Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

1 of 41

PC, DVI, HDMI, VIDEO INTERFACE CONTROLLER

FOR TFT PANEL

Model: SVX-1920v2

Part number : 41744022X-3 or up

INSTRUCTIONS

CONTENTS

Page: 2. Introduction, How to Proceed, Usage Note, Disclaimer

3. System design – Diagram of a suggested system

4. Assembly notes – Important information about system elements

6. Connection & Operation – How to use the controller

10. Connectors, pinouts & jumpers – Essential connection information

21. Controller dimensions

22. Application notes

24. Troubleshooting

25. Specifications

26. Appendix I – Supported graphics modes table

28. Appendix II – RS-232 control protocols

32. Appendix III – Mapping definition

36. Appendix IV – DV remote control unit work for SVX-1920v2

37. Appendix V – Function description for de-interlacing mode MADI, DCDi

37. Appendix VI – PIP mix table

38. Appendix VII - Network connection

39. Warranty, Caution & Limitation of Liability, Trademarks

40. Contact details

41. Revision history

It is essential that these instructions are read and understood before connecting or

powering up this controller.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

2 of 41

Introduction

Designed for LCD monitor and other flat panel display applications, the SVX-1920v2 is a feature rich interface

controller for :

TFT (active matrix) LCD panels of 1920x1200, 1920x1080, 1920x480, 1680x1050, 1600x1200, 1600x900, 1440x900,

1366x768, 1280x1024, 1280x800, 1280x768 1024x768, 1024x600, 800x600, 800x480 and 640x480 resolutions.

Computer video signals of VGA, SVGA, XGA, SXGA, WXGA, UXGA, WUXGA standard.

Support true 10 bits panel

Support image flip function

Support HDMI, DVI, VGA, Component Video input

Ordering information :

Controller Part number Ordering part number

SVX-1920v2 P/N 41744022X-3 P/N 4174402XX-3

HOW TO PROCEED

Ensure you have all parts & that they are correct, refer to:

• Connection diagram

• Connector reference (in following section)

• Assembly notes

Check controller switch & jumper settings (errors may damage the panel)

Prepare the PC

Connect the parts

Understand the operation & functions

IMPORTANT USAGE NOTE

This equipment is for use by developers and integrators, the manufacturer accepts no liability for damage or injury

caused by the use of this product. It is the responsibility of the developer, integrators or other user of this product to:

• Ensure that all necessary and appropriate safety measures are taken.

• Obtain suitable regulatory approvals as may be required.

• Check power settings to all component parts before connection.

DISCLAIMER

There is no implied or expressed warranty regarding this material.

Controller Solution Generator

Full web resource matching controllers & panels with connection diagrams for download.

See at : http://www.digitalview.com/csg

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

3 of 41

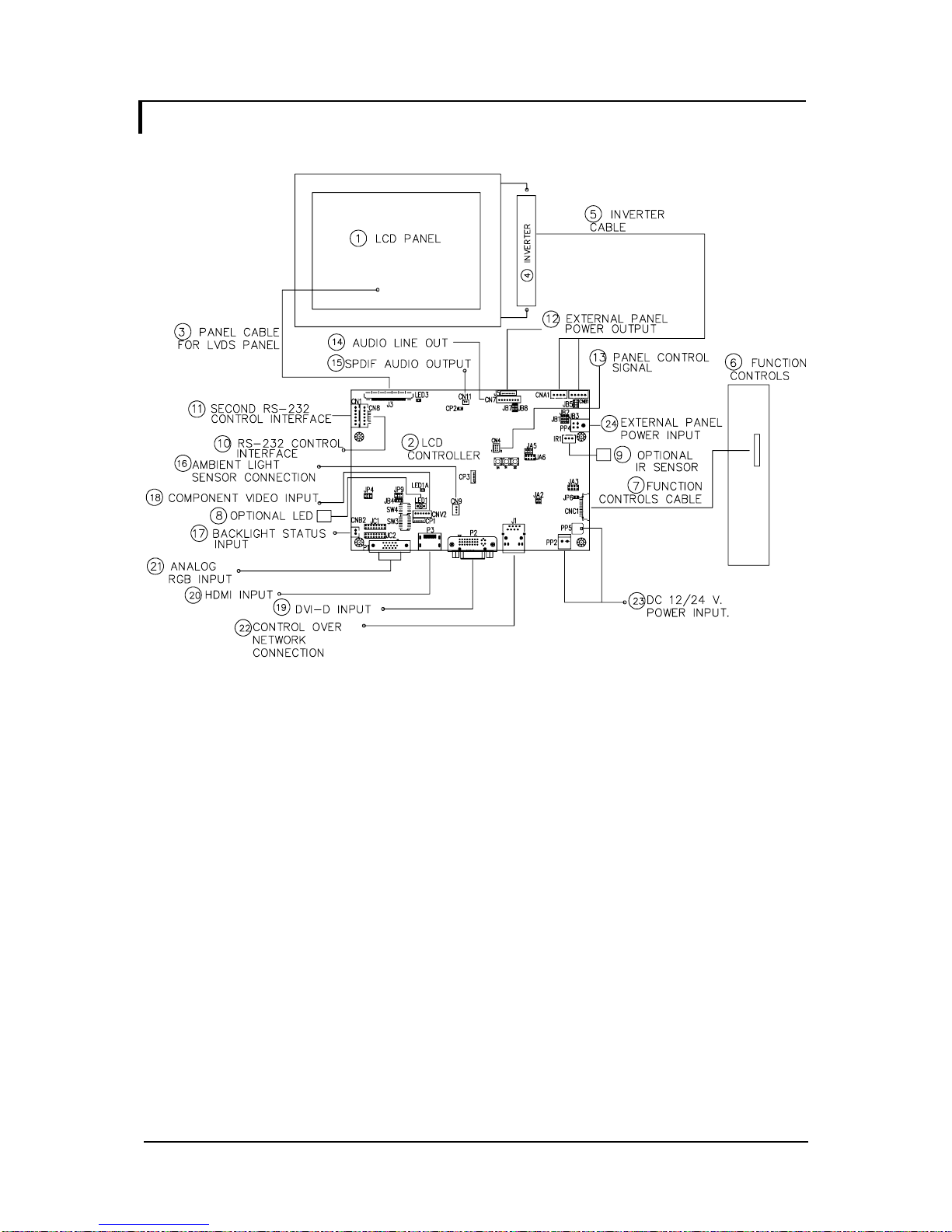

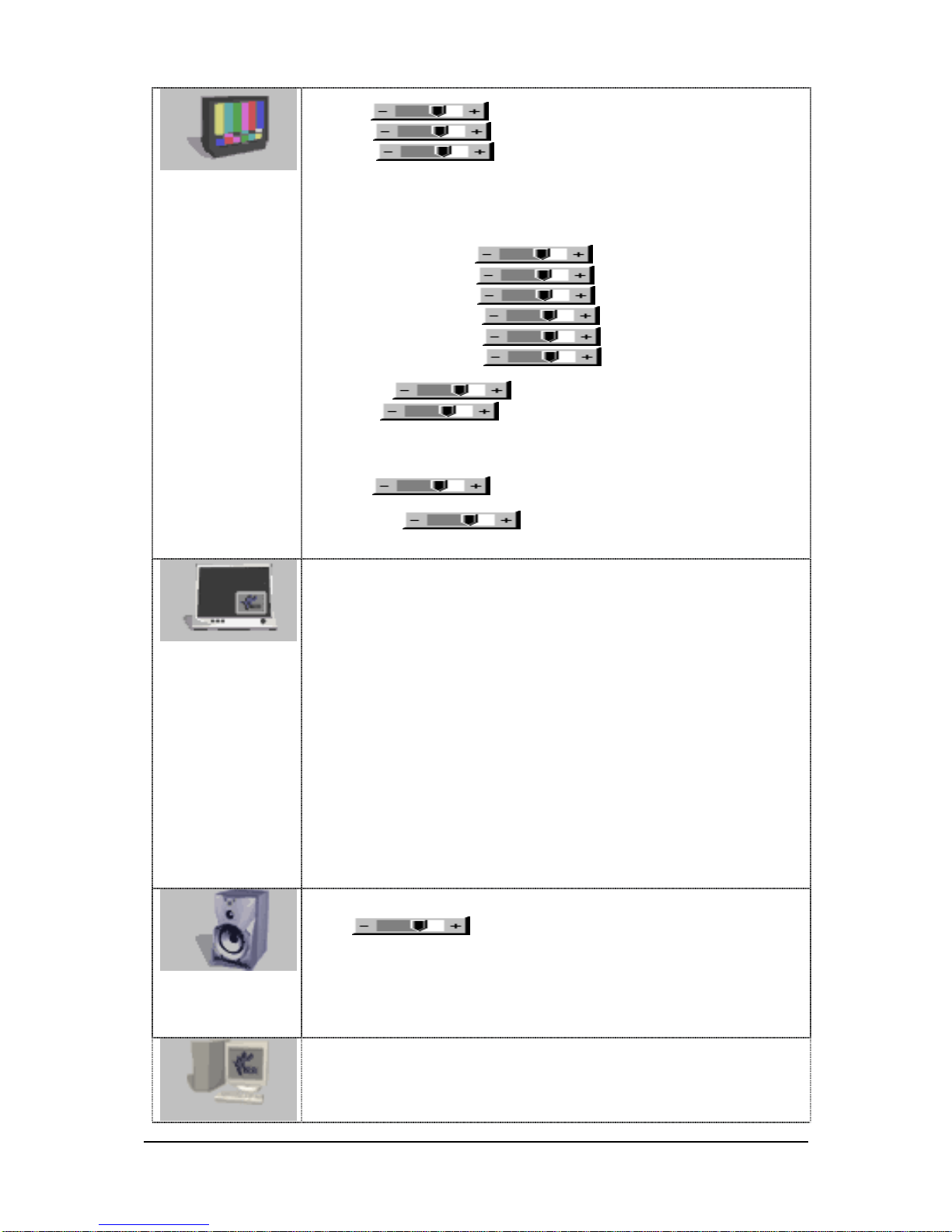

SYSTEM DESIGN

A typical LCD based display system utilizing this controller is likely to comprise the following:

Summary:

1. LCD panel

2. LCD controller card, SVX-1920v2

3. LCD signal cable (use for LVDS panel)

4. Inverter for backlight (if not built into LCD)

5. Inverter cable

6. Function controls

7. Function controls cable

8. Status LED (optional)

9. IR sensor (optional)

10. RS-232 control interface

11. Second RS-232 control interface

12. External panel power output

13. Panel control signal

14. Audio line out

15. SPDIF Audio output

16. Ambient light sensor connection

17. Backlight status input

18. HD/SD Component video input

19. DVI-D input

20. HDMI input

21. Analog RGB input

22. Control over network connection

23. +12V / +24V DC power input

24. External panel power input

Digital View provides a range of parts, such as listed above, to make up complete display solutions.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

4 of 41

ASSEMBLY NOTES

This controller is designed for monitor and custom display projects using 1920x1200 or 1920x1080 or 1600x1200 or 1680x1050

or 1440x900 or 1366x768 or 1280 x 1024 or 1024 x 768 or 800x600 or 640x480 resolution TFT panels with a VGA, SVGA,

WXGA, XGA, SXGA, UXGA or WUXGA signal input. The following provides some guidelines for installation and preparation of

a finished display solution.

