Page 1

BIG FIFTY

RELOADER

Machine Manual

Page 2

PART# 29023 3/8/2010

2

Introduction

The Dillon Big Fifty Reloader is our largest and most powerful machine – please use care

and thought while setting up to avoid problems.

Suggested Minimum Equipment:

1) Loading Manual

2) Powder Scale

3) Safety Glasses

4) Dial Caliper

5) 50 BMG Headspace Gauge

6) 50 BMG Die Set, 1½ - 12 UNF Thread

Safety Points to Know Before you Begin

The reloading of ammunition involves the use of highly explosive primers and

flammable powder which can be inherently dangerous. Accidents can and do occur,

sometimes with disastrous results including, but not limited to, loss of vision, hearing or life.

These accidents are nondiscriminatory, they can occur with both the novice and the

experienced loader. You should recognize this danger and take certain minimum

precautions to lessen your exposure to injury. We cannot guarantee your complete

safety. In order to minimize your risk please use common sense when reloading and follow

these following basic rules.

Never operate the machine without wearing ear and eye protection. Call our

customer service department at (800) 223-4570 for information on the wide variety of

shooting/safety glasses and hearing protection that Dillon has to offer. Or visit our website

at www.dillonprecision.com

• PAY ATTENTION: Load only when you can give your complete attention to the loading

process. Do not watch television or try to carry on a conversation and load at the same

time. If you are interrupted or must leave and come back to your loading, always inspect

the cases at every station to insure that the proper operations have been accomplished.

• SMOKING: Do not smoke while reloading or allow anyone else to smoke in your

reloading area. Do not allow open flames in reloading area.

• SAFETY DEVICES: Do not remove any safety devices from your machine or modify your

machine in any way.

• MODIFICATIONS: Any modifications performed to your machine, or the addition of any

unapproved equipment from other manufacturers will void the warranty.

Page 3

PART# 29023 3/8/2010

3

• LEAD WARNING: Be sure to have proper ventilation while handling lead components or

when shooting lead bullets. Lead is known to cause birth defects, other reproductive

harm and cancer. Wash your hands thoroughly after handling anything made of lead.

• LOADS AND LENGTHS: Avoid maximum loads and pressures at all times. Use only

recommended loads from manuals and information supplied by reliable component

manufacturers and suppliers. Since Dillon Precision has no control over the components

which may be used on their equipment, no responsibility is implied or assumed for results

obtained through the use of any such components. Try to seat bullets as close to

maximum cartridge length as possible. Under some conditions, seating bullets excessively

deep can raise pressures to unsafe levels. Refer to a reliable loading manual for overall

length (OAL).

• QUALITY CHECKS: Every 40-50 rounds perform periodic quality control checks on the

ammunition being produced. Check the amount of powder being dropped and primer

supply.

• RELOADING AREA: Keep your components safely stored. Clear your work area of loose

powder, primers and other flammables before loading.

• COMPONENTS: Never have more than one type of powder in your reloading area at a

time. The risk of a mix-up is too great. Keep powder containers closed. Be sure to inspect

brass prior to reloading for flaws, cracks, splits or defects. Throw these cases away. Keep

components and ammunition out of reach of children.

• BLACK POWDER: Do not use black powder or black powder substitutes in any Dillon

powder measure. Loading black powder cartridges requires specialized loading

equipment and techniques. Failure to do so can result in severe injury or death.

• PRIMERS: Never force primers. If they get stuck in the operation of the machine,

disassemble it and gently remove the obstruction. Never attempt to clear primers that are

stuck. Never, under any circumstances, insert any type of rod to attempt to force stuck

primers out. Trying to force primers out may cause the primers to explode causing serious

injury or even death. If primers get stuck in the primer seat die flood the die with

penetrating oil (WD-40) before attempting to clear the unit. Never attempt to de-prime

live primers – eventually one will go off. When it does it will detonate the others in the

spent primer cup. De-priming live primers is the single most dangerous thing you can do in

reloading and can cause grave injury or death.

• LOADED AMMUNITION: Properly label all of your loaded ammunition (Date, Type of

Bullet, Primer, Powder, Powder Charge, etc.).

