Page 1

INSTALLATION AND SERVICING INSTRUCTIONS

BE GIVEN TO THE USER

TO

Ref. : 1871184 - 0106157

Cast iron installed

electric boiler

Made in France

Model MA

• Electronic regulation

• 1 heating circuit

Model : ASCMA 12

Informations given in this manual are not contractuals, may therefore change technical caractéristics or components without notice

Ascari - 12kW -page 1 -

Page 2

CONTENTS

1 - Generalities............................................................................................................... p. 04

1.1 - Introduction ................................................................................................................................. p. 03

1.2 - Important information................................................................................................................... p. 03

1.3 - Description.................................................................................................................................. p. 04

1.4 - Dimensions - Hydraulic Connections........................................................................................... p. 06

1.5 - Datas.......................................................................................................................................... p. 07

2 - Installation ................................................................................................................. p. 08

2.1 - Location...................................................................................................................................... p. 08

2.2 - Fitting the boiler .......................................................................................................................... p. 08

2.3 - Hydraulic connections................................................................................................................. p. 09

2.4 - Mixing valve ................................................................................................................................ p. 09

2.5 - Expansion vessel - Pressure safety relief .................................................................................... p. 09

2.6 - Frost protection........................................................................................................................... p. 09

2.7 - Bleeding...................................................................................................................................... p. 09

2.8 - Plumbing .................................................................................................................................... p. 10

2.9 - Filling loop .................................................................................................................................. p. 10

3 - Electric connections .................................................................................................. p. 11

3.1 - Electric flow rate, number and cross-section of power connectors,

fuse protection ............................................................................................................................ p. 12

3.2 - Power terminal ............................................................................................................................ p. 14

3.3 - Connection to mains depending on power supply ........................................................................ p. 15

3.4 - Regulation circuit ........................................................................................................................ p. 16

3.5 - Control accessories wiring .......................................................................................................... p. 17

3.6 - Wiring diagrams.......................................................................................................................... p. 18

3.7 - Heating elements connections .................................................................................................... p. 20

4 - Basic hydraulic patterns............................................................................................. p. 21

4.1 - Direct heating circuit ................................................................................................................... p. 21

5 - 3 speed water pump.................................................................................................. p. 22

6 - Electronic 2 circuits regulation ................................................................................... p. 23

6.1 - Généralities ................................................................................................................................ p. 23

6.2 - Control command pannel ............................................................................................................ p. 24

6.3 - Setting the regulation .................................................................................................................. p. 25

6.4 - Operating .................................................................................................................................... p. 27

6.5 - Counters ..................................................................................................................................... p. 29

6.6 - Failures display........................................................................................................................... p. 29

7 - Heating diagram........................................................................................................ p. 31

7.1 - Underfloor heating ....................................................................................................................... p. 31

7.2 - Radiators .................................................................................................................................... p. 31

7.3 - Specific heating diagram ............................................................................................................. p. 32

8 - Maintenance.............................................................................................................. p. 33

9 - Troubleshooting......................................................................................................... p. 33

Spare p arts ............................................................................................................... p. 34

Ascari - 12kW -page 2 -

Page 3

1 - GENERALITIES

Features

• Selectable Water Temperature

- radiators / Underfloor (21-80°C)

• 60°C or 100°C thermal cut-out suitable for underfloor heating or radiators

• Room thermostat operation

• Frost protection, 5°C minimum temperature

• Pump protection -once a day operation when system is off

• Pump overrun facility

• 4-stage stepped turn on/off

• Weekly alternative switch start-up for prolonged life

• Automatic water temperature variation for 50% on-off cycles (with room thermostat)

• Switch operation counter -monitors switch usage

• System pressure display

Water heating

It is recommended that the boiler be used for central heating purposes only and hot water be stored and

heated by a direct electric hot water cylinder. This allows hot water to be heated over night on an off-peak

tariff and reduces heat losses between the boiler and the cylinder.

1.1 - Introduction

The Dimplex Ascari boiler is an all electric domestic central heating boiler suitable for use on a 230V 52A

50Hz supply. The unit is easy to install and requires no flue, making it ideal for apartments or properties in

conversation areas.

The unit is supplied ready for operation as a 12kW 230V sigle phase boiler and will automatically modulate

down to 10, 8 and 6kW. The maximum output power may also be manually limited to operation at maximum

power levels of 10, 8, 6 or 4kW upon which the boiler will proportionnaly modulate to lower power levels.

Finished in a clean white case and with dimensions of 620mm height x 405mm width, the boiler is suitable for

installation in a kitchen area. With thermal cut out selectable at 60°C or 100°C the boiler is suitable for

standard wet radiators systems or underfloor heating.

There are no ventilation requirements associated with the operation of this boiler , however to maintain a dry

atmosphere a well ventilated room is recommended.

1.2 - Important information

• The information given in this booklet is a guide only. All installations must follow the current regulations for

this type of device and where no information or conflicting information is given in this guide to that of the

current regulations, the current regulations will apply .

• Disconnect the Electricity Supply before attempting to remove the cover of the boiler .

• The boiler weighs 38kg and requires two persons to lift and install the product. Please ensure all mounting

fixings and the wall onto which it is to be installaed are sufficiently strong to take the weight of the unit plus

its water contents.

Ascari - 12kW -page 3 -

Page 4

• The heating system must be installed by a competent person and to current regulations in force at the time.

• All wiring should conform to the regulations in force at the time. The appliance is approved to a protection

rating of IPX1. Therefore if the appliance is to be installed in a room containing a bath or a shower, any

electrical switch or control utilising mains electricity must be so situated that it cannot be touched by a

person using the bath or shower. Attention is drawn to the requirements of the current BS 7671 (I.E.E.

Wiring Regulations) and in Scotland the electrical provisions of the Building Regulations applicable in Scotland.

• Complete all plumbing work before connecting ther boiler to the electricity supply.

• this appliance must be earthed !

• The boiler should be permanently connected to the electricity supply , direct from a 63A fused supply on the

consumer unit via a double pole linked switch with minimum contact gap of 3mm. No other appliances

should be powered from this supply .

• The expansion vessel is pre-charged to 1 bar (0.1MPa). During the installation process and before operating

the boiler this should be checked using a suitable pressure gauge.

• A 3 bar (0.3MPa) pressure relief device is incorporated within the product, the cold system pressure should

not exceed 1.5bar (0.15MPa).