Preparation: Before proceeding it is important to familiarize yourself with the parts making up the system and the various

connectors, mounting holes and general layout of the controller. As much as possible connectors have been labeled. Guides

to connectors and mounting holes are shown in the following relevant sections.

1. LCD Panel: This controller is designed for typical LVDS interfaced panels with panel voltage 3.3V, 5V, 12V or 18V,

External for 12V~18V interface. Due to the variation between manufacturers of panels signal timing and other panel

characteristics, factory setup and confirmation should be obtained before connecting to a panel. (NOTE: Check panel

power jumper settings before connection)

2. Controller: Handle the controller with care as static charge may damage electronic components. Make sure correct

jumper and dip switches settings to match the target LCD panel.

3. LCD signal cable (LVDS panel): In order to provide a clean signal it is recommended that LVDS signal cables are no

longer than 46cm (18 inches). If those wire cabling is utilized these can be made into a harness with cable ties. Care

should be taken when placing the cables to avoid signal interference. Additionally it may be necessary in some systems to

add ferrite cores to the cable to minimize signal noise.

4. Inverter: This will be required for the backlight of an LCD, some LCD panels have an inverter built in. As LCD panels may

have 1 or more backlight tubes and the power requirements for different panel backlights may vary it is important to match

the inverter in order to obtain optimum performance. See Application notes page 20 for more information on connection.

5. Inverter Cables: Different inverter models require different cables and different pin assignment. Make sure correct cable

pin out to match inverter. Using wrong cable pin out may damage the inverter.

6. Function Controls: The following section discusses the controls required and the section on connectors provides the

detail. The controls are minimal: On/Off, Backlight Brightness (depends on inverter), OSD (5 momentary buttons) analog

VR type or (8 momentary buttons) digital type.

The 8 momentary buttons OSD switch mount P/N 416100520-3 or OSD membrane interface P/N 416100120-3 must be

used when 24VDC input.

7. Function controls cable: The cables to the function switches should be of suitable quality and length so that impedance

does not affect performance. Generally lengths up to 1 meter (3 feet) should be acceptable.

8. Status LED: The pin direction of the LED should be corrected for right color indication. Red color stands for standby.

Green colors stands for signal on. The status LED is an optional part only, can be unconnected.

9. IR sensor: It is an optional part only, can be unconnected if not using IR remote control. See Appendix IV in details.

10. RS-232 control interface : Firmware upgrade and serial control via this interface port.

11. Second RS-232 control interface : This interface port is no function now.

12. External panel power output : User for specific panel model.

13. Panel control signal : Use for specific panel model.

14. Audio line out : This interface port is no function now.

15. SPDIF Audio output : This port support SPDIF audio output from the HDMI audio source inputted.

16. Ambient light sensor connection : 3 ways connector provides interface for ambient light sensor connection by using Kit

70220-3.

17. Backlight status input : 2 ways connector provides interface for connection with the specific panel type which support the

panel with backlight status monitoring function.

18. HD / SD Component video input : Plug the component video input cable P/N 426000600-3 on CNV2 connector

19. DVI-D input cable : Plug the DVI cable to the connector P3 on the controller board.

20. HDMI input : Plug the HDMI cable to the connector P2 on the controller board. This port is not supported when CN5 is

connected.

21. Analog RGB Input : As this may affect regulatory emission test results and the quality of the signal to the controller a

suitably shielded cable should be utilized.

22. Control over network connection : This is a network device that allow to control RS-232 enable devices over a TCP/IP

based Ethernet and the Internet using a web browser. Please refer to Appendix VII in details.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

5 of 41

23. Power Input: 12V/24VDC is required, this should be a regulated supply. The power rating is depending on the panel and

inverter used. Normally, power supply with 3.5Amp current output should enough for most of 4x CCFT panels. Although

the controller provides power regulation for the LCD power this does not relate to the power supplied to the backlight

inverter. If an unregulated power supply is provided to an inverter any fluctuations in power may affect operation,

performance and lifetime of the inverter and or backlight tubes.

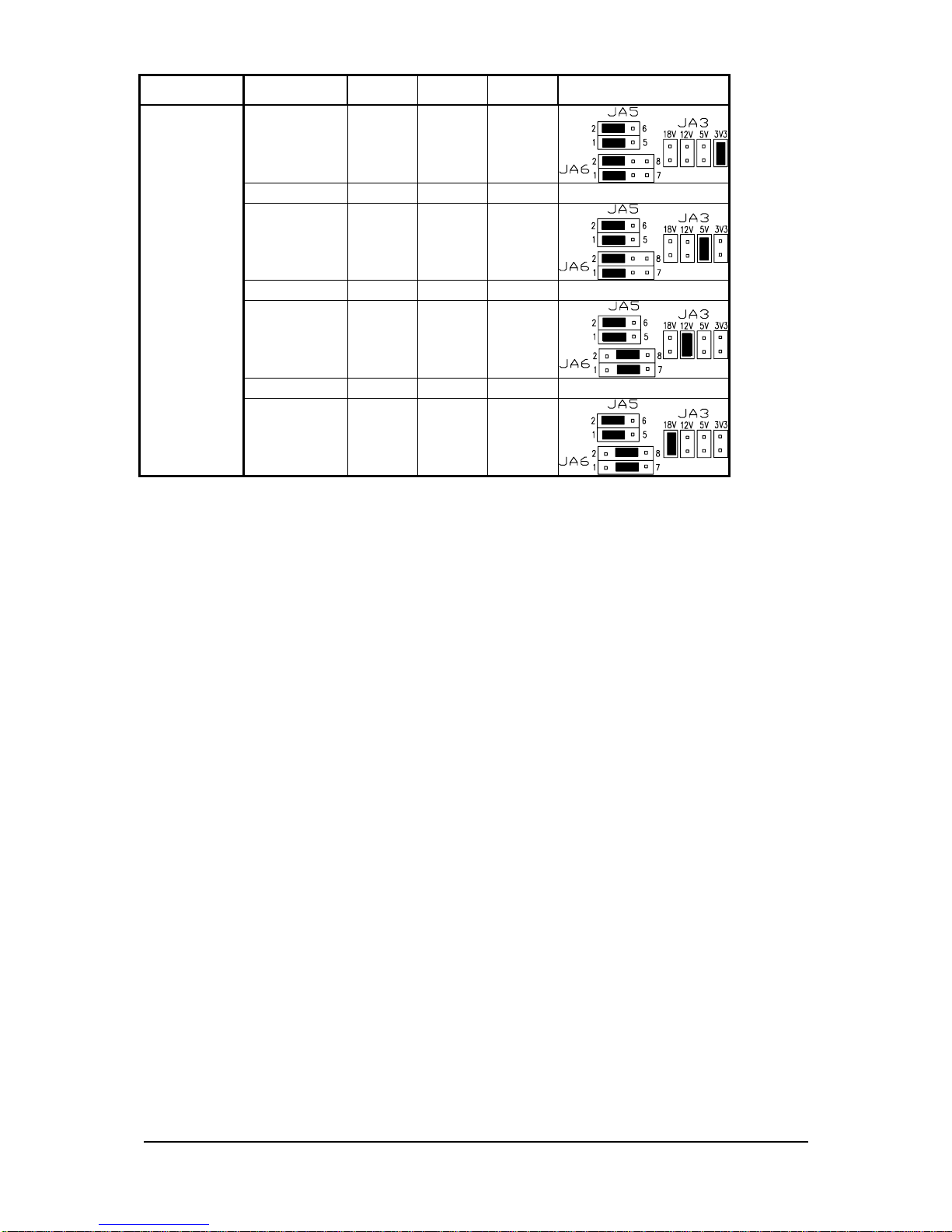

24. External panel power input : Allow to supply external power to the panel separately for max 3.3V (7A) or 5V (7A) or 12V

(5A) or 18V (3.5A) via PP4 power input connector. Corresponding jumper setting of JA3, JA5 & JA6 are required for each

panel power input by referring to page 14.

• Power output: Note the controller has an overall 3Amp current limit and the current available from the auxiliary power

output will be dependent on the power input and other system requirements.

• Power Safety: Note that although only 12V / 24VDC is required as ‘power-in’ a backlight inverter for panel backlighting

produces significantly higher voltages (the inverter does not connect to the ground plane). We strongly advise appropriate

insulation for all circuitry.

• EMI: Shielding will be required for passing certain regulatory emissions tests. Also the choice of external Controller to PC

signal cable can affect the result.

• Ground: The various PCB mounting holes are connected to the ground plane.

• Servicing: The board is not user serviceable or repairable. Warranty does not cover user error in connecting up to the

controller and is invalidated by unauthorized modification or repairs.

• Controller Mounting: It is recommended that a clearance of at least 10mm is provided above and 5mm below the

controller when mounted. Additionally consideration should be given to:

• Electrical insulation.

• Grounding.

• EMI shielding.

• Cable management. Note: It is important to keep panel signal cables apart from the inverter & backlight cables to

prevent signal interference.

• Heat & Ventilation: Heat generated from other sources, for example the backlight of a very high brightness panel may

generate significant heat which could adversely affect the controller.

• Other issues that may affect safety or performance.

• PC Graphics Output: A few guidelines:

• Signal quality is very important, if there is noise or instability in the PC graphics output this may result in visible noise

on the display.

• Refer to graphics modes table in specifications section for supported modes.

• Non-interlaced & interlaced video input is acceptable.

IMPORTANT: Please read the Application Notes section for more information.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

6 of 41

CONNECTION & OPERATION

CAUTION: Never connect or disconnect parts of the display system when the system is powered up as this may cause serious

damage.

CONNECTION

Connection and usage is quite straight forward (it is useful to have the relevant connection diagram available at this time):

1. LCD panel & Inverter: Connect the inverter (if it is not built-in the panel) to the CCFT lead connector of the LCD panel.

2. LVDS type panels: The controller board has the built-in LVDS transmitter driver. Plug the LVDS cable to J3. Insert the

panel end of the cable the LCD panel connector.

3. Inverter & Controller: Plug the inverter cable to CNB1 and CNA1 (if necessary). Plug another end to the connector on

the inverter.

4. Function switch & Controller: Plug the OSD switch mount cable to CNC1 on the controller board and another to the

OSD switch mount.

5. LED & Controller: Plug in a 3-way with dual color LED to connector LED1 on the controller board.

6. IR & Controller: Plug in a 3-way with IR sensor to connector IR1 on the controller board.

7. Jumpers & Switches: Check all jumpers and switches (SW3, SW4) are set correctly. Details referring the connection

diagram (a separate document) or the jumpers and switches setting table (in the following section).

