Digital View ALR-1920-120 Instructions Manual

HDMI, DISPLAY PORT INTERFACE CONTROLLER

FOR TFT PANEL

Model: ALR-1920-120

Part number : 41731003X-3 or up

INSTRUCTIONS

CONTENTS

Page: 2. Introduction, How to Proceed, Usage Note, Disclaimer

3. System design – Diagram of a suggested system

4. Assembly notes – Important information about system elements

6. Connection & Operation – How to use the controller

10. Connectors, pinouts & jumpers – Essential connection information

18. Controller dimensions

19. Application notes

20. Troubleshooting

21. Specifications

23. Appendix I – Mode Support Table

24. Appendix II – RS-232 control protocols

28. Appendix III – DDC/CI support at HDMI & Display port

29. Appendix IV – Mapping definition

33. Appendix V – DV remote control unit work for ALR-1920-120

34. Warranty, Caution & Limitation of Liability, Trademarks

35. Contact details

It is essential that these instructions are read and understood before connecting or

powering up this controller.

Page 2 of 35

Introduction

ALR-1920-120 is the controller board equipped with IE-1010 and ALR-1920 engine integrated. ALR-1920-120 is capable

to drive the panel up to 1920x1200 resolution and also supporting up to 120Hz panel. This controller supports HDMI

and Display Port input. And it will be the lower cost solution for 120Hz panel.

¾ TFT (active matrix) LCDs with LVDS interface of 1920x1200, 1920x1080, 1280x1024 resolution

¾ Computer video signals of WUXGA, UXGA, SXGA, XGA, SVGA, VGA standard

¾ Support HDMI, Display port input

¾ Support LVDS interface panel

¾ Support DDC/CI at HDMI & Display port.

Ordering information :

Controller Part number Ordering part number

ALR-1920-120 P/N 41731003X-3 P/N 4173100XX-3

HOW TO PROCEED

¾ Ensure you have all parts & that they are correct, refer to:

• Connection diagram (separate document for each panel)

• Connector reference (in following section)

• Assembly notes

¾ Check controller switch & jumper settings (errors may damage the panel)

¾ Prepare the signal source

¾ Connect the parts

¾ Understand the operation and functions (in following section)

IMPORTANT USAGE NOTE

This product is for use by system developers and integrators, the manufacturer accepts no liability for damage or

injury caused by the use of this product. It is the responsibility of the developer, integrators or other user of this

product to:

¾ Ensure that all necessary and appropriate safety measures are taken.

¾ Obtain suitable regulatory approvals as may be required.

¾ Check power settings to all component parts before connection.

¾ Understand the operation and connectivity requirements of this controller.

DISCLAIMER

There is no implied or expressed warranty regarding this material.

Controller Solution Generator

Full web resource matching controllers & panels with connection diagrams for download.