1.3 - Description

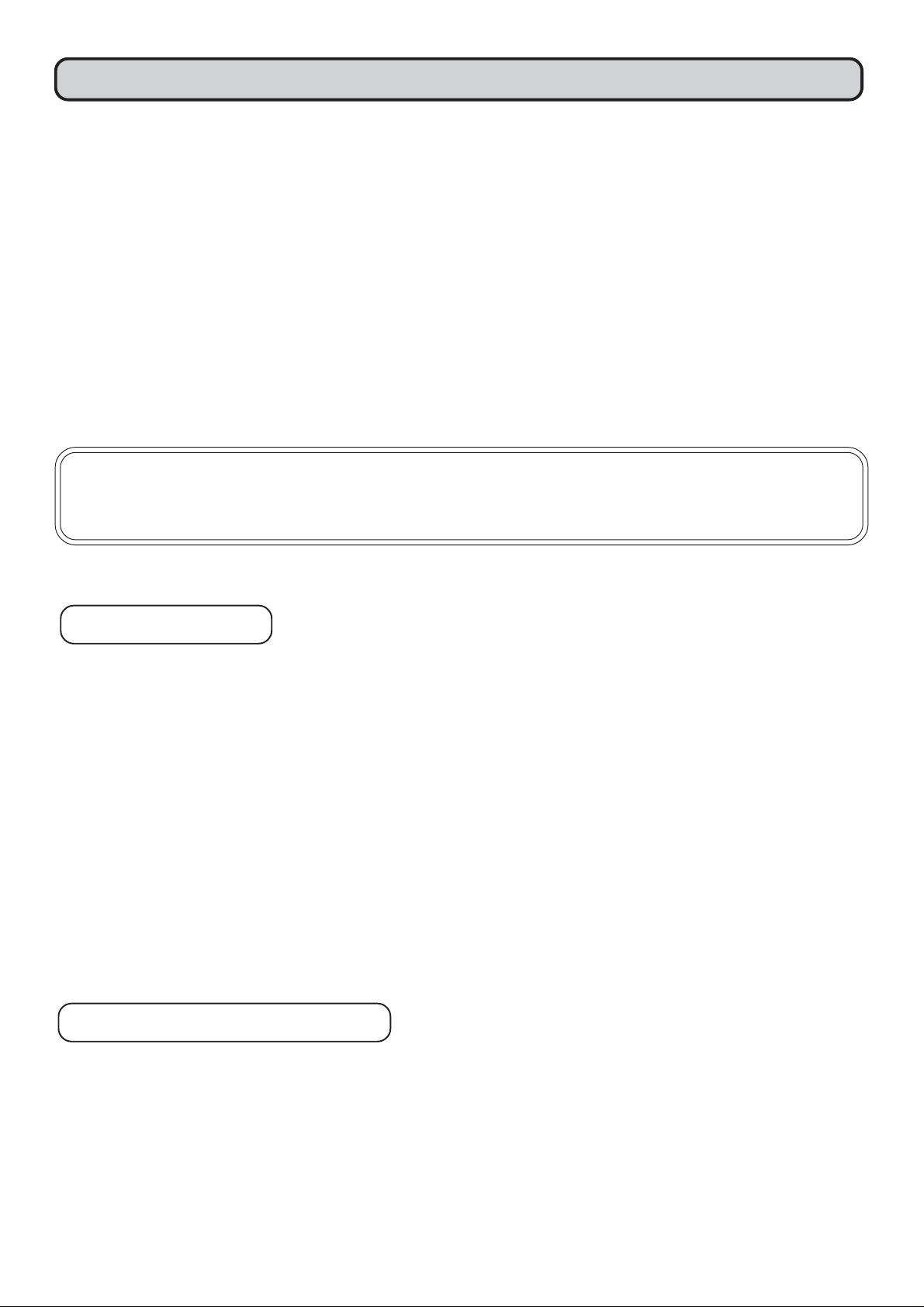

1.3.1 - Settings for low temperature systems (floor heating only)

ASCARI boiler is supplied ready for connection to a high temperature system ranging from 0 to 80 °C with

a high temperature safety limitator set at 100 °C (radiators or floor heating and Domestic Hot Water production).

For connection to a low temperature system ranging from 21 to 50 °C with a high temperature limitator set at

60 °C, adjust parapeter #

limitator.

The two safety limitators are located over the electric pannel (see Pic. 1 below).

Safety limitators with manual reset

Dual connector

(TCMA) to a 50°C or lower value (see § 6.3) and connect the 60 °C safety

60°C

100°C

Ex-work wiring for high temperature system with 100°C high temperature cut-out

Ascari - 12kW -page 4 -

Page 5

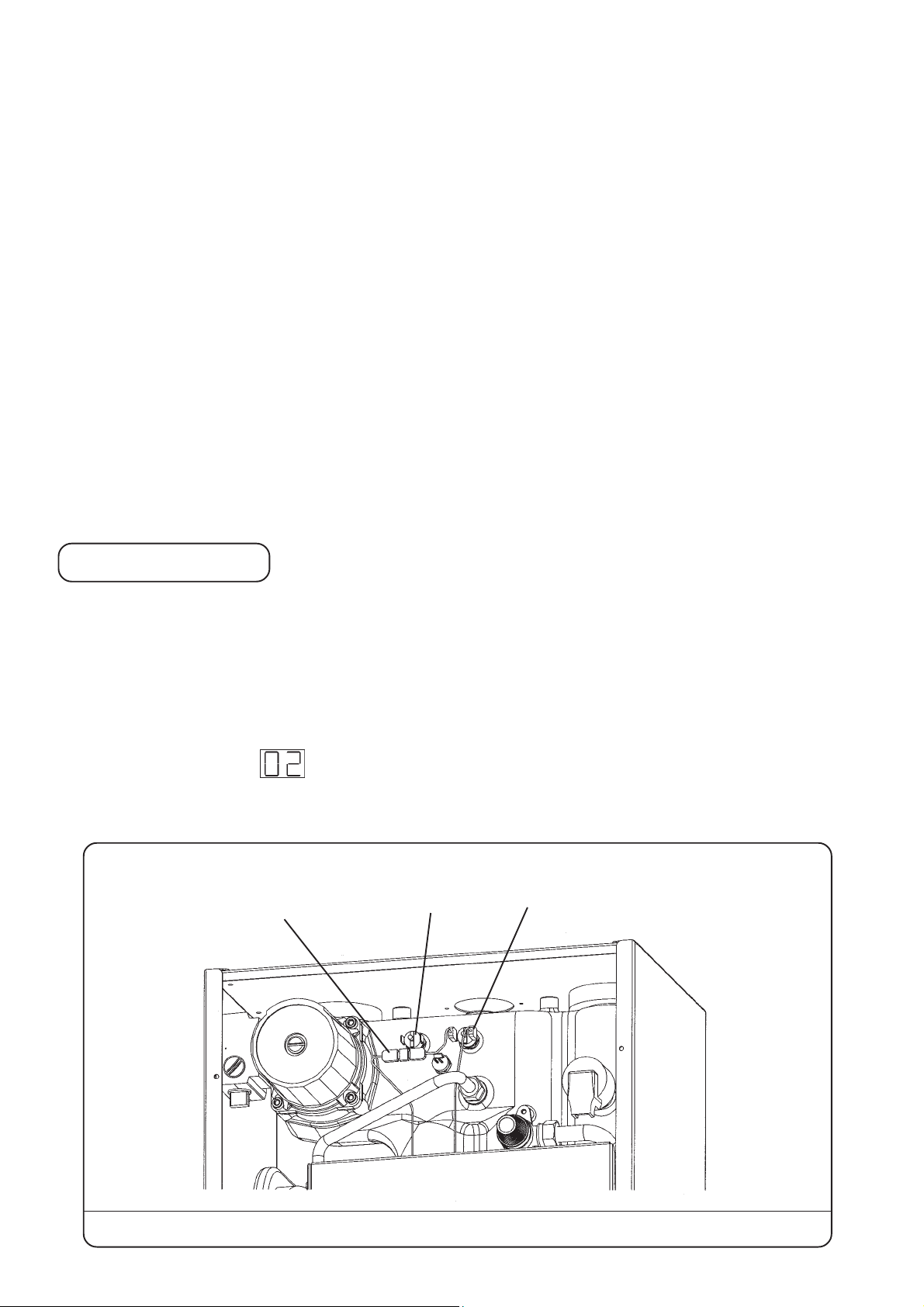

Electric connection of the 60°C temperature limitator for use with a low temperature system.

60°C

100°C

Dual connector

60°C

100°C

Disconnect the dual

connector and connect the

two female connectors to the

60°C safety limitator .

1.3.2 - Water temperatures settings summary

Parameter # 02

Heating system

Floor heating (ex-work

settings)

Radiators

or floor heating with

Domestic Hot Water

production (ex-work

settings)

Maximum boile r's

temperature (TCMA)

