Page 1

DIAMOND

PRODUCTS

HYDRAULIC POWER UNIT

PARTS LIST &

OPERATOR’S MANUAL

MODELS:

CB150/240

March 2013

PART#: 1800944

Page 2

Proposition 65

State of California

Warning !

Engine exhaust and some its constituents are known to the State

of California to cause cancer, birth defects, and/or other

reproductive harm.

Notification of Spark Arrester Requirement for

State of California

It is a violation of Section 4442 or 4443 to use or operate the

engine on any forest-covered, brush-covered, or grass-covered land

unless the engine is equipped with a spark arrester, as defined in

Section 4442, maintained in effective working order or the engine

is constructed, equipped, and maintained for the prevention of fire

pursuant to Section 4443.

Page 3

Table of Contents

Description Page No.

1. CB150/240 COMMON PARTS ................................................................4

2. CB150/240 HYDRAULIC TANK .............................................................10

3. HYDRAULIC SCHEMATIC .....................................................................11

4. HOSE KITS .............................................................................................12

5. CB240 GAS COMPONENTS ..................................................................14

6. ELECTRIC SCHEMATIC ........................................................................16

7. BRAKE ASSEMBLY ...............................................................................17

8. CB150 ELECTRIC COMPONENTS ........................................................18

9. STARTER BOX ......................................................................................19

10. STARTER BOX ASSEMBLY .................................................................20

11. REFERENCE VIEWS .............................................................................23

12. GENERAL SAFETY PRECAUTIONS ....................................................24

13. DESCRIPTION & SPECIFICATIONS ....................................................26

14. OPERATING INSTRUCTIONS ..............................................................27

15. DRIVEN EQUIPMENT ............................................................................29

16. MAINTENANCE .....................................................................................29

17. TROUBLESHOOTING ...........................................................................30

18. WARRANTY…………………………………………………….REAR COVER

Page 4

4646107 CB150/240 COMMON PARTS

4

44

TANK POSITION

FOR GAS UNIT

57

18

20

5

58

43

15

6059

1314

9

9

17

52

53

33

36

54

18

A

10

9

22

19

35

23

27

DETAIL A

SCALE 1 : 4

55

31

34

Page 5

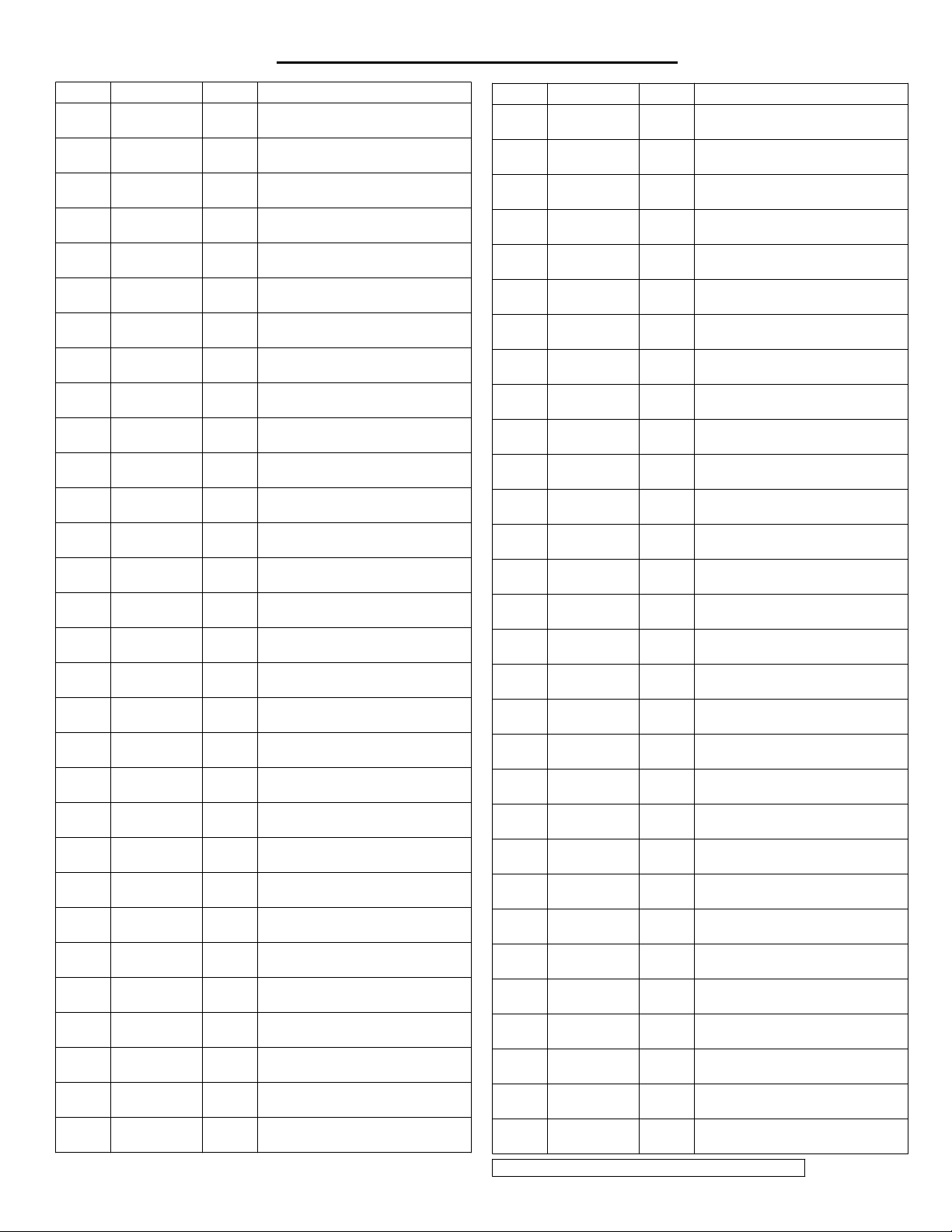

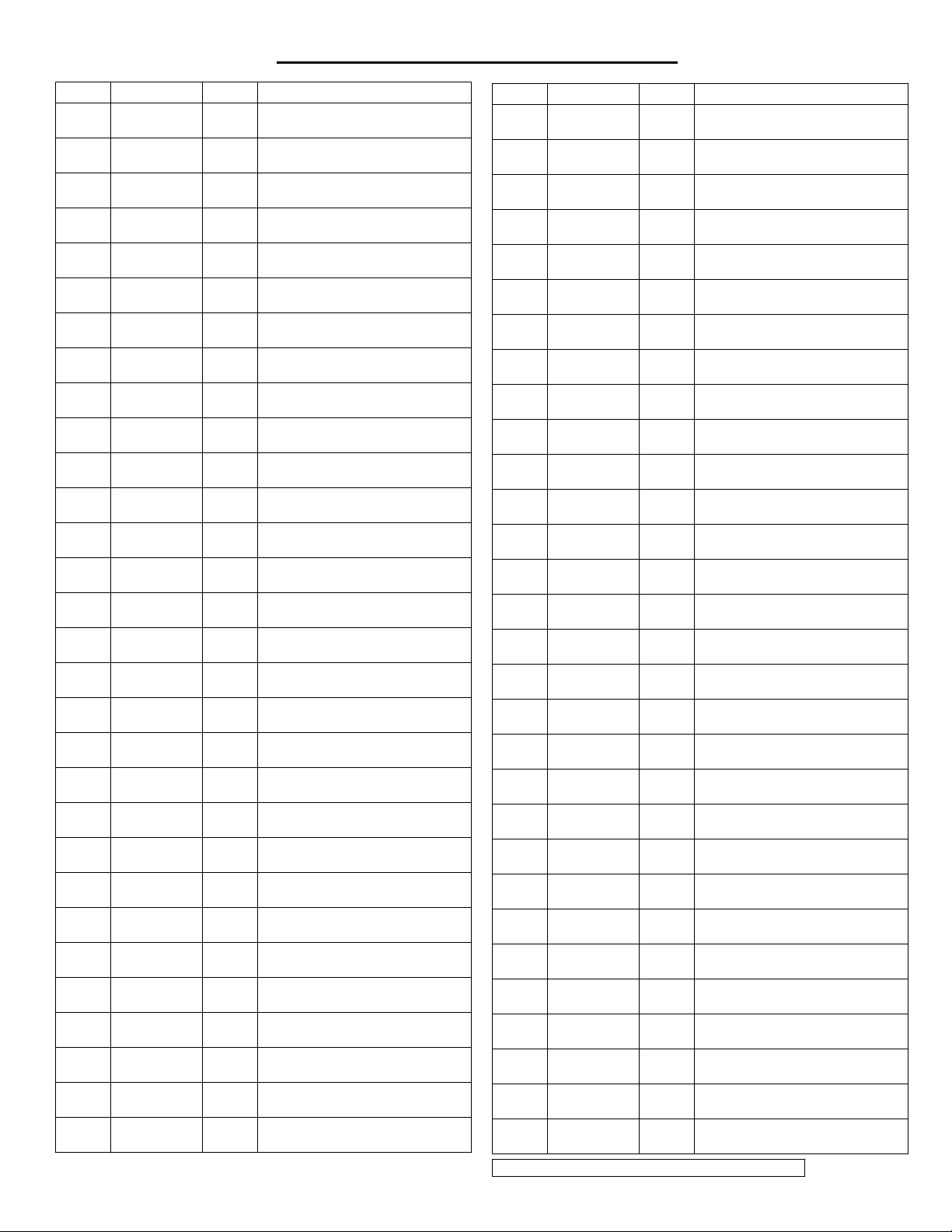

4646107 CB150/240 COMMON PARTS.

5

PART NO.