See at : http://www.digitalview.com/csg

Page 3 of 35

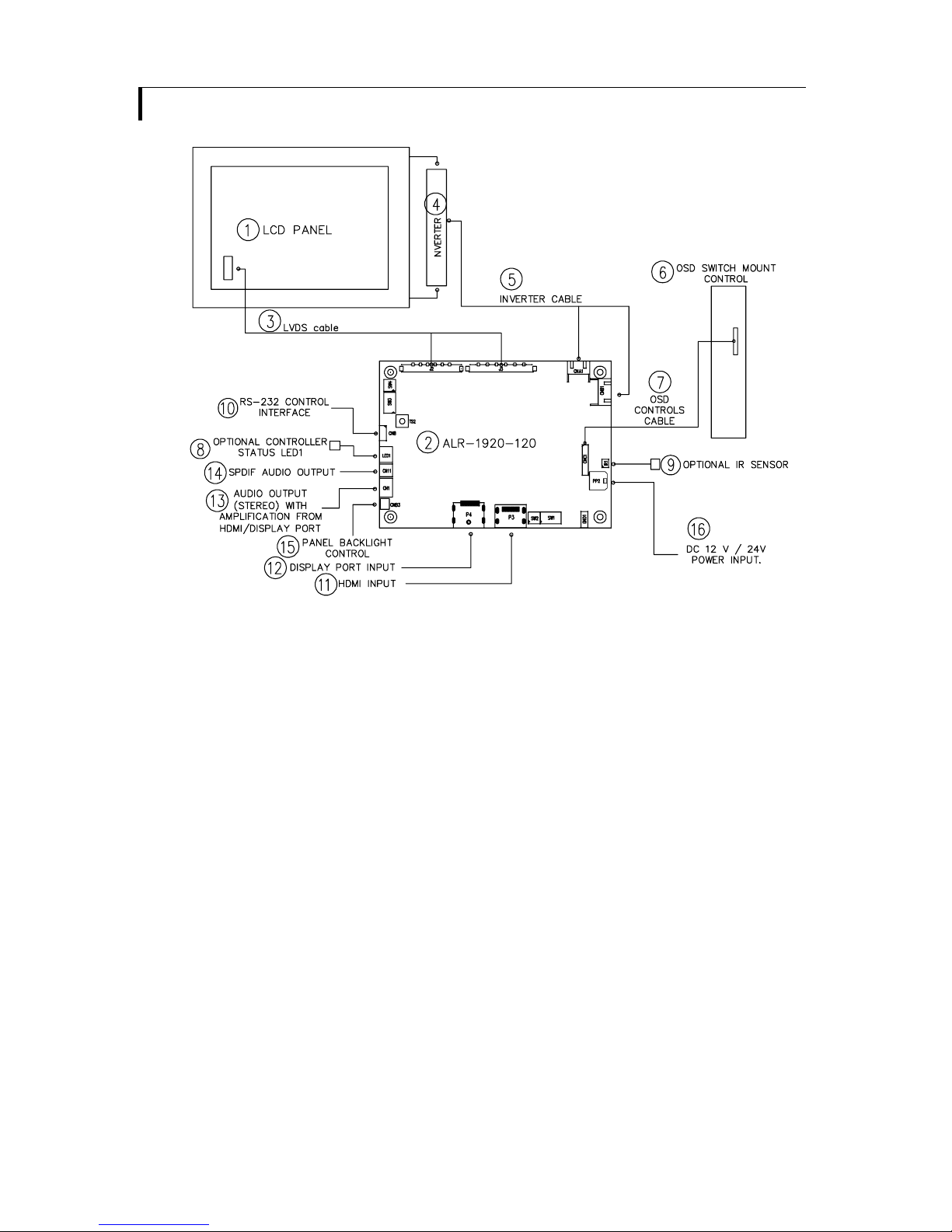

SYSTEM DESIGN

A typical LCD based display system utilising this controller is likely to comprise the following:

Summary:

1. LCD panel

2. LCD controller card, ALR-1920-120

3. LVDS cable

4. Inverter for backlight (if not built into LCD)

5. Inverter cable

6. OSD switch mount control

7. OSD controls cable

8. Optional Controller status LED1

9. Optional IR sensor

10. RS-232 control interface

11. HDMI input

12. Display Port Input

13. Audio output (Stereo) with amplication from HDMI / Display Port

14. SPDIF Audio output

15. Panel backlight control (for 120Hz panel used only)

16. Power input (12VDC / 24VDC)

Digital View offers a range of accessories such as listed above, to make up complete display solution.

Page 4 of 35

ASSEMBLY NOTES

ALR-1920-120 is the controller board equipped with IE-1010 and ALR-1920 engine integrated. ALR-1920-120 is capable to

drive the panel up to 1920x1200 resolution and also supporting up to 120Hz panel. This controller supports HDMI and Display

Port input. And it will be the lower cost solution for 120Hz panel.

Preparation: Before proceeding it is important to familiarize yourself with the parts making up the system and the various

connectors, mounting holes and general layout of the controller. As much as possible connectors have been labeled. Guides

to connectors and mounting holes are shown in the following relevant sections.

1. LCD Panel: This controller is designed for typical LVDS interface TFT panels with panel voltage 3.3V or 5V or 12V or 18V

LVDS interface. Due to the variation between manufacturers of signal timing and other panel characteristics factory setup

and confirmation should be obtained before connecting to a panel. (NOTE: Check panel power jumper settings before

connection)

2. Controller card: Handle the controller card with care as static charge may damage electronic components.

3. LVDS signal cable : In order to provide a clean signal it is recommended that LVDS signal cables are no longer than

46cm (18 inches). If loose wire cabling is utilized these can be made into a harness with cable ties. Care should be taken

when placing the cables to avoid signal interference. Additionally it may be necessary in some systems to add ferrite cores

to the cables to minimize signal noise.

4. Inverter: This will be required for the backlight of an LCD, some LCD panels have an inverter built in. As panels may have

1 or more backlight tubes and the power requirements for different panel models backlights may vary it is important to

match the inverter in order to obtain optimum performance. See page 19 for the Application notes “Inverter connection

section for more informations.

5. Inverter Cables: Different inverter models require different cables and different pin assignment. Make sure correct cable

pin out to match the inverter. Using wrong cable pin out may damage the inverter.

6. OSD switch mount controls: The following section discusses the controls required and the section on connectors

provides the detail. The controls are minimal: On/Off, Backlight Brightness (depends on inverter), OSD (5 momentary

buttons) analog VR type or (8 momentary buttons) digital type.

7. OSD switch mount controls cable: The cables to the function switches should be of suitable quality and length so that

impedance does not affect performance. Generally lengths up to 1 metre (3 feet) should be acceptable.

8. Controller status LED (Optional) : This LED indicates the controller status. The pin direction of the LED should be

corrected for right colour indication. Red colour stands for standby. Green colours stands for signal on. The status LED

is an optional part only, can be unconnected.