see § 6.3

21 - 50°C

22 - 80°C

Safety limitator AQS

60°C

permanent

100°c

permanent

Ascari - 12kW -page 5 -

Page 6

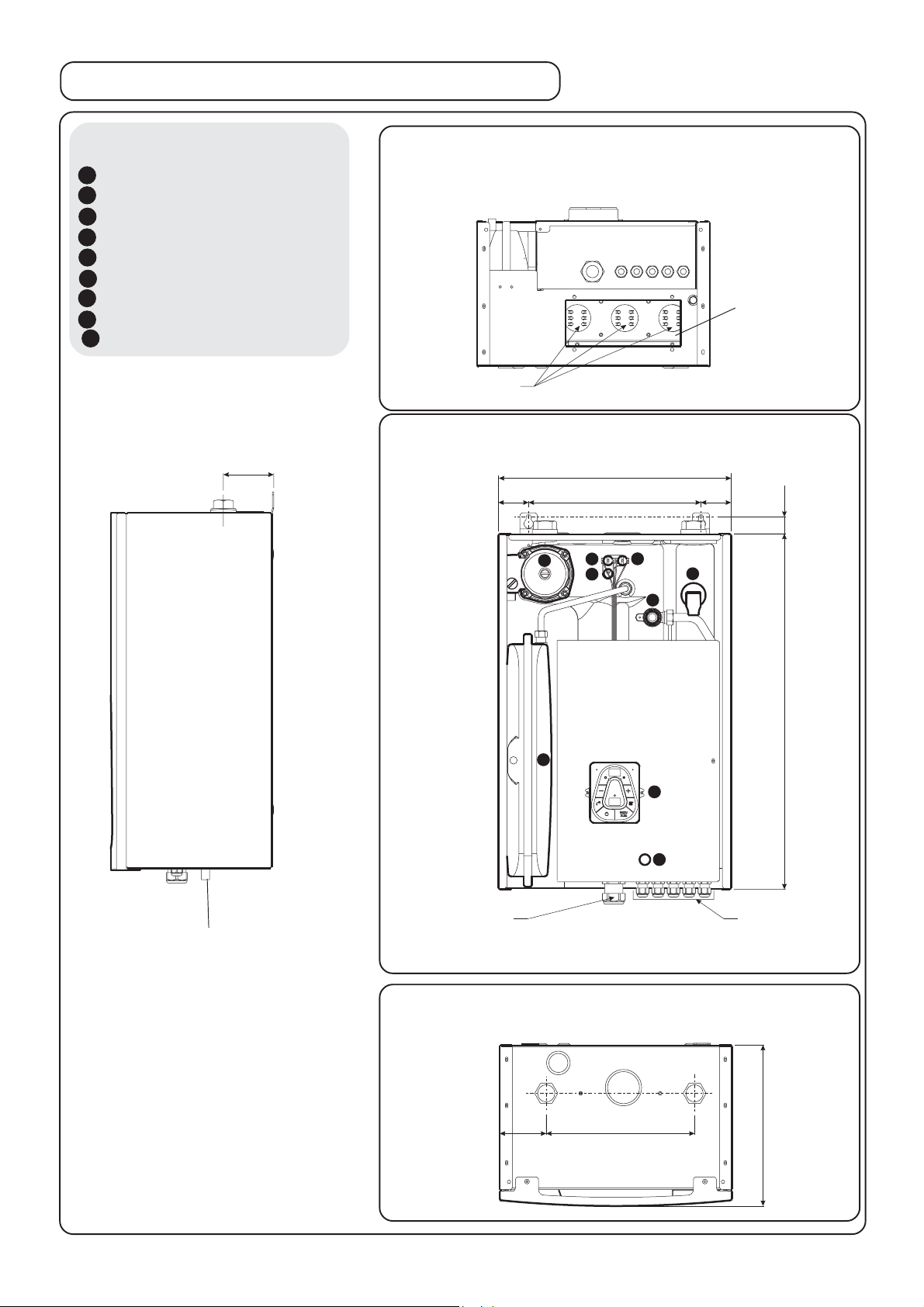

1.4 - Dimensions - Hydraulic connections

Decoding

1 - 3 speed pump

2 - 8 liters expansion vessel

3 - 3 bar safety relief bleeder

4 - La ck of water sensor

6 - 60°C safety limitator

7 - 100°C safety limitator

8 - Boiler's sensor

9 - Control pannel

11 - Fuse

Side view

87,5

(Trapdoor to access elements removed)

Heating elements

Bottom view

Front view

1

6

8

405

300

Elements fastener

29

7

4

3

619

2

9

11

Safety relief drain

Power wire entry

Accessories

connection entries

Ø15

Top view

DR

D = Heating outflow 1" female nut (26/34)

R = Heating backflow 1" female nut (26/34)

81

259

280

Ascari - 12kW -page 6 -

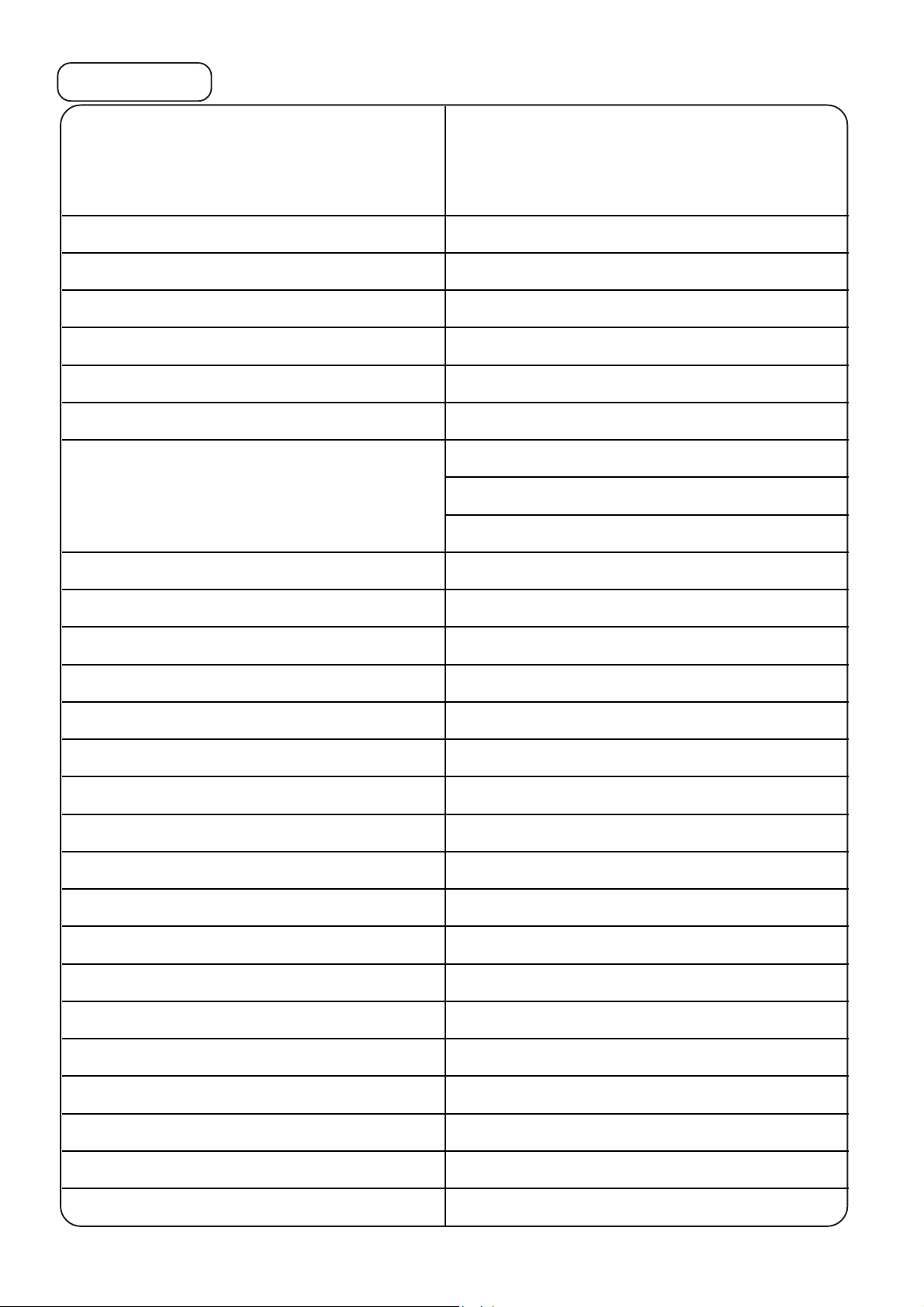

Page 7

1.5 - Datas

ASCARI

Designation

12 MA

230 V mono

Heat exchanger

Elements

Maximum output P1 (ex-work wiring)

Nbr of power stages

230 V mono 50Hz * power supply

230V tri 50Hz * power supply

Maximum output P1 adjustment * changing

heating elements wiring

Remote cut-out of one or two power stages

Water capacity 5 litres

2 heaters comprising 3 x 2kW incoloy elements

Cast iron

12 kW

4

YES

NO

P4 = 6kW

P3 = 8kW

P2 = 10 kW

6 kW

Expansion vessel

Water connections

Minimum pressure

Nominal pressure

Maximum pressure

Minimum temperature

Maximum operating temperature

Minimum water flow

Nominal water flow

Maximum water flow

Weight

Dimensions Width 405 mm

Height

80 °C (ex-work) adjustable to 50°C

8 litres

1" (26/34)