146460971

2

4

6

8

10

11 3201654 1 Valve, Flow Control

12 4646080

13

14

15 2900538 12

17

2900303

3200250

3201675

2900039

2 Lock Nut, M8 Nylon

1

1

1

4290006916

16

DESCRIPTIONQTY.ITEM

Frame, Power Supply

Flat Washer, 3/4" SAE42900003

Wheel, 8 x 2 x 3/4"425014393

Set Collar, 3/4"42400615

Instrument Panel146461005

Manifold, 3/4 NPT14646101

Manifold, SAE O-Ring146461027

Heat Exchanger12400256

Flat Washer, 5/16" SAE3429000229

Handle

Gauge, Hydraulic, 3000

PSI

Elbow, 1/4" M. JIC to 1/4"

F. Pipe

Cap Screw, Hex Hd., 5/1618 x 1-3/4"

Cap Screw, Hex Hd., 5/1618 x 2-3/4"

Lock Nut, 5/16-18 Nylon

ITEM PART NO. QTY. DESCRIPTION

31 3200479 1

32 3201434 1 Plug, 1/2" SAE O-Ring Hex

33 3200137 1 Hex Nipple, 3/4" NPT

34 3200383 1

35 3200371 1

36 3200330 1

37 4646010 1 Pump Mount (Machined)

38 2600490 1

39 2900006 2 Lock Washer, 3/8" Split

40 2900005 2

41 3200298 1

42 3200297 1

43 4646106 1

44 4646105 1 Hydraulic Tank Assembly

45 3201671 1 Hex Nipple, 1" NPT

46 3200289 1

47 3200288 2 Plug, 1" NPT

Plug, 3/4" NPT Square

Head

Nipple, Hex, 3/4" MPT TO

1/2" MPT

Adaptor, 1/2" MPT to 1/2"

O-Ring

Adapter, 3/4" M. Pipe to

3/4" O-Ring

Hydraulic Pump, .85 CI, W/

Key

Cap Screw, Hex Hd., 3/816 x 1"

Elbow, 3/4" O-Ring to 1/2"

M. JIC

Elbow, 1" O-Ring to 1" M.

JIC

Tank / Box Mounting

Bracket

Elbow, 1" M. Pipe to 1" M.

JIC

24

29

290100019

3200400

320129127

Flat Washer, 1/4" SAE20290000918

Cap Screw, Hex Hd., 1/4-

8

20 x 2-1/4"

Cap Screw, Hex Hd., 1/4-

2290100120

20 x 2-1/2"

Lock Nut, 1/4-20 Nylon10290001021

Fitting, 3/4" M. Pipe to 3/4"

2320165922

M. Garden

Fitting, 3/4" F. Garden

1320017723

Union Swivel

Elbow, 3/4" O-Ring to 3/4"

2

Male JIC

Elbow, 5/8" O-Ring to 1/2"

3320036625

Male JIC, 90 Deg.

Elbow, 1/2" O-Ring to 1/2"

1320028526

Male JIC

Adapter, 1/2"M.O-Ring to

1

1/4" MJIC

Adapter, 3/4" M. JIC to 3/4"

1320009728

M. Pipe

Elbow, 3/4" F. JIC to 3/4"

13200417

M. JIC

Adapter, 3/4" M. Pipe to

1320152230

1/2" M. JIC

48 3200505 1 Filter Head

49 3200111 1

50 3201175 1 Hydraulic Filter Element

51 3200502 1 Gauge, Hydraulic Pressure

52 3200100 1

53 3200101 1

54 3200104 1 Coupler, 1/2" Q.D.

55 3200105 1 Nipple, 1/2" Q.D.

56 4646138 1

57 1800924 1 Decal, CB 15/24XL Valve

58 1800941 1

59 1800169 1 Serial Number Plate, US

60 2900096 2 Rivet, 3/32" Dia.

Not Shown: PUMP SEAL KIT, #2703142

Elbow, 1" M. Pipe to 3/4"

M. JIC

Coupler, 3/4" Quick

Disconnect

Nipple, 3/4" Quick

Disconnect

Brake Assembly,

CB150/240

Decal, Hydraulic Power

Supply

Page 6

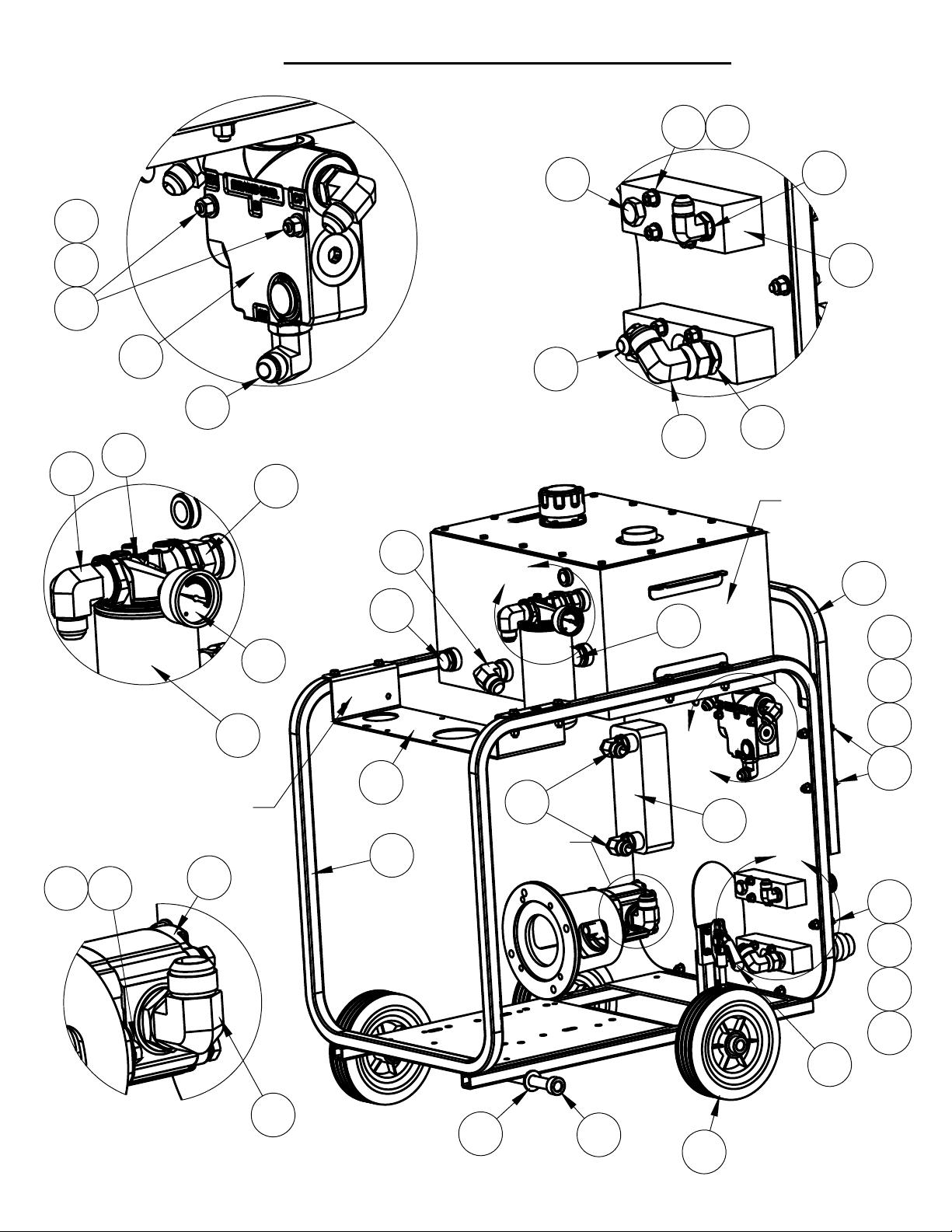

4646107 CB150/240 COMMON PARTS

6

18 21

18

21

20

11

48

49

DETAIL F

SCALE 1 : 4

3x

25

50

51

45

DETAIL C

SCALE 1 : 3

46

47

32

DETAIL B

SCALE 1 : 4

30

F

29

47

26

7

28

TANK & FILTER

POSITION

FOR GAS UNIT

12

17

9

9

BRACKET POSITION

FOR GAS UNIT

39

40

DETAIL E

SCALE 1 : 3

38

42

43

C

24

8

1

2

E

B

56

4

3

16

15

9

9

17

Page 7

4646107 CB150/240 COMMON PARTS.

7

PART NO.

