Page 1

Digi Connect® Sensor

User Guide

Page 2

Revision history—90001491

Revision Date Description

L October 2018

M April 2019

N May 2019

P December 2019 Removed HART® protocol information as it is no longer

R January 2021

Trademarks and copyright

Digi, Digi International, and the Digi logo are trademarks or registered trademarks in the United

States and other countries worldwide. All other trademarks mentioned in this document are the

property of their respective owners.

© 2021 Digi International Inc. All rights reserved.

Updated range specifications: Connect Sensor product

specifications.

Added LEDinformation.

Added information about the external power source and

battery usage.

Added gasket lubricant information.

supported.

Removed gasket lubricant information as it is no longer

needed.

Removed references to the abt/alm datapoint.

Removed information about the CEmark.

Disclaimers

Information in this document is subject to change without notice and does not represent a

commitment on the part of Digi International. Digi provides this document “as is,” without warranty of

any kind, expressed or implied, including, but not limited to, the implied warranties of fitness or

merchantability for a particular purpose. Digi may make improvements and/or changes in this manual

or in the product(s) and/or the program(s) described in this manual at any time.

Warranty

To view product warranty information, go to the following website:

www.digi.com/howtobuy/terms

Send comments

Documentation feedback: To provide feedback on this document, send your comments to

techcomm@digi.com.

Customer support

Digi Technical Support: Digi offers multiple technical support plans and service packages to help our

customers get the most out of their Digi product. For information on Technical Support plans and

pricing, contact us at +1 952.912.3444 or visit us at www.digi.com/support.

Digi Connect® Sensor User Guide

2

Page 3

Contents

Digi Connect® Sensor

Get started

Learn about Connect Sensor product components 8

Verify product components 8

Connect Sensor LEDs 10

Connect Sensor ports and buttons 12

Wake Connect Sensor 13

Set up a Connect Sensor 14

Safety information 14

Activate the SIMcard 15

Assemble Connect Sensor 16

Install the magnet mount 19

Configure the cellular connection 20

Check the cellular connection 22

Wire the I/O sensors 22

Add a device to Digi Remote Manager 22

Technical specifications

Maximum power and frequency bands 24

Connect Sensor product specifications 24

Cell modem transmit (TX) output power 25

Hardware

Battery inspection 26

Battery life 26

Battery percentage ranges and replacement 26

Battery passivization 27

Battery percentage and external power 27

CSENSE Continuous Monitoring power source 27

Connect Sensor hardware replacement 28

Firmware

CSENSE Continuous Monitoring firmware 29

Enable CSENSEContinuous Monitoring 30

Digi Connect® Sensor User Guide

3

Page 4

Enable continuous monitoring on digital input 30

Enable continuous monitoring on analog input 31

Configure the buffer time for continuous monitoring 31

Configure pins and protocols

Enable and configure analog inputs 33

Enable and configure analog power outputs 34

Enable and configure a digital input 35

Enable and configure a digital pulse counter 36

Enable and configure a digital output 37

Enable and configure a digital power output 38

Enable and configure the Modbus protocol 39

Enable and configure a serial power output 41

Modbus station addresses and locations 41

About analog and digital input options 43

Alarms 43

Hysteresis 44

Custom scaled sensor values 45

Oversampling 48

Schedule options 48

Immediate 48

One-Time 49

Recurring 49

Configure Connect Sensor device settings

Configure cellular options 50

Configure Remote Manager settings 51

Configure battery life percentage alarms 51

Battery life alarm and alarm notification 52

Create a battery life alarm for Connect Sensor devices 52

Configure the global battery alarm for a device 57

Configure internal temperature settings 58

Configure local interface settings: CLIand Bluetooth 59

Configure device (report) settings 60

View device information

View device information in Remote Manager 62

View battery life for a device in Remote Manager 63

View device and sensor data streams

Use Remote Manager to view device and sensor data streams 64

About data streams 64

View device data streams 65

Use the mobile app to view sensor data streams 66

Connect Sensor maintenance

Firmware updates 68

Digi Connect® Sensor User Guide

4

Page 5

Update the firmware using Remote Manager 68

Update firmware from Connect Sensor 69

Update the firmware using the CLI 69

Battery replacement 71

Remote Manager option definitions for Connect Sensor

Analog Current Loop Input and Voltage Input option definitions 73

Analog Power, Digital Power, and Serial Output option definitions 76

Cellular option definitions 77

Device Cloud option definitions 77

Device (report) settings option definitions 78

Digital Input option definitions 80

Digital Output option definitions 81

Toggle digital output on alarm 81

Digital Pulse Counter option definitions 83

Global Alarm Settings option definitions 84

Internal Temperature option definitions 85

Local Interface Settings option definitions 86

Modbus Protocol Settings option definitions 86

Data stream definitions

Group definitions for Connect Sensor data streams 89

Connect Sensor device-specific (ts1 and ui) data stream definitions 90

Analog input (ain and cl) data stream definitions 91

Analog (avout), digital (dvout1),and serial power output data stream definitions 92

Digital input (din1) data stream definitions 93

Digital output (dout1) data stream definitions 94

Digital pulse counter (pcnt1) data stream definitions 95

Temperature sensor (temp1) data stream definitions 95

Modbus (modb1) data stream definitions 96

Data streams for Modbus protocol 98

Use the CLI with Connect Sensor

Open a terminal program and use CLIcommands 99

Use the CLIto view status information for the device 101

Verify cellular network coverage using the CLI 101

View battery life using the CLI 102

CLI commands

fwupdate 104

status 104

set 105

Analog input CLI commands 106

Digital input CLI commands 109

Digital output CLI commands 111

Digital pulse counter CLI commands 112

Analog and digital power output CLI commands 114

Cellular CLI commands 115

Remote Manager CLI commands 117

Digi Connect® Sensor User Guide

5

Page 6

Internal temperature CLI commands 118

Modbus CLI commands 120

Troubleshooting

Connect Sensor LEDs for troubleshooting 121

Device not responding 121

Check the battery 121

Reset the device 121

Restore factory defaults to the device 122

Device not connected to the cellular network 122

Verify SIM configuration 122

Check cellular antenna 122

Verify cellular network coverage 122

Check battery life 123

Device does not connect to Remote Manager 123

Device does not appear in the mobile app 123

Verify Bluetooth connectivity 123

Reset the device 124

Regulatory information

FCC certifications and regulatory information 125

Declaration of Conformity (DoC) 125

Safety notices 126

Installation considerations 127

Warnings: Explosion hazards 128

RF exposure statement 129

UL/cUL conformity 129

Special conditions for safe use (ATEX) 129

ATEX marking 130

Digi Connect® Sensor User Guide

6

Page 7

Digi Connect® Sensor

Connect Sensor is a low-power cellular sensor gateway for wireless drop-in networking to remotely

monitor industrial environments and control systems, such as pipeline flow, air pressure, and light

levels. To power Connect Sensor, use either the internal battery or an external power source, such as

solar panels, for setups with no power or limited power.

Connect Sensor includes an external input/output (I/O) interface inside a waterproof enclosure for

connecting third-party sensors. The sensors gather information (sensor readings) from their

environment, and Connect Sensor reports that information to Digi Remote Manager® using a lowbandwidth cellular connection. You can sign in to your Remote Manager account to view the reports or

use the Digi Connect Wizard app on a mobile device and pair it with a nearby Connect Sensor to view

real-time sensor and device data in the field.

Note Make sure there is adequate cellular network coverage where you plan to install the gateway

before purchasing cellular service.

This guide shows you how to:

n Set up and maintain Connect Sensor

n Use Remote Manager to configure external sensors and data reports

n View sensor data and Connect Sensor system information

See the Digi Connect Sensor I/O Wiring Guide for details about wiring analog or digital I/O sensors and

power to Connect Sensor.

Digi Connect® Sensor User Guide

7

Page 8

Get started

Use the following sections to get started with Connect Sensor.

1. Learn about Connect Sensor product components

2. Set up a Connect Sensor

3. Add a device to Digi Remote Manager

4. Configure pins and protocols

5. Configure Connect Sensor device settings

Learn about Connect Sensor product components

These sections include a list of Connect Sensor components, and reference information about the

Connect Sensor LEDs, ports, and buttons.

Verify product components

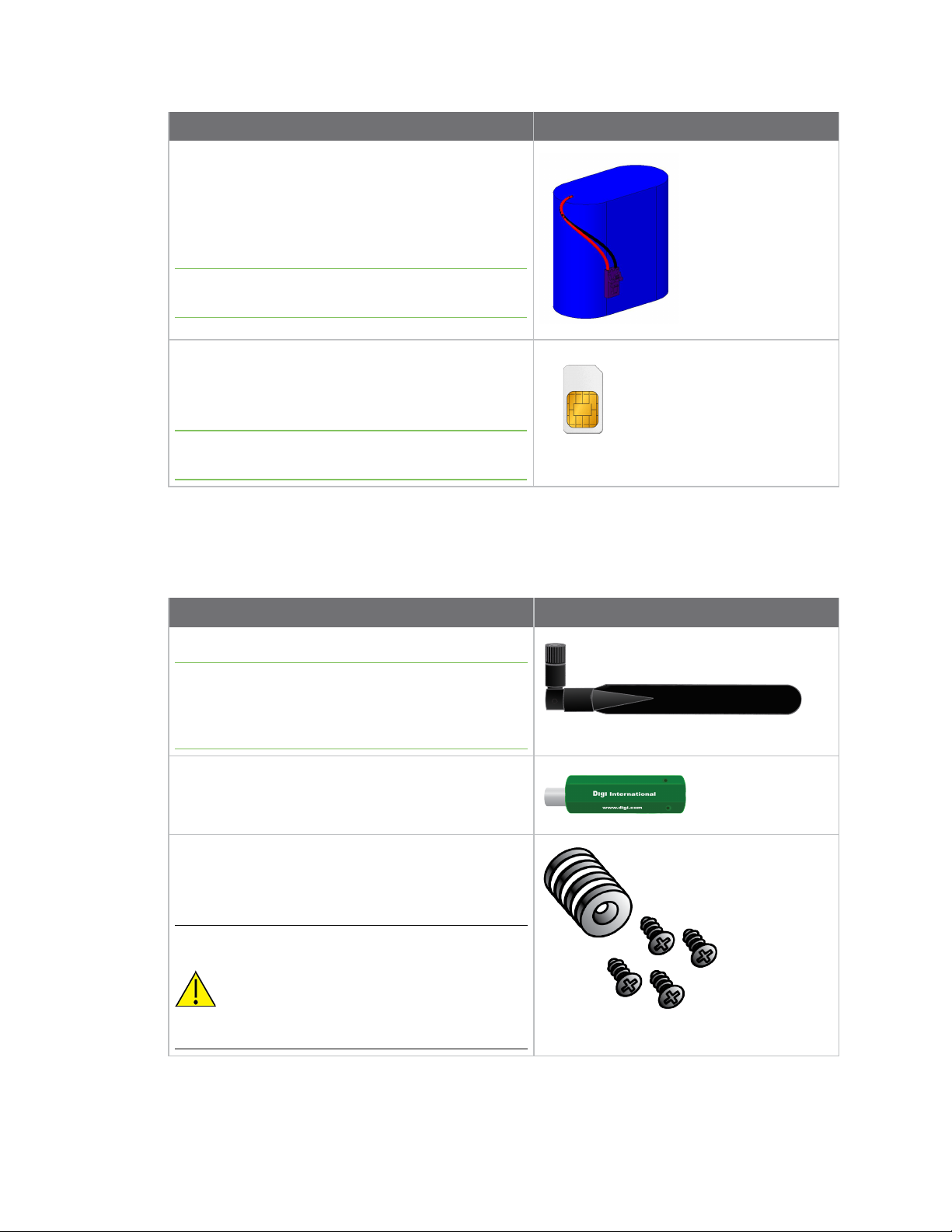

Connect Sensor includes the following components:

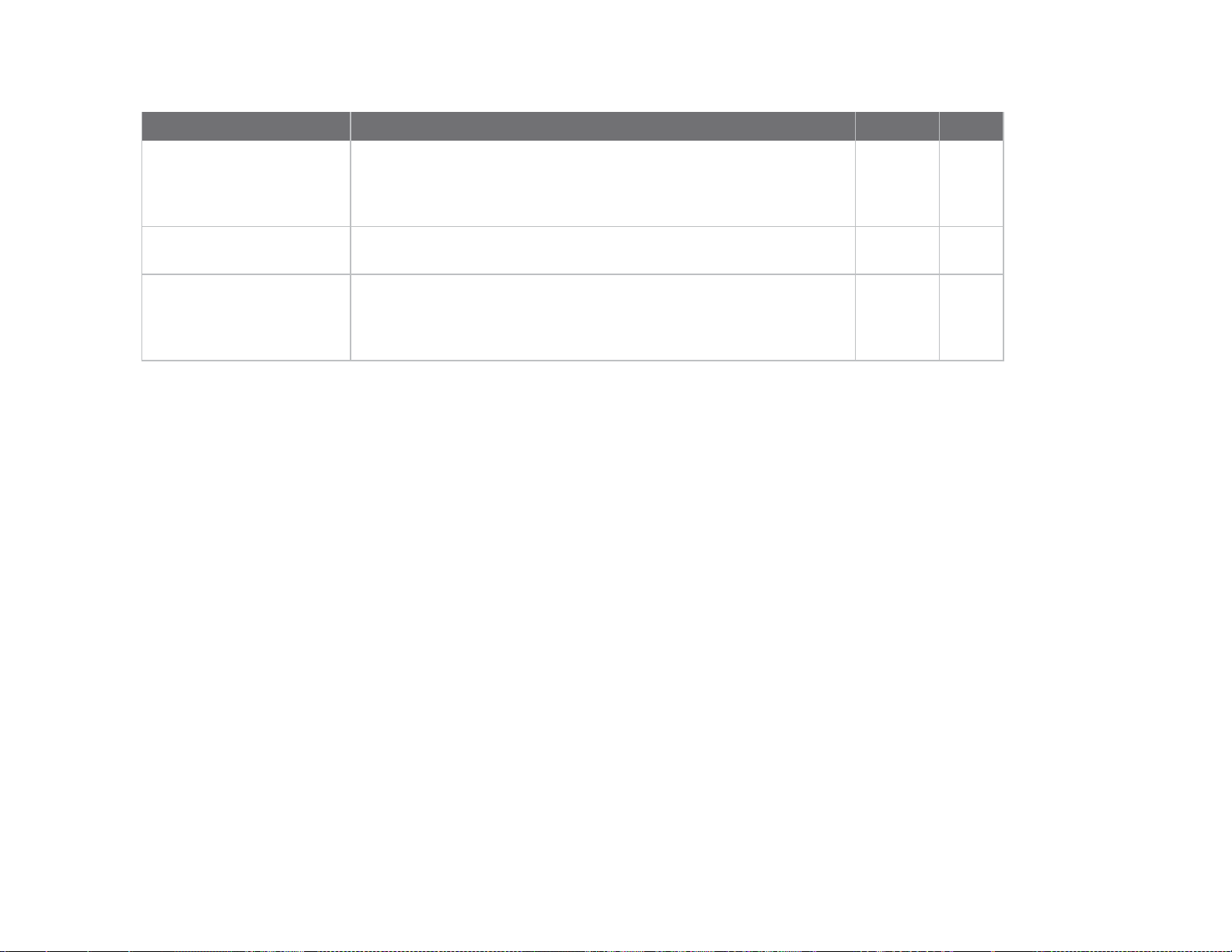

Component Description

Connect Sensor

Digi Connect® Sensor User Guide

8

Page 9

Get started Learn about Connect Sensor product components

Component Description

Battery

Connect Sensor uses a lithium metal battery. The

battery voltage is almost consistent from initial use

to near the end of the battery's useful life. See

Battery inspection for lithium battery safety

considerations.

Note The battery is included for all versions except

for the -N versions.

SIMcard

The SIMcard can be activated or replaced by an

activated SIMcard from your cellular service

provider.

Note If you have purchased Digi Bundled Services,

the SIMcard is activated by default.

Optional accessories

The following accessories are available through Digi International Inc. For more information, visit the

Digi Connect Sensor product page.

Component Description

Cellular antenna

Note This antenna is PN 76000926 and is an indoor-

only antenna. Only outdoor-rated antennas should be

used outdoors. For more information about antenna

options, see the Connect Sensor product page.

Magnet

Used for manually waking the device.

Magnet mount accessory pack

The pack includes four screws, and four magnets

separated by plastic discs. See Install the magnet

mount for installation instructions.

CAUTION! The magnets are extremely

powerful. Keep magnets separated. If

they touch each other they are difficult

to separate. Use caution when handling

the magnets to avoid injury due to

pinching.

Digi Connect® Sensor User Guide

9

Page 10

Get started Learn about Connect Sensor product components

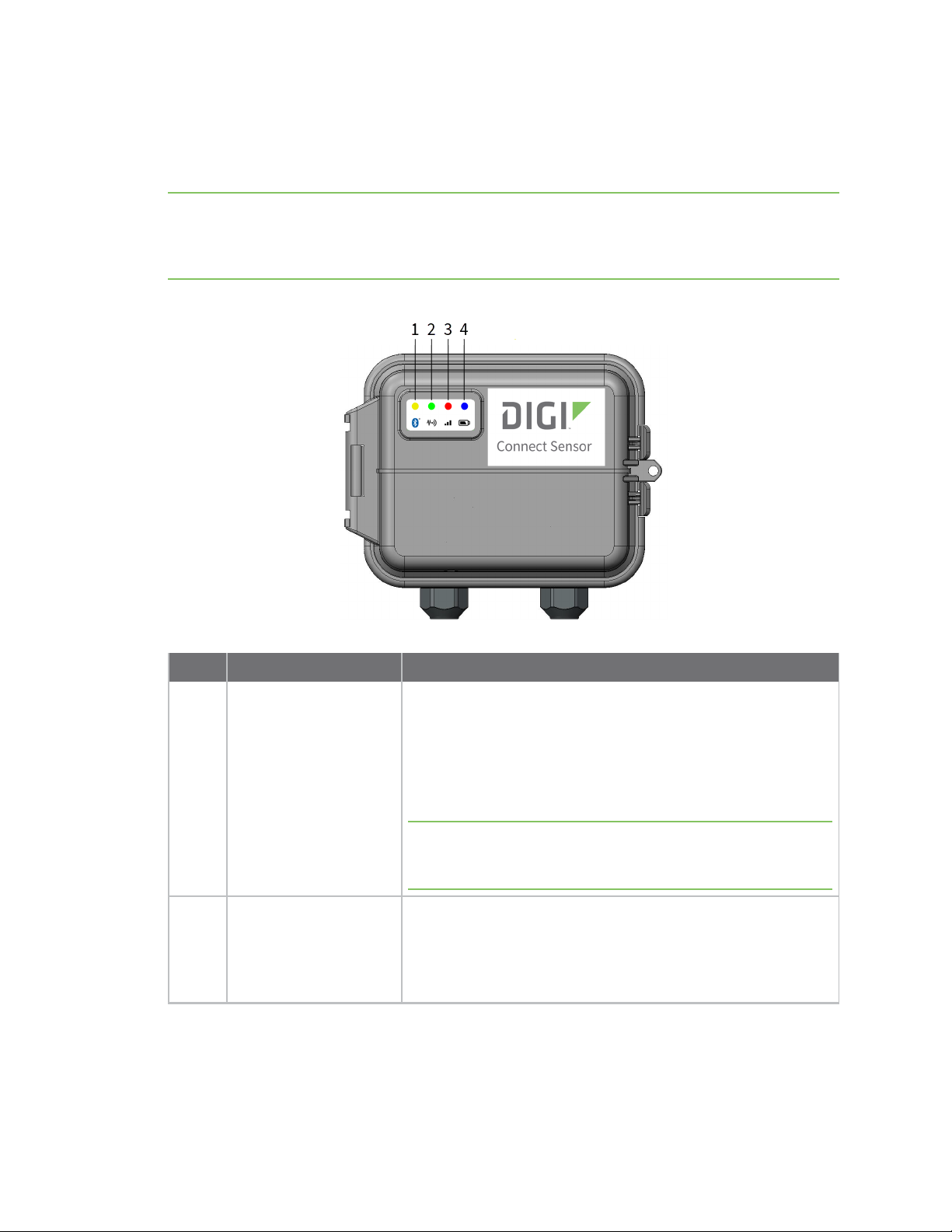

Connect Sensor LEDs

Connect Sensor has four LED indicators to monitor Bluetooth connection, sensor activity, cellular

connection, and battery life. If Connect Sensor is powered and all LEDs are off, it is in sleep mode.

Note The LEDindicators only light up when you wake the device by manual intervention: pressing the

Wake button on the device or using a magnet. When the device wakes up to take and push readings,

the LEDs do not light up since no one may be physically present to see the LED start-up sequence. See

Wake Connect Sensor for more information about the LEDindicators start-up sequence.

Item LED Description

1 Bluetooth

Indicator light for Bluetooth communication:

n Yellow blinking: Bluetooth is on and Connect Sensor is

discoverable. The LED blinks for up to 30 seconds.

n Yellow solid: A Bluetooth device is attached.

n Not lit: No Bluetooth devices were found or attached.

Note Bluetooth must be enabled on the Connect Sensor for the

Bluetooth LEDto light up. See Configure local interface settings:

CLIand Bluetooth.

2 Sensor reading

Indicator light for the sensor(s):

n Green blinking: One or more sensors are reading the

environment.

n Not lit: The LED turns off when readings are complete.

Digi Connect® Sensor User Guide

10

Page 11

Get started Learn about Connect Sensor product components

Item LED Description

3 Cellular

4 Battery

Indicator light for the cellular network connection:

n Solid purple: Connect Sensor is waking.

n Red blinking: Searching for the cellular network.

n Blue:

l Blinking: Connected to the cellular network and

attempting to communicate with Remote Manager

l Solid light: Successfully sent data to Remote

Manager. LED turns off after a few seconds.

Indicator light for battery function:

n Solid purple: Connect Sensor is waking

The following patterns are based on the Global Alarm >

Battery Life setting in Remote Manager:

n Red blinking: Indicates battery life is less than or equal to

the Battery Life alarm.

n Blue blinking: Indicates battery life is greater than the

Battery Life alarm.