0,5 bar

2 bar

3,0 bar

21 °C

350

700

2400 l/h

38 Kg

620 mm

Security class

Power rate at 70°C

* : see § 3.3

Depth

Ascari - 12kW -page 7 -

280 mm

IPX1

3,40 kWh / 24 h

Page 8

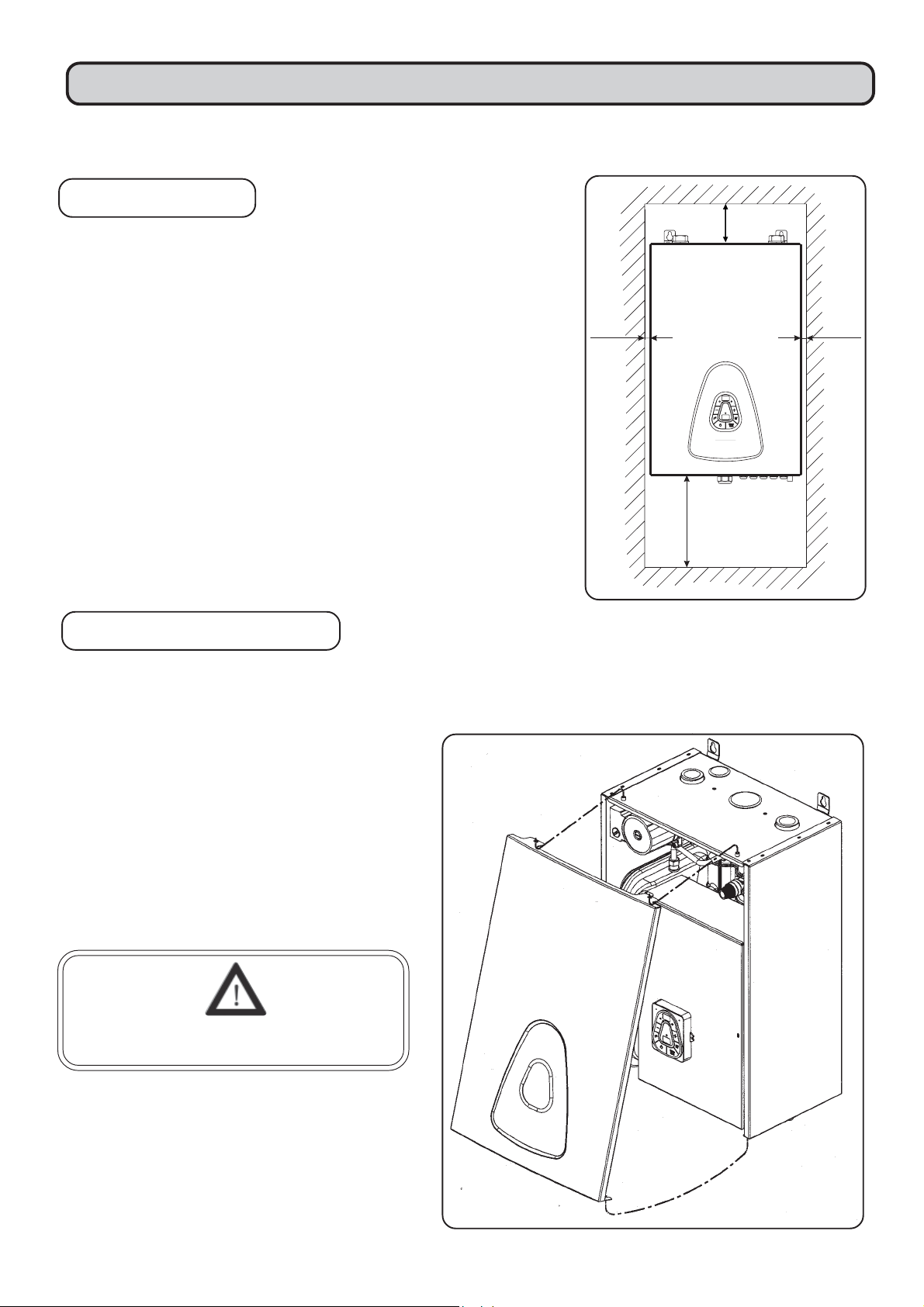

2 - INSTALLATION REQUIREMENTS

2.1 - Location

• The boiler must be located at least 300mm above any object to

allow the elements to be removed. At least 100mm is required at

the top of the boiler to allow for connection of pipework.

• 10mm is required at the sides of the unit.

• The boiler must be mounted on an internal solid masonry wall

capable of withstanding the weight of the product when full of

water.

• Consideration should be given to the rounting of electric cables to

the product and the wiring to a thermostat (if used).

• The location must be free from frost and excessives moisture.

2.2 - Fitting the boiler

10

100

10

300

2.21 - Opening case

The boiler may be opened by unscrewing the

bottom two bolts a couple of turns (they do not

need to be removed completely). The front

cover may then be pulled out from the bottom

and lifted off the two top pins.

Switch off the electricity supply to the

boiler before opening the internal cover.

Ascari - 12kW -page 8 -

Page 9

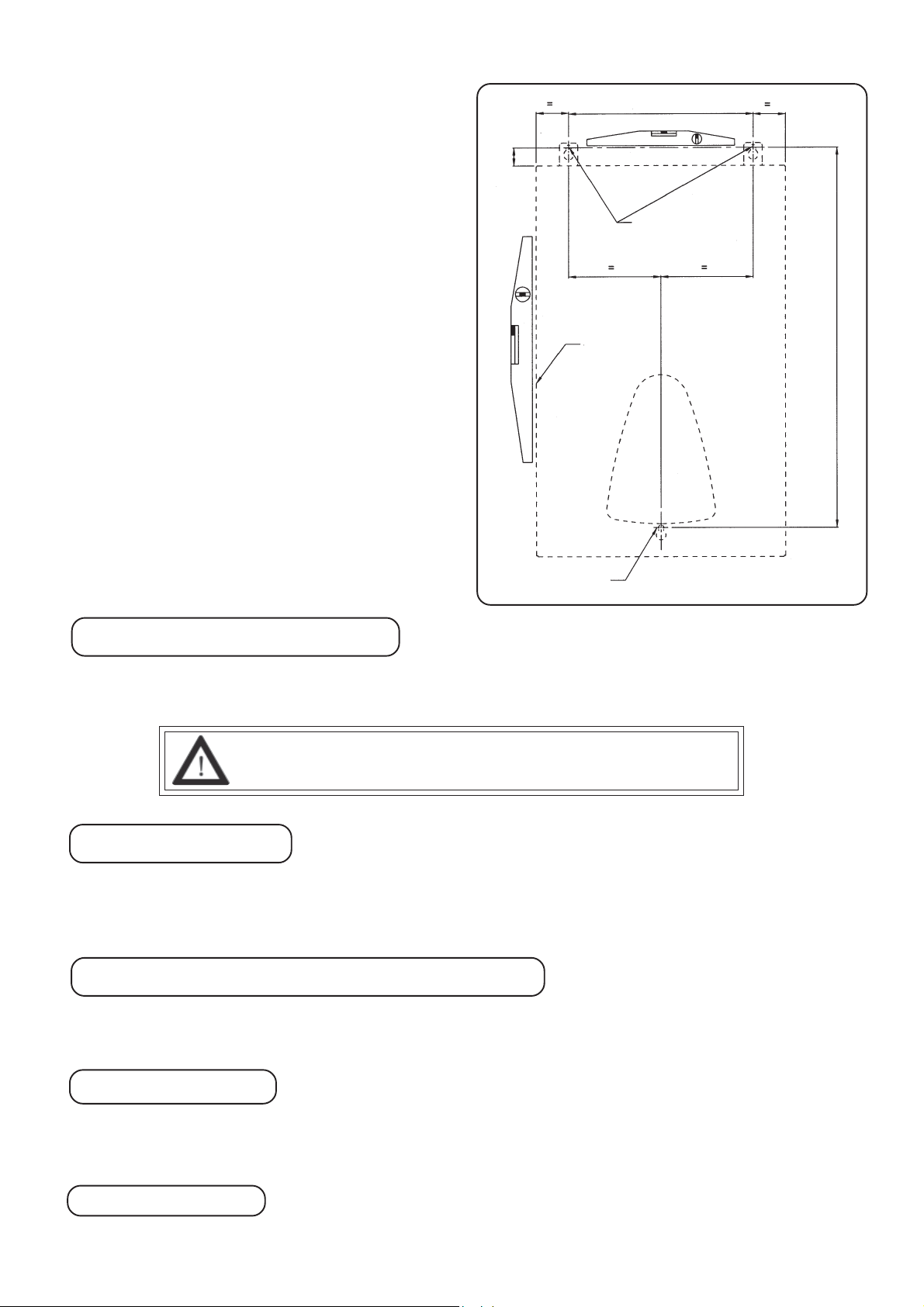

2.2.2 - Main unit

• Once the location of the boiler has been selected,

mark the hole positions as per firgures below. Use

a spirit-level to ensure the holes are aligned

correctly. Access to the bottom screw hole is

achieved by removing the bottom element plate.

• Once marked out, drill 8mm diameter holes and

plug with masonry plugs. Screw in high strengh

screws to a depth that allows the inner face of the

screw head to protrude from the wall a distance to

allow the mounting plates at the rear of the boiler

to engage (approx. 5mm).