8. Jumpers & Inverter & Panel voltage: Particularly pay attention to the settings of JA3, JA5, JA6, JB2 and JB3. JB2 & JB3

are used for inverter control (read inverter specification and information on the jumper table to define the correct settings).

JA3 & JA5 & JA6 is used for panel voltage input (read panel specification and information on the jumper table to define the

correct settings).

9. Input signal cable & Controller: Plug the corresponding signal input to the connector on the controller board.

10. Power supply & Controller: Plug the DC 12V/24V power in to the connector PP5 or PP2. You can consider to use

DigitalView mating power cable P/N 426013800-3, 160mm for PP5 connection.

11. External panel power input : Plug power cable : P/N 426013700-3 for external panel power input (3.3 (max 7A) / 5V

(max 7A) / 12V (max 5A) / 18V (max3.5))

12. Power on: Switch on the controller board and panel by using the OSD switch mount.

General:

• If you are using supplied cables & accessories, ensure they are correct for the model of panel and controller.

• If you are making your own cables & connectors refer carefully to both the panel & inverter specifications and the section

in this manual, “Connectors, Pinouts & Jumpers” to ensure the correct pin to pin wiring.

PC SETTINGS

The controller has been designed to take a very wide range of input signals however to optimize the PC’s graphics performance

we recommend choosing 60Hz vertical refresh rate – this will not cause screen flicker.

OPERATION

Once the system has been connected and switched on there are a number of functions available to adjust the display

image as summarized in the following sections. The settings chosen will be saved for each mode independently.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

7 of 41

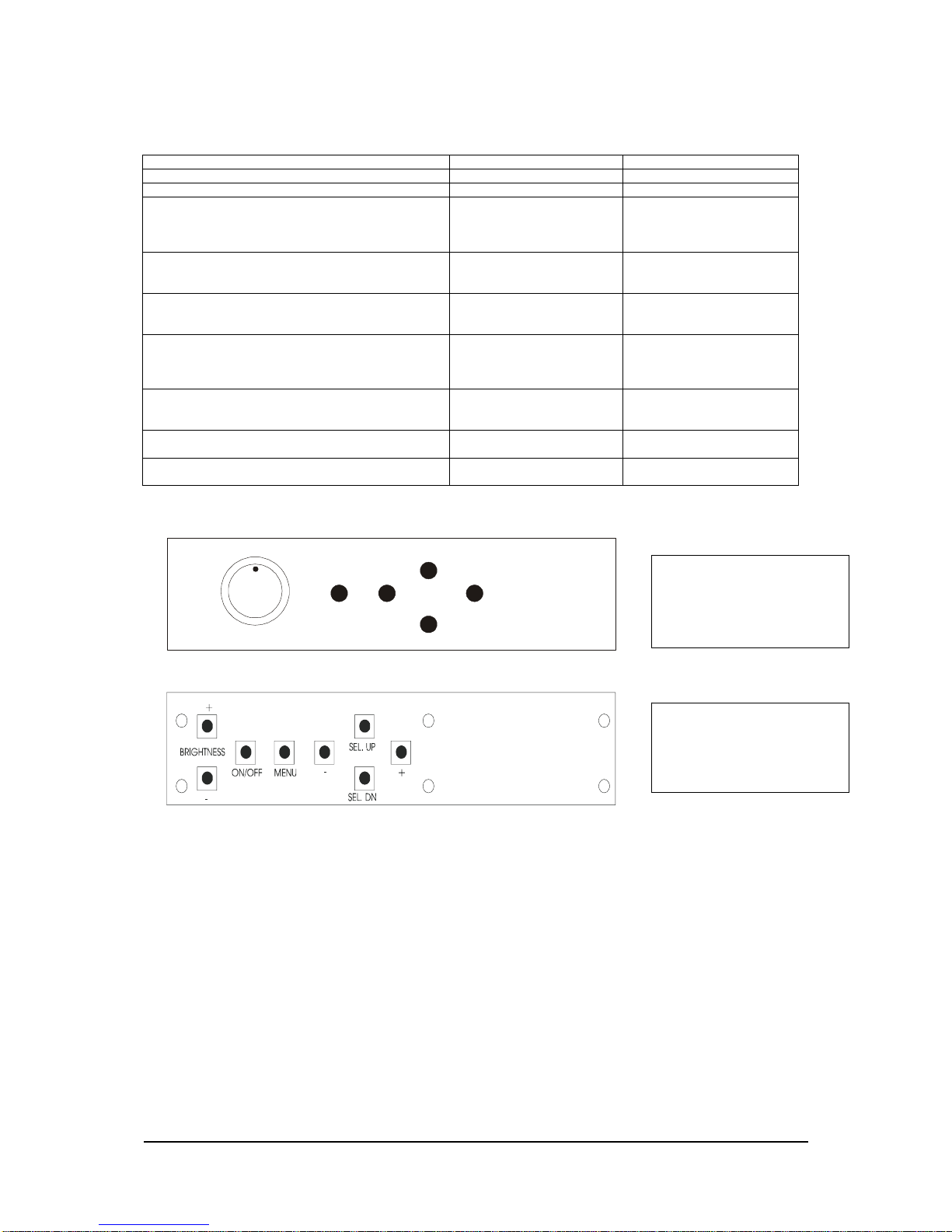

LCD DISPLAY SYSTEM SETTINGS

NOTE: By way of explanation the following refers to a set of sample buttons that may be obtained as an option. In addition

to power on/off and connection for backlight brightness the controller provides an On Screen Display of certain functions

which are controlled by 5 momentary type buttons (analog VR type) or 8 momentary type buttons (digital type):

Controls Analog VR type Digital type

On/Off – turns controller board power on VR toggle switch On/Off button

Brightness – controls backlight brightness Rotary VR Brightness +/- buttons

Menu

– Turns OSD menu On or Off (it will auto time

off)

– Back to previous OSD menu page

Menu button Menu button

Select down

– Moves the selector to the next function (down)

SEL DN SEL DN

Select up

– Moves the selector to the previous function

(up)

SEL UP SEL UP

+

– Increase the OSD parameter values

– Go into the sub-menu page from the top

– Confirm to select the OSD function

+ +

-

– Decrease the OSD parameter values

- Go into the sub-menu page from the bottom

- -

Reset to Factory Defaults Press and hold SEL DN button,

then power on the controller

Press and hold SEL DN button,

then power on the controller

Access “Programming Mode” Press and hold MENU button,

then power on the controller

Press and hold MENU button,

then power on the controller

ON/Off/Brightness

SEL UP

SEL DN

+

-

Menu

Analog VR type

Digital type

12V / 24VDC power input :

Analog 10K VR Type OSD

switch mount uses

P/N 410680550-3 or up

12V / 24VDC power input :

Digital 10K Type OSD

switch mount uses

P/N 416100520-3 or up

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

8 of 41

OSD functions

Image Settings :

Brightness

Increase/decrease panel brightness level, total: 100 steps

Contrast

Increase/decrease panel contrast level, total: 100 steps

Sharpness*

Increase/decrease sharpness, total: 30 steps

Color 4

Color Temp

6500K

7500K

9300K

User4

Red Gain :

Green Gain :

Blue Gain :

Red Offset :

Green Offset :

Blue Offset :

Saturation*

Increase/decrease saturation, total: 100 steps

Hue*

Increase/decrease Hue level, total: 100 steps

VGA Setup4

Auto Adjustment

#

: Off/ On : Auto adjust the image position, phase and size

Image Position

#

: Move the image position upward/downward/left/right.

Phase

#

: Fine tune the data sampling position (adjust image

quality)

Clocks/Line

#

: Adjust the image horizontal size

* : DISPLAY IN VIDEO MODE ONLY

# : FUNCTION IN ARGB MODE ONLY

Display Settings

Main Source : Select the input video signal

VGA

DVI

HDMI1

CMPT1 (Component)

Aspect Ratio 4

- Full screen : Enable full screen expansion for lower resolution Image

- Pillar Box: scaling format in 4:3

- Letterbox expand : Enable fill screen expansion for lower resolution

image according to aspect ratio

PIP 4

PIP mode4 Off / Large PIP / Small PIP / Side by Side

The PIP capability on display input sources refer to Appendix VII – PIP mix table

PIP Position4 Bottom-Right / Top-Left / Top-Right / Bottom-Left

PIP Source 4 HDMI / DVI

Image rotation 4 Off / H rotation / V rotation / H/V rotation

Audio Settings : (No function)

Mute 4 Off /On

Volume

Increase/decrease volume level, total : 100 steps

Video :

DCDi 4

Main DCDi 4 On / Off

Main MADI mode 4 Normal / Adaptive / Off

[See Appendix V for DCDi, MADI function description]

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

9 of 41

Setup :