Digi Connect® Sensor User Guide

11

Page 12

Get started Learn about Connect Sensor product components

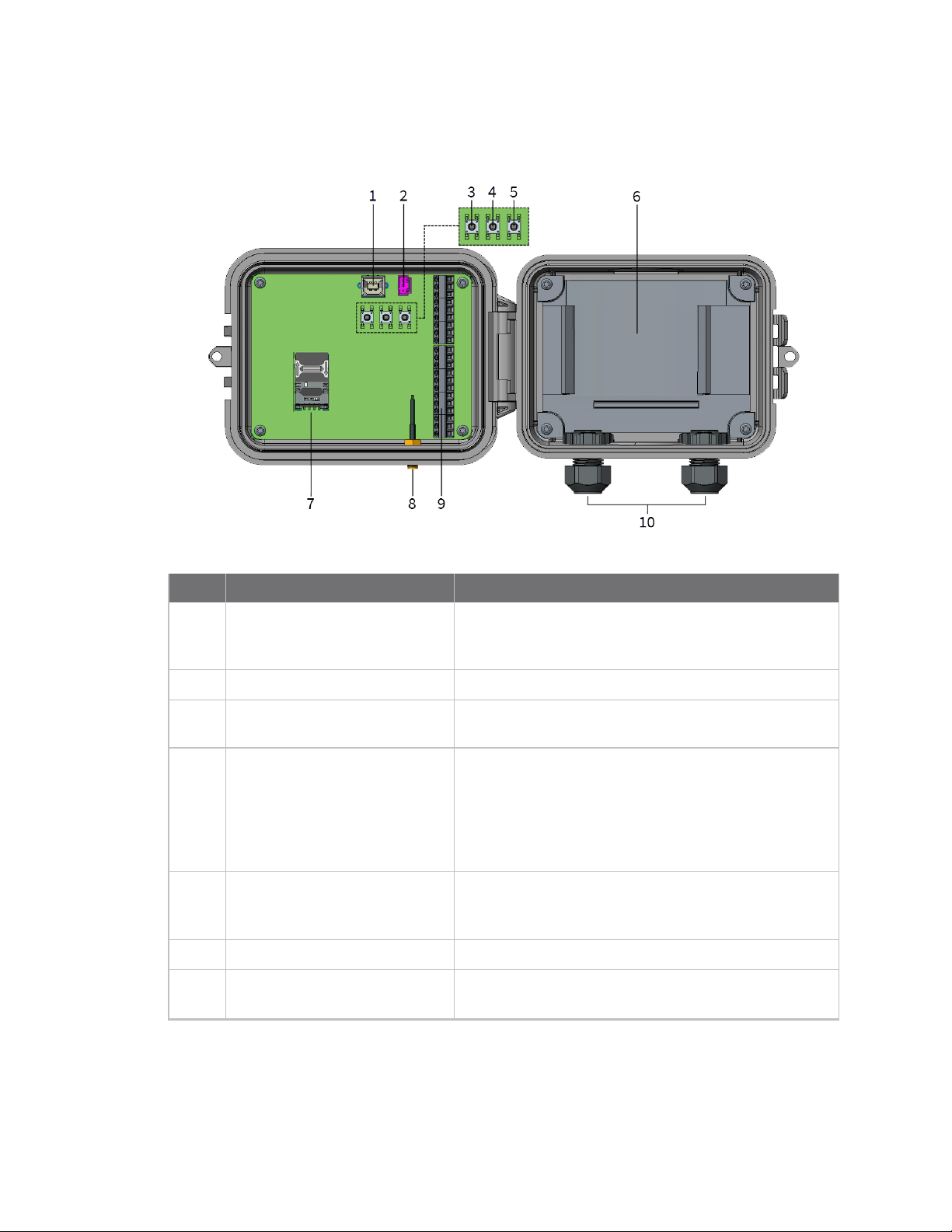

Connect Sensor ports and buttons

The following figure shows the controls for setting up and configuring Connect Sensor.

Item Name Description

1 Console port Connects

type A to B cable for access to the command line

interface (CLI).

2 Battery port

3 Wake button

.4 Factory button Removes all configuration changes and restores

5 Reset button Restarts the device when it is not responding to input

6 Battery tray Holds the battery in place.

7 SIM card tray Connects the SIMcard to

Connects the battery wire to power Connect Sensor.

Wakes Connect Sensor. See Wake Connect Sensor.

Connect Sensor

when you press and hold it for 3 seconds. If you press

this button, but do not hold it down, the device briefly

wakes and returns to sleep mode, and no settings are

affected.

(from the CLI or otherwise). Pressing this button does

not remove previous configuration changes.

inserted by default.

Connect Sensor

to its original factory default settings

to a computer using a USB

Connect Sensor

. A SIM card is

Digi Connect® Sensor User Guide

12

Page 13

Get started Learn about Connect Sensor product components

Item Name Description

8 Cellular antenna port Connects an external cellular antenna to

Sensor

.

9 Input/Output (I/O) interface

10 Cable glands Thread sensor cables through these openings into

Wire analog or digital input and output sensors or power

to this interface. For more information, see the Digi

Connect Sensor I/O Wiring Guide.

Connect Sensor

.

Connect

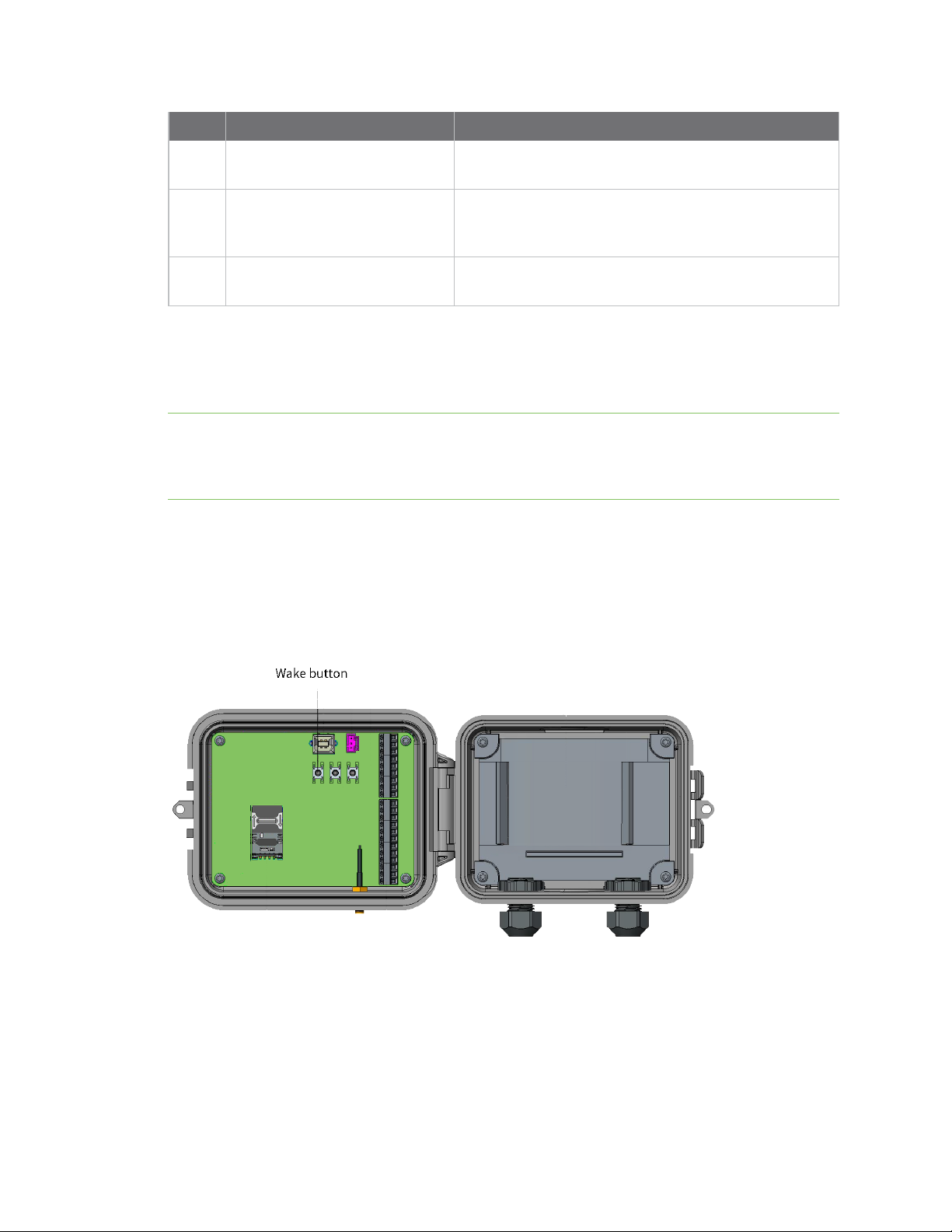

Wake Connect Sensor

If Connect Sensor is powered and all LEDs are off, it is in sleep mode. You can wake the device

manually, if needed.

Note The LEDindicators only light up when you wake the device by manual intervention: pressing the

Wake button inside the device or using a magnet. When the device automatically wakes up as

scheduled to take and push readings, the LEDs do not light up since no one may be physically present

to see the LED start-up sequence. See Connect Sensor LED start-up sequence.

Manually wake the device

To wake the device, you can either swipe a magnet across the top of the device, or press the Wake

button inside the device.

When you wake Connect Sensor, the LED buttons are activated as the device wakes up. The start-up

sequence is described below.

Connect Sensor LED start-up sequence

The LEDindicators light up in a predetermined sequence when you manually wake the Connect

Sensor. For a description of where the LEDs are located on the device, see Connect Sensor LEDs.

Digi Connect® Sensor User Guide

13

Page 14

Get started Set up a Connect Sensor

1. Press the Wake button inside the device or swipe a magnet across the device.

2. The cellular and battery LEDs light up purple for one second and then turn off.

3. The sensor LED blinks green as readings are taken and then turns off when readings are

complete.

4. If Bluetooth is enabled, the Bluetooth LED blinks yellow for 30 seconds. If a Bluetooth device is

attached, the Bluetooth LED turns solid and remains lit.

Note If Bluetooth is not enabled, the Bluetooth LED does not light up.

5. Connect Sensor takes and pushes data readings.

a. The Connect Sensor takes a battery life reading. The battery LED blinks either blue

or red, depending on the status of the battery life.

b. The cellular LED blinks blue until the connection to Remote Manager is complete.

c. The Connect Sensor pushes the data. When the data transfer is complete, the

cellular LED is solid blue.

d. After a few seconds, the cellular LED turns off.

CLIcommands and waking Connect Sensor

You can connect a USB cable from a computer to Connect Sensor and use CLIcommands to perform

actions on the device.

Connect Sensor has a 30-second timeout period between when a CLI command has been entered and

the command is processed. When Connect Sensor has finished processing the command, the device

goes to sleep, and "zzz... " appears in the terminal program.

If you press the Wake button or use a magnet to wake Connect Sensor during this 30-second timeout

period, the LED lights will not be activated, as the device is already awake. Make sure "zzz..." appears

in the terminal program before you try to wake the device.

See Open a terminal program and use CLIcommands for more details about this process.

Set up a Connect Sensor

Complete all of the tasks in this section in order to set up a Connect Sensor.

1. Review safety information

2. Activate the SIMcard

3. Assemble Connect Sensor

4. Configure the cellular connection

5. Check the cellular connection

6. Wire the I/O sensors

Safety information

The following safety information provides guidelines when assembling the Connect Sensor device. For

additional safety guidelines, see Safety notices.

Digi Connect® Sensor User Guide

14

Page 15

Get started Set up a Connect Sensor

CAUTION! The device is sensitive to electrostatic discharge (ESD).

The Connect Sensor device must be maintained only by Digi or a Digi qualified technician. Before

assembling the device, note the following:

n To avoid the risk of the battery falling into a protected area, do not assemble the device in the

installation area.

n Move the device to a non-hazardous and unclassified area before opening the enclosure and

connecting the hardware.

n Always use the designated battery, model number 76000912, from Digi International Inc.

n Allow only a trained technician to replace the lithium thionyl chloride batteries used in Connect

Sensor.

n Prior to installation, the battery should be inspected for any signs of damage. If the battery

appears to be damaged or is dropped during the installation, do not use the battery and

dispose of it properly. See Battery inspection for more information.

n You may be required to have a licensed electrician install or perform maintenance on this

equipment. Always follow applicable local, state, and federal codes and guidelines.

Activate the SIMcard

Follow this step if you need to activate your SIMcard. You can skip this step if:

n You purchased bundled services, and therefore have a pre-activated SIM card.

n You are using an activated SIMcard (standard size) from your cellular service provider.

Activate the SIM card provided by Digi

Connect Sensor has a SIM card inserted in the device by default. To use a cellular connection, you

must activate the inserted SIM card.

1. Note the Connect Sensor IMEI number. The IMEInumber is on the label on the device and on

the box the device was shipped in.

2. Activate the SIMcard.

a. Call Digi International Inc. at 952-912-3444 or 877-912-3444.

b. Press 3 for the Technical Support option.

c. Select the wireless data plan activation option. You will be asked to provide the

Connect Sensor IMEI number.

Activate a SIMcard not provided by Digi

You can activate a SIMcard from your cellular provider or from a supplier other than Digi.

Digi Connect® Sensor User Guide

15

Page 16

Get started Set up a Connect Sensor

1. Your SIM card provider will need the following information:

n Connect Sensor IMEI number: The IMEInumber is on the label on the Connect Sensor

device and on the box the device was shipped in.

n SIM card number: The SIMnumber is printed on the SIMcard.

2. Call your SIMcard provider to activate the SIMcard.

Assemble Connect Sensor

This section describes how to assemble Connect Sensor. Be sure to complete these steps before

wiring sensors to the I/O interface.

CAUTION! This product contains a lithium metal battery. Prior to installation, the

battery should be inspected for any signs of damage. If the battery appears to be

damaged or is dropped during the installation, do not use the battery and be sure to

dispose of it properly. See Battery inspection for more information.

Make sure you have the following equipment available:

n Activated SIMcard: See Activate the SIM card

n Battery

n Cellular antenna

Note You must use a passive (non-amplified) antenna with Connect Sensor.

