Page 1

ConnectCore 6 Plus

Hardware Reference Manual

Page 2

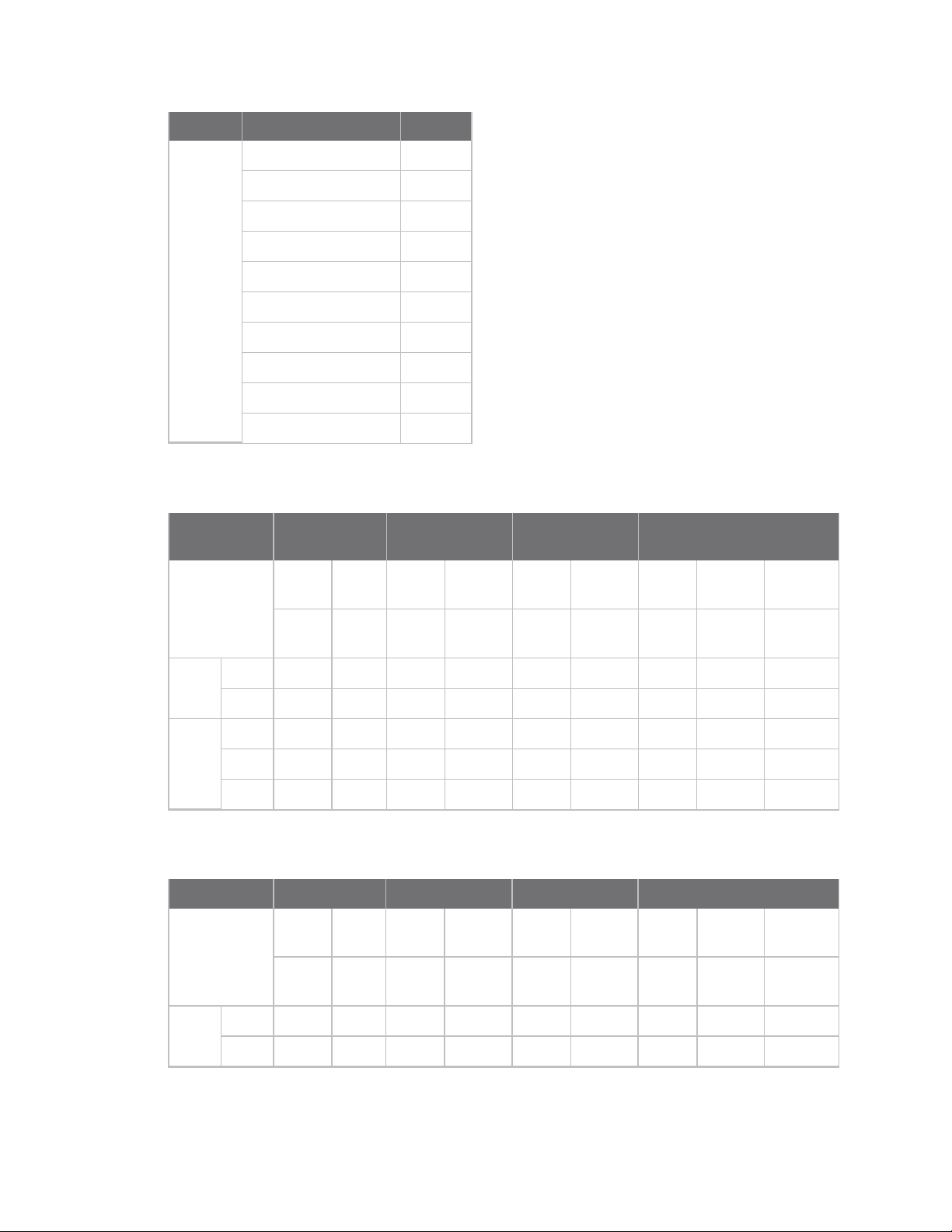

Revision history—900002278

Revision Date Description

A April 2018 First release

Trademarks and copyright

Digi, Digi International, and the Digi logo are trademarks or registered trademarks in the United

States and other countries worldwide. All other trademarks mentioned in this document are the

property of their respective owners.

© 2018 Digi International Inc. All rights reserved.

Disclaimers

Information in this document is subject to change without notice and does not represent a

commitment on the part of Digi International. Digi provides this document “as is,” without warranty of

any kind, expressed or implied, including, but not limited to, the implied warranties of fitness or

merchantability for a particular purpose. Digi may make improvements and/or changes in this manual

or in the product(s) and/or the program(s) described in this manual at any time.

Warranty

To view product warranty information, go to the following website:

www.digi.com/howtobuy/terms

Send comments

Documentation feedback: To provide feedback on this document, send your comments to

techcomm@digi.com.

Customer support

Digi Technical Support: Digi offers multiple technical support plans and service packages to help our

customers get the most out of their Digi product. For information on Technical Support plans and

pricing, contact us at +1 952.912.3444 or visit us at www.digi.com/support.

ConnectCore 6 Plus Hardware Reference Manual

2

Page 3

Contents

About the ConnectCore 6 Plus

Features and functionality 6

Block diagram 7

Power supply architecture 8

Bootstrap 13

Wireless interfaces 14

WLAN IEEE 802.11a/b/g/n/ac 15

Modulation and data rates 15

RF channels 17

Receive sensitivity 19

Transmit power 19

Bluetooth 20

MCA hardware 20

Supported devices 20

MCA pinout 22

Shared I2C bus 31

Shared SPI bus 32

CryptoAuthentication device 33

Module pinout 34

Signal usage limitations 84

Specifications for the ConnectCore 6 Plus

Electrical characteristics 87

Voltage supplies 87

Power consumption 87

Power consumption use cases 87

Global power consumption 88

Mechanical specifications 88

Host PCB footprint 90

Environmental specifications 90

Linux - Android users 91

Assembly instructions

Moisture sensitivity and shelf life 93

Mounting 93

Solder Paste 93

Solder paste print 93

Stencil 93

ConnectCore 6 Plus Hardware Reference Manual

3

Page 4

Coplanarity 94

SMT pick and place 94

SMT process parameter reference 94

Reflow profile 94

Regulatory information and certifications

United States FCC 97

Labeling requirements 97

Maximum power and frequency specifications (FCC) 98

FCC notices 99

FCC-approved antennas 99

RF exposure 100

Canada (ISED) 100

Maximum power and frequency specifications 100

Labeling requirements 100

Transmitters with detachable antennas 101

Europe ETSI 101

Maximum power and frequency specifications (Europe ETSI) 102

OEM labeling requirements 104

CE labeling requirements 104

Declarations of Conformity 104

Approved antennas 104

Bluetooth SIG-qualified hardware and firmware 104

ConnectCore 6 Plus Hardware Reference Manual

4

Page 5

About the ConnectCore 6 Plus

The ConnectCore 6 Plus is an ultra-compact and highly integrated system-on-module solution based

on the NXP i.MX6QP Cortex-A9 processor family.

With processor speed up to 1.0 GHz, the ConnectCore 6 Plus offers a truly future-proof platform

solution with scalable performance and pre-certified dual-band Wi-Fi (802.11a/b/g/n/ac) with

Bluetooth 4.2 dual mode connectivity.

Its innovative and scalable design maximizes integration flexibility and significantly reduces design

risk in a highly cost-effective, reliable, low-profile surface mount form factor with optimal thermal

management even in the most demanding quad-core system configurations.

Seamless Cloud Connector integration as part of the Digi Linux and Android software platform support

offers secure remote management and web services capabilities through the scalable Digi Remote

Manager.

In addition, Digi offers custom Remote Manager hardware and wireless design services as well as endto-end solutions services for cloud integration and app development.

This System-On-Module aims to be the next generation of the ConnectCore 6 Plus for i.MX6 family

modules and is pin-to-pin compatible with them.

Features and functionality 6

Block diagram 7

Power supply architecture 8

Bootstrap 13

Wireless interfaces 14

MCA hardware 20

CryptoAuthentication device 33

Module pinout 34

Signal usage limitations 84

ConnectCore 6 Plus Hardware Reference Manual

5

Page 6

About the ConnectCore 6 Plus Features and functionality

Note To serve our customers most effectively, Digi International Inc. has consolidated our cloud

services, Digi Device Cloud and Digi Remote Manager®, under the Remote Manager name. This phased

process does not affect device functionality or the functionality of the web services and other

features. However, you will find instances of both Device Cloud and Digi Remote Manager in some

documentation, firmware, and user interfaces.

Features and functionality

The ConnectCore 6 Plus module is based on the i.MX6QP processor from NXP. This processor offers a

high number of interfaces. Most of these interfaces are multiplexed and are not available

simultaneously. The module has the following features:

n i.MX6QP ARM Cortex-A9 cores operating at speed up to 1.0 GHz

l 32 Kbytes L1 Instruction cache

l 32 Kbytes L1 Data cache

l Up to 1 MB unified Instruction/Data L2 cache

l NEON MPE (Media Processing Engine) co-processor

n Graphical hardware accelerators:

l IPU (Image Processing Unit)

l VPU (Video Processing Unit)

l 3D GPU (Graphics Processing Unit) version 6

l 2D GPU (Graphics Processing Unit) version 3

l GPU (OpenVG 1.1 Graphics Processing Unit)

l Prefetch and Resolve Engine

l Prefetch and Resolve Gasket

l ASRC (Asynchronous Sample Rate Converter)

n 64-bit DDR3-1066 memory interface with a density up to 2 GBytes

n 8-bit eMMC support

n Dialog DA9063 power management IC (PMIC)

l 6x DC/DC buck converters

l 11x LDO regulators

l RTC with rechargeable coin cell battery support

l 10-bit ADC channels

l GPIO pins

n IEEE 802.11 a/b/g/n/ac WLAN interface

n Bluetooth version 4.2 dual mode

n Cortex-M0+/Cortex-M4 MCA (Microcontroller Assist) subsystem

ConnectCore 6 Plus Hardware Reference Manual

6

Page 7

About the ConnectCore 6 Plus Block diagram

n Debug interfaces:

l Standard JTAG controller IEEE 1149.1

l ETM/ETB support

n Support of i.MX6QP typical interfaces:

l 16/32-bit data/address bus

l SATA II, 3.0 Gbps (24-bit parallel bus, LVDS, HDMI, MIPI/DSI)

l Display support

o

HDMI

o

24-bit parallel bus

o

Dual LVDS

o

MIPI/DSI

l 2x camera (20-bit parallel bus, MIPI/CSI)

l MMC/SD/SDIO

l 1x USB OTG with integrated PHY

l 3x USB Host

l PCI Express Gen 2.0 lane

l 10/100/1000 M Ethernet MAC

l UART, SPI, I2C, PWM, CAN, I2S and GPIO

n Ultra-miniature SMT module (50x50mmx5mm) based on 400-LGA pads

n Security accelerators:

l ARMTrustZone

l CAAM (cryptographic acceleration and assurance module)

l SNVS (secure non-volatile storage)

l CSU (central security unit)

l A-HABv4 (advanced high-assurance boot)

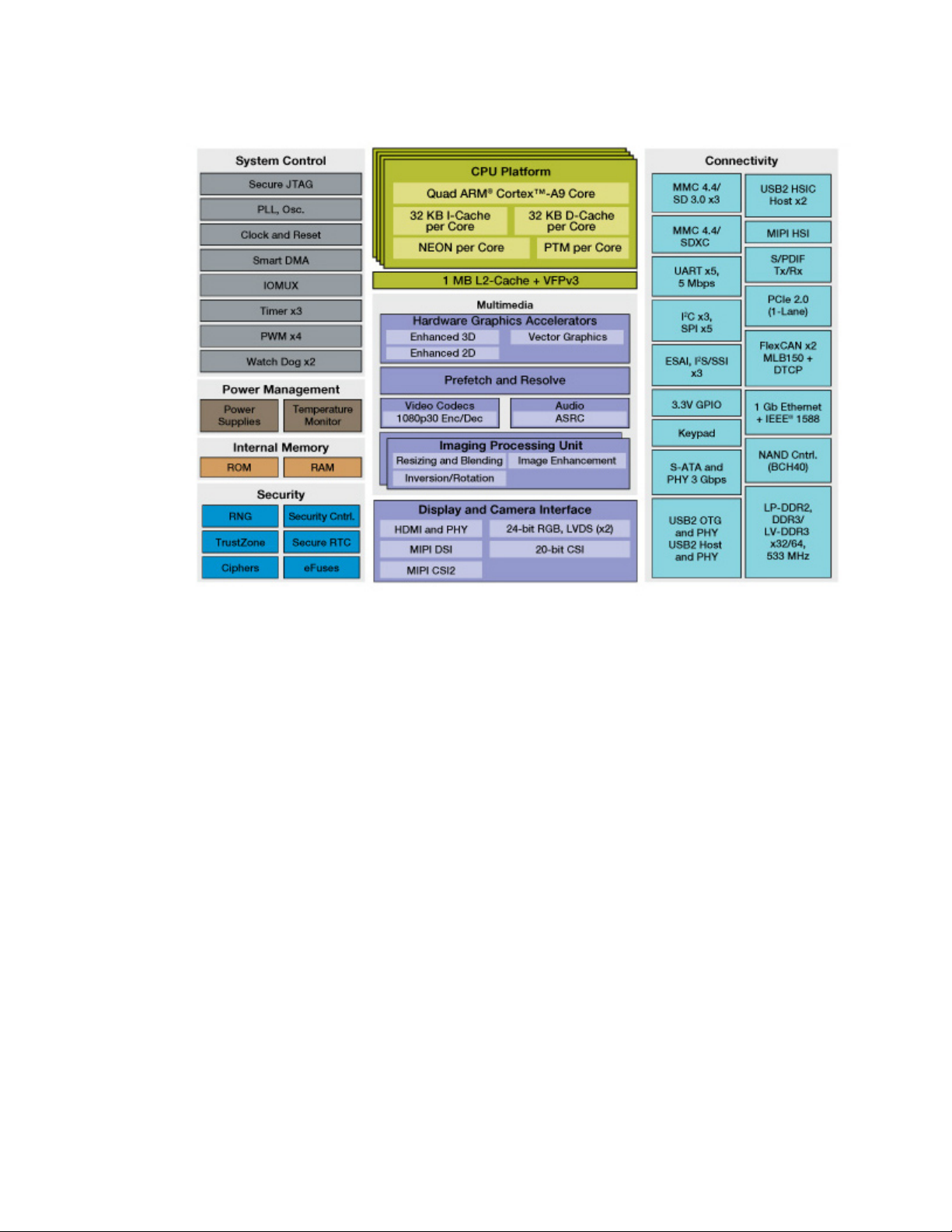

Block diagram

The figure below shows the block diagram of the NXP i.MX6QP application processor.

ConnectCore 6 Plus Hardware Reference Manual

7

Page 8

About the ConnectCore 6 Plus Power supply architecture

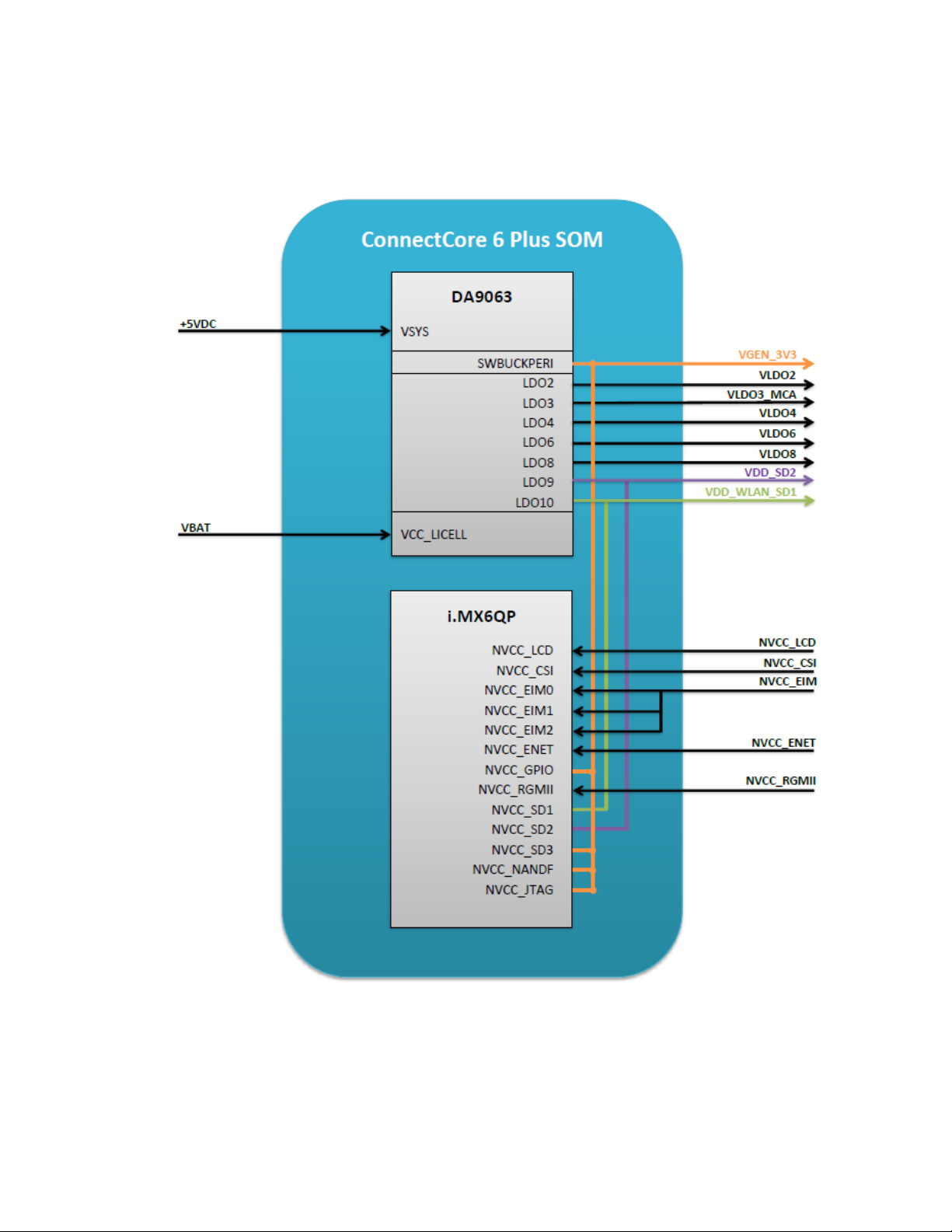

Power supply architecture

The ConnectCore 6 Plus provides a primary 5 V power supply input. This supply is the main power

domain to the on-module Dialog DA9063 power management IC (PMIC), which generates all required

supply voltages for the module components as well as the carrier board.

The module provides support for a backup battery (coin-cell or super cap) powering the real-time

clock (RTC) on the module. In addition, rechargeable backup batteries (ML414, others) are also

supported.

