Digital Combo DK20S User Manual

Digital Combo

Multi-Purpose press

1

Table of Contents

T able of Contents .............................................................2

Introduction .....................................................................3

Setup & Suggestions ........................................................4

Basic Use .......................................................................... 4

Setting Time ..................................................................... 4

Setting T emperature .........................................................5

Setting Height / Pressure ..................................................6

Guidelines & Standard Settings .......................................7

Removing a heat platen....................................................8

Interchangeable Heat Platens............................................8

Attaching a heat platen ..................................................... 9

Aligning the pedestal...................................................... 1 0

Cap Holddown Device ................................................... 10

(included with cap attachment only)................................................................................................... 1 0

Interchangeable T ables................................................... 1 0

Programmable Presets.................................................... 11

User Options Menu ........................................................1 2

Fahrenheit / Celsius........................................................ 12

Timer Counter................................................................ 12

Recorded Pressings ........................................................ 12

Pressure / Height Gauge Calibration .............................. 1 3

Height Gauge - High Point ............................................. 13

Height Gauge - Low Point.............................................. 13

Pressure / Height Gauge Sensitivity ............................... 14

Drop Sense..................................................................... 14

Beep ............................................................................... 15

Alarms............................................................................ 15

Maintenance ................................................................... 16

Troubleshooting.............................................................17

Troubleshooting (cont.) ................................................. 18

Limited W arranty............................................................ 19

2

Introduction

Congratulations on your purchase of the Digital Combo swinger!

This heat press machine has many exciting features, all of which are

meant to help make your heat transfer pressing endeavors as successful

and easy as possible. Please take the time now to thoroughly read

through this manual to become acquainted with them. It will explain

some key features, concepts and methods that will save much time

and effort in using this press and in your heat pressing applications.