• With suitable equipment or an assistant raise the

boiler to the fixing point and ensure each screw

has engaged into the mounting slots. Tighten the

screws to secure the boiler to the wall.

• Once fixed to the wall the boiler may be plumbed

into the central heating system.

29

Overall frame

pattern

300

Ø8 screw plug

605

Ø8 screw plug

2.3 - Hydraulic connection

Connections to heating circuit are located atop the boiler. Left connection for outflow, right connection for

backflow (see § 1.2).

UU

HEAHEA

HEA

HEAHEA

SESE

U

SE

SESE

UU

TINGTING

TING

TINGTING

MANDMAND

MAND

MANDMAND

OUTFLOUTFL

OUTFL

OUTFLOUTFL

AA

TT

A

T

AA

TT

OO

WW

O

W

OO

WW

ORILORIL

ORIL

ORILORIL

ANDAND

AND

ANDAND

YY

Y

YY

BRASSBRASS

BRASS

BRASSBRASS

BB

AA

CKFLCKFL

B

A

CKFL

BB

AA

CKFLCKFL

CONNECTCONNECT

CONNECT

CONNECTCONNECT

OO

WW

WITHOUTWITHOUT

O

W

WITHOUT

OO

WW

WITHOUTWITHOUT

ORSORS

ORS

ORSORS

SUPPLIEDSUPPLIED

SUPPLIED

SUPPLIEDSUPPLIED

REMOREMO

REMO

REMOREMO

VINGVING

VING

VINGVING

ONON

ON

ONON

THEMTHEM

THEM

THEMTHEM

..

.

..

2.4 - Mixing valve

Ascari installed boiler easily support a backflow temperature higher than the ambient temperature of

surrounding area, which makes unnecessary the use of a mixing valve.

2.5 - Expansion - Pressure safety relief

Expansion is collected by a pressurized 8 liters vessel.

Safety relief bleeder must be connected to a bleed collector with drain (see § 1.2).

2.6 - Antifreeze

Use ethylene glycol only with incorporated corrosion inhibitor .

Glycol ratio must be under 10 %.

2.7 - Bleeding

Make sure to have a bleeding point at the highest level of the hydraulic circuit.

Ascari - 12kW -page 9 -

Page 10

2.8 - Plumbing

• The system should be flushed prior to connecting the boiler to remove all particles from the pipework. Do

not use the fitted pressure relief valve to flush the system as particles trapped in the valve will cause

incorrect valve operation.

• At least one air bleeding device should also be connected to the highest point of the plumbing system to

remove trapped air and ensure silent running of the heating system.

• If using radiators with Thermostatic Radiator Valves a bypass radiator must be fitted with lockshield valves

that will allow a flow of 350 litres/hour.

• Service valves should be connected to the inlet and outlet of the boiler for easy maintenance.

• Although the boiler can operate without a room thermost at this is required for automatic adjustment of boiler

output temperature.

• Where underfloor heating is being used, the 60°C thermal cut-out must connected in place of the factory

selected 100°C device (see section 1.3.1).

• A drain cock is required to be fitted in the lowest part of the heating system to allow the system fluid to be

drained fully.

• A filling loop must be installed that isolates from the cold mains water supply from the heating system and

complies with the current building and water regulations in force at the time.

• The boiler incorporates an 8-litre expansion vessel which is suitable for heating systems as follow :

Initial system pressure (bar) 0,50 0,75 1,00 1,50

Total water in heating system (litres) 96 84 73 50

For larger systems Multiply the volume water by these factors 0,0833 0,093 0,109 0,156

2.9 - Filling loop

This boiler is not fitted with a filling loop. Any filling loop being fitted should comply with the water supply (water

fittings) regulations 1999 Section G24.1 and G24.2. A filling loop should be fitted at some point to allow the CH

system to be filled.

Two tipes are shown below : METHODS OF FILLING A SEALED SYSTEM

Recommended and appro v ed method for filling closed circuits in a house.

(R24-2a Water Regulations Guide)

METHOD A

T emporary Flexible Hose

Connection

T o be removed

immediately after filling

F

METHOD B

Cistern &

Overflow

F

Mains

water

supply

Stop

valve

Double

check

valve

assembly

Stop

valve

Heating

System

Return

Ascari - 12kW -page 10 -

Mains

water

supply

Pressure Pump &

reducing valve

(if required)

Stop

valve

Heating

System

Return

Page 11

3 - ELECTRIC CONNECTIONS

IMPORTANT NOTICE

Electric connections might be loosed during transportation.

To avoid abnormal overheat, carefully check quick connection terminals and screwed connections.

• Wiring external to the appliance must be in accordance with the current I.E.E. Wiring Regulations (BS

7671) for electrical installation and any local regulations, which apply .

• With the boiler plumbed in the electrical connections can be made to the boiler :

• This appliance must be earthed !

• The Ascari boiler comes with cage-clamp connectors. These are operated using a 2.5mm x 0.4mm blade

screwdriver for accessory terminals and 3.5mm x 0.5mm blade screwdriver for power terminals.

• The boiler should be permanently connected to the electricity supply , direct from a 63A fused supply on the

consumer unit wia a double pole linked switch with minimum contact gap of 3mm. No other appliances

should be powered from this supply .

• To connect a wire, insert the blade of the screwdriver into the opening located just above or below the

central mark of the terminal block and pivot the blade towards the centre. The wire may then be inserted

into the cage and the screwdriver blade removed.

• External command (a phase 230V common to the boiler must be connected to terminal 25).

• The power supply cable should be routed through the large cable entry point at the bottom of the boiler. If

desired the cable entry may be moved to the top of the boiler by removing the self sealing nut from the

bottom to the top entry point.

• The Earth wire should be connected to the top terminal marked with the Earth symbol.

• The Neutral wire should be connected to the large terminal marked "N".

• The live wire to the large terminal labelled PH.

• Do not switch on the electricity supply until asked to do so in the Commissioning and Testing section.

• As a minimum it is recommended that a room thermostat be installed to control the appliance. Thermost atic

radiator valves may be fitted to the system, however they must not be fitted in the room where the room

thermostat is fitted. There must be at least one radiator installed with lock shield valves that should not be

closed and will allow 350 litre/hour circulation. Further guidance can be obtained from the Domestic Heating

and Hot Water Guide to the building regulations.

Ascari - 12kW -page 11 -

Page 12

3.1- Electric flow rate, number and cross-section of the power

connectors, fuse protection

3.1.1 - Electric datas

Amperes for each phase

Maximum output P1Boiler

230 V mono

ASCARI 12

12 kW 52 A

3.1.2 - Number and cross-section of connectors

IMPORTANT

Follow local existing regulations regarding electric connections

Electric connections to mains must be installed according to local and national regulations, which generally

specify:

• Type of connectors :

- Type of slipcover

- Number and cross-section of wires,

- etc...

• Type of inst allation :

- Magnetic interferences inside bundles,

- Ambient temperature,

- Open or covered wires,

- Length of cords,

- etc...

Example: Cord type U1000, loose in open air rack, ambient temperature 20°C, lenght 15 m.

MINIMUM cross-section for each connector in mm²

Boiler

Maximum

output P1

and number of connectors for above example

230 V mono

Ph = Phase = 16²

ASCARI 1 2

12 kW 2 x 16² + T *

N = Neutral = 16²

Ascari - 12kW -page 12 -

Page 13

Boiler

Maximum

output P1

MAXIMUM cross-section for each connector in mm²

and number of connector for above example

230 V mono

ASCARI 1 2

* : Cross-section of ground connection must be equivalent to cross-section of largest phase/neutral.

Manufacturer cannot be, for any reason, regarded as faulty in case of improper choice of connection

wires to mains, or in any case of damages resulting from installation solutions.

12 kW

2 x 16² + G *

3.1.3 - Fuses

Fuses for connection to mains

230 V mono

Boiler

Maximum

output

P1

ASCARI 1 2

12 kW 63 A

Ascari - 12kW -page 13 -

Page 14

3.2 - Power terminal

Put the self-sealing nut (supplied with the boiler) for

connection to mains from the bottom of the casing.

Put the self-sealing nut (supplied with the boiler) for

connection to mains from the top of the casing. In

this case remove the plastic cap and close the hole

below casing using same.

or

Screw A

5 self-sealing nuts for accessories connections

(Ambience thermostat, outside and/or Domestic Hot

Water sensor and remote cut-out)

Connections are cage-clamp terminals, to be used as to follow :

- For accessories terminals use a 2,5 x 0,4mm blade screwdriver

- For power terminal use a 3,5 x 0,5mm or 5,5 x 0,8mm blade

screwdriver.