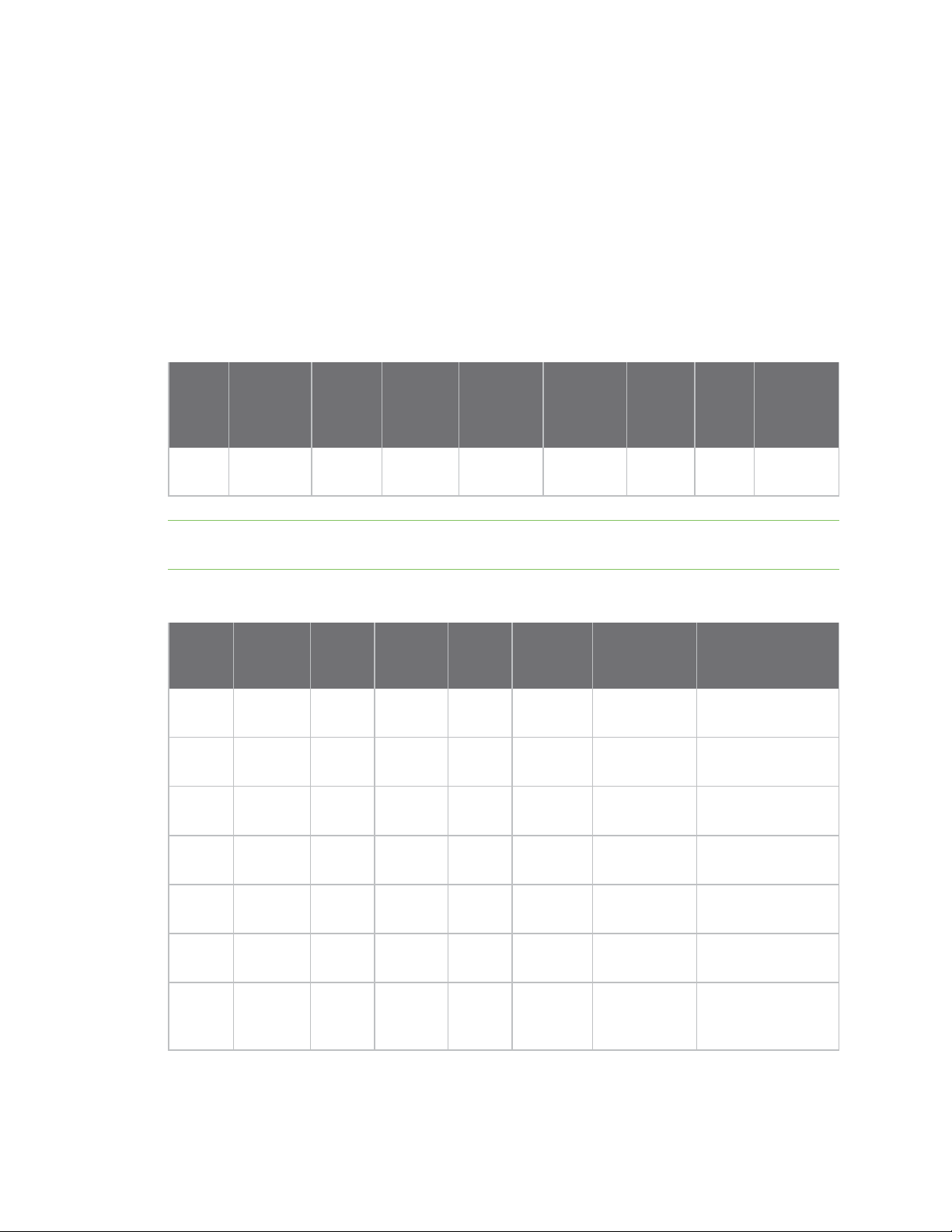

The PMIC generates the following power domains that are available on the module pads:

n One PMIC switching regulator:

l VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

8

Page 9

About the ConnectCore 6 Plus Power supply architecture

n Five PMIC LDO:

l VLDO2

l VLDO3_MCA

l VLDO4

l VLDO6

l VLDO8

l VDD_SD2

l VDD_WLAN_SD1

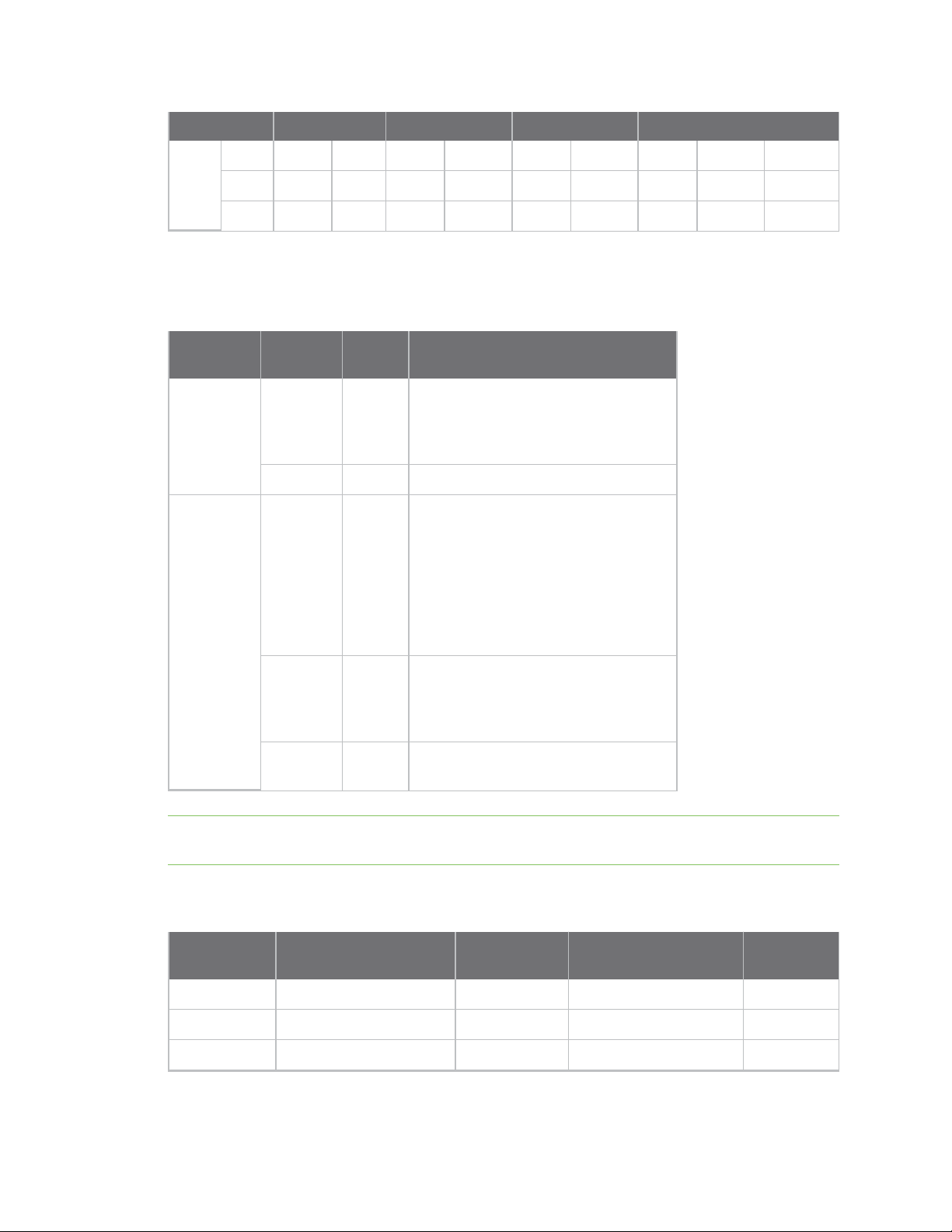

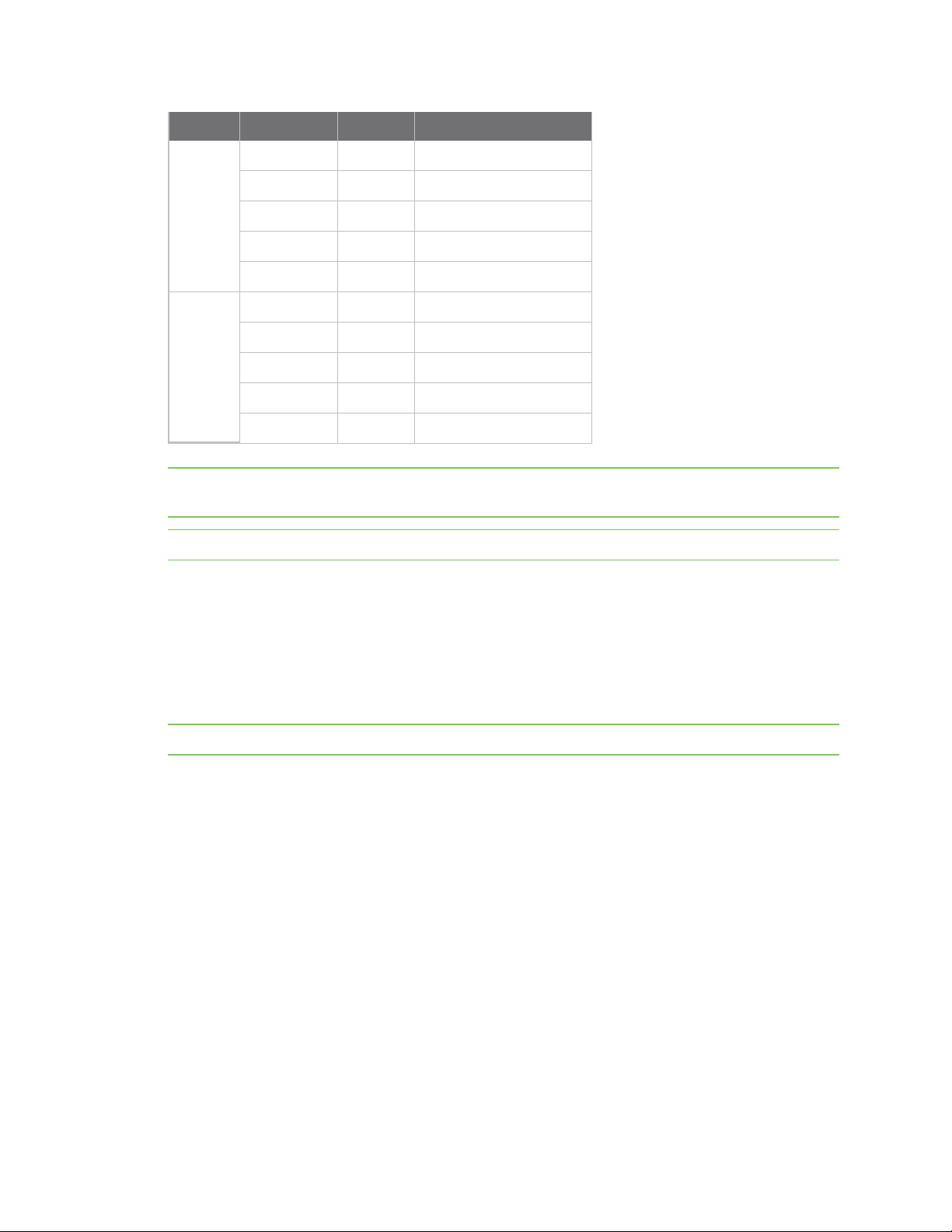

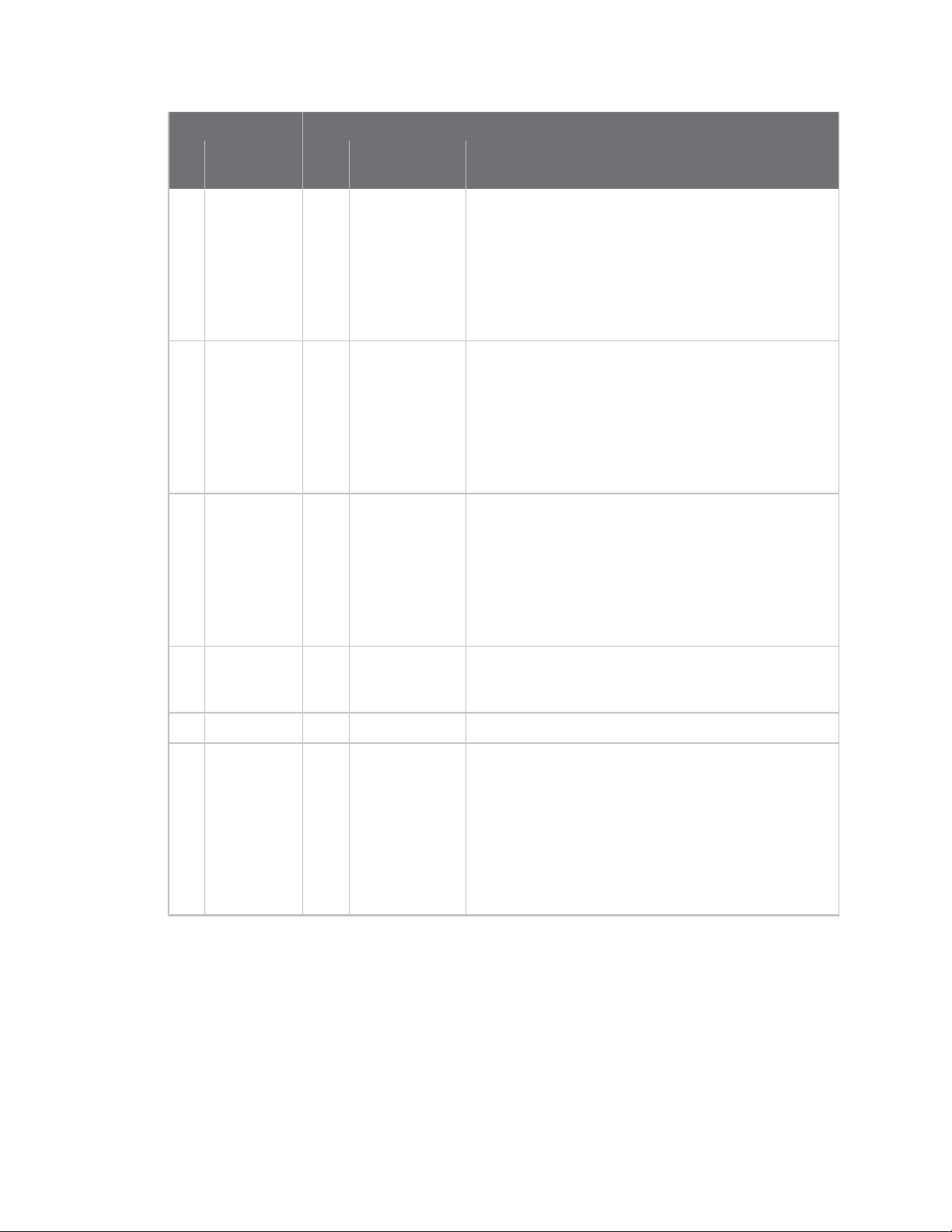

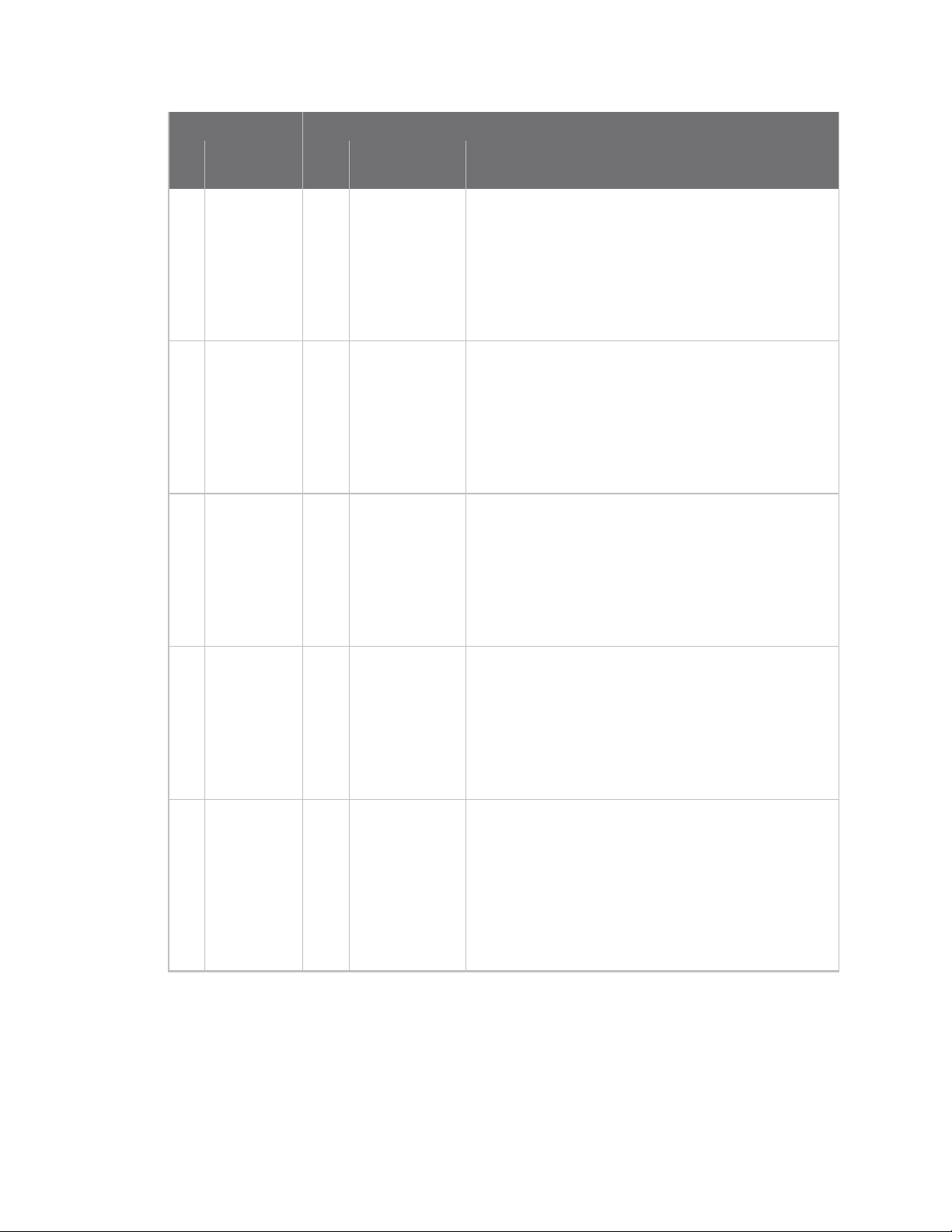

Signal

name

VGEN_

Turn

PMIC

regulator

Output

voltage

Output

accuracy

Maximum

current

Dropout

voltage

(MAX)

Turn on

time

(MAX)

off

time

(MAX)

BUCKPERI 3.3 V +/-3% 1500 mA - 1 µA 1.2 ms -

Quiescent

current in

OFF mode

(TYP)

3V3

Note The maximum current consumption mentioned in the previous table is a combination of the

current consumed by the module (max 500mA) and by the carrier board for external use (1000mA).