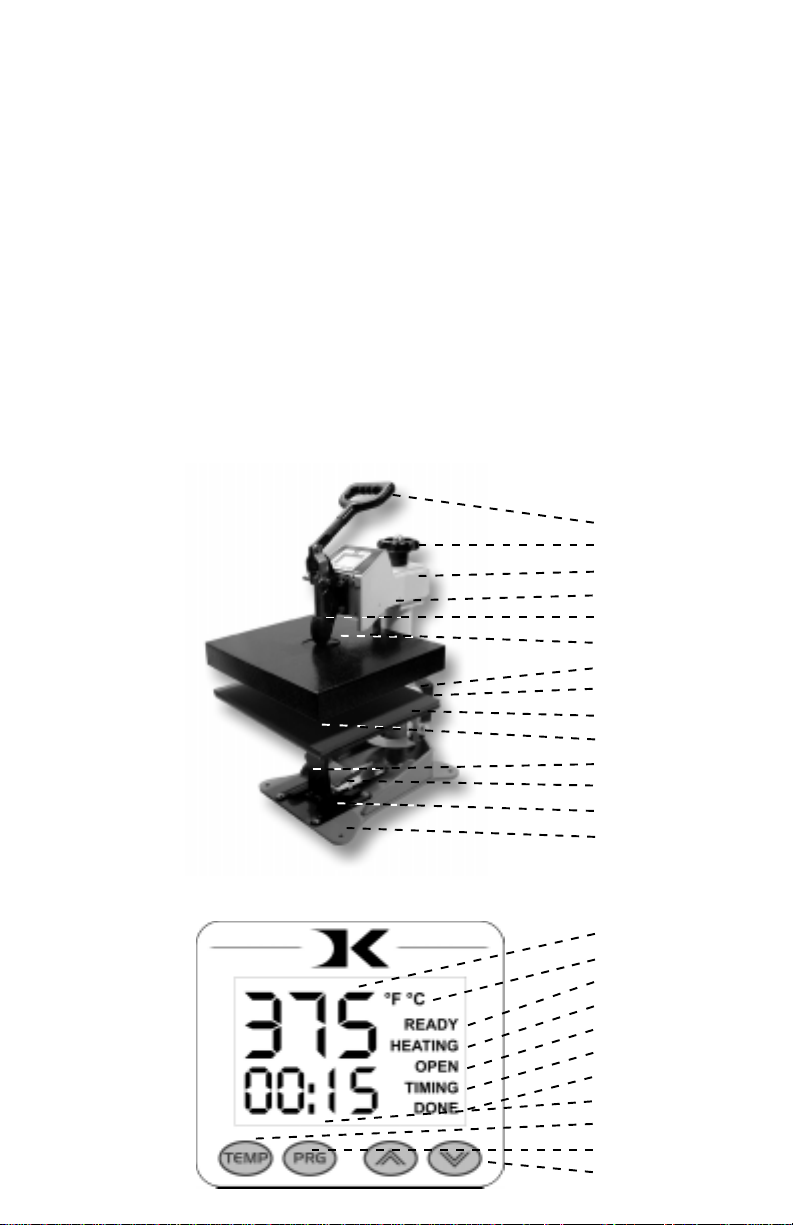

Throughout this manual, many areas and components of this

machine will be referred to by specific names. Please refer to the

illustrations below in order to become familiar with some of the

terminology used in this manual.

Handle

Pressure Knob

Top Head

Power Inlet

Clamp / Linkage

Heat Platen

Stop Collar

Height Sensor

Lower T able

Silicone Pad

Pedestal

Cap Holddown

Gibb Plates

Base

Default Operating Mode of Controller

Temperature

°Far/°Cel Indicator

Ready Indicator

Heating Indicator

Open Indicator

Timing Indicator

Done Indicator

Time

TEMP Button

PRG Button

Up/Down Arrows

3

Setup & Suggestions

• Locate the press on a firm, sturdy work surface.

• The height of the bench/work space the press is located on would be

ideally 27” to 32” high.

• Attach the power cord from the rear to the underside of the top head.

• There is a power inlet under the top head that the modular cord will

plug into.

• Make sure the cord does no interfere with the lower table pressing

area, or the height sensor.

• The press should remain in the unclamped position when not in use.

Do not leave the heater block closed on the table surface when hot if

not using.

• The top head should be swung over and above the pressing table when

not in use.

Basic Use

Setting Time

The time setting is always editable in the default operating mode

of the controller. The left two digits of the time display are minutes.

The right two digits are seconds. This can be changed to Hours/

Minutes in the User Options Menu.

• Use the Up & Down arrow keys to change the time.

• Hold the Up or Down arrow key down to increment the values quickly.

After a brief pause, the values will accelerate.

• Press the Up & Down arrow keys together to clear the setting to 00:00

• When the press is closed, the timing cycle starts. The “TIMING”

indicator will appear.

• When the timing cycle is finished, the “DONE” indicator will appear.

• Depending on the timer alarm chosen, the alarm may continue to sound

at the end of the timing cycle until the press is opened.

• When the press is opened up, the “OPEN” indicator will appear.