• BE PATIENT: Our loading equipment is conservatively rated and you should have no

trouble achieving the published rates with a smooth, steady hand. If something doesn’t

seem right, stop, look, and listen. If the problem or the solution is not obvious, call us. The

Page 4

PART# 29023 3/8/2010

4

reloading bench is no place to get into a hurry. We have done everything we know how

to make your machine as safe as possible. We cannot, however, guarantee your

complete safety. To minimize your risk, use common sense when reloading and follow

these basic rules.

• REMEMBER: If your machine does not perform to your expectations, or if you are having

technical difficulties, give us a call.

Mounting the DILLON BFR for use.

A fully equipped

Dillon BFR can weigh

on the order of 90

pounds. At full stroke

could very well

provide 600 foot

pounds of torque

wanting to break

your bench. We

suggest a heavy

hardwood bench, or

our optional steel

pedestal. The Dillon

BFR was designed to

be operated while

standing. With the

machine handle

cycled all the way

down, the handle

ball should be in

hand with the

operators’ arms

comfortably resting

full length at their side. Thus, the bench top should be 18 inches higher than the center of

the palm, with arms resting at full length. Keep in mind to provide about 12 inches of work

space on each side of the machine for various loading peripherals and components.

Place the base of the machine, with the lip resting flush with the edge of the mount. Using

the machine itself as a template, mark and drill four 3/8 inch holes in your bench for your

Dillon BFR. Use GRADE 5 or better, 3/8 inch bolts to mount your machine. If you are unsure

of the bolts you are using please consult a local hardware store or call our experts at

Dillon for a 50 BMG Mounting Hardware Kit Part# 50140.

Page 5

PART# 29023 3/8/2010

5

PARTS DIAGRAM

This is the basic layout of the machine. Noted above are the primary sub

assemblies which are detailed in the following pages. Once your machine is

mounted you will need to install the “Spent Primer Catch System” on to your

machine. Start by removing the four mounting screws and nuts from the

assembly (Part# 29009 and 16340). Assemble it onto the front left side post on

the machine as shown in the diagrams below.

Page 6

PART# 29023 3/8/2010

6

PRIMER CHUTE ASSEMBLY

NOTE:

When adjusting the primer

chute assembly, with the

platform at the top of its stroke,

the chute should be in line with

the spent primer hole of the

platform as shown at right in

“DETAIL A”

The chute should only make

contact with the platform and

never touch the main shaft (PN:

19827) at any position.

Page 7

PART# 29023 3/8/2010

7

TO BEGIN RELOADING

The Dillon “Big Fifty Reloader” or “BFR” is semi-progressive four-station press. The

press can either be set up to rotate in a clockwise or counter-clockwise direction allowing

the user some flexibility in their reloading process. As offered by the entire line of Dillon

products, the machine has the capability of interchangeable tool heads to allow the user

to have multiple setups for the machine.

Changing the Toolhead will require the removal of the three Toolhead Bolts, then lift

the Toolhead straight up and off of the three Uprights. To replace the Toolhead simply

place it back on the three Uprights aligning the pockets on the bottom of the Toolhead

and the steps on the top of the Uprights. It may be necessary to loosen the lower right

front Upright mounting bolt to get the Toolhead to seat fully. Replace and tighten the

Toolhead Bolts (35-40 ft/lbs torque).

Page 8

PART# 29023 3/8/2010

8

Choosing your dies

The Dillon BFR will perform well with any manufacturer’s standard 1½”-12 UNF threaded

dies. Be ware that many 50 BMG dies currently available are for use in single-stage

presses, and may have a sharp lead in, which may not be very forgiving in a progressive

press.

The Dillon 50 BMG full length carbide sizing/de-priming die is manufactured to minimum

tolerances. DO NOT run this die down to the shellplate and size your brass, it will undersize

the case beyond the specified minimum dimensions. We strongly suggest that a

headspace case gage be used to correctly adjust the size die. You MUST CLEAN AND

LUBE your 50 BMG cases before attempting to size with the 50 BMG carbide sizing/depriming die.

To adjust:

1. Move the handle down to raise the platform.

2. Screw the sizing/de-priming die into station one of your reloader.

3. The 50 BMG sizing/de-priming carbide should not touch the shellplate. It will undersize

the case beyond the specified minimum dimensions if screwed down to the shellplate.