146460971

2

4

6

8

10

11 3201654 1 Valve, Flow Control

12 4646080

13

14

15 2900538 12

17

2900303

3200250

3201675

2900039

2 Lock Nut, M8 Nylon

1

1

1

4290006916

16

DESCRIPTIONQTY.ITEM

Frame, Power Supply

Flat Washer, 3/4" SAE42900003

Wheel, 8 x 2 x 3/4"425014393

Set Collar, 3/4"42400615

Instrument Panel146461005

Manifold, 3/4 NPT14646101

Manifold, SAE O-Ring146461027

Heat Exchanger12400256

Flat Washer, 5/16" SAE3429000229

Handle

Gauge, Hydraulic, 3000

PSI

Elbow, 1/4" M. JIC to 1/4"

F. Pipe

Cap Screw, Hex Hd., 5/1618 x 1-3/4"

Cap Screw, Hex Hd., 5/1618 x 2-3/4"

Lock Nut, 5/16-18 Nylon

ITEM PART NO. QTY. DESCRIPTION

31 3200479 1

32 3201434 1 Plug, 1/2" SAE O-Ring Hex

33 3200137 1 Hex Nipple, 3/4" NPT

34 3200383 1

35 3200371 1

36 3200330 1

37 4646010 1 Pump Mount (Machined)

38 2600490 1

39 2900006 2 Lock Washer, 3/8" Split

40 2900005 2

41 3200298 1

42 3200297 1

43 4646106 1

44 4646105 1 Hydraulic Tank Assembly

45 3201671 1 Hex Nipple, 1" NPT

46 3200289 1

47 3200288 2 Plug, 1" NPT

Plug, 3/4" NPT Square

Head

Nipple, Hex, 3/4" MPT TO

1/2" MPT

Adaptor, 1/2" MPT to 1/2"

O-Ring

Adapter, 3/4" M. Pipe to

3/4" O-Ring

Hydraulic Pump, .85 CI, W/

Key

Cap Screw, Hex Hd., 3/816 x 1"

Elbow, 3/4" O-Ring to 1/2"

M. JIC

Elbow, 1" O-Ring to 1" M.

JIC

Tank / Box Mounting

Bracket

Elbow, 1" M. Pipe to 1" M.

JIC

24

29

290100019

3200400

320129127

Flat Washer, 1/4" SAE20290000918

Cap Screw, Hex Hd., 1/4-

8

20 x 2-1/4"

Cap Screw, Hex Hd., 1/4-

2290100120

20 x 2-1/2"

Lock Nut, 1/4-20 Nylon10290001021

Fitting, 3/4" M. Pipe to 3/4"

2320165922

M. Garden

Fitting, 3/4" F. Garden

1320017723

Union Swivel

Elbow, 3/4" O-Ring to 3/4"

2

Male JIC

Elbow, 5/8" O-Ring to 1/2"

3320036625

Male JIC, 90 Deg.

Elbow, 1/2" O-Ring to 1/2"

1320028526

Male JIC

Adapter, 1/2"M.O-Ring to

1

1/4" MJIC

Adapter, 3/4" M. JIC to 3/4"

1320009728

M. Pipe

Elbow, 3/4" F. JIC to 3/4"

13200417

M. JIC

Adapter, 3/4" M. Pipe to

1320152230

1/2" M. JIC

48 3200505 1 Filter Head

49 3200111 1

50 3201175 1 Hydraulic Filter Element

51 3200502 1 Gauge, Hydraulic Pressure

52 3200100 1

53 3200101 1

54 3200104 1 Coupler, 1/2" Q.D.

55 3200105 1 Nipple, 1/2" Q.D.

56 4646138 1

57 1800924 1 Decal, CB 15/24XL Valve

58 1800941 1

59 1800169 1 Serial Number Plate, US

60 2900096 2 Rivet, 3/32" Dia.

Not Shown: PUMP SEAL KIT, #2703142

Elbow, 1" M. Pipe to 3/4"

M. JIC

Coupler, 3/4" Quick

Disconnect

Nipple, 3/4" Quick

Disconnect

Brake Assembly,

CB150/240

Decal, Hydraulic Power

Supply

Page 8

SQUARE HOLE

8

ALWAYS AT

FILTER END.

4646107 CB150/240

COMMON PARTS

47

FILTER POSITION FOR

ELECTRIC UNIT

TANK POSITION FOR

ELECTRIC UNIT

Page 9

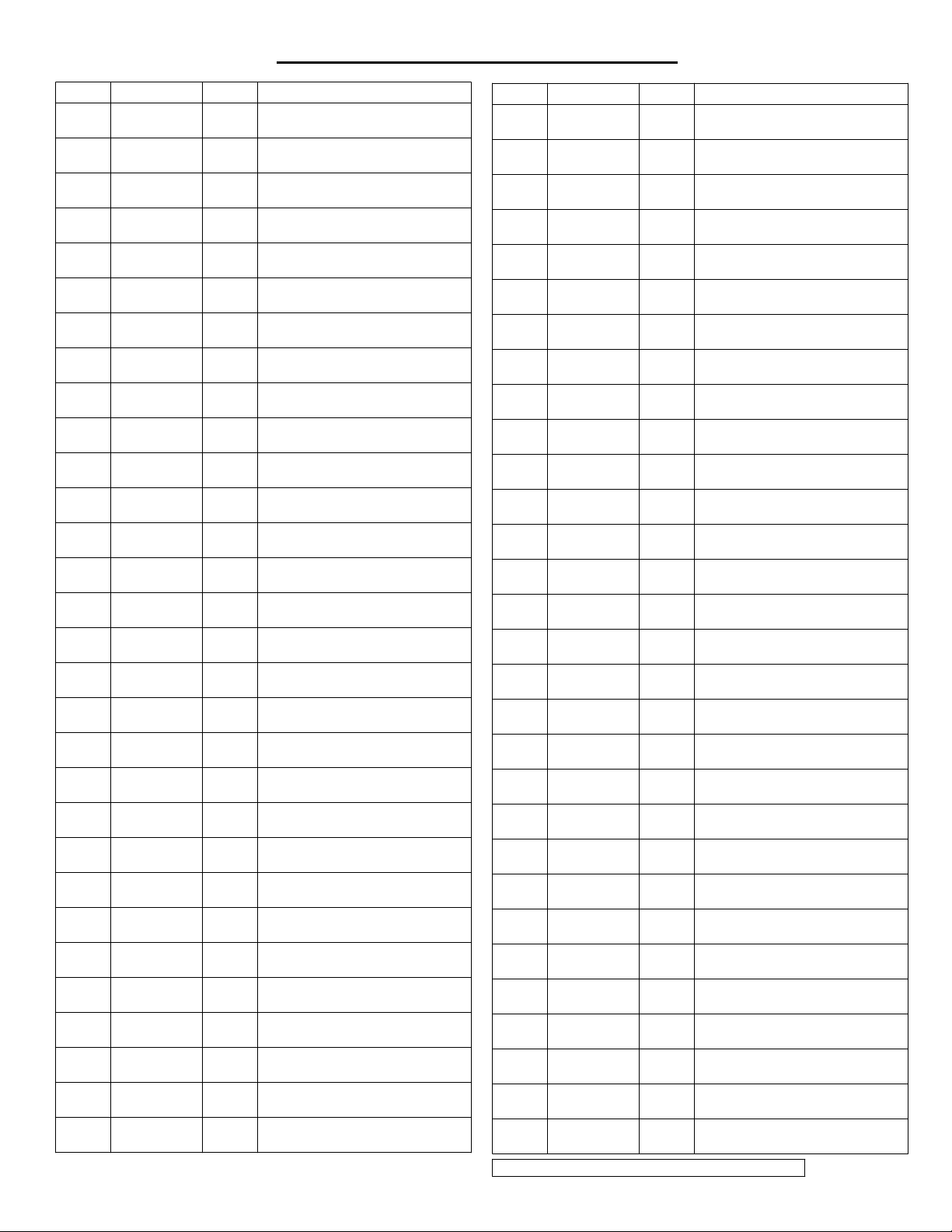

4646107 CB150/240 COMMON PARTS.

9

PART NO.