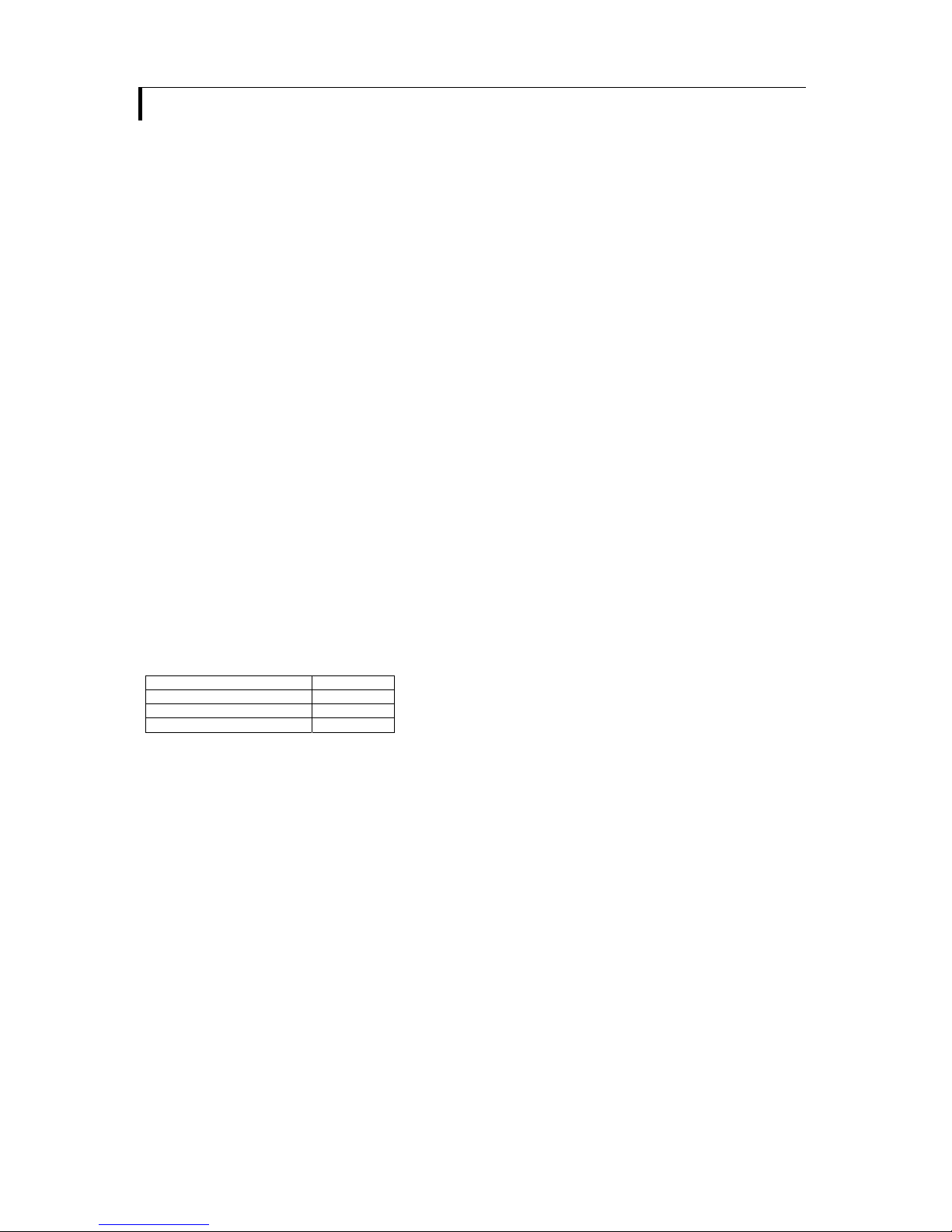

Controller LED status (LED1) :

State LED color

No signal & backlight off RED

No signal & backlight on ORANGE

With signal & backlight on GREEN

9. IR sensor: It is an optional part only, can be unconnected if not using IR remote control. See Appendix VI for button

definition.

10. RS-232 control interface : Firmware upgrade and serial control via this interface port. See Appendix II for the RS-232

serial control protocols.

11. HDMI input : Support HDMI 1.3 input up to 1080p/WUXGA resolution. Plug the HDMI cable to the connector P3 on

the controller board. This port support DDC/CI (See Appendix III in details).

12. Display Port Cable : Support single-link Display Port 1.1a. Plug the Display Port cable to the connector P4 on

the controller board. This port support DDC/CI (See Appendix III in details).

13. Audio output (Stereo) with amplication from HDMI / Display Port : This port support Stereo audio output from the HDMI

/ Display Port audio source inputted. This port has the same audio path output from J1. It requires to select the audio port

“Speakers” via OSD menu under “Sound” > “Output” OSD menu page.

14. SPDIF Audio output : This port support SPDIF audio output from the HDMI / Display Port audio source inputted. It

requires to select the audio port “SPDIF” via OSD menu under “Sound” > “Output” OSD menu page.

15. Panel Backlight control : Used for 120Hz panel connection only.

16. Power Input: 12V / 24V DC is required, this should be a regulated supply. Although the controller provides power

regulation for the LCD power this does not relate to the power supplied to the backlight inverter. If an unregulated power supply

is provided to an inverter any fluctuations in power may affect operation, performance and lifetime of the inverter and or

backlight tubes. 24VDC input is required when the panel output voltage is 18VDC. Please refer to page 11-12 for proper jumper

settings.

• Power Safety: Note that although only 12VDC / 24VDC is supplied as ‘power-in’ a backlight inverter for panel backlighting

produces significantly higher voltages (the inverter does not connect to the ground plane). We strongly advise appropriate

insulation for all circuitry.

Page 5 of 35

• EMI: Shielding will be required for passing certain regulatory emissions tests. Also the choice of external Controller to PC

signal cable can affect the result.

• Ground: The various PCB mounting holes are connected to the ground plane.

• Servicing: The board is not user serviceable or repairable. Warranty does not cover user error in connecting up to the

controller and is invalidated by unauthorized modification or repairs.

• Controller Mounting: It is recommended that a clearance of at least 10mm is provided above and 5mm below the

controller when mounted. Additionally consideration should be given to:

• Electrical insulation.

• Grounding.

• EMI shielding.

