Page 1

Digi Connect® Tank

v2

User Guide

Page 2

Revision history—90001469

Revision Date Description

G July 2017

H August 2017 Added battery safety information.

J May 2018

K October 2018

L December 2020 Updated ATEX requirements.

Trademarks and copyright

Digi, Digi International, and the Digi logo are trademarks or registered trademarks in the United

States and other countries worldwide. All other trademarks mentioned in this document are the

property of their respective owners.

© 2020 Digi International Inc. All rights reserved.

n Updated graphics and text with information about

correctly aligning the cover and base when

assembling the device.

n Updated the product specifications temperature

range.

n Updated insert SIM card instructions.

n Added note to Connect Tank range specifications.

Updated range specifications: Cellular specifications and

General product specifications.

Disclaimers

Information in this document is subject to change without notice and does not represent a

commitment on the part of Digi International. Digi provides this document “as is,” without warranty of

any kind, expressed or implied, including, but not limited to, the implied warranties of fitness or

merchantability for a particular purpose. Digi may make improvements and/or changes in this manual

or in the product(s) and/or the program(s) described in this manual at any time.

Warranty

To view product warranty information, go to the following website:

www.digi.com/howtobuy/terms

Send comments

Documentation feedback: To provide feedback on this document, send your comments to

techcomm@digi.com.

Digi Connect® Tank v2 User Guide

2

Page 3

Customer support

Digi Technical Support: Digi offers multiple technical support plans and service packages to help our

customers get the most out of their Digi product. For information on Technical Support plans and

pricing, contact us at +1 952.912.3444 or visit us at www.digi.com/support.

Digi Connect® Tank v2 User Guide

3

Page 4

Contents

Digi Connect® Tank v2 User Guide

Get started

Verify product components 8

Assemble the device 8

Activate a SIMcard 12

LED indicators 12

Device controls 13

Technical specifications

Cellular specifications 15

Sensor specifications 15

General product specifications 16

Hardware

Maximum power and frequency bands 18

Safety notices 18

Installation considerations 19

Warnings: Explosion hazards 19

RF exposure statement 20

UL/cUL conformity 20

Special conditions for safe use (ATEX) 21

ATEX marking 22

Safety information 24

Remote Manager reporting 24

Scheduled reports 24

Alarms 24

Cellular and GPS communication 25

Battery inspection 25

Battery life 25

Initial Connect Tank configuration

About waking the device 27

Wake the device 27

Connect to the device using the CLI 27

Digi Connect® Tank v2 User Guide

4

Page 5

Register Connect Tank on a cellular network 29

CLI commands 30

Install Connect Tank

Before you begin 35

Install the device on a tank 35

Check network coverage 36

Manage Connect Tank with Remote Manager

About using Remote Manager with Connect Tank 38

Before you begin 38

Add a device to Digi Remote Manager 38

Alarm reports and options 39

Configure alarms 39

High and low thresholds 40

Hysteresis 41

Sensor error and battery life 42

Configure device (report) settings 43

Custom scaled values for tank data 44

Configure cellular options 45

Configure Remote Manager settings 45

Remote Manager option definitions for Connect Tank 46

Alarm options 46

Cellular option definitions 46

Device Cloud option definitions 47

Device (report) settings option definitions 47

Use Remote Manager to view device and sensor data streams

About data streams 50

View device data streams 51

Data streams reference information 51

Connect Tank maintenance

Firmware updates 55

Update the firmware using Remote Manager 55

Update the firmware using the CLI 56

Battery replacement 58

Troubleshooting

Device not responding 61

Reset the device 61

Restore factory defaults to the device 61

Device not connected to the cellular network 61

Troubleshooting Connect Tank reports and alarms 62

Empty tank reports 62

No reports in Remote Manager 62

High liquid reports 63

Digi Connect® Tank v2 User Guide

5

Page 6

Alarms while filling the tank 65

Metal tank issues 65

Regulatory information

FCC certifications and regulatory information 66

Declaration of Conformity (DoC) 66

CE mark (Europe) 67

Digi Connect® Tank v2 User Guide

6

Page 7

Digi Connect® Tank v2 User Guide

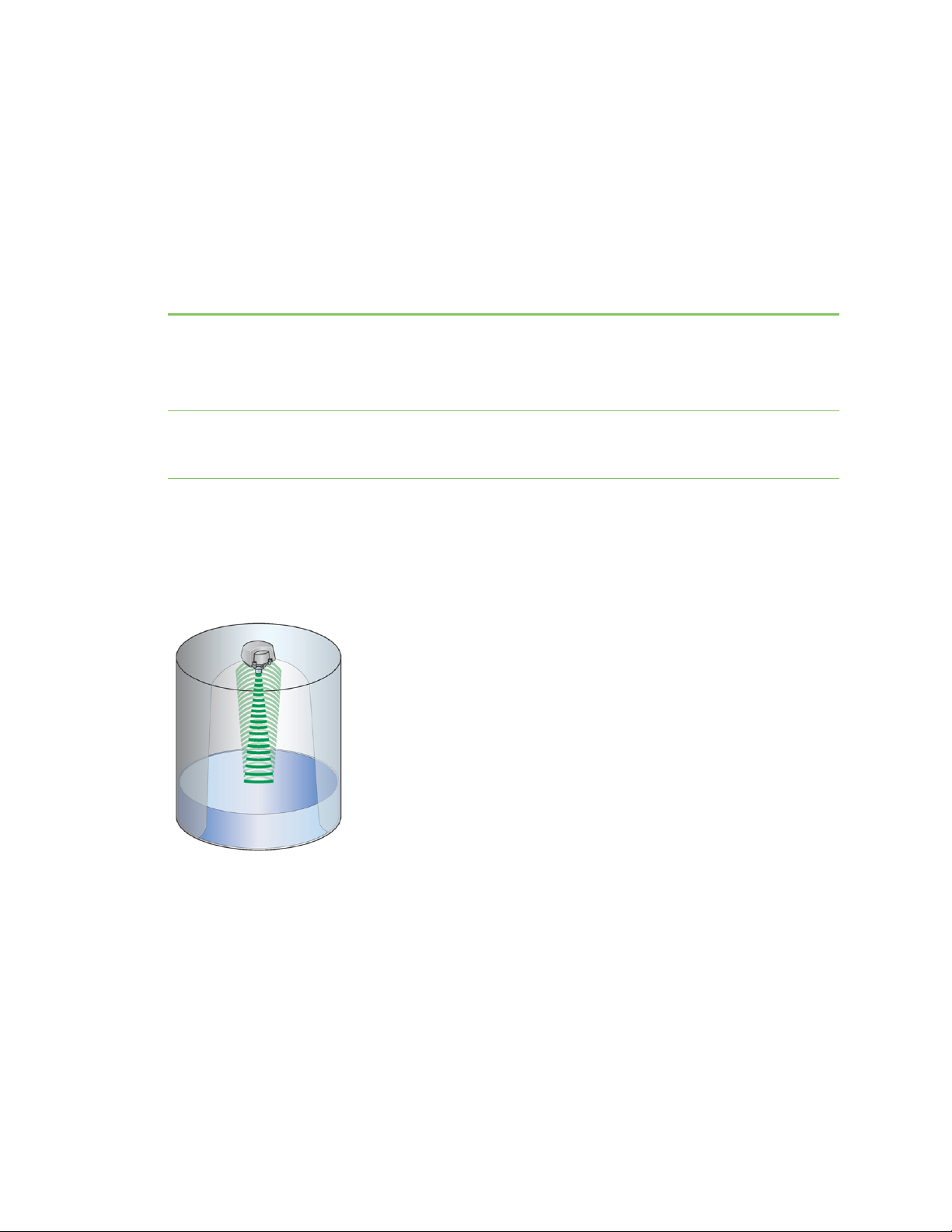

Digi Connect Tank v2 allows you to remotely monitor the liquid level in a single tank. The Connect

Tank device operates wirelessly by running on a long-life battery and communicating through the

cellular network.

Note Do not use Connect Tank to measure levels of non-liquid tanks. The Connect Tank device uses

ultrasonic sensing, which requires a uniform surface to take accurate measurements. Solid material

does not provide a uniform surface.

Using its ultrasonic sensor, the Connect Tank device transmits a narrow ultrasonic sound beam to the

surface of the liquid and reflects back to the sensor, as shown in the following figure. The device

measures the amount of time it takes for the ultrasonic sound beam to travel down to the surface of

the liquid and reflect back to the sensor. The device then converts the amount of time into a

measurement showing how far the liquid is from the top of the tank in inches and reports that

information to your Digi Remote Manager account.

Digi Connect® Tank v2 User Guide

7

Page 8

Get started

Before installing the Connect Tank device in a tank, make sure you review the information in this

section and complete all of the tasks.

Verify product components

Make sure you have the necessary parts in the box.

Connect Tank includes the following components:

Connect Tank Battery Gasket lubricant

The following accessories are available through Digi International Inc. For more information, see the

Digi Connect Tank product support page.

Activated SIMcard

(when you purchase Digi

Bundled Services)

Assemble the device

Before you begin, make sure you have the following required equipment to assemble the Connect

Tank device:

n One 9/64-inch or 3.5 mm hex key

n Activated SIMcard: See Activate a SIMcard

Digi Connect® Tank v2 User Guide

NPT adapter

(for some tank configurations)

Magnet

(for manually waking the device)

8

Page 9

Get started Assemble the device

CAUTION! This product contains a lithium metal battery. Prior to installation, the

battery should be inspected for any signs of damage. If the battery appears to be

damaged or is dropped during the installation, do not use the battery and dispose of it

properly. See Battery inspection for more information.