Follow these steps to assemble Connect Sensor:

1. Open the Connect Sensor enclosure.

2. If desired, replace the existing SIM card with an activated SIMcard (standard size) from your

cellular service provider.

Note You can skip this step if you are using the existing SIM card inserted in the device.

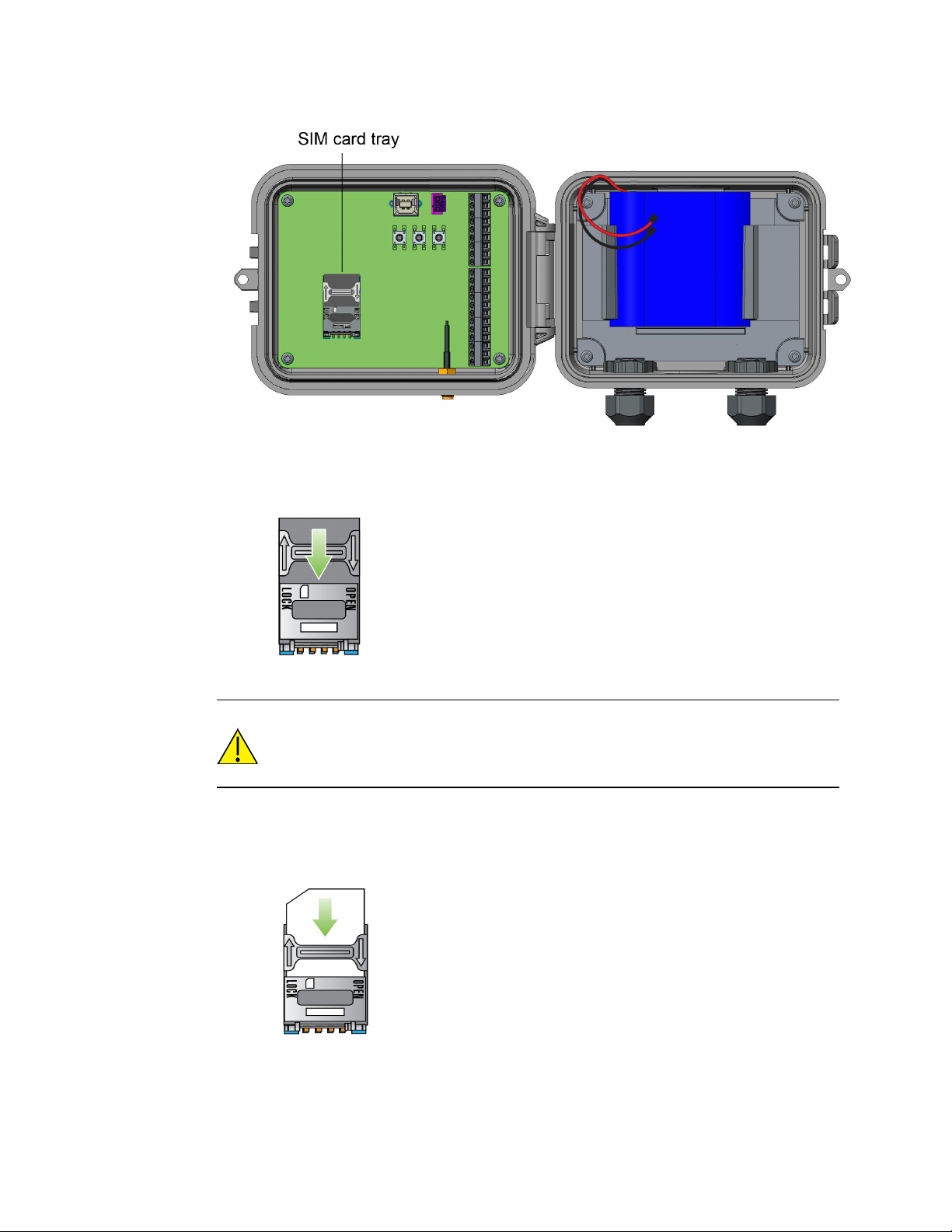

a. Orient Connect Sensor to match the picture below.

Digi Connect® Sensor User Guide

16

Page 17

Get started Set up a Connect Sensor

b. Unlock the SIM card tray by gently pushing the metal bar toward the bottom of the

tray.

c. Open the SIMcard tray by pulling the tray up from the top or right side of the tray.

CAUTION! Do not pull the SIMcard tray up from the left side or use a tool to

open the tray. These actions may damage the SIM detect switch, which is

beneath the left side of the tray.

d. Remove and discard the existing SIM card from the SIMcard tray.

e. Insert your own SIM card into the SIMcard tray, with the metal contacts face-down

and the flat edge inserted into the holder.

f. Press the SIMcard tray onto the board.

Digi Connect® Sensor User Guide

17

Page 18

Get started Set up a Connect Sensor

g. Lock the SIM card tray by gently pushing the metal bar toward the top of the

SIMcard holder.

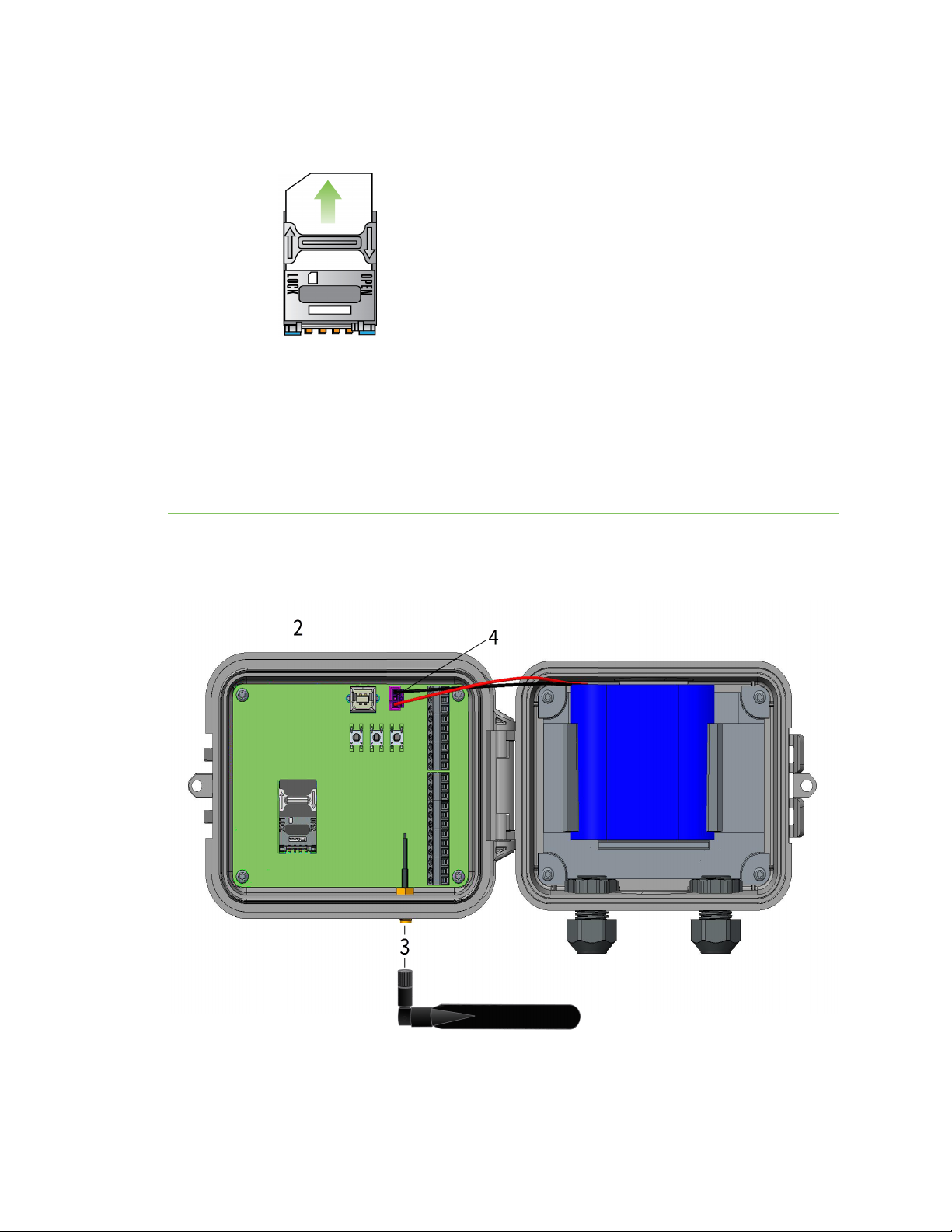

3. Connect the cellular antenna.

4. Insert and connect the battery.

5. Close the cover on the device. The cover snaps into place.

6. Optional: Install the magnet mount to the bottom of Connect Sensor if you have purchased this

accessory. See Install the magnet mount.

Note It is recommended that you complete configuration, including verifying cellular and Remote

Manager connectivity, before wiring external sensors to Connect Sensor. See the Digi Remote Manager

User Guide for information about Remote Manager.

Digi Connect® Sensor User Guide

18

Page 19

Get started Set up a Connect Sensor

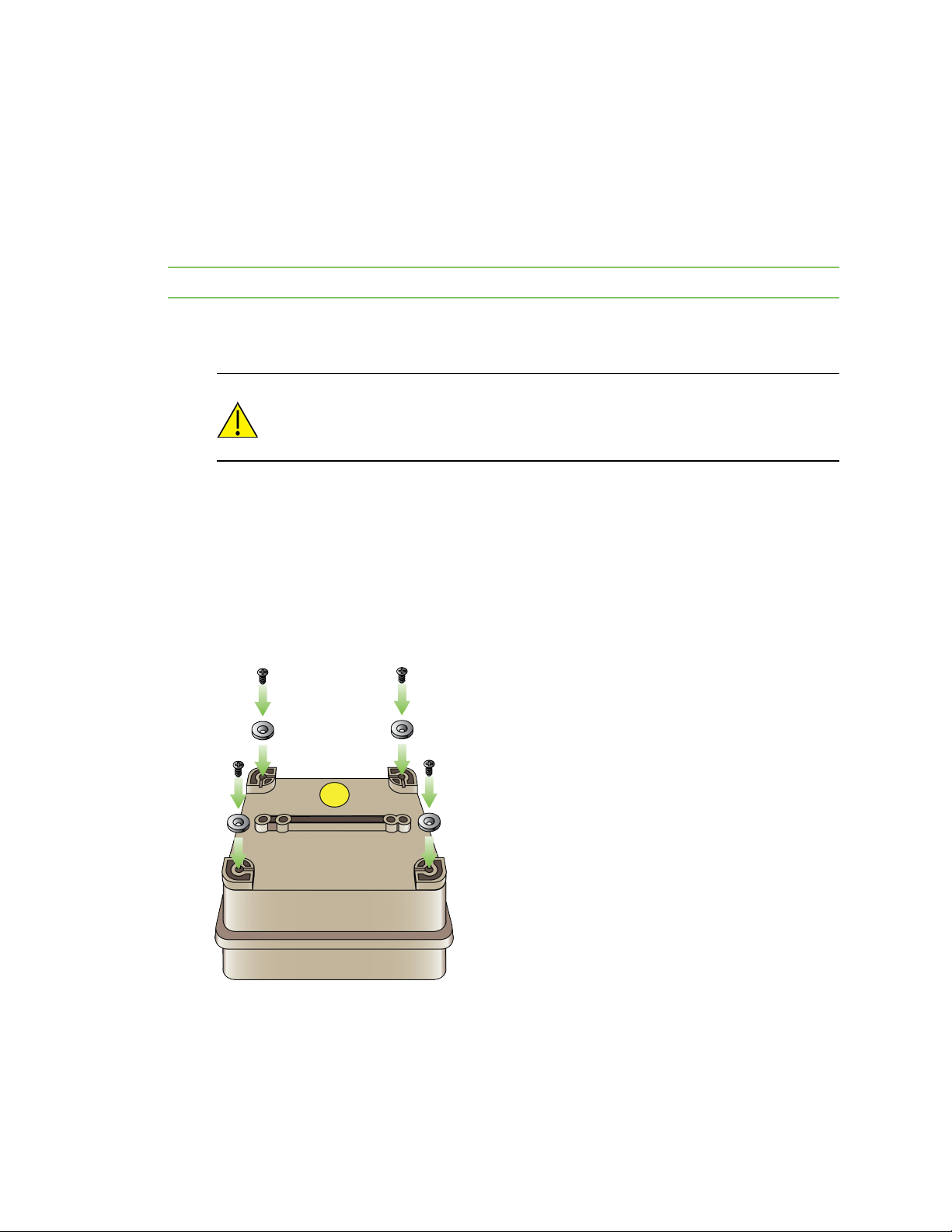

Install the magnet mount

You can install a magnet mount on Connect Sensor so that you can securely place the device on a

metal object.