Smart ISP

Language : English

Factory Reset : Yes / No

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

10 of 41

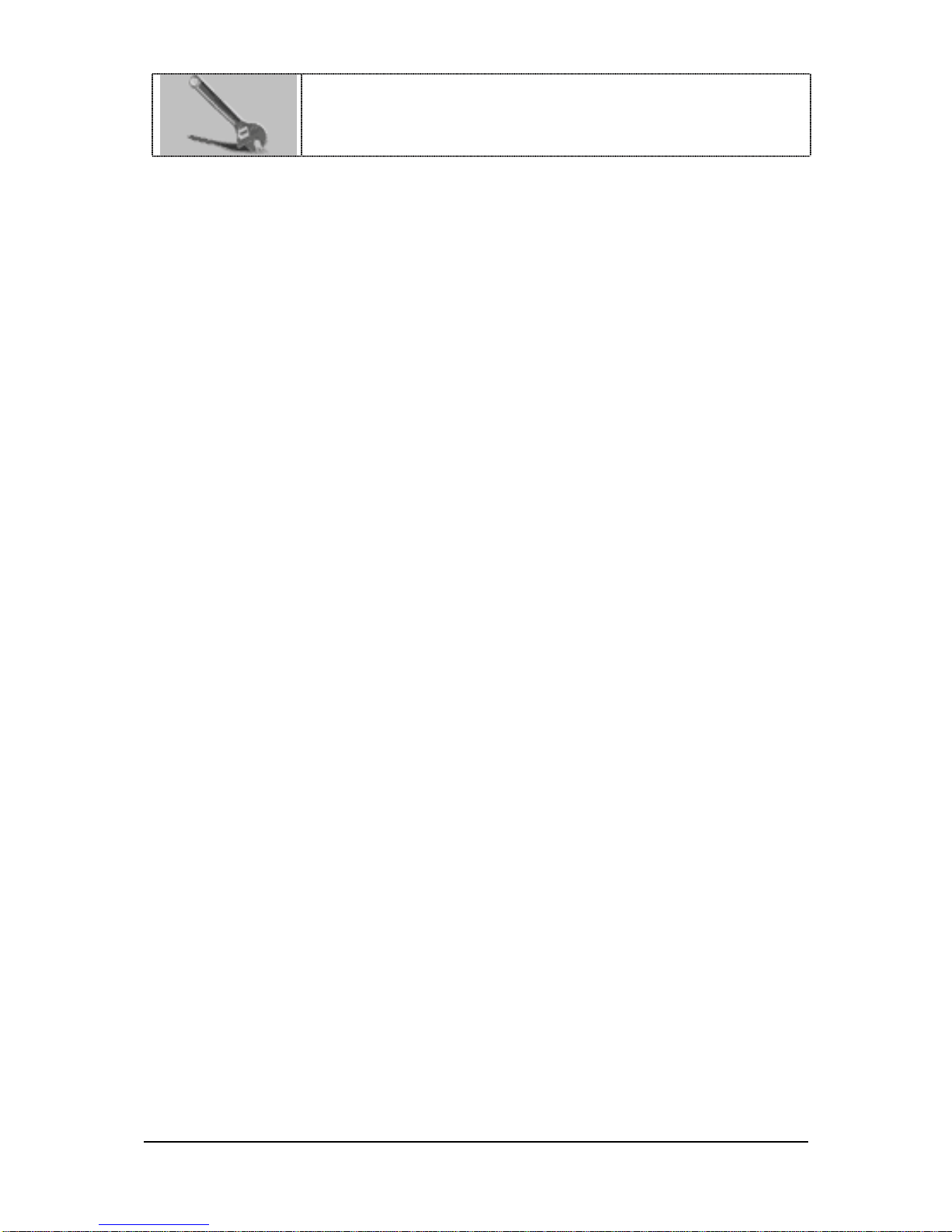

CONNECTORS, PINOUTS & JUMPERS

The various connectors are:

Summary: Connectors

Ref Purpose Description

CN1 Reserved for second RS-232 serial

control

JST 6-way, B6B-XH-A (Matching type : XHP-6)

CN4 Panel control signal connector Hirose 10-pin, DF20G-10DP-1V (Matching type : DF20A-10DS-1C)

CN7 Reserved for Audio line out JST 8-way, B8B-PH-K (Matching type : PHR-8)

CN8 RS-232 serial control JST 6-way, B6B-XH-A (Matching type : XHP-6)

CN9 Ambient light sensor connector JST 3-way, B3B-PH-K (Matching type : PHR-3)

CN11 SPDIF Audio output JST B2B-ZR (Matching type : ZHR-2)

(Matching extend cable P/N 426007400-3)

CNA1 Auxiliary power output JST 4-way, B4B-XH-A (Matching type : XHP-4)

(Matching cable P/N 426040200-3)

CNB1 Backlight inverter JST 5-way, B5B-XH-A (Matching type : XHP-5)

(Matching cable P/N 426058300-3)

CNB2 Backlight status input connector JST 2 way, B2B-XH-A (Matching type : XHP-2)

(Matching cable P/N 426020800-3)

CNC1 OSD control Hirose DF13A-12P-1.25H (Mating type : XHP-12)

CNV2 Component (YPbPr) video input

connector

JST 6-way, B6B-PH-K (Matching type : PHR-6)

(Matching video cable P/N 426000600-3)

CP1 Reserved for internal programming Reserved

CP3 Reserved for internal programming Reserved

IR1 Infra-red sensor connector JST 3-way, B3B-XH-A (Matching type : XHP-3)

J1 Ethernet RJ-45 connector

J3 LVDS panel signal output JAE FI-RE51S-HF (Matching type : FI-RE51HL)

J5 Panel power output JS-1147A-08 Top 1.25mm (Matching type : JS-1146-08)

LED1 Dual color LED connector (Controller

status)

Header pin 3x1

P1 VGA DB-15 way high density 3 row

P2 DVI-D DVI-D connector

P3 HDMI HDMI connector

PP2 Power input (alternative) DC power Molex 2 pin 0.156” pitch

PP4 External panel power input Molex 43045-0400 compatible

(Matching connector type : Molex 43025-0400 compatible)

(Matching power cable : P/N 426013700-3)

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

11 of 41

PP5 Power input Molex 43650-0200 compatible

(Matching connector type : Molex 43645-0200 compatible)

(Matching power cable : P/N 426013800-3)

S1 Reset button (for Ethernet function) Tact switch button

S2 Reserved Tact switch button

S4 Config Menu button (for Ethernet

function)

Tact switch button

SW3 Panel selection 8-way DIP Switch

SW4 Function selection 6-way DIP Switch

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

12 of 41

Summary: Jumpers setting

Ref

Purpose Note

JA2 On board +3.3V logic power enable 1-2 & 3-4 closed, factory set, do not remove

JA3 Panel power voltage select

CAUTION: Incorrect setting can damage

panel

See panel voltage setting table 1

JA5 Panel power voltage select

CAUTION: Incorrect setting will cause panel

damage

See panel voltage setting table 1

JA6 Panel power voltage select

CAUTION: Incorrect setting will cause panel

damage

See panel voltage setting table 1

JB1 Backlight brightness voltage range 1-2 closed = 5V max

2-3 closed = 3.3V max

JB2 Backlight inverter on/off control – signal level 2-3 = On/Off control signal ‘High’ = +5V

1-2 = On/Off control signal ‘High’ = +3.3V

Open = On/Off control signal ‘High’ = Open collector

CAUTION: Incorrect setting can damage inverter.

JB3 Backlight inverter on/off control – polarity 1-2 = control signal ‘high’ = CCFT ON

2-3 = control signal ‘low’ = CCFT ON

JB4 GPIO pins voltage selection 1-2 = 3.3V

2-3 = 5V

JB5 Backlight control type selection 1-2 = VR/Digital switch mount control

3-4 = Reserved

5-6 = Reserved

JB7 Reserved for audio voltage control Reserved

JB8 Reserved for audio logic control Reserved

JC1 Custom configuration Reserved

JC2 Custom configuration Position 1 : Enable J3 – pin 16 (OP1) controlled by JB4

Position 2 : Enable J3 – pin 17 (OP2) controlled by JB4

JP4 Custom configuration 1-2 closed = Reserved

3-4 closed = On-board programming

5-6 closed = Reserved

JP6 Input power control Short = External switch control

Open = Switch mount control

JP9 Factory use Default Open

S1 Reserved Reserved

S4 Reserved Reserved

S5 Reserved Reserved

SW3 Panel & function selection See table 2

SW4 Panel & function selection See table 3

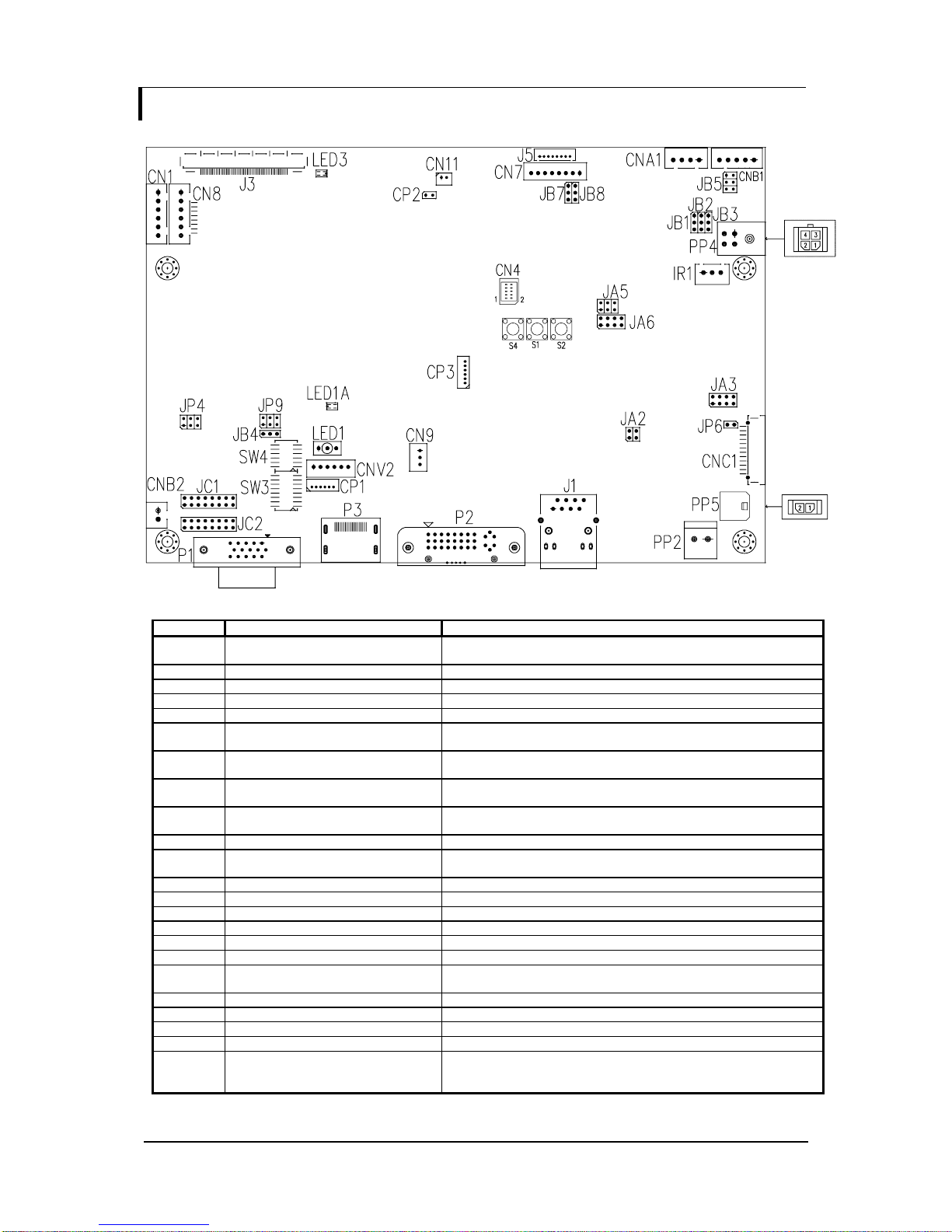

Table 1 : Panel voltage setting table :

Input voltage via

PP2/PP5 Panel Voltage JA3 JA5 JA6 Jumper on board

3.3V 3V3 closed 1-3 & 2-4 1-3 & 2-4

5V 5V closed 1-3 & 2-4 1-3 & 2-4

12VDC

12V OPEN 1-3 & 2-4 5-7 & 6-8

CAUTION: Incorrect setting can damage panel & controller

]

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

13 of 41

Input voltage via

PP2/PP5 Panel Voltage JA3 JA5 JA6 Jumper on board

3.3V 3V3 closed 1-3 & 2-4 1-3 & 2-4

5V 5V closed 1-3 & 2-4 1-3 & 2-4

12V 12V closed 1-3 & 2-4 3-5 & 4-6

24VDC**

18V

18V closed 1-3 & 2-4 3-5 & 4-6

CAUTION: Incorrect setting can damage panel & controller

** Ensure that the backlight inverter supports 24V operation prior to connecting a 24VDC input.

Because CNA1 pin 1 and CNB1 pin 2 will output 24VDC if input 24VDC via PP2 or PP5.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

14 of 41

Input voltage via

PP4

Input voltage via

PP2 / PP5 Panel Voltage JA3

JA5 JA6 Jumper on board

3.3V OPEN 3-5 & 4-6 1-3 & 2-4

5V OPEN 3-5 & 4-6 1-3 & 2-4

12V OPEN 3-5 & 4-6 3-5 & 4-6

3.3 / 5 / 12 /

18VDC*

12V / 24VDC

18V

OPEN 3-5 & 4-6 3-5 & 4-6

* Maximum current for 3.3V, 5V = 7A, Maximum current for 12V = 5A, Maximum current for 18V =

3.5A

JA3, JA5 & JA6 location on board : (Please pay attention to the jumper settings on JA3, JA5

& JA6 which are red in color)

!