The table below provides the characteristics of the optional LDO outputs:

Signal

name

PMIC

regulator

Output

voltage

VLDO2 LDO2 0.6-

Drop output

Output

accuracy

Default

voltage

Maximum

current

voltage

(MAX)

+/-3% 1.8 V 200 mA 150 mV

Quiescent current

in OFF mode

(TYP)

1 µA

1.86 V

VLDO3_

MCA

VLDO4 LDO4 0.9-

LDO3 0.9-

3.44 V

+/-3% 3.3 V 200 mA 150 mV 1 µA

+/-3% 3.3 V 200 mA 150 mV 1 µA

3.44 V

VLDO6 LDO6 0.9-3.6V+/-3% 3.3 V 200 mA 150 mV 1 µA

VLDO8 LDO8 0.9-3.6V+/-3% 3.3 V 200 mA 150 mV 1 µA

VDD_

SD2

VDD_

LDO9 0.95 -

+/-1% 3.3 V 200 mA 150 mV

3.6 V

LDO10 0.9 - 3.6V+/-3% 3.3 V 300 mA 150 mV

WLAN_

SD1

ConnectCore 6 Plus Hardware Reference Manual

1 µA

1 µA

9

Page 10

About the ConnectCore 6 Plus Power supply architecture

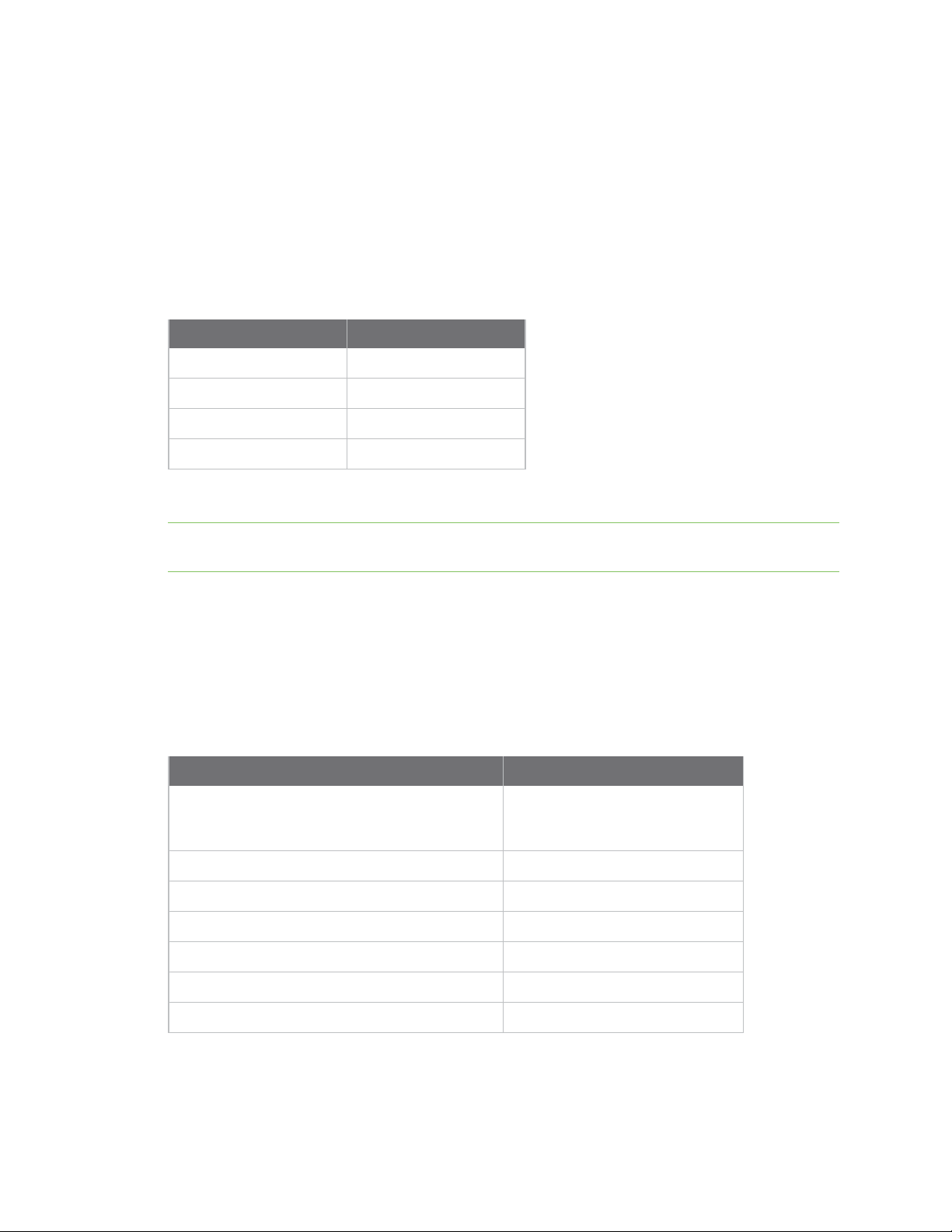

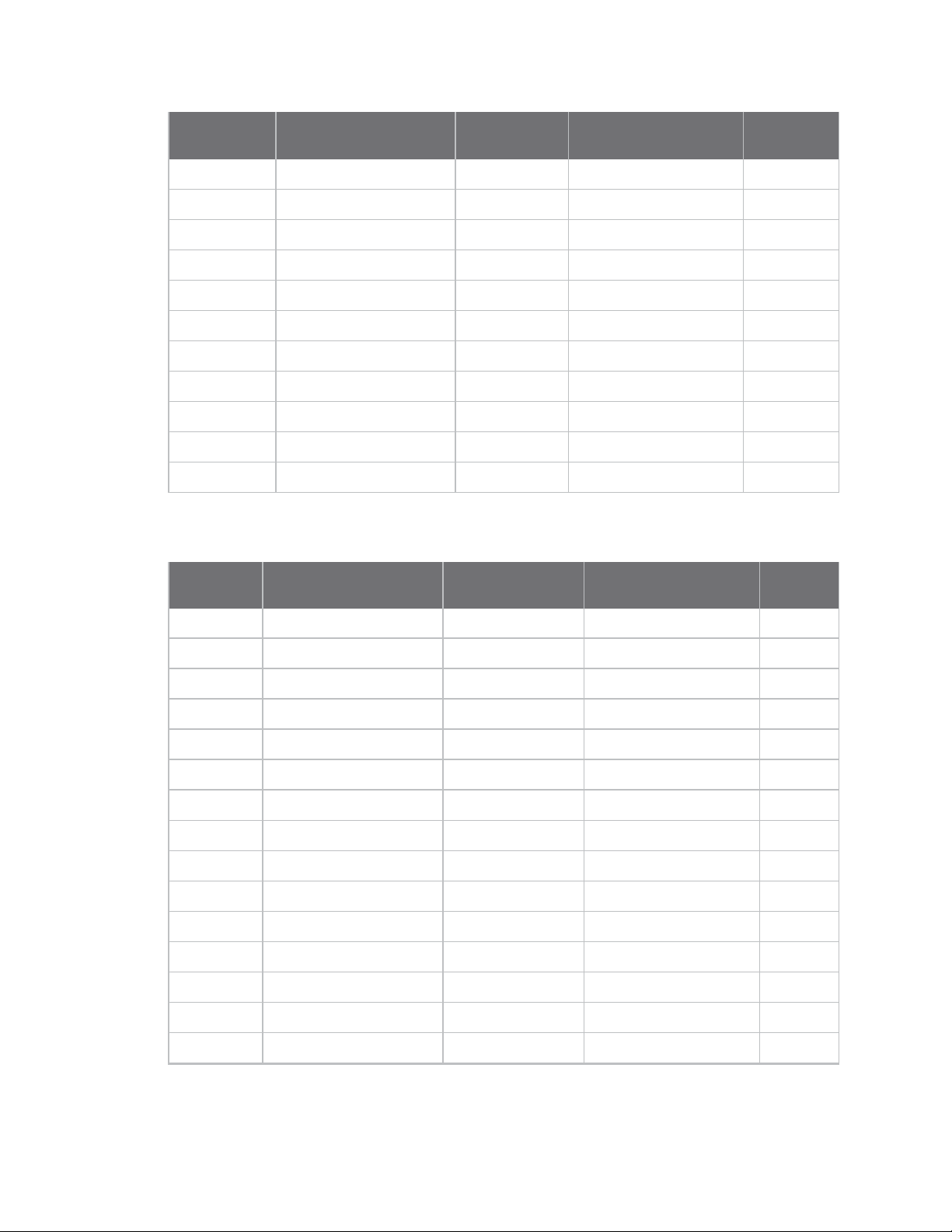

Signal name Turn on time (MAX) Turn off time (MAX)

VLDO2

150 µs

1 ms

VLDO3_MCA 300 µs 1 ms

VLDO4 300 µs 1 ms

VLDO6 200 µs 1 ms

VLDO8 300 µs 1 ms

VDD_SD2 200 µs 1 ms

VDD_WLAN_SD1 200 µs 1 ms

Note For information about using the LDO options, please contact Digi.

VLDO3 is used for supplying MCA processor on the module.

The power management IC located on the module is responsible for generating all required i.MX6QP

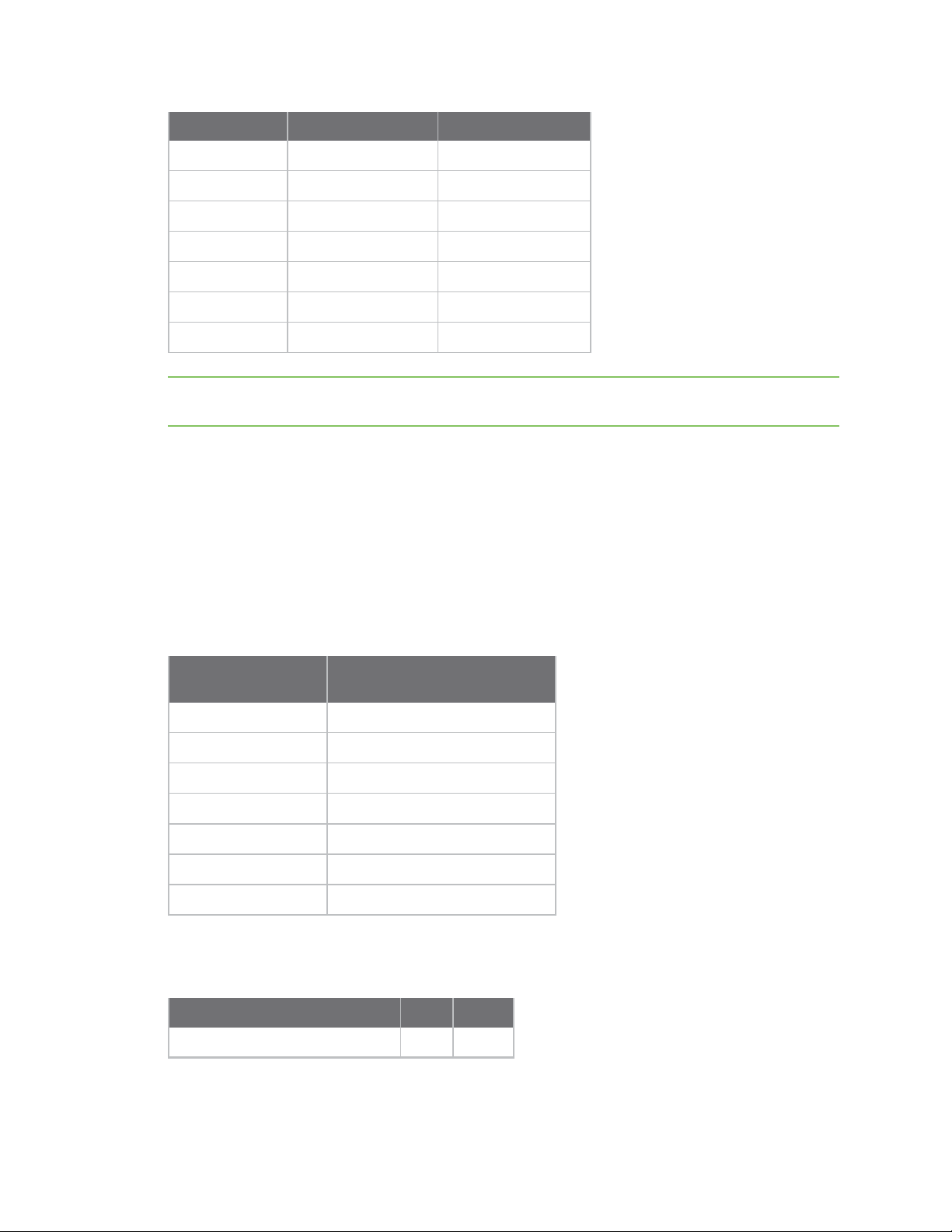

processor supply voltages. The following i.MX6QP supplies are available on the module pads:

n NVCC_ENET

n NVCC_EIM

n NVCC_LCD

n NVCC_CSI

n NVCC_RGMII

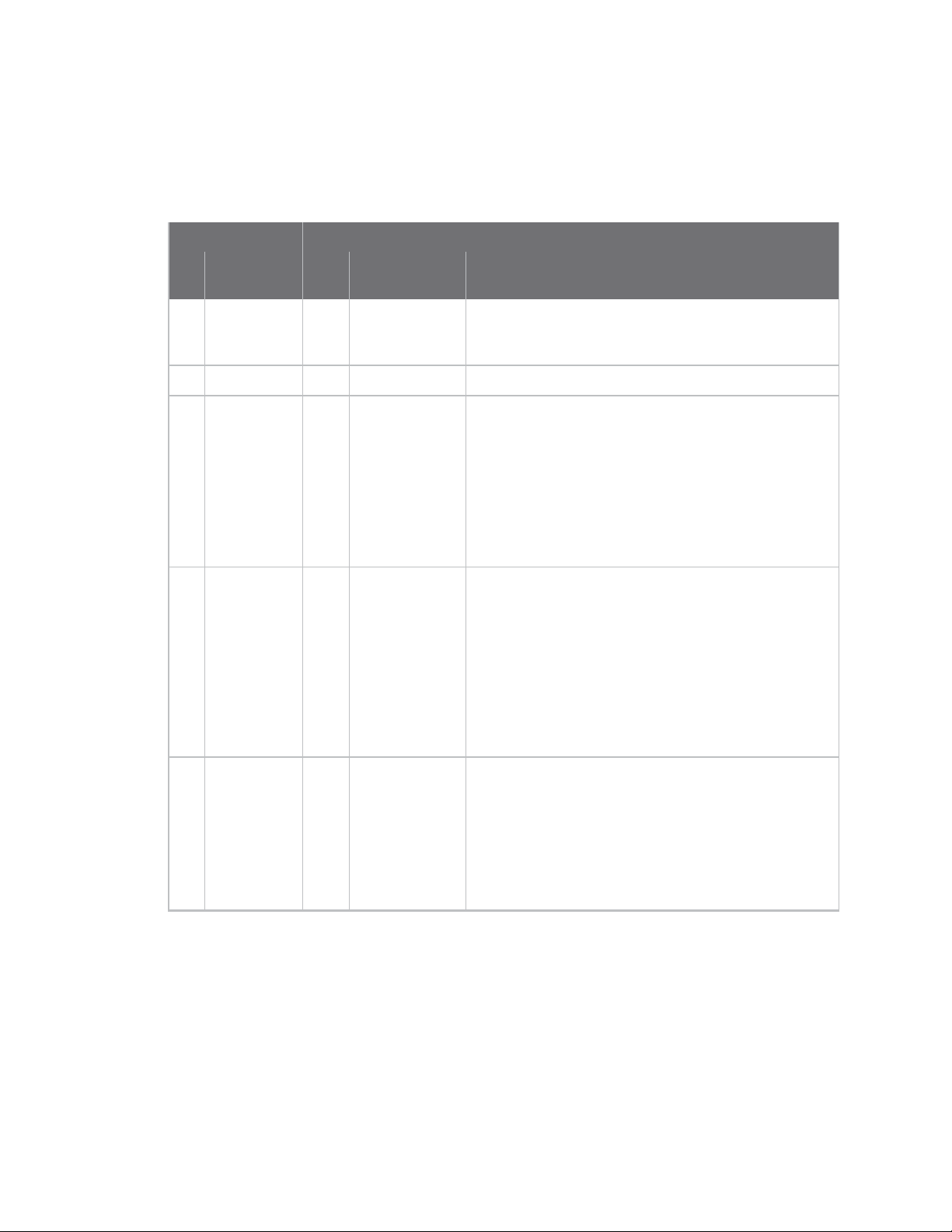

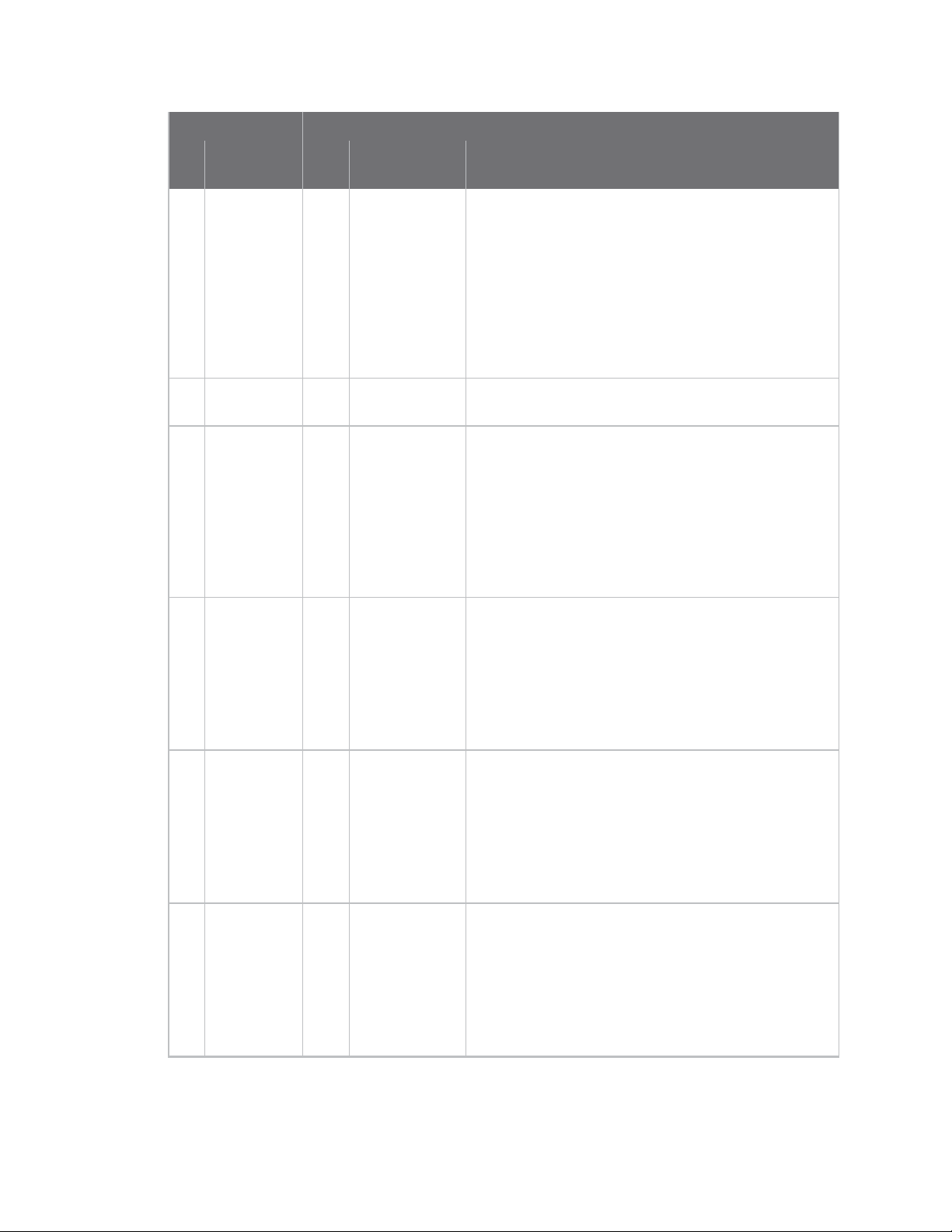

Some of the I/O supplies are set on the module. See the following table:

Power domain Connection

NVCC_GPIO VGEN_3V3

NVCC_JTAG VGEN_3V3

NVCC_NANDF VGEN_3V3

NVCC_SD1 VDD_WLAN_SD1

NVCC_SD2 VDD_SD2

NVCC_SD3 VGEN_3V3

PCIE_VPH 2.5V (VDDHIGH_CAP_2V5)

The remaining I/O voltages must be set externally and are left open on the ConnectCore 6 Plus

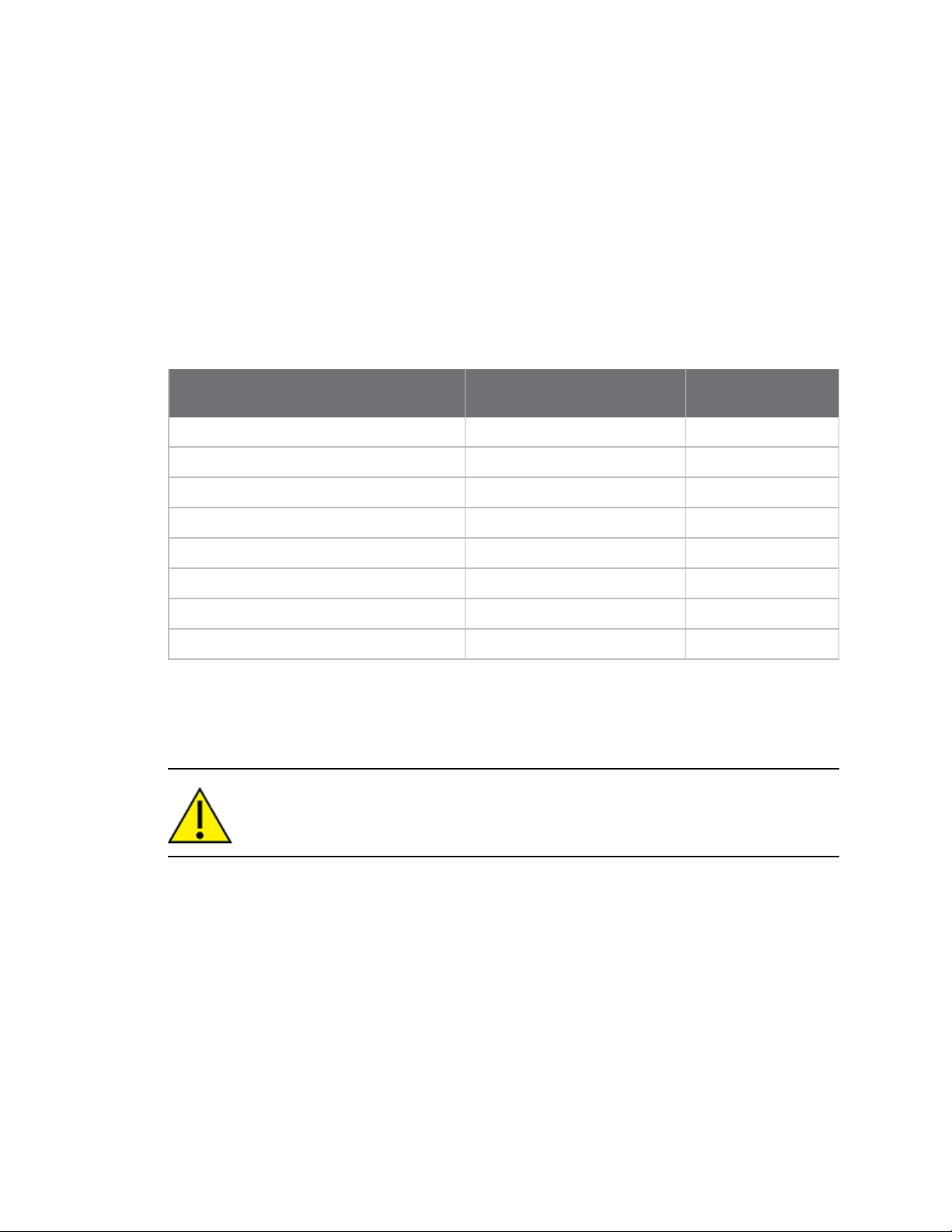

module. See the following table for operating ranges of the remaining I/O supplies.