• Cable management. Note: It is important to keep panel signal cables apart from the inverter & backlight cables to

prevent signal interference.

• Heat & Ventilation: Heat generated from other sources, for example the backlight of a very high brightness panel may

generate significant heat which could adversely affect the controller.

• Other issues that may affect safety or performance.

IMPORTANT: Please read the Application Notes section for more information.

Page 6 of 35

CONNECTION & OPERATION

CAUTION: Never connect or disconnect parts of the display system when the system is powered up as this may cause serious

damage.

CONNECTION

Connection and usage is quite straight forward (it is useful to have the relevant connection diagram available at this time):

1. LCD panel & Inverter: Connect the inverter (if it is not built-in the panel) to the CCFT lead connector of the LCD

panel.

2. LVDS type panels: Plug the LVDS signal cable direct to J2 and/or J3 (if necessary). Insert the panel end of the

cable to the LCD panel connector.

3. Inverter & Controller: Plug the inverter cable to CNB1 and CNA1 (if necessary). Plug another end to the connector

on the inverter.

4. Function switch & Controller: Plug the OSD switch mount cable to CNC1 on the controller board and another to

the OSD switch mount.

5. LED 1 : Plug in a 3-way with dual colour LED to connector LED1 on the controller board for indicating the controller

status.

6. IR & Controller: Plug in a 3-way with IR sensor to connector IR1 on the controller board.

7. Jumpers : Check all jumpers are set correctly. Details referring the connection diagram at

http://www.digitalview.com/controllers/csg.php

8. Jumpers & Inverter & Panel voltage: Particularly pay attention to the settings of JA3, JA6, JB2, JB3. JB2 & JB3

are used for inverter control (read inverter specification and information on the jumper table to define the correct

settings). JA3 & JA6 are used for panel voltage input (read panel specification and information on the jumper table to

define the correct settings).

10. HDMI cable : Plug the HDMI cable to the connector P3 on the controller board.

12. Display port cable : Plug the Display port cable to connector P4 on the controller board.

13. Audio output connector / SPDIF audio connector : audio output port CN1 support audio output (stereo) from the

HDMI / Display Port and CN11 support audio SPDIF audio output from HDMI / Display Port audio source inputted. It

requires to select the audio port “Speakers” / “SPDIF” via OSD menu under “Sound” > “Output” OSD menu page.

14. Power supply & Controller: Plug the DC 12V / 24V power in to the connector PP2. You can consider to use

DigitalView mating power cable P/N 426013800-3, 160mm. Please read the jumper table in page 11-12 to define the

correct settings. Otherwise it may break down the panel.

15. Power on: Switch on the controller board and panel by using the OSD switch mount.

CAUTION: Never connect or disconnect parts of the display system when the system is powered up as this may cause serious

damage.

On board LED status :

Power status on LED2 :

State LED color

Power on state Green

Power status on LED3 :

State LED color

Panel Power on state Green

Controller LED status (LED1A) :

State LED color

No signal & backlight off RED

No signal & backlight on ORANGE

With signal & backlight on GREEN

General:

• If you are using supplied cables & accessories, ensure they are correct for the model of panel and controller.

• If you are making your own cables & connectors refer carefully to both the panel & inverter specifications and the section

in this manual, “Connectors, Pinouts & Jumpers” to ensure the correct pin to pin wiring.

OPERATION

Once the system has been connected and switched on there are a number of functions available to adjust the display

image as summarized in the following sections. The settings chosen will be saved for each mode independently.