!

JA3

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

15 of 41

Table 2 : DIP Switch selection – SW3

Pos #1 Pos #2 Pos #3 Pos.#4 Description Panel resolution

For WUXGA panels

OFF ON ON OFF LG LM260WU1-SLB1/Samsung LTM220CS01 1920x1200

ON ON ON OFF LG LM240WU2-SLA1 1920x1200

OFF OFF OFF OFF Sharp LQ445D3LZ19 1920x1080

ON OFF OFF OFF Samsung LTA460H2-L02 1920x1080

OFF ON OFF OFF Sharp LQ170M1LZ04 1920x1200

ON ON OFF OFF Samsung LTA700HH-LH1 (1st trial testing) 1920x1080

OFF OFF ON OFF Samsung LTA700HH-LH1 (2nd trial testing) 1920x1080

OFF OFF ON ON AU Optronics P645HW03 V0 (1920x1080) 1920x1080

OFF OFF ON ON AU Optronics P645HW03 V0 1920x1080

For UXGA panels

OFF OFF OFF OFF Fujitsu FLC59UXC8V-02A 1600x1200

ON OFF OFF OFF Samsung LTM213U6-L01 1600x1200

For WXGA panels

OFF OFF OFF OFF LG LC420W02-A4 1366x768

ON OFF OFF OFF Sharp LQ315T3LZ24 1366x768

ON ON OFF OFF Samsung LTA320W2-L01 / LTA230W1-L02 1366x768

ON ON ON ON NEC NL12876BC26-21 / Samsung LTM170W1-L01 1280x768

OFF ON ON ON CHI MEI N154I4-L01 1280x800

OFF OFF ON OFF AU Optronics M190PW01 1440x900

OFF OFF ON ON Sharp LQ072K1LA03 1280x768

For SXGA panel

OFF OFF OFF OFF Sharp LQ181E1LW31 1280x1024

ON OFF OFF OFF AU Optronics M170EN05 1280x1024

For XGA panel

OFF OFF OFF OFF Sharp LQ150X1LGN2A / LQ150X1LGB1 1024x768

AUO M150XN07V2 1024x768

For SVGA panel

OFF OFF OFF OFF Sharp LQ121S1DG11/41 800x600

Toshiba LTM08C351 800x600

For WVGA panel

OFF OFF OFF OFF NEC NL8048BC24-01 800x480

ON OFF OFF OFF Kyocera TCG085WV1AB-G00 800x480

ON OFF ON OFF Sharp LQ070Y3LG4A 800x480

For VGA panel

OFF OFF OFF OFF Sharp LQ104V1DG51 640x480

ON OFF OFF OFF Sharp LQ104V1DG21 640x480

ON OFF ON OFF Kyocera TCG075VG2AC-G00 640x480

Others

OFF ON OFF OFF AU Optronics M201EW02 V8 1680x1050

ON OFF OFF ON Samsung LTM201M1-L01 1680x1050

OFF OFF ON OFF Samsung LTI430LA01 1920x480

OFF ON ON OFF NEC NL10260BC19-01D 1024x600

ON ON ON OFF AU Optronics M200RW01 1600x900

Samsung LTM200KP01 1600x900

Remark : The above panel timings are copy the panel data direct from SVX-1920. Some of the panel timings settings

may not exactly to match the panel model we specified in this table.

Pos #5 Pos #6 Pos #7 Description

OFF OFF OFF WUXGA

ON OFF OFF UXGA

OFF ON OFF SXGA

ON ON OFF WXGA

OFF OFF ON XGA

ON OFF ON SVGA

OFF ON ON VGA

ON ON ON WVGA / Others

Pos. #8 Video lock ON – Disable : The output refresh rate locks to the input for 50Hz / 60Hz mode

(other resolution lock the output be 60Hz. )

OFF – Enable : Always fix the output be 60Hz.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

16 of 41

Table 3 : DIP switch selection – SW4

Pos. # Function Description

1 Reserved

2 Panel pixel format OFF : Double Pixel

ON : Single Pixel

3 Panel selection ON : LVDS panel

OFF : Reserved

4 LVDS data mapping select

(Refer to Table 2)

If SW4 position 5 = OFF (8 bit)

OFF : Mapping B

ON : Mapping A

Please adjust to get the correct picture. See as Appendix I for details of

mapping of A and B.

If SW4 position 5 = ON (10 bit)

OFF : JEIDA (LVDS panel)

ON : VESA (LVDS panel)

Please adjust to get the correct picture. See as Appendix I for details of

mapping of VESA and JEIDA.

5 Output LVDS display mode selection OFF : 8 bit

ON : 10 bit

6 Reserved

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

17 of 41

CN1 – Slave RS-232 serial control: JST B6B-XH-A (Matching type : XHP-6)

PIN SYMBOL DESCRIPTION

1 EXT_MSTR2_SCL Reserved

2 EXT_MSTR2_SDA Reserved

3 VCC +5V

4 TXD RS-232 Tx data

5 GND Ground

6 RXD RS-232 Rx data

CN4 – Panel connector: HIROSE DF20G-10DP-1V (Matching type : DF20A-10DS-1C)

PIN SYMBOL DESCRIPTION

1 OP1 Reserved

2 OP2 Reserved

3 OP3 Reserved

4 OP4 Reserved

5 IP1 Reserved

6 IP2 Reserved

7 IP3 Reserved

8 IP4 Reserved

9 EXT_MSTR2_SDA Reserved

10 EXT_MSTR2_SCL Reserved

CN8 – RS-232 serial control: JST B6B-XH-A (Matching type : XHP-6)

PIN SYMBOL DESCRIPTION

1 EXT_MSTR2_SCL Reserved

2 EXT_MSTR2_SDA Reserved

3 VCC +5V

4 TXD RS-232 Tx data

5 GND Ground

6 RXD RS-232 Rx data

CN9 – Ambient light sensor connector : JST B3B-PH-K (Matching type : PHR-3)

PIN SYMBOL DESCRIPTION

1 GND Ground

2 VCC_5V VCC 5V

3 ALSF Ambient light sensing feedback

CN11 – SPDIF audio output connector : JST B3B-PH-K (Matching type : PHR-3)

PIN SYMBOL DESCRIPTION

1 SPDIF SPDIF Digital audio output

2 GND Ground

CNA1 - Auxiliary power output: JST B4B-XH-A (Matching type : XHP-4)

PIN SYMBOL DESCRIPTION

1 AUX 12V / 24V +12V / +24V DC

2 GND Ground

3 GND Ground

4 AUX 5V +5V DC, 500mA max

CNB1 – Backlight inverter connector: JST B5B-XH-A (Matching type : XHP-5)

PIN SYMBOL DESCRIPTION

1 GND Ground

2 VBKL +12V / +24V DC, backlight power supply

3 BLCTRL On/Off control (enable) – see JB2 & JB3

4 BVR_WIP Brightness VR – WIP

5 BVR_A Brightness VR A

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

18 of 41

CNC1 – OSD switch mount control, Hirose DF13A-12P-1.25H (Mating type : DF13-12S-1.25C)

PIN SYMBOL DESCRIPTION

1 PSWIN Power button A

2 SW_ON Power button B

3 BVR_A Backlight Brightness VR pin A

4 BVR_WIP Backlight Brightness R pin WIP

5 BVR_B Backlight Brightness VR pin B (470 ohm resistor to +5V Vcc)

6 GND Ground

7 MENU OSD menu

8 -/LEFT OSD -/Left

9 +/RIGHT OSD +/Right

10 SEL_DN OSD Select down

11 SEL_UP OSD Select up

12 NC No connection

The VR for brightness depends on the inverter. The main power load for On/Off is handled by a relay on the controller.

CNV2 – Component (YPbPr) video input connector: JST 6-way, B6B-PH-K (Matching type : XHP-6)

PIN SYMBOL DESCRIPTION

1 A_Y1 Luma in / Green in

2 GND Ground

3 A_CB1 Cb in / Blue in

4 GND Ground

5 A_CR1 Cr in / Red in

6 GND Ground

IR1 – Infra-Red sensor connector: JST B3B-XH-A (Matching type : XHP-3)

PIN SYMBOL DESCRIPTION

1 GND Ground

2 STDBY_Vcc Stand by voltage

3 IR Data IR data

J3 – LVDS output connector: JAE FI-RE51S-HF (Matching type : JAE FI-RE51HL)

PIN SYMBOL DESCRIPTION

1 VDD (+12/18V) Panel power supply (+12/18V) (selected by JA3, JA5 & JA6)

2 VDD (+12/18V) Panel power supply (+12/18V) (selected by JA3, JA5 & JA6)

3 VDD (+12/18V) Panel power supply (+12/18V) (selected by JA3, JA5 & JA6)

4 VDD (+12/18V) Panel power supply (+12/18V) (selected by JA3, JA5 & JA6)

5 VDD (+12/18V) Panel power supply (+12/18V) (selected by JA3, JA5 & JA6)

6 VDD (3,3V/5V) Panel power supply (3,3V/5V) (selected by JA3, JA5 & JA6)

7 VDD (3,3V/5V) Panel power supply (3,3V/5V) (selected by JA3, JA5 & JA6)

8 VDD (3,3V/5V) Panel power supply (3,3V/5V) (selected by JA3, JA5 & JA6)

9 VDD (3,3V/5V) Panel power supply (3,3V/5V) (selected by JA3, JA5 & JA6)

10 VDD (3,3V/5V) Panel power supply (3,3V/5V) (selected by JA3, JA5 & JA6)

11 GND Ground

12 GND Ground

13 GND Ground

14 GND Ground

15 GND Ground

16 OP1 17 OP2 18 NC No function

19 NC No function

20 GND Ground

21 GND Ground

22 TXA4+ Positive differential LVDS data bit A4

23 TXA4- Negative differential LVDS data bit A4

24 TXA3+ Positive differential LVDS data bit A3

25 TXA3- Negative differential LVDS data bit A3

26 GND Ground

27 TXAC+ Positive LVDS clock for A channel

28 TXAC- Negative LVDS clock for A channel

29 GND Ground

30 TXA2+ Positive differential LVDS data bit A2

31 TXA2- Negative differential LVDS data bit A2

32 TXA1+ Positive differential LVDS data bit A1

33 TXA1- Negative differential LVDS data bit A1

34 TXA0+ Positive differential LVDS data bit A0

35 TXA0- Negative differential LVDS data bit A0

36 GND Ground

37 TXB4+ Positive differential LVDS data bit B4

38 TXB4- Negative differential LVDS data bit B4

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

19 of 41

39 TXB3+ Positive differential LVDS data bit B3

40 TXB3- Negative differential LVDS data bit B3

41 GND Ground

42 TXBC+ Positive LVDS clock for B channel

43 TXBC- Negative LVDS clock for B channel

44 GND Ground

45 TXB2+ Positive differential LVDS data bit B2

46 TXB2- Negative differential LVDS data bit B2

47 TXB1+ Positive differential LVDS data bit B1

48 TXB1- Negative differential LVDS data bit B1

49 TXB0+ Positive differential LVDS data bit B0

50 TXB0- Negative differential LVDS data bit B0

51 GND Ground

J5 – LVDS Panel connector: Molex 53261-0871, (Matching type : 51021-0800)