146460971

2

4

6

8

10

11 3201654 1 Valve, Flow Control

12 4646080

13

14

15 2900538 12

17

2900303

3200250

3201675

2900039

2 Lock Nut, M8 Nylon

1

1

1

4290006916

16

DESCRIPTIONQTY.ITEM

Frame, Power Supply

Flat Washer, 3/4" SAE42900003

Wheel, 8 x 2 x 3/4"425014393

Set Collar, 3/4"42400615

Instrument Panel146461005

Manifold, 3/4 NPT14646101

Manifold, SAE O-Ring146461027

Heat Exchanger12400256

Flat Washer, 5/16" SAE3429000229

Handle

Gauge, Hydraulic, 3000

PSI

Elbow, 1/4" M. JIC to 1/4"

F. Pipe

Cap Screw, Hex Hd., 5/1618 x 1-3/4"

Cap Screw, Hex Hd., 5/1618 x 2-3/4"

Lock Nut, 5/16-18 Nylon

ITEM PART NO. QTY. DESCRIPTION

31 3200479 1

32 3201434 1 Plug, 1/2" SAE O-Ring Hex

33 3200137 1 Hex Nipple, 3/4" NPT

34 3200383 1

35 3200371 1

36 3200330 1

37 4646010 1 Pump Mount (Machined)

38 2600490 1

39 2900006 2 Lock Washer, 3/8" Split

40 2900005 2

41 3200298 1

42 3200297 1

43 4646106 1

44 4646105 1 Hydraulic Tank Assembly

45 3201671 1 Hex Nipple, 1" NPT

46 3200289 1

47 3200288 2 Plug, 1" NPT

Plug, 3/4" NPT Square

Head

Nipple, Hex, 3/4" MPT TO

1/2" MPT

Adaptor, 1/2" MPT to 1/2"

O-Ring

Adapter, 3/4" M. Pipe to

3/4" O-Ring

Hydraulic Pump, .85 CI, W/

Key

Cap Screw, Hex Hd., 3/816 x 1"

Elbow, 3/4" O-Ring to 1/2"

M. JIC

Elbow, 1" O-Ring to 1" M.

JIC

Tank / Box Mounting

Bracket

Elbow, 1" M. Pipe to 1" M.

JIC

24

29

290100019

3200400

320129127

Flat Washer, 1/4" SAE20290000918

Cap Screw, Hex Hd., 1/4-

8

20 x 2-1/4"

Cap Screw, Hex Hd., 1/4-

2290100120

20 x 2-1/2"

Lock Nut, 1/4-20 Nylon10290001021

Fitting, 3/4" M. Pipe to 3/4"

2320165922

M. Garden

Fitting, 3/4" F. Garden

1320017723

Union Swivel

Elbow, 3/4" O-Ring to 3/4"

2

Male JIC

Elbow, 5/8" O-Ring to 1/2"

3320036625

Male JIC, 90 Deg.

Elbow, 1/2" O-Ring to 1/2"

1320028526

Male JIC

Adapter, 1/2"M.O-Ring to

1

1/4" MJIC

Adapter, 3/4" M. JIC to 3/4"

1320009728

M. Pipe

Elbow, 3/4" F. JIC to 3/4"

13200417

M. JIC

Adapter, 3/4" M. Pipe to

1320152230

1/2" M. JIC

48 3200505 1 Filter Head

49 3200111 1

50 3201175 1 Hydraulic Filter Element

51 3200502 1 Gauge, Hydraulic Pressure

52 3200100 1

53 3200101 1

54 3200104 1 Coupler, 1/2" Q.D.

55 3200105 1 Nipple, 1/2" Q.D.

56 4646138 1

57 1800924 1 Decal, CB 15/24XL Valve

58 1800941 1

59 1800169 1 Serial Number Plate, US

60 2900096 2 Rivet, 3/32" Dia.

Not Shown: PUMP SEAL KIT, #2703142

Elbow, 1" M. Pipe to 3/4"

M. JIC

Coupler, 3/4" Quick

Disconnect

Nipple, 3/4" Quick

Disconnect

Brake Assembly,

CB150/240

Decal, Hydraulic Power

Supply

Page 10

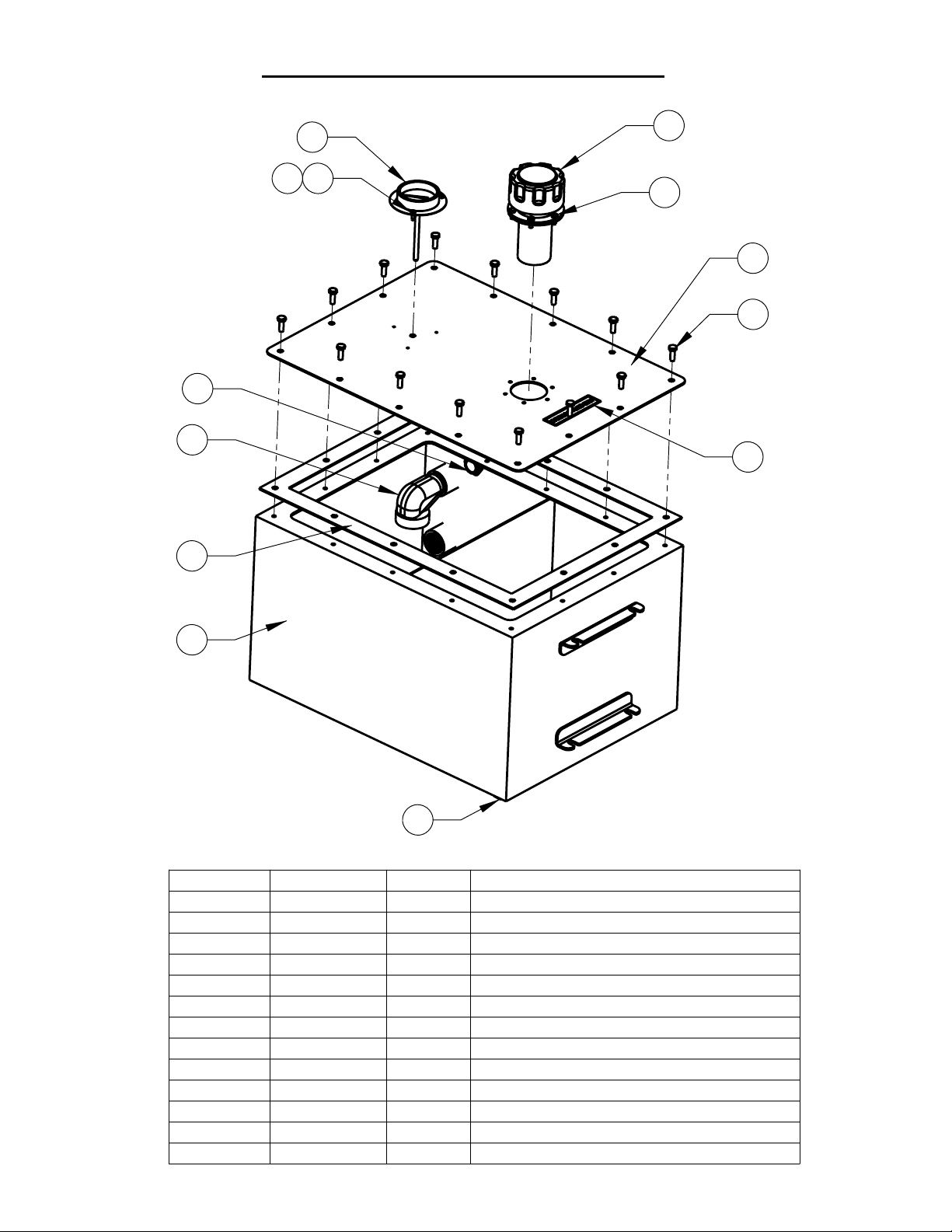

4646105 CB150/240 HYDRAULIC TANK

10

5

8

76

9

10

11

4

3

13

2

1

12

ITEM NO. PART NO. QTY. DESCRIPTION

1 4646099 1 Hydraulic Tank Weldment

2 4646103 1 Gasket

3 3200409 1 Street Elbow, 1" NPT

4 2400258 1 Fluid Level Sight Port

5 2400184 1 Thermometer, Panel Mount

6 2900092 3 Lock Washer, #6 Split

7 2900090 3 Machine Screw, Rd. Hd., #6-32 x 1/2"