Page 7 of 35

BUTTONS & DEMO MODES

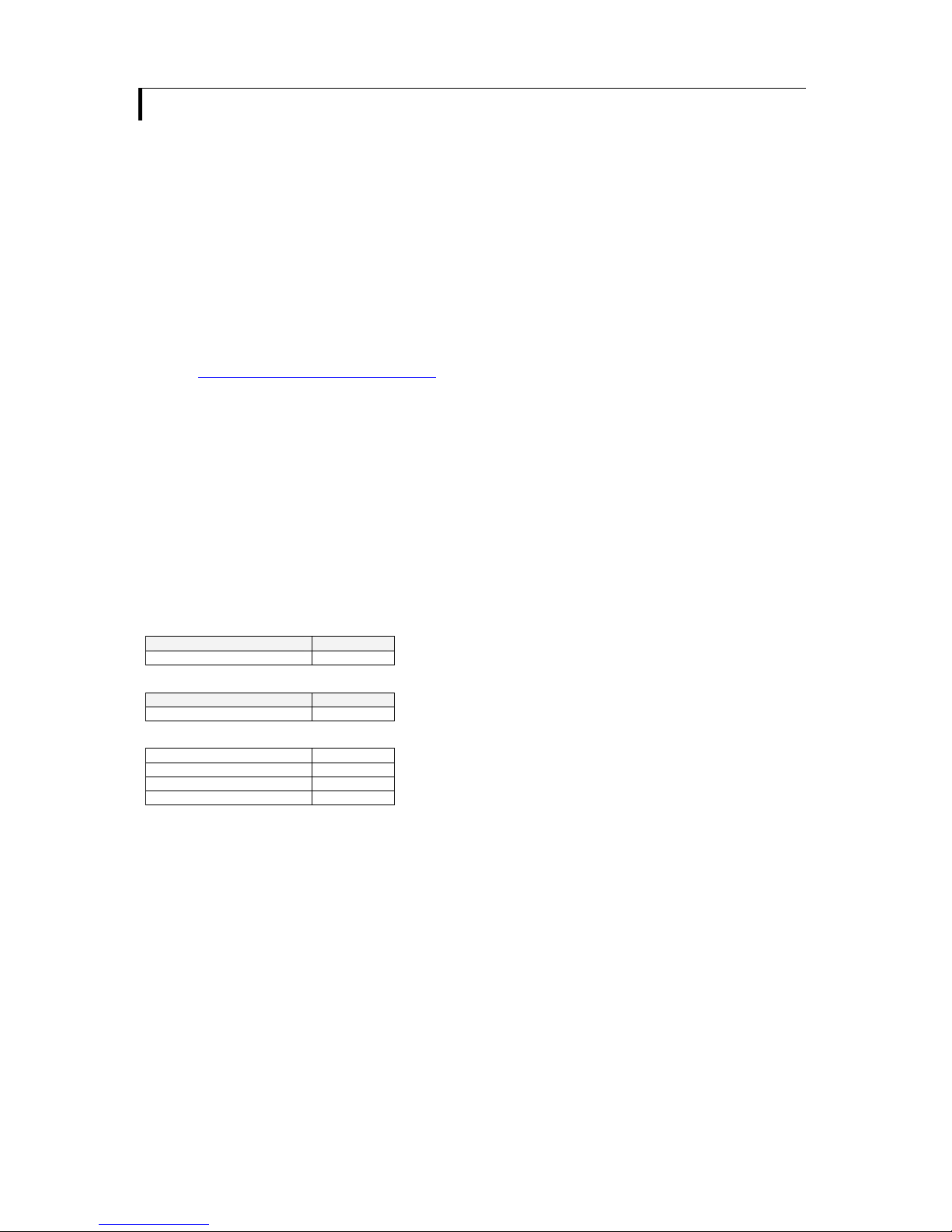

• Button switch – TS2 : Push TS2 to cycle between the 4 different demo modes (This function is activated when JP3 sets

OPEN only)

Mode 1 (default) = RIGHT demo mode, right side of screen with smoothed motion while left side without (a box with yellow

border appear on RIGHT hand side of screen);

Mode 2 = CENTRE demo mode, centre part of screen with smoothed motion while other areas without (a box with yellow border

appear in the CENTRE of the screen);

Mode 3 = whole screen without smoothed motion

Mode 4 = whole screen with smoothed motion

The controller will not memorize the demo mode after you power cycle the controller. It will resume back to mode 1 always.

* This function will not activate in static text mode (i.e : SW3 position 8 sets ON).