To assemble the device:

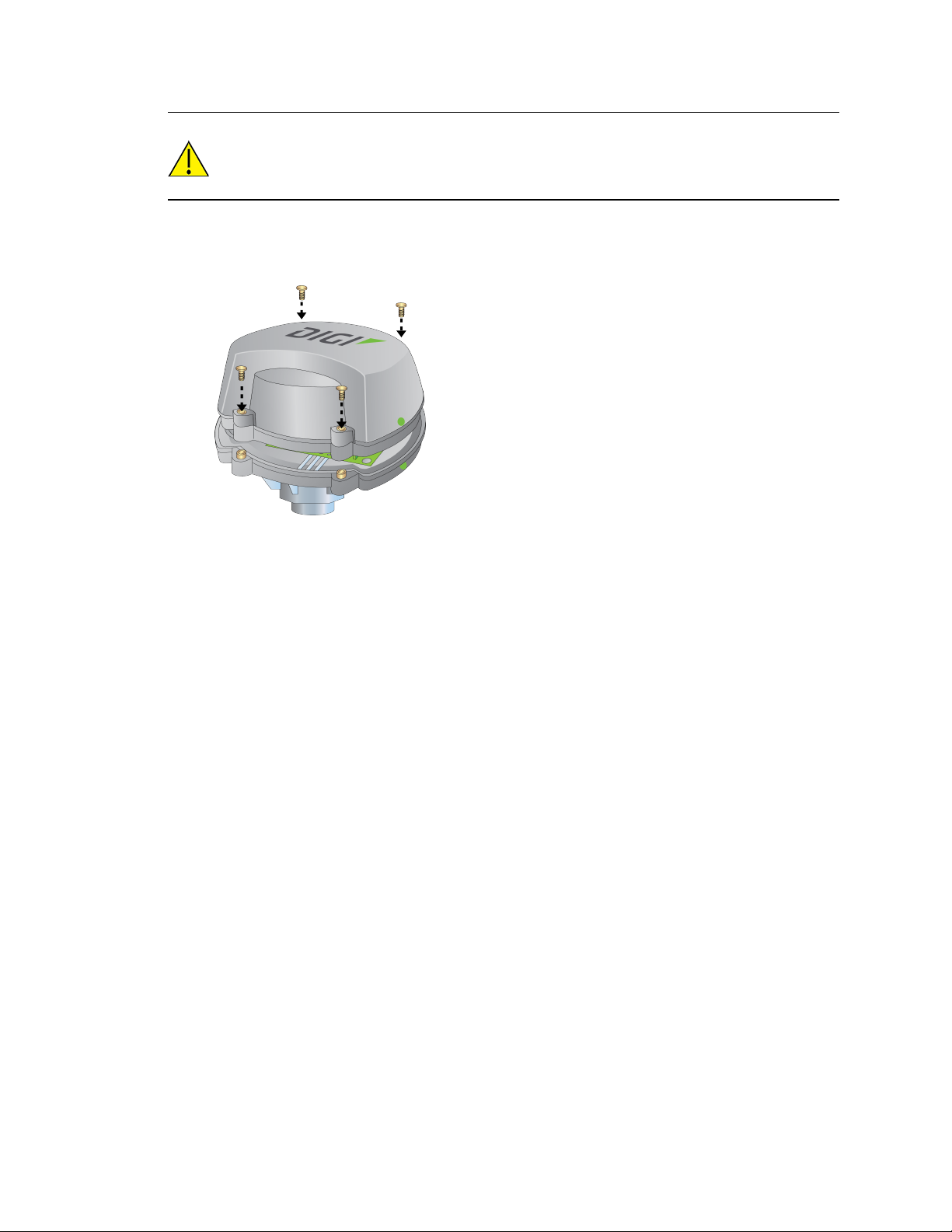

1. Use a 9/64-inch or 3.5 mm hex key to loosen the four retaining screws and open the Connect

Tank enclosure cover.

Digi Connect® Tank v2 User Guide

9

Page 10

Get started Assemble the device

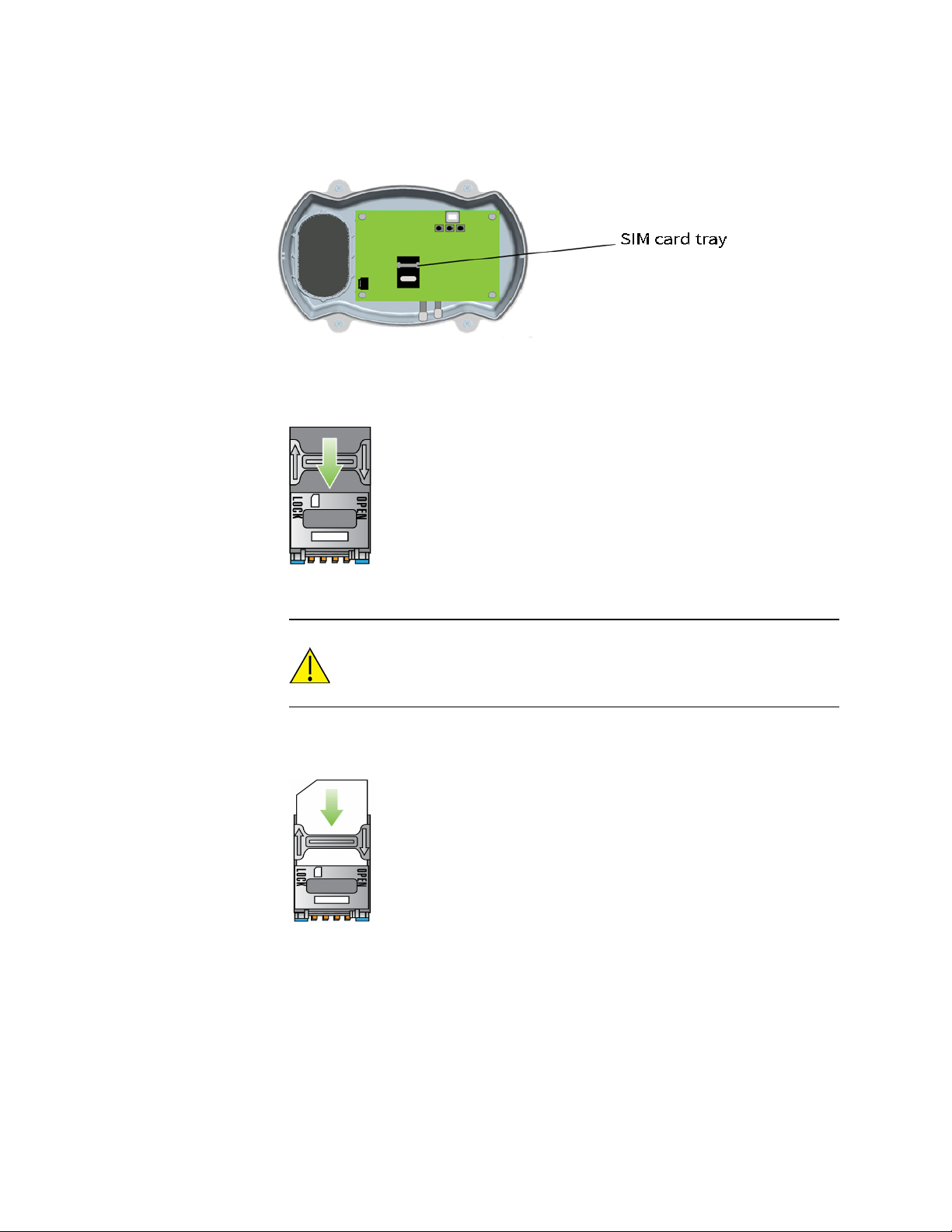

2. Insert the activated SIM card.

a. Orient Connect Tank to match the picture below.

b. Unlock the SIM card tray by gently pushing the metal bar toward the bottom of the

tray.

c. Open the SIMcard tray by pulling the tray up from the top or right side of the tray.

CAUTION! Do not pull the SIMcard tray up from the left side or use a

tool to open the tray. These actions may damage the SIM detect

switch, which is beneath the left side of the tray.

d. Insert the SIM card into the SIMcard tray, with the metal contacts face-down and

the flat edge inserted into the holder.

e. Press the SIMcard tray onto the board.

f. Lock the SIM card tray by gently pushing the metal bar toward the top of the

SIMcard holder.

Digi Connect® Tank v2 User Guide

10

Page 11

Get started Assemble the device

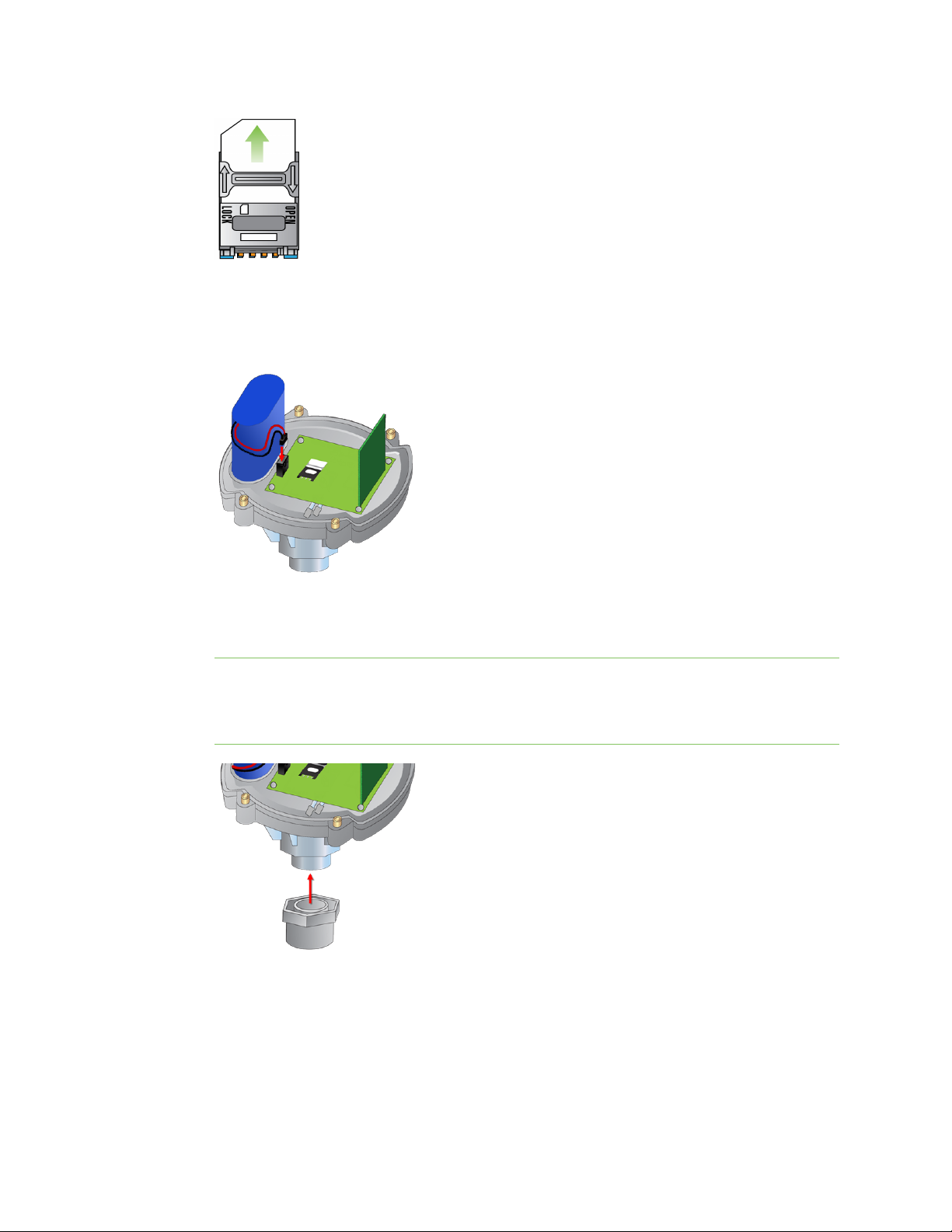

3. Place the battery in the battery holder. Make sure that the wiring attached to the top of the

battery is NOTplaced in the battery holder, as shown below.

