Page 1

DIAMOND

P R O D U C T S

OPERATOR’S MANUAL

CONCRETE SAW

MODEL:

CC7074

Manual # 1801371

Page1

Page 2

Table of Contents

Safety Precautions ................................................. 1

Safety Alerts ................................................................ 1

Proposition 65 ............................................................. 1

Spark Arrester Requirement ....................................... 1

Respiratory Hazards ................................................... 1

General Safety ............................................................ 2

Battery and Electrical Safety ....................................... 2

Blade Safety ................................................................ 3

Blade Guard Safety..................................................... 3

Fuel Safety .................................................................. 3

Engine Safety .............................................................. 4

Cutting Safety ............................................................. 4

Hydraulic Safety .......................................................... 4

Belt Safety ................................................................... 4

Transporting Safety..................................................... 4

Introducing the CC7074 ......................................... 7

Controls ....................................................................... 7

Dimensions ................................................................. 9

Specifications ............................................................ 10

Operating the CC7074 ......................................... 11

Tie-Downs ................................................................. 11

Footrest ..................................................................... 11

Weight Bar (Optional) ............................................... 11

Spotlight .................................................................... 11

Handlebars ................................................................ 11

Adjusting the Handlebars .............................................. 11

Fuel System .............................................................. 12

Adding Fuel ................................................................... 12

Blade Guard .............................................................. 12

Installing the Blade Guard ............................................. 12

Removing the Blade Guard ........................................... 13

Flange Guard ............................................................ 13

Installing the Flange Guard ........................................... 13

Removing the Flange Guard ......................................... 13

Diamond Blades ........................................................ 13

Inspecting the Blade ..................................................... 13

Blade Speed ................................................................. 14

Wrench ......................................................................... 14

Installing the Blade ........................................................ 14

Removing the Blade ...................................................... 15

Engine ....................................................................... 15

Tasks Prior to Starting the Engine ................................ 16

Starting the Engine ....................................................... 16

Stopping the Engine ...................................................... 16

Speed Control Lever ................................................. 16

Blade Lowering Speed .............................................. 17

Water Supply ............................................................ 17

Using the Water Supply ................................................ 17

Cutting Guides .......................................................... 17

Adjusting the Front Pointer ........................................... 17

Adjusting the Rear Pointer(s) ........................................ 18

Concrete Cutting ....................................................... 18

Helpful Hints Prior to Cutting ........................................ 18

Tasks Prior to Cutting ................................................... 18

Making a Cut ................................................................ 18

Making a Cut Using the Blade Depth Stop ................... 19

Continuing a Partial-Cut................................................ 19

Finishing a Cut .............................................................. 19

Maintaining the CC7074 ....................................... 21

Maintenance Overview ............................................. 21

Daily ............................................................................. 21

Every 100 Hours ........................................................... 21

Every 250 Hours ........................................................... 21

Every 500 Hours ........................................................... 21

Part Lubrication ........................................................ 21

Water Filter Strainer (Optional) ................................ 21

Speed Control Lever ................................................. 22

Adjusting the Lever Tension ......................................... 22

Adjusting the Spring Plungers ...................................... 22

Inner Blade Flange ................................................... 22

Installing the Inner Blade Flange .................................. 22

Removing the Inner Blade Flange ................................ 22

Drive Alignment ........................................................ 22

Drive Alignment ............................................................ 22

Wheels ...................................................................... 22

Replacing the Front Wheels ......................................... 23

Replacing the Rear Wheels .......................................... 23

Maximum Cutting Depth ........................................... 23

Handlebar Cylinder Rod ........................................... 24

Removing the Cylinder Rod .......................................... 24

Connecting the Cylinder Rod ........................................ 24

Battery ...................................................................... 24

Battery Type ................................................................. 25

Servicing the Battery .................................................... 25

Electrical System ...................................................... 25

Radiator .................................................................... 25

Adding Radiator Fluid ................................................... 25

Changing the Radiator Fluid ......................................... 26

Hydraulic System ...................................................... 26

Adding Fluid to the Hydraulic Lift Pump ........................ 26

Adding Hydraulic Fluid to the Reservoir Tank ............... 27

Replacing the Hydraulic Oil Filter ................................. 27

Upper Gearbox ......................................................... 27

Changing the Upper Gearbox Oil ................................. 27

Draining the Upper Gearbox Heat Sink ........................ 27

Lower Gearbox ......................................................... 28

Changing the Lower Gearbox Fluid .............................. 28

Cleaning the In-Line Oil Suction Filter .......................... 28

Belt Sheaves ............................................................ 28

Removing the Belt Sheaves ......................................... 28

Installing the Belt Sheaves ........................................... 29

Blade Drive Belts ...................................................... 29

Tensioning/Replacing the Blade Drive Belts ................. 29

In-Line Fuel Filter ...................................................... 30

Engine ...................................................................... 30

Cleaning the Engine ..................................................... 30

Air Cleaner ................................................................ 31

Page 3

Restriction Indicator ...................................................... 31

Rubber Dust Ejector Boot ............................................. 31

Cleaning/Replacing the Outer Primary Filter ................. 31

Replacing the Inner Safety Filter ................................... 32

Storing ....................................................................... 33

Disposal .................................................................... 33

References .......................................................... 35

Appendix A ................................................................ 35

Serial Tags .................................................................... 35

Appendix B ................................................................ 36

Daily Maintenance Task Chart ...................................... 36

Appendix C ............................................................... 37

Belt Tension Settings .................................................... 37

Appendix D ............................................................... 38

Troubleshooting ............................................................ 38

Appendix E ................................................................ 39

Additional Resources .................................................... 39

Page 4

Safety Precautions

Operate the CC7074 Concrete Saw and all of its

components according to this manual. Failure to comply

with and understand the following safety, operation and

maintenance instructions can result in serious injuries

and/or death. All operators must be properly trained or

supervised by experienced personnel prior to using this

saw and should understand the risks and hazards

involved. Diamond Products discourages improper or

unintended saw usage and cannot be held liable for any

resulting damages.

Saw modifications should be made by Diamond

Products to ensure safety and design. Any modifications

made by the owner(s) are not the responsibility of

Diamond Products and void all saw warranties if a

problem arises as a result of the modification.

Refer to the CC7074 Parts List for additional information

and part diagrams. Refer to the engine manual and

manufacturer as the primary source for all safety,

operations, and maintenance instructions regarding the

engine. Prior to operating, record the saw’s serial

number, and the engine’s model and serial numbers in

Appendix A.

Notice: The information in this manual may be

updated at any time!

Safety Alerts

DANGER

Serious injuries and/or death will occur if these

instructions are not followed.

WARNING

Serious injuries and/or death could occur if these

instructions are not followed.

CAUTION

Mild and/or moderate injuries could occur if these

instructions are not followed.

Proposition 65

WARNING

Engine exhaust and some of its

constituents are known to the State of

California to cause cancer, birth defects,

and/or other reproductive harm.

Spark Arrester Requirement

WARNING

In the State of California it is a violation of section

4442 or 4443 to use or operate the engine on any

forest-covered, brush-covered, or grass-covered

land unless the engine is equipped with a spark

arrester, as defined in section 4442, maintained in

effective, working order or the engine is

constructed, equipped, and maintained for the

prevention of fire pursuant to section 4443.

Respiratory Hazards

WARNING

Concrete cutting produces dust and fumes known

to cause illness, death, cancer, respiratory

disease, birth defects, and/or other reproductive

harm. Safety protection techniques include, but are

not limited to:

Wearing gloves.

Wearing safety goggles or a face shield.

Using approved respirators.

Washing work clothes daily.

Using water when wet cutting to minimize

dust.

Washing the hands and face prior to

eating/drinking.

For additional safety and self-protection

information contact your employer, the

Occupational Safety and Health Administration

(OSHA), and/or The National Institute for

Occupational Safety and Health (NIOSH).

1

Page 5

General Safety

Read and understand all safety, operations, and

maintenance instructions provided in this manual

prior to operating or servicing the saw.

Keep saw components clean and free of slurry,

concrete dust, and debris.

Inspect water hoses prior to operating the saw.

Clean, repair, or replace damaged components.

Raise the saw to a proper height for access when

working underneath the saw. Use chocks to block

the wheels, and fit blocks or jacks under the frame

edges.

WARNING – Do NOT work on saw

using the hydraulic lift system to keep

the saw in the raised position for

maintenance or repair. Accidental loss

of hydraulic pressure could cause the

saw to drop suddenly, causing serious

injury or death.

When using a jack to raise the saw, place the jack

against a solid, flat area under the frame base to

properly support the saw.