Plastic cap moved from top

to bottom

1:Introduce the blade of the driver into the opening located just

above or bellow the mark with a slight pivoting move to center.

2:Introduce the connector's terminal inside the cage.

3:Remove the screwdriver

Ascari - 12kW -page 14 -

Page 15

3.3 - Connection to mains depending on power supply

Ground

Neutral

: see § 3.1 for connectors cross section

and requested fused switch or

Phase

electro-thermic breaker.

I

OTE : Denuded length of wires between 16 and 17mm

N

Ascari - 12kW -page 15 -

Page 16

3.4 - Regulation circuit drawing

phase

A1

A2

brown

11

14

brown

S.Ext

external

command

25

red

R

brown

R

L1

1

brown

2

white

SC

white

grey

5

grey

6

pink

3

pink

4

F

red

blue

orange

black

CP

7

8

grey

yellow

white

white

A1

A2

C1

K1

yellow

A1

A2

K2

red

A1

K3

black

A1

K4

A2A2

blue

CC

60°C

neutral

blue

N

9

10

11

DT

blue

AQS1

blue

T

Decoding :

L1 : Phase

N : Neutral

F : 4A fuse size 5 x 20

C1 : Electronic card with display

C C : 3 speed pump

SC : Boiler's sensor

AQS1 : 60°C safety limitator with manual reset

blue

100°C

AQS2

T

blue

12

DP1

13

blue

14

15

DP2

AQS2 : 100°C safety limitator with

manual reset

K1 to K4 : 20A power breakers

DT : Total cut-out (remove the bridge)

DP1 & DP2 : Partial cut-out (remove the bridge)

R : External command relay

S.Ext : Outside Temperature sensor

Ascari - 12kW -page 16 -

Page 17

3.5 - Control accessories wiring

CC

11

1

R

2

S.Ext

14

43

1 - 2 : External command relay contact

3 - 4 : Outside temperature sensor

10 - 1 1: To tal cut-out DT (remove the bridge) and / or 65°C heating

6

5

floor safety limitator (mandatory) with manual reset.

7

8

9

1110

12

External

command

1413

15

25

See § 1.3.1.

12 - 13: Partial cut-out DP1 (remove the bridge)

14 - 15: Partial cut-out DP2 (remove the bridge)

25 : External command (use phase 230V common to the

boiler on pin L1)

• To avoid electro-magnetic interferences, power connection and sensors connections will be

isolated. Also avoid using diversion box.

• Connectors will be of electrolitic quality brass (no corrosion of denuded ends at connection

points).

• Never use telephone wire (cross-section of sub-connectors too thin and easy breakable at

connections points).

• Cross-section of connectors must be between 0,5 and 1mm².

Ascari - 12kW -page 17 -

Page 18

3.6 - Wiring diagrams

GND 1

blanc

pressure sensor power

gris

+Vdc 2

3

OUT 4

pressure sensor connect.

jaune

pink

pink Outside sensor (S.Ext)

grey

grey DHW sensor (S.ECS)

white

SC

white

brown

brown

ambience thermostat (T A)

boiler's sensor (SC)

black

GND

OUT

+Vdc

red

F

orange

230 V / 12 V

adaptator

Heating pump CC

DHW pump C.ECS

6

5

4

3

2

1

230V power

blue

black

red

yellow

white

brown

red

black

white

brown

S.Ext

13

4

2

5678

green

yellow

brown

CC

blue

10

9

blue

PH

11

12

13 14

PH

15

white

AQS 1

blue

60°C

white

AQS 2

100°C

PH

red

red

black

blue

black

NNNPH

NPH

blue

(1)

: In optionnal

PH : Phase

N : Neutral

F : 4A fuse size 5 x 20

C 1 : Electronic card with display

C C : 3-speed pump

TA : Ambience thermostat

TT

Légende :

AqECS : Domestic Hot Water Safety limitor

ou

(1)

SExt

SC : Boiler's sensor

Ascari - 12kW -page 18 -

blue

: Outside sensor

Page 19

black

red

yellow

white

red

black

white

brown

brown

blue

12

14

11

a1

a2

white

L1

L2

L3

L4 A1

yellow

K2

T1

T2

T3

red

L1

red

L2 L3

R

25

white

balck

L4

white

A1

T4

A2

bleu

L1

red

L2

K1

T1

red

T2

black

T3

T4

A2

blue

T2

T1

red

balck

white

L1 L4 A1

L2 L3

K4

T1

white

black

L4

A1

L3

K3

A2

T4T3

blue

red

black

T4T3T2

A2

blue

T1 T2

bleu

bleu

AQS1 : 60°C Safety limitor with manual reset

AQS2 : 100°C safety limitor with manual reset

Ascari - 12kW -page 19 -

Légende :

K1 to K4 : 20A power breakers

T1 & T2 : 6kW heating elements

Page 20

3.7 - Heating elements connections

Connections of the heating elements will have to be adjusted according to requested output, depending on

the volume and the insulation of the space to heat.

R

WBl WBlR

BBBB

BB

R

WBl WBlR

BBB

BB

12 kW 10 kW*

ex-work wiring

R

R

WBl WBlR

WBl WBlR

BBB

B

8 kW* 6 kW*

RBBWBl WBlR

4 kW*

View from bellow

* Remove bleu connectors between power terminal and elements

according to drawing.

See § 1.4 to access elements.

BB

B

R : Red

Bl : Black

W : White

B : Blue

Ascari - 12kW -page 20 -

Page 21

4 - BASIC HYDRAULIC PATTERNS

1234

1234

1234

1234

Commissioning & T esting

WATER TREATMENT, CLEANSING AND FLUSHING THE HEATING SYSTEM

NOTE : Bristish Standard BS7593 : 1992 stresses the importance of cleansing and flushing of the system to

ensure it continues to run efficiently with the minimum of maintenance necessary . Dimplex fully support this

professional approach and recommend that the system is cleased with an effective chemical cleanser and

protected long term with a suitable inhibitor. Such product s are available from Fernox and Sentinal.

• Check the pressure of the expansion vessel, this should be factory set to 1 bar (0.1MPa)

• The heating system should be filled using the approved installed filling loop.

Ensure all radiator valves are open. The initial system pressure when cold should be between 1.0 (0.1MPa)

and 1.5 bar (0.15MPa)