Power domain Min Max

NVCC_ENET 1.65 V 3.6 V

ConnectCore 6 Plus Hardware Reference Manual

10

Page 11

About the ConnectCore 6 Plus Power supply architecture

Power domain Min Max

NVCC_EIM 1.65 V 3.6 V

NVCC_LCD 1.65 V 3.6 V

NVCC_CSI 1.65 V 3.6 V

NVCC_RGMII in HSIC 1.2 V mode 1.15 V 1.30 V

NVCC_RGMII in RGMII 1.5 V mode 1.43 V 1.58 V

NVCC_RGMII in RGMII 1.8 V mode 1.70 V 1.90 V

NVCC_RGMII in RGMII 2.5 V mode 2.25 V 2.625 V

As shown in the table above, the supplies have a wide operating range. In order to provide the most

cost-effective and flexible solution for a given use-case, the supplies listed in the table need to be

provided by the carrier board integrating the ConnectCore 6 Plus module. However, PMIC power

domains 3.3 V—and LDO2/3/4/6/8 options—are dedicated power sources for supplying i.MX6QP power

domains.

The MCU - assist specific power domain (VLDO3_MCA) available on the ConnectCore 6 Plus LGA pads is

a power supply output powering the on-module Kinetis processor.

ConnectCore 6 Plus Hardware Reference Manual

11

Page 12

About the ConnectCore 6 Plus Power supply architecture

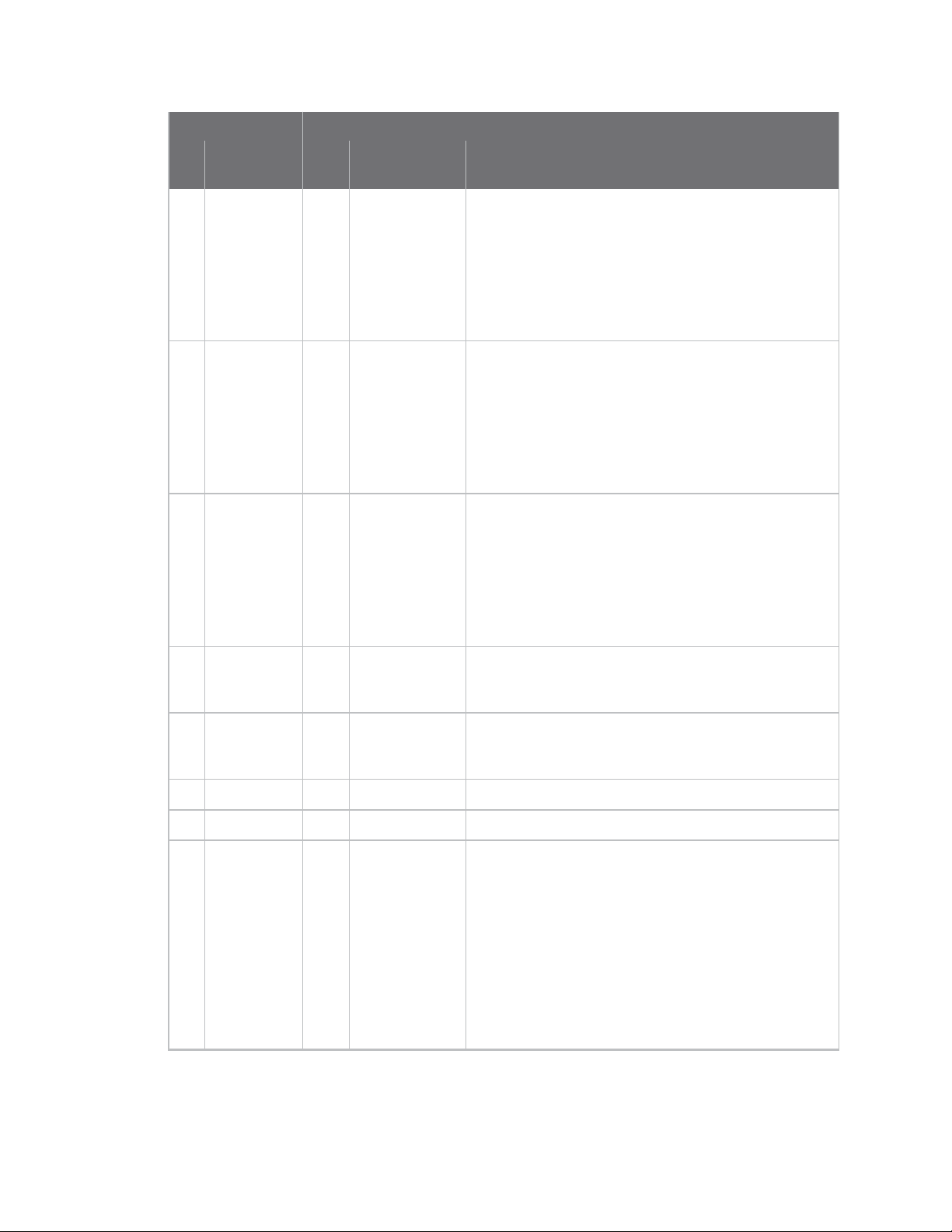

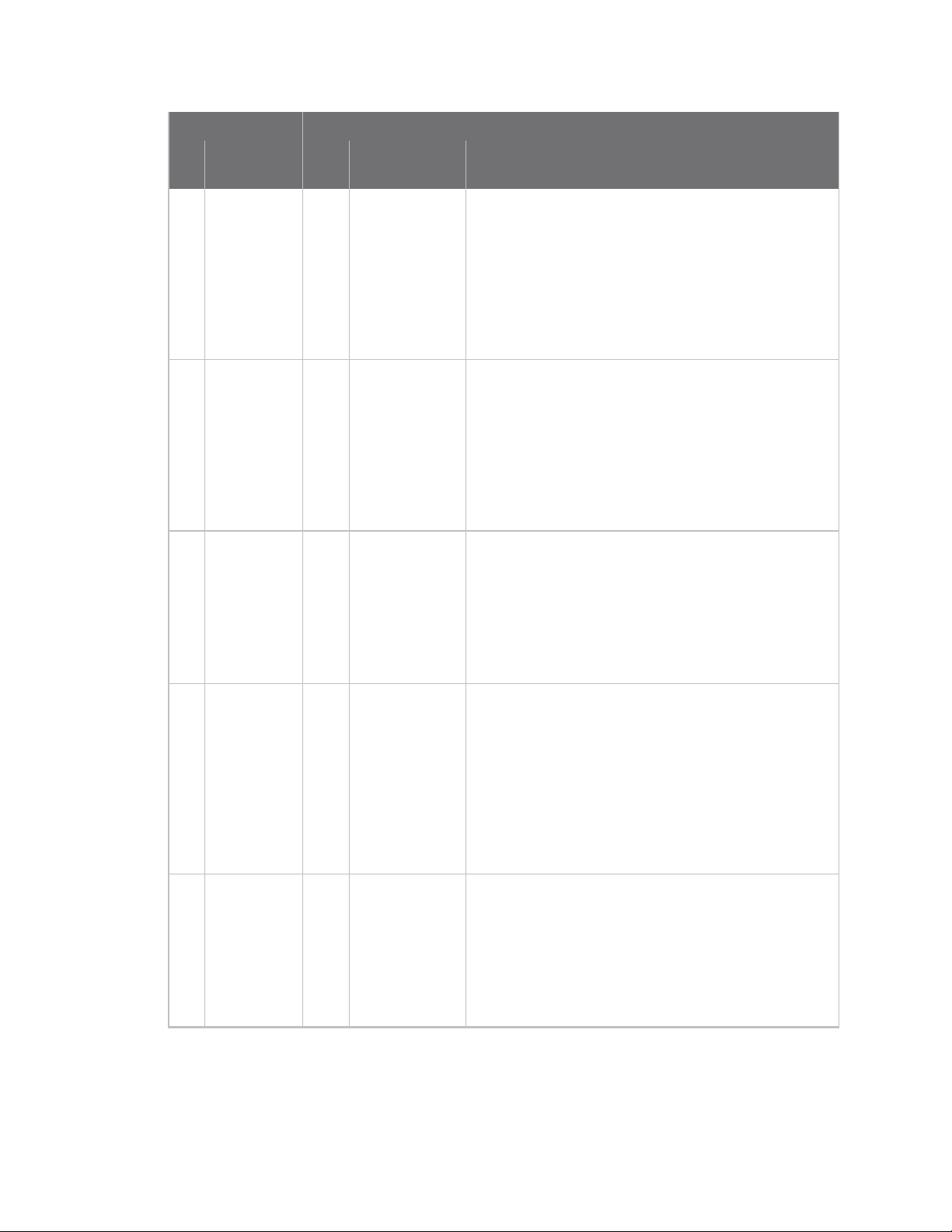

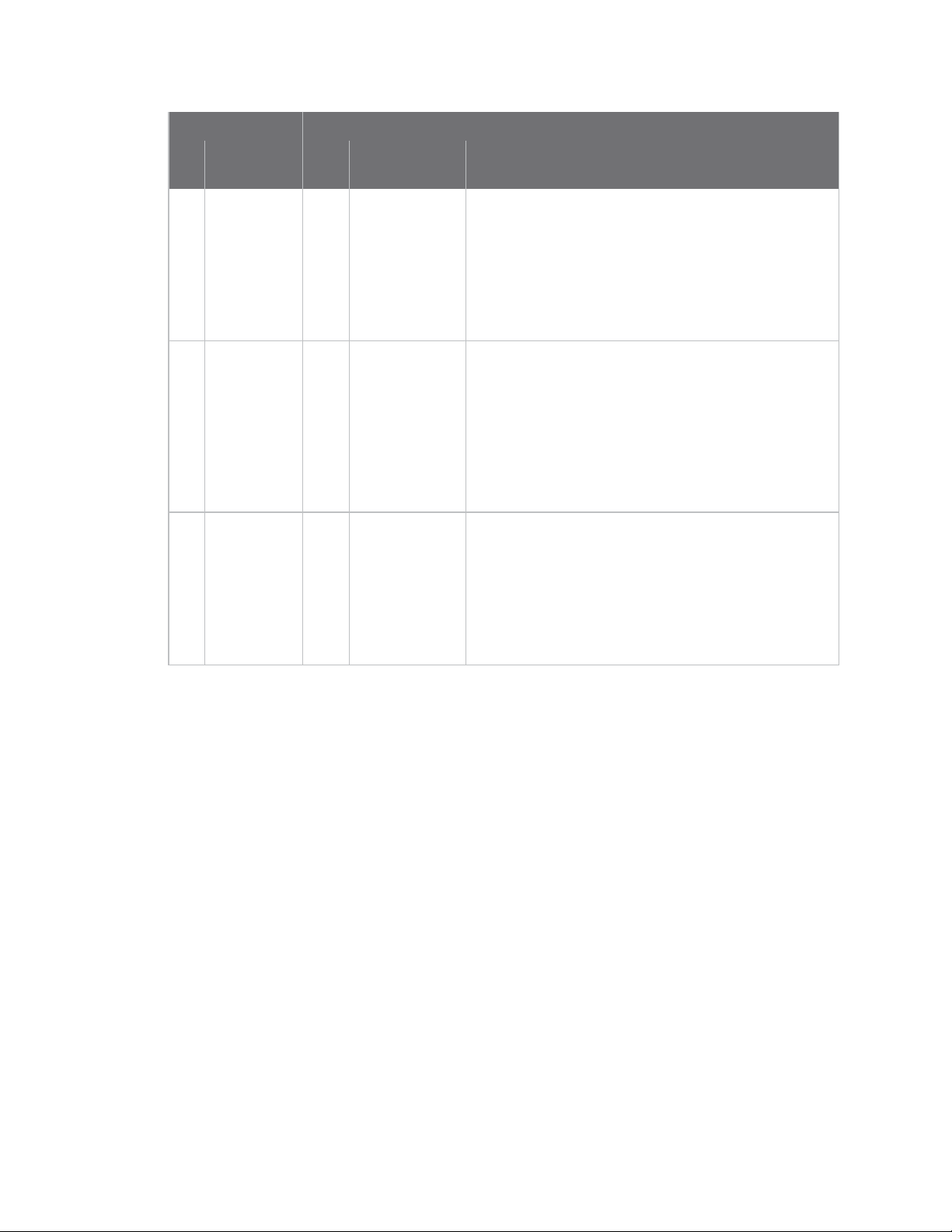

The following diagram outlines the power supply approach of the ConnectCore 6 Plus. Inputs are

marked red, blue marks are outputs.

ConnectCore 6 Plus Hardware Reference Manual

12

Page 13

About the ConnectCore 6 Plus Bootstrap

Bootstrap

The ConnectCore 6 Plus module can be configured to boot from different devices and interfaces

determined by the Boot ROM. The configuration of the CPU booting process is done through:

n BOOT_MODE register, which selects the boot mode of the processor

n eFUSEs and/or GPIOs, which determine the boot configuration

Four boot modes are available on the i.MX6QP processor. Selection between them is done through

BOOT_MODE[1:0] bits. The bits are externally configurable on two processor IOs, whose values are

latched during boot-up:

BOOT_MODE [1:0] Boot type

00 Boot from fuses

01 Serial downloader

10 Internal boot (default)

11 Reserved

BOOT_MODE[0] and BOOT_MODE[1] are available on dedicated pads on the module.

Note BOOT_MODE[1:0] is set internally to [10] through 10K pull-up and 10K pull-down resistors. So, by

default, the SOM is configured to Internal boot.

Boot from fuses

Boot from fuses is the recommended boot mode for production purposes. When this boot mode is

selected, you must configure several parameters in order to select and configure the system boot

device. These parameters are configured through fuses, which are burned in order to set their values.

This means that the configuration is irreversible.

BOOT_CFG1 register selects the boot device through BOOT_CFG1[7:4] bits:

BOOT_CFG1[7:4] Boot device

0000

0001 Reserved

1xxx Raw NAND

0010 SSD/Hard Disk (SATA)

010x SD/eSD/SDXC

0011 Serial ROM (I2C/SPI)

NOR/OneNAND (EIM)

011x MMC/eMMC

ConnectCore 6 Plus Hardware Reference Manual

13

Page 14

About the ConnectCore 6 Plus Wireless interfaces

There are many other registers that configure the different boot devices. For a complete description

of the booting configuration, refer to the NXP i.MX6QP Applications Processor Reference Manual

(Chapter 8: System Boot).

Internal Boot

Internal boot is the recommended boot mode for development purposes. When this boot mode is

selected, the selection and configuration of the booting process is done through the same registers

used when booting from fuses. However, this time the values of some registers are overridden using

multiple GPIOs—which are latched during power-up.

The following configuration is done internally in the ConnectCore 6 Plus module in order to enable

booting from the internal eMMC memory:

Default

Bootstrap register bit Corresponding GPIO

BOOT_CFG1[4] EIM_DA4 10K pull-down

BOOT_CFG1[5] EIM_DA5 10K pull-up

BOOT_CFG1[6] EIM_DA6 10K pull-up

configuration

BOOT_CFG1[7] EIM_DA7 10K pull-down

BOOT_CFG2[3] EIM_DA11 10K pull-up

BOOT_CFG2[4] EIM_DA12 10K pull-up

BOOT_CFG2[5] EIM_DA13 10K pull-down

BOOT_CFG2[6] EIM_DA14 10K pull-up

By default, the system is configured to boot from MMC/eMMC (BOOT_CFG1[7:5] = 011). You can

externally change the configuration of these lines to select between different boot devices. To see a

detailed implementation of the boot configuration, check the ConnectCore 6 Plus carrier board

reference design.

CAUTION! Make sure that EIM_EB3 (pad AA18) is not pulled high during boot. Pulling this

signal high enables an infinite loop at start of boot ROM. This feature is exclusively used

for debugging purposes.

Wireless interfaces

The ConnectCore 6 Plus system-on-module combines a wireless local area network (WLAN) and

Bluetooth dual solution to support IEEE802.11 a/b/g/n/ac WLAN standards and Bluetooth 4.2, enabling

seamless integration of WLAN/Bluetooth and Low Energy technology.

The following sections include specifications for the wireless interfaces available on the i.MX6QP

module.

ConnectCore 6 Plus Hardware Reference Manual

14

Page 15

About the ConnectCore 6 Plus Wireless interfaces

WLAN IEEE 802.11a/b/g/n/ac

The 2.4 GHz band on the ConnectCore 6 Plus module supports 20/40 MHz bandwidths, and the 5 GHz

band supports 20/40/80 MHz bandwidths.

The following sections specify the performance of the WLAN IEEE 802.11a/b/g/n/ac interface on the

ConnectCore 6 Plus module.

Modulation and data rates

The following tables list modulation values for ConnectCore 6 Plusmodule supports the following

WLAN standards.