4. Connect the wiring to the battery port on the circuit board.

5. (Optional) If your tank has a 2-inch NPT threaded opening, you can attach a 1-inch to 2-inch

adapter to the bottom of the device.

Note If you are using a 2-inch NPT adapter, you should only use the adapter available through

Digi International (part number 76000910). This adapter has been modified specifically to not

cause reflections of the ultrasonic signal. Standard 2-inch NPT adapters will interfere with the

ultrasonic signal and cause incorrect tank level readings.

6. If this is the first time you are assembling the device, complete initial configuration using the

CLI. For more information, see Initial Connect Tank configuration. If initial configuration has

been completed, you can skip this step.

Digi Connect® Tank v2 User Guide

11

Page 12

Get started Activate a SIMcard

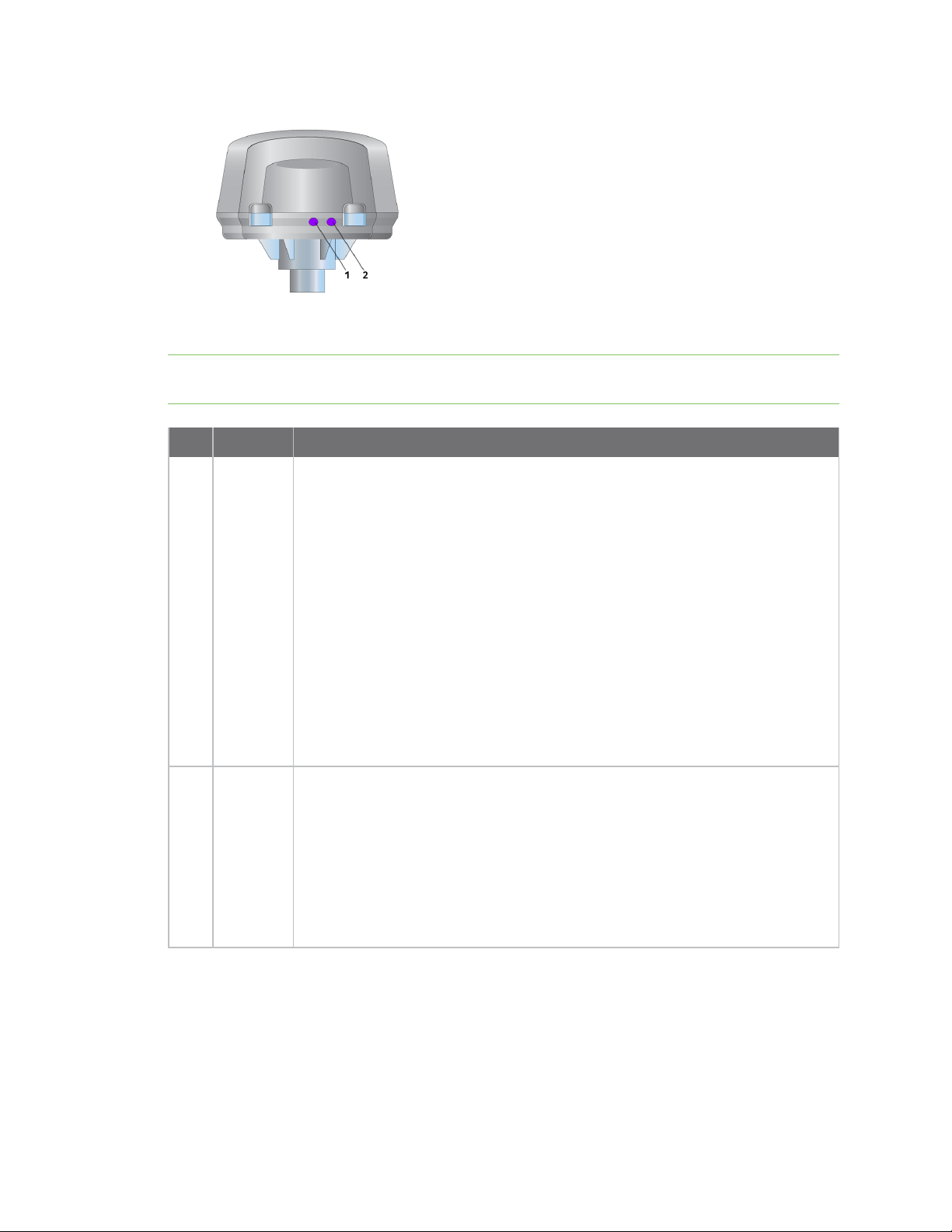

7. Reassemble the device.

a. Place the enclosure cover onto the base. To ensure that a gap does not appear

between the cover and the base:

n The green dots on the cover and the base must both be on the same side of

the device, as shown below.

n Make sure that the battery holder in the cover aligns with the battery holder

in the base.

b. Verify that an adequate seal is present between the cover and the base.

c. Tighten the screws

CAUTION! Cover screws are required as part of the safety rating. When tightening the

cover screws, use a screw torque of 0.79 to 1.92 newton meters (7 to 17 inch pounds).

Activate a SIMcard

You can activate a SIMcard from your cellular provider or from Digi.

1. Your SIM card provider needs the following information:

n Connect Tank IMEI number: The IMEInumber is on the label on the Connect Tank

device and on the box the device was shipped in.

n SIM card number: The SIMnumber is printed on the SIMcard.

2. Call your SIMcard provider to activate the SIMcard.

LED indicators

The Connect Tank device has two LED indicators to monitor the battery function, and the cellular

network connection, and GPS locating.

Digi Connect® Tank v2 User Guide

12

Page 13

Get started Device controls

The following table describes LED functions.

Note A solid light for an extended period of time may indicate the device needs service. For

assistance, contact Digi Technical Support.

Item Name Description

1 Cellular

and

GPSLED

2 Battery

LED

Indicator light for the cellular network connection:

n Purple: The device is awake.

n Red:

l Slowly blinking: Performing GPS location; the LED slowly blinks red for

an extended period of time during the first time the device performs

GPS location.

l Quickly blinking: Searching for the cellular network.

n Blue:

l Blinking: Connected to the cellular network and attempting to

communicate with Remote Manager.

l Solid light: Successfully sent data to Remote Manager; turns off after

a few seconds.

Indicator light for battery function:

n Purple: The device is awake.

n Red blinking: Indicates the battery life is less than or equal to the Battery

Life threshold alarm.

n Blue blinking: Indicates the battery life is greater than the Battery Life

threshold alarm.

For more information about the Battery Life threshold, see Battery life.

Device controls

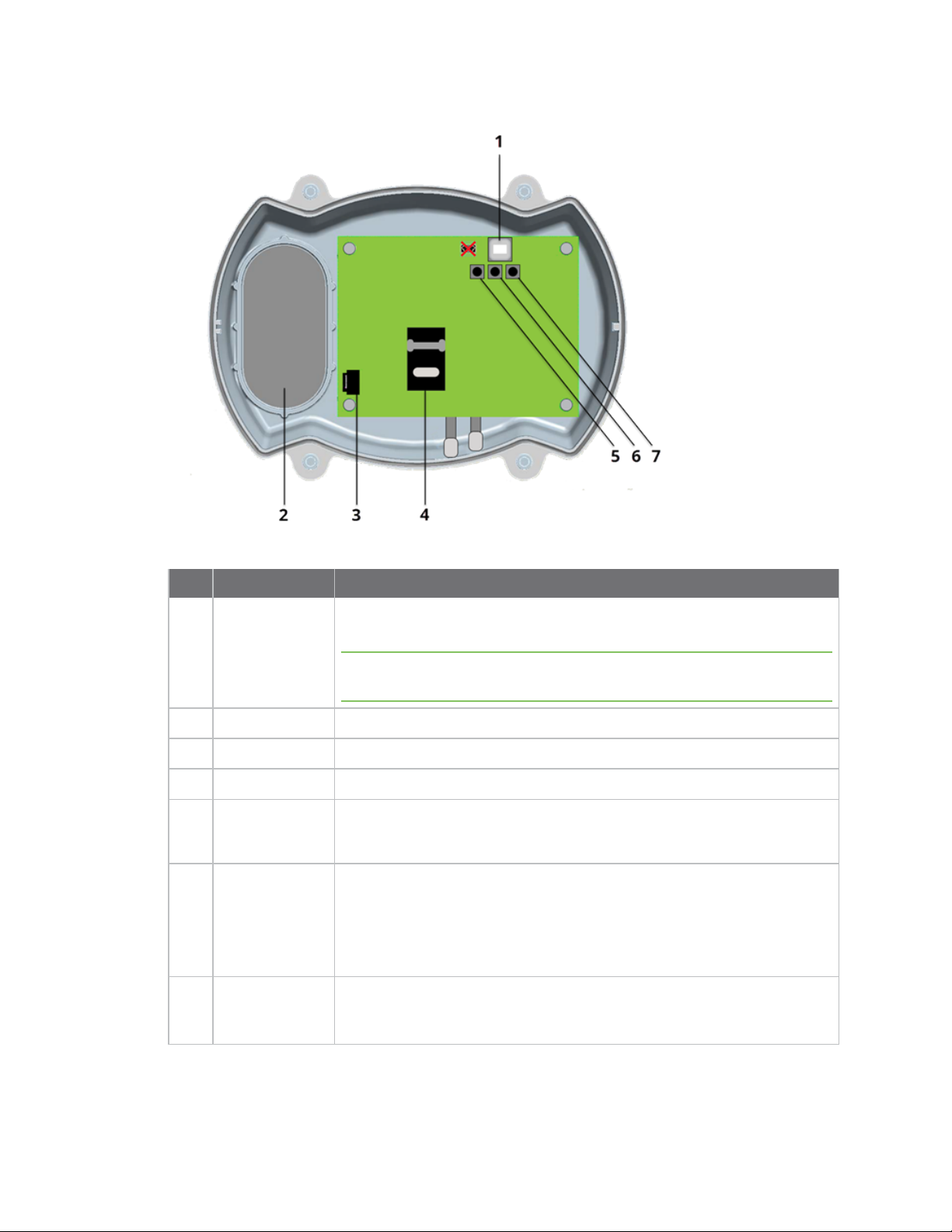

The following figure shows the controls for setting up and configuring the Connect Tank device.

Digi Connect® Tank v2 User Guide

13

Page 14

Get started Device controls

Item Name Description

1 USB type B port

Connects the device to a computer using a standard USB type A to B cable;

used to access the command line interface (CLI).

Note Do not use the mini USB port, which is covered by a red X in the

graphic.