Page 8 of 35

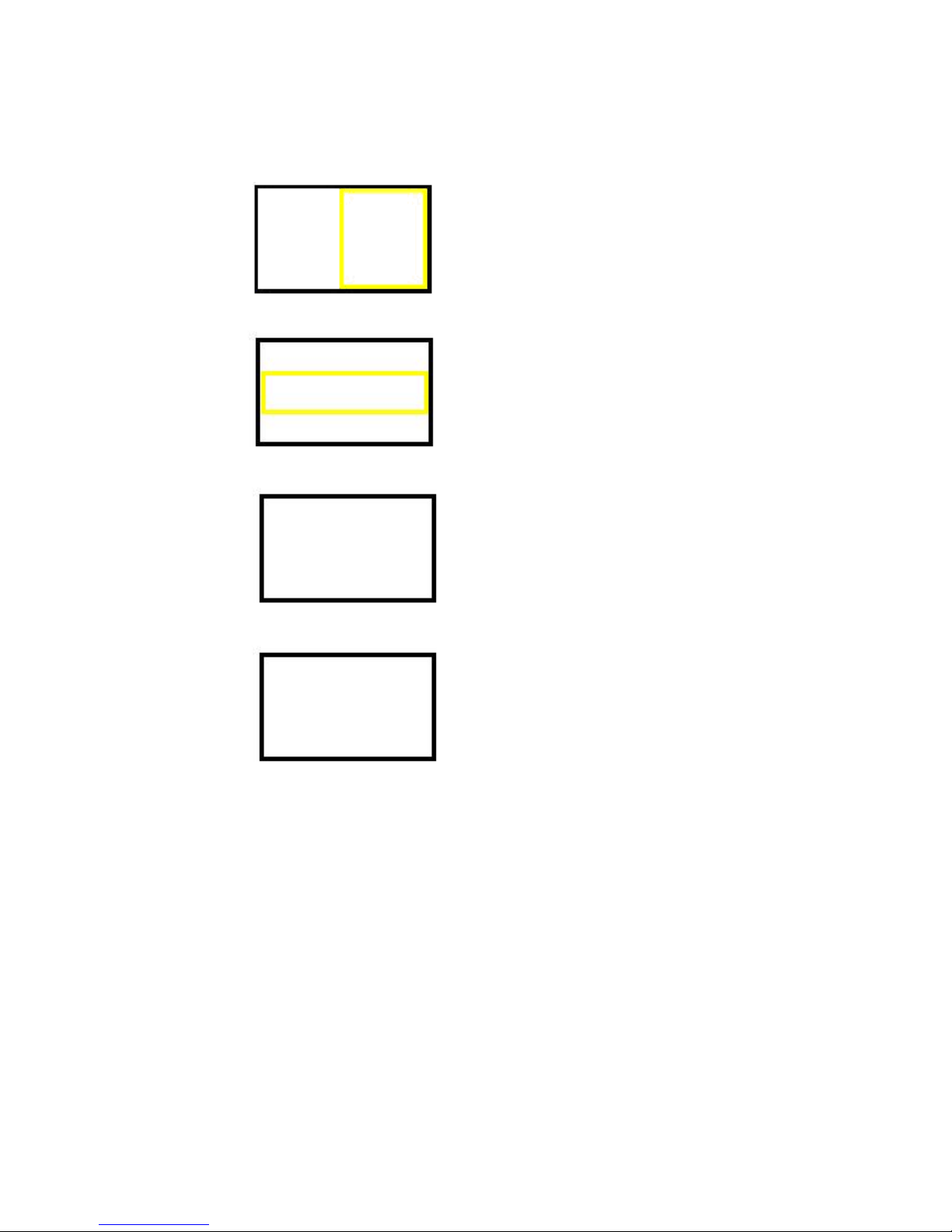

LCD DISPLAY SYSTEM SETTINGS

NOTE: By way of explanation the following refers to a set of sample buttons that may be obtained as an option. In addition

to power on/off and connection for backlight brightness the controller provides an On Screen Display of certain functions

which are controlled by 5 momentary type buttons (analog VR type) or 8 momentary type buttons (digital type):

Controls Analog VR type Digital type

On/Off – turns controller board power on VR toggle switch On/Off button

Brightness – controls backlight brightness Rotary VR Brightness +/- buttons

Menu – turns OSD menu On or Off (it will auto time

off) (Function with signal input only)

Menu button Menu button

Select – Select function / Confirm

(under OSD menu on state)

SEL DN SEL DN

Move up to select individual RGB color level OSD

page

(under OSD menu on state)

SEL UP SEL UP

+ – increase the setting / moves the selector to the

next function

(under OSD menu on state)

+ +

- - decrease the setting / moves the selector to the

previous function

(under OSD menu on state)

- -

Reset to Factory Defaults Press and hold SEL DN

button, then power on the

controller

Press and hold SEL DN button,

then power on the controller

Switch to next input source

(under OSD menu off state)

+ +

ON/Off/Brightness

SEL UP

SEL DN

+

-

Menu

Analog VR type

Digital type

12V / 24VDC power input :

Analog 10K VR Type OSD

switch mount uses

P/N 410680550-3 or up

12V / 24VDC power input :

Digital 10K Type OSD

switch mount uses

P/N 416100520-3 or up

12VDC power input :