Mode

802.11b DBPSK 1 Mbps

802.11ga BPSK-1/2 6 Mbps

802.11n BPSK-1/2 MCS0

Modulation & coding

DQPSK 2 Mbps

CCK 5.5 Mbps

CCK 11 Mbps

BPSK-3/4 9 Mbps

QPSK-1/2 12 Mbps

QPSK-3/4 18 Mbps

16QAM-1/2 24 Mbps

16QAM-3/4 36 Mbps

64QAM-2/3 48 Mbps

64QAM-3/4 54 Mbps

QPSK-1/2 MCS1

Rate

QPSK-3/4 MCS2

16QAM-1/2 MCS3

16QAM-3/4 MCS4

64QAM-2/3 MCS5

64QAM-3/4 MCS6

64QAM-5/6 MCS7

ConnectCore 6 Plus Hardware Reference Manual

15

Page 16

About the ConnectCore 6 Plus Wireless interfaces

Mode

802.11ac BPSK-1/2 MCS0

Modulation & coding

QPSK-1/2 MCS1

QPSK-3/4 MCS2

16QAM-1/2 MCS3

16QAM-3/4 MCS4

64QAM-2/3 MCS5

64QAM-3/4 MCS6

64QAM-5/6 MCS7

256QAM-3/4 MCS8

256QAM-5/6 MCS9

Rate

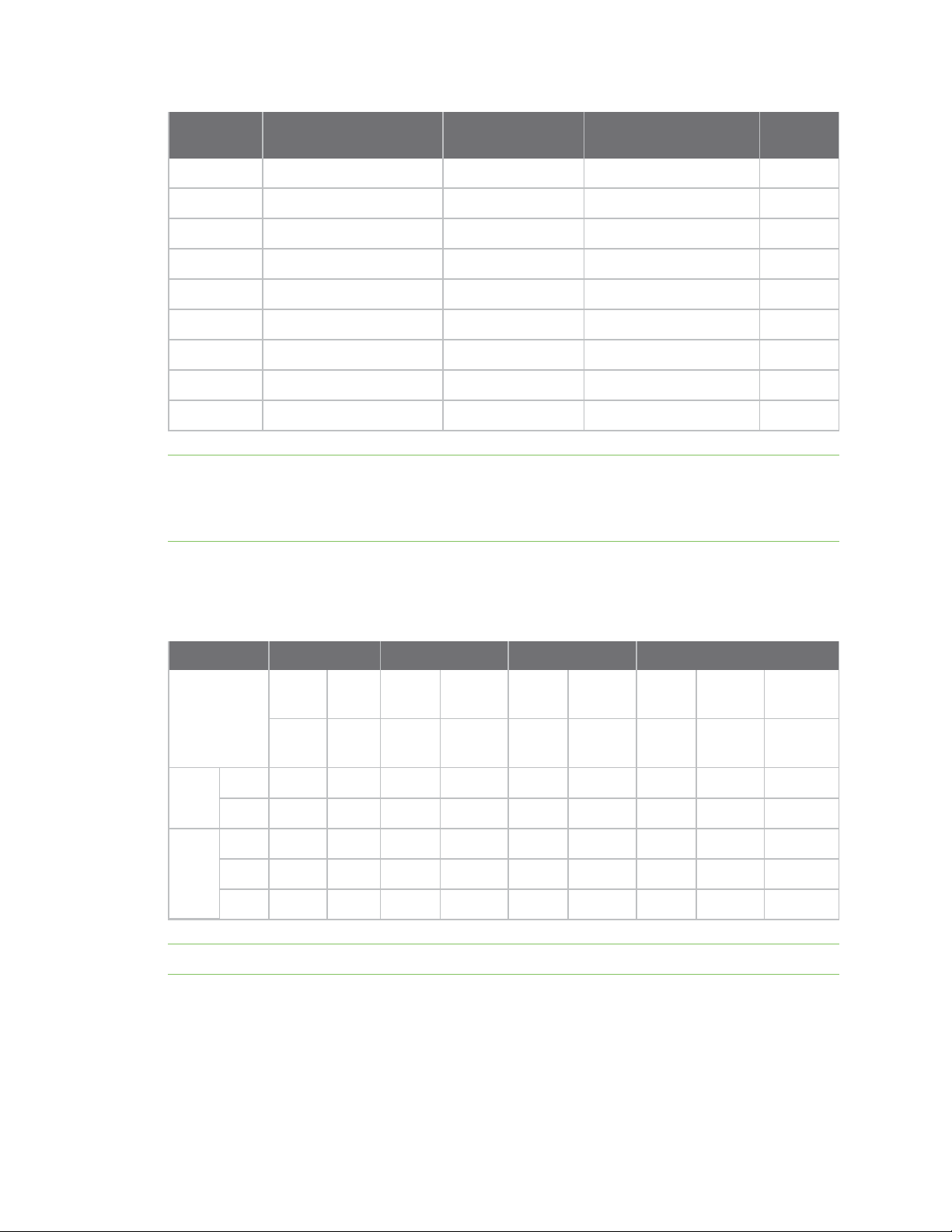

Data rate (Mbps) - Non Short Guard Interval (Non-SGI)

Data rate

(Mbps) 802.11b 802.11ga 802.11n 802.11ac

Modulation DBPSK CCK BPSK-

1/2

64QAM3/4

BPSK1/2

64QAM5/6

BPSK1/2

64QAM5/6

256QAM5/6

1

Mbps11Mbps6Mbps54Mbps

2.4

GHz

5 GHz HT20 6 54 6.5 65 6.5 65

HT20 1 11 6 54 6.5 65 6.5 65

HT40 13.5 135 13.5 135 180

HT40 13.5 135 13.5 135 180

HT80 29.3 292.5 390

MCS0 MCS7 MCS0 MCS7 MCS9

Data rate (Mbps) - Short Guard Interval (SGI)

Mode

Modulation DBPSK CCK BPSK-

2.4

GHz

HT20 1 11 6 54 7.2 72.2 7.2 72.2

HT40 15 150 15 150 200

802.11b 802.11ga 802.11n 802.11ac

64QAM-

1/2

1

Mbps11Mbps6Mbps54Mbps

3/4

BPSK1/2

MCS0 MCS7 MCS0 MCS7 MCS9

64QAM5/6

BPSK1/2

64QAM5/6

256QAM5/6

ConnectCore 6 Plus Hardware Reference Manual

16

Page 17

About the ConnectCore 6 Plus Wireless interfaces

Mode

5 GHz HT20 6 54 7.2 72.2 7.2 72.2

HT40 15 150 15 150 200

HT80 32.5 325 433.3

802.11b 802.11ga 802.11n 802.11ac

RF channels

The ConnectCore 6 Plus module supports the following frequency bands.

Ch.

RF band Ch. BW

2.4 GHz 20 MHz 5 MHz 1(2412), 2(2417), 3(2422), 4(2427), 5

40 MHz 5 MHz 3(2422), 11(2462)

5 GHz 20 MHz 20 MHz 36(5180), 40(5200), 44(5220), 48

spacing Channel number (Center freq. MHz)

(2432), 6(2437), 7(2442), 8(2447), 9

(2452), 10(2457), 11(2462), 12(2467),

13(2472), 14(2484)

(5240), 52(5260), 56(5280), 60(5300),

64(5320), 100(5500), 104(5520), 108

(5540), 112(5560), 116(5580), 120

(5600), 124(5620), 128(5640), 132

(5660), 136(5680), 140(5700), 144

(5720), 149(5745), 153(5765), 157

(5785), 161(5805), 165(5825)

40 MHz 40 MHz 38(5190), 46(5230), 54(5270), 62

(5310), 102(5510), 110(5550), 118

(5590), 126(5630), 134(5670), 142

(5710), 151(5755), 159(5795)

80 MHz 80 MHz 42(5210), 58(5290), 106(5530), 122

(5610), 138(5690), 155(5775)

Note See Regulatory information and certifications for further details about available RF channels and

their maximum transmit power.

2.4 GHz

2.4 GHz band

channel #

1 2412 ✔ ✔ ✔

2 2417 ✔ ✔ ✔

3 2422 ✔ ✔ ✔

Center frequency

(MHz)

EUROPE

(ETSI)

NORTH AMERICA

(FCC) JAPAN

ConnectCore 6 Plus Hardware Reference Manual

17

Page 18

About the ConnectCore 6 Plus Wireless interfaces

2.4 GHz band

channel #

4 2427 ✔ ✔ ✔

5 2432 ✔ ✔ ✔

6 2437 ✔ ✔ ✔

7 2442 ✔ ✔ ✔

8 2447 ✔ ✔ ✔

9 2452 ✔ ✔ ✔

10 2457 ✔ ✔ ✔

11 2462 ✔ ✔ ✔

12 2467 ✔ No ✔

13 2472 ✔ No ✔

14 2484 No No 802.11b only

Center frequency

(MHz)

EUROPE

(ETSI)

NORTH AMERICA

(FCC) JAPAN

5 GHz

5 GHz band

channel # Center frequency (MHz) EUROPE (ETSI) NORTH AMERICA (FCC) JAPAN

36 5180 Indoors ✔ ✔

40 5200 Indoors ✔ ✔

44 5220 Indoors ✔ ✔

48 5240 Indoors ✔ ✔

52 5260 Indoors / DFS / TPC DFS DFS / TPC

56 5280 Indoors / DFS / TPC DFS DFS / TPC

60 5300 Indoors / DFS / TPC DFS DFS / TPC

64 5320 Indoors / DFS / TPC DFS DFS / TPC

100 5500 DFS / TPC DFS DFS / TPC

104 5520 DFS / TPC DFS DFS / TPC

108 5540 DFS / TPC DFS DFS / TPC

112 5560 DFS / TPC DFS DFS / TPC

116 5580 DFS / TPC DFS DFS / TPC

120 5600 DFS / TPC No Access DFS / TPC

124 5620 DFS / TPC No Access DFS / TPC

ConnectCore 6 Plus Hardware Reference Manual

18

Page 19

About the ConnectCore 6 Plus Wireless interfaces

5 GHz band

channel # Center frequency (MHz) EUROPE (ETSI) NORTH AMERICA (FCC) JAPAN

128 5640 DFS / TPC No Access DFS / TPC

132 5660 DFS / TPC DFS DFS / TPC

136 5680 DFS / TPC DFS DFS / TPC

140 5700 DFS / TPC DFS DFS / TPC

149 5745 SRD ✔ No Access

153 5765 SRD ✔ No Access

157 5785 SRD ✔ No Access

161 5805 SRD ✔ No Access

165 5825 SRD ✔ No Access

Note

DFS = Dynamic Frequency Selection

TPC = Transmit Power Control

SRD = Short Range Devices 25 mW max power

Receive sensitivity

The following table lists typical receive sensitivity values for the ConnectCore 6 Plus module.

Mode 802.11b 802.11ga 802.11n 802.11ac

Modulation DBPSK CCK BPSK-

1/2

1

Mbps11Mbps

2.4

GHz

5 GHz HT20 - - -90 -75 -82 -64 -82 -64 -

Note Specification is subject to change.

HT20 -90 -88 -90 -75 -82 -64 -82 -64 -

HT40 - - - - -79 -61 -79 -61 -54

HT40 - - - - -79 -61 -79 -61 -54

HT80 - - - - - - -76 -58 -51

6 Mbps 54 Mbps MCS0 MCS7 MCS0 MCS7 MCS9

64QAM3/4

BPSK1/2

64QAM5/6

BPSK1/2

64QAM5/6

256QAM5/6

Transmit power

The following table lists nominal transmit power values for the ConnectCore 6 Plus module.

ConnectCore 6 Plus Hardware Reference Manual

19

Page 20

About the ConnectCore 6 Plus MCA hardware

RF Band Channel BW Standard Output Power (dBm)

2.4 GHz 20 MHz 802.11b 18 (1Mbps) - 18 (11Mbps)

20 MHz 802.11g 18 (6Mbps) - 16 (54Mbps)

20 MHz 802.11n 18 (MCS0) - 15 (MCS7)

40 MHz 802.11n 17 (MCS0) - 15 (MCS7)

40 MHz 802.11ac 17 (MCS0) - 13 (MCS9)

5 GHz 20 MHz 802.11a 13 (6Mbps) - 11 (54Mbps)

20 MHz 802.11n 13 (MCS0) - 10 (MCS7)

40 MHz 802.11n 12 (MCS0) - 9 (MCS7)

40 MHz 802.11ac 12 (MCS0) - 5 (MCS9)

80 MHz 802.11ac 11 (MCS0) - 4 (MCS9)

Note See Regulatory information and certifications for further details about available RF channels and

their maximum transmit power.

Note Due to manufacturing tolerance these nominal output powers may be reduced up to 3 dB.

Bluetooth

The ConnectCore 6 Plus module supports both Bluetooth and Bluetooth Low Energy protocols:

n Bluetooth 4.2; backwards compatible with Bluetooth 1.X, 2.X + Enhanced Data Rate, Bluetooth

3.X, Bluetooth 4.0 and Bluetooth 4.1 Bluetooth class 1 and class 2 power-level transmissions

n Integrated WLAN-Bluetooth coexistence

Note See Bluetooth SIG-qualified hardware and firmware for more information.

MCA hardware

Supported devices

The ConnectCore 6 Plus module is designed to support a Kinetis processor in a QFN48 package. See

below for a list of compatible Kinetis processors that can be used in this package size:

n MKL14Z32VFT4

n MKL14Z64VFT4

n MKL15Z128VFT4

n MKL15Z32VFT4

n MKL15Z64VFT4

n MKL24Z32VFT4

ConnectCore 6 Plus Hardware Reference Manual

20

Page 21

About the ConnectCore 6 Plus MCA hardware

n MKL24Z64VFT4

n MKL25Z128VFT4

n MKL25Z32VFT4

n MKL25Z64VFT4

n MKL26Z128VFT4

n MKL26Z64VFT4

n MKL26Z32VFT4

n K10P48M50SF0

n K20P48M50SF0

By default, NXP MKL14Z32VFT4 is populated on the module variants supporting the MCA unit.

ConnectCore 6 Plus Hardware Reference Manual

21

Page 22

About the ConnectCore 6 Plus MCA hardware

MCA pinout

The table below contains the pinouts for the MCA unit on ConnectCore 6 Plus module. The pinout

information assumes the use of NXP MKL14Z32VFT4 microcontroller. Using a different Kinetis

microcontroller may change the functions available on the MCA pins.

MCA ConnectCore 6 Plus

PinNrSignal

name

1 VDD - LDO3_MCA MCA power supply

2 VSS - GND MCA ground

3 ADC0_SE1

PTE16

SPI0_PCS0

UART2_TX

TPM_

CLKIN0

-

-

-

4 ADC0_SE5a

PTE17

SPI0_SCK

UART2_RX

TPM_

CLKIN1

LPTMR0_

ALT3

-

Pad

Nr Signal name Usage on module

1x 100nF + 1x1µF capacitors connected to GND are

placed close to this pin on ConnectCore 6 Plus SOM.

N20 MCA_IO/USB0_PNot used on module.

For KL24, KL25 and K20 processors, this pin is USB0_

DP.

MCA_IO/USB0_P (N20) and MCA_IO/USB0_N (P20)

have been routed as differential pair for supporting

USB functionality on KL24, KL25 and K20 processors.

P20 MCA_IO/USB0_NNot used on module.

For KL24, KL25 and K20 processors, this pin is USB0_

DN.

MCA_IO/USB0_P (N20) and MCA_IO/USB0_N (P20)

have been routed as differential pair for supporting

USB functionality on KL24, KL25 and K20 processors.

5 ADC0_SE2

PTE18

SPI0_MOSI

I2C0_SDA

SPI0_MISO

-

-

ConnectCore 6 Plus Hardware Reference Manual

Y22 MCA_IO27 Not used on module.

For KL24 and K20 processors, this pin is VOUT33.

ConnectCore 6 Plus SOM has a 0R resistor foreseen on

this pin for connecting this signal to LDO3_MCA. By

default, the resistor is not populated and MCA_IO27 is

available on module pad.

22

Page 23

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

6 ADC0_SE6a

PTE19

SPI0_MISO

I2C0_SCL

SPI0_MOSI

-

-

7 ADC0_SE0

PTE20

TPM1_CH0

UART0_TX

-

-

-

8 ADC0_SE4a

PTE21

TPM1_CH1

UART0_RX

-

-

-

Pad

Nr Signal name Usage on module

P21 MCA_IO14 Not used on module.

T23 MCA_IO0 Not used on module.

P23 MCA_IO1 Not used on module.

9 VDDA - LDO3_MCA MCA power supply

A 100 nF capacitor connected to GND is placed close to

this pin on ConnectCore 6 Plus SOM.

10 VREFH AC10 MCA_VREFH Not used on module.

A 100 nF capacitor connected to GND is placed close to

this pin on ConnectCore 6 Plus SOM.

11 VREFL - GND MCA ground

12 VSSA - GND MCA ground

13 CMP0_

IN5/ADC0_

SE4b

PTE29

TPM0_CH2

TPM_

CLKIN0

-

-

-

Y23 MCA_IO23 Not used on module.

ConnectCore 6 Plus Hardware Reference Manual

23

Page 24

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

14 ADC0_

SE23/CMP0_

IN4

PTE30

TPM0_CH3

TPM_

CLKIN1

-

-

-

15 -

PTE24

TPM0_CH0

I2C0_SCL

-

-

16 -

PTE25

TPM0_CH1

I2C0_SDA

-

-

Pad

Nr Signal name Usage on module

- - This MCA pin is connected to the gate of an N-channel

MOSFET. A 10K pull-down resistor is connected to GND

on this signal too. The drain of the MOSFET is

connected to ConnectCore 6 Plus signal ON/OFF (pad

D18). The source of the MOSFET is connected to GND.

This signal is reserved on the module and allows MCA

to control ON/OFF signal over software.

- KINETIS_32K This MCA pin is connected to 32K output of the PMIC.

It’s the clock input of the MCA processor.

AC21 MCA_IO28 Not used on module.

For K10 and K20 processors, this pin is VBAT.

ConnectCore 6 Plus SOM has a 0R resistor foreseen on

this pin for connecting this signal to LDO3_MCA. By

default, the resistor is not populated and MCA_IO28 is

available on module pad.

1x 100 nF + 1x1 µF capacitors connected to GND are

placed close to this pin on ConnectCore 6 Plus SOM.

17 -

18 -

L23 MCA_SWD_CLK Not used on module.

PTA0

TPM0_CH5

-

-

SWD_CLK

AA22 MCA_IO25 Not used on module.

PTA1

UART0_RX

TPM2_CH0

-

-

-

-

ConnectCore 6 Plus Hardware Reference Manual

24

Page 25

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

19 -

PTA2

UART0_TX

TPM2_CH1

-

-

-

-

20 -

PTA3

I2C1_SCL

TPM0_CH0

-

-

SWD_DIO

21 -

PTA4

I2C1_SDA

TPM0_CH1

-

-

NMI_b

Pad

Nr Signal name Usage on module

AA23 MCA_

IO6/PMIC_GP_

FB2

M23 MCA_SWD_DIO Not used on module.

AA21 MCA_IO26 Not used on module.

Connected on ConnectCore 6 Plus SOM to PMIC signal

GP_FB2.

22 VDD - LDO3_MCA MCA power supply

1x 100 nF + 1x1 µF capacitors connected to GND are

placed close to this pin on ConnectCore 6 Plus SOM.

23 VSS - GND MCA ground

24 EXTAL0

PTA18

UART1_RX

TPM_

CLKIN0

-

-

-

- PMIC_STBY_

REQ

Connected on ConnectCore 6 Plus SOM to i.MX6QP

processor signal PMIC_STBY_REQ (ball F11) and PMIC

signal SYS_EN/GPIO8 (ball B9).

ConnectCore 6 Plus Hardware Reference Manual

25

Page 26

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

25 XTAL0

PTA19

UART1_TX

TPM_

CLKIN1

LPTMR0_

ALT1

-

26 RESET_b

PTA20

27 ADC0_SE8

PTB0/LLWU_

P5

I2C0_SCL

TPM1_CH0

-

-

-

-

Pad

Nr Signal name Usage on module

T20 MCA_IO24 Not used on module.

N23 #MCA_RESET Not used on module.

R23 MCA_IO2 Not used on module.

28 ADC0_SE9

PTB1

I2C0_SDA

TPM1_CH1

-

-

-

-

29 ADC0_SE12

PTB2

I2C0_SCL

TPM2_CH0

-

-

-

-

30 ADC0_SE13

PTB3

I2C0_SDA

TPM2_CH1

-

-

-

-

H21 NANDF_

CS1/#MCA_INT

- INTERNAL_

I2C_SCL

- INTERNAL_

I2C_SDA

Connected to i.MX6QP processor signal NANDF_CS1

(ball C16).