Repair the saw immediately when a problem arises.

Replace saw decals if unreadable.

Dispose of all hazardous waste materials according

to city, state, and federal regulations.

Always have a phone nearby, and locate the nearest

fire extinguisher and first aid kit prior to operating the

saw.

Operate the saw wearing flame resistant clothing.

Always wear safety glasses when removing retaining

rings.

Persons under the statutory age limit should not

operate the saw.

Keep all body parts away from rotating machinery.

Replace all guards and access panels (unless stated

otherwise) prior to operating the saw.

Always pivot front of blade guard fully to avoid

serious injuries.

DO NOT assume the saw will remain still when in

neutral or when parking/stopping the saw on a

slope. Chock the wheels to help prevent

unnecessary movement.

DO NOT:

Drop equipment, supplies, tools, etc., when handling

Lift and carry equipment, supplies, tools, etc., that

to help prevent injuries.

are too heavy and/or cannot be lifted easily.

DO NOT (cont.)

Operate the saw without using the appropriate

safety equipment required for the work task.

Operate or service the saw with any clothing, hair, or

accessories that can snag in the machinery, which

could lead to serious injuries or death!

Operate the saw using attachments not associated

with or recommended for the saw.

Operate the saw around combustible materials or

fumes to prevent fires/explosions.

Operate the saw with anyone near the work area or

within the direct line of the blade.

Operate the saw until all unnecessary materials

have been removed from the work area.

Operate the saw with loose nuts, screws, and bolts.

Operate the saw when ill or fatigued.

Operate the saw under the influence of drugs and/or

alcohol.

Operate the saw on steep slopes.

Cut concrete with guards and access panels

removed.

Grease the saw with the engine running.

Touch hot components when operating the saw.

Leave the saw unattended until the engine is off and

the blade has stopped spinning.

Place the saw into storage until it has cooled down.

Service the saw until it has cooled down.

Service the saw with the engine running.

:

Battery and Electrical Safety

Ignitable explosive gases are

emitted from the battery. DO NOT

expose the battery to sparks or open

flames.

Keep the area around the battery well-ventilated.

Keep the battery level when handling it.

Use protective eyewear or a face shield, and avoid

contact with the skin when handling/servicing the

battery.

Use a proper battery tester when testing the battery

strength.

Always be sure to connect the battery cables to the

proper terminal when reconnecting the cables.

Occasionally inspect the battery, cables, clamps,

and terminals for damages. Service components as

necessary.

2

Page 6

Always keep the battery cable clamps away from the

battery terminals when the battery is disconnected to

avoid accidental connections while servicing.

Immediately rinse your clothing, skin, or eyes with

water if exposed to battery acid. Seek medical

attention immediately!

Disconnect the battery prior to servicing all saw

components (unless stated otherwise).

Remove the battery when storing the saw for longer

periods.

Always use the correct size fuses (amps) to prevent

fires.

Blade Safety

Always use reinforced abrasive blades or steel-

centered diamond blades.

Never use a wet cutting blade without an adequate

water supply to properly lubricate the blade.

Inspect all blades prior to usage and discard

damaged blades.

DO NOT install or remove a blade with the engine

running.

Keep all body parts away from rotating blades.

Inspect the blade flanges for damages, wear, and

cleanliness. Clean or replace dirty/damaged

components immediately.

DO NOT expose yourself or anyone

else to the direct line of the blade when

operating the saw.

Always use an appropriate size blade and the

correct blade type based on the cutting task and the

type of material being cut.

The blade must always fit snug on the blade shaft,

outer flange, and/or inner flange.

Wear gloves and be alert to the surrounding

environment when handling blades.

When installing the blade, always point the arrow

printed on the blade in the direction of the blade

shaft’s rotation.

DO NOT exceed the blade’s maximum

recommended speed when cutting. Excessive blade

speeds can cause blade breakage, resulting in

serious injuries and/or death!

DO NOT use damaged blades when cutting to avoid

harming yourself, others, or the saw.

DO NOT use a blade for cutting that requires a lower

speed than the blade shaft speed.

Always tighten the blade shaft bolt/screw as directed

to properly secure the outer flange and blade.

Failure to properly secure the outer flange and blade

may cause parts to loosen or fall off the saw,

resulting in serious injuries or death!

Let the blade cool prior to removal when dry cutting

(applicable models).

Blade Guard Safety

DO NOT operate the saw with the blade guard

raised or removed.

Blade exposure should not exceed 180° while

cutting.

When pivoting the front of the blade guard,

raise/lower it cautiously and slowly to avoid serious

injuries.

DO NOT pivot the blade guard front up or down

when installing/removing very large blades.

Attempting to pivot the front of a heavy guard when

the guard is positioned higher up for blade

installation/removal makes the guard difficult to lift

and/or lower. In this situation, install/remove the

blade guard front instead of pivoting it.

Always pivot the front of the blade guard

180° (fully upward) so the guard does

not swing down unexpectedly, causing

serious injuries.

Always secure the pivoted section of the blade

guard using the detent pin (guards 26” and up).

Use extreme caution when installing/removing parts

of a guard or the entire guard as guards can be

extremely heavy and may require

installation/removal at moderate heights.

DO NOT install or remove the blade guard with the

engine running.

Always use a blade guard that corresponds with the

blade size.

Inspect the blade guard and water tubes prior to

starting the saw. Clean or replace dirty/damaged

components immediately.

Fuel Safety

Always use caution when refueling.

Store all fuel in appropriate safety containers.

DO NOT operate the saw with a fuel leak.

DO NOT fuel the saw with the engine running.

Let the engine cool prior to adding fuel.

Refer to the engine manual for recommended fuels.

Always use appropriate fuels in cold weather.

Move the saw away from the refueling area prior to

starting the engine.

DO NOT smoke or expose fuel to open

flames when filling the fuel tank or

working with fuel.

Clean up any spilled fuel prior to starting the engine.

3

Page 7

Drain the fuel tank and fuel lines when storing the

saw for longer periods of time. Refer to the engine

manual for additional recommendations.

Engine Safety

Refer to the engine manual as the primary source

for engine safety.

Always know how to turn off the engine quickly for

emergency purposes.

Make sure the saw is in neutral when starting the

engine.

Fill the fuel tank and check the oil level prior to

starting the engine.

Keep all body parts away from

rotating saw parts with the engine

running.

DO NOT start the engine without the air filter(s)

installed.

DO NOT allow dust to enter the air intake tube when

cleaning/replacing air filter(s).

Replace damaged components immediately that

may allow dust to enter the engine.

DO NOT leave the engine running unattended.

Always operate the saw in well-ventilated

areas. Concentrated engine exhaust can

cause loss of consciousness and/or death.

DO NOT touch the engine/muffler assembly with the

engine running, and always let them cool down prior

to touching or servicing the saw.

Handle hot oil carefully when changing the oil.

Let the engine cool prior to removing pressurized

caps (applicable models).

DO NOT use any starter substances or starter fluids

(e.g., starter fluid sprayed into the air filter) when

starting the engine using a glow plug (applicable

models). These materials are extremely flammable

and explosive, and can melt parts or possibly

explode when used to help start the engine.

Cutting Safety

The direct work area should not contain buried or

embedded electrical, gas, or water lines that could

be damaged and/or cause personal injury while

cutting.

Turn off all electricity, gas, and water around the

direct work area prior to cutting.

DO NOT expose yourself or anyone else to the

direct line of the blade when operating the saw.

DO NOT allow any person, animal, and/or objects in

and around the work area while cutting.

Hydraulic Safety

Turn off the engine prior to servicing hydraulic

components.

Lower the saw completely prior to servicing to

decrease the hydraulic pressure in the lines.

Always make sure any hydraulic components being

serviced are not supporting the weight of other saw

components. If a particular component is under

pressure when connection points are loosened, oil

may spray out forcefully.

Always place a piece of cardboard or

paper up against hydraulic components,

or use a leak detection fluid to check for

hydraulic fluid leaks. Keep all body

parts away from leaks and/or areas that may eject

hydraulic fluid. Pressurized hydraulic fluid can

penetrate the skin, causing serious injuries. Seek

medical attention immediately!

Belt Safety

Turn off the engine and let the belts cool down prior

to servicing them.

Regularly inspect the belts for fraying, stress cracks,

and/or breakage and replace immediately when

damaged. Always check the belt alignment prior to

operating the saw.

Use extreme caution when working with belts and

rotating machine parts to avoid entanglement.

Over-tensioning belts may reduce the life of the

gearbox bearings. Under-tensioning belts may

cause slippage, shorter belt life, and/or poor saw

performance.