Make sure you have the following equipment available:

n Magnet mount accessory pack. See Verify product components for purchasing information.

n Appropriate screw driver.

Note You can skip this step if you did not purchase the magnet mount accessory pack.

1. Turn Connect Sensor to access the bottom of the device.

2. Remove one magnet from the set of four magnets in the accessory pack.

CAUTION! The magnets are extremely powerful. Keep magnets separated. If

they touch each other they are difficult to separate. Use caution when handling

the magnets to avoid injury due to pinching.

3. Place the magnet on one corner of the device. Be sure to match the hole in the magnet to the

hole in the corner.

4. Remove one of the screws from the accessory pack.

5. Using the screwdriver, screw the magnet onto the device.

6. Repeat this process to screw the remaining magnets onto the corners of Connect Sensor.

When you have completed this process, a magnet should be screwed onto each corner of the

device.

Digi Connect® Sensor User Guide

19

Page 20

Get started Set up a Connect Sensor

Configure the cellular connection

Note If you purchased Digi Bundled Services, the cellular connection is already configured on your

Connect Sensor and you can skip this section.

Connect Sensor is configured with a default APN that you need to change to register Connect Sensor

on the cellular network for your cellular service provider. Use the command line interface (CLI) to

initially configure the cellular connection.

Before you begin, make sure you have the following required equipment and information:

n Computer running a terminal emulator program

n USB type A to B cable

n APN from your cellular service provider

To register Connect Sensor on a cellular network:

1. Open the enclosure and make sure the battery is connected and the SIM card is installed.

2. Connect a USB type A to B cable from your computer to the USB type B port.

Note Do not use the mini USB port, which is covered by a red X in the graphic below.

You may need to install device drivers or wait for your computer to automatically install them

when connecting Connect Sensor to a computer using a USB cable. Digi recommends drivers

available at www.ftdichip.com/Drivers/VCP.htm.

Digi Connect® Sensor User Guide

20

Page 21

Get started Set up a Connect Sensor

3. Open a terminal program on a computer and connect to Connect Sensor using the following

configuration:

n Connection port: Connect to the COM port associated with the USB cable connected to

Connect Sensor

n Baud rate or bits per second: 115200

n Data: 8 bit

n Parity: None

n Stop: 1 bit

n Flow control: None

4. Press the Wake button on the device.

5. At the command prompt, type set apn=<yourCarrierAPN> where yourCarrierAPN is the string

supplied by your cellular service provider.

6. Press Enter. The terminal program displays the APN configuration setting’s current value and

the pending value.

7. If required, set a user name, password, and PIN for the SIMcard. At the command prompt, type

the following and press Enter after each command:

o

set usr=<username>

Where username is the name of your cellular account.

o

set pwd=<password>

Where password is the password for your cellular account.

o

set pin=<pin>

Where pin is the PIN for your SIMcard.

For details about these commands, see CLI commands.

8. Type activate at the command prompt and press Enter to immediately make the change.

Connect Sensor goes to sleep and immediately wakes up to report the change to Remote

Manager. After the change completes, it goes to sleep again.

9. (Optional) Verify the new settings:

a. Press the Wake button.

b. At the command prompt type set commandname where commandname is one of

the settings you updated, such as apn.

After setting up and configuring Connect Sensor, use the following sections in this guide to configure

additional settings and remotely manage Connect Sensor:

n Check the cellular connection

n Configure pins and protocols

n Configure Connect Sensor device settings

n View device and sensor data streams

Digi Connect® Sensor User Guide

21

Page 22

Get started Add a device to Digi Remote Manager

Check the cellular connection

Make sure the cellular network provides an adequate signal where you install Connect Sensor to

maintain a consistent cellular connection.

Note Proper network coverage helps reduce power consumption, leading to improved battery life.

To check the cellular network connection at the install location:

1. Wake Connect Sensor:

n If the enclosure is open, press the Wake button.

n If the enclosure is closed, swipe the magnet across the magnet icon on the outside of

the device.

2. The LEDindicators light up in a predetermined sequence when you manually wake the device.

3. If Connect Sensor does not connect to the cellular network, see Device not connected to the

cellular network.

You can now complete I/O interface wiring, see the Digi Connect Sensor I/O Wiring Guide.

Wire the I/O sensors

You can wire the analog and digital input/output sensors or power using the I/O interface. For detailed

information, see the Digi Connect Sensor I/O Wiring Guide.

Note All external or field wiring must be in accordance with NFPA 70 Article 501.10(B).

After wiring sensors, use the following sections in this guide to configure additional settings and

remotely manage Connect Sensor.

n Configure pins and protocols

n View device and sensor data streams

n Configure Connect Sensor device settings

Add a device to Digi Remote Manager

To remotely manage Connect Sensor and get sensor data, you need to create a Remote Manager

account and add your Connect Sensor device to your account.

Note To serve our customers most effectively, Digi International Inc. is consolidating its cloud

services, Digi Device Cloud and Digi Remote Manager®, under the Remote Manager name. This phased

process does not affect device functionality or the functionality of the web services and other

Digi Connect® Sensor User Guide

22

Page 23

Get started Add a device to Digi Remote Manager

features. However, you will find instances of both Device Cloud and Digi Remote Manager in some

documentation, firmware, and user interfaces.

Note If you purchased Digi Bundled Services, the following steps were completed for you. You can skip

this section.

To add a device to Remote Manager:

1. Sign in to your Remote Manager account:

n If you need to create an account, go to Remote Manager at remotemanager.digi.com,

click Sign up, and complete the form to create your account.

n If you already have an account, go to Remote Manager at remotemanager.digi.com and

sign in with your user name and password.

2. Locate the 15-digit device IMEI number on the Connect Sensor label.

3. Click Device Management > Devices.

4. Click Add Devices. The Add Devices dialog appears.

You cannot use the Discover button to discover Connect Sensor devices automatically because

the devices are not available on the local network.

5. From the Add Devices drop-down menu, select IMEI, and enter the number.

6. Click Add to add the device.

7. Click OK to close the Add Devices dialog. The device appears in the Device Management list.

Note If the device does not display in the Device Management list, you can wake Connect

Sensor to force a connection with Remote Manager and update the data. For instructions, see

Update the firmware using the CLI or Update firmware from Connect Sensor.

8. Click Refresh if the device data does not appear on its own after a short period of time.

Device data appears after the first time it communicates with Remote Manager.

Digi Connect® Sensor User Guide

23

Page 24

Technical specifications

Maximum power and frequency bands

This section contains the maximum power and frequency bands for Connect Sensor.