2 Battery holder Compartment for the battery.

3 Battery port Port where the battery connects to the device.

4 SIMcard tray Holds the SIM card.

5 Wake button

6 Factory button

n Wakes up the device.

n Skips the GPS location process during device configuration.

n Press and hold this button for a few seconds to remove all

configuration changes and restore the device to its original state.

n If you accidentally press this button, but do not hold it down, the

device wakes and immediately returns to sleep mode.

7 Reset button Press this button to restart the device when it is not responding to inputs

(from the CLI or otherwise), such as when one or both lights remain on for

an extended period of time.

Digi Connect® Tank v2 User Guide

14

Page 15

Technical specifications

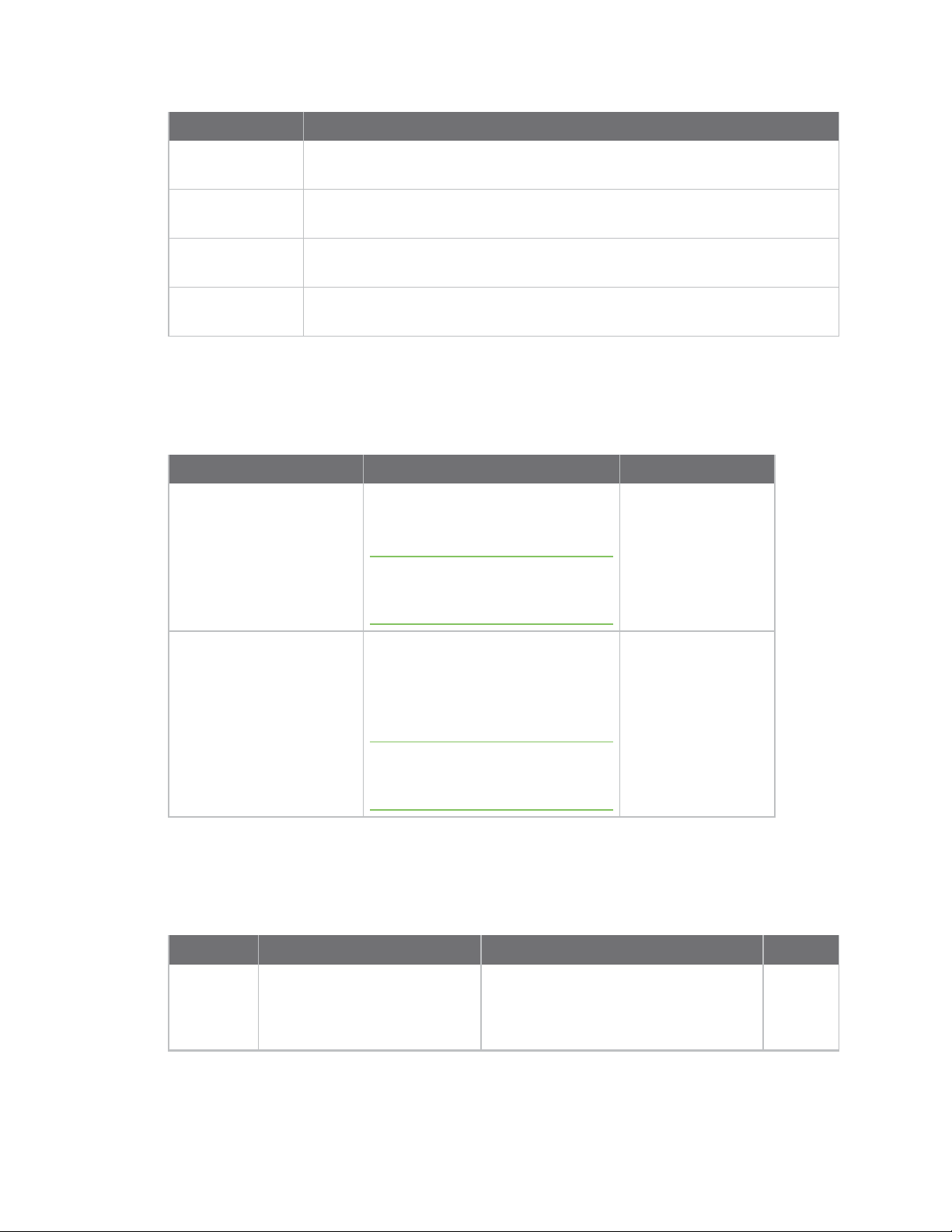

Cellular specifications

The following table summarizes the wireless WAN specifications for Connect Tank v2.

Specification Details

Carriers AT&T, International GSM Carriers

Frequency

band

Data rate

Antenna Built-in

SIMslot 1

North American Version: Dual Band UMTS/HSPA+ (850/1900 MHZ)

International Version: Dual Band UMTS/HSPA+ (900/2100 MHZ) Dual-Band GSM

(900/1800 MHZ)

HSDPA Cat. 10 / HSUPA Cat.6 data rates:

n DL: up to a maximum of 14.4 Mbps

n UL: up to a maximum of 5.76 Mbps

EDGE class 12 data rates:

n DL: up to a maximum of 237 kbps

n UL: up to a maximum of 237 kbps

GPRS class 12 data rates

n DL: up to a maximum of 85.6 kbps

n UL: up to a maximum of. 85.6 kbps

Sensor specifications

The following table provides a summary of the Connect Tank v2 sensor specifications.

Note Range figure estimates are based on free-air terrain with limited sources of interference. Actual

range will vary based on transmitting power, orientation of transmitter and receiver, height of

transmitting antenna, height of receiving antenna, weather conditions, interference sources in the

area, and terrain between receiver and transmitter, including indoor and outdoor structures such as

walls, trees, buildings, hills, and mountains.

Digi Connect® Tank v2 User Guide

15

Page 16

Technical specifications General product specifications

Sensor Short range Mid range

Model Massa M-300/150 Massa M-300/95

Type Ultrasonic, built-in temperature/sound speed compensation

Range

Range when temperature is -20˚ C to +60˚

C:

n 4 inches (100 mm) to

n 7 feet (2.1 meters)

Range when temperature is -30˚ C to -20˚

C:

n 4 inches (100 mm) to

n 5 feet (1.5 meters)

General product specifications

The following table provides a summary of the Connect Tank v2 general product specifications.

GPS/Glonass

Channels 56

Tracking sensitivity

Horizontal accuracy

GPS: up to -161 dBm

Glonass: up to -158 dBm

GPS: up to 2.5m

Glonass: up to 4m

Range when temperature is -20˚ C to +60˚

C:

n 1 foot (0.3meters) to

n 13 feet (4 meters)

Range when temperature is -30˚ C to -20˚

C:

n 1 foot (0.3meters) to

n 12 feet (3.7 meters)

Antenna Built-in

Management

Configuration &

Device Cloud/Local USB to Serial CLI Protocol

management

Protocol TCP

Power

Battery 7.2V, 14.5 Ah, Lithium Thionyl Chloride, non-rechargeable,

replaceable

Battery life Approximately 2 years (@ 2 reads/transmits per day)

Environmental

Operating temperature

-30˚ C to +60˚ C (see range limitations in Sensor specifications)

Storage temperature -40˚ C to +85˚ C

Relative humidity 90% (non-condensing after 90%)

Battery discharge up to 1%/year if stored at +30˚ C

Digi Connect® Tank v2 User Guide

16

Page 17

Technical specifications General product specifications

GPS/Glonass

Physical

Dimensions

(L x W x H)

Weight 1.25 lbs

LEDs Battery, Network

Enclosure material Valox (note: Massa sensor is PVC/PPA)

Enclosure rating NEMA 4X

Mounting 1” NPT

7.0 in x 5.15 in x 6.0 in (17.8 cm x 12.9 cm x 15 cm)

Digi Connect® Tank v2 User Guide

17

Page 18

Hardware

Maximum power and frequency bands

This section contains the maximum power and frequency bands for Connect Tank.

Maximum power Associated frequencies

2 W Cellular 850 and 900 MHz bands

1 W Cellular 1800 and 1900 MHz bands

Safety notices

Digi products are designed to the highest standards of safety and international standards compliance

for the markets in which they are sold. However, cellular-based products contain radio devices that

require specific consideration. Make sure you read and understand all of the safety notices, warnings,

and cautions for this product. Digi International assumes no liability for failure to comply with these

precautions.

Digi Connect® Tank v2 User Guide

18

Page 19

Hardware Safety notices

Installation considerations

n Read all instructions before installing and powering the device and keep these instructions in a

safe place for future reference. See Nonincendive Field Wiring Diagram for additional ATEX

wiring safety guidelines.

n USB (P2) (J1) and SIM (P6) connectors are intended for maintenance use within a Division 2

classified area. These connectors can only be used if the power is disconnected or the area is

known to be free of ignitable concentrations of flammable gases or vapors.

All external or field wiring must be in accordance with NFPA 70 Article 501.10(B).

n v2 is intended for fixed installations only.

n Push button switches are not for normal operational or maintenance use in hazardous

locations.

n If the device shows any signs of damage or malfunction when connecting the battery, remove

the battery connection immediately and contact your supplier for repair or replacement.

n Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment. Use only the accessories and battery

provided by the manufacturer; connecting non-approved accessories and batteries may

damage the device.

n Do not attempt to repair the product. Any attempt to service or repair the device by the user

will void the product warranty.

n Connect Tank must be maintained by Digi or a Digi qualified technician only. Always use the

designated battery, model number 76000912, from Digi. You must remove the unit from the

installation or unclassified hazard location before opening the enclosure due to the risk of

screws or batteries falling into the storage tank.

n When inserting wires into the terminal block, we recommend tightening torque to 0.2N-m.

n Allowable wire size for terminal blocks is 0.5-1.5mm

2

.

ATEX requirements

n Connect Tank should be used in an area of not more than pollution degree 2, as defined in EN

60664-1.

Warnings: Explosion hazards

Review the following explosion hazard warnings for the Connect Tank device.

Note The Connect Tank device contains internal batteries.

WARNING! Connect Tank is suitable for use in UL/cUL Class I, Division 2, Groups A, B, C,

and D hazardous locations or non-hazardous locations only. Substitution of any

component may impair suitability for Class I, Division 2.

Digi Connect® Tank v2 User Guide

19

Page 20

Hardware Safety notices

WARNING - EXPLOSION HAZARD: BATTERIES MUST ONLY BE CHANGED IN AN AREA

FREE OF ignitable CONCENTRATIONS.

WARNING - EXPLOSION HAZARD: DO NOT DISCONNECT WHILE THE CIRCUIT IS LIVE OR

UNLESS THE AREA IS FREE OF ignitable CONCENTRATIONS.

WARNING! Electrostatic discharge (ESD) can damage equipment and impair electrical

circuitry. ESD damage occurs when electronic components are improperly handled and

can result in complete or intermittent failures.

RemarqueL’unité Connect Tank contient des batteries internes.