Squealing belts indicate looseness.

DO NOT use old and new belts together on the

same sheave.

Transporting Safety

Remove the blade prior to transporting the saw.

Make sure the truck/trailer is in good, working

condition and sufficient to transport the load. DO

NOT tow the saw behind a vehicle.

Close the fuel shutoff valve (applicable models)

when transporting.

Drain the fuel tank when transporting long distances.

Use heavy-duty ramps that will support the weight of

the saw and yourself when loading or unloading.

Raise the saw to avoid damaging components while

moving up and down ramps.

4

Page 8

Transporting Safety (cont.)

Use extreme caution when guiding the saw up and

down ramps. Slowly drive the saw forward down

the ramp. Slowly back the saw in reverse up the

ramp. Avoid standing directly downhill from the

saw to prevent machine rollover.

Place the saw in neutral and turn off the engine once

the saw is loaded in the truck/trailer.

Chock the wheels and secure the saw in the

truck/trailer prior to transporting.

Refer to the Department of Transportation (DOT) for

additional transportation recommendations.

Lifting Safety

Move yourself and all others away from

the lifting area when hoisting the saw to

prevent being crushed.

Secure the appropriate hoisting cables, straps,

and/or chains to the saw’s designated lift points prior

to hoisting.

Never use the tie-down brackets (applicable models)

to lift the saw.

DO NOT attempt to lift the saw irresponsibly and/or

improperly.

5

Page 9

Page 10

Introducing the CC7074

Controls

6

7

8

9

10

11

12

2a

5

4

3

15

1

16

17

18

19

20

25

21

22

26

23

4

14

24

13

2b

1

1. Handlebar Lock Lever–Locks handlebar in

position.

2a. Water Valve and Hose Fitting–(LH side) -

Lever controls water flow rate; hose fitting

connects to water source hose.

2b. Water Valve and Hose Fitting–(RH side)-

Lever controls water flow to blade guard; hose

fitting connects to water supply hose.

3. Fuel Tank Cap–Fill port; indicates fuel level.

4. Spotlight Bar Lock Knob–Locks spotlight bar

in position.

5. Blade Gearbox Temperature Light–Indicates

high oil temperature in blade gearbox.

Figure 1: CC7074 Controls

6. Radiator Cap–Fill port when adding or changing

radiator fluid.

7. Cable Cleat–Secures front pointer rope.

8. Blade Lowering Speed Valve–Adjusts saw’s

lowering speed.

9. Emergency Stop Button–Stops the engine.

10. Low Blade Water Light–Indicates low water

pressure to blade.

11. Blade Depth Stop Switch–Sets and resets

blade depth setting.

12. Blade Depth Set Light–Indicates blade depth is

set.

13. Spotlight–Light source.

7

Page 11

14. Cutting Depth Indicator–Indicates blade’s

depth from surface.

15. Vernier Throttle–Increases or decreases

engine speed.

16. Coolant Temperature Gauge–Indicates engine

coolant temperature. Note: Check the cooling

system when the coolant temperature light turns

on, or when the coolant temperature gauge

passes the red mark.

17. Ignition Switch–Four-position switch acti v a t e s

the glow plug, stops the engine, provides power

to certain accessories, or starts the engine.

18. Engine Warning Light Gauge–Indicates high

coolant temperature, low oil pressure, low

battery voltage, and an energized glow plug.

19. Blade Tachometer/Hour Meter–Indicates blade

speed and total number of saw hours operated.

20. Auto Water Switch–Activates automatic water

system. Water turns on/off when depth indicator

enters Auto Water On/Off Zone.

21. Free Wheel Switch–Allows operator to move

saw forward/backward (with ignition switch at

Run).

22. Speed Control Lever–Forward, stop (neutral),

and reverse control.

23. Control Grip–Two pushbuttons on front of grip

raise or lower the saw and blade. Pushbutton

on side of grip tilts handlebars, allowing them to

be moved up or down to desired position.

24. Blade Clutch Switch (optional)–Allows

operator to engage or disengage blade rotation.

25. Spotlight Switch–Activates spotlight.

26. Water Pump Switch (optional)–Activates water

pump.

8

Page 12

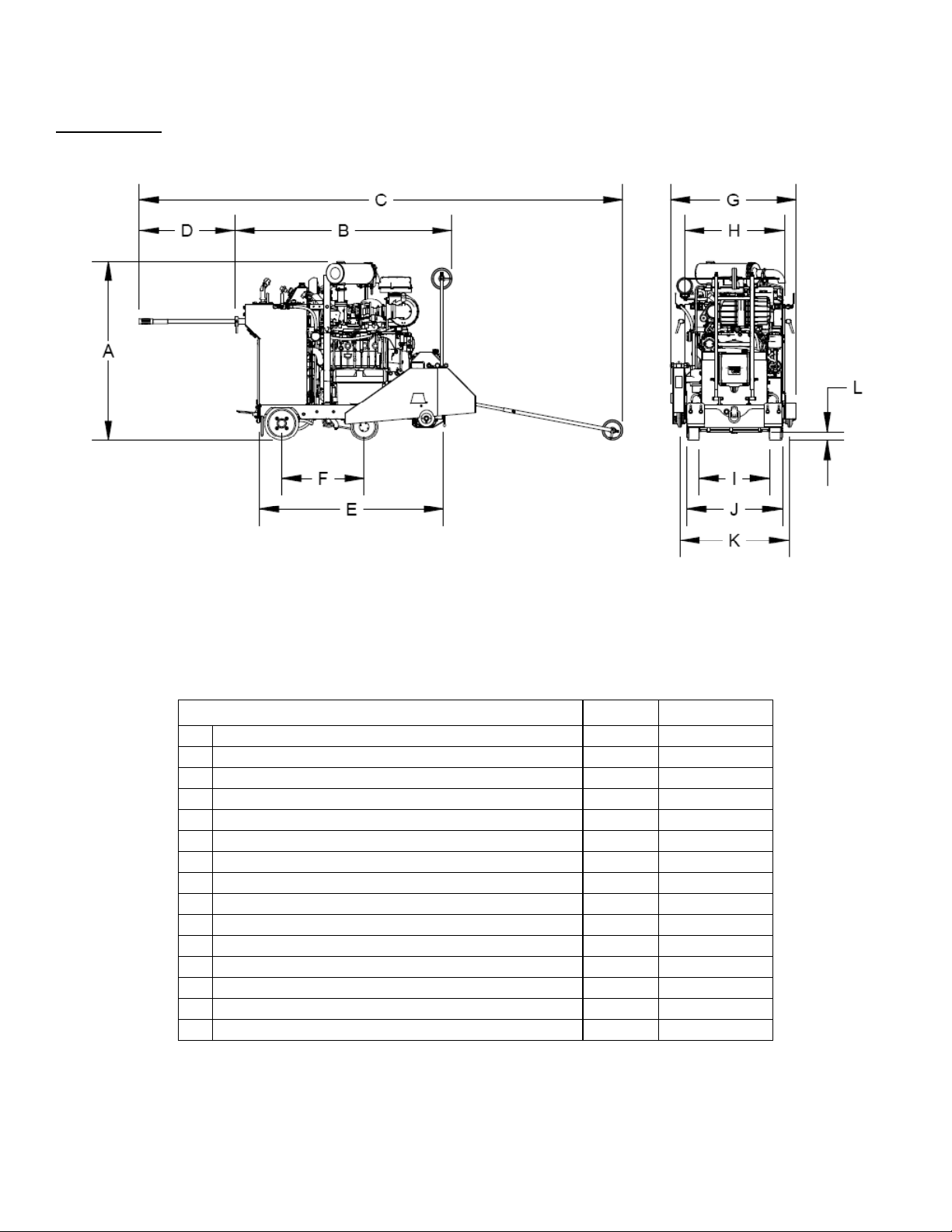

Dimensions

Figure 2: CC7074 Dimensions

Table 1: CC7074 Dimensions Inches Millimeters

A Saw height 52-1/2" 1334 mm

B Minimum Saw Length 63-1/2" 1613 mm

C Maximum Saw Length 140" 3556 mm

D Maximum Handle Extension 28" 711 mm

E Frame Length 53-3/4" 1365 mm

F Wheel Base Length 24-1/4" 616 mm

G Saw Width 36-1/2" 927 mm

H Frame Width 29" 737 mm

I Front wheels - Inside Width 20-1/2" 520 mm

J Rear wheels - Outside Width 27-3/4" 705 mm

K Inner Flange to Inner Flange Width 31-3/4" 806 mm

L1 Ground Clearance when level 2-1/2" 63 mm

L2 Ground Clearance when raised 1-3/4" 44 mm

maximum height - blade shaft(not shown) 26" 660 mm

Crated dimensions (L x W x H) - 70" x 44" x 59"