Connected directly to PMIC I2C_SCL signal and to

i.MX6QP processor I2C2_SCL/KEY_COL3 signal (ball

U5) over N-channel MOSFET.

Connected directly to PMIC I2C_SDA signal and to

i.MX6QP processor I2C2_SDA/KEY_ROW3 signal (ball

T7) over N-channel MOSFET.

ConnectCore 6 Plus Hardware Reference Manual

26

Page 27

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

31 -

PTB16

SPI1_MOSI

UART0_RX

TPM_

CLKIN0

SPI1_MISO

-

-

32 -

PTB17

SPI1_MISO

UART0_TX

TPM_

CLKIN1

SPI1_MOSI

-

-

33 ADC0_SE14

PTC0

EXTRG_IN

CMP0_OUT

-

-

Pad

Nr Signal name Usage on module

N22 MCA_IO7 Not used on module.

P22 MCA_IO8 Not used on module.

U24 MCA_IO4 Not used on module.

34 ADC0_SE15

PTC1/LLWU_

P6/RTC_

CLKIN

I2C1_SCL

TPM0_CH0

-

-

-

35 ADC0_SE11

PTC2

I2C1_SDA

TPM0_CH1

-

-

-

- KINETIS_32K This MCA pin is connected to 32K output of the PMIC.

For KL14, KL15, KL24 and KL25 this pin can be

configured as RTC_CLKIN signal.

R22 MCA_IO9 Not used on module.

ConnectCore 6 Plus Hardware Reference Manual

27

Page 28

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

36 -

PTC3/LLWU_

P7

UART1_RX

TPM0_CH2

CLKOUT

-

-

37 -

PTC4/LLWU_

P8

SPI0_PCS0

UART1_TX

TPM0_CH3

-

-

-

38 -

PTC5/LLWU_

P9

SPI0_SCK

LPTMR0_

ALT2

-

CMP0_OUT

-

Pad

Nr Signal name Usage on module

T22 MCA_IO10 Not used on module.

U22 MCA_IO11 Not used on module.

M21 MCA_IO12 Not used on module.

39 CMP0_IN0

PTC6/LLWU_

P10

SPI0_MOSI

EXTRG_IN

SPI0_MISO

-

-

40 CMP0_IN1

PTC7

SPI0_MISO

-

SPI0_MOSI

-

-

N21 MCA_IO13 Not used on module.

R20 MCA_IO19 Not used on module.

ConnectCore 6 Plus Hardware Reference Manual

28

Page 29

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

41 -

PTD0

SPI0_PCS0

TPM0_CH0

-

-

-

42 ADC0_SE5b

PTD1

SPI0_SCK

TPM0_CH1

-

-

-

43 -

PTD2

SPI0_MOSI

UART2_RX

TPM0_CH2

SPI0_MISO

-

-

Pad

Nr Signal name Usage on module

A6 CSI0_

DAT11/ECSPI2_

SS0

D6 CSI0_

DAT8/ECSPI2_

SCLK

K5 CSI0_

DAT10/ECSPI2_

MISO

Connected to i.MX6QP processor signal CSI0_DAT11

(ball M3) and to LGA pad A6.

This pin can be configured as a SPI chip select shared

between MCA and i.MX6QP processor.

Connected to i.MX6QP processor signal CSI0_DAT8

(ball N6) and to LGA pad D6.

This pin can be configured as a SPI clock shared

between MCA and i.MX6QP processor.

Connected to i.MX6QP processor signal CSI0_DAT10

(ball M1) and to LGA pad K5.

This pin can be configured as a SPI MISO shared

between MCA and i.MX6QP processor.

44 -

45 -

PTD3

SPI0_MISO

UART2_TX

TPM0_CH3

SPI0_MOSI

-

-

PTD4/LLWU_

P14

SPI1_PCS0

UART2_RX

TPM0_CH4

-

-

-

D5 CSI0_

DAT9/ECSPI2_

MOSI

R21 MCA_IO16 Not used on module.

Connected to i.MX6QP processor signal CSI0_DAT9

(ball N5) and to LGA pad D5.

This pin can be configured as a SPI MOSI shared

between MCA and i.MX6QP processor.

ConnectCore 6 Plus Hardware Reference Manual

29

Page 30

About the ConnectCore 6 Plus MCA hardware

MCA ConnectCore 6 Plus

PinNrSignal

name

46 ADC0_SE6b

PTD5

SPI1_SCK

UART2_TX

TPM0_CH5

-

-

-

47 ADC0_SE7b

PTD6/LLWU_

P15

SPI1_MOSI

UART0_RX

SPI1_MISO

-

-

48 -

PTD7

SPI1_MISO

UART0_TX

SPI1_MOSI

-

-

Pad

Nr Signal name Usage on module

T21 MCA_IO22 Not used on module.

T24 MCA_IO3 Not used on module.

AA20 MCA_IO21 Not used on module.

The i.MX6QP pads listed above are connected to ConnectCore 6 Plus pads. If the MCA microcontroller

firmware doesn’t use these signals, they are available on the carrier board and can be used in any of

the alternative functions listed above.

ConnectCore 6 Plus Hardware Reference Manual

30

Page 31

About the ConnectCore 6 Plus MCA hardware

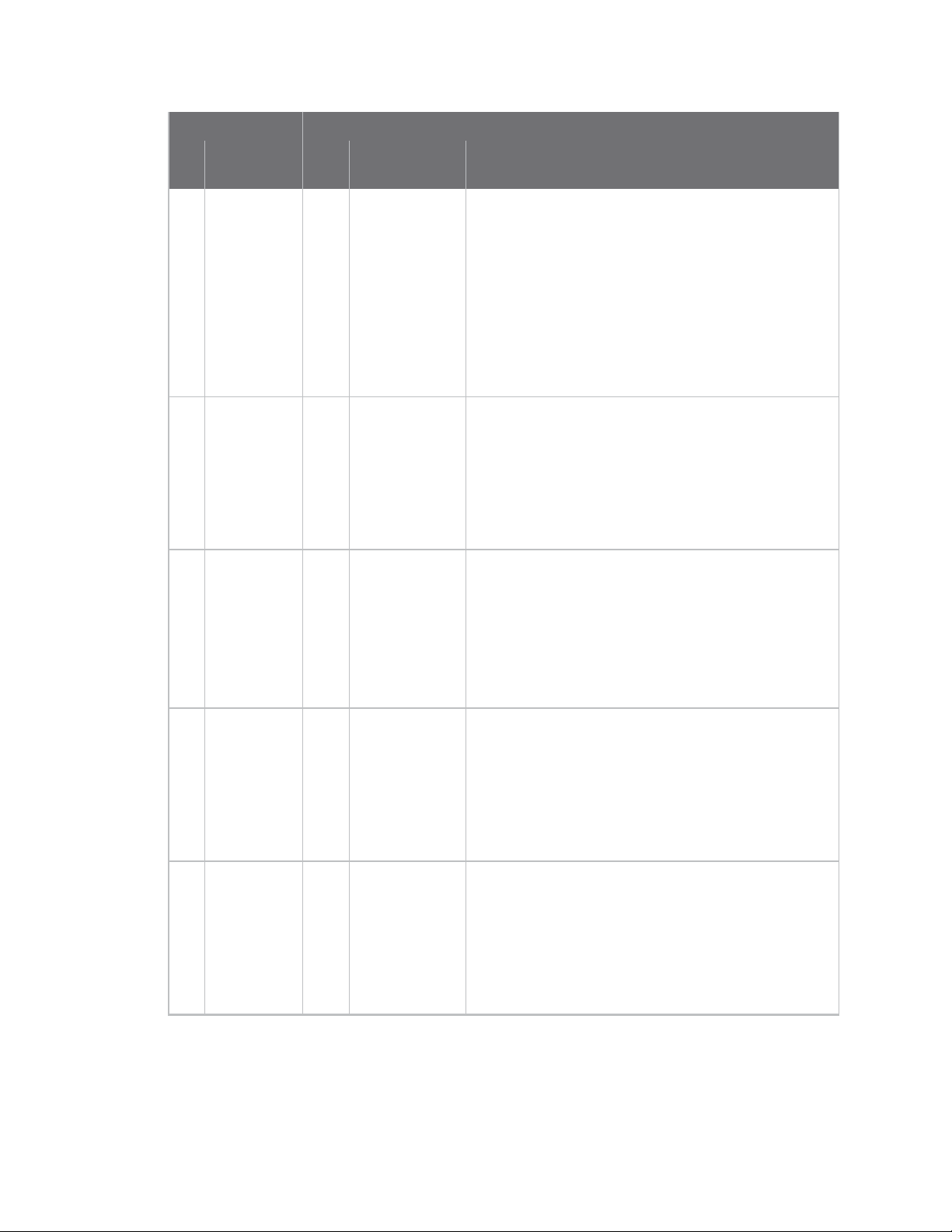

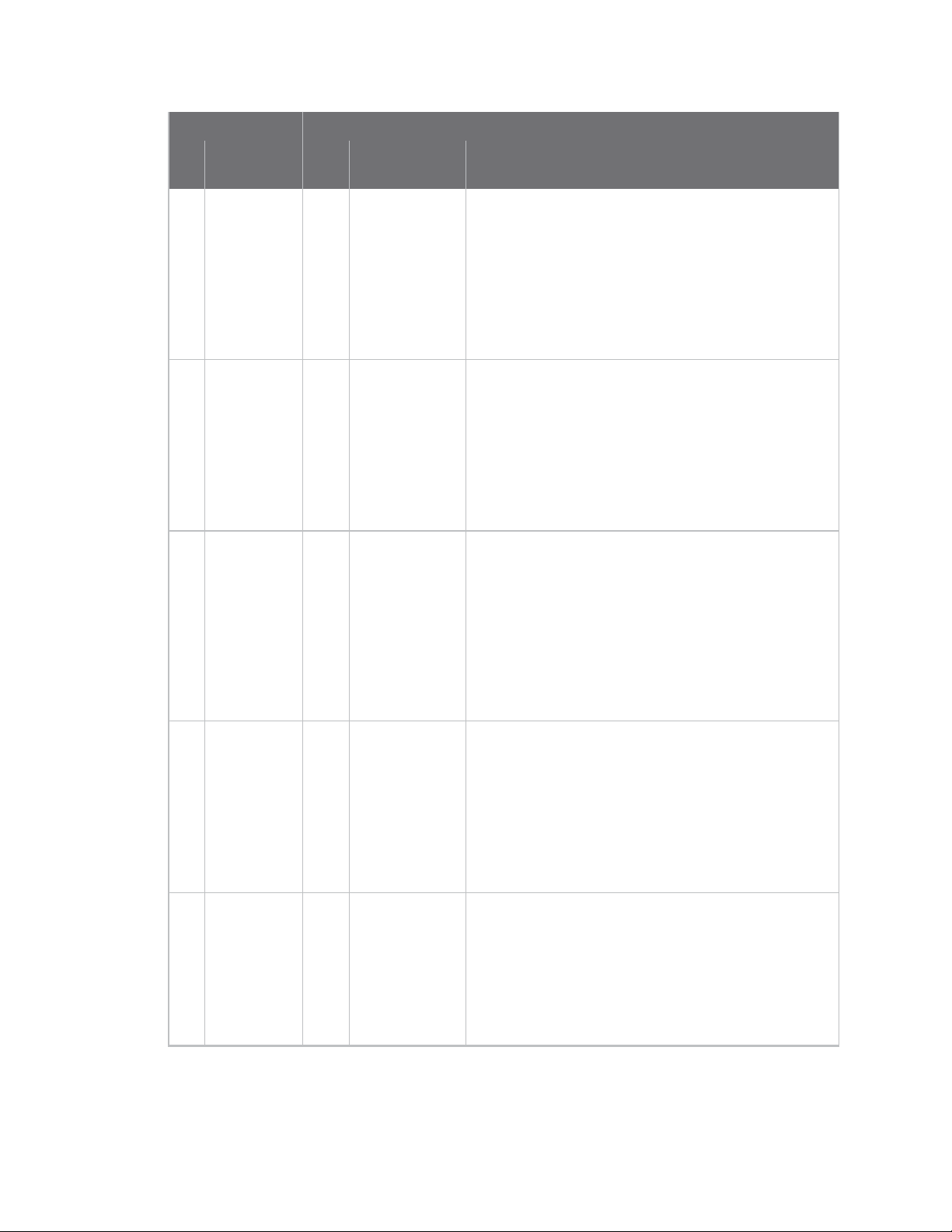

Shared I2C bus

The screenshot below shows how the I2C bus (I2C2) is used on ConnectCore 6 Plus module. The bus is

shared between i.MX6QP processor and the PMIC, the MCA, and the cryptochip. The usage of Nchannel MOSFET ensures the bus is fully isolated and allows the i.MX6QP processor to be shut off

while MCA and PMIC are powered.

ConnectCore 6 Plus Hardware Reference Manual

31

Page 32

About the ConnectCore 6 Plus MCA hardware

Shared SPI bus

In addition to an I2C interface, i.MX6QP shares an SPI bus with the MCA microcontroller. The table

below shows this connection:

SPI function i.MX6QP pad MCA I/O

SPI Chip Select CSI0_DAT11 (ConnectCore 6 Plus LGA pad

A6):

Alt0: IPU1_CSI0_DATA11

Alt1: AUD3_RXFS

Alt2: ECSPI2_SS0

Alt3: UART1_RX_DATA

Alt4: Alt5: GPIO6_IO03

Alt6: Alt7: ARM_TRACE14

SPI Clock CSI0_DAT8 (ConnectCore 6 Plus LGA pad D6):

Alt0: IPU1_CSI0_DATA08

Alt1: EIM_DATA06

Alt2: ECSPI2_SCLK

Alt3: KEY_COL7

Alt4: I2C1_SDA

Alt5: GPIO5_IO26

Alt6: Alt7: ARM_TRACE05

SPI MISO CSI0_DAT10 (ConnectCore 6 Plus LGA pad

K5):

Alt0: IPU1_CSI0_DATA10

Alt1: AUD3_RXC

Alt2: ECSPI2_MISO

Alt3: UART1_TX_DATA

Alt4: Alt5: GPIO5_IO28

Alt6: Alt7: ARM_TRACE07

PTD0 (MCA pin 41):|

Alt0: Alt1: PTD0

Alt2: SPI0_PCS0

Alt3: Alt4: Alt5: TPM0_CH0

Alt6: Alt7: -

PTD1 (MCA pin 42):

Alt0: ADC0_SE5b

Alt1: PTD1

Alt2: SPI0_SCK

Alt3: Alt4: TPM0_CH1

Alt5: Alt6: Alt7: -

PTD2 (MCA pin 43):

Alt0: Alt1: PTD2

Alt2: SPI0_MOSI

Alt3: UART2_RX

Alt4: TPM0_CH2

Alt5: SPI0_MISO

Alt6: Alt7: -

SPI MOSI CSI0_DAT9 (ConnectCore 6 Plus LGA pad D5):

Alt0: IPU1_CSI0_DATA09

Alt1: EIM_DATA07

Alt2: ECSPI2_MOSI

Alt3: KEY_ROW7

Alt4: I2C1_SCL

Alt5: GPIO5_IO27

Alt6: Alt7: ARM_TRACE06

ConnectCore 6 Plus Hardware Reference Manual

PTD3 (MCA pin 44):

Alt0: Alt1: PTD3

Alt2: SPI0_MISO

Alt3: UART2_TX

Alt4: TPM0_CH3

Alt5: SPI0_MOSI

Alt6: Alt7: -

32

Page 33

About the ConnectCore 6 Plus CryptoAuthentication device

CryptoAuthentication device

The ConnectCore 6 Plus includes an Atmel CryptoAuthentication Device. This is a highly secure

cryptographic co-processor with secure hardware-based key storage. It includes the following

features:

n Performs high-speed public key (PKI) algorithms (ECDSA and ECDH).

n NIST standard P256 elliptic curve support.

n SHA-256 hash algorithm with HMAC option.

n 256-bit key length.

n Storage for up to 16 keys.

n Two high-endurance monotonic counters.

n Guaranteed unique 72-bit serial number.

n Internal High-quality FIPS Random Number Generator (RNG).

n 10 Kb EEPROM memory.

See the software documentation for information about supported cryptoauthentication features.

ConnectCore 6 Plus Hardware Reference Manual

33

Page 34

About the ConnectCore 6 Plus Module pinout

Module pinout

The module has a LGA pad structure based on 400 pads. See the following diagram for the general

layout, which shows the top view of the module pinouts.

The following table provides the pinout of the ConnectCore 6 Plus module.

Additional timing and electrical information can be found in either NXP i.MX6QP processor datasheet

(www.nxp.com) or in Dialog DA9063 product datasheet (www.dialog-semiconductor.com).

LGA

pad Pad name Multiplexing Power group Comments

A5 CSI0_MCLK ALT0: IPU1_CSI0_HSYNC

ALT1:

ALT2:

ALT3: CCM_CLKO1

ALT4:

ALT5: GPIO5_IO19

ALT6:

ALT7: ARM_TRACE_CTL

NVCC_CSI

ConnectCore 6 Plus Hardware Reference Manual

34

Page 35

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

A6 CSI0_DAT11 ALT0: IPU1_CSI0_DATA11

ALT1: AUD3_RXFS

ALT2: ECSPI2_SS0

ALT3: UART1_RX_DATA

ALT4:

ALT5: GPIO5_IO29

ALT6:

ALT7: ARM_TRACE08

A7 CSI0_DAT17 ALT0: IPU1_CSI0_DATA17

ALT1: EIM_DATA13

ALT2:

ALT3: UART4_CTS_B

ALT4:

ALT5: GPIO6_IO03

ALT6:

ALT7: ARM_TRACE14

A8 GND -

A9 HDMI_D0_N HDMI_VPH

A10 GND -

A11 CSI_CLK0_P NVCC_MIPI

A12 GND -

NVCC_CSI Connected to the

NVCC_CSI

on-module MCA

microcontroller.

A13 CSI_D1_N NVCC_MIPI

A14 PCIE_RX_N PCIE_VPH

A15 PCIE_TX_N PCIE_VPH

A16 CLK2_P VDD_HIGH_CAP

A17 GND -

A18 CLK1_P VDD_HIGH_CAP

A19 MLB_DP VDD_HIGH_CAP

A20 MLB_DN VDD_HIGH_CAP

B4 LVDS0_TX2_P NVCC_LVDS_2P5

B5 GND -

B6 CSI0_DAT14 ALT0: IPU1_CSI0_DATA14

ALT1: EIM_DATA10

ALT2:

ALT3: UART5_TX_DATA

ALT4:

ALT5: GPIO6_IO00

ALT6:

ALT7: ARM_TRACE11

NVCC_CSI

ConnectCore 6 Plus Hardware Reference Manual

35

Page 36

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

B7 CSI0_DAT4 ALT0: IPU1_CSI0_DATA04

ALT1: EIM_DATA02

ALT2: ECSPI1_SCLK

ALT3: KEY_COL5

ALT4: AUD3_TXC

ALT5: GPIO5_IO22

ALT6:

ALT7: ARM_TRACE01

B8 HDMI_D1_N HDMI_VPH

B9 HDMI_D0_P HDMI_VPH

B10 DSI_D0_P NVCC_MIPI

B11 CSI_CLK0_N NVCC_MIPI

B12 CSI_D2_N NVCC_MIPI

B13 CSI_D1_P NVCC_MIPI

B14 PCIE_RX_P PCIE_VPH

B15 PCIE_TX_P PCIE_VPH

B16 CLK2_N VDD_HIGH_CAP

B17 GND -

NVCC_CSI

B18 CLK1_N VDD_HIGH_CAP

B19 GND -

B20 GND -

B21

C3 KEY_COL3

C4 LVDS0_TX2_N NVCC_LVDS_2P5

SD3_CLK/

BT_UART_RTS

ALT0: SD3_CLK

ALT1: UART2_RTS_B

ALT2: FLEXCAN1_RX

ALT3:

ALT4:

ALT5: GPIO7_IO03

ALT6:

ALT7:

ALT0: ECSPI1_SS3

ALT1: ENET_CRS

ALT2: HDMI_TX_DDC_SCL

ALT3: KEY_COL3

ALT4: I2C2_SCL

ALT5: GPIO4_IO12

ALT6: SPDIF_IN

ALT7:

VGEN_3V3 Signal only

VGEN_3V3

available

externally in nonwireless variants

of the SOM.