AVERTISSEMENT! L’unité Connect Tank est adaptée pour utilisation seulement dans des

endroits non dangereux ou des endroits dangereux UL/cUL de classe I, division 2,

groupes B, C et D. Le remplacement de tout composant risquerait de compromettre la

convenance à la classe I, division 2.

AVERTISSEMENT - RISQUE D’EXPLOSION: LES BATTERIES DOIVENT ÊTRE REMPLACÉES

DANS UN ENDROIT EXEMPT DE CONCENTRATIONS INFLAMMABLES.

AVERTISSEMENT - RISQUE D’EXPLOSION: NE DÉCONNECTEZ PAS LORSQUE LE CIRCUIT

EST SOUS TENSION OU À MOINS QUE LA ZONE SOIT LIBRE DE TOUTE CONCENTRATION

INFLAMMABLE.

AVERTISSEMENT! Les décharges électrostatiques peuvent endommager le matériel et

nuire aux circuits électriques. Les dommages des décharges électrostatiques

surviennent lorsque les composants électroniques sont mal manipulés et peuvent

entraîner une défaillance complète ou intermittente.

RF exposure statement

In order to comply with RF exposure limits established in the ANSI C95.1 standards, ensure users

maintain a distance from the product of no less than 20 cm (approximately 7.8 inches).

UL/cUL conformity

Conformity to UL / cUL standards in the United States and Canada is in accordance with the following:

Digi Connect® Tank v2 User Guide

20

Page 21

Hardware Safety notices

Issue

Standard Title

date

ANSI/ISA

12.12.01, 2012

CAN/CSA C22.2

No. 213-M1987

UL2054 UL Standard for Safety for Household and Commercial Batteries October

UN 38.3 Recommendations on the Transport of Dangerous Goods Manual of

UL 60950-1 Safety Requirements for Electrical Equipment for Measurement,

Nonincendive Electrical Equipment for Use in Class I and II, Division 2

and Class III, Divisions 1 and 2 Hazardous (Classified) Locations

Nonincendive Electrical Equipment for Use in Class I, Division 2

Hazardous Locations

Tests and Criteria

Control, and Laboratory Use

2012

1987

29, 2004

2009

October

14, 2014

Essential health and safety requirements

Connect Tank complies with the essential health and safety requirements provided by the following

standards:

Standard Title Issue date

EN 600790:2012/A11:2013

EN 6007915:2010

Explosive Atmospheres - Part 0: Equipment - General Requirements 2013

Explosive Apparatus for Explosive Gas Atmospheres - Part 15:

Construction, Test and Marking of Type Protection "n" Electrical

Apparatus

2010/05/01

Special conditions for safe use (ATEX)

n Digi complies with the ATEX Directive to ensure a safe working environment when working

with equipment in potentially explosive atmospheres.

n Connect Tank is intended for fixed installation, where the installation is intended to minimize

the risk from electrostatic discharge.

n Connect Tank should be used in an area of not more than pollution degree 2, as defined in EN

60664-1.

Digi complies with the ATEX Directive to ensure a safe working environment when working with

equipment in potentially explosive atmospheres. The Connect Tank device is compliant to the ATEX

Directive under Certification DEMKO 14 ATEX 1416X.

Applicability

Connect Tank has been evaluated according to the following conditions. The ATEX evaluation and the

special conditions in this section apply to part numbers 50001884-xx.

WARNING! Connect Tank is suitable for use in ATEX Zone 2, Group IIC hazardous

locations or non-hazardous locations only.

Digi Connect® Tank v2 User Guide

21

Page 22

Hardware Safety notices

WARNING! The Connect Tank unit should not be installed in process tanks containing

either pressurized or flammable materials. The battery should be replaced in

unclassified areas only.

WARNING! Connect Tank is intended for fixed installation, where the installation is

intended to minimize the risk from electrostatic discharge. Follow all installation safety

guidelines in this section to minimize the risk from electrostatic discharge.

WARNING! Install Connect Tank in an area that does not have more than pollution

degree 2 as defined in EN/ IEC 60664-1.

WARNING! To avoid potentially dangerous electrostatic discharges, control all likely

ignition sources, minimize the harmful effects of any accidental fire or explosion by using

explosion relief and suppression systems. All zoned areas containing potentially

explosive atmospheres should be clearly marked using ATEX Ex hazardous area warning

signs.

WARNING! Potential electrostatic charging hazard. To avoid building up an electrostatic

charge when cleaning the enclosure of this device, you must use a damp cloth moistened

only with water. Do not use flammable cleaning agents.

ATEX marking

The device must include the markings described in the following table.

Mark Description

ATEX logo

Digi Connect® Tank v2 User Guide

22

Page 23

Hardware Safety notices

Mark Description

ATEX symbol and classification:

II 3 G Ex nA IIC T6 Gc

n

— The ATEX symbol. This symbol indicates certification

for use in an explosive atmosphere. The symbols that

follow it provide the details of that certified use.

n II — This indicates Group II (Clause 4.2). The equipment is

intended for use in places with an explosive gas

atmosphere other than mines susceptible to firedamp.

n 3 — This indicates Equipment category 3. Category 3

comprises products designed to be capable of keeping

within its operational parameters, stated by the

manufacturer, and based upon a normal level of protection

for its intended use, considering areas in which explosive

atmospheres caused by mixtures of air and gases, vapors,

mists or air/dust mixtures are unlikely to occur and if they

do occur, do so infrequently and for a short period of time

only.

n G — This indicates that the Environment is based on

International Electrotechnical Commission (IEC) 60079-0,

Clause 29.4.

n Ex — This indicates that the product has been evaluated

for use in potentially explosive atmospheres.

n nA — This indicates that the product provides ignition

protection by using components that are non-sparking

during normal operations.

n IIC — The Group symbol where IIC is electrical equipment

for places with an explosive gas atmosphere other than

mines susceptible to firedamp.

n T6 — This is the Temp Code, indicating a maximum surface

temperature of 85° C.

n Gc — This indicates the Equipment Protection Level. Gc

means equipment for explosive gas atmospheres, having

an “enhanced” level of protection, which is not a source of

ignition in normal operation and which may have some

additional protection to ensure that it remains inactive as

an ignition source in the case of regular expected

occurrences (for example, failure of a lamp).

Digi Connect® Tank v2 User Guide

23

Page 24

Hardware Safety information

Safety information

The following safety information provides guidelines when assembling the Connect Tank device. For

additional safety guidelines, see Safety notices.

CAUTION! The device is sensitive to electrostatic discharge (ESD).

The Connect Tank device must be maintained only by Digi or a Digi qualified technician. Before

assembling the device, note the following:

n To avoid the risk of the screws or battery falling into the storage tank, do not assemble the

device in the installation area.

n Move the device to a non-hazardous and unclassified area before opening the enclosure and

connecting the hardware.

n Always use the designated battery, model number 76000912, from Digi International Inc.

n Allow only a trained technician to replace the lithium thionyl chloride batteries used in Connect

Tank.

n Prior to installation, the battery should be inspected for any signs of damage. If the battery

appears to be damaged or is dropped during the installation, do not use the battery and

dispose of it properly. See Battery inspection for more information.

n You may be required to have a licensed electrician install or perform maintenance on this

equipment. Always follow applicable local, state, and federal codes and guidelines.

Remote Manager reporting

The Connect Tank device sends its tank liquid level data to your Remote Manager account. You can

configure when the device reads the liquid level and how often it reports that data. You can also set

device alarms to report when a tank is nearly full, nearly empty, or the tank level drastically changes.

Scheduled reports

By default, the Connect Tank device checks and reports the liquid level in a tank twice a day. However,

you can change the frequency that it sends reports to accommodate your tank environment.

For example, you might want the device to check the tank liquid level twice a day, but send that data

to Remote Manager only once a day.

Alarms

You can configure the Connect Tank device to send an alarm separately from scheduled reports to

communicate liquid level and device information, including:

n Low and high thresholds

n Delta low and delta high thresholds

n Hysteresis

Digi Connect® Tank v2 User Guide

24

Page 25

Hardware Cellular and GPS communication

n Sensor error

n Battery life

Note Sending more than two reports a day to Remote Manager reduces the battery life.

For more information, see Configure alarms.

Cellular and GPS communication

The Connect Tank device has an internal cellular antenna and an optional GPS antenna for

communications. There are no external antennas required to operate the device. Before installing the

device, make sure your cellular service provider has enough network coverage where your tanks are

located. For more information about using the device to check network coverage, see Check network

coverage.

CAUTION! Unauthorized antenna modifications and attachments invalidate the device

type specifications and may violate local RF emission regulations.

Battery inspection

CAUTION! This product contains a lithium metal battery. Prior to installation, the

battery should be inspected for any signs of damage. If the battery appears to be

damaged or is dropped during installation, do not use the battery and dispose of it

properly.

Please contact Digi Technical Support at 952-912-3444 or Tech.support@digi.com to order a

replacement battery.

The MSDS (Material Safety Data Sheet) for the battery can be found at

www.digi.com/documentation/ConnectTank.

The Connect Tank enclosure top and bottom have green alignment dots to ensure the top is placed

correctly on the product. These alignment dots should align on top of each other when installed

correctly. If the top of the product is reversed 180 degrees, the product will be susceptible to water

ingress and the battery will be subject to additional shock and vibration during handling, potentially

damaging the battery. For more information about aligning the dots and correctly assembling the

Connect Tank, see Assemble the device.

Battery life

The Connect Tank device uses sleep and wake modes to manage power use. By default, the device

wakes only to check the liquid level in a tank and send reports. It is in sleep mode at all other times,

which reduces power consumption to the lowest possible levels.

The Connect Tank battery can operate for up to two years when you maintain these conditions:

n The device has adequate network coverage in the area.

n The device sends a report two times a day (or less).

The battery LED on the front of the device indicates battery life; for details, see LED indicators.

Digi Connect® Tank v2 User Guide

25

Page 26

Initial Connect Tank configuration

Before installing Connect Tank in the field, complete the initial configuration steps to register it with a

cellular network. When configuring Connect Tank, the device must be awake.

The following sections describe how to wake Connect Tank and register it with a cellular network

using the command line interface (CLI).

After initial configuration using the CLI, you can use Remote Manager to configure additional settings

and remotely manage the Connect Tank device; see Manage Connect Tank with Remote Manager.

About waking the device 27

Wake the device 27

Connect to the device using the CLI 27

Register Connect Tank on a cellular network 29

CLI commands 30

Digi Connect® Tank v2 User Guide

26

Page 27

Initial Connect Tank configuration About waking the device

About waking the device

You can wake the Connect Tank device by pressing the Wake button or swiping the optional magnet

across the front of the device. When you press the Wake button or activate the magnetic switch, the

following occurs:

n The device sends a report to Remote Manager with the following information:

l Sensor connection status

l Measured distance reading

l Measured temperature reading

l GPS location (optional, based on configuration)

l Battery life (the current battery percentage remaining)

l Device settings

l Cellular network signal strength

n Battery and network status LEDs glow indicating their respective functions. For more

information, see LED indicators.

