chimney. Shut down the air supply by closing air vents, close

stove door fully and call re brigade immediately.

Chimneys must be swept at least once anually, more frequently if

smokey fuels are used. Regular chimney maintenance will prevent

chimney res. Seek advice from a Qualied Chimney Sweep.

Page 9

- 9 -

The Clean Air Act 1993 and Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole

or part of the district of the authority to be a smoke control area. It

is an offence to emit smoke from a chimney of a building, from a

furnace or from any xed boiler if located in a designated smoke

control area. It is also an offence to acquire an “unauthorised fuel”

for use within a smoke control area unless it is used in an “exempt”

appliance (“exempted” from the controls which generally apply in

the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs

has powers under the Act to authorise smokeless fuels or

exempt appliances for use in smoke control areas in England. In

Scotland and Wales this power rests with Ministers in the devolved

administrations for those countries. Separate legislation, the Clean

Air (Northern Ireland) Order 1981, applies in Northern Ireland.

Therefore it is a requirement that fuels burnt or obtained for use

in smoke control areas have been “authorised” in Regulations

and that appliances used to burn solid fuel in those areas (other

than “authorised” fuels) have been exempted by an Order made

and signed by the Secretary of State or Minister in the devolved

administrations.

The Bellingham Inset 4.7kW stove has been recommended as

suitable for use in smoke control areas when burning wood and

manufactured smoke less fuels. The air control has been set to

ensure a minimum burn rate for clean burning during operation.

Further information on the requirements of the Clean Air Act can

be found here : http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean

Air Act 1993 including designation and supervision of smoke

control areas and you can contact them for details of Clean Air

Act requirements.

After Sales Service

As a sign of our commitment to quality, all new Dimplex solid

fuel stoves are guaranteed against casting faults and other

manufacturing defects for 10 years in the case of non-boiler

stoves and 5 years in the case of boiler models, subject to certain

conditions and exclusions. The guarantee covers the main body

of the stove and external cast parts under normal domestic use

- it does not cover use in commercial premises. The guarantee

period begins on the date of purchase. The guarantee covers

replacement of the parts found to be defective but does not cover

labour charges.

Conditions and Exclusions:

The guarantee does not cover the following items which are

deemed to be consumable items under normal use: glass, rope

seals, grate, ashpan, cast iron liners, riddling lever, bafe plate,

re bricks and log retainer.

It is a condition of the guarantee that the installation complies

with relevant Building Regulations and is carried out by a suitably

qualied individual (HETAS registered in England and Wales, or

equivalent in other countries) with certicate of installation and

appropriate commissioning retained by the end-user along with

proof of purchase.

Whilst the guarantee does not cover any aspect of the flue

arrangements for the installation, or the installation work itself, as

these are beyond the control of Dimplex as the manufacturer of

the stove, it is a condition of the guarantee that the ue be swept

by a suitably qualied individual as appropriate but at a minimum

interval of once per year. It is expected that the stove would be

inspected for developing faults at the time of sweeping to allow

any necessary maintenance to be carried out.

Damage or defects caused by the following are excluded: overfiring, use of inappropriate fuels such as petroleum coke or

household rubbish, ue draft problems, ventilation issues, accident,

misuse, fair wear and tear, unauthorised modications or repairs

made using incorrect spares.

In normal usage the paint nish of the stove may change colour

slightly or lighten in shade over time. This is considered normal and

is not covered by the guarantee. Damage caused by over-ring is

excluded from the guarantee.

It is a condition of the guarantee that only genuine Dimplex spare

parts are used. Parts that may need occasional replacement are

re bricks, ashpan, grate and log retainer. NB: sealing rope and

rope adhesive are generic stove spares that can be purchased

from most stove retailers. Provided the rope seals are replaced

like for like and xed with appropriate stove rope adhesive, this

will not invalidate the guarantee.

Genuine Dimplex spare parts are available in the UK direct from

the manufacturer and can be ordered via www.dimplex.co.uk or

by telephone on 0844 879 3588. For Republic of Ireland orders

see www.dimpco.ie or Tel: 01 842 8222

Dimplex reserves the right to provide either replacement parts or

a replacement stove, at their sole discretion, in order to satisfy

claims made under this guarantee.

Replacement parts or stoves are covered only for the remainder

of the original guarantee period.

Dimplex will not be held responsible for any consequential or

incidental loss, damage or injury, howsoever caused.

The Dimplex stove guarantee does not affect, and is in addition

to, your statutory rights.

Should you require after sales service or should you need to

purchase any spares, please contact the retailer from whom the

appliance was purchased. Please do not return a faulty product

to us in the rst instance as this may result in loss or damage and

delay in providing you with a satisfactory service. Please retain

your receipt as proof of purchase.

Page 10

- 10 -

Page 11

8

6

5 4

19 17

23

10

7

24

12

20

11 9

3 2

22

1 13

18

21

15

14

16

BELLINGHAM 4.7KW INSET STOVE (BLM4iSE) - SPARE PARTS

Item Description Part Number Item Description Part Number

1 HAND TOOL 1/70186/0 13 GRATE 1/70645/0

2 FASCIA 1/70628/0 14 REAR BRICK 1/70646/0

3 FASCIA BASE 1/70629/0 15 SIDE BRICK 1/70647/0

4 AIRWASH 1/70630/0 16 BAFFLE PLATE 1/70648/0

5 AIRWASH SLIDE 1/70631/0 17 FLUE COLLAR 1/70649/0

6 AIRWASH HANDLE 1/70632/0 18 ASHPAN 1/70651/0

7 DOOR 1/70633/0 19 CLAMP 1/70653/0

8 GLASS 1/70634/0 20 PRIMARY SLIDE HANDLE 1/70818/0

9 GLASS FIXING BRACKET 1/70635/0 21 LOG BAR 1/70819/0

10 DOOR PIN 1/70636/0 22 PROTECTIVE GLOVE 1/71118/0

11 PRIMARY AIR SLIDE 1/70637/0 23 OUTER WRAP ASSEMBLY 2/61996/0

12 HANDLE CATCH 1/70639/0 24 HANDLE ASSEMBLY 4/19204/0

Bellingham 4.7kW Inset (BLM4iSE)

- 11 -

Page 12

[c]A Division of GDC Group Ltd.

All rights reserved. Material contained in this publication may not be reproduced in whole or in part, without prior permission in writing

of GDC Group Ltd.

Great Britain:

GDC Group Ltd

Millbrook House

Grange Drive

Hedge End

Southampton

SO30 2DF

t +44 (0)844 879 3588

f +44 (0)1489 773050

e aftersales@dimplex.co.uk

w www.dimplex.co.uk

Northern Ireland:

Glen Dimplex Northern Ireland

5 Charlestown Avenue

Charlestown Industrial Estate

Craigavon

Co. Armagh

BT63 5ZF

t +44 (0) 2838 337 317

f +44 (0) 2838 350 208

e info@glendimplexni.co.uk

w www.glendimplexni.co.uk

Republic of Ireland:

Dimpco Ltd

Old Airport Road

Cloghran

Co Dublin

Ireland

t +353 (0) 1842 8222

f +353 (0) 1842 4943

e sales@dimpco.ie

w www.dimpco.ie

Loading...

Loading...