Connected to MCA

processor and

PMIC. Not

recommended as

main I2C port.

4,7K pull-up on

module.

ConnectCore 6 Plus Hardware Reference Manual

36

Page 37

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

C5 CSI0_DAT6 ALT0: IPU1_CSI0_DATA06

ALT1: EIM_DATA04

ALT2: ECSPI1_MISO

ALT3: KEY_COL6

ALT4: AUD3_TXFS

ALT5: GPIO5_IO24

ALT6:

ALT7: ARM_TRACE03

C6 CSI0_DAT13 ALT0: IPU1_CSI0_DATA13

ALT1: EIM_DATA09

ALT2:

ALT3: UART4_RX_DATA

ALT4:

ALT5: GPIO5_IO31

ALT6:

ALT7: ARM_TRACE10

C7 CSI0_DAT5 ALT0: IPU1_CSI0_DATA05

ALT1: EIM_DATA03

ALT2: ECSPI1_MOSI

ALT3: KEY_ROW5

ALT4: AUD3_TXD

ALT5: GPIO5_IO23

ALT6:

ALT7: ARM_TRACE02

NVCC_CSI

NVCC_CSI

NVCC_CSI

C8 HDMI_D1_P HDMI_VPH

C9 GND -

C10 DSI_D0_N NVCC_MIPI

C11 GND -

C12 CSI_D2_P NVCC_MIPI

C13 GND -

C14 GND -

C15 GND -

C16 USB_H1_DN VDD_USB_CAP

C17 TAMPER VDD_SNVS_IN

C18 PCM_IN VGEN_3V3

C19 MLB_SP VDD_HIGH_CAP

C20 MLB_SN VDD_HIGH_CAP

ConnectCore 6 Plus Hardware Reference Manual

37

Page 38

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

C21 SD3_DAT7

C22

D2 KEY_ROW4

SD3_DAT4/

BT_UART_RXD

ALT0: SD3_DATA7

ALT1: UART1_TX_DATA

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO17

ALT6:

ALT7:

ALT0: SD3_DATA4

ALT1: UART2_RX_DATA

ALT2:

ALT3:

ALT4:

ALT5: GPIO7_IO01

ALT6:

ALT7:

ALT0: FLEXCAN2_RX

ALT1: IPU1_SISG5

ALT2: USB_OTG_PWR

ALT3: KEY_ROW4

ALT4: UART5_CTS_B

ALT5: GPIO4_IO15

ALT6:

ALT7:

VGEN_3V3

VGEN_3V3 Signal only

available

externally in nonwireless variants

of the SOM.

VGEN_3V3

D3 KEY_ROW1

D4 GND -

D5 CSI0_DAT9 ALT0: IPU1_CSI0_DATA09

ALT0: ECSPI1_SS0

ALT1: ENET_COL

ALT2: AUD5_RXD

ALT3: KEY_ROW1

ALT4: UART5_RX_DATA

ALT5: GPIO4_IO09

ALT6: SD2_VSELECT

ALT7:

ALT1: EIM_DATA07

ALT2: ECSPI2_MOSI

ALT3: KEY_ROW7

ALT4: I2C1_SCL

ALT5: GPIO5_IO27

ALT6:

ALT7: ARM_TRACE06

VGEN_3V3

NVCC_CSI Connected to the

on-module MCA

microcontroller.

ConnectCore 6 Plus Hardware Reference Manual

38

Page 39

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

D6 CSI0_DAT8 ALT0: IPU1_CSI0_DATA08

ALT1: EIM_DATA06

ALT2: ECSPI2_SCLK

ALT3: KEY_COL7

ALT4: I2C1_SDA

ALT5: GPIO5_IO26

ALT6:

ALT7: ARM_TRACE05

D7 HDMI_DDCCEC HDMI_VPH

D8 GND -

D9 DSI_D1_P NVCC_MIPI

D10 GND -

D11 CSI_D3_P NVCC_MIPI

D12 PCM_OUT VGEN_3V3

D13 #BT_DISABLE WLAN/BT_3V3

D14 JTAG_TDI VGEN_3V3

D15 #JTAG_TRST VGEN_3V3

D16 USB_H1_DP VDD_USB_CAP

NVCC_CSI Connected to the

on-module MCA

microcontroller.

D17 TEST_MODE VDD_SNVS_IN 10K pull-down on

module.

D18 ON/OFF VDD_SNVS_IN Input power on/off

line of the module

(active-low).

D19 SATA_TX_N SATA_VPH

D20 GND -

D21 SD3_DAT1

ALT0: SD3_DATA1

ALT1: UART1_RTS_B

ALT2: FLEXCAN2_RX

ALT3:

ALT4:

ALT5: GPIO7_IO05

ALT6:

ALT7:

VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

39

Page 40

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

D22 SD3_RST

D23

E1 LVDS1_CLK_N NVCC_LVDS_2P5

E2 KEY_ROW0

SD3_DAT5/

BT_UART_TXD

ALT0: SD3_RESET

ALT1: UART3_RTS_B

ALT2:

ALT3:

ALT4:

ALT5: GPIO7_IO08

ALT6:

ALT7:

ALT0: SD3_DATA5

ALT1: UART2_TX_DATA

ALT2:

ALT3:

ALT4:

ALT5: GPIO7_IO00

ALT6:

ALT7:

ALT0: ECSPI1_MOSI

ALT1: ENET_TX_DATA3

ALT2: AUD5_TXD

ALT3: KEY_ROW0

ALT4: UART4_RX_DATA

ALT5: GPIO4_IO07

ALT6: DCIC2_OUT

ALT7:

VGEN_3V3

VGEN_3V3 Signal only

VGEN_3V3

available

externally in nonwireless variants

of the SOM.

E3 KEY_COL1

E4 LVDS0_TX1_P NVCC_LVDS_2P5

E5 CSI0_DATA_EN ALT0: IPU1_CSI0_DATA_

ALT0: ECSPI1_MISO

ALT1: ENET_MDIO

ALT2: AUD5_TXFS

ALT3: KEY_COL1

ALT4: UART5_TX_DATA

ALT5: GPIO4_IO08

ALT6: SD1_VSELECT

ALT7:

EN

ALT1: EIM_DATA00

ALT2:

ALT3:

ALT4:

ALT5: GPIO5_IO20

ALT6:

ALT7: ARM_TRACE_CLK

VGEN_3V3

NVCC_CSI

ConnectCore 6 Plus Hardware Reference Manual

40

Page 41

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

E6 CSI0_DAT15 ALT0: IPU1_CSI0_DATA15

ALT1: EIM_DATA11

ALT2:

ALT3: UART5_RX_DATA

ALT4:

ALT5: GPIO6_IO01

ALT6:

ALT7: ARM_TRACE12

E7 GND -

E8 HDMI_CLK_N HDMI_VPH

E9 DSI_D1_N NVCC_MIPI

E10 DSI_CLK0_N NVCC_MIPI

E11 CSI_D3_N NVCC_MIPI

E12 PCM_SYNC VGEN_3V3

E13 PCM_CLK VGEN_3V3

E14 JTAG_TDO VGEN_3V3

E15 Reserved -

E16 GND -

NVCC_CSI

E17 BOOT_MODE0 VDD_SNVS_IN 10K pull-down on

module.

ConnectCore 6 Plus Hardware Reference Manual

41

Page 42

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

E18 #POR VDD_SNVS_IN Active low, bi-

directional line

which is also

driven by the PMIC

in an open-drain

output

configuration. It

can be used as

either input or

output:

n Input:

asserting

this line

resets the

module

CPU (only

the CPU).

E19 SATA_TX_P SATA_VPH

E20 VGEN_3V3 VGEN_3V3

VGEN_3V3

E21 SD3_DAT6

ALT0: SD3_DATA6

VGEN_3V3

ALT1: UART1_RX_DATA

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO18

ALT6:

ALT7:

n Output: line

asserted

during

reset. Can

be used to

synchronize

external

circuitry

reset.

ConnectCore 6 Plus Hardware Reference Manual

42

Page 43

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

E22

E23

E24 SD3_DAT2

NANDF_CLE/

BT_WAKE

SD3_CMD/

BT_UART_CTS

ALT0: NAND_CLE

ALT1: IPU2_SISG4

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO07

ALT6:

ALT7:

ALT0: SD3_CMD

ALT1: UART2_CTS_B

ALT2: FLEXCAN1_TX

ALT3:

ALT4:

ALT5: GPIO7_IO02

ALT6:

ALT7:

ALT0: SD3_DATA2

ALT1:

ALT2:

ALT3:

ALT4:

ALT5: GPIO7_IO06

ALT6:

ALT7:

VGEN_3V3 Signal only

available

externally in nonwireless variants

of the SOM.

VGEN_3V3 Signal only

available

externally in nonwireless variants

of the SOM.

VGEN_3V3

F1 LVDS1_CLK_P NVCC_LVDS_2P5

F2 KEY_ROW3

F3 GPIO_8

F4 LVDS0_TX1_N NVCC_LVDS_2P5

F5 GND -

ALT0:

ALT1: ASRC_EXT_CLK

ALT2: HDMI_TX_DDC_SDA

ALT3: KEY_ROW3

ALT4: I2C2_SDA

ALT5: GPIO4_IO13

ALT6: SD1_VSELECT

ALT7:

ALT0: ESAI_TX5_RX0

ALT1: XTALOSC_REF_

CLK_32K

ALT2: EPIT2_OUT

ALT3: FLEXCAN1_RX

ALT4: UART2_RX_DATA

ALT5: GPIO1_IO08

ALT6: SPDIF_SR_CLK

ALT7: USB_OTG_PWR_

CTL_WAKE

VGEN_3V3 Connected to MCA

VGEN_3V3

processor and

PMIC. Not

recommended as

main I2C port.

4,7K pull-up on

module.

ConnectCore 6 Plus Hardware Reference Manual

43

Page 44

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

F6 CSI0_DAT18 ALT0: IPU1_CSI0_DATA18

ALT1: EIM_DATA14

ALT2:

ALT3: UART5_RTS_B

ALT4:

ALT5: GPIO6_IO04

ALT6:

ALT7: ARM_TRACE15

F7 HDMI_D2_N HDMI_VPH

F8 HDMI_CLK_P HDMI_VPH

F9 GND -

F10 DSI_CLK0_P NVCC_MIPI

F11 GND -

F12 GND -

F13 JTAG_TCK VGEN_3V3

F14 JTAG_TMS VGEN_3V3

F15 BOOT_MODE1 VDD_SNVS_IN 10K pull-up to

NVCC_CSI

VDD_SNVS_IN on

module.

F16 USB_H1_VBUS -

F17 MLB_CP -

F18 MLB_CN -

F19 GND -

F20 SD3_DAT0 ALT0: SD3_DATA0

ALT1: UART1_CTS_B

ALT2: FLEXCAN2_TX

ALT3:

ALT4:

ALT5: GPIO7_IO04

ALT6:

ALT7:

F21 NANDF_CS0 ALT0: NAND_CE0_B

ALT1:

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO11

ALT6:

ALT7:

VGEN_3V3

VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

44

Page 45

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

F22 #NANDF_WP ALT0: NAND_WP_B

ALT1: IPU2_SISG5

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO09

ALT6:

ALT7:

F23 NANDF_CS3 ALT0: NAND_CE3_B

ALT1: IPU1_SISG1

ALT2: ESAI_TX1

ALT3: EIM_ADDR26

ALT4:

ALT5: GPIO6_IO16

ALT6: IPU2_SISG1

ALT7:

F24 SD3_DAT3 ALT0: SD3_DATA3

ALT1: UART3_CTS_B

ALT2:

ALT3:

ALT4:

ALT5: GPIO7_IO07

ALT6:

ALT7:

VGEN_3V3

VGEN_3V3

VGEN_3V3

G1 GND -

G2 GPIO_0 ALT0: CCM_CLKO1

ALT1:

ALT2: KEY_COL5

ALT3: ASRC_EXT_CLK

ALT4: EPIT1_OUT

ALT5: GPIO1_IO00

ALT6: USB_H1_PWR

ALT7: SNVS_VIO_5

G3 GPIO_2 ALT0: ESAI_TX_FS

ALT1:

ALT2: KEY_ROW6

ALT3:

ALT4:

ALT5: GPIO1_IO02

ALT6: SD2_WP

ALT7: MLB_DATA

G4 GND -

VGEN_3V3

VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

45

Page 46

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

G5 CSI0_PIXCLK ALT0: IPU1_CSI0_PIXCLK

ALT1:

ALT2:

ALT3:

ALT4:

ALT5: GPIO5_IO18

ALT6:

ALT7: ARM_EVENTO

G6 CSI0_DAT19 ALT0: IPU1_CSI0_DATA19

ALT1: EIM_DATA15

ALT2:

ALT3: UART5_CTS_B

ALT4:

ALT5: GPIO6_IO05

ALT6:

ALT7:

G7 HDMI_D2_P HDMI_VPH

G8 GND -

G9 HDMI_HPD HDMI_VPH

G10 GND -

G11 CSI_D0_P NVCC_MIPI

NVCC_CSI

NVCC_CSI

G12 CSI_D0_N NVCC_MIPI

G13 JTAG_MOD VGEN_3V3

G14 USB_OTG_VBUS USB_OTG_VBUS

G15 #USB_OTG_CHD VDD_USB_CAP

G16 USB_OTG_DN VDD_USB_CAP

G17 USB_OTG_DP VDD_USB_CAP

G18 GND -

G19 SATA_RX_N SATA_VPH

G20 VGEN_3V3

G21 NANDF_D2 ALT0: NAND_DATA02

ALT1: SD1_DATA6

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO02

ALT6:

ALT7:

VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

46

Page 47

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

G22 NANDF_D6 ALT0: NAND_DATA06

ALT1: SD2_DATA6

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO06

ALT6:

ALT7:

G23 NANDF_D3 ALT0: NAND_DATA03

ALT1: SD1_DATA7

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO03

ALT6:

ALT7:

G24 NANDF_ALE ALT0: NAND_ALE

ALT1: SD4_RESET

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO08

ALT6:

ALT7:

VGEN_3V3

VGEN_3V3

VGEN_3V3

H1 LVDS1_TX0_N NVCC_LVDS_2P5

H2 KEY_ROW2 ALT0: ECSPI1_SS2

ALT1: ENET_TX_DATA2

ALT2: FLEXCAN1_RX

ALT3: KEY_ROW2

ALT4: SD2_VSELECT

ALT5: GPIO4_IO11

ALT6: HDMI_TX_CEC_

LINE

ALT7:

H3 GPIO_9 ALT0: ESAI_RX_FS

ALT1: WDOG1_B

ALT2: KEY_COL6

ALT3: CCM_REF_EN_B

ALT4: PWM1_OUT

ALT5: GPIO1_IO09

ALT6: SD1_WP

ALT7:

H4 LVDS0_TX0_P NVCC_LVDS_2P5

H5 GND -

VGEN_3V3

VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

47

Page 48

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

H6 CSI0_DAT16 ALT0: IPU1_CSI0_DATA16

ALT1: EIM_DATA12

ALT2:

ALT3: UART4_RTS_B

ALT4:

ALT5: GPIO6_IO02

ALT6:

ALT7: ARM_TRACE13

H19 SATA_RX_P SATA_VPH

H20 GND -

H21

H22 NANDF_D1

NANDF_CS1/

#MCA_INT

ALT0: NAND_CE1_B

ALT1: SD4_VSELECT

ALT2: SD3_VSELECT

ALT3:

ALT4:

ALT5: GPIO6_IO14

ALT6:

ALT7:

ALT0: NAND_DATA01

ALT1: SD1_DATA5

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO01

ALT6:

ALT7:

NVCC_CSI

VGEN_3V3 Connected to MCA

VGEN_3V3

processor.

H23 NANDF_D7

H24 NANDF_CS2

J1 LVDS1_TX0_P NVCC_LVDS_2P5

ALT0: NAND_DATA07

ALT1: SD2_DATA7

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO07

ALT6:

ALT7:

ALT0: NAND_CE2_B

ALT1: IPU1_SISG0

ALT2: ESAI_TX0

ALT3: EIM_CRE

ALT4: CCM_CLKO2

ALT5: GPIO6_IO15

ALT6: IPU2_SISG0

ALT7:

VGEN_3V3

VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

48

Page 49

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

J2 KEY_COL0

J3 GPIO_6

J4 LVDS0_TX0_N NVCC_LVDS_2P5

J5 CSI0_VSYNC ALT0: IPU1_CSI0_VSYNC

ALT0: ECSPI1_SCLK

ALT1: ENET_RX_DATA3

ALT2: AUD5_TXC

ALT3: KEY_COL0

ALT4: UART4_TX_DATA

ALT5: GPIO4_IO06

ALT6: DCIC1_OUT

ALT7:

ALT0: ESAI_TX_CLK

ALT1:

ALT2: I2C3_SDA

ALT3:

ALT4:

ALT5: GPIO1_IO06

ALT6: SD2_LCTL

ALT7: MLB_SIG

ALT1: EIM_DATA01

ALT2:

ALT3:

ALT4:

ALT5: GPIO5_IO21

ALT6:

ALT7: ARM_TRACE00

VGEN_3V3

VGEN_3V3

NVCC_CSI

J20

J21 SD1_DAT2

J22 SD1_DAT1

VGEN_3V3

ALT0: SD1_DATA2

ALT1: ECSPI5_SS1

ALT2: GPT_COMPARE2

ALT3: PWM2_OUT

ALT4: WDOG1_B

ALT5: GPIO1_IO19

ALT6: WDOG1_RESET_B_

DEB

ALT7:

ALT0: SD1_DATA1

ALT1: ECSPI5_SS0

ALT2: PWM3_OUT

ALT3: GPT_CAPTURE2

ALT4:

ALT5: GPIO1_IO17

ALT6:

ALT7:

VDD_WLAN_SD1 Signal only

available

externally in nonwireless variants

of the SOM.

VDD_WLAN_SD1 Signal only

available

externally in nonwireless variants

of the SOM.

ConnectCore 6 Plus Hardware Reference Manual

49

Page 50

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

J23 SD1_CMD

J24 NANDF_D0

K1 GND -

K2 KEY_COL2

ALT0: SD1_CMD

ALT1: ECSPI5_MOSI

ALT2: PWM4_OUT

ALT3: GPT_COMPARE1

ALT4:

ALT5: GPIO1_IO18

ALT6:

ALT7:

ALT0: NAND_DATA00

ALT1: SD1_DATA4

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO00

ALT6:

ALT7:

ALT0: ECSPI1_SS1

ALT1: ENET_RX_DATA2

ALT2: FLEXCAN1_TX

ALT3: KEY_COL2

ALT4: ENET_MDC

ALT5: GPIO4_IO10

ALT6: USB_H1_PWR_

CTL_WAKE

ALT7:

VDD_WLAN_SD1 Signal only

available

externally in nonwireless variants

of the SOM.

VGEN_3V3

VGEN_3V3

K3 GPIO_1

K4 GND -

K5 CSI0_DAT10 ALT0: IPU1_CSI0_DATA10

K20 VGEN_3V3

ALT0: ESAI_RX_CLK

ALT1: WDOG2_B

ALT2: KEY_ROW5

ALT3: USB_OTG_ID

ALT4: PWM2_OUT

ALT5: GPIO1_IO01

ALT6: SD1_CD_B

ALT7:

ALT1: AUD3_RXC

ALT2: ECSPI2_MISO

ALT3: UART1_TX_DATA

ALT4:

ALT5: GPIO5_IO28

ALT6:

ALT7: ARM_TRACE07

VGEN_3V3

NVCC_CSI Connected to the

on-module MCA

microcontroller.