PIN SYMBOL DESCRIPTION

1 VDD (3,3V/5V) Panel power supply (3,3V/5V)

2 VDD (3,3V/5V) Panel power supply (3,3V/5V)

3 GND Ground

4 GND Ground

5 GND Ground

6 VDD (12V/18V) Panel power supply (12V/18V)

7 VDD (12V/18V) Panel power supply (12V/18V)

8 VDD (12V/18V) Panel power supply (12V/18V)

LED1 – Status LED connector: 3-pin header

PIN DESCRIPTION

1 Green LED pin (anode)

2 LED pin common (cathode)

3 Red LED pin (anode)

P1 - Analog VGA in - 15 way connector

PIN SYMBOL DESCRIPTION

1 PCR Red, analog

2 PCG Green, analog

3 PCB Blue analog

4 ID2 Reserved for monitor ID bit 2 (grounded)

5 DGND Digital ground

6 AGND Analog ground red

7 AGND Analog ground green

8 AGND Analog ground blue

9 DDC_5V +5V power supply for DDC (optional)

10 DGND Digital ground

11 ID0 Reserved for monitor ID bit 0 (grounded)

12 DDC_SDA DDC serial data

13 HS_IN Horizontal sync or composite sync, input

14 VS_IN Vertical sync, input

15 DDC_SCL DDC serial clock

P2 – DVI-D in

PIN SYMBOL DESCRIPTION

1 /RX2 TMDS Data 2-

2 RX2 TMDS Data 2+

3 GND Digital Ground

4 NC No connection

5 NC No connection

6 DDC_CLK DDC Clock

7 DDC_DAT DDC Data

8 NC No connection

9 /RX1 TMDS Data 110 RX1 TMDS Data 1+

11 GND Digital Ground

12 NC No connection

13 NC No connection

14 DDC_5V +5V power supply for DDC (optional)

15 GND Ground (+5, Analog H/V Sync)

16 NC No connection

17 /RX0 TMDS Data 018 RX0 TMDS Data 0+

19 GND Digital Ground

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

20 of 41

20 NC No connection

21 NC No connection

22 GND Digital Ground

23 RXC TMDS Clock+

24 /RXC TMDS Clock-

C1 NC No connection

C2 NC No connection

C3 NC No connection

C4 HS_IN Analog horizontal sync

C5 GND Ground

C6 NC No connection

P3 – HDMI connector

PIN SYMBOL DESCRIPTION

1 DATA2+ TMDS Data2+

2 DATA2S TMDS Data2 Shield

3 DATA2- TMDS Data2–

4 DATA1+ TMDS Data1+

5 DATA1S TMDS Data1 Shield

6 DATA1- TMDS Data1–

7 DATA0+ TMDS Data0+

8 DATA0S TMDS Data0 Shield

9 DATA0- TMDS Data0–

10 CLK+ TMDS Clock+

11 CLK@ TMDS Clock Shield

12 CLK- TMDS Clock–

13 CEC CEC

14 NC No connection

15 SCL SCL (I²C Serial Clock for DDC)

16 SDA SDA (I²C Serial Data Line for DDC)

17 CEC/GND Ground

18 +5V +5 V Power (max 50 mA)

19 HPDET Hot Plug Detect

PP2 – Alternate 12V/24VDC input power supply

PIN DESCRIPTION

1 +12VDC / 24VDC in

2 Ground

PP4 – External panel power input

PIN DESCRIPTION

1 External panel power

2 Ground

3 External panel power

4 Ground

PP5 – 12V/24VDC input power supply

PIN DESCRIPTION

1 +12V / +24VDC

2 Ground

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

21 of 41

CONTROLLER DIMENSIONS

Ready-made 3D Pro-E (SLDPRT) drawing files - Save time and effort for your system volumetric analysis design.

Includes jpg file previews. Please go to download at http://www.digitalview.com/products/svx-1920v2-lcd-controller

The maximum thickness of the controller is 16.9mm with or without video add-on board (measured from bottom of

PCB to top of components, including any underside components & leads). We recommend clearances of:

• 5mm from bottom of PCB - if mounting on a metal plate we also recommend a layer of suitable insulation

material is added to the mounting plate surface.

• 10mm above the components

• 3~5mm around the edges

Any of the holes shown above can be used for mounting the PCB, they are 3.2mm in diameter.

CAUTION: Ensure adequate insulation is provided for all areas of the PCB with special attention to high

voltage parts such as the inverter.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

22 of 41

APPLICATION NOTES

USING THE CONTROLLER WITHOUT BUTTONS ATTACHED

This is very straightforward:

• Firstly setup the controller/display system with the buttons. With controls attached and display system active make any

settings for color, tint and image position as required then switch everything off.

• Remove the control switches, the 12-way (CNC1) cable.

• Use a jumper or similar to connect pins 1 & 2 on CNC1, this will fix the board On.

• Refer to inverter specifications for details as to fixing brightness to a desired level, this may require a resistor, an open

circuit or closed circuit depending on inverter.

Summary: On CNC1 the only pins that are used are for On/Off and Brightness (if controller mounted inverter is used). On

CNC1 the pins are for momentary type buttons so it doesn’t matter that no buttons are attached.

INVERTER CONNECTION

There are potentially 3 issues to consider with inverter connection:

• Power

• Enable

• Brightness

Please read the following sections for a guide to these issues.

Inverter Power: As per the table for CNB1 pin 1 is ground and pin 2 provides 12V/24V DC. This should be matched with the

inverter specification: see table.

CNB1

PIN DESCRIPTION

1 Ground

2 +12V/+24VDC

Remark: For higher power inverter, more current (for 12V/24V) can be taken from CNA1 pin 1.

Enable: This is a pin provided on some inverters for On/Off function and is used by this panel controller for VESA DPMS

compliance. If the inverter does not have an enable pin or the enable pin is not used then DPMS will not be operational. Pin 3

should be matched to the inverters specification for the ‘enable’ or ‘disable’ pin.

CNB1

PIN DESCRIPTION

3 Enable

Further, jumpers JB2 & JB3 should be set to match the inverters specification for the enable pin power and High or Low setting:

see table.

Ref

Purpose Note

JB2 Inverter enable voltage 1-2 H = 12V/24V, 2-3 H = 5V (Vcc), OPEN H = open collector

JB3 Inverter control 1-2 H = On, 2-3 L = On

Brightness: There are various methods for brightness control and it is important to consider the specifications for the inverter to

be used. Generally the situation is:

• Brightness can control by using a resistor or VR (Variable Resistor).

• Brightness controlled by adding a circuit such as PWM (Pulse Width Modulation).

• No adjustment of brightness is possible.

CNB1 pins 4 & 5 are available for connecting to an inverter or circuit where VR control is supported.

CNB1

PIN DESCRIPTION

4 VR WIP

5 VR A

This can then be matched with function controls connected to CNC1 pins 4 & 3 or 5: see table.

CNC1

PIN DESCRIPTION

3 VR A

4 VR WIP

5 VR B

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

23 of 41

Design Guideline for making VR circuitry :

CNB1 – Backlight inverter connector: JST B5B-XH-A (Matching type : XHP-5)

PIN SYMBOL DESCRIPTION

1 GND Ground

2 VBKL +12V/24VDC, backlight power supply

3 BLCTRL On/Off control (enable) – see JB2 & JB3

4 BVR_WIP Brightness VR - WIP

5 BVR_A Brightness VR A

CNC1 – OSD switch mount control, Hirose DF13A-12P-1.25H (Mating type : DF13-12S-1.25C)

PIN SYMBOL DESCRIPTION

1 PSWIN Power button A

2 SW_ON Power button B

3 BVR_A Backlight Brightness VR pin A

4 BVR_WIP Backlight Brightness R pin WIP

5 BVR_B Backlight Brightness VR pin B (470 ohm resistor to +5V Vcc)

6 GND Ground

7 MENU OSD menu

8 -/LEFT OSD -/Left

9 +/RIGHT OSD +/Right

10 SEL_DN OSD Select down

11 SEL_UP OSD Select up

12 NC No connection

The VR for brightness depends on the inverter. The main power load for On/Off is handled by a relay on the controller.

Example for circuit design :

Signal description / Notes :

1) R1 : 470ohm on board

2) RPOT is an external potentiometer (in-line dip

style) that can be plugged directly into CNC1 pins

3,4,5. RPOT must be supplied / installed by user.

3) BVR_B : Voltage tapped from “top” of

potentiometer, the node of R1 and RPOT.

4) BVR_WIP : Voltage tapped from wiper arm of

RPOT.

5) BVR_A : Voltage tapped from “bottom” of

RPOT.

Note : BVR_A voltage is left floating on the

controller board. To use this circuit, you need

to tie this point to a potential (usually GND,

available at CNC1

p

in 6).

1.)Choose RPOT = 10K

2.) Tie BVR_A to GND

3.) Circuit analysis gives BVR_WIP as the

following (see Figure 1)

BVR_WIP = 5 x (Rbc/10.47)

where BVR_WIP is in Volts.

And Rbc is the resistance from the wiper arm

to bottom of pot in Kohms.

To evaluate, plug in different values of Rbc :

Rbc BVR_WIP

0 0 V

2.5 K 1.2 V

5 K 2.4 V

7.5 K 3.6 V

10 K 4.8 V

So this circuit could provide Brightness

adjust voltage ranging from 0V to 5V.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

24 of 41

TROUBLESHOOTING

General

A general guide to troubleshooting a flat panel display system it is worth considering the system as separate elements, such as:

Controller (jumpers, PC settings)

Panel (controller, cabling, connection, panel, PC settings)

Backlight (inverter, cabling, backlight tubes)

Cabling

Computer system (display settings, operating system)

Through step by step cross checking with instruction manuals and a process of elimination to isolate the problem it is usually

possible to clearly identify the problem area.