Wake the device

You can wake the Connect Tank device as follows:

n If the Connect Tank enclosure is open, press the Wake button.

n If the Connect Tank enclosure is closed, swipe the magnet across the magnet icon on the

outside of the device.

Note This feature was not included in the ATEX evaluation. For more information, see Special

conditions for safe use (ATEX).

The LEDs blink indicating the device is on. For more information about LED behavior, see LED

indicators.

After the device wakes and sends a report to Remote Manager, it enters sleep mode. The device

remains in sleep mode until the next scheduled or manual wake cycle.

Connect to the device using the CLI

Perform the following initial configuration steps using a terminal program and CLI commands.

Before you begin, make sure you have the following required equipment for this step:

n Computer running a terminal program.

n USB type A to B cable.

To connect to the device using a terminal program:

1. Open the enclosure and make sure the battery is connected and the SIM card is installed. For

information, see Assemble the device.

2. Connect a USB type A to B cable from your computer to the USB type B port.

Note Do not use the mini USB port, which is covered by a red X in the graphic below.

Digi Connect® Tank v2 User Guide

27

Page 28

Initial Connect Tank configuration Connect to the device using the CLI

You may need to install device drivers or wait for your computer to automatically install them

when connecting Connect Tank to a computer using a USB cable. Digi recommends drivers

available at www.ftdichip.com/Drivers/VCP.htm.

3. Open a terminal program on a computer and connect to Connect Tank using the following

configuration:

n Connection port: Connect to the COM port associated with the USB cable connected to

Connect Tank

n Baud rate or bits per second: 115200

n Data: 8 bit

n Parity: None

n Stop: 1 bit

n Flow control: None

Digi Connect® Tank v2 User Guide

28

Page 29

Initial Connect Tank configuration Register Connect Tank on a cellular network

4. Press the Wake button.

n The command prompt appears in the terminal program window and the device

attempts to connect to the cellular network and obtain GPS location.

n The cellular and GPS LED slowly blinks red for an extended period while the device

performs GPS location for the first time.

Note To skip the GPS location process, press the Wake button again.

5. In the terminal program, type status at the command prompt and press Enter to see device

information, such as firmware version, battery life, serial number, and connection state.

6. In the terminal program, type set to view configuration information for the device, including

access point name (APN), user name, password, PIN, and ISN.

7. To change any of the configuration information:

a. Type set [configuration option]=[value] at the command prompt and press Enter.

The [configuration option] is the device setting you want to change and [value] is

the new option setting.

For device configuration options, see CLI commands.

b. [Optional] Type set again before the device goes to sleep to view the current and

pending values.

The device goes to sleep and immediately wakes up to make the change. After the

device completes the change it goes to sleep again.

c. Press the Wake button and type set at the command prompt to verify the change is

correct.

Register Connect Tank on a cellular network

The Connect Tank device is configured with a default APN that you might need to change to register

the device on the cellular network for your cellular account provider. Contact your cellular service

provider to get the correct APN before completing the following steps.

Note If you purchased Digi Bundled Services, the cellular connection is already configured on your

Connect Tank and you can skip this section.

To register the device on a cellular network:

1. Make sure the battery is connected and the SIM is installed, the device is connected to a

computer, and the terminal program is configured to communicate with the device. For

instructions, see Connect to the device using the CLI.

2. Open the terminal program and connect to the Connect Tank device. For instructions, see

Connect to the device using the CLI.

Digi Connect® Tank v2 User Guide

29

Page 30

Initial Connect Tank configuration CLI commands

3. Press the Wake button.

n The command prompt appears in the terminal program window and the device

attempts to connect to the cellular network and obtain GPS location.

n The cellular and GPS LED slowly blinks red for an extended period while the device

performs GPS location for the first time.

Note To skip the GPS location process, press the Wake button again.

4. At the command prompt, type set apn=thecellular.apn where thecellular.apn is the string

supplied by your cellular service provider.

5. Press Enter.

n The terminal program displays the APN configuration setting’s current value and the

pending value.

n The device goes to sleep and immediately wakes up to make the change. After the

device completes the change it goes to sleep again.

6. Press the Wake button and type set at the command prompt to verify your change was made

and that it is correct.

7. Use other commands in the CLI to see additional information about the device, such as

firmware version, battery life, cellular network strength, and more. See CLI commands.

CLI commands

The following table provides all of the available CLI commands for configuring the device and viewing

status information.

Command Use Options

fwupdate Update the

firmware with a

firmware image

Make sure the terminal program is able to transfer YMODEM files.

Digi Connect® Tank v2 User Guide

30

Page 31

Initial Connect Tank configuration CLI commands

Command Use Options

status Display device

information

View the following:

n Device Type: Name and version of the device hardware.

n Device ID: ID number for the Connect Tank device.

n Firmware Version: Version of the device’s current

firmware.

n UTC Time: Last reported date and time.

n Battery Life: Amount of battery life remaining.

n Sensor: Status of the sensor.

n Mobile support software: Version of the mobile software.

n Device type: Cellular network type the device connects to.

n Manufacturer: Cellular modem manufacturer.

n Model: Cellular modem model number.

n Modem revision: Modem firmware version.

n Serial number: Modem serial number.

n Phone number: Phone number registered to the activated

SIM card.

n SIM IMSI: Unique user identifier for the cellular network.

n SIM ICCID: SIM serial number.

n SIM PIN status: State of the SIM card.

n Connection state: Cellular connection state.

n Connection duration: Amount of time the cellular modem

was connected during last wake cycle.

n Disconnect reason: Cause of the cellular modem

disconnection during last wake cycle.

n Connections: Number of cellular connection attempts

since power up.

n Connection errors: Number of failed connections since

power up.

n User disconnects: Number of normal disconnections since

power up.

n Monitoring errors: Number of cellular modem errors since

power up.

n Device resets: Number of times cellular modem was reset

to recover from errors since power up.

Digi Connect® Tank v2 User Guide

31

Page 32

Initial Connect Tank configuration CLI commands

Command Use Options

set Manage device

configuration

Use the following commands to change settings:

n apn: Access point name for the cellular network (supplied

by your cellular service provider). Settings:

Note If you purchased Digi Bundled Services, the cellular

connection is already configured on your Connect Tank.

l Minimum length: 1 character

l Maximum length: 63 characters

l Alpha-numeric characters, hyphen, period

l Cannot be disabled

n isn: URL to connect to Remote Manager; this is configured

by default and should only be changed when directed by a

Digi representative. Settings:

l IPv4 address, such as 10.20.30.40 or an FQDN, such as

devicecloud.digi.com

l Minimum length: 1 character

l Maximum length: 63 characters

l Alphanumeric characters, hyphen, period

l Cannot be disabled

n pin: PIN for your SIM card, if required (supplied by your

cellular service provider). Settings:

l Minimum length: 4 characters

l Maximum length: 8 characters

l Numeric only

l No value: disabled (no PIN required)

n pwd: Password for your cellular account, if required

(supplied by your cellular service provider). Settings:

l Minimum length: 1 character

l Maximum length: 63 characters

l Printable characters and spaces only (no quotation

marks or backslashes)

l No value: disabled (no user name required)

n usr: User name for your cellular account, if required

(supplied by your cellular service provider). Settings:

Digi Connect® Tank v2 User Guide

32

Page 33

Initial Connect Tank configuration CLI commands

Command Use Options

l Minimum length: 1 character

l Maximum length: 63 characters

l Printable characters and spaces only (no quotation

marks or backslashes)

l No value: disabled (no user name required)

Digi Connect® Tank v2 User Guide

33

Page 34

Install Connect Tank

You must install the device correctly to ensure the ultrasonic sound beam reflects back to the sensor.

If the device is not installed correctly, it might cause false echoes, inaccurate measurements, or no

measurements.

Note Do not use the device to measure levels of non-liquid tanks. The device uses ultrasonic sensing,

which requires a uniform surface to take accurate measurements. Solid material does not provide a

uniform surface.

Use the information in the following sections to install the Connect Tank device correctly and to

troubleshoot inaccurate liquid level issues.

Before you begin 35

Install the device on a tank 35

Check network coverage 36

Digi Connect® Tank v2 User Guide

34

Page 35

Install Connect Tank Before you begin

Before you begin

Do the following before installing the Connect Tank device:

n Follow all of the safety and certification guidelines and requirements for the Connect Tank

device.

n Assemble the device and complete initial configuration using the CLI.

n Make sure you have the necessary tools and equipment for your tank type and mounting

option, such as NPT adapters.

n Review the installation information in this section to avoid incorrectly installing the device.

Incorrect installation results in inaccurate or missed liquid level measurements.

Install the device on a tank

Consider the following when installing the Connect Tank device:

n The sensor must be level (perpendicular to the liquid surface) to allow the ultrasonic sound

beam to travel straight down.

n Make sure there is a minimum of 7 inches between the Connect Tank sensor and the maximum

liquid level.

n Mounting the device vertically ensures proper orientation. If the device is not mounted

vertically, it may send incorrect readings.

n Make sure the ultrasonic sound beam’s transmission path does not have any obstructions.

n Position the device as close as possible to the center of the tank’s diameter.

For troubleshooting installation, see Troubleshooting.

Digi Connect® Tank v2 User Guide

35

Page 36

Install Connect Tank Check network coverage

Check network coverage

The Connect Tank device has an internal antenna for cellular and an optional antenna for GPS

communications. There are no external antennas required to operate the device.

CAUTION! Unauthorized antenna modifications and attachments invalidate the device

type specifications and may violate local RF emission regulations.

To check network coverage:

1. Place the device in the area where it will be installed.

2. Wake the device.

3. Make sure the cellular LED blinks blue to show it is connected to the network and that there is

an adequate network signal in the area.

If the device does not connect to the cellular network, see Device not connected to the cellular

network.

Note Proper network coverage helps reduce power consumption, leading to improved battery life.

Digi Connect® Tank v2 User Guide

36

Page 37

Manage Connect Tank with Remote Manager

Digi Remote Manager is a cloud-based device management platform that allows you to connect any

device to any application, anywhere. Remote Manager gives you the tools you need to manage many

devices quickly and effectively, as well as insight into the health and current state of your entire

device network.

The following sections describe how to use Remote Manager to remotely monitor and control all of

your Connect Tank devices from any web browser.

About using Remote Manager with Connect Tank 38

Before you begin 38

Add a device to Digi Remote Manager 38

Alarm reports and options 39

Configure device (report) settings 43

Configure cellular options 45

Configure Remote Manager settings 45

Remote Manager option definitions for Connect Tank 46

Digi Connect® Tank v2 User Guide

37

Page 38

Manage Connect Tank with Remote Manager About using Remote Manager with Connect Tank

About using Remote Manager with Connect Tank

After registering the Connect Tank device on a cellular network, use Remote Manager to remotely

change device configuration, review device information, set up device reporting, and review data

about liquid levels.