• Once filled check the system for leaks

• Open the drain cock and drain the system fully

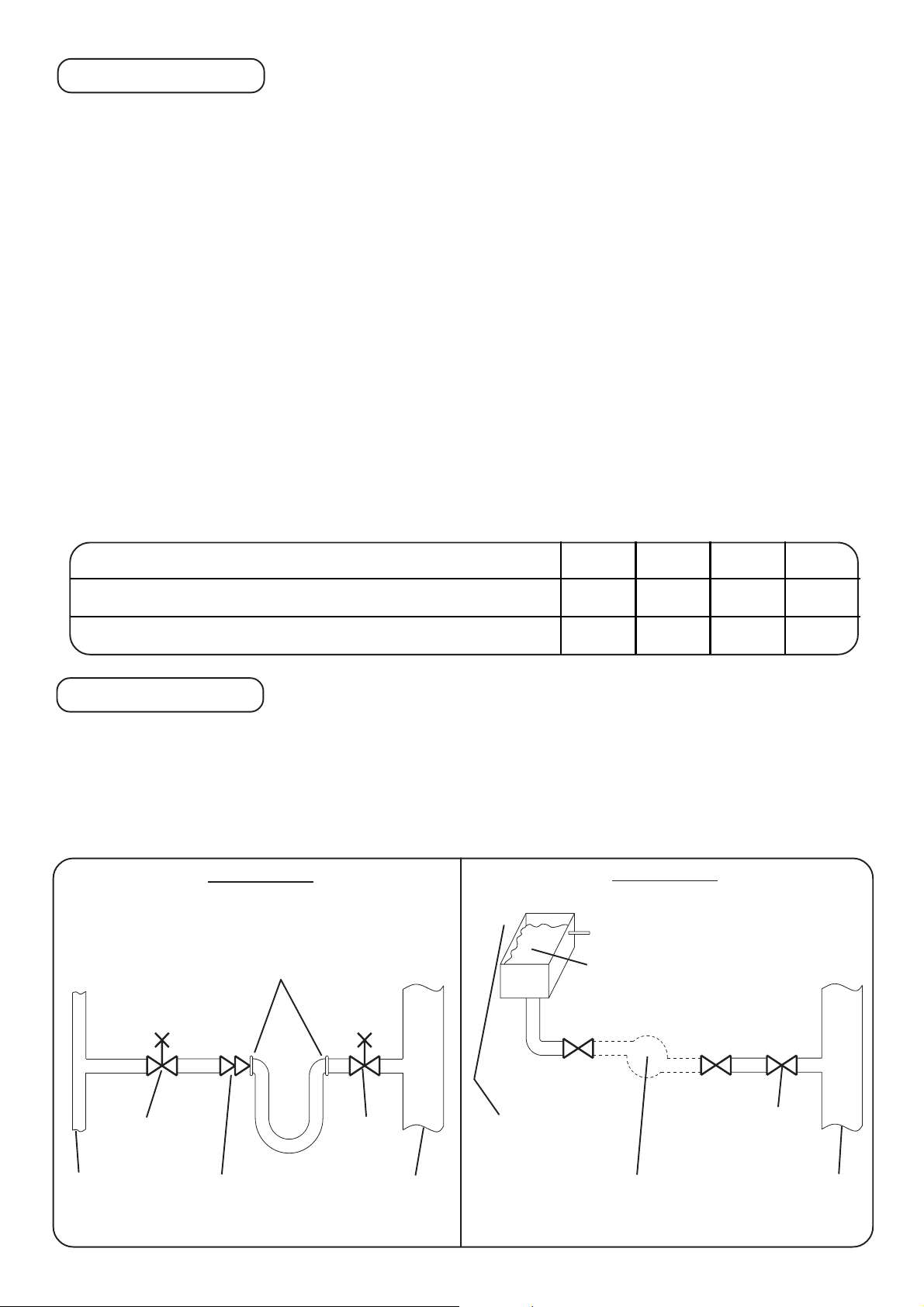

4.1 - Direct heating circuit

TA

Rm

Underfloor heating

Rt

Radiators

OR

4

1

2

electric boiler

4

RD

3

6

5

5

Decoding :

1 : 3 speed pump

2 : 8 liters expansion vessel

3 : 3 bar safety relief

4 : Stopcocks

5 : Automatic air bleeders

6 : Pressure sensor

D : Heating outlet 1" female

R : Heating inlet 1" female

Rm : Handcock (room housint the ambience thermostat TA)

Rt : Thermostatic cock

TA : Ambience thermostat with or without timer

SExt : Outside temperature sensor

Ascari - 12kW -page 21 -

SExt

Page 22

5 - 3 SPEED WATER PUMP

IIIIII

III

IIIIII

IIII

II

IIII

II

I

II

3 speed (I, II et III) water pump for adjustment to operating needs, depending on insulation and circuit

The boiler is factory set at pump speed 3, for lower pump speeds the selector in the centre of the pump may

be turned to 1 or 2 using a large flat bladed screwdriver .

Electric datas

Speed

III 90 0,40

II 67 0,30

I 47 0,20

Nominal

output (W)

Nominal

intensity (A)

Ascari - 12kW -page 22 -

Page 23

6 - 2 CIRCUITS ELECTRONIC REGULATION

6.1 - Generalities

- Possible monitoring of the heating circuit water pump to the external command for a better adjustment.

- Possible automatic adjustment of the requested temperature when using an external command without

timer.

- Choice of manual or automatic operating (with outside sensor)

- Manual or automatic shift to Summertime or Wintertime mode (with outside sensor)

- Step-by-step st art and/or stop of the four power stages (with 1 to 6 min intervals) with overheat protection.

- Cyclic weekly shift of the 4 power stages starting sequence.

- Cycles counter for each power stage.

- Water pump unstickage in Summer mode.

- Frost protection of the Domestic Hot Water and heating circuits when the boiler is off.

Ascari - 12kW -page 23 -

Page 24

bar

° C

6.2 - Control pannel description

Usual operating functions

Boiler's temperature display in °C.

When the boiler is off and the two

middle horizontal LEDs on, antifrost

protection is operating.

(flashing in case of sensor failure)

Summer mode green LED

Used to decrease

temperature during settings

(instant touch) or cancell

operating postponement of

running power stage (press

3 sec)

(Glittering • displays normal

operating)

Winter modegreen LED

Used to increase

temperature during settings

(instant touch)

Operating display red LED

Hot Water selection (if fitted)

On/Off switch (with

automatic anti frost

protection for DHW and

heating circuits) (instant

touch)

Auto

Manu

Pressure display in bar.

Boiler stops automatically below 0,3 bar

with automatic reset over 0,5 bar .

(0,2 blinking displays a pressure loss -

other value flashing displays a

pressure sensor failure)

Ascari - 12kW -page 24 -

Used to enter requested

heating temperature menu

(instant touch) or start the

winter mode (heating and

DHW) (press 3 sec.)

Used to choice manual or

automatic operating (press 3

sec. + instant touch) (with

outside sensor

Page 25

6.3 - Regulation settings

For fitter's use only .

The regulation must be adjusted according the use of the boiler .

• Press

• Parameter # starts blinking in front of "°C"

• Press

• To start setting the displayed parameter press or (instant touch).

• The parameter value, i.e*

• Press or (instant touch) to change setting.

• Press

and (3 sec) to start setting menu for 4 minutes.

or (instant touch) to select next parameter, i.e °C, ... until °C

starts blinking in front of "bar".

or (instant touch) to confirm setting and return to setting menu.

• Press and (3 sec) any time to exit the setting menu.

* When outside minimum temperature (TEMI) below 0°C, a glittering point is on display right at bottom of

displayed figure : ie

in front of "bar" means -5°C (and not 5°C)

Ascari - 12kW -page 25 -

Page 26

PARAMETERS LISTING

A

Press and during 3 sec to access parameters menu.

Available if Paremeter # Description Setting range Ex-wo rd settings

Electric boiler (no = O ; yes = 1) 0 or 1 1 mandatory

Maximum requested boiler's temperature

si = 1

(1)

(TCMA)

Minimum requested boiler's temperature

(1)

(TCMI)

External command installed

(no = O ; yes = 1)

Heating circuit pump linked to exter nal

comm and (no = O ; yes = 1)

21 to 80°C 80°C

21 to TCMA °C 30°C

0 or 1 0

0 or 1 0

si = 1

Autoadaptability or automatic adjustment of the

requested temp erature (no = O ; yes = 1)

0 or 1

(2)

0

Outside se nsor (no = O ; yes = 1) 0 or 1 0

(1)

si = 1

si = 1

si = 1

si = 1 DHW sensor (no = O ; yes = 1)

si = 1

si = 1

si = 0

si = 0

si = 0

si = 0

si = 0

si = 0

(1)

: See § 7 to set the heating diagram according to 4 paremeters (TCMA, TCMI, TEMA and TEMI)

(2)

: Prohibited when using a scheduled external command

(3)

: Depending on water flow rate and volume inside the heating circuit, the boiler might start at very short intervals with

Maxim um outside tem perature (TEM A) 11 to 25°C 20°C

(1)

Minimum outside tem perature (T EMI) -30 to +10°C -5°C

utomatic ti pping up summer mode

(no = O ; yes = 1)

Operating postponement

Domestic Hot Water production

(no = O ; yes = 1)

Legionnai re s disease free mode (off)

(no = O ; yes = 1)

Engaging of 6 pow er stages

(no = O ; yes = 1)

Engaging stage 1

(no = O ; yes = 1)

Engaging stage 2

(no = O ; yes = 1)

Engaging stage 3

(no = O ; yes = 1)

Engaging stage 4

(no = O ; yes = 1)

Engaging stage 5

(no = O ; yes = 1)

Engaging stage 6

(no = O ; yes = 1)

0 or 1 0

1 to 6 min

(3)

0 or 1 0

(4)

0 or 1

(5)

0 or 1

0 or 1 1

0 or 1 1

0 or 1 1

0 or 1 1

0 or 1 1

0 or 1 1

0 or 1 1

2 min.

1

0

wear and tear resulting. To reduce the number of cycles, increase postponement.

(4)

: No = 0 = with electromechanical sensor (Temperature setting achieved on the water sensor, not on the control

panel). In this case, no antifrost control for the Domestic Hot Water.

(5)

Yes = 1 with element sensor. Domestic Hot Water antifrost control is operating.

: Warning: The Legionnaires Disease Free mode will increase the Domestic hot Water temperature up to 65°C. A

thermostatic mixer is then mandatory at Domestic Hot Water outlet to avoid scalding.