ConnectCore 6 Plus Hardware Reference Manual

50

Page 51

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

K21 SD2_DAT1

K22 SD2_CLK

K23 SD2_DAT3

ALT0: SD2_DATA1

ALT1: ECSPI5_SS0

ALT2: EIM_CS2

ALT3: AUD4_TXFS

ALT4: KEY_COL7

ALT5: GPIO1_IO14

ALT6:

ALT7:

ALT0: SD2_CLK

ALT1: ECSPI5_SCLK

ALT2: KEY_COL5

ALT3: AUD4_RXFS

ALT4:

ALT5: GPIO1_IO10

ALT6:

ALT7:

ALT0: SD2_DATA3

ALT1: ECSPI5_SS3

ALT2: KEY_COL6

ALT3: AUD4_TXC

ALT4:

ALT5: GPIO1_IO12

ALT6:

ALT7:

VDD_SD2

VDD_SD2

VDD_SD2

K24 NANDF_D4

L1 LVDS1_TX1_P NVCC_LVDS_2P5

L2 KEY_COL4

ALT0: NAND_DATA04

ALT1: SD2_DATA4

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO04

ALT6:

ALT7:

ALT0: FLEXCAN2_TX

ALT1: IPU1_SISG4

ALT2: USB_OTG_OC

ALT3: KEY_COL4

ALT4: UART5_RTS_B

ALT5: GPIO4_IO14

ALT6:

ALT7:

VGEN_3V3

VGEN_3V3

ConnectCore 6 Plus Hardware Reference Manual

51

Page 52

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

L3 GPIO_4

L4 LVDS0_CLK_P NVCC_LVDS_2P5

L5 CSI0_DAT12 ALT0: IPU1_CSI0_DATA12

L20 SD1_DAT3

ALT0: ESAI_TX_HF_CLK

ALT1:

ALT2: KEY_COL7

ALT3:

ALT4:

ALT5: GPIO1_IO04

ALT6: SD2_CD_B

ALT7:

ALT1: EIM_DATA08

ALT2:

ALT3: UART4_TX_DATA

ALT4:

ALT5: GPIO5_IO30

ALT6:

ALT7: ARM_TRACE09

ALT0: SD1_DATA3

ALT1: ECSPI5_SS2

ALT2: GPT_COMPARE3

ALT3: PWM1_OUT

ALT4: WDOG2_B

ALT5: GPIO1_IO21

ALT6: WDOG2_RESET_B_

DEB

ALT7:

VGEN_3V3

NVCC_CSI

VDD_WLAN_SD1 Signal only

available

externally in nonwireless variants

of the SOM.

L21 SD1_CLK

L22 GND -

L23 MCA_SWD_CLK

ALT0: SD1_CLK

ALT1: ECSPI5_SCLK

ALT2:

ALT3: GPT_CLKIN

ALT4:

ALT5: GPIO1_IO20

ALT6:

ALT7:

ALT0: ALT1: PTA0

ALT2: ALT3: TMP0_CH5

ALT4: ALT5: ALT6: ALT7: SWD_CLK

VDD_WLAN_SD1 Signal only

available

externally in nonwireless variants

of the SOM.

LDO3_MCA

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

ConnectCore 6 Plus Hardware Reference Manual

52

Page 53

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

L24 NANDF_D5

M1 LVDS1_TX1_N NVCC_LVDS_2P5

M2 GPIO_19 ALT0: KEY_COL5

M3 GPIO_16 ALT0: ESAI_TX3_RX2

ALT0: NAND_DATA05

ALT1: SD2_DATA5

ALT2:

ALT3:

ALT4:

ALT5: GPIO2_IO05

ALT6:

ALT7:

ALT1: ENET_1588_

EVENT0_OUT

ALT2: SPDIF_OUT

ALT3: CCM_CLKO1

ALT4: ECSPI1_RDY

ALT5: GPIO4_IO05

ALT6: ENET_TX_ER

ALT7:

ALT1: ENET_1588_

EVENT2_IN

ALT2: ENET_REF_CLK

ALT3: SD1_LCTL

ALT4: SPDIF_IN

ALT5: GPIO7_IO11

ALT6: I2C3_SDA

ALT7: JTAG_DE_B

VGEN_3V3

NVCC_GPIO

(VGEN_3V3)

NVCC_GPIO

(VGEN_3V3)

M4 LVDS0_CLK_N NVCC_LVDS_2P5

M5 CSI0_DAT7 ALT0: IPU1_CSI0_DATA07

ALT1: EIM_DATA05

ALT2: ECSPI1_SS0

ALT3: KEY_ROW6

ALT4: AUD3_RXD

ALT5: GPIO5_IO25

ALT6:

ALT7: ARM_TRACE04

M20 SD2_CMD ALT0: SD2_CMD

ALT1: ECSPI5_MOSI

ALT2: KEY_ROW5

ALT3: AUD4_RXC

ALT4:

ALT5: GPIO1_IO11

ALT6:

ALT7:

NVCC_CSI

NVCC_SD2

(VGEN_3V3)

ConnectCore 6 Plus Hardware Reference Manual

53

Page 54

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

M21 MCA_IO12 ALT0: -

ALT1: PTC5/LLWU_P9

ALT2: SPI0_SCK

ALT3: LPTMR0_ALT2

ALT4: ALT5: ALT6: CMP0_OUT

ALT7: -

M22 LDO3_MCA LDO3_MCA

M23 MCA_SWD_DIO ALT0: -

ALT1: PTA3

ALT2: I2C1_SCL

ALT3: TPM0_CH0

ALT4: ALT5: ALT6: ALT7: SWD_DIO

M24 NANDF_RB0 ALT0: NAND_READY

ALT1: IPU2_DI0_PIN01

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO10

ALT6:

ALT7:

LDO3_MCA

LDO3_MCA

NVCC_NANDF

(VGEN_3V3)

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

N1 GND -

N2 GPIO_18 ALT0: ESAI_TX1

ALT1: ENET_RX_CLK

ALT2: SD3_VSELECT

ALT3: SDMA_EXT_EVENT1

ALT4: ASRC_EXT_CLK

ALT5: GPIO7_IO13

ALT6: SNVS_VIO_5_CTL

ALT7:

N3 VCC_LICELL

N4 GND -

N5 VGEN_3V3

NVCC_GPIO

(VGEN_3V3)

ConnectCore 6 Plus Hardware Reference Manual

54

Page 55

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

N20 MCA_IO/USB0_PALT0: ADC0_SE1

ALT1: PTE16

ALT2: SPI0_PCS0

ALT3: UART2_TX

ALT4: TPM_CLKIN0

ALT5: ALT6: ALT7: -

N21 MCA_IO13 ALT0: CMP0_IN0

ALT1: PTC6/LLWU_P10

ALT2: SPI0_MOSI

ALT3: EXTRG_IN

ALT4: ALT5: SPI0_MISO

ALT6: ALT7: -

N22 MCA_IO7

ALT0: ALT1: PTB16

ALT2: SPI1_MOSI

ALT3: UART0_RX

ALT4: TPM_CLKIN0

ALT5: SPI1_MISO

ALT6: ALT7: -

LDO3_MCA

LDO3_MCA

LDO3_MCA

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

N23 #MCA_RESET

N24 SD1_DAT0

P1 LVDS1_TX2_N NVCC_LVDS_2P5

ALT0: RESET_b

ALT1: PTA20

ALT2: ALT3: ALT4: ALT5: ALT6: ALT7: -

ALT0: SD1_DATA0

ALT1: ECSPI5_MISO

ALT2:

ALT3: GPT_CAPTURE1

ALT4:

ALT5: GPIO1_IO16

ALT6:

ALT7:

LDO3_MCA

NVCC_SD1

(VGEN_3V3)

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Signal only

available

externally in nonwireless variants

of the SOM.

ConnectCore 6 Plus Hardware Reference Manual

55

Page 56

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

P2 ENET_CRS_DV ALT0: ENET_RX_EN

ALT1: ESAI_TX_CLK

ALT2: SPDIF_EXT_CLK

ALT3:

ALT4:

ALT5: GPIO1_IO25

ALT6:

ALT7:

P3 GPIO_7 ALT0: ESAI_TX4_RX1

ALT1: ECSPI5_RDY

ALT2: EPIT1_OUT

ALT3: FLEXCAN1_TX

ALT4: UART2_TX_DATA

ALT5: GPIO1_IO07

ALT6: SPDIF_LOCK

ALT7: USB_OTG_HOST_

MODE

P4 LVDS0_TX3_P NVCC_LVDS_2P5

P5 NVCC_CSI

P20 MCA_IO/USB0_

N

ALT0: ADC0_SE5a

ALT1: PTE17

ALT2: SPI0_SCK

ALT3: UART2_RX

ALT4: TPM_CLKIN1

ALT5: ALT6: LPTMR0_ALT3

ALT7: -

NVCC_ENET

NVCC_GPIO

(VGEN_3V3)

LDO3_MCA Signal only

available in

variants carrying

the MCA.

P21 MCA_IO14

P22 MCA_IO8

ALT0: ADC0_SE6a

ALT1: PTE19

ALT2: SPI0_MISO

ALT3: ALT4: I2C0_SCL

ALT5: SPI0_MOSI

ALT6: ALT7: -

ALT0: ALT1: PTB17

ALT2: SPI1_MISO

ALT3: UART0_TX

ALT4: TPM_CLKIN1

ALT5: SPI1_MOSI

ALT6: ALT7: -

LDO3_MCA Signal only

available in

variants carrying

the MCA.

LDO3_MCA Signal only

available in

variants carrying

the MCA.

ConnectCore 6 Plus Hardware Reference Manual

56

Page 57

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

P23 MCA_IO1

P24 SD2_DAT0 ALT0: SD2_DATA0

R1 LVDS1_TX2_P NVCC_LVDS_2P5

R2 ENET_RX_ER ALT0: USB_OTG_ID

ALT0: ADC0_SE4a

ALT1: PTE21

ALT2: ALT3: TPM1_CH1

ALT4: UART0_RX

ALT5: ALT6: ALT7: -

ALT1: ECSPI5_MISO

ALT2:

ALT3: AUD4_RXD

ALT4: KEY_ROW7

ALT5: GPIO1_IO15

ALT6: DCIC2_OUT

ALT7:

ALT1: ENET_RX_ER

ALT2: ESAI_RX_HF_CLK

ALT3: SPDIF_IN

ALT4: ENET_1588_

EVENT2_OUT

ALT5: GPIO1_IO24

ALT6:

ALT7:

LDO3_MCA

NVCC_SD2

(VGEN_3V3)

NVCC_ENET

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

R3 GPIO_5 ALT0: ESAI_TX2_RX3

ALT1:

ALT2: KEY_ROW7

ALT3: CCM_CLKO1

ALT4:

ALT5: GPIO1_IO05

ALT6: I2C3_SCL

ALT7: ARM_EVENTI

R4 LVDS0_TX3_N NVCC_LVDS_2P5

R5 NVCC_RGMII

R20 MCA_IO19

ALT0: CMP0_IN1

ALT1: PTC7

ALT2: SPI0_MISO

ALT3: ALT4: ALT5: SPI0_MOSI

ALT6: ALT7: -

NVCC_GPIO

(VGEN_3V3)

LDO3_MCA

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

ConnectCore 6 Plus Hardware Reference Manual

57

Page 58

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

R21 MCA_IO16

R22 MCA_IO9

R23 MCA_IO2

ALT0: ALT1: PTD4/LLWU_P14

ALT2: SPI1_PCS0

ALT3: UART2_RX

ALT4: TPM0_CH4

ALT5: ALT6: ALT7: -

ALT0: ADC0_SE11

ALT1: PTC2

ALT2: I2C1_SDA

ALT3: ALT4: TPM0_CH1

ALT5: ALT6: ALT7: -

ALT0: ADC0_SE8

ALT1: PTB0/LLWU_P5

ALT2: I2C0_SCL

ALT3: TPM1_CH0

ALT4: ALT5: ALT6: ALT7: -

LDO3_MCA

LDO3_MCA

LDO3_MCA

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

R24 SD2_DAT2 ALT0: SD2_DATA2

ALT1: ECSPI5_SS1

ALT2: EIM_CS3

ALT3: AUD4_TXD

ALT4: KEY_ROW6

ALT5: GPIO1_IO13

ALT6:

ALT7:

T1 GND -

T2 GND -

T3 GPIO_3 ALT0: ESAI_RX_HF_CLK

ALT1:

ALT2: I2C3_SCL

ALT3: XTALOSC_REF_

CLK_24M

ALT4: CCM_CLKO2

ALT5: GPIO1_IO03

ALT6: USB_H1_OC

ALT7: MLB_CLK

T4 GND -

NVCC_SD2

(VGEN_3V3)

NVCC_GPIO

(VGEN_3V3)

ConnectCore 6 Plus Hardware Reference Manual

58

Page 59

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

T5 GND -

T20 MCA_IO24

T21 MCA_IO22

T22 MCA_IO10

ALT0: XTAL0

ALT1: PTA19

ALT2: ALT3: UART1_TX

ALT4: TPM_CLKIN1

ALT5: ALT6: LPTMR0_ALT1

ALT7: -

ALT0: ADC0_SE6b

ALT1: PTD5

ALT2: SPI1_SCK

ALT3: UART2_TX

ALT4: TPM0_CH5

ALT5: ALT6: ALT7: -

ALT0: ALT1: PTC3/LLWU_P7

ALT2: ALT3: UART1_RX

ALT4: TPM0_CH2

ALT5: CLKOUT

ALT6: ALT7: -

LDO3_MCA

LDO3_MCA

LDO3_MCA

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

T23 MCA_IO0

T24 MCA_IO3

U1 LVDS1_TX3_N NVCC_LVDS_2P5

ALT0: ADC0_SE0

ALT1: PTE20

ALT2: ALT3: TPM1_CH0

ALT4: UART0_TX

ALT5: ALT6: ALT7: -

ALT0: ADC0_SE7b

ALT1: PTD6/LLWU_P15

ALT2: SPI1_MOSI

ALT3: UART0_RX

ALT4: ALT5: SPI1_MISO

ALT6: ALT7: -

LDO3_MCA

LDO3_MCA

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

ConnectCore 6 Plus Hardware Reference Manual

59

Page 60

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

U2 ENET_TXD0 ALT0:

ALT1: ENET_TX_DATA0

ALT2: ESAI_TX4_RX1

ALT3:

ALT4:

ALT5: GPIO1_IO30

ALT6:

ALT7:

U3 GND -

U4 RGMII_TXC ALT0: USB_H2_DATA

ALT1: RGMII_TXC

ALT2: SPDIF_EXT_CLK

ALT3:

ALT4:

ALT5: GPIO6_IO19

ALT6:

ALT7: XTALOSC_REF_

CLK_24M

U5 RGMII_TD0 ALT0: HSI_TX_READY

ALT1: RGMII_TD0

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO20

ALT6:

ALT7:

NVCC_ENET

NVCC_RGMII

NVCC_RGMII

U6 DISP0_DAT21 ALT0: IPU1_DISP0_

DATA21

ALT1: IPU2_DISP0_

DATA21

ALT2: ECSPI1_MOSI

ALT3: AUD4_TXD

ALT4:

ALT5: GPIO5_IO15

ALT6:

ALT7:

U19 EIM_DA3 ALT0: EIM_DA03

ALT1: IPU1_DISP1_

DATA06

ALT2: IPU2_CSI1_DATA06

ALT3:

ALT4:

ALT5: GPIO3_IO03

ALT6:

ALT7: SRC_BOOT_CFG03

NVCC_LCD

NVCC_EIM

ConnectCore 6 Plus Hardware Reference Manual

60

Page 61

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

U20 EIM_DA0 ALT0: EIM_AD00

ALT1: IPU1_DISP1_

DATA09

ALT2: IPU2_CSI1_DATA09

ALT3:

ALT4:

ALT5: GPIO3_IO00

ALT6:

ALT7: SRC_BOOT_CFG00

U21 EIM_LBA ALT0: EIM_LBA

ALT1: IPU1_DI1_PIN17

ALT2: ECSPI2_SS1

ALT3:

ALT4:

ALT5: GPIO2_IO27

ALT6:

ALT7: SRC_BOOT_CFG26

U22 MCA_IO11

ALT0: ALT1: PTC4/LLWU_P8

ALT2: SPI0_PCS0

ALT3: UART1_TX

ALT4: TPM0_CH3

ALT5: ALT6: ALT7: -

NVCC_EIM

NVCC_EIM

LDO3_MCA

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

U23 EIM_DA6 ALT0: EIM_AD06

ALT1: IPU1_DISP1_

DATA03

ALT2: IPU2_CSI1_DATA03

ALT3:

ALT4:

ALT5: GPIO3_IO06

ALT6:

ALT7: SRC_BOOT_CFG06

U24 MCA_IO4

V1 LVDS1_TX3_P NVCC_LVDS_2P5

ALT0: ADC0_SE14

ALT1: PTC0

ALT2: ALT3: EXTRG_IN

ALT4: ALT5: CMP0_OUT

ALT6: ALT7: -

NVCC_EIM 10K pull-up to

LDO3_MCA

NVCC_EIM on

module.

Assuming NXP

MKL14Z32VFT4 is

populated.

Signal only

available in

variants carrying

the MCA.

ConnectCore 6 Plus Hardware Reference Manual

61

Page 62

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

V2 ENET_TXD1 ALT0: MLB_CLK

ALT1: ENET_TX_DATA1

ALT2: ESAI_TX2_RX3

ALT3:

ALT4: ENET_1588_

EVENT0_IN

ALT5: GPIO1_IO29

ALT6:

ALT7:

V3 NVCC_ENET

V4 RGMII_RX_CTL ALT0: USB_H3_DATA

ALT1: RGMII_RX_CTL

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO24

ALT6:

ALT7:

V5 RGMII_TD1 ALT0: HSI_RX_FLAG

ALT1: RGMII_TD1

ALT2:

ALT3:

ALT4:

ALT5: GPIO6_IO21

ALT6:

ALT7:

NVCC_ENET

NVCC_RGMII

NVCC_RGMII

V6 DISP0_DAT16 ALT0: IPU1_DISP0_

DATA16

ALT1: IPU2_DISP0_

DATA16

ALT2: ECSPI2_MOSI

ALT3: AUD5_TXC

ALT4: SDMA_EXT_EVENT0

ALT5: GPIO5_IO10

ALT6:

ALT7:

V7 DISP0_DAT22 ALT0: IPU1_DISP0_

DATA22

ALT1: IPU2_DISP0_

DATA22

ALT2: ECSPI1_MISO

ALT3: AUD4_TXFS

ALT4:

ALT5: GPIO5_IO16

ALT6:

ALT7:

NVCC_LCD

NVCC_LCD

ConnectCore 6 Plus Hardware Reference Manual

62

Page 63

About the ConnectCore 6 Plus Module pinout

LGA

pad Pad name Multiplexing Power group Comments

V8 DI0_PIN3 ALT0: IPU1_DI0_PIN03

ALT1: IPU2_DI0_PIN03

ALT2: AUD6_TXFS

ALT3:

ALT4:

ALT5: GPIO4_IO19

ALT6:

ALT7:

V9 DI0_DISP_CLK ALT0: IPU1_DI0_DISP_

CLK

ALT1: IPU2_DI0_DISP_

CLK

ALT2:

ALT3:

ALT4:

ALT5: GPIO4_IO16

ALT6:

ALT7:

V10 DI0_PIN15 ALT0: IPU1_DI0_PIN15

ALT1: IPU2_DI0_PIN15

ALT2: AUD6_TXC

ALT3:

ALT4:

ALT5: GPIO4_IO17

ALT6:

ALT7:

NVCC_LCD

NVCC_LCD

NVCC_LCD

V11 VSYS