Once you screw it in and touches the shellplate then back the die up 1¾ to 2½ turns. This

will give you a good starting point for determining case dimension. The die was designed

to allow for a very wide margin of adjustment for the shoulder setback.

4. Using one lubed, boxer primed, case to test your sizing and headspace adjust the die

as needed to achieve proper headspace. (Wipe the case clean of lube before inserting

it into the case gage. Lube will cause grit and dust to cling to the inner surface and cause

the gage to give false readings. The base of the sized case should fall between the high

and low steps on the base of the case gage. If it does not, adjust your die and resize the

case. It may be necessary to use another case for this step. Repeat this process until the

case falls between the high and low steps on the base of the case gage.)

5. When properly adjusted, with a case in the die, snug the lock ring and its set screws to

set the desired position.

The de-priming assembly

The Dillon de-priming assembly includes a carbide expander ball for neck expansion. With

the handle pulled all the way down and a case inside of the die adjust the de-priming

stem down until it stops and then back it up 1½ to 2 turns. Once adjusted, tighten the nut

to lock the assembly in place. The number one danger in reloading is attempting to deprime a live primer. Under no circumstances should you ever attempt to de-prime a live

primer.

Page 9

PART# 29023 3/8/2010

9

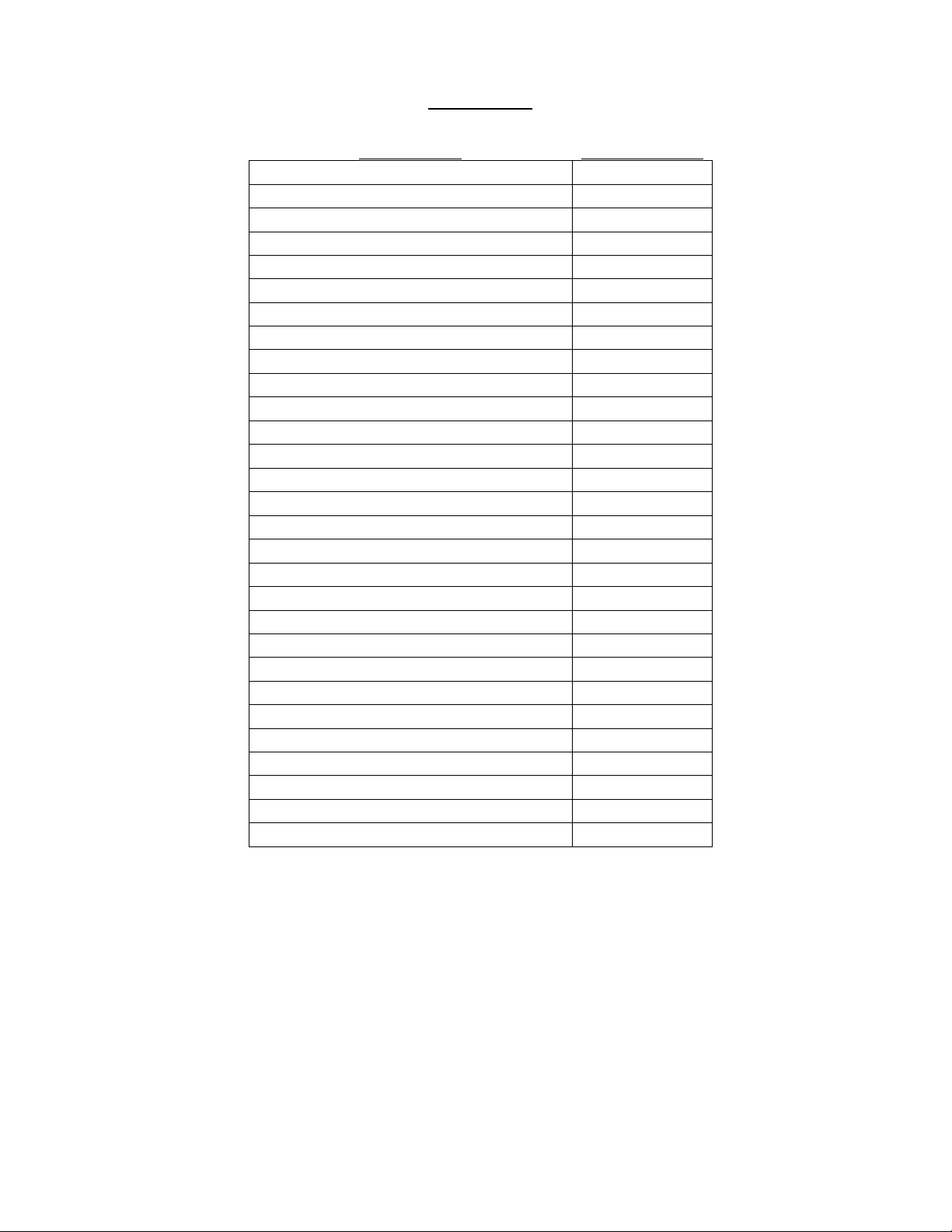

PART NAME

PART

NUMBER

50 BMG LOCK RING SET SCREW

14536

50 BMG DECAP STEM LOCK NUT

14544

50 BMG DECAP STEM

14545

50 BMG DIE LOCK RING

14793

50 BMG DECAP PIN

19465

50 BMG SIZE DIE BODY

19466

50 BMG CARBIDE EXPANDER BALL

19481

THE DILLON 50 BMG SIZING/DE-PRIMING DIE

Page 10

PART# 29023 3/8/2010

10

PRIMING

The 50 BMG priming system is a departure from typical Dillon priming systems. It has been

our experience that a magazine of No. 35 primers is a very dangerous prospect due to

the comparatively massive amount of explosive contained therein. So we are

introducing our 50 BMG “Top of Toolhead” primer seater. This configuration allows for easy

access for manual “one at a time” loading of primers, while taking full advantage of the

final cam portion of the stroke to seat the primer.

Primer Punch options

Included with your priming system are two styles of primer seat punches, a concave and

flat-surfaced punch. The concave punch is used for the majority of 50 BMG applications

providing excellent seating and support of the primer cup, while preventing any “precrush” on the primer anvil. In high-accuracy or bench-rest style applications, a flat punch