4

Setting Temperature

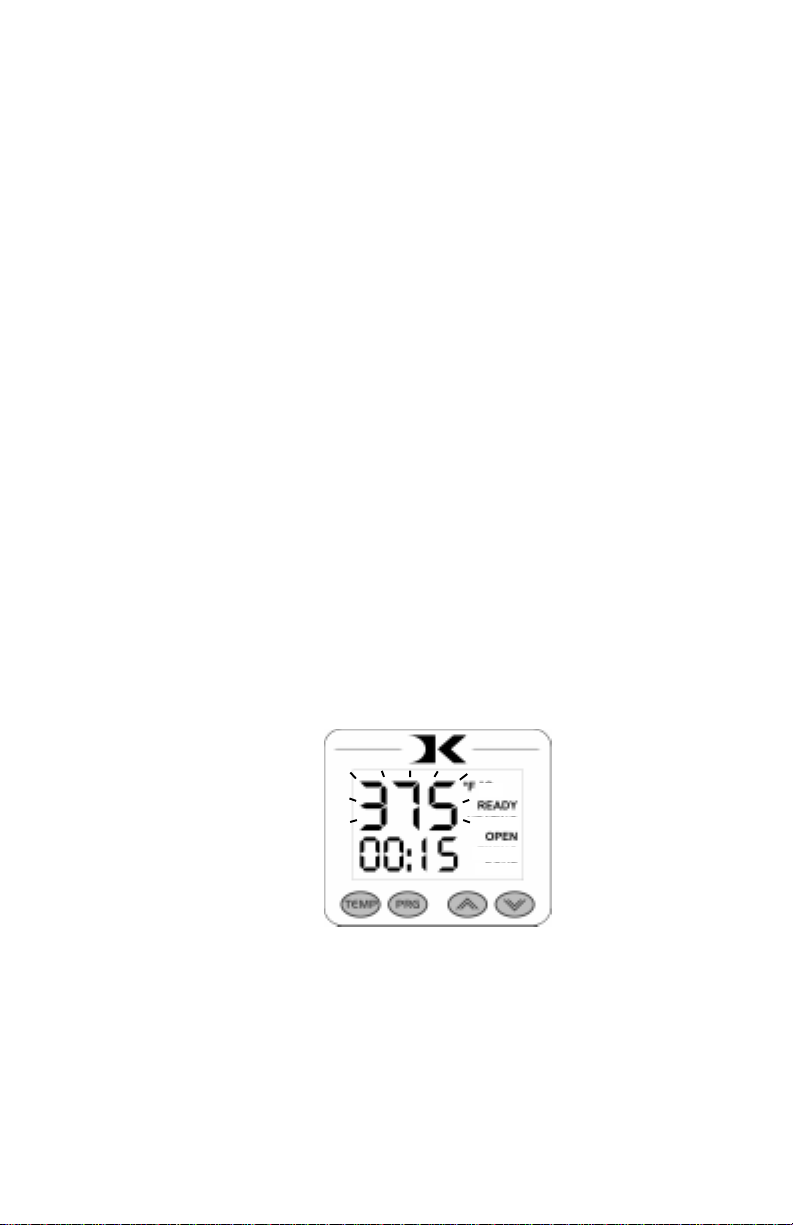

In the default operating mode of the controller, the displayed

temperature is the Current temperature. This is the actual temperature

of the heat platen surface. Please note that the operating range of the

controller is from 150°F to 550°F (65°C to 288°C). During the first

heat up cycle of the press, the controller will display 150°F (65°C)

until the heat platen temperature rises above that temperature.

The Set Point temperature is the temperature the operator sets

the press for. This is the value the press will regulate the Current

temperature based on. The set point temperature may be changed

whenever necessary:

• When in the default operating mode, press the TEMP button.

• The Current temperature will be replaced by the blinking Set Point

temperature.

• Use the Up & Down arrow keys to change the Set Point temperature.

• Hold the Up or Down arrow key down to increment the values quickly.

After a brief pause, the values will accelerate.

• Press the Up & Down arrow keys together to set the temperature to

350.

• When finished setting the temperature, press the TEMP button to return

to the default operating mode.

• The control will regulate the heat platen temperature based on the set

point temperature. When the temperature falls below the Set Point,

the “HEATING” indicator will appear.

• When the temperature reaches the Set Point, the “HEATING” indicator

will disappear and the “READY” indicator will appear.

• If the Set Point temperature is set to a temperature below the Current

temperature, the press will wait to cool down to that Set Point. At that

time, neither the “READY” or “HEATING” indicators will appear.