8 2401305 1 Filler/Breather Cap (Top Mount)

9 2900339 6 Cap Screw, Hex Hd., M5 x 12mm

10 4646098 1 Cover, Hydraulic Tank

11 2900144 14 Cap Screw, Hex Hd., 1/4-20 x 3/4"

12 3200160 1 Plug, 1/2-14 NPT

13 1800535 1 Decal, "Hydraulic Fluid Only"

Page 11

END TO MANIFOLD

11

HOSE 4646056

90

4646078

HOSE

RETURN PORTS

4646108 (ELECTRIC)

6017344 (GAS)

HOSE

HEAT

EXCHANGER

EX

HOSE

4646057 (ELECTRIC)

4646160 (GAS)

IN

FLOW CONTROL VALVE

CF

1801441 CB150/240 HYDRAULIC SCHEMATIC

HOSE 4646109

FILTER

PUMP

TANK

HOSE

4646124 (ELECTRIC)

6040057 (GAS)

TANK

HOSE 6040061

ALL HOSES ARE IN KITS

4646114 ELECTRIC

PRESSURE PORTS

4646162 GAS

Page 12

4646162 CB 240 HOSE KIT

12

FOR CB240 UNITS MANUFACTURED AFTER DECEMBER 2009

13.25

19.25

21.3

18.0

41.4

19.4

34.0

1

2

3

4

5

6

ITEM PART NO. QTY. DESCRIPTION

1 6040061 1 Hose Assembly, 1/2"X 13-1/4"

3200290 2 Fitting, 1/2" Female JIC to 1/2" Hose Crimp

2 4646056 1 Hose Assembly, 1/2" X 19-1/4"

3200290 1 Fitting, 1/2" Female JIC to 1/2" Hose Crimp

3200408 1 Elbow, 1/2" F. JIC to 1/2" Parkrimp 90 deg.

3 4646160 1 Hose Assembly, 1/2"X 21-1/4"

4646160A 1 Hose, 1/2", 2500psi

3200290 2 Fitting, 1/2" Female JIC to 1/2" Hose Crimp

4 6017344 1 Hose Assembly 3/4" x 18"

3201989 2 Fitting, 3/4" F.JIC to 3/4" Hose Barb

3200135 2 Hose Clamp #16

5 4646161 1 Hose Assembly, 3/4 x 41-1/2"

3200129 2 Fitting, 3/4" F. JIC to 3/4" Hose Crimp

6 4646109 1 Hose Assembly, 1/4" x 19-3/8"

3200128 2 Fitting, 1/4" F. JIC to 1/4" Hose Crimp

7 6040057 1 Hose Assy., 1 x 34"

3202317 2 Fitting, 1" FJIC to 1" Hose Barb

3200135 2 Hose Clamp #16

7

Page 13

4646114 CB 150/240 HOSE KIT

13

FOR ALL CB150 UNITS AND CB240 UNITS MANUFACTURED PRIOR TO JANUARY 2010

13.25

19.25

16.40

15.06

21.56

19.38

26.24

1

2

3

4

5

6

ITEM PART NO. QTY. DESCRIPTION

1 6040061 1 Hose Assembly, 1/2"X 13-1/4"

3200290 2 Fitting, 1/2" Female JIC to 1/2" Hose Crimp

2 4646056 1 Hose Assembly, 1/2" X 19-1/4"

3200290 1 Fitting, 1/2" Female JIC to 1/2" Hose Crimp

3200408 1 Elbow, 1/2" F. JIC to 1/2" Parkrimp 90 deg.

3 4646057 1 Hose Assembly, 1/2" X 16.4"

3200290 2 Fitting, 1/2" Female JIC to 1/2" Hose Crimp

4 4646078 1 Hose Assembly, 3/4 x 15"

3200129 2 Fitting, 3/4" F. JIC to 3/4" Hose Crimp

5 4646108 1 Hose Assembly, 3/4 x 21-1/2"

3200129 2 Fitting, 3/4" F. JIC to 3/4" Hose Crimp

6 4646109 1 Hose Assembly, 1/4" x 19-3/8"

3200128 2 Fitting, 1/4" F. JIC to 1/4" Hose Crimp

7 4646124 1 Hose Assembly, 1" X 26-1/4"

3202317 2 Fitting, 1" FJIC to 1" Hose Barb

3200135 2 Hose Clamp #16

7

Page 14

4646163 CB240

14

GAS COMPONENTS

35 36

DETAIL B

SCALE 1 : 5

11

34

34

33

34

37

35

40

39

PHANTOM PARTS

ARE REFERENCE ONLY

5

TO FUEL

FILTER

41

44

16

17 184X

16

4

38

24

7

9

7

25

DETAIL C

SCALE 1 : 3

45

43

23

12

13

28

3029

31

14

26

27

15

VENT

LINE

1

2

32

42

20

19

DETAIL A

SCALE 1 : 4

21

4X

22

9

10

7

7

8

6

Page 15

ITEM PART NO. QTY. DESCRIPTION

15

1 4646097 1 Frame, Power Supply

2 4646100 1 Instrument Panel

3 4646106 1 Tank / Box Mounting Bracket

4 4641051 1 Honda, GX660, Short Shaft & Elec. Con.

5 2708046 1 Honda Muffler, R Side Exhaust

6 2701670 1 Rectifier Assembly

7 2900009 8 Flat Washer, 1/4" SAE

8 2900052 2 Cap Screw, Hex Hd., 1/4-20 x 1-1/4"

9 2900010 4 Lock Nut, 1/4-20 Nylon

10 4646018 1 Wire Assembly, 12 Gage

11 3201968 1 Adapter, M20x1.5 M. to 3/8" F. Pipe

12 3201468 1 3/8" MPT to 3/8" FJIC, Swivel

13 3205603 1 3/8 MJIC - 3/8 MJIC, 90 Deg.

14 4645037 1 Hose Assy., 3/8 x10-3/4", FJIC-FJIC

15 3201897 1 3/8" JIC Plug

16 2900014 8 Flat Washer, 3/8" SAE

17 2900317 4 Cap Screw, Hex Hd., M10 x 45mm

18 2900304 4 Lock Nut, M10 Nylon

19 6048134 1 Key, 1/4" Sq. x 2-1/4"

20 2702225 1 Coupling Assembly, 3/4 - 1-1/8"

21 2900006 4 Lock Washer, 3/8" Split

22 2900183 4 Capscrew, Soc Hd., 3/8"-16 X 1-3/8"

23 2500584 1 Battery, 12 Volt Group Size U1

24 4646122 1 BatterySupport

25 2901405 2 Cap Screw, Hex Hd., 1/4-20 x 7-1/2"

26 4646015 1 Battery Cable Assy., Red

27 4646016 1 Battery Cable Assy., Black

28 6010869 1 Fuel Tank, 4.4 Gallon

29 2506716 1 Grommet

30 2505503 1 Roll Over Vent, 3/8" Hose Barb

4646163 CB240 GAS COMPONENTS

31 2500649 1 Fuel Tank Cap

32 4641107 1 CB240 Vent Line

33 4646136 1 Heat Shield

34 2900022 6 Flat Washer, 5/16" SAE

35 2900019 4 Cap Screw, Hex Hd., 5/16-18 x 3/4"

36 2900039 2 Lock Nut, 5/16-18 Nylon

37 2900031 2 Lock Washer, 5/16" Split

38 3200012 1 Street Elbow, 1/4" NPT

39 3200108 1 Fuel Shut-Off Valve, 1/4"

40 3200418 1 Adapter, 1/4" M. Pipe to 1/4" M. JIC

41 4646210 1 Hose Assy., Fuel, 1/4 x 7.5"

42 2800120 1 Tach/Hour Meter, W/#6 Screws

43 2801367 1 E-Stop Switch

44 4646188 1 Wire Assy., Emergency Off, 46.6"

45 1800943 1 Decal, Core Bore CB240

46 4646162 1 Hose Kit, CB 240

A CATALYTIC

MUFFLER IS

AVAILABLE:

2702624.