may be used, with increased caution, where you may find having “pre-crush” is desirable

for decreasing lock time for match type applications.

Adjusting your primer seater

The primer seat is threaded 1½”-12 UNF to function as a die in the tool head. It operated

by making contact with the shellplate platform, to seat the primer, and resetting with the

spring-loaded punch.

To adjust:

1. Move the handle down to raise the platform.

2. Screw the Primer seater die into the desired station of your reloader. Continue screwing

in, after it has made contact with the platform, until the punch face is flush with the floor

primer seater shell holder.

3. Adjust the orientation of the shell holder slot as desired, and then snug the lock ring and

its set screws to set this position.

4. Once set, use the fine adjustment knob that contacts the platform, to set the final

depth of the primer punch.

5. Tighten the two set screws and the jam nut to lock the adjustment screw.

Page 11

PART# 29023 3/8/2010

11

PART NAME

PART NUMBER

50 BMG LOCK RING SET SCREW

14536

50 BMG PRIMER SYSTEM RETURN SPRING

14539

PRIMER SEAT DIE BODY

14712

PRIMER SEAT DIE SHELL HOLDER

14713

50 BMG PRIMER (CONCAVE) SEAT DIE PUNCH

14714

50 BMG PRIMER SEAT (FLAT) DIE PUNCH

14715

50 BMG PRIMER SEAT DIE ADJUSTMENT BOLT

14737

50 BMG PRIMER SEAT DIE ADJUSTMENT NUT

14738

50 BMG DIE LOCK RING

14793

DILLON BFR PRIMING SYSTEM

Page 12

PART# 29023 3/8/2010

12

Dillon 50 BMG Case Trimmer

TO OPERATE: You will need a pair of calipers to set the trim die properly. THIS DIE IS NOT

DESIGNED TO SIZE THE CASE AS IT HOLDS THE CASE NECK ONLY. For best results you need to

clean, size, and lube your brass before trimming. Place a clean, sized, and lubed case

into the station for the trimmer and raise the platform. Install the trim die (without the trim

motor) into the Toolhead on your reloading machine. Adjust it down until it is in full

contact with the case. If you screw the die down too far or all the way, without checking,

YOU MAY INADVERTENTLY PUSH THE CASE SHOULDER BACK. Once the trim die is adjusted

correctly, tighten the size/trim die lock nut. You should always have a case in the trim die

before beginning trim adjustments. You need to do this to avoid screwing the motor

assembly down too far causing the carbide cutter to contact the bottom of the port

window of the size/trim die. This will cause the carbide cutter to shatter, possibly causing

injury to nearby persons or damage to the unit. So with a case in the die, thread the trim

motor onto the size/trim die until the cutter makes contact with the case mouth. Then

lower the platform and turn the cutter motor down another 1/8 turn. Lock motor jam nut.