5

Setting Height / Pressure

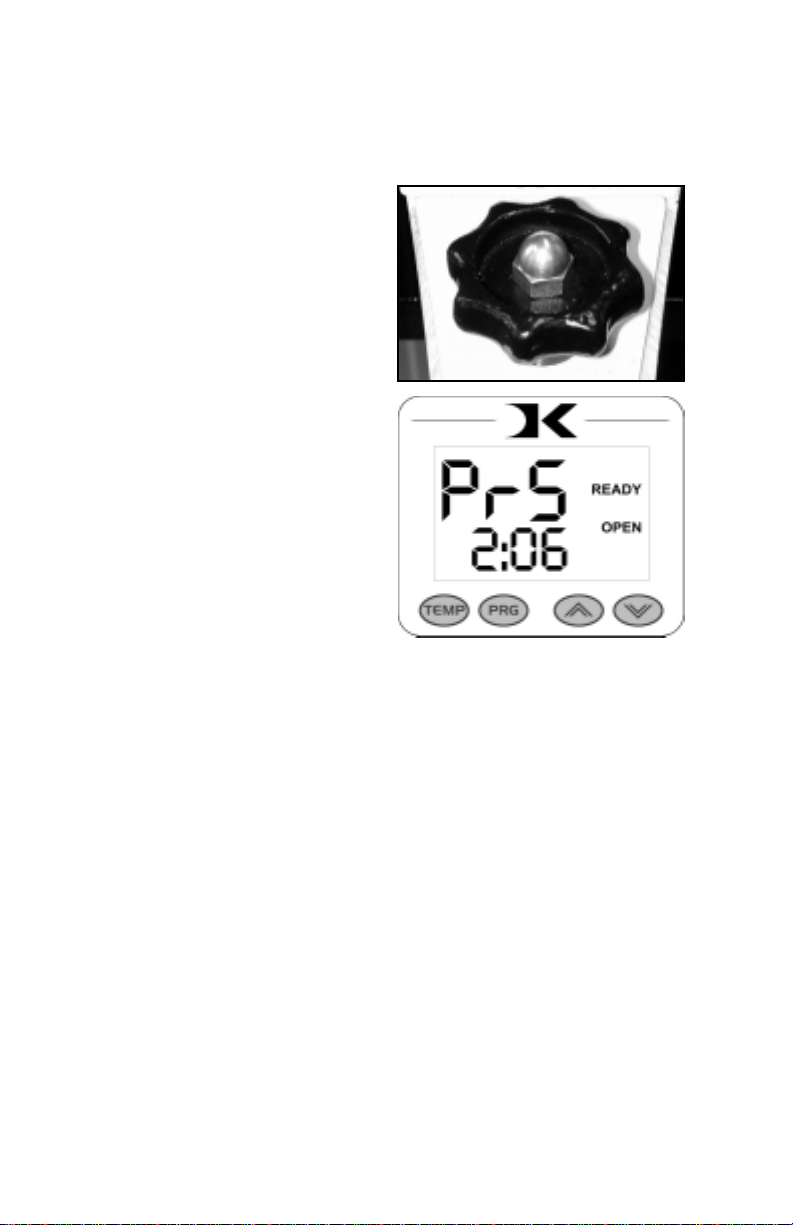

The Digital Height/Pressure gauge is a helpful indicator of the

current height of the top head as the operator adjusts the pressure.

• To decrease the pressure, turn the

pressure knob to the left,

counterclockwise.

• The top head will rise away from

the lower table.

• To increase the pressure, turn the

pressure knob to the right,

clockwise.

• The top head will lower toward the

pressing table.

• If the pressure knob is turned

rapidly enough, the display will

change to the pressure gauge

display. The units of measure are

a relative scale from 0:00 to 10:00,

with :02 increments.

• To view the current pressure display value without changing it, simply

pull the pin up on the pressure gauge device on the pack post and let

it drop back down. This will force the PRS display to appear.

The gauge displays a reference value based on the height of the

heat platen in relation to the lower table. The closer the heat platen is

to the substrate on the table, the heavier the pressure. The further

away, the lighter the pressure. The amount of actual force exerted

depends on the thickness of the item being pressed and the distance

from the heat platen to the table. The digital height/pressure gauge

simply shows a relative value from 0:00 to 10:00 in fine resolution

increments as to the current height of the platen.

This helps the user return to an exact pressure setting without

the need of multiple experimentations to find the proper pressure

setting. By simply changing the pressure until the correct value

appears, previous heights and pressure settings for different thickness

substrates can be quickly reset without error.

6

Loading...

Loading...