Remote Manager allows you to change Connect Tank device settings, update firmware, and schedule

the following tasks during wake cycles:

n Monitor the tank liquid level

n Report data to Remote Manager

n Check for and make scheduled configuration changes

n Check liquid level alarms

n Check battery life

For more information about Remote Manager, see http://www.digi.com/products/cloud/digi-remote-

manager.

Note The Connect Tank battery can operate for up to 2 years when you follow standard operating

conditions. Changes made to Remote Manager settings can affect battery life. For more information

on standard operating conditions, see Battery life.

Before you begin

Before using Remote Manager to manage the Connect Tank device, do the following:

n Get the Connect Tank IMEI:

l If you have physical access to the device, locate the 15-digit device IMEI number on the

Connect Tank label.

l If you need to remotely access the device, connect to the device using the CLI.

n Create a Remote Manager account. To complete this step, see the Remote Manager login

page.

Note For initial device test and development, you can use a free Developer Edition Remote Manager

account. When you are ready to deploy Connect Tank devices in the field, you need a Premiere account

to access all Connect Tank features in Remote Manager.

Add a device to Digi Remote Manager

To remotely manage Connect Tank and get sensor data, you need to create a Remote Manager

account and add your Connect Tank device to your account.

Note To serve our customers most effectively, Digi International Inc. is consolidating its cloud

services, Digi Device Cloud and Digi Remote Manager®, under the Remote Manager name. This phased

process does not affect device functionality or the functionality of the web services and other

features. However, you will find instances of both Device Cloud and Digi Remote Manager in some

documentation, firmware, and user interfaces.

Note If you purchased Digi Bundled Services, the following steps were completed for you. You can skip

this section.

Digi Connect® Tank v2 User Guide

38

Page 39

Manage Connect Tank with Remote Manager Alarm reports and options

To add a device to Remote Manager:

1. Sign in to your Remote Manager account:

n If you need to create an account, go to Remote Manager at remotemanager.digi.com,

click Sign up, and complete the form to create your account.

n If you already have an account, go to Remote Manager at remotemanager.digi.com and

sign in with your user name and password.

2. Locate the 15-digit device IMEI number on the Connect Tank label.

3. Click Device Management > Devices.

4. Click Add Devices. The Add Devices dialog appears.

You cannot use the Discover button to discover Connect Tank devices automatically because

the devices are not available on the local network.

5. From the Add Devices drop-down menu, select IMEI, and enter the number.

6. Click Add to add the device.

7. Click OK to close the Add Devices dialog. The device appears in the Device Management list.

Note If the device does not display in the Device Management list, you can wake Connect Tank

to force a connection with Remote Manager and update the data. For instructions, see Update

the firmware using the CLI.

8. Click Refresh if the device data does not appear on its own after a short period of time.

Device data appears after the first time it communicates with Remote Manager.

Alarm reports and options

You can configure the Alarm Settings options in the Remote Manager to have the Connect Tank device

send reports indicating when liquid level measurements do not meet normal conditions for your tank

environment. The alarms appear as reports in Remote Manager

Configure alarms

This section explains how to configure the Alarm Settings in Remote Manager. For details about Alarm

Settings options for the Connect Tank device, see Alarm options.

1. Sign into Remote Manager.

2. Click Device Management > Devices.

3. Double-click the Connect Tank device you want to configure.

4. Click Configuration > Alarm Settings.

5. Determine the alarms that you want to receive.

a. Select On for each alarm you want to receive.

o

High and low thresholds

o

Hysteresis

o

Sensor error and battery life

b. Enter an appropriate value for each alarm option.

Digi Connect® Tank v2 User Guide

39

Page 40

Manage Connect Tank with Remote Manager Alarm reports and options

6. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

c. Click Schedule. Connect Tank downloads and applies configuration changes the

next time it connects to Remote Manager.

Note The Recurring option does not work with the Connect Tank device.

High and low thresholds

Use these settings to define if the liquid level in the tank is too high, too low, or changes too quickly

between two consecutive readings.

For example, the device is configured to take measurements every hour and send reports twice every

day at 8:00 and 20:00. If a device senses that the liquid level reached a high or low alarm threshold at

11:00, it immediately sends a report to Remote Manager with that information.

When configuring alarms, make sure you use correct measurements. The Connect Tank sensor

measures the distance in inches from the top of the sensor to the top of the liquid in the tank. A

smaller distance (such as 10 inches) is near the top of the tank; a larger distance (such as 70 inches) is

near the bottom of the tank.

Note Actual measurements depend on your tank size.

Digi Connect® Tank v2 User Guide

40

Page 41

Manage Connect Tank with Remote Manager Alarm reports and options

Threshold Description

High Sends an alarm report when the measurement indicates the liquid level is near the

1

top of the tank.

For example, the high threshold value might be 15 inches.

Low Sends an alarm report when the measurement indicates the liquid level is near the

2

bottom of the tank.

For example, the low threshold might be 75 inches.

Delta

3

high

Delta low Sends an alarm report when the liquid level decreases too much between two

4

Sends an alarm report when the liquid level increases too much between two

consecutive readings.

For example, the delta high threshold value might be 20 inches because liquid levels

should not increase more than 20 inches between two consecutive readings.

consecutive readings.

For example, the delta low threshold value might be 10 inches because liquid levels

should not decrease more than 10 inches between two consecutive readings.

Hysteresis

The liquid levels in your tanks may sometimes fluctuate during an alarm condition, which causes

repeated alarm reports.

For example, in a Connect Tank the liquid level increased to the high alarm threshold and the device

sent a high alarm report. Note that during this alarm condition, the liquid level may continue to

increase and decrease repeatedly between normal and high thresholds. In this situation, if you do not

set a hysteresis range, the Connect Tank device sends an alarm report every time the device

measures the liquid level at the high threshold.

Hysteresis works with the high and low alarm thresholds to tell the device when to keep an alarm on

without sending additional alarm reports, or when to shut off an alarm. Use this to avoid repeated

alarms during common liquid level fluctuations.

For example, if your high alarm threshold is 20 inches and your hysteresis value is 10 inches, then your

high alarm hysteresis is 30 inches. The following figure shows how a high alarm and hysteresis work in

a tank.

Digi Connect® Tank v2 User Guide

41

Page 42

Manage Connect Tank with Remote Manager Alarm reports and options

Alarm

state Description

1 On The device measures that the water increased above the high threshold. The device

sends an alarm report to

2 On The device measures that the water decreased below the high threshold, but it is still

above the hysteresis so the alarm remains on. If the water increases again above the

high threshold, no additional alarm reports are sent.

3 Off The water decreased below the hysteresis so the alarm turns off. If the water increases

again above the high threshold, the alarm turns on and the device sends another alarm

report.

For a low alarm hysteresis, if your low alarm threshold is 70 inches and the hysteresis value is 10

inches, then your low alarm hysteresis is 60 inches. The alarm is on and stays on when the liquid level

decreases below the low threshold and remains below the hysteresis. The alarm turns off when the

water increases above the 60-inch hysteresis.

Setting the hysteresis threshold to 0 (zero) causes Connect Tank to send an alarm report every time

the liquid level reaches a high or low alarm threshold.

Note Setting the hysteresis threshold to 0 (zero) may cause excessive data usage and reduce battery

life.

Remote Manager

.

Sensor error and battery life

Connect Tank includes alarm reports for the sensor and battery.

n Sensor error: Connect Tank reports an error to Remote Manager when it detects an issue with

the device's sensor.

n Battery life: Connect Tank reports the battery life percentage when it falls below the

percentage that you configure for this option.

Digi Connect® Tank v2 User Guide

42

Page 43

Manage Connect Tank with Remote Manager Configure device (report) settings

Configure device (report) settings

Use the Device Settings options in Remote Manager to configure Connect Tank reporting. Together,

these options control how often Connect Tank captures tank data, how often data is reported, and

how much data is included when it is sent to Remote Manager.

For details about the configuration options, see Device (report) settings option definitions.

CAUTION! If Connect Tank sends reports less than 15 minutes apart, it may result in an

internal temperature that is above the ambient temperature.

Note Reporting to Remote Manager more than twice a day reduces the battery life.

For example, the following settings cause the device to read the tank’s liquid level every half hour,

report that information twice a day, and send only the last four readings:

n Read Sensor Every: 30 minutes

n Report Sensor Data Every: 24 reads

n Send Last: 4 readings

If the sensor value reaches an alarm threshold, that data is sent as an alarm report during the next

device wake cycle regardless of device settings.

To configure device options:

1. Sign into Remote Manager.

2. Click Device Management > Devices.

3. Double-click the Connect Tank you want to configure.

4. Click Configuration > Device Settings.

5. Enter appropriate values for each option.

6. Apply the configuration changes:

Digi Connect® Tank v2 User Guide

43

Page 44

Manage Connect Tank with Remote Manager Configure device (report) settings

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

c. Click Schedule. Connect Tank downloads and applies configuration changes the

next time it connects to Remote Manager.

Custom scaled values for tank data

Connect Tank reports sensor data in inches. You can use the following Device Settings in Remote

Manager to convert inches into a custom value that makes sense for your tank configuration, such as

gallons or liters:

n Tank Volume Unit: Unit of measurement that you are converting to, such as gallons or liters.

n Tank Total Height: Total tank height in inches.

n Tank Sensor Offset: Distance from the Connect Tank sensor to the top of the liquid in a full

tank. The following images provide offset examples.

n Tank Total Volume: Total volume of the tank in the defined unit, such as gallons (unit defined

in Tank Volume Unit).

For example, you want the Connect Tank to report sensor values in gallons. The tank holds a

maximum of 5000 gallons and has a height of 8.1 feet (rounded to 97 inches). The Connect Tank is

mounted on a standpipe, so there is a 10-inch clearance between the Connect Tank sensor and the

top of the liquid when the tank is full. You should enter the tank information in Remote Manager as

shown in the following figure:

The result of the custom value calculations is reported in the cval data stream. For more information,

see Data streams reference information.

Digi Connect® Tank v2 User Guide

44

Page 45

Manage Connect Tank with Remote Manager Configure cellular options

Configure cellular options

You configured necessary cellular settings during the initial Connect Tank setup. Use these options to

review the cellular configuration. Make changes to these settings only when instructed by your

cellular service provider and when you have physical access to the device. For details about these

options, see Cellular option definitions.

CAUTION! If you make changes to cellular settings that result in a disconnected device,

you must use the CLI to reconnect it to the cellular network; see Register Connect Tank

on a cellular network. Using the CLIrequires physical access to the device.