9

Page 13

Specifications

Table 1: CC7074 Specifications

Maximum Cutting Depth 19-3/4” with 48” blade

Blade Shaft Diameter 2”

Arbor Diameter 1” with single drive pin

Blade Shaft Bearings Multiple ball bearings in oil bath

Blade Shaft Drive 20 V-belts (four power bands)

Blade Mounting Right or left

Blade Raise/Lower Electro-hydraulic pump

Blade Coolant Dual multi-spray tubes

Blade Guard Attachment

Handlebars Length and tilt adjustable

Drive Speed 0-250 ft/min

Front Wheels 8” x 3”

Rear Wheels 10” x 3”

Transmission Hydro pump powering dual wheel motors

Uncrated Weight

(add 125 lb for crated weight)

Table 2: Engine Specifications

Manufacturer Kubota

Model V3307-DI-T-E3-B

Maximum Horsepower (HP) 74.3 HP @ 2,600 RPM

Fuel Capacity Nine gallons

Fuel Type Low sulfur/ultra-low sulfur diesel fuel

Air Filter Four-stage with restriction indicator

Power at Blade Shaft 70 HP

Note: Refer to the engine manual and manufacturer for additional engine information and

specifications.

Slip-on through 30”, bolt-on 36” and up

2,000-2,225 lb

(weight depends on model and added options)

10

Page 14

Operating the CC7074

For additional information and detailed diagrams on

individual saw components, refer to the CC7074 Parts

List in conjunction with this manual.

Tie-Downs

Use the tie-downs (one at the back and one at the front

end of the saw) when securing the saw in a truck/trailer

for transportation. DO NOT over-tighten a chain/rope to

the front end tie-down, which may bend the frame and

damage the saw.

Footrest

Use the footrest, if desired, to add body weight to the

rear of the saw and improve the rear wheel traction

when cutting.

5. Remove the weight bar as necessary.

Spotlight

1. Loosen both spotlight bar lock knobs and slide the

spotlight bar from side-to-side to adjust the length of

the bar.

2. Tighten the lock knobs to secure.

3. Turn the spotlight switch on or off as needed for

additional lighting.

Handlebars

The handlebars help to guide and maneuver the saw.

Place the handlebars in the desired position for better

leverage when lifting and steering. To maneuver the saw

forward or backward, turn on the Free Wheel switch and

move the saw as desired (the free wheel component

only works with the ignition key at Run).

Figure 3: Footrest

Weight Bar (Optional)

The weight bar (optional) adds 55 lb to the saw to

improve the rear wheel traction when cutting. Note: The

weight bar is a standard feature on the 48” blade saw.

1. Attach the second footrest to the back of the frame

base using the screws, washers, and lock nuts

provided.

2. Rest the weight bar on top of both footrests.

3. Place a flat washer onto both screws. Fit the screws

through the screw holes on top of the weight bar and

through the slot on both footrests.

4. Place a fender washer onto each screw underneath

the footrest and secure with a lock nut.

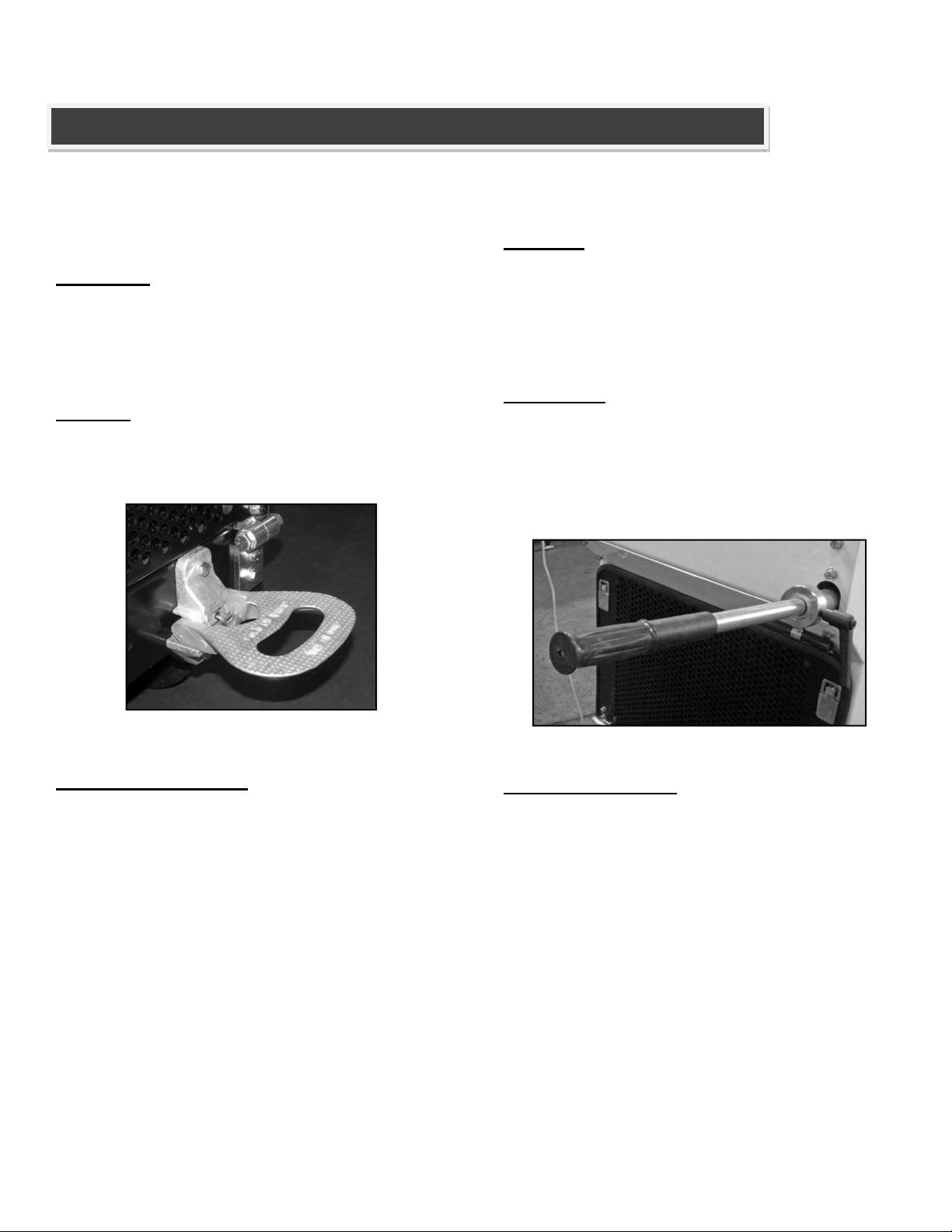

Figure 4: Handlebar

Adjusting the Handlebars

1. Loosen the handlebar adjusting lever.

2. Move the handlebar forward or backward to adjust

the length and retighten the adjusting lever to

secure.

3. Press the Tilt Handlebar pushbutton and move the

handlebar up or down to adjust the angle. Note: The

button only works with the ignition key at the Run

position.

4. To reposition adjustment lever, pull out and move to

desired lever position.

11

Page 15

Control Grip Pushbuttons

The control grip pushbuttons only work with the ignition

key at Run or with the engine running.

Figure 5: Control Grip

Pushbuttons

1. Press the Raise (left) pushbutton to raise the saw

and blade, and release to stop. Note: Always raise

the blade when maneuvering the saw to provide

proper clearance between the blade and the ground.

2. Press the Lower (right) pushbutton to lower the saw

and blade, and release to stop.

3. Press the Tilt Handlebar pushbutton and move the

handlebar up or down to adjust the angle.

Fuel System

WARNING

Always use caution when refueling.

DO NOT operate the saw with a fuel leak.

DO NOT fuel the saw with the engine running.

DO NOT smoke or expose fuel to

open flames when filling the fuel

tank or working with fuel.

CAUTION

Clean up any spilled fuel prior to starting the

engine.

Fuel may seep out from the fuel cap vent

(applicable models) when raising the saw if the

fuel tank is overfilled.

Adding Fuel

1. Lower the saw to level the frame.

2. Turn off the engine and let the saw cool down.

3. Remove the fuel tank cap.

4. Fill the fuel tank with low sulfur or ultra-low sulfur

diesel fuel. DO NOT overfill the tank for expansion

purposes. Refer to the engine manual for

information on appropriate diesel fuels in normal and

cold weather temperatures.