Maximum power Associated frequencies

2 W Cellular 850 and 900 MHz bands

1 W Cellular 1800 and 1900 MHz bands

Connect Sensor product specifications

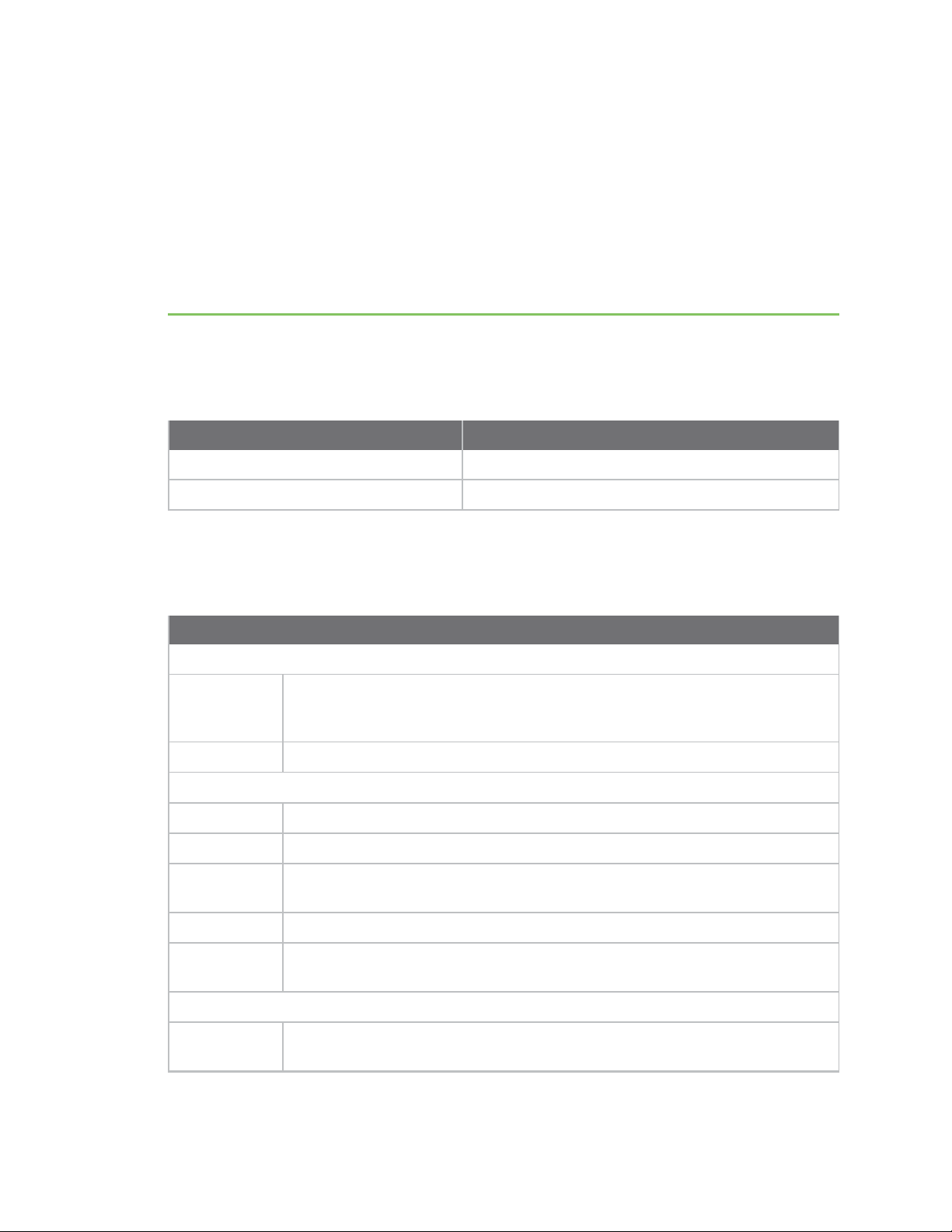

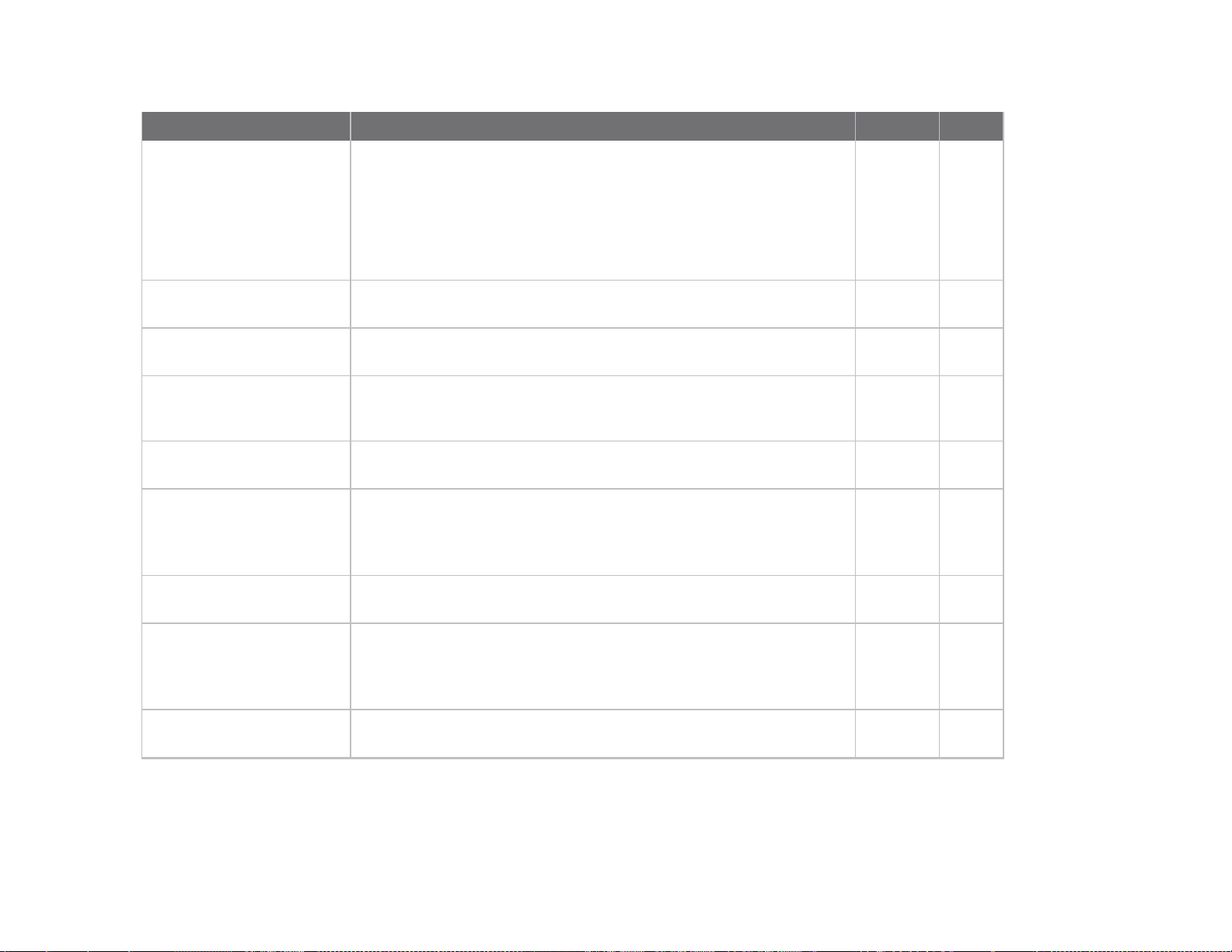

The following table provides a summary of general product specifications for Connect Sensor.

Specifications

Management

Configuration

and

management

Protocol TCP

Power

Battery 7.2V, 14 Ah, Lithium Thionyl Chloride, non-rechargeable, replaceable

Battery life

Battery self

discharge

Battery use -35°C ≤ Tamb ≤ 60°C ambient temperature range

External power

requirement

Environmental

Operating

temperature

Remote Manager

2 to 3 years (when following guidelines in Battery life)

up to 1%/year if stored at +30˚ C

8 VDC to 30 VDC at 1A

-35˚ C to +70˚ C

/Local USB to Serial CLI Protocol

Digi Connect® Sensor User Guide

24

Page 25

Technical specifications Cell modem transmit (TX) output power

Specifications

Storage

temperature

Relative

humidity

Ingress

Protection (IP)

rating

Physical

Dimensions

(L x W x H)

Weight 1.25 lbs

LEDs Bluetooth®, Sensor reading, Cellular, Battery

Enclosure

material

Enclosure

rating

-40˚ C to +85˚ C

90% (Non-condensing after 90%)

IP66

Note IP66 is for Class I Division 2 hazardous locations and ordinary locations only.

For more information on ATEXinstallation requirements, see ATEX requirements.

15.2 cm x 11.4 cm x 7.6 cm (6.0 in x 4.5 in x 3 in)

10% fiberglass reinforced polycarbonate

NEMA Type 4, 4X, 6, and 6P

UL 94 V-0

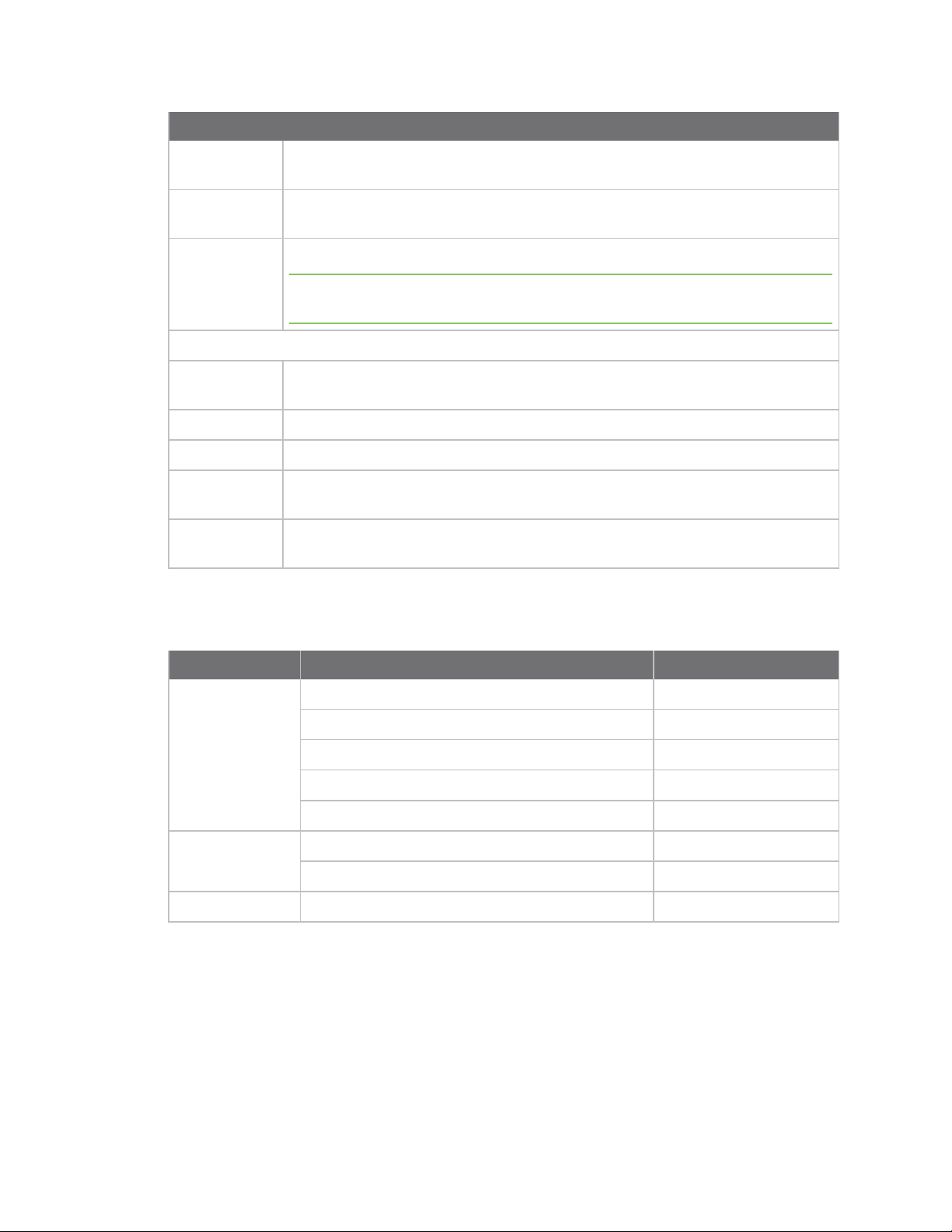

Cell modem transmit (TX) output power

Modem Band Power Class

HE910-D GSM 850 / 900 4 (2W)

DCS1800 / PCS 1900 1 (1W)

EDGE, 850/900 MHz E2 (0.5W)

EDGE, 1800/1900 MHz Class E2 (0.4W)

WCDMA FDD B1, B2, B4, B5, B8 Class 3 (0.25W)

LE910-NA1 LTEAll Bands Class 3 (0.2W)

WCDMA All Bands Class 3 (0.25W)

LE910-SV1 LTEAll Bands Class 3 (0.2W)

Digi Connect® Sensor User Guide

25

Page 26

Hardware

Battery inspection

CAUTION! This product contains a lithium metal battery. Prior to installation, the

battery should be inspected for any signs of damage. If the battery appears to be

damaged or is dropped during installation, do not use the battery and dispose of it

properly.

Please contact Digi Technical Support at 952-912-3444 or Tech.support@digi.com to order a

replacement battery.

The MSDS (Material Safety Data Sheet) for the battery can be found at

www.digi.com/documentation/ConnectSensor.

Battery life

Connect Sensor uses sleep and wake modes to manage power use. The device wakes only for sensor

readings and sending reports to Remote Manager. It is in sleep mode at all other times to maintain

low power consumption.

The battery will last 2 to 3 years in these conditions:

n Adequate cellular network coverage where Connect Sensor is installed

n Connect Sensor sends reports to Remote Manager a maximum of two times a day

n Connect Sensor is not powering high-current sensors with long read delays

The temperature at the device's location also affects the battery. Battery power is used more quickly

in a cold environment than in a warm environment. A battery in a device located where the

temperature is consistently 20° F will not last as long as a battery in a device located where the

temperature is consistently 80° F.

Extend battery life by scheduling less frequent sensor readings and reports. Scheduling more frequent

sensor readings and reports may shorten the battery life to less than 2 years.

Note When using the Continuous Monitoring feature, it is recommended that you use an external

power source rather than relying on the battery within Connect Sensor. See CSENSE Continuous

Monitoring power source for more information.

Battery percentage ranges and replacement

When the battery life percentage is above 30%, the battery has enough power to power the device,

and the device will function as expected.

Digi Connect® Sensor User Guide

26

Page 27

Hardware Battery percentage and external power

When the battery life percentage drops below 30%, the battery power is low and, depending on the

conditions in which the device is operating, may cease to power the device. To ensure that readings

continue as expected, it is recommended that you change the battery when the battery percentage

decreases to 30%. See Battery replacement.

You can view the battery life percentage in Remote Manager. See View battery life for a device in

Remote Manager.

Battery passivization

Unused lithium batteries that have been in storage acquire a state of passivization that can cause the

battery to report a low battery percentage for a time after initial installation. As the device uses the

battery, the passivization is removed and the battery percentage increases to a maximum of 90 100% (depending on the temperature). The passivization removal process could take a week or more,

if the number of times Connect Sensor wakes to take sensor readings and send reports to Remote

Manager is once per day or less.

Note Passivization may never be removed if the device sends reports to Remote Manager too

infrequently.

Battery percentage and external power

The device is powered by either external power connected to the device, or by an internal battery that

is connected to the device. The device is not powered by both power sources at the same time.

You can view the battery life percentage for a device in Remote Manager. See View battery life for a

device in Remote Manager. The battery life percentage depends on whether the device is using the

external power source or the battery.

n If the device is using the external power source and the battery is connected to the device,

then the battery life is 100%. This will occur whether the battery has any battery life remaining

or is dead.

n If the device is using the external power source and the battery is not connected to the device,

then the battery life is 0%.

n If the device is not using external power and the device is using the battery, the actual battery

life percentage displays, and is a percentage other than 100% or 0%.

CSENSE Continuous Monitoring power source

For some customers, the scheduling paradigm of the standard Connect Sensor offering is inadequate.

Digi offers an alternate firmware image that trades alarm reactivity for power consumption. The

CSENSE Continuous Monitoring firmware image can be downloaded and installed on a Connect

Sensor.

When using the Continuous Monitoring feature, Connect Sensor never sleeps. For best performance

and ease of use it is recommended that you use an external power source rather than relying on the

battery within Connect Sensor. If the battery is used, the battery life is significantly reduced. The

Connect Sensor battery can be used as a short-term battery backup if the external power source fails.

For more information about the Continuous Monitoring feature, see CSENSE Continuous Monitoring

firmware.

Digi Connect® Sensor User Guide

27

Page 28

Hardware Connect Sensor hardware replacement

Connect Sensor hardware replacement

The Connect Sensor hardware can be replaced with Connect Sensor+ hardware. Additional external

device monitoring features are available with Connect Sensor+ hardware:

n Modbus protocol

Digi Connect® Sensor User Guide

28

Page 29

Firmware

This section includes information about the Connect Sensor firmware options that are available in

addition to the standard firmware. These firmware options provide additional features. Note that

these firmware options contain all of the features in the standard Connect Sensor firmware in

addition to the features available in the firmware option you select.