No image:

If the panel backlight is not working it may still be possible to just see some image on the display.

A lack of image is most likely to be caused by incorrect connection, lack of power, failure to provide a signal or incorrect

graphic card settings.

Image position:

If it is impossible to position the image correctly, i.e. the image adjustment controls will not move the image far enough, then

test using another graphics card. This situation can occur with a custom graphics card that is not close to standard timings or if

something is in the graphics line that may be affecting the signal such as a signal splitter (please note that normally a signal

splitter will not have any adverse effect).

Image appearance:

A faulty panel can have blank lines, failed sections, flickering or flashing display

Incorrect graphics card refresh rate, resolution or interlaced mode will probably cause the image to be the wrong size, to

scroll, flicker badly or possibly even no image.

Incorrect jumper settings on the controller may cause everything from total failure to incorrect image. CAUTION: Do not set

the panel power input incorrectly.

Sparkling on the display: faulty panel signal cable.

Backlight:

Items to check include: Power input, Controls, Inverter and Tubes generally in this order.

If half the screen is dimmer than the other half:

Check cabling for the inverter.

For a specific backlight tube check the AC pins orientation (CAUTION: Never reverse any DC power pins).

Also:

If adjusting brightness control has no effect the chances are that the VR rating or method of adjusting brightness is not

compatible or correctly connected to the inverter.

If system does not power down when there is a loss of signal

Continued failure:

If unit after unit keeps failing consider and investigate whether you are short circuiting the equipment or doing something else

seriously wrong.

Generally after common sense issues have been resolved we recommend step by step substitution of known working parts to

isolate the problem.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

25 of 41

SPECIFICATIONS

Panel compatibility Compatible with 1920x1200, 1920x1080, 1920x480, 1680x1050, 1600x1200,

1600x900, 1440x900, 1366x768, 1280x1024, 1280x800, 1280x768 1024x768,

1024x600, 800x600, 800x480 and 640x480 resolutions of TFT LCD panels.

A specified BIOS and some factory adjustment may be required for individual panel

timings.

No. of colors Up to 3 x 10 bit providing 1.06 billion colors.

Panel power DC 3.3V, 5V, 12V, 18V

Panel signal LVDS

Vertical refresh rate 60Hz at 1920x1200, 60Hz at 1920x1080, 60Hz at UXGA and up to 75Hz other

lower resolution

Display clock maximum 165MHz

ADC clock maximum 195 MHz

DVI differential input clock maximum 165MHz

Graphics formats Standard VESA VGA, SVGA, XGA, SXGA, WXGA, UXGA, WUXGA

Other special formats through specified BIOS and factory adjustment.

Graphics auto mode detect VGA, SVGA, XGA, SXGA, WXGA, UXGA & WUXGA interlaced and non-interlaced

Standard input at source (analog RGB) VGA analog (15 pin) standard with automatic detection of:

Digital Separate Sync;

Composite Sync

Sync On Green.

Video formats PAL, NTSC & SECAM

Video inputs ARGB

DVI-D

Component video

HDMI

Functions display On screen display (OSD) of functions

OSD menu functions Image controls:

Panel brightness/contrast, Saturation, Hue, Color temperature, Sharpness, Aspect

ratio, PIP, Image orientation, etc.

OSD menu controls available Power On/Off

Backlight brightness

OSD Menu

OSD Select up

OSD Select down

Setting +

Setting Control interface Buttons, RS-232, Remote control

Settings memory Settings are stored in non volatile memory

PC Connectivity VGA / SVGA / XGA / SXGA / UXGA / WUXGA analog or digital

Controller dimensions 179mm x 120.4mm (7.” x 4.74”)

Power consumption 10w approx. (not including panel power consumption)

Power load maximum The controller has an overall 3Amp current limit.

Input voltage 12V/24VDC +/- 5%

On board battery lifetime 3 years at storage (without applying power to the unit). The battery is not

rechargeable.

Power protection Fuse fitted (Resettable)

DC Power handling Reverse power polarity protection is equipped on the board

Storage temperature limits -40oC to +70oC

Operating temperature limits 0oC to +60oC

NOTES

Please note the following:

• For specific panel setup a sample of an LCD may be required (this will be returned) and a copy of the full

technical specifications for the panel from the manufacturer.

• Re-layout and custom development services are available.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

26 of 41

APPENDIX I – SIGNAL SUPPORT MODE TABLE

ARGB (P1) PORT :

Mode Resolution Clk [MHz] Horizontal

freq [KHz]

Vertical

freq [Hz]

Sync Mode

V_60 640x480

60Hz

25.175 31.469 59.940 Digital Separate Sync

V_60 640x480

60Hz

25.175 31.469 59.940 Composite Sync

V_72 640x480

72Hz

31.500 37.861 72.809 Digital Separate Sync

V_72 640x480

72Hz

31.500 37.861 72.809 Sync On Green

V_72 640x480

72Hz

31.500 37.861 72.809 Composite Sync

V_75 640x480

75Hz

31.500 37.500 75.000 Digital Separate Sync

V_75 640x480

75Hz

31.500 37.500 75.000 Sync On Green

V_75 640x480

75Hz

31.500 37.500 75.000 Composite Sync

SV_56 800x600

56Hz

36.000 35.156 56.250 Digital Separate Sync

SV_56 800x600

56Hz

36.000 35.156 56.250 Composite Sync

SV_60 800x600

60Hz

40.000 37.879 60.317 Digital Separate Sync

SV_60 800x600

60Hz

40.000 37.879 60.317 Sync On Green

SV_60 800x600

60Hz

40.000 37.879 60.317 Composite Sync

SV_72 800x600

72Hz

50.000 48.077 72.188 Digital Separate Sync

SV_72 800x600

72Hz

50.000 48.077 72.188 Sync On Green

SV_72 800x600

72Hz

50.000 48.077 72.188 Composite Sync

SV_75 800x600

75Hz

49.500 46.875 75.000 Digital Separate Sync

SV_75 800x600

75Hz

49.500 46.875 75.000 Sync On Green

SV_75 800x600

75Hz

49.500 46.875 75.000 Composite Sync

X_60 1024x768

60Hz

65.000 48.363 60.004 Digital Separate Sync

X_60 1024x768

60Hz

65.000 48.363 60.004 Sync On Green

X_60 1024x768

60Hz

65.000 48.363 60.004 Composite Sync

X_70 1024x768

70Hz

75.000 56.476 70.069 Digital Separate Sync

X_70 1024x768

70Hz

75.000 56.476 70.069 Sync On Green

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

27 of 41

X_70 1024x768

70Hz

75.000 56.476 70.069 Composite Sync

X_75 1024x768

75Hz

78.750 60.023 75.029 Digital Separate Sync

X_75 1024x768

75Hz

78.750 60.023 75.029 Sync On Green

X_75 1024x768

75Hz

78.750 60.023 75.029 Composite Sync

SX_60 1280x1024

60Hz

108 63.81 60.020 Digital Separate Sync

SX_60 1280x1024

60Hz

108 63.81 60.020 Sync On Green

SX_60 1280x1024

60Hz

108 63.81 60.020 Composite Sync

SX_75 1280x1024

75Hz

135 79.976 75 Digital Separate Sync

SX_75 1280x1024

75Hz

135 79.976 75 Sync On Green

SX_75 1280x1024

75Hz

135 79.976 75 Composite Sync

WUX_60 1920x1080

60Hz

172.8 67.5 60 Digital Separate Sync

WUX_60 1920x1080

60Hz

172.8 67.5 60 Sync On Green

WUX_60 1920x1080

60Hz

172.8 67.5 60 Composite Sync

Remark :

The controller has been designed to take a very wide range of input signals however to optimize the PC’s graphics

performance we recommend choosing 60Hz vertical refresh rate. To support on higher refresh rate over 60Hz, the

LCD panel may not support.

HDMI / DVI input port :

Mode Resolution Clk [MHz] Horizontal

freq [KHz]

Vertical

freq [Hz]

V_60 640x480 60Hz 25.175 31.469 59.940

V_67 640x480 67Hz 31.5 37.5 67

V_75 640x480 75Hz 31.5 37.5 75

SV_56 800x600 56Hz 36 35.156 56

SV_60 800x600 60Hz 40.000 37.879 60.317

SV_72 800x600 72Hz 50 48.077 72

SV_75 800x600 75Hz 49.5 46.875 75

X_60 1024x768 60Hz 65.000 48.363 60.004

X_70 1024x768 70Hz 75 56.476 70

X_75 1024x768 75Hz 78.75 60.023 75

SX_60 1280x1024 60Hz 108 63.81 60.020

SX_75 1280x1024 75Hz 135 79.976 75

UX_60 1600x1200 60Hz 162 75.000 60

WUX_60 1920x1080 60Hz 172.8 67.5 60

1080p60 1920x1080p 60Hz 135 67.5 60

1080p59 1920x1080 59Hz 148.35 67.433 60

1080p50 1920x1080 50Hz 149 62.75 50

720p60

1280x720P 60Hz

74.25 45 60

576p50

720x576P 50Hz

26.9568 31.2 50

480p60

720x480P 60Hz

26.9568 31.4 60

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

28 of 41

Appendix II – RS-232 control protocols

RS-232 Serial control (Baud rate 2400, 8 bits, 1 stop bit and no parity)

Physical connection :

Controller side Computer side

Connector interface : CN8 Connector interface : Serial port

Mating connector : JST XHP-6 Mating connector : DB9 Female

PIN# Description PIN# Description

4 RS-232 Tx Data 2 RS-232 Rx Data

5 Ground 3 RS-232 Tx Data

6 RS-232 Rx Data 5 Ground

Remark :

(1) : RS-232 connection cable, 600mm P/N 4260902-00 can be ordered separately for connection.

Software connection :

The OSD function can be controlled through sending the RS-232 protocol.

The RS-232 program can be custom-made to fit for application or it can be used the serial control program, like Accessport,

Telix or Serial Utility program developed by DigitalView. Please contact your local support for information.

54

6

3

1

7

8

9

Mating face of CN8 Mating face of RS-232 DB9 Male

5 463

1

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

29 of 41

1. Commands to implement switch mount control buttons

Function Command Description Remark

Menu button 0xf7 Menu button pressed Button equivalent

Select-down

button

0xfa Select-down button pressed Button equivalent

Select-up button 0xfb Select-up button pressed Button equivalent

Right/+ button 0xfc Right/+ button pressed Button equivalent

Left/- button 0xfd Left/- button pressed Button equivalent

2. Parameter setting - immediate, relativ e, reset and query

Function Command Description Acknowledge (if enabled)

Brightness control 0x81,

nn | “+” | “-” |

“r” | “R” |

“?”

Set brightness =

value/increment/decrement

Reset

Query Current Source

Brightness.