Page 16

4646163 CB240 ELECTRIC SCHEMATIC

16

4646188

STOP SWITCH TO

MATING CONNECTORS

AT IGNITION SWITCH

ENGINE

23

24

4646016

GROUND

TO ENGINE

MOUNTING BOLT

12

11

SWITCH

STOP

4646015

TO COIL

+ -

BATTERY

FOR EASE OF ASSEMBLY, ATTACH WIRES TO STOP SWITCH

BEFORE INSTALLING IN PANEL.

Page 17

4646138 BRAKE ASSEMBLY

17

2

3

4

1

5

6 7

6 8

ITEM PART NO. QTY. DESCRIPTION

1 4646137 1 Bracket, Brake Mount

2 2500847 1 Clamp

3 2900247 4 Cap Screw, Soc. Hd., 1/4-20 x 3/4"

4 2900141 1 Hex Nut, 5/16-18

5 2900019 1 Cap Screw, Hex Hd., 5/16-18 x 3/4"

6 2900022 4 Flat Washer, 5/16" SAE

7 2900538 2 Cap Screw, Hex Hd., 5/16-18 x 1-3/4"

8 2900039 2 Lock Nut, 5/16-18 Nylon

Page 18

4646111(230/460V)

18

4646113 (575V)

CB 150 ELECTRICAL

COMPONENTS

23

22

DETAIL A

SCALE 1 : 2

21

13

1414

16 15

4

7

668

CRIMP TO

109

MOTOR LEADS.

17

5

18 18

19 20

12

11

ITEM

NO.

PART

NUMBER

4600079

4

4600080 Electric Motor, 15 HP, 3 Ph., 575V.

5

2701801 1 Coupling Assembly, 1-3/8 - 3/4" Shafts

6 2900014 8 Flat Washer, 3/8" SAE

7 2900005 4 Cap Screw, Hex Hd., 3/8-16 x 1"

8 2900018 4 Lock Nut, 3/8-16 Nylon

9 2900084 4 Lock Washer, 1/2" Split

10 2900511 4 Cap Screw,Soc. Hd., 1/2-13 x 1-1/4"

11 2800193 1 Lock Nut, 1"

12 2800312 1 Connector, 1" Sealtite Elbow

4646126

13

4646127

QTY.

Electric Motor, 15 HP, 3 Ph., 230/460 V.

1

1

DESCRIPTION

Starter Box Assy., 230/460V

Starter Box Assy., 575 Volt

ITEM

NO.

PART

NUMBER

14 2900009 8 Flat Washer, 1/4" SAE

15 2900008 4 Cap Screw, Hex Hd., 1/4-20 x 1"

16 2900010 4 Lock Nut, 1/4-20 Nylon

17 2800083 9 Terminal, #10 Ring (16-14 AWG) Blue

18 2900016 18 Flat Washer, #10 USS

19 2900159 9 Machine Screw, Rd. Hd., #10-24 x 5/8"

20 2900017 9 Lock Nut, #10-24 Nylon

21 2500549 1 Plug, 7/8" Hole

22 1800942 1 Decal, Core Bore CB150

23 4646114 1 Hose Kit

QTY. DESCRIPTION

Page 19

4646125 STARTER BOX 208-460 Volt

19

13

11

16

14

16

15

9

10

7

5

12

6

8

4

3

1

2

ITEM ITEM

NO.

PART

NUMBER

2 2901332 4 1/4-20 Threaded Insert

3 6040301B 1 Backup Plate, Starter Box

4 2900676 4

5 2800899 1 Overload Relay, 13-52 Amp

6 2900016 5 Flat Washer, #10 USS

7 2900087 2 Cap Screw, Soc. Hd., #10-32 x 5/8"

8 2800449 1 Contactor Coil, 208-240V, 15HP

QTY.

11 6040300G Electrical Box Base

Machine Screw, Pan Hd., M4-0.7 x

8mm

DESCRIPTION

PART

NO.

NUMBER

9 2900121 3 Cap Screw, Soc. Hd., #10-32 x 3/8"

10 4645254 1 Cover, Electric Box, 2 Hole

11 2800322 1 Start Button

12 2701414 4 Fastener, Electrical Box Top

13 2800222 1 Clear Protective Boot

14 1801638 1 Decal, Start

15 1801639 1 Decal, Stop

16 2801636 1 E-Stop Switch, 600V

QTY. DESCRIPTION

Page 20

4646126(230/460V), ...127(575V) STARTER BOX ASSEMBLY

20

ROUTE INTO

16

STARTER BOX

B

TO STOP

SWITCH

6

5

1

1

1

8

15

13

14

6

7

TO CUSTOMER

SUPPLIED PLUG.

3

4

DETAIL B

SCALE 1 : 4

2

TO MOTOR

REPLACE COIL WITH

2800277 FOR 575 VOLT

10

DETAIL A

SCALE 1 : 2

A

9

11

12

ITEM NO. PART NUMBER QTY. DESCRIPTION

1 4646125 1 Starter Box, 208-460 Volt

2 2800315 1 Grounding Lug

3 2900016 1 Flat Washer, #10 USS

4 2900448 1 Machine Screw, Hex Hd., #10-32 x 1/2"

5 2800898 1 Connector, 1", Sealtite, 90 Deg.

6 2800193 2 Lock Nut, 1"

7 2804009 1 Cord Connector, 1"Thd., .87-1.02" Cord, Nylon

8 4646134 1 Conduit, Seal Tite, 1" x 34"

9 4646133 1 Wire Assy., 6 Gage, Green, 55"

10 4646132 3 Wire Assy., 8 Gage, Black, 60"

11 4646130 1 Wire Assy., 14 Gage, 52"

12 4646131 1 Wire Assy., 14 Gage, Orange, 50"

13 4646128 1 Wire, 14 Gage, Orange, 11"

14 4646129 1 Wire Assy., 14 Gage, Brown, 15"

15 4646135 1 Cable, 8 Gage, 4 Wire, 16"

16 1800810/11/12 1 Voltage Label, 230/460/575V

Page 21

4646126/27 WIRING SCHEMATIC, CB 150, 3 PHASE, 230/460/575 VOLT

21

WIRES IN MOTOR WIRING BOX MUST BE JOINED PER SCHEMATIC ON MOTOR.

230V:

SET OVERLOAD TO 34 AMPS.

SET OVERLOAD TO 17 AMPS.460V:

SET OVERLOAD TO 14 AMPS. REPLACE COIL WITH 2800277.575V:

4646128

ORANGE,

14 GA.

95

96

1

3

5

2

STOP

4646135

POWER CORD

4646129

BROWN,

14 GA.

COIL

OVERLOAD

4646132

BLACK, 8 GA.

4646131 ORANGE, 14 GA.

230/460V, TO MOTOR WIRE 7

575V, TO MOTOR WIRE 1.

RELAY

SETTINGS

5

30

PHASE UNBALANCE - ON

PHASE LOSS - ON

RESET MODE - AUTO

GROUND FAULT - OFF

4646130 BROWN, 14 GA.

230/460V, TO MOTOR WIRE 8

575V, TO MOTOR WIRE 2.

GREEN

4646133

GREEN, 6 GA.