N

OTE : To reset autoadaptability, zero parameter # , then set value to 1.

Ascari - 12kW -page 26 -

Page 27

6.4 - Operating

Display in front of symbol "°C" means the boiler is off, connected to power supply, with anti frost

protection operating (boiler starts automatically when the boiler's temperature or the Domestic Hot Water

temperature turns below 5°C).

Press

to turn the boiler On or Off.

6.4.1 - Automatic / Manual Operation

The boiler must be set to Manual operation as follows :

Press and hold the Auto/Man button for 3 seconds. The display will show Au or Man, press the Auto/Man

button again for a short period to toggle the display so that it shows Man. With the correct display showing,

press and hold Auto/Man for 3 seconds to return to normal operating mode.

6.4.2 - Requested heating temperature setting in manual mode

Press to display the requested temperature blinking in front of symbol "°C".

Press or to or decrease the requested temperature between TCMI and TCMA. (see § 6.3).

Press to confirm setting.

6.4.3 - Summer / Winter shift

(Available in manual mode only (see § 6.4.1 above)

Press during 3 sec to start the summertime mode and lit Summertime LED;

Press during 3 sec to start the wintertime mode and lit the Wintertime LED.

Ascari - 12kW -page 27 -

Page 28

6.4.4 - Programming the maximum output setting of the boiler

To allow the power supply of the boiler with small size connectors and fuses (see

§ 3.1) it is mandatory to disconnect the heating elements (see § 3.7) to fully stop

the power supply of the boiler.

The boiler is delivered with a maximum output of 12kW (parameter = 1).

Set the parameter = 0

Set parameters of to to requested value according following tables to adjust the maximum

output of the boiler :

Power stage #

Power stage value

Parameter number

Parameter value

to obtain the

requested

maximum output

(0 = no ; 1 = yes)

12 kw110101

10 kW100101

8 kW100100

6 kW100001

4 kW010001

123456

4 kW 2 kW 0 kW 4 kW 0 kW 2 kW

6.4.5 - Temperatures display

During normal operating the boiler's temperature, i.e : is on display in front of symbol "°C".

1st pressure on

displays the ambience sensor display.

Parameter #

external command status is on display in front of "bar" :

2nd pressure on

(or 1st if no external command) displays the outside temperature. Parameter #

is displayed in front of symbol "°C"

for boiler's run not requested

for boiler's run requested

is displayed in front of symbol "°C". Outside temperature can be read on bottom display i.e with a

glittering LED down right the display if a negative value (-5°c in this example).

3rd (or 2nd or 1st) pressure displays the temperature correction in °K (parameter #

)

(see § 6.3 to zero this correction).

Ascari - 12kW -page 28 -

Page 29

6.5 - Counters

The regulation is equiped with 6 counters to count heating cycles (the unit is 100 cycles).

Press

The setting menu starts (see § 6.3).

Press

meaning power breaker #1 K1 is totalling more than 0999 x 100 = 99.900 cycles.

Press

St arting this menu will automatically restore the weekly shift of the 6 power stages starting sequence back to

the 1 to 6 order, but will not zero the counters.

Press

and during 3 sec.

during 3 sec. : °C will be on display for counter #1, alternating with °C and bar,

to shift to counter #2. Conversely press to return to previous counter.

and during 3 sec. to exit the counters menu.

6.6 - Failures display

The boiler has many selectable options. Please ensure the correct selections are made for the type of

installation you have made. If you have selected the use of a room thermostat, or hot water cylinder , the boiler

will not operate until these devices are connected.

The boiler indicates a boiler fault by flashing all segments of the temperature display.

In case of boiler's temperature failure, all 14 LEDs

the water pump still running.

In case of Domestic Hot Water sensor failure, all 14 LEDs

boiler is automatically restricted to heating.

In case of outside temperature sensor failure, all 14 LEDS

restricted to heating.

Please call the Dimplex Customer Service department -see Servicing section2 FLASHING SEGMENTS in front of bar -indicate the system pressure has fallen below the minimum operating

pressure.

• Check if water has discharged from the pressure relief valve. If so call a Dimplex service agent.

• Check for leakage in the system.

Once the fault has been cleared the boiler will turn on again if the system is filled and pressurised to over 0.5

bar.

in front of symbol "°C" are blinking. The boiler is off,

in front of symbol "°C" are blinking. The

in front of "°C" are blinking. The boiler is

Ascari - 12kW -page 29 -

Page 30

Servicing

It is recommended that the boiler be installed and serviced regularly by a Dimplex service agent to ensure

continual trouble-free operation. For details of service agents in your area please contact :

Glen Dimplex UK Limited

Millbrook House

Grange Drive

Hedge End

Hampshire

S030 2DF

Dimplex customer Services on 0870 727 0101

Ascari - 12kW -page 30 -

Page 31

7 - HEATING DIAGRAM

The heating diagram will be set according the following four parameters (see § 6.3) :

- TCMA = Maximum boiler's temperature

- TCMI = Minimum boiler's temperature

- TEMA = Maximum outside temperature

or temperature of summer/winter shift

- TEMI = Minimum outside temperature

or basic outside temperature

7.1 - Underfloor heating

The boiler is delivered with a 100°C safety limitator , to lower the maximum boiler's temperature at 60°C (see

§ 1.3.1).

T ypical use :

Requested boiler's temperature TC (°C)

80

70

60

TCMA = 50°C

Max with floor

heating

TCMI = 21°C

50

40

30

20

10

-30

-25 -20

-15 -10

TEMI = -5°C

-5

0 5 10 15 2520

Outside temperature Text (°C)

7.2 - Radiators

Ex-work factory settings with a 100°C boiler's temperature limitator.

T ypical use :

Requested boiler's temperature TC (°C)

80

TCMA = 70°C

TCMI = 40°C

70

60

50

40

30

20

10

TEMA = 20°C

-30

-25 -20

TEMI = -15°C

-15 -10

Ascari - 12kW -page 31 -

-5

0 5 10 15 2520

Outside temperature Text (°C)

TEMA = 18°C

Page 32

7.3 - Specific heating diagram

Requested boiler's temperature TC (°C)

80

70

60

50

40

30

20

10

-30

-25 -20 -15 -10 -5 20

0 5 10 15 25

Outside temperature Text (°C)

Ascari - 12kW -page 32 -

Page 33

8 - MAINTENANCE

Once a year we recommend to have the boiler checked by a qualified technician.

- Pressure inside the heating circuit needs to be controlled a a regular basis (pressure when cold will have to

remain over 1 bar).

- Frist a few days after cut-over , later at least once a year, check electric connections tightness of the heating

elements and power supply.

9 - TROUBLESHOOTING

- Floor heating: In case of overheat the temperature limitator (60°C) will cut power supply to heating

elements .

- Radiators: The limitator (100°C) also cuts power to heating elements.

- Af ter solving the failure, reset the boiler pressing the small red button in the middle of the sensor's head.

(see §1.3.1).

- Numerous power losses or lack of power: it might happened one (or several) connection(s) from power to

heating elements is(are) defective (powerloss) or cut (power failure). In this case change defective element(s).

Cut the power supply , drain, disconnect elements, remove elements fastener and remove/replace damaged

element(s). (seer § 1.2 to access heating elements).

Front view

(electric box removed)

View from below

(Access trap-door to elements removed)

Heating elements

O-ring

Ascari - 12kW -page 33 -

element fastener

Heating elements

Page 34

Fastening the pump

If the pump is producing some abnormal noise, slightly unscrew without creating leackage, then screw

again following instructions below .

1 - screw two opposite screws with a stroke of 3

Nm.

3 - screw the first two opposite screws with a

stroke of 5 Nm.

SPARE PARTS LIST

Designation Reference

Side casing

Front casing

2 - screw the other two opposite screws with a

stroke of 3 Nm

4 - screw the last two opposite screws with a

stroke of 5 Nm.

0105276

12 MA

230 V mono

B4484737 1

B4484730 1

Control panel

Pump

Klixon 60°

Klixon 100°

3bar relief valve

8L expansion vessel

Water sensor

Outside sensor (option)

6kW heating element

Heating element gasket

20A tetrapole switch

Fuse holder

4A fuse size 5 x 20

Display

C1 electronic card

B1758741 1

B1243544 1

B1243400 1

B1243418 1

B1239103 1

B1472534 1

B1243546 1

B1243586 1

B1243558 2

B1657044 3

B1243561 4

B1243146 1

B1243147 1

B1943599 1

B1943600 1

Temperature display

B1243534 1

Ascari - 12kW -page 34 -

Loading...

Loading...