5. Replace the fuel tank cap and secure.

Blade Guard

WARNING

DO NOT operate the saw with the blade guard

raised or removed.

DO NOT remove the blade guard with the

engine running.

Blade exposure should not exceed 180° while

cutting.

Always pivot the front of the blade

guard 180° (fully upward) so the

guard does not swing down

unexpectedly, which may cause serious

injuries.

Always secure the pivoted section of the blade

guard using the detent pin (guards 26” and

up).

When pivoting the front of the blade guard,

raise/lower it cautiously and slowly to avoid

serious injuries.

The blade guard shields the blade and must always be

in place when operating the saw. Blade guards generally

stay in place at all times, except for when changing to

another guard size or when using the guard on the

opposite side of the saw. Regularly inspect the blade

guard and water tubes. Clean, repair, or replace dirty or

damaged components immediately. Note: Always use a

guard size that matches the blade size. Refer to the

parts list for additional information.

Installing the Blade Guard

Always install the blade guard with the blade off the saw.

1. Holding the blade guard handle, face the front of the

blade guard forward and fit the tapered mount on the

side of the guard onto the tapered mount on the

frame.

12

Page 16

Figure 6: Frame Base Mount

2. Insert the lock pin through the hole on the tapered

frame mount to secure the guard.

3. For guards 36” and up, raise the saw slightly. Place

a lock washer and then a flat washer onto the blade

guard screw. Fit the screw through the slot near the

back of the guard and through the hole on the frame

base, and secure the guard to the frame using the

provided wrench.

4. Connect the water supply hose to the blade guard.

Removing the Blade Guard

Always remove the blade guard with the blade off the

saw.

1. Disconnect the water supply hose from the blade

guard.

2. For guards 36” and up, raise the saw slightly.

Remove the screw from the frame base and blade

guard.

3. Remove the lock pin from the tapered frame mount.

4. Use the handle on the blade guard to rock the guard

back and forth while lifting the guard off the tapered

frame mount.

Figure 7: Flange Guard Installed

Removing the Flange Guard

1. Remove the lock pin from the tapered frame mount.

2. Remove the flange guard from the tapered frame

mount.

Diamond Blades

WARNING

DO NOT exceed the blade’s

maximum recommended speed

when cutting. Excessive blade

speeds can cause blade breakage, resulting in

serious injuries and/or death.

DO NOT use damaged blades when cutting to

avoid harming yourself, others, or the saw.

Using the proper blade (size and type) preserves the

blade and improves efficiency, resulting in lower costs.

Refer to the Association of Equipment Manufacturers

(AEM) safety brochure for diamond blades and

www.diamondproducts.com for additional blade

information.

Flange Guard

Install the flange guard over the blade flange that is not

in use.

Installing the Flange Guard

1. Fit the tapered mount on the back of the flange

guard onto the tapered mount on the frame.

2. Insert the lock pin through the hole on the tapered

frame mount to secure the guard.

Inspecting the Blade

Inspect each blade prior to installation and discard all

damaged blades. Inspect the blades for:

Cracks, nicks, and dents

A damaged/deformed arbor (center hole)

Darkness/discoloration near edge of blade

A deformed blade circumference

Segment loss/cracks

Core wear

Bending

Uneven side-widths

13

Page 17

Blade Speed

Refer to the CC7074 RPM Chart, the blade, or the blade

packaging information for the recommended blade

speeds when cutting. DO NOT exceed the maximum

recommended blade speed. DO NOT use a blade for

cutting that requires a lower speed than the minimum

blade shaft speed.

Wrench

Use the wrench provided when installing or removing a

blade. Apply force to the opposite end of the wrench and

tighten the blade shaft bolt/screw to 125 ft-lb (170 Nm)

minimum to secure the outer flange and blade. Note:

125 ft-lb is equivalent to applying 125 pounds at the end

of a 12” wrench.

Figure 8: Wrench

Installing the Blade

WARNING

DO NOT install a blade with the

engine running.

Failure to properly secure the

outer flange and blade may cause parts to

loosen or fall off the saw, resulting in serious

injuries or death!

DO NOT pivot the front of the blade guard up

or down when installing very large blades.

Attempting to pivot the front of a heavy guard

when the guard is positioned higher up for

blade installation makes the guard difficult to

lift and/or lower. In this situation, remove the

blade guard front instead of pivoting it.

Always secure the pivoted section of the blade

guard using the detent pin (guards 26” and

up).

CAUTION

Wear gloves and be alert to the surrounding

environment when handling blades.

The blade can be installed on the right or left side of the

saw. Install the blade on the side preferred or most

appropriate for the cutting task.

1. Select a blade size and type. Remember to check

the blade for damages and discard as necessary.

Note: If changing the blade size, adjust and/or

change all necessary saw components according to

the information in the CC7074 Parts List.

2. Remove the detent pin (guards 26” and up) from the

guard hinge and pivot the front of the blade guard

180° (fully upward) to gain access to the blade

flanges. For larger, heavier guards that are

positioned too high up and are unsafe to pivot,

remove the lock nut and screw from the center of the

guard hinge. Remove the front of the guard. Note:

Have a second trained operator hold the guard in

place while removing the hinge screw and nut.

Figure 9: Detent Pin

3. On the pivoted guards, insert the detent pin through

the interlocking barrels on the top of the guard to

secure the front of the guard. Note: Failure to fully

pivot and secure the front of the guard may cause

serious injuries.

4. Remove the blade shaft bolt. Note: clockwise

loosens on right side, counterclockwise loosens on

left side (when viewed from the operating position)

using the provided wrench.

5. Carefully remove the outer flange. Inspect the flange

assembly and clean or replace dirty/damaged

components.

6. Place the blade against the inner flange. For large

blades, carefully roll the blade up to the inner flange.

Adjust the height of the saw to align the flange and

blade arbor. Note: Point the arrow printed on the

blade in the direction of the blade shaft’s rotation.

7. Align and fit the outer flange and flange pin through

the blade and into the inner flange and blade shaft.

Note: The outer flange should fit snug with the

blade, inner flange, and blade shaft.

8. Slightly rotate the outer flange and blade backward

to eliminate backlash (looseness) between parts.

14

Page 18

9. Place the lock washer and then the flat washer onto

the blade shaft screw and insert the screw into the

blade shaft through the center of the outer flange.

10. Tighten the screw by hand. Slowly lower the saw, if

necessary, until the blade just touches the ground.

11. Tighten the screw again, using the wrench, to 125 ftlb (170 Nm) minimum to secure the outer flange and

blade.

12. Remove the detent pin (guards 26” and up) from the

guard hinge and pivot the front of the guard down

over the blade to secure.

13. If replacing the front of the guard, fit the front and

back of the blade guard together. Place the screw

through the center of the guard hinge and tighten the

lock nut to the other end of the hinge screw to

secure the guard together. Note: Have a second

trained operator hold the guard in place while

replacing the hinge screw and nut.

Removing the Blade

CAUTION

DO NOT remove a blade with the

engine running.

DO NOT pivot the front of the blade guard up

or down when removing very large blades.

Attempting to pivot the front of a heavy guard

when the guard is positioned higher up for

blade removal makes the guard difficult to lift

and/or lower. In this situation, remove the

blade guard front instead of pivoting it.

Always secure the pivoted section of the blade

guard using the detent pin (guards 26” and

up).

1. Remove the detent pin (guards 26” and up) from the

guard hinge and pivot the front of the blade guard

180° (fully upward) to gain access to the blade. For

larger, heavier guards that are positioned too high

up and are unsafe to pivot, remove the lock nut and

screw from the center of the guard hinge. Remove

the front of the guard. Note: Have a second trained

operator hold the guard in place while removing the

hinge screw and nut.

2. On the pivoted guards, insert the detent pin through

the interlocking barrels on the top of the guard to

secure the front of the guard. Note: Failure to fully

pivot and secure the front of the guard may cause

serious injuries.

3. Slowly lower the saw, if necessary, until the blade

just touches the ground.

4. Remove the blade shaft screw using the wrench.

5. Carefully remove the outer flange and blade. Place

the blade in an appropriate storage location. Note: If

the outer flange is difficult to remove, tighten a

setscrew into two of the holes on the outer flange to

help separate the outer flange from the blade.

6. Inspect the flange assembly and clean or replace

dirty/damaged components.

7. Carefully fit the outer flange back into the inner

flange and/or blade shaft.

8. Place the lock washer and then the flat washer onto

the blade shaft screw and insert the screw into the

blade shaft through the center of the outer flange.