GROUND

LUG

Page 22

NOTES

22

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

Page 23

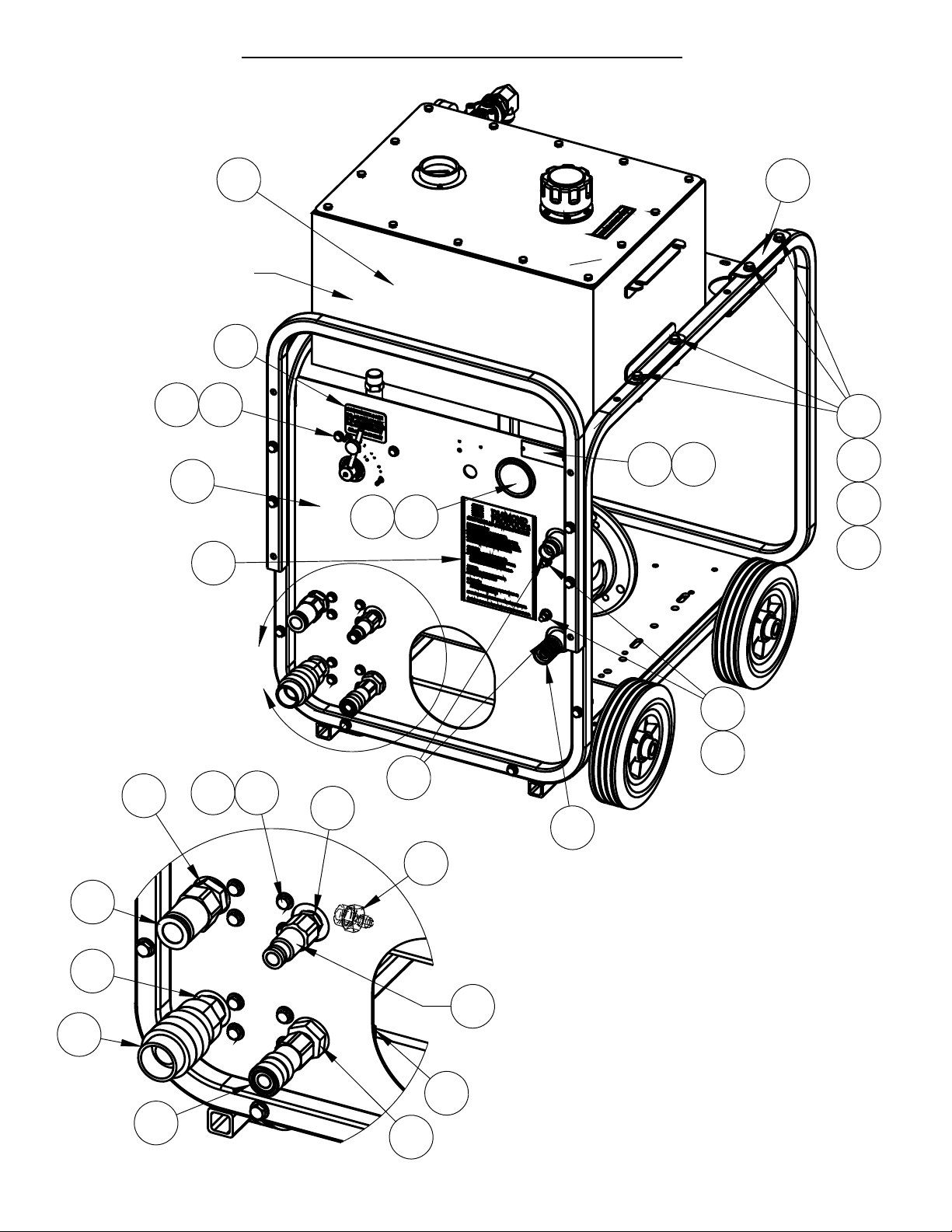

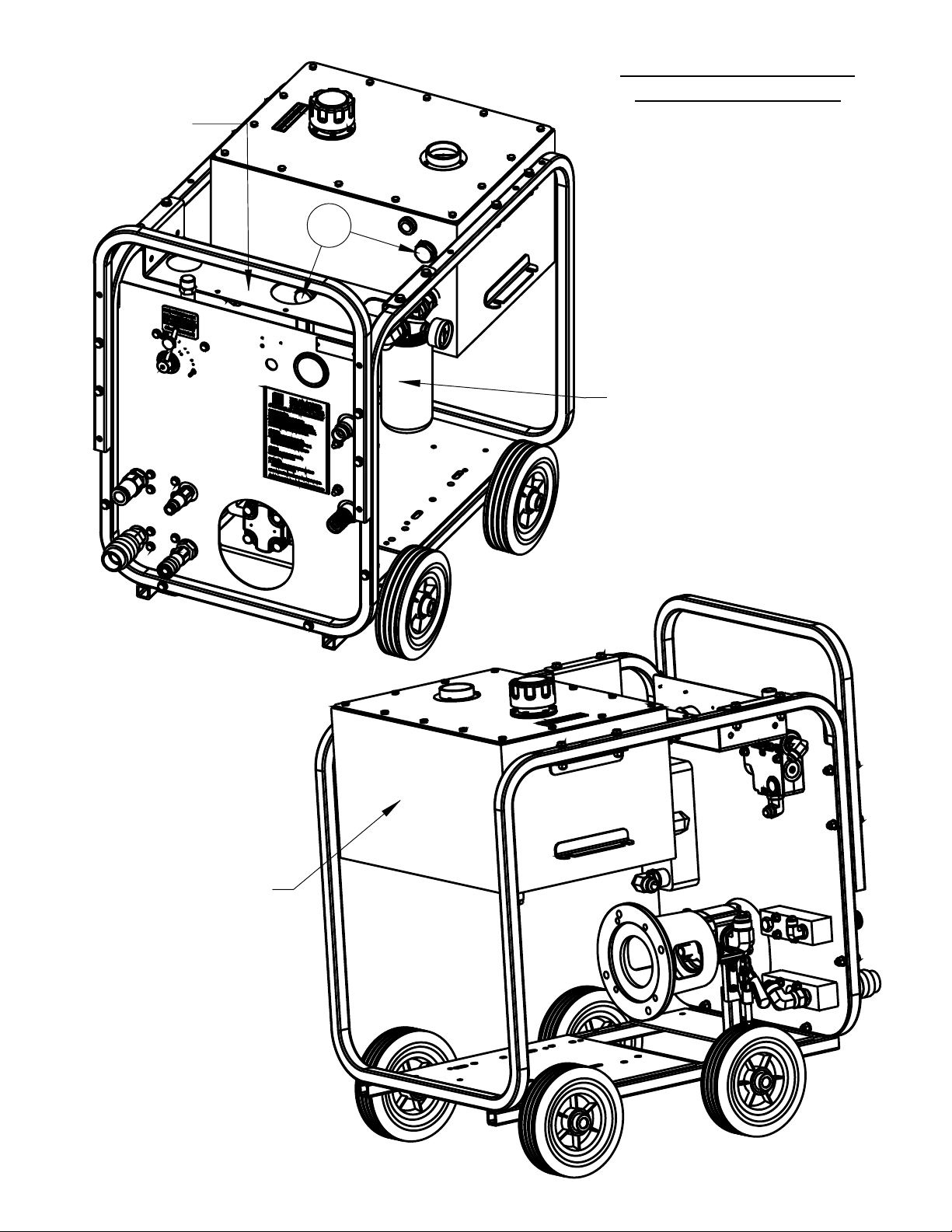

(

)

23

GASLINEVALVE,

BELOWTANK

KEYSTART

&THROTTLE

GAGE,OIL

FILTER

CHOKE

EMERGENCY STOP

GASUNITS

RELIEF

CARTRIDGE

FLOW

CONTROL

QUICK

DISCONNECTS

WATER

CONNECTIONS

Page 24

GENERAL SAFETY PRECAUTIONS

24

WARNING: Do not operate power unit without reading this entire manual and the engine

operation manual first. Keep manuals with power unit at all times for reference.

This manual describes the operating procedures, care, maintenance, adjustments, and safety

precautions for proper use of this machine. This equipment is intended for industrial

applications by experienced operators. It is to be operated in conformance with applicable

federal, state, and local codes or regulations pertaining to safety, air pollution, noise, etc.

Tool operators and maintenance personnel must always comply with the safety precautions

given in this manual and on the stickers and tags attached to the equipment.

These safety precautions are given for your safety. Review them carefully before operating

the tool and before performing general maintenance or repairs.

Supervising personnel should develop additional precautions relating to the specific work

area and local safety regulations.

In addition to this manual, read and understand safety and operating instructions in the

Engine Operation Manual furnished with the Power Unit in addition to this manual.

Establish a training program for all operators to ensure safe operation.

Do not operate the power unit unless thoroughly trained or under the supervision of an

instructor.

Do not inspect or clean the power unit while it is running.

Always use hoses and fittings rated at a minimum 2600 p.s.i. (179 bar) with a 4 to 1

safety factor for pressure lines.

Be sure all hose connections are tight.

Make sure all hoses are connected for correct flow direction to and from the tool being

used.

Do not inspect hoses and fittings for leaks by using bare hands. “Pin-hole” pressure leaks

can penetrate the skin.

Never operate the gas power unit in a closed space. Inhalation of engine exhaust can

be fatal.

Do not operate a damaged or improperly adjusted power unit.

Never wear loose clothing that can get entangled in the working parts of the power unit.

Keep all parts of your body away from the working parts of the power unit.

Page 25

Always wear appropriate safety equipment such as goggles, ear protection, head

25

protection and safety shoes. Certain tools used in conjunction with the power unit may

require other safety equipment such as breathing filters.

Keep clear of hot engine exhaust.

Do not add fuel to the power unit while the power unit is still running or is still hot.

Do not operate the power unit if a gasoline odor is present.