To configure cellular options:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Tank device you want to configure.

4. Expand the Configuration menu.

5. Click Cellular Settings.

6. Enter an appropriate value for each cellular option.

7. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

c. Click Schedule. Connect Tank downloads and applies configuration changes the

next time it connects to Remote Manager.

Configure Remote Manager settings

Remote Manager settings options for Connect Tank are configured by default and require updates

only when instructed by Digi Technical Support. For details about these options, see Device Cloud

option definitions.

To configure Remote Manager options:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Tank device you want to configure.

4. Expand the Configuration menu.

5. Click Device Cloud Settings.

6. Enter appropriate values for each option.

7. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

c. Click Schedule. Connect Tank downloads and applies configuration changes the

next time it connects to Remote Manager.

Digi Connect® Tank v2 User Guide

45

Page 46

Manage Connect Tank with Remote Manager Remote Manager option definitions for Connect Tank

Remote Manager option definitions for Connect Tank

The following tables provide definitions for Remote Manager user interface options and data streams

for Connect Tank devices.

Alarm options

The following table provides Remote Manager alarm setting options for Connect Tank. For additional

information about using these options, see Configure alarms.

Option Description Range Default

High

Alarm

High

Threshold

Low Alarm Enables or disables Low Alarm reports for liquid levels below the

Low

Threshold

Delta Low

Alarm

Delta Low

Threshold

Delta High

Alarm

Delta High

Threshold

Hysteresis

Enables or disables High Alarm reports for liquid levels above the

High Threshold value.

Specifies the liquid level measurement in inches that generates a

High Alarm report when High Alarm isOn.

Low Threshold value.

Specifies the liquid level measurement in inches that generates a

Low Alarm report when Low Alarm isOn.

Enables or disables Delta Low Alarm reports when the liquid level

decreases more than the Delta Low Threshold value for two

consecutive readings.

Specifies the liquid level measurement in inches that generates a

Delta Low Alarm report when Delta Low Alarm isOn.

Enables or disables Delta High Alarm reports when the liquid

level increases more than the Delta High Threshold value for two

consecutive readings.

Specifies the liquid level measurement in inches that generates a

Delta High Alarm report when Delta High Alarm isOn.

Specifies the measurement in inches to keep an alarm on or shut

off an alarm during high and low alarm states.

0 — hysteresis is off

1 or more — hysteresis is on and managing alarms

On/Off Off

0.0-511.0 0

On/Off Off

0.0-511.0 511

On/Off Off

0.0-511.0 511

On/Off Off

0.0-511.0 511

0.0-511.0 0

Sensor

error

Battery

Life

Enables or disables the sensor error alarm that reports when the

device cannot get a valid reading from the sensor.

Specifies the battery life percentage that generates a low

battery alarm report.

Cellular option definitions

The following table provides Remote Manager cellular setting options for Connect Tank. For additional

information about using these options, see Configure cellular options.

Digi Connect® Tank v2 User Guide

On/Off Off

1-100 75

46

Page 47

Manage Connect Tank with Remote Manager Remote Manager option definitions for Connect Tank

Option Description

APN

User Name Specifies the user name for your cellular network account. Use only when

Password Specifies the password for your cellular network account. Use only when

SIMPIN Specifies the PIN for your cellular network SIM card. Use only when required by

Identifies the access point name that connects your device to the correct

cellular network.

required by your cellular service provider.

required by your cellular service provider.

your cellular service provider.

Device Cloud option definitions

The following table provides Remote Manager server name settings for Connect Tank. For additional

information about using these options, see Configure Remote Manager settings.

Option Description Value

Server Name

Specifies the URL that connects your

device to Remote Manager. This

setting is configured by default.

Note Do not make changes to this

setting without help from Digi

Technical Support.

my.devicecloud.com

NTP Server Name

Network Time Protocol (NTP) server

name that synchronizes Connect

Tank time with Coordinated

Universal Time (UTC). This setting is

configured by default.

Note Do not make changes to this

setting without help from Digi

Technical Support.

time.devicecloud.com

Device (report) settings option definitions

The following table provides Remote Manager device (report) setting options for Connect Tank. For

details about setting these options, see Configure device (report) settings.

Option Description Range Default

Read

Sensor

Every

How often the device sensor

reads the liquid level in a tank.

The time is measured in

minutes.

5 minutes to 1440 minutes (24 hours) 720

minutes

(12

hours)

Digi Connect® Tank v2 User Guide

47

Page 48

Manage Connect Tank with Remote Manager Remote Manager option definitions for Connect Tank

Option Description Range Default

Report

Sensor

Data Every

Report

Sensor

Every N

Days

First Daily

Report At

HHMM

How often the device wakes

and sends sensor data to

Remote Manager.

How often the device sensor

reads the liquid level in a tank.

The frequency is measured in

days.

Specifies the time that is used

to reset the device's schedule

to the beginning of a new day

and send the first daily report.

The time is noted as the

number of minutes after

midnight UTC.

Examples:

n 0 minutes = midnight

UTC

n 60 minutes = 1 hour

after midnight UTC

n 360 minutes = 6 hours

after midnight UTC

1 to 96 readings; setting this to more

than 96 results in lost data

0 days to 1439 days

0 to 1439 (minutes)

1

0 days

0

Send Last

Send

Location

Every

How many sensor values are

included in each report to

Remote Manager. If set to 0, all

buffered data is sent.

Specifies in number of reports

how often the device sends its

GPS location to Remote

Manager. Example:

n 10 = sends the GPS

location once every 10

reports

n If 2 reports are sent per

day, then the GPS

location is sent once

every 5 days.

0 to 50 readings 144

1 to 96 reports 1

Digi Connect® Tank v2 User Guide

48

Page 49

Manage Connect Tank with Remote Manager Remote Manager option definitions for Connect Tank

Option Description Range Default

Tank

Upload

Method

GPS Enable

Waveform

collection

Specifies which mode of

communication to use when

sending data to Remote

Manager.

Enables or disables GPS

location.

Enables or disables waveform

data collection when each

report is sent. Use for

debugging.

Note Enabling this option

increases your cellular data

usage and should be used only

for debugging purposes.

n TCP/IP only

n SMS only

n TCP/IP with SMS fallback

n SMS with TCP/IP fallback

TCP/IP

only

Off/On Off

Off/On Off

Digi Connect® Tank v2 User Guide

49

Page 50

Use Remote Manager to view device and sensor data streams

The Connect Tank device and sensor data appear as data streamsin Remote Manager.

About data streams

Data streams are detailed, time-based information about a tank that the Connect Tank device sends

to Remote Manager. For Connect Tank, data streams include detailed information such as distance,

temperature, alarms, thresholds, hysteresis, and more.

You can select a specific data stream to see its current value, as well as historical data. The Connect

Tank settings in Remote Manager have a corresponding three-letter short name, as shown in the

following image. The short names are useful when using data streams to analyze sensor data.

To learn more about:

Digi Connect® Tank v2 User Guide

50

Page 51

Use Remote Manager to view device and sensor data streams View device data streams

n Connect Tank data streams and their details, see Data streams reference information.

n General information for Remote Manager data streams, see the Remote Manager

documentation.

View device data streams

To view data for a Connect Tank device:

1. Sign into Remote Manager.

2. Access the Data Streams view:

n Click Device Management, double-click your device, and click View Device Streams.

n Click Data Services and enter the 15-digit device IMEI in the search field.

The Data Streams view appears showing all reported data for the selected device.

3. Click a data stream to display the details for the stream.

4. To view historical information for a data stream, click one of the following options in the

bottom half of the window:

n Click Charts to view the data as a graph.

n Click Raw Data to view the data in a table (see the following image).

Data streams reference information

The following table provides Remote Manager data streams descriptions for Connect Tank. For

additional information about data streams, see About data streams.

Short

name Long name Description

abt Alarm

battery

Digi Connect® Tank v2 User Guide

Battery Life threshold setting; for example, 75 (percent).

51

Page 52

Use Remote Manager to view device and sensor data streams Data streams reference information

Short

name Long name Description

adh Alarm delta

high

adl Alarm delta

low

aem Alarm enable

mask

ahy Alarm

hysteresis

alh Alarm high High Threshold setting; for example, 5 (inches).

all Alarm low Low Threshold setting; for example, 500 (inches).

alt Altitude Altitude location of the device in meters.

apn APN Access point name for the cellular network your device uses.

Delta High threshold setting; for example, 10 (inches).

Delta Low threshold setting; for example, 10 (inches).

Alarms that are enabled during the report; the value in the data stream

equals the sum of the enabled alarms:

1 — Alarm high enabled (alh)

2 — Alarm low enabled (all)

4 — Alarm delta low enabled (adl)

8 — Alarm delta high enabled (adh)

64 — Alarm on sensor error

For example, if you have the Alarm high and Alarm low enabled, the aem data

stream value is 3. If you have all alarms enabled, the aem data stream value

is 79.

Hysteresis setting; for example, 1.0 (inch).

arm Alarm reason

mask

bat Battery level Estimated percentage of battery life remaining.

cval Custom

value

dwt Device wake

reason

Alarms that are active during the report; the value in the data stream equals

the sum of the enabled alarms:

1 — Alarm high (alh)

2 — Alarm low (all)

4 — Alarm delta low (adl)

8 — Alarm delta high (adh)

64 — Alarm on sensor error

For example, if you have the Alarm high and Alarm low enabled, the aem data

stream value is 3. If you have all alarms enabled, the aem data stream value

is 79.

Value calculated from the raw value (val) using the following device settings:

Tank Volume Unit (unit)

Tank Total Height (tht)

Tank Sensor Offset (off)

Tank Total Volume (vol)

Reason the device woke up:

2 — normal reading or report

3 — alarm reading or report

8 — wakeup report

Digi Connect® Tank v2 User Guide

52

Page 53

Use Remote Manager to view device and sensor data streams Data streams reference information

Short

name Long name Description

fix GPS fix type

fwv Firmware

version

gin GPS interval GPS information sent to

gps GPS feature

isn Cloud server

name

lat Latitude Geographic latitude location of the device.

lon Longitude Geographic longitude location of the device.

off Tank sensor

offset

phn SMS phone

number

GPS location (fix) information:

0 — no fix

1 — valid fix

2 — invalid fix

Firmware version on the device; for example, 2.0.1.19.

Remote Manager

range is 1-96 reports. For example, GPS information is sent every 7 reports.

GPS enabled or disabled on the device:

0 — GPS off

1 — GPS on

URL or server address you use to connect to

Distance from the Connect Tank sensor to the top of the liquid in a full tank.

Phone number associated with your device’s SIM card.

every x-number of reports. The

Remote Manager

.

rdp Read period

(minutes)

rsi RSSI Signal strength of the cellular network.

scs Sensor

connected

status

sdc Send count Maximum number of readings that are sent during one report.