9. Retighten the blade shaft screw to secure the

flanges.

10. Remove the detent pin (guards 26” and up) from the

guard hinge and pivot the front of the guard down

over the blade flanges to secure.

11. If replacing the front of the guard, fit the front and

back of the blade guard together. Place the screw

through the center of the guard hinge and tighten the

lock nut to the other end of the hinge screw to

secure the guard together. Note: Have a second

trained operator hold the guard in place while

replacing the hinge screw and nut.

Engine

WARNING

Operate the saw in well-ventilated

areas. Concentrated engine exhaust

can cause loss of consciousness

and/or death.

DO NOT touch the engine/muffler with the

engine running, and always let them cool down

prior to touching or servicing the saw.

DO NOT leave the saw unattended while the

engine is running.

Figure 10: Vernier Throttle

15

Page 19

Vernier Throttle Operation

1. Turn the Hold/Release knob counterclockwise to

loosen the knob.

2. Turn the throttle counterclockwise to increase the

engine/blade speed, or push in the throttle’s springloaded tip and pull the throttle out to increase the

engine/blade speed. Turn the throttle clockwise to

decrease the engine/blade speed, or push in the

throttle’s spring-loaded tip and push the throttle in to

decrease the engine/blade speed.

3. Turn the Hold/Release knob clockwise to tighten the

knob and secure the engine/blade speed.

Tasks Prior to Starting the Engine

Complete the tasks listed below prior to starting the

engine to ensure a safe start:

Check fluids and fill to appropriate levels.

Turn off controls and switches.

Remove tools from area.

The engine will not start unless the following tasks are

completed:

Place speed control lever at Stop.

Pull up emergency stop button.

Close radiator door.

Stopping the Engine

CAUTION

DO NOT leave the saw unattended until the

engine is off and the blade has stopped

spinning.

1. Place the speed control lever at Stop and raise the

blade from the cut.

2. Turn off all controls, switches, and water.

3. Decrease the engine speed to idle for five minutes to

cool down the engine after full load operation.

4. Turn the ignition key to Stop and remove the key.

Speed Control Lever

The speed control lever moves the saw forward and

backward at up to 250 ft/min. Note: The engine must be

running at half throttle or greater to move the saw using

the speed control lever.

Starting the Engine

Notice: In an emergency, press the emergency stop

button to immediately stop the engine and any saw

movement!

1. Increase the engine speed to half throttle.

2. Insert the key into the ignition and turn it to Glow;

hold in this position until glow light turns off, turn the

key to Start and release when the engine starts.

Refer to the chart in the engine manual when using

the glow plug in temperatures below 23°F (-5°C).

Note: If the engine does not start within 10 seconds,

turn off the key and try again approximately 30

seconds later. Refer to Appendix D or the engine

manual for troubleshooting recommendations after

several failed attempts.

3. Let the engine warm up. Check all warning lights

and turn off the engine immediately if there are any

problems prior to operating the saw.

Figure 11: Speed Control Lever

1. Slowly push the lever toward Forward to move the

saw forward and release when at the desired

traveling speed.

2. Slowly pull the lever toward Reverse to move the

saw backward and release when at the desired

traveling speed.

3. Place the lever at Stop to put the saw in neutral. DO

NOT assume at any time that the neutral position will

act as a brake when saw is running. Note: Always

start the engine with the speed control lever at Stop.

16

Page 20

Blade Lowering Speed

Turn the Blade Lowering Speed valve counterclockwise

to increase the blade’s lowering speed and clockwise to

decrease the blade’s lowering speed. Note: The valve

does not adjust the blade’s raising speed.

5. Connect water supply hose (54”) from the hose

fitting at bottom right side of the upper gearbox to

the manifold on the blade guard.

6. Move the water valve lever on right side of saw to

full open. Increase or decrease water flow by

moving the valve lever on the left side of the saw

connected to the source hose. Note: water on/off

operation and flow adjustment can be made from

either side of saw, if desired.

7. When finished cutting, shut off water supply to the

blade guard, shut off water supply at source and

remove source hose from the saw.

8. Drain water from upper gearbox heat sink. (ref.

maintenance instructions: upper gearbox)

Cutting Guides

Figure 12: Blade Lowering Speed Valve

Water Supply

The water supply cools the gearbox, blade and

minimizes dust when cutting. Note: Always test the water

supply for adequate pressure and flow prior to cutting.

Using the Water Supply

1. Connect the water source hose to the water valve

fitting on the left side of the saw.

2. Connect one end of the water supply hose (60”) to

fitting on the right side of the saw (fig. 13).

Use the cutting guides as needed to help follow the

cutting line. Always check the cutting guides for proper

alignment with the blade prior to cutting.

Adjusting the Front Pointer

1. Remove the lanyard from the cable cleat.

2. Lower the front pointer frame to the ground.

3. Loosen both front pointer frame screws.

4. Divide an 8–10 ft piece of string in half.

5. Place the looped end of string into a gullet on the

backside of the blade.

6. Place one string line up against the backside of the

blade and one string line up against the front side of

the blade. Holding the string ends in one hand,

tension the lines out toward the front pointer rod.

Figure 13: Water Supply Hose

3. Connect the other end of the water supply hose

(60”) to right side of water solenoid valve located

above the upper gearbox.

4. Connect the short water supply hose (32”) from the

left side of the water solenoid valve to hose fitting at

bottom left side of the upper gearbox.

Figure 14: Tensioned String Line

7. Adjust the pointer rod to place the tip between the

tensioned string lines.

8. Retighten both front pointer frame screws.

9. Lift the frame off the ground when finished.

10. Tension the lanyard and secure it to the cable cleat.

17

Page 21

Adjusting the Rear Pointer(s)

1. Loosen the rear pointer nut and screw on the back

of the frame base.

2. Adjust the orientation of the rear pointer rod and

retighten the screw and nut to secure.

Concrete Cutting

WARNING

DO NOT expose yourself or anyone

else to the direct line of the blade

when operating the saw.

The direct work area should not contain buried

or embedded electrical, gas, or water lines that

could be damaged and/or cause personal

injury while cutting.

Note: Always raise the blade to provide proper clearance

between the blade and the ground when maneuvering

the saw.

Making a Cut

1. Align the blade and cutting guide(s) with the cut line.

2. If the saw is equipped with a clutch (optional), turn

on the Blade Clutch switch with engine at idle to

start the blade rotation.

3. Turn on the water and adjust the water flow.

4. Lower the blade to just above the cutting surface

and set the cutting depth indicator at zero (ref. fig.

15).

Helpful Hints Prior to Cutting

Keep the following in mind for better efficiency while

cutting:

Use just enough handle pressure to guide the saw

down the cutting line. DO NOT forcibly direct (twist)

the saw from side to side when cutting. DO NOT

jam, cock, or wedge the blade in a cut.

Moving too quickly when cutting may stall the saw,

or may cause the blade to climb out from the cut. If

the saw stalls while cutting, put the saw in neutral

and raise the blade from the cut to restart the

engine.

Avoid sawing excessively deep to preserve the

blade and reduce sawing costs.

DO NOT lower the blade too quickly or move the

saw forward too quickly when finishing a partial-cut

to avoid forcing the blade into the concrete.

Always have a proper water flow when cutting for

maximum blade efficiency. Using too much water

when cutting will make the slurry look clear. Not

using enough water will make the slurry look thick

and pasty.

Refer to the Diamond Products’ Guide for

Professional Concrete Cutters for additional cutting

tips and information.

Tasks Prior to Cutting

Complete the following tasks prior to cutting:

Align the cutting guide(s) with the blade.

Clearly mark the cutting line.

Turn off all electricity, gas, and water around the

direct work area.

Figure 15: Cutting Depth

Indicator

5. Turn on the Auto Water switch if desired for

automatic water on/off when cutting. Note: When the

cutting depth indicator enters the Auto Water On/Off

Zone the water will turn on/off automatically and will

not require the water flow to be reset every time the

blade is lowered back into the cut. If the auto water

feature is functioning in reverse (water goes off

when blade is lowered into cut), rotate depth

indicator 360 degrees to reset.

6. Slowly lower the blade into the surface at the start of

the cut line for the initial cut. Make the initial pass

across the entire cutting line using the most effective

travel speed. If the blade is coming up out of the cut,

decrease travel speed and/or feed depth. DO NOT

CUT FULL DEPTH IN ONE PASS. Always use the

step-cut method when cutting for maximum

efficiency. For example, when cutting to a depth of

ten inches, begin with a two-inch deep maximum

initial pass, then a four-inch deep pass, and finish

with another four-inch deep pass to complete the

cut.