Range : “4””E”-“B””2”

Default : “8””0”

Contrast control all channels

0x82, “a” | “A”,

nn | “+” | “-” |

“r” | “R” |

“?”

Set all contrast =

value/increment/decrement

Reset

Query

Contrast

Range : “0””0”-“F””F”

Default : “8””0”

Color control 0x83,

nn | “+” | “-” |

“r” | “R” |

“?”

Set color =

value/increment/decrement

Reset

Query

PAL/NTSC color (In video mode

only )

Range : “0””0”-“F””F”

Default : “8””0”

Tint control 0x84,

nn | “+” | “-” |

“r” | “R” |

“?”

Set tint =

value/increment/decrement

Reset

Query

NTSC tint (In NTSC mode only)

Range : “0””0”-“F””F”

Default : “8””0”

Phase (tuning)

control

0x85,

nn | “+” | “-” |

“?”

Set dot clock phase =

value/increment/decrement

Query

Dot clock phase.

(In PC mode only)

Image H position 0x86,

nnnn | “+” | “-” |

“?”

Set img_hpos =

value/increment/decrement

Query

Image horizontal position.

(In PC mode only)

Range : “0””0””6””4” ~

“F””F””9””C”

Default : “0””0””0””0”

Image V position 0x87,

nnnn | “+” | “-” |

“?”

Set img_vpos =

value/increment/decrement

Query

Image vertical position.

(In PC mode only)

Range : “F””F””D””C” ~

“0””0””2””4”

Default : “0””0””0””0”

Frequency 0x8b,

nnnn | “+” | “-“ |

“?”

Set frequency =

Value/increment/decrement

Query

Graphic mode H active size (in

pixels)

Set display

orientation

0x8e,

n |

“r” | “R” |

“?”

Set display orientation =

value/increment/decrement

Reset

Query

“0” – normal (Default)

“1” – vertical inverse.

“2” – horizontal inverse.

“3” – inverted.

Input main select 0x98,

nn | “+” | “-” |

“r” | “R” |

“?”

Select input main =

PC or VIDEO or next available

Reset

Query

Main selected.

“0x41,0x31” ARGB (Default)

“0x44,0x31” Component

“0x46,0x31” DVI

“0x48,0x31” HDMI

Runtime counter 0xa1,

nnnnn |

runtime counter value =

nnnnn (* 0.5 hour)

Runtime = nnnnn.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

30 of 41

“r” | “R” |

“?”

Reset

Query

Graphic horizontal

resolution enquiry

0xb7 Horizontal resolution (in pixels)

in 3 digit hex number

“nnn” = horizontal resolution

Graphic vertical

resolution enquiry

0xb8 Vertical resolution (in lines) in 3

digit hex number

“nnn” = vertical resolution

Graphic horizontal

sync frequency

enquiry

0xb9 Horizontal sync frequency (in

units of 100Hz) in 3 digit hex

number

“nnn” = horizontal frequency

Graphic vertical

sync frequency

enquiry

0xba Vertical sync frequency (in units

of Hz) in 3 digit hex number and

1 char

“nnnn” = vertical frequency

nnn = 3 digit hex

c= “i” or “p”

interlace or Progressive

0xba added the interlace(i)

or Progressive(p) feedback.

OSD turn off 0xbd Turn off the OSD. “0” – fail.

“1” – successful.

3. Other control

Function Command Description Acknowledge (if enabled)

Select RS-232

acknowledge

0xc1, “0” | “1” Disable/enable command

acknowledge.

“0” – acknowledge disabled.

“1” – acknowledge enabled.

Auto-setup 0xc3 Start auto-setup of current

vmode.

“0” – fail.

“1” – successful.

The RS-232 command strings sent in one time can support up to 380 bytes via CN8 port

The RS-232 command string sent in one time can support up to 50 bytes via CN1 or J1 port.

n = 1-byte ascii-coded hex number, e.g., parameter value of 0x1 is represented by “1” (0x31).

mn or nn = 2-byte ascii-coded hex number, e.g., parameter value of 0x1e is represented by “1”, “e” | “E”

(0x31, 0x6e|0x4e).

Please refer to the ASCII to Hex convert table below.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

31 of 41

Hex to ASCII conversion table

Hex ASCII Hex ASCII Hex ASCII Hex ASCII

0x30 0 0x41 A 0x61 a 0x2B +

0x31 1 0x42 B 0x62 b 0x2D -

0x32 2 0x43 C 0x63 c 0x3F ?

0x33 3 0x44 D 0x64 d

0x34 4 0x45 E 0x65 e

0x35 5 0x46 F 0x66 f

0x36 6 0x47 G 0x67 g

0x37 7 0x48 H 0x68 h

0x38 8 0x49 I 0x69 i

0x39 9 0x4A J 0x6A j

0x4B K 0x6B k

0x4C L 0x6C l

0x4D M 0x6D m

0x4E N 0x6E n

0x4F O 0x6F o

0x50 P 0x70 p

0x51 Q 0x71 q

0x52 R 0x72 r

0x53 S 0x73 s

0x54 T 0x74 t

0x55 U 0x75 u

0x56 V 0x76 v

0x57 W 0x77 w

0x58 X 0x78 x

0x59 Y 0x79 y

0x5A Z 0x7A z

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

32 of 41

Appendix III – Mapping definition

• Definition of Mapping A :

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

33 of 41

• Definition of Mapping B :

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

34 of 41

• Definition of VESA :

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

35 of 41

• Definition of JEIDA :

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

36 of 41

Appendix IV – DV remote control unit work for SVX-1920v2

BUTTON FUNCTION

POWER BUTTON Soft power ON/OFF button.

SEL UP ( ) / SEL DN ( )

Use this button to direct control the hotkey function. Press the “SEL UP” button to

increase the pre-set hotkey parameter value and the “SEL DN” button to decrease the

pre-set hotkey parameter value. In OSD menu, pressing this button to select the items.

+ / - BUTTON

Use this button to direct control the hotkey function. Press the “+” button to increase

the pre-set hotkey parameter value and the “-” button to decrease the pre-set hotkey

parameter value. In OSD menu, pressing this button to adjust the settings.

OSD BACK BUTTON Use to display the OSD menu and go to the previous OSD screen.

OSD NEXT BUTTON Use to display the OSD menu and go to the next OSD screen.

DISPLAY BUTTON

Use to view an on-screen information. When OSD menu displayed, press this button to

turn it off.

P/N 559000106-3 :

DigitalView remote control unit

(without DV logo silk screen

printing)

P/N 559000105-3 :

DigitalView remote control unit

(with DigitalView logo silk

screen printing)

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

37 of 41

Appendix V – Function description for de-interlacing mode MADI, DCDi

MADI = Motion adaptive de-interlacing :

It is a pixel based method which used for the input fields have no fixed relation between them

If the object moving very too fast, it will get worst quality.

DCDi = Directional Correlation Deinterlacing :

It is a digital enhancement method developed by Faroudja. DCDi technology is primarily used for

improving the image quality of low resolution images. This is done by deinterlacing the image and

blending rough edges occurring in diagonal lines.

Appendix VI – PIP mix table

INPUT SOURCES

VGA

HDMI DVI

Component

1

VGA X

HDMI

X

DVI

X

INPUT

Component 1

X

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

38 of 41

Appendix VII – Network connection

The SVX-1920v2 LCD interface controller has an RJ-45 Ethernet port for control and

monitoring over a network. This application note introduces the two user interface modes:

• Command line direct mode(this is the default mode)

• Browser based web server mode

There is also a short overview of the command set and how it is implemented.

QUICK GUIDE

For experienced users the following quick guide to trying out the network connection and

functions may be useful.

Command line direct mode: The SVX-1920v2 ships with the command line direct mode

installed as default. This is relevant when a PC application is used to send and receive

commands over the network port.

Browser based web server mode : The network port will require an alternative firmware

version if the browser based web server mode is required.

• Works with a normal network with DHCP, i.e. must use a router.

• Connect the SVX-1920v2 to the network and ensure power is on.

• Use the IP Locator utility available from the IP-50 web-page.

http://www.digitalview.com/media/downloads/IPLocator.zip

(Windows only)

• Double click on the IP address in the IP Locator window, it will open the SVX-1920v2

browser page in your default browser. Alternatively copy the IP address into your

browser address line.

• Test the functions that come up on the browser.

For details, please refer to the separate application note.

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

39 of 41

WARRANTY

The products are warranted against defects in workmanship and material for a period of three (3) year from the date of

purchase provided no modifications are made to it and it is operated under normal conditions and in compliance with the

instruction manual.

The warranty does not apply to:

• Product that has been installed incorrectly, this specifically includes but is not limited to cases where electrical short circuit

is caused.

• Product that has been altered or repaired except by the manufacturer (or with the manufacturer’s consent).

• Product that has subjected to misuse, accidents, abuse, negligence or unusual stress whether physical or electrical.

• Ordinary wear and tear.

Except for the above express warranties, the manufacturer disclaims all warranties on products furnished hereunder, including

all implied warranties of merchantability and fitness for a particular application or purpose. The stated express warranties are in

lieu of all obligations or liabilities on the part of the manufacturer for damages, including but not limited to special, indirect

consequential damages arising out of or in connection with the use of or performance of the products.

CAUTION

Whilst care has been taken to provide as much detail as possible for use of this product it cannot be relied upon as

an exhaustive source of information. This product is for use by suitably qualified persons who understand the nature

of the work they are doing and are able to take suitable precautions and design and produce a product that is safe

and meets regulatory requirements.

LIMITATION OF LIABILITY

The manufacturer’s liability for damages to customer or others resulting from the use of any product supplied hereunder shall in

no event exceed the purchase price of said product.

TRADEMARKS

The following are trademarks of Digital View Ltd:

• Digital View

• SVX-1920v2

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

40 of 41

CONTACT DETAILS

Digital View has offices in Asia, Europe and USA :

USA

Digital View Inc.

18440 Technology Drive

Building 130

Morgan Hill,

California, 95037

USA

Tel: (1) 408-782 7773 Fax: (1) 408-782 7883

Sales: ussales@digitalview.com

EUROPE

Digital View Ltd.

The Lake House

Knebworth Park

Herts, SG3 6PY

UK

Tel: +44-(0)20-7631-2150 Fax: Fax: +44-(0)20-7631-2156

Sales: uksales@digitalview.com

ASIA

Digital View Ltd

2

nd

Floor Bamboos Center

52 Hung To Road

Kwun Tong

Hong Kong

Tel: (852) 2861 3615 Fax: (852) 2520 2987

Sales: hksales@digitalview.com

WEBSITE

www.digitalview.com

Specifications subject to change without notice

© Digital View Ltd – Doc Ver 1.0: 7 July, 2014 (SVX-1920v2_manual.doc) Page

41 of 41

Revision History

Date Rev No. Page Summary

7 July 2014 1.00 All First issued

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Digital View:

4174400XX-3

Loading...

Loading...