Digital 10K Type OSD

switch mount uses

P/N 416100510-3

Page 9 of 35

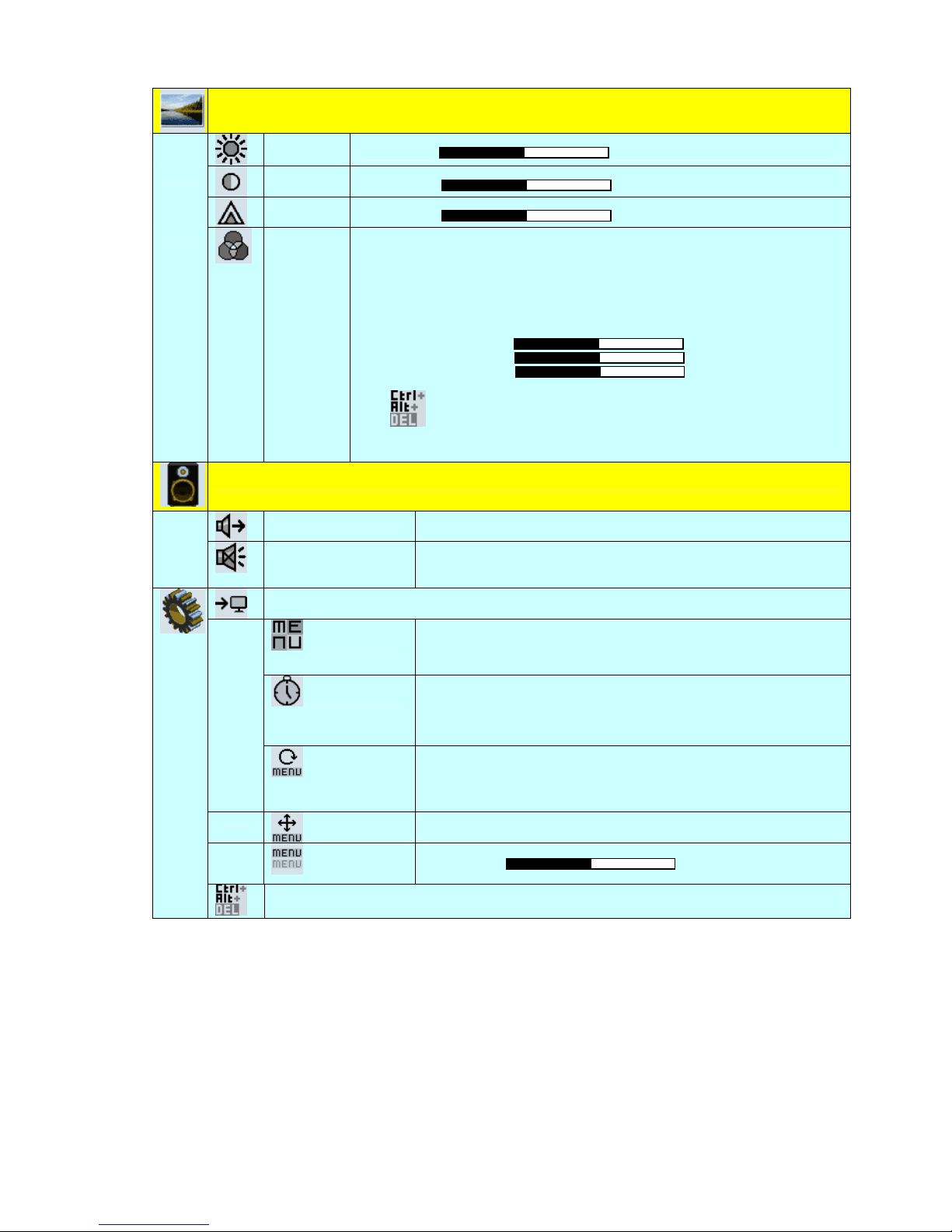

OSD Functions

Image

Brightness

Increase/decrease brightness level.

Press – or + (- + ) Total : 100 steps

Contrast

Increase/decrease contrast level.

Press – or + (- + ) Total : 100 steps

Sharpness

Increase/decrease sharpness level.

Press – or + (- + ) Total : 8 steps

Color

Color temp4 (Adjust the warmness of the image displayed. The higher temperature the

coolest image looks like. The lower temperature the warmest image looks like.)

4200k

5000k

6500k

7500k

9300k

User 4

R Press – or + (- + ) Total : 100 steps

G Press – or + (- + ) Total : 100 steps

B Press – or + (- + ) Total : 100 steps

Reset

Gamma (0.4/0.6/1.0/1.6/2.2)

Sound

Mute

Mute

Output

Select audio output port

Speakers : via CN1 connector

SPDIF : via CN11 connector

System4

Input : Select the input video signal

Display Port

DVI/HDMI

Autoscan : Enable the Auto source seek function

Timer : OSD Timeout in seconds

3 sec

6 sec

12 sec

Always On

Rotation : OSD menu rotation in degree

0

90

180

270

Position : Adjust OSD menu position

Transparency : Set OSD transparency

Press – or + (- + ) Total : 100 steps

Reset : Load factory default settings.

Press down on OSD keypad to factory reset

[Firmware version : V0.02.00 / V1.02.00 or up]

Items marked 4 have sub menus.