Connect the power cords and turn the motor on. Trim a case and check it for overall

length using a pair of calipers. To check for overall length, set the case firmly into the case

gage and set the gage on a clean, flat surface. The case mouth should be between the

high and low step of the case gage. Adjust the motor up or down and repeat these steps

until the right overall length is achieved. Once the right length is reached, lock the motor

jam nut. Before turning the unit on, always retighten the motor jam nut.

NOTE: The vacuum assembly clamps around the lower bell of the trimmer motor

assembly. It should surround the chip exhaust port on the trim die. The vacuum

attachment may need to be modified to fit your vacuum cleaner model.

Page 13

PART# 29023 3/8/2010

13

PART NAME

PART

NUMBER

50 BMG TRIM DIE

14709

50 BMG TRIMMER END BELL

18959

50 BMG TRIM DIE NUT

14710

50 BMG TOOL HOLDER

14711

TRIMMER MOTOR

14722

CARBIDE CUTTER

13141

TRIMMER MANIFOLD BASE

12996

TRIMMER MANIFOLD

12996

CASE TRIMMER INSERT SCREW

14012

50 BMG DIE LOCK RING

14793

50 BMG LOCK RING SET SCREW

14536

Dillon 50 BMG Case Trimmer

Page 14

PART# 29023 3/8/2010

14

PART NAME

PART NUMBER

#7 LOCATOR PIN

13436

3/8" DIA. INDEX BALL

13891

MAIN SHAFT BOTTOM SET SCREW

13923

PLATFORM BOLT

13966

550 INDEX BALL SPRING

13997

50 BMG SHELLPLATE BOLT

14494

50 BMG CRANK PIN

14495

50 BMG LOWER CRANK PIN

14496

50 BMG UPPER LINK ARM PIN

14497

50 BMG BRASS TIP SET SCREW

14498

50 BMG PLATFORM STOP

14500

50 BMG TOOL HEAD BOLT

14522

50 BMG REAR UPRIGHT BOLT 2.5"

14523

50 BMG FRONT UPRIGHT BOLT 2.5"

14529

50 BMG LOWER CRANK BEARING*

14531

50 BMG CRANK PIN CAP

14532

50 BMG LINK ARM BEARING*

14533

50 BMG MAIN SHAFT

19827

50 BMG PLATFORM

19828

50 BMG LINK ARM

19829

50 BMG UPRIGHT

19830

50 BMG TOOL HEAD

19831

50 BMG SHELLPLATE

19834

50 BMG HANDLE

19835

50 BMG BASE

19836

50 BMG CRANK

19837

50 BMG BRASS BALL KNOB

29010

50 BMG CRANK PIN CAP BOLT

29013

50 BMG HANDLE NUT

50024

PARTS LIST

* INDICATES NON-REMOVABLE PRESSED PARTS

Page 15

PART# 29023 3/8/2010

15

DILLON BFR SCHEMATIC

PLATFORM ASSEMBLY

Page 16

PART# 29023 3/8/2010

16

NOTE: Before attempting to remove the shellplate bolt (PN: 14494) be sure that the

shellplate bolt set screw (PN: 13923) is removed.

The shellplate bolt (PN: 14494) should be tightened only as far as needed for smooth

operation of the shellplate. IT CAN BE OVER TIGHTENED.

Page 17

PART# 29023 3/8/2010

17

Dillon Precision Products, Inc.

8009 E. Dillon’s Way

Scottsdale, AZ 85260

(480) 948-8009

FAX (480) 998-2786

Web Site: www.dillonprecision.com

Technical Support E-mail: dillon@dillonprecision.com

See our Troubleshooting Section online at www.dillonprecision.com

Technical Support & Customer Service

(800) 223-4570

Loading...

Loading...