7. Raise the blade out of the cut and reposition the saw

at the start of the cut line. DO NOT move backwards

with the blade in a previous cut.

18

Page 22

8. At the start of the cut line, lower the blade back into

the cut and make a second, deeper pass across the

entire cutting line.

9. Continue the step-cut process to reach the

maximum depth. DO NOT cut any deeper than

required.

Making a Cut Using the Blade Depth Stop

1. Align the blade and cutting guide(s) with the cut line.

2. If the saw is equipped with a clutch (optional), turn

on the Blade Clutch switch with the engine at idle to

start the blade rotation.

3. Turn on the water and adjust the water flow.

4. Lower the blade to just above the cutting surface

and set the cutting depth indicator at zero.

5. Turn on the Auto Water switch if desired for

automatic water on/off when cutting.

6. Slowly lower the blade into the surface to the

desired cut depth. Note: Initial cut should be less

than 2 inches.

7. Push the Blade Depth Stop button to the “Set Blade

Depth” position. The Blade Depth Set light will turn

on, which means the cutting depth is set.

8. Raise the blade out of the cut and reposition the saw

at the start of the cut. DO NOT move backwards with

the blade in a previous cut.

9. Push the Blade Depth Stop button to the “Override

Blade Depth” position and hold it down for

approximately three seconds, noting when the Blade

Depth Set light goes out. Set the cutting depth at a

different depth measurement following guidelines in

steps 6 & 7.

10. Continue the step-cut process using the depth stop

to reach the maximum depth. DO NOT cut any

deeper than required.

Continuing a Partial-Cut

1. Maneuver the saw to the desired location.

2. Align the blade with the previous cut and slowly

lower the blade back into the concrete. Use extreme

caution to make sure the blade is perfectly aligned

within the cut. DO NOT continue cutting until the

blade is aligned within the cut!

3. Continue the step-cut process (using the blade

depth stop if preferred) to reach the maximum depth.

DO NOT cut any deeper than required.

Finishing a Cut

1. Place the speed control lever at Stop.

2. Raise the blade from the cut (provide proper ground

clearance).

3. If the saw is equipped with a clutch (optional), turn

off the Blade Clutch switch with engine at idle to stop

the blade rotation.

4. Turn off the Auto Water switch and water supply.

19

Page 23

Page 24

Maintaining the CC7074

Failure to read and comply with the maintenance

instructions provided in this manual prior to performing

maintenance may result in serious injuries and/or death,

and may harm the saw. DO NOT attempt to perform

maintenance on the saw if you are not properly trained

for it, or are not supervised by an experienced person.

Refer to the CC7074 Parts List for additional information

and part diagrams when performing maintenance tasks.

Refer to the engine manual and manufacturer as the

primary source for all safety, operations, and

maintenance instructions for the engine. Contact the saw

and/or engine manufacturer with any additional

questions.

Remove all necessary guards and access panels prior to

servicing the saw. Replace prior to operating.

Maintenance Overview

Complete the following tasks as required. DO NOT delay

maintenance! Print the Daily Maintenance Task Chart

from Appendix B to help keep track of maintenance

tasks completed daily.

Daily

Inspect the saw for damages and repair.

Tighten loose nuts, screws, and bolts.

Check all fluid levels (fuel, engine oil, hydraulic fluid,

radiator fluid, upper and lower gearbox oil) and fill as

necessary.

Wipe down and clean all saw components to remove

dust, debris, and slurry (especially from fans).

Inspect all belts for tension and wear. Replace or

tension as necessary.

Clean the air cleaner (see engine manual).

Check and clean the water filter strainer at water

valve fitting.

Clean the radiator and wipe down the cooling fan.

Drain the upper gearbox heat sink.

Look for fluid leaks and check all hoses. Repair all

damaged components.

Every 250 Hours

Change the hydraulic oil filter (replace once after

first 50 hours, then as scheduled).

Change the in-line fuel filter.

Every 500 Hours

Change the radiator fluid.

Note: Refer to the engine manual and manufacturer for a

full list of routine engine maintenance tasks.

Part Lubrication

WARNING

DO NOT grease parts with the

engine running.

Lubricate all necessary parts on schedule for maximum

saw efficiency. Occasionally lubricate controls, cables,

and linkages with a spray lubricant when movement

becomes stiff and/or sluggish. Use one to two full pumps

of NLGI No. 2 premium, lithium-based grease when

lubricating all grease fittings. Note: Use more grease on

bearing grease fittings if they are too hot to touch after

completing work.

Figure 16: Water Filter Strainer

Every 100 Hours

Lubricate the front axle bearing grease fittings (2).

Lubricate the hydraulic lift cylinder grease fitting (1).

Clean the upper and lower gearbox breather vents.

Change the upper and lower gearbox oil.

Clean the in-line oil suction filter.

Water Filter Strainer (Optional)

Inspect the water filter strainer (component included with

optional water pump) daily and clean as necessary.

1. Twist off the filter strainer cap.

2. Remove the mesh strainer and rinse out with water.

Wipe out the inside of the filter container.

21

Page 25

3. Reinsert the mesh strainer and retighten the strainer

cap to the filter.

Speed Control Lever

Adjusting the Lever Tension

Adjust the tension felt in the speed control lever, when

moving the lever forward and backward, to the desired

setting as necessary.

1. Remove front access panel.

2. Remove the grease cap from the pivot housing.

3. Loosen the jam nut on the opposite side of the

speed control frame using provided wrench.

4. Use the Allen wrench provided to adjust the

shoulder screw.

5. Retighten the jam nut.

6. Move the speed control lever forward and backward

to test the lever tension. Readjust the shoulder

screw/jam nut if desired.

7. Secure the grease cap to the pivot housing.

8. Replace access panel and retighten.

Adjusting the Spring Plungers

Adjust the spring plungers if the speed control lever feels

floppy or loose when moving the lever forward and

backward, or when the lever is hard to place into or out

of the Stop position.

1. Loosen both hex nuts from the speed control tube.

2. Screw the spring plungers slightly out to let the

speed control lever move easily into and out of the

Stop position. Screw the spring plungers slightly in

to let the speed control lever move forward and

backward firmly in the forward/reverse slot.

3. Retighten both hex nuts to secure.

Installing the Inner Blade Flange

1. Inspect the inner flange for damages. Clean or

replace damaged components as necessary.

2. Align the flange with the blade shaft key and place

the flange onto the blade shaft.

3. Apply Loctite 262 (red) or an equivalent to the

setscrew threads.

4. Tighten the setscrew(s) into the back of the inner

flange to secure.

Removing the Inner Blade Flange

1. Remove the setscrew(s) from the back of the inner

flange using an Allen wrench.

2. Carefully remove the flange from the blade shaft.

Drive Alignment

Drive Alignment

Adjust the rear axle when the saw’s drive alignment is off

(saw will not cut in a straight line). Note: The rear axle

does not have to be adjusted for straightness; it can also

be adjusted based on the specifications of the cutting

job.

1. Turn the tap bolt clockwise using the provided

wrench to adjust the drive alignment toward the

right, or counterclockwise to adjust the drive

alignment toward the left.

Inner Blade Flange

Figure 16: Inner Flange

Figure 17: Adjustment Bolt

Wheels

WARNING

Raise the saw to a proper height for

access when working underneath

the saw. Use chocks to block the

22

wheels, and fit blocks or jacks under the frame

edges at the front and back of the frame.

Page 26

1. Move the saw to level ground. Use a jack to lift the

rear wheels off the ground.

2. Pry the hubcap off the wheel using a screwdriver or

pry bar.

3. Remove all four lug nuts from the wheel.

4. Remove the wheel and place a new wheel onto the

wheel hub.

5. Replace the lug nuts and tighten to secure.

6. Replace the hubcap and secure in place using a

rubber mallet.

7. Replace the second rear wheel as directed.

8. Slowly lower the jack and remove the jack stand

when the wheels are firmly touching the ground.

Figure 189: Front Wheels

Replacing the Front Wheels

Replace the front wheels when they are damaged and/or

affecting saw performance.

1. Move the saw to level ground. Use a jack to lift the

front wheels off the ground.

2. Remove all four screws from the wheel cover.

3. Pry the wheel cover gasket and wheel cover off the

wheel using a screwdriver or pry bar.

4. Remove the screw securing the wheel, and then

remove the wheel from the front axle.

5. Place a new wheel onto the front axle.

6. Fit the lock washer and then the flat washer onto the

wheel screw and retighten the screw through the

center of the wheel to secure.