Exit the OSD menu to save the setting chosen

Page 10 of 35

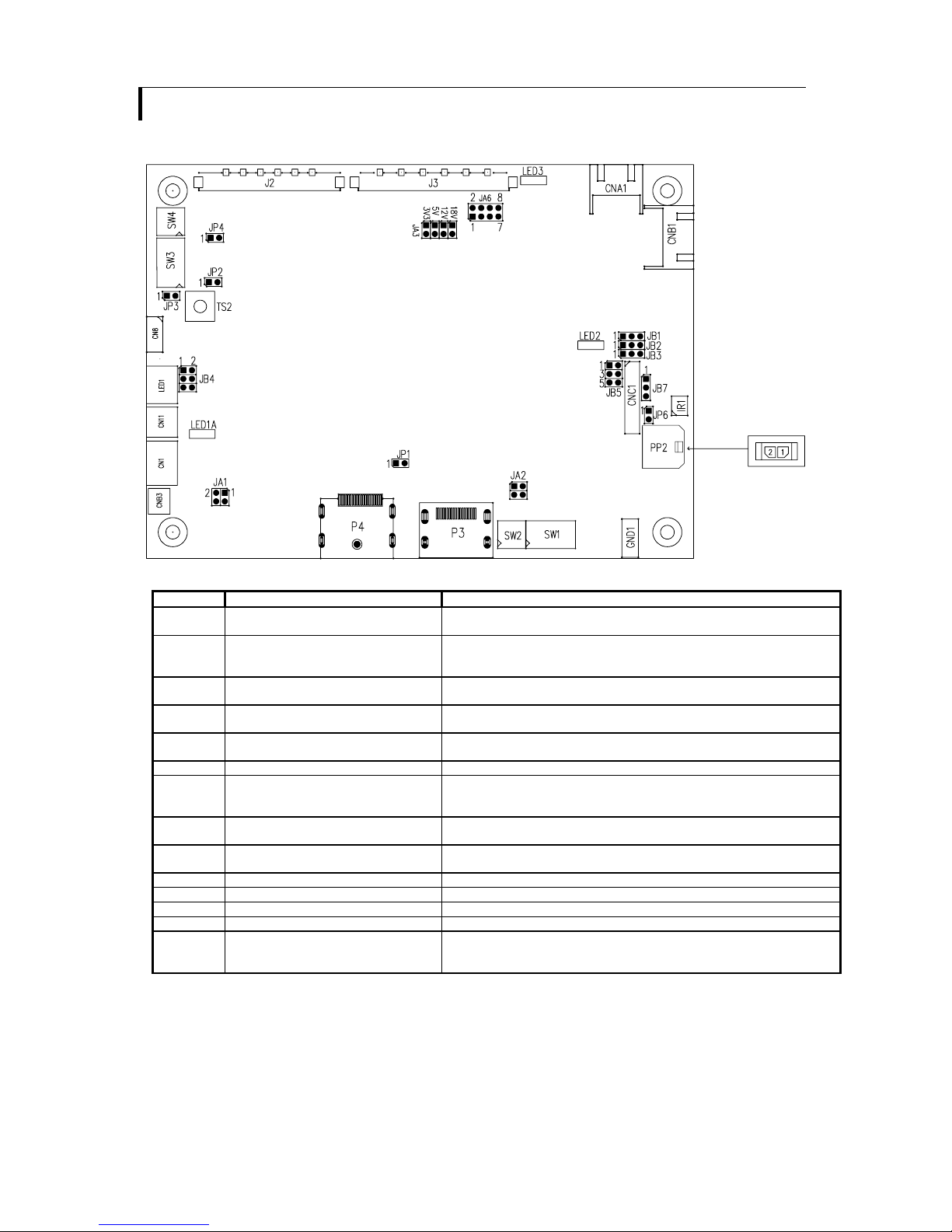

CONNECTORS, PINOUTS & JUMPERS

The various connectors are:

Summary: Connectors

Ref Purpose Description

CN1 Audio output (Stereo) with amplication

from HDMI / Display port

JST 4-way, S4B-ZR-SM4A (Mating type : ZHR-4)

(Matching connection cable P/N 426685400-3)

CN8 Serial control Molex 53261-0671, 6 ways 1.25mm pitch

(Mating type : Molex 51021-0600)

(Matching connection cable P/N 426171800-3)

CN11 SPDIF Audio Output JST 2-way, S2B-ZR-SM4A (Mating type : ZHR-2)

(Matching connection cable P/N 426007400-3)

CNA1 Auxiliary power output JST 4-way, S4B-XH-A (Mating type : XHP-4)

(Matching cable P/N 426040200-3)

CNB1 Backlight inverter JST 5-way, S5B-XH-A (Mating type : XHP-5)

(Matching cable P/N 426058300-3)

CNB3 Panel backlight control JST 2-way, B2B-XH-A (Matching type : XHP-2)

CNC1 OSD controls Hirose DF13A-12P-1.25H (Mating type : DF13-12S-1.25C)

(Matching OSD switch mount cable P/N 426122200-3 (150mm) or

426122210-3 (250mm)

IR1 Infra-Red sensor connector Molex 53261-0371, 3 way 1.25mm pitch (Mating type : 51021-0300)

(Matching connection cable P/N 426031500-3)

LED1 Dual color LED connector for controller

status

JST 3-way, S3B-ZR-SM4A (Mating type : ZHR-3)

(Matching connection cable P/N 426031400-3)

J2 LVDS panel signal output 1 JAE FI-RE41S-HF (Mating type : JAE FI-RE41HL)

J3 LVDS panel signal output 2 JAE FI-RE51S-HF (Mating type : JAE FI-RE51HL)

P3 HDMI signal input HDMI connector (Type A)

P4 Display Port input Display port connector

PP2 Power input Molex 43650-0200 compatible (Mating type : Molex 43645-0200

compatible)

(Matching power cable : P/N 426013800-3, 160mm)

Page 11 of 35

Summary: Jumpers setting

Ref Purpose Note

JA1 On board +1V logic power enable 1-3 & 2-4 closed, factory set, do not remove

JA2 On board +5V logic power enable 1-2 & 3-4 closed, factory set, do not remove

JA3 Panel power voltage select See panel voltage setting table 1

CAUTION: Incorrect setting will cause panel damage

JA6 Panel power voltage select See panel voltage setting table 1

CAUTION: Incorrect setting will cause panel damage

JB1 Backlight brightness voltage range 1-2 closed = 3.3V max

2-3 closed = 5V max

JB2 Backlight inverter on/off control – signal level 1-2 = On/Off control signal ‘High’ = +3.3V

2-3 = On/Off control signal ‘High’ = +5V

Open = On/Off control signal ‘High’ = Open collector

CAUTION: Incorrect setting can damage inverter.

JB3 Backlight inverter on/off control – polarity 1-2 = control signal ‘high’ = CCFT ON

2-3 = control signal ‘low’ = CCFT ON

JB4 Reserved for firmware upgrade 1-3 & 2-4 closed = Firmware upgrade on U10

3-5 & 4-6 closed = Firmware upgrade on U15

JB5 Backlight control type selection 1-2 = VR/Digital switch mount control

3-4 = Analog backlight brightness control via RS-232

command (0xe0) – voltage range 0~5V

5-6 = PWM

JB7 Backlight brightness orientation 1-2 = Normal backlight brightness

3-4 = Invert for the backlight brightness

Activate when JB5 sets 1-2 closed only.

JP1 Reserved Reserved for internal programming use (Always 1-2

closed)

JP2 Reserved for firmware upgrade Short = Firmware upgrade on U15

Open = Default

JP3 Demo mode selection Short = Disable demo mode

Open = Enable demo mode

JP4 Internal use Internal use

JP6 Input power control Short = External switch control

Open = Switch mount control

SW1 Panel selection See table below

SW2 Panel selection See table below

Table 1 : Panel voltage setting table :

Input voltage via

PP2 Panel Voltage JA3 JA6 Jumper on board

3.3V 3V3 closed 1-3 & 2-4

5V 5V closed 1-3 & 2-4

12VDC

12V OPEN 5-7 & 6-8

CAUTION: Incorrect setting can damage panel & controller

Loading...

Loading...