If you want to use any of the optional features, you must upgrade from the standard Connect Sensor

firmware to the firmware variant that includes those features. The firmware upgrade can happen only

when Connect Sensor is awake and connected to Remote Manager. Any firmware upgrades,

configuration changes, or commands that have been added to a schedule in Remote Manager are

pushed to Connect Sensor at that time. If you need to upgrade the firmware before a scheduled push

from Connect Sensor, you can physically wake the Connect Sensor device to force a connection

between Connect Sensor and Remote Manager. For information on how to update the firmware, see

Firmware updates.

CSENSE Continuous Monitoring firmware

Note It is strongly recommended that an external power source for the Connect Sensor device is used

with continuous monitoring.

For some customers, the scheduling paradigm of the standard Connect Sensor offering is inadequate.

With continuous monitoring, Connect Sensor can constantly monitor sensors for an alarm by

continually sampling sensor data. This enables Connect Sensor to find alarms faster, and to not miss

any alarms that may have occurred between scheduled sensor readings.

The Connect Sensor device should be configured to specify a buffer time range for before and after an

alarm occurs. When an alarm occurs, Connect Sensor continues to sample data until the time limit of

the buffer is reached. When the buffer time limit is reached, the following information is pushed to

Remote Manager:

n Sample data in the buffer for the time range specified

n Alarm information

n Information from a scheduled reading stored in the device's memory

In addition to continuous monitoring, scheduled sensor readings still occur, and that data is stored in

the Connect Sensor memory.

n If a sensor alarm occurs, the data samples taken during the buffer time range plus any other

diagnostic information stored in the device's memory is pushed when the buffer time range is

reached.

n If an alarm doesn't occur between scheduled pushes, the information from a scheduled reading

stored in the device's memory is pushed to Remote Manager as scheduled.

Digi Connect® Sensor User Guide

29

Page 30

Firmware CSENSE Continuous Monitoring firmware

Continuous monitoring can occur simultaneously for up to five inputs: four analog and 1 digital.

n Analog 4-20mA Current Loop 1 or Analog Voltage Input 1

n Analog 4-20mA Current Loop 2 or Analog Voltage Input 2

n Analog 4-20mA Current Loop 3 or Analog Voltage Input 3

n Analog 4-20mA Current Loop 4 or Analog Voltage Input 4

n Digital Input

When using this feature, Connect Sensor never sleeps. For best performance and ease of use it is

recommended that you use an external power source rather than relying on the battery within

Connect Sensor. The Connect Sensor battery can be used as a battery backup if the external power

source fails.

Enable CSENSEContinuous Monitoring

Follow these steps to enable and configure continuous monitoring.

1. Upgrade to the CSENSE Continuous Monitoring firmware. For upgrade information, see

Firmware updates.

2. Enable the continuous monitoring feature on an Analog 4-20mA Current Loop, Analog Voltage

Input, or a Digital Input. For information, see Enable continuous monitoring on analog input or

Enable continuous monitoring on digital input.

3. Configure the buffer time range for all sensors using continuous monitoring to ensure the

desired amount of data is stored when an alarm occurs. For information, see Configure the

buffer time for continuous monitoring.

Enable continuous monitoring on digital input

Note The Connect Sensor firmware must be upgraded before continuous monitoring can be enabled

on the analog or digital input. For information, see CSENSE Continuous Monitoring firmware.

1. Follow the standard process to configure a digital input. For instructions, see Enable and

configure a digital input.

2. The digital input must be enabled. Verify that the Interface Enable (ena) option is set to On.

3. Verify that the Continuous Monitoring Enable (mon) option is set to On.

4. Click Save.

5. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Digi Connect® Sensor User Guide

30

Page 31

Firmware CSENSE Continuous Monitoring firmware

6. Configure the buffer time for the sensor to ensure the desired amount of data is stored when

an alarm occurs. For information, see Configure the buffer time for continuous monitoring.

Enable continuous monitoring on analog input

Note The Connect Sensor firmware must be upgraded before continuous monitoring can be enabled

on the analog or digital input. For information, see CSENSE Continuous Monitoring firmware.

1. Follow the standard process to configure an Analog 4-20mA Current Loop or Analog Voltage

Input. For instructions, see Enable and configure analog inputs.

2. The analog input must be enabled. Verify that the Interface Enable (ena) option is set to On.

3. Verify that the Continuous Monitoring Enable (mon) option is set to On.

4. Click Save.

5. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

6. Configure the buffer time for the sensor to ensure the desired amount of data is stored when

an alarm occurs. For information, see Configure the buffer time for continuous monitoring.

Configure the buffer time for continuous monitoring

To ensure the desired amount of data is stored when an alarm occurs, you should configure the buffer

time range for the sensor.

1. Sign in to Remote Manager.

2. Click Device Management > Devices.

3. Double-click on the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

5. Click Device Settings.

6. Configure the buffer time range for before and after the alarm event. The time is measured in

seconds.

a. In the Buffer Sensor Data Before Alarm field, select the number of seconds of

sample data that occurred before the alarm that should be saved and pushed.

b. In the Buffer Sensor Data After Alarm field, select the number of seconds of

sample data that occurred after the alarm that should be saved and pushed.

7. Apply the configuration changes:

Digi Connect® Sensor User Guide

31

Page 32

Firmware CSENSE Continuous Monitoring firmware

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Digi Connect® Sensor User Guide

32

Page 33

Configure pins and protocols

Before you begin configuring the analog and digital pins, and the Modbus protocols, make sure you

have completed the following steps:

n Configure the cellular connection

n Check the cellular connection

n Wire the I/O sensors

n Add a device to Digi Remote Manager

After completing those steps, you can use Remote Manager with Connect Sensor to remotely

configure sensors, schedule sensor readings and reports, review reports (sensor and device data), and

manage the device. Connect Sensor automaticallydetects the device version and provides support for

its configuration within the available options in Remote Manager.

You can also configure Connect Sensor to send alarm reports when an alarm condition occurs in an

environment. Alarm reports are separate from scheduled reports. Use alarm reports to communicate

changes in your environment and the device, including:

n Low and high sensor input values

n Rapid changes in sensor input values

n Battery life

See Configure pins and protocols, Configure battery life percentage alarms, and View device

information.

Enable and configure analog inputs

Connect Sensor has four analog inputs, each of which you can configure as either a 4-20 mA current

loop or a voltage input. For details about the configuration options, see Analog Current Loop Input and

Voltage Input option definitions.

To set analog input options:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

Digi Connect® Sensor User Guide

33

Page 34

Configure pins and protocols Enable and configure analog power outputs

5. Select the analog input for your sensor:

n Analog: 4-20mA Current Loop 1-4

n Analog: Voltage Input 1-4

Note Configure each analog input as either a current loop or a voltage input, not both. For

example, if you enable Analog: 4-20mA Current Loop 1, make sure you disable Analog: Voltage

Input 1.

6. Enable the input by selecting On for Interface Enable.

7. Select On for the alarms you want to enable and enter an appropriate value for each threshold

that you enabled. For more information, see Alarms.

8. Enter a value for Hysteresis to prevent multiple alarms when the sensor input value is near a

high or low threshold. For more information, see Hysteresis.

9. Enter a user-friendly name that describes the sensor in the Sensor Description field.

10. Enter the unit of measurement type, such as inches, that you are using for your application in

the Custom Scaled Sample Unit field.

11. Enter the sensor manufacturer's values for y1 and y2 in the Custom Scaled Sample Value

fields. For more information about the Custom Scaled fields, see Custom scaled sensor values.

12. Enable the oversampling feature, if desired. For more information about this feature, see

Oversampling.

a. From the Oversampling (ovs) list box, select the option that describes the desired

value for the sampled data: Average, Minimum, or Maximum.

b. In the Oversampling Inter-sample Delay field, specify the time interval between

readings. The time is measured in milliseconds.

c. In the Oversampling Number Samples field, specify the number of data samples

that must be taken.

13. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Enable and configure analog power outputs

Note Powering sensors reduces battery life.

Enable and configure the power output options when you use Connect Sensor to power the analog

sensors.

Digi Connect® Sensor User Guide

34

Page 35

Configure pins and protocols Enable and configure a digital input

Each of the four analog inputs also has four corresponding power outputs to power sensors. The

analog power outputs work independently—each one powers only its corresponding analog input.

For example:

n Analog:Power Output 1 powers either Analog: 4-20mA Current Loop 1 or Analog:Voltage Input

1.

n Analog:Power Output 2 powers either Analog: 4-20mA Current Loop 2 or Analog:Voltage Input

2, and so on.

When Connect Sensor powers multiple sensors, it powers only one sensor at a time for each sensor

reading. This also allows you to set different voltage ranges for each power output. For example, you

can set Analog:Power Output 1 to 3.3 V and Analog:Power Output 2 to 15 V.

For details about the configuration options, see Analog Power, Digital Power, and Serial Output option

definitions.

To set analog power output options in in Remote Manager:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

5. Click Analog:Power Output and select the power output that corresponds to your analog

input.

6. Enable the output by selecting On for Power Output Enable.

7. Select the appropriate voltage Output Level for your power output. Refer to the manufacturer

specifications for the sensor.

8. Enter the appropriate Read Delay that your sensor needs to stabilize before reading the

sensor input value. Refer to the manufacturer specifications for the sensor.

For example, a sensor may need 7 seconds to power on and stabilize before it can get an

accurate reading.

Note A higher read delay keeps the device powered on longer, which reduces battery life.

9. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Enable and configure a digital input

Connect Sensor has one digital I/O pin. You can configure the pin as a digital input, pulse counter, or

digital output, but not more than one I/O function simultaneously.

Digi Connect® Sensor User Guide

35

Page 36

Configure pins and protocols Enable and configure a digital pulse counter

In addition to the standard alarm and user-friendly name settings, the digital input options include

rising edge wake, falling edge wake, and a pull-up resistor.

For details about the configuration options, see Digital Input option definitions.

To configure digital input options:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

5. Select Digital: Input.

6. Select On for Interface Enable and disable the interface for all other digital I/O settings:

n Digital: Output >Interface Enable: Off

n Digital: Pulse Counter >Interface Enable:Off

7. Select On for the alarms you want to enable.

8. Select On for Rising Edge Wake and Falling Edge Wake to enable them.

9. Select On for Enable pullup when your application requires it.

10. Enter a user-friendly name for the sensor in the Sensor Description field.

11. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Enable and configure a digital pulse counter

Connect Sensor has one digital I/O pin. You can configure the pin as a digital input, pulse counter, or

digital output, but not more than one I/O function simultaneously.

When using a digital pulse counter, Connect Sensor continues to count pulses during sleep cycles and

reports them to Remote Manager during normal reporting intervals.

For example, if Connect Sensor reports every hour, the sensor counts pulses during each hour

Connect Sensor is in sleep mode. At the end of each hour, Connect Sensor wakes and reports the total

pulse count for that hour to Remote Manager. The pulse counter resets to zero after each wake cycle

and stores the values until the next reporting interval.

For details about the configuration options, see Digital Pulse Counter option definitions.

To set digital pulse counter options:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

Digi Connect® Sensor User Guide

36

Page 37

Configure pins and protocols Enable and configure a digital output

5. Click Digital: Pulse Counter.

6. Select On for Interface Enable and disable the interface for all other digital I/O settings:

n Digital: Input > Interface Enable: Off

n Digital: Output >Interface Enable: Off

7. Select On for the alarms you want to enable and enter an appropriate value for each threshold

that you enabled.

8. Enter a value for Hysteresis to prevent multiple alarms when the sensor input value is near a

high or low threshold.

9. Select On for Enable pullup when your application requires it.

10. Enter a user-friendly name for the sensor in the Sensor Description field.

11. Enter the unit of measurement type, such as inches, that you are using for your application in

the Custom Scaled Sample Unit field.

12. Enter the sensor manufacturer's values for y1 and y2 in the Custom Scaled Sample Value

fields. For more information about the Custom Scaled fields, see Custom scaled sensor values.

13. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Enable and configure a digital output

Connect Sensor has one digital I/O pin. You can configure the pin as a digital input, pulse counter, or

digital output, but not more than one I/O function simultaneously. Use Remote Manager to control a

digital output level and enable an internal pull-up resistor. For details about the configuration options,

see Digital Output option definitions.

To set digital output options:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

5. Select Digital: Output.

6. Select On for Interface Enable and disable the interface for all other digital I/O settings:

n Digital: Input > Interface Enable: Off

n Digital: Pulse Counter >Interface Enable:Off

7. Select the appropriate Output Level for your digital output. Refer to the manufacturer

specifications for the sensor.

Digi Connect® Sensor User Guide

37

Page 38

Configure pins and protocols Enable and configure a digital power output

8. Select the appropriate Toggle Output on option If you want to toggle the digital output on a

selected alarm. For more detailed information, see Toggle digital output on alarm.

9. Select On for Enable pullup when your application requires it.

10. Enter a user-friendly name for the sensor in the Sensor Description field.

11. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Enable and configure a digital power output

Note Powering sensors reduces battery life.

Configure the digital power output options when you use Connect Sensor to power an external device.

For details about the configuration options, see Analog Power, Digital Power, and Serial Output option

definitions.

To set digital power output options in Remote Manager:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

5. Select Digital: Power Output.

6. Enable the output by selecting On for Power Output Enable.

7. Select the appropriate voltage Output Level for your power output. Refer to the manufacturer

specifications for the sensor.

8. Enter the appropriate Read Delay that your sensor needs to stabilize before reading the

sensor input value. Refer to the manufacturer specifications for the sensor.

For example, a sensor may need 7 seconds to power on and stabilize before it can get an

accurate reading.

Note A higher read delay keeps the device powered on longer, which reduces battery life.

9. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

Digi Connect® Sensor User Guide

38

Page 39

Configure pins and protocols Enable and configure the Modbus protocol

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Enable and configure the Modbus protocol

Modbus is an industrial automation protocol used for sending and receiving digital information across

a single, external RS-485 serial bus.

Note The Modbus protocol is available only with Connect Sensor+ hardware.

The Modbus protocol allows Connect Sensor to collect remote diagnostic information from a Modbusenabled sensor as well as alert a user remotely if the sensor malfunctions. You can configure Connect

Sensor to collect remote diagnostic information from up to four Modbus-enabled sensors.

The Modbus protocol uses the serial pins on the I/O terminal block in Connect Sensor. The

configuration settings specified in the Modbus Protocol Settings page in Remote Manager must

exactly match the Modbus protocol settings on the external sensor device(s). The configuration

includes a list of variables, which specify the locations on the Modbus device that the Connect Sensor

should read to collect diagnostic information.

You can also choose to enable the Modbus protocol alarm option. This ensures that when an error

occurs with the Modbus-enabled sensor, error information is pushed to Remote Manager without

waiting for the next scheduled push.

You can review diagnostic information from the Modbus-enabled sensor in the Data Services tab in

Remote Manager. For more information about reviewing Modbus information in the data stream, see

Modbus (modb1) data stream definitions.

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

5. Click Modbus Protocol Settings.

6. For the Protocol Enable (ena) field, select the On option.

7. Determine whether error information should be pushed immediately. For the Device Status

Alarm Mask (aem) option:

n Select the On option if error information should be pushed immediately.

n Select the Off option if error information should be pushed with the next scheduled

push.

8. The following settings must match the configuration of the external sensor device. Select the

appropriate option from the list box.

n Serial framing mode (mode)

n Serial baud rate (baud)

n Serial data bits (dbt)

n Serial stop bits (sbt)

n Serial parity (par)

Digi Connect® Sensor User Guide

39

Page 40

Configure pins and protocols Enable and configure the Modbus protocol

9. For each Modbus sensor that you want to monitor, you can specify the station address and

then include a list of variable addresses. The items in the list must be separated by a comma

without spaces. The list is limited to 63 characters, which allows for 8 to 10 variables in a list.

For more information about identifying Modbus stations and locations, see Modbus station

addresses and locations.

a. In the Station1: Slave Address (saddr1) field, select the station address.

b. In the Station 1: Variable list (vars1) field, enter the list of variable addresses.

c. Repeat this process for any additional stations. You can specify up to four stations.

10. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

11. If Connect Sensor is providing power to the Modbus device, you must enable the serial power

output. For instructions, see Enable and configure a serial power output.

Digi Connect® Sensor User Guide

40

Page 41

Configure pins and protocols Enable and configure the Modbus protocol

If the external sensor device has an alternate power source, you can skip this step.

Enable and configure a serial power output

This section describes how to configure serial power. Note that powering sensors reduces battery life;

to reduce unnecessary battery consumption, only wake the device when needed.

Note The serial power output option is available only with Connect Sensor+, and is used only with a

Modbus device.

If Connect Sensor is providing power to the Modbus device, you must enable the serial power output.

To set serial power output options in Remote Manager:

1. Sign in to Remote Manager.

2. Click Device Management > Devices tab.

3. Double-click the Connect Sensor device you want to configure.

4. Expand the Configuration menu.

5. Select Serial: Power Output.

6. Enable the output by selecting On for Power Output Enable.

7. Select the appropriate voltage Output Level for your power output. Refer to the manufacturer

specifications for the sensor.

8. Enter the appropriate Read Delay that your sensor needs to stabilize before reading the

sensor input value. Refer to the manufacturer specifications for the sensor. For example, a

sensor may need 7 seconds to power on and stabilize before it can get an accurate reading.

Note A higher read delay keeps the device powered on longer, which reduces battery life.

9. Apply the configuration changes:

a. Click Save > Schedule. The Save Device Properties dialog appears.

b. Select a scheduling option. See Schedule options.

Note The Recurring option does not work with the Connect Sensor device.

c. Click Schedule. Connect Sensor downloads and applies configuration changes the

next time it connects to Remote Manager.

Modbus station addresses and locations

In Modbus, a station address acts as a unique identifier for the external sensor device. A station

address is assigned when the external sensor device is configured and installed. Multiple stations

listen to the bus and can respond only to the commands that match their unique station address.

Connect Sensor acts as a master to the slave station addresses. All Modbus devices connected to

Connect Sensor must have the exact same serial configuration.

In the Connect Sensor configuration, you can specify a list of variable addresses for each station

address. The variable addresses identify the values that should be pulled from each station device.

If Connect Sensor is configured to read a variable that is unsupported by a Modbus station, no data

sample is stored.

Digi Connect® Sensor User Guide

41

Page 42

Configure pins and protocols Enable and configure the Modbus protocol

Finding the Modbus address

A Modbus variable address includes a combination of the reading category, the logical address of the

information, and the interpretation method. Together these create a variable address that can be

added to a variable list in the Connect Sensor configuration.

Step 1: Determine the reading category

The reading category is the single digit prefix of the variable address. Each variable type has a unique

prefix.

Modbus variable type Number of bits Prefix value

Coil 1 0

Discrete input 1 1

Input register 16 3

Holding register 16 4

Step 2: Determine the logical address

Many Modbus device specifications list variables using a 0-based physical address. Since Modbus uses

a 1-based logical address, the logical address is calculated by adding one to the physical address. The

logical address must have either four or five digits, padded on the left by zeroes if required.

For each configured station address, you can configure a corresponding variable list. The variable list

is limited to 63 characters, which limits the number of variables to between 8 and 10.

A variable address can be either 5 or 6 decimal digits in length.

Five decimal digits:

00001 - 09999 Coils: physical addresses 0 - 9998

10001 - 19999 Discrete inputs: physical addresses 0 - 9998

30001 - 39999 Input registers: physical addresses 0 - 9998

40001 - 49999 Holding registers: physical addresses 0 - 9998

Six decimal digits:

00001 - 065536 Coils: physical addresses 0 - 65535

10001 - 165536 Discrete inputs: physical addresses 0 - 65535

30001 - 365536 Input registers: physical addresses 0 - 65535

40001 - 465536 Holding registers: physical addresses 0 - 65535

Step 3: Determine the interpretation method

Generally, a single-bit value is interpreted as either 0 or 1, and a 16-bit value is interpreted as an

integer between 0 and 65535. These are the default interpretations for the four categories, and no

extra specification is required.

Digi Connect® Sensor User Guide

42

Page 43

Configure pins and protocols About analog and digital input options

Some Modbus devices, however, specify that a pair of consecutive 16-bit registers should be combined

and the 32-bits be interpreted as an IEEE 754 floating point value instead. To indicate this, the

Connect Sensor variable address requires a suffix of either ‘f’ or ‘F’:

If the 32-bit value can be represented as DCBA, where D represents the most significant byte of the

value, and A represents the least significant byte of the value, two floating point encodings are

supported as follows:

f IEEE 754 floating point value with bytes in the following order: B A D C

F IEEE 754 floating point value with bytes in the following order: D C B A

Examples

n If the device specification defines a simple holding register at physical address 4002, the prefix

is 4, the logical address is 4003, and there is no interpretation suffix. The combined logical

address is 44003.

n If the device specification defines a coil at physical address 17, the prefix is 0, the logical

address is 0018 (zero padded), and there is no interpretation suffix. The combined logical

address is 00018.

n If the device specification defines an input register at physical address 7002 that is 32-bit

floating point value with bytes presented in D C B A order, the prefix is 3, the logical address is

7003, and the interpretation suffix is ‘F’. The combined logical address is 37003F.

About analog and digital input options

Use Remote Manager to:

n Enable each of the analog and digital inputs and configure their options to get sensor data in

Remote Manager. For more information, see Enable and configure analog inputs or Enable and

configure a digital input.

n Alarms: Configure alarms for each sensor to alert you when there are sudden changes in your

industrial environment. For additional information, see Alarms and Hysteresis.

n Custom Scaling: Use custom scaled sensor values to convert raw data into custom units that

are meaningful to your application. For additional information, see Custom scaled sensor

values.

n Oversampling: Configure oversampling to increase the precision of a data sample collected at

a scheduled reading by reading multiple samples. For additional information, see

Oversampling.

Alarms

Use alarms to send reports to Remote Manager when unusual changes occur in sensor values. Alarm

reports are sent when a sensor reaches an alarm value during a sensor reading, even if it is between

reporting intervals.

Connect Sensor sends alarm reports as follows:

Digi Connect® Sensor User Guide

43

Page 44

Configure pins and protocols About analog and digital input options

n High alarm: Sends an alarm report when the input value is greater than the high threshold.

n Low alarm:Sends an alarm report when the input value is less than the low threshold.

n Delta high alarm:Sends an alarm report when the input value increases too much between

two consecutive readings.

n Delta low alarm:Sends an alarm report when the input value decreases too much between

two consecutive readings.

n Rising edge: Sends an alarm report when the device wakes on a digital input change from low

voltage to high voltage.

n Falling edge: Sends an alarm report when the device wakes on a digital input change from

high voltage to low voltage.

For example, with high alarms enabled and configured, Connect Sensor is configured to read sensor

input values every hour and scheduled to send reports twice every day, at 8:00 and 20:00. An input

value suddenly reaches its high threshold at 11:00. When Connect Sensor wakes at 11:00 to take a

reading, it sends a high alarm report to Remote Manager.

Alarms are available for the following:

n Analog: 4-20mA Current Loop Input

n Analog: Voltage Input

n Digital: Input

n Digital: Pulse Counter

For Connect Sensor+, an alarm is also available for the following:

n Modbus protocol: Enable and configure the Modbus protocol

Hysteresis

Sensor values may sometimes fluctuate during an alarm condition, which causes Connect Sensor to

send multiple alarm reports.

Hysteresis works with the high and low alarm thresholds to tell the device when to keep an alarm on

without sending additional alarm reports, or when to shut off an alarm. Use this to avoid repeated

alarms during common sensor input value fluctuations.

For example, a pressure sensor input value increases to the high threshold and the device sends a

high alarm report. However, the pressure sensor input value continues to increase and decrease

repeatedly between normal and high thresholds during this alarm condition. If you have not set a

hysteresis range, the Connect Sensor device sends an alarm report every time the sensor input value

reaches the high threshold.

The following are examples of how high and low hysteresis works with a voltage input:

n High hysteresis: If your high threshold is 10 volts and your hysteresis value is 2 volts, then

your high alarm hysteresis is 8 volts. This means that the alarm turns on when the sensor input