7. Replace the wheel cover gasket and wheel cover,

and retighten all four wheel cover screws to secure.

8. Replace the second front wheel as directed above.

9. Slowly lower the jack and remove the jack stand

when the wheels are firmly touching the ground.

Replacing the Rear Wheels

Replace the rear wheels when they are damaged and/or

affecting saw performance.

Maximum Cutting Depth

WARNING

Raise the saw to a proper height for

access when working underneath

the saw. Use chocks to block the

wheels, and fit blocks or jacks under the frame

edges at the front and back of the frame.

Always adjust the maximum cutting depth when

changing the blade size, sheave size, flange size, and

belt size to avoid damaging saw components. Refer to

the CC7074 Parts List for additional information.

1. Raise the saw to gain access to the maximum

cutting depth bolts underneath the frame base.

2. Loosen the nut on both bolts.

3. Turn the bolts counterclockwise to decrease the

maximum cutting depth, or turn the bolts clockwise

to increase the maximum cutting depth. Note: Both

bolts must be the same length when finished.

Figure 191: Maximum Depth Bolts

4. Bottom out the nut on each bolt with the frame base

Figure 20: Rear Wheels

to secure the bolts.

23

Page 27

5. Remove all tools from the area and lower the saw

completely. The blade flanges must be at least 1/4”

from the ground to prevent component damage.

Note: Make sure both skid plates on the front of the

saw are in the correct set of holes in order to lower

the saw completely (refer to CC7074 Parts List).

6. Readjust the depth bolts as necessary.

Handlebar Cylinder Rod

The handlebar cylinder rod must be serviced by

Diamond Products if the handlebars can be moved up or

down in excess amounts when locked in place

(movement may feel sluggish). Send the entire assembly

to Diamond Products to be recharged or pressurized.

Removing the Cylinder Rod

1. Disconnect the two wires from the solenoid block

valve.

2. Remove the hairpin cotter and clevis pin from the

cylinder rod end.

Figure 20: Clevis Pin

3. Holding the cylinder, remove the hairpin cotter and

clevis pin from the isolator mount tube.

4. Remove the entire assembly from the saw.

Connecting the Cylinder Rod

1. Fit the cylinder into the cylinder rod end mount and

isolator mount tube.

2. Fit the clevis pin through the cylinder rod end mount

and cylinder rod end. Secure in place with the

hairpin cotter.

3. Fit the second clevis pin through the isolator mount

tube and cylinder u-block. Secure in place with the

hairpin cotter.

Figure 21: Clevis Pin

4. Connect the two wires to the solenoid block valve

according to the wiring diagrams in the CC7074

Parts List.

Battery

WARNING

Ignitable explosive gases are emitted

from the battery. DO NOT expose the

battery to sparks or open flames, and

keep the area around the battery

well-ventilated.

Disconnect the battery prior to servicing the

saw (unless stated otherwise).

Always keep the battery cable clamps

away from the battery terminals when

the battery is disconnected to avoid

accidental connections while servicing.

Always be sure to connect the battery cables

to the proper terminal when reconnecting.

CAUTION

Use a proper battery tester when testing the

battery strength.

Use protective eyewear or a face shield and

avoid contact with the skin when

handling/servicing the battery.

The saw contains a charged battery with one positive

cable lead and one negative cable lead.

24

Page 28

Figure 22: Battery

Battery Type

12 Volt, Group 24

Servicing the Battery

1. Remove both wing nut/washer assemblies from the

battery lid and remove the lid.

2. Remove the hose standoffs and wing nuts from the

battery hold-down bracket and remove the bracket.

3. Disconnect the negative cable lead from the

negative terminal. Note: Always disconnect the

negative cable first.

4. Disconnect the positive cable lead from the positive

terminal.

5. Carefully remove the battery from the battery box

using the carry strap.

6. When replacing the battery, carefully place a new

battery into the battery box. Bring the old battery to a

recycling facility; many battery retailers also accept

old batteries.

7. When cleaning the battery, inspect the terminals,

clamps, and cables for damages and corrosion.

Clean the terminals and clamps using a wire brush,

or use another approved technique for cleaning. Use

acid-free, acid-resistant grease to grease the battery

clamps and terminals. Carefully place the battery

back into the battery box.

8. Reconnect the positive cable lead to the positive

battery terminal. Note: Always reconnect the positive

cable first.

9. Reconnect the negative cable lead to the negative

battery terminal.

10. Make sure the j-bolts are hooked onto the eyebolts

at the bottom of the battery box. Fit the battery holddown bracket through the j-bolts and rest the bracket

on the battery.

11. Fit a fender washer and then a lock washer onto

both j-bolts and retighten the wing nuts to the j-bolts

to secure the battery.

12. Fit the hose standoffs onto both j-bolts.

13. Replace the battery lid, fit a fender washer and then

a lock washer onto each j-bolt, and retighten both

wing nuts to secure the lid.

Electrical System

WARNING

Disconnect the battery when

servicing the electrical system

unless stated otherwise.

Always use the correct size fuses (amps) to

prevent fires.

Inspect all fuses if switches or controls are not working

properly and replace as necessary. If fuses are failing

frequently, determine the cause and repair immediately.

Refer to the CC7074 Parts List for electrical diagrams.

Radiator

Open radiator door, power wash the radiator and

wipe down the radiator fan daily.

Turn off the saw and inspect the cooling system

when the coolant temperature light turns on, or when

the coolant temperature gauge passes the red mark.

Adjust the radiator door latches if the door becomes

too difficult to latch, or when gaps between the door

and the frame allow air flow through the door.

Adding Radiator Fluid

1. Remove the coolant recovery tank cap.

2. Add a 50/50 mix of water and anti-freeze to the tank.

Note: Refer to the Cold Full and Hot Full marks

when filling and operating.

3. Replace the coolant recovery tank cap and tighten to

secure.

Figure 23: Recovery Tank

25

Page 29

Changing the Radiator Fluid

Change the radiator fluid every 500 hours of operation,

or every two years (whichever comes first). DO NOT

drain the radiator fluid when hot.

1. Open the radiator door.

2. Place a drain pan under the radiator drain valve.

Figure 26: Drain Valve Wing Nut

3. Loosen the drain valve wing nut (below radiator

door) and drain the fluid completely. Dispose of the

used fluid according to city, state, and federal

regulations.

4. Tighten the drain valve wing nut to secure.

5. Open the air bleed valve wing nut (inside radiator

door, near top of door). Slowly remove the radiator

cap. Note: Remove the radiator cap only when it

feels cool to the touch, and always open it slowly to

relieve any built up pressure.

9. Replace the radiator cap and retighten to secure.

Hydraulic System

WARNING

Always place a piece of

cardboard or paper up against

hydraulic components, or use a

leak detection fluid to check for hydraulic fluid

leaks. Keep all body parts away from leaks

and/or areas that may eject hydraulic fluid.

Pressurized hydraulic fluid can penetrate the

skin, causing serious injuries. Seek medical

attention immediately!

Always make sure any hydraulic components

being serviced are not supporting the weight of

other saw components. If a particular

component is under pressure when

connections points are loosened, oil may spray

out forcefully.

Inspect all hydraulic hoses and fittings daily for leaks.

Remember to use cardboard or a piece of paper when

checking for leaks and replace damaged component s

immediately.

Adding Fluid to the Hydraulic Lift Pump

Figure 24: Air Bleed Valve Wing Nut

6. Add a 50/50 mix of water and anti-freeze through the

radiator fill port until it begins to leak out of the air

bleed valve.

7. Close the air bleed valve wing nut.

8. Add more radiator fluid through the fill port until the

fluid reaches the overflow hole inside the filler neck.

Figure 28: Hydraulic Lift Pump

Check the fluid daily and add fluid to the pump as

necessary.

1. Lower the saw to level the frame.

2. Remove pump cover.

3. Remove the shorter hydraulic pump breather cap.

4. Add SAE15W-40 oil or an equivalent to just below

where the fill port extends into the hydraulic pump.

Do not overfill, as this will cause oil leakage through

the breather cap when raising the saw.

5. Replace the breather cap and retighten to secure.

26

Page 30

Adding Hydraulic Fluid to the Reservoir Tank

Check the hydraulic fluid daily and add fluid to the

reservoir tank as necessary.

1. Lower the saw to level the engine.

2. Remove the reservoir tank cap.

3. Add SAE 15W-40 oil or equivalent to the reservoir

tank fill line. DO NOT overfill as fluid will leak out

from the reservoir cap.

4. Replace the cap and tighten to secure.

Figure 25: Reservoir Tank

Replacing the Hydraulic Oil Filter