Do not use flammable solvents around the power unit engine.

Do not operate the power unit within 3 ft. (1 meter) of buildings or flammable objects.

Allow the engine to cool before storing the unit in an enclosed area.

To avoid personal injury or equipment damage, all tool repair, maintenance and service

must only be performed by authorized and properly trained personnel.

IMPORTANT: The red stop button at the front panel (gas units) or top of the starter box

(electric units) will immediately stop the engine. Hydraulic pressure and flow will go to

zero. This button must be in the out position to start the unit.

DANGER: Improper use or alteration of this equipment may be extremely hazardous.

SAFETY SYMBOLS

Safety symbols are used to emphasize actions which could result in a life-threatening

situation, bodily injury, or damage to equipment.

Always observe safety symbols. They are included for your safety and for the protection of

the tool.

! DANGER !

This safety symbol may appear

on the tool. It is used to alert the

operator of an action that could

place him/her or others in a life

threatening situation.

!WARNING: !

This safety symbol appears

in these instructions to identify

an action that could cause bodily

injury to the operator or to other

threatening situation.

! IMPORTANT !

This safety symbol appears in

these instructions to identify an

an action or condition that could

result in damage to the tool or

other equipment.

Page 26

DESCRIPTION AND SPECIFICATIONS

26

Pump: Gear, pump rotation is clockwise (motor is CCW).

Maximum GPM: 12-3/4 GPM (48.2L/M). Flow will decrease as pressure increases.

Hydraulic Fluid Tank Capacity: 12-1/2 gallons (47.3Liters)

Hose Couplings: Bruning quick disconnect, 3/4 inch & ½ inch

Relief Pressure: CB240, Factory set at 2600 PSI /179.3 Bar (at valve outlet port).

A higher relief setting will stall the engine. Adjustable to750 PSI,

CB150, Factory set at 2100 PSI/145 Bar (at valve outlet port). Adjustable to 750 PSI,

CURRENT LIMITTED TO 2100 PSI.

Gas Engine: Honda 21H (15.7KW) Net @3600RPM, Air-cooled, RPM set at 3550.

Fuel tank: 5 Gal (18.9L).

Electric Motor: Baldor 15 HP, C Face, 3450 RPM, 230/460 Volts, 575 Volts (Canada only).

This unit is compatible with most hydraulically driven sawing and drilling components. The

system may not be compatible with components of some manufacturers.

The power unit was inspected and operated before shipment and should not require any

additional adjustments prior to its initial use.

Hydraulic Fluid: The reservoir of the

hydraulic power unit must be full prior to

start-up. The use of high quality petroleum

based hydraulic oil with the following

properties is recommended:

Anti-wear

Low foaming

Rust and oxidation inhibitors

Wide temperature range

Fluid viscosity: 8-1000 Centistokes

(52-4600 SUS). The unit is shipped

with an ISO 46 Viscosity grade

(8Cs/52SUS @ 212F/100C and

46Cs/210SUS @ 104F/40C).

The oil must be kept free of contamination

to avoid damage to system components.

The strainer in the fill cap must always be

in place when adding oil. Quick

disconnects must be cleaned before

connections are made.

Control Valve: The pressure

compensated flow control valve on this unit

allows full flow control while the gas engine

remains at its most efficient wide-open

throttle. This allows a higher operating

pressure at all flows. Flow settings are:

0-2, all flow routed to tank; 2-8, adjustable

range, 8-10 full flow.

Relief pressure can be adjusted by

removing the cap at the top of the main

control and using an Allen wrench to adjust

the relief cartridge. The relief can be set

as low as 750 psi; do not exceed 2600 psi

(gas) or 2100 psi (electric). To adjust, the

flow control must be set at 10 and no tool

should be attached. This will force all flow

over relief. Securely replace the cap as oil

seepage will occur through the relief

cartridge. The relief is factory set at 2600

psi (gas) and 2100 psi (electric) and should

rarely need adjustment.

Hydraulic Oil Cooler: The power unit is

equipped with a brazed plate style oil

cooler. Water should be passed through

the cooler before being used for dust

control or blade & bit cooling. Some tools

will automatically shut off water flow when

not actively cutting, drilling, etc. This may

result in higher oil temperatures if the

power unit continues to run for long periods

without cooling water.

IMPORTANT: If there is a risk of frost

the water must be drained from the

cooler to prevent damage by freezing.

Page 27

27

HOSES: Large diameters and short

lengths are preferred and offer the highest

system efficiency. If one is operating 50 ft

(15.2M) from the power source, there is

also a 50 ft (15.2M) return for a 100 ft

(35.5M) total hose length. With 12 GPM

and oil at 100 deg. F (37.8C), this could

result in a 300 psi (20.6 Bar) pressure loss

with ½” hose and a 100 psi (6.9 Bar) loss

with 5/8” hose. Pressure loss will change

dramatically with oil temperature.

OPERATING INSTRUCTIONS

Operator Responsibilities

It is the operator’s responsibility to use this

unit and any attached tools under safe

working conditions and to follow proper

safety procedures for themselves, coworkers, observers, and the public at large.

The operator must be aware of the

machine’s capabilities and limitations and

follow the safety precautions in each

section of this manual. Periodic

maintenance is required, in accordance

with the instructions herein, to promote

safe and reliable operations.

WARNING: Keep bystanders out of the

immediate work area.

Wear approved:

Safety glasses

Ear protection

Hard hat

Gloves

Safety shoes

Any other protective equipment

required for compliance with standard

safety practices or federal, state, and

local codes and regulations

Hose Connections: It is best to connect

the hoses to the unit before starting as

even very low residual pressure can make

hose installation more difficult. Push

couplings together until you hear it click.

Turn locking ring of coupling to the secured

position.

Gas Engine: Make sure that the engine

crankcase is filled with oil to the proper

level! Refer to your engine manual for oil

checking and changing procedures, along

with oil specifications, etc.

IMPORTANT: Operating the engine

without oil will ruin the engine.

Fuel: Use regular grade unleaded

gasoline to fuel the engine. Premium

grade may be used if necessary. Fill the

tank when the engine is off and has been

allowed to cool. Care should be taken to

prevent spilling fuel. Do not overfill the

fuel tank. Always leave enough space for

expansion due to environmental heating.

WARNING: In the event of fuel spillage,

do not start the engine or operate any

nearby electrical component until the

spilled fuel has been removed.

Starting Procedure:

GAS:

Set the flow control valve to zero.

Open the fuel shut off valve below the

gas tank.

Be certain the emergency off switch

has been pulled out.

Set throttle at about 1/3, set choke if

necessary (cold engine). Turn key to

start and release. Refer to engine

manual for details of control functions.

Let engine warm and gradually open

the choke and set the throttle to

maximum.

Page 28

ELECTRIC:

28

Set the flow control valve to zero.

Be certain the stop switch has been

pulled out.

Be certain the unit is connected to the

proper voltage and a proper gage

power cord is used.

Press the start button at the top of the

starter box.

DANGER

: Exhaust from the gas engine

contains carbon monoxide, a

poisonous, odorless, invisible gas,

which can cause serious illness or

death. Do not operate the gas engine

where ventilation is restricted. Open

windows and doors may not be

sufficient to prevent this hazard.

Heating Cold Oil: Forcing the oil over

relief will quickly increase the oil

temperature. With no tool connected to the

unit, move the valve setting toward 10.

This will force an increasing percentage of

oil over relief. Heat cold oil to room

temperature or ~100F/38C maximum. Cold

oil greatly increases pressure loss in hoses

and fittings and may affect tool operation.

Maintaining Oil Temperature: With an

ample water supply, it is unlikely

overheating will be an issue except in the

most extreme ambient temperatures. To

force high oil temperatures down, run the

unit with the flow control set to zero. This

unloads the unit yet circulates oil through

the cooling system. The rate of cooling will

depend on the ambient temperature and

how much water is being passed through

the cooler.

Some control valves at the external tool

may create backpressure and heat even

when off. It is best to set the flow control to

IMPORTANT

at the top of the hydraulic tank.

Maximum recommended oil

temperature is 180 degrees Fahrenheit

(82 deg C).

Shutting Down:

GAS:

Shift the flow control valve to zero to

unload the system.

Throttle the engine back to a low RPM.

Turn the key to the off position.

IMPORTANT

button at the front panel will

immediately stop the engine. Hydraulic

pressure and flow will go to zero. This

button must be in the out position to

start the engine.

ELECTRIC:

Shift the flow control valve to zero to

unload the system.

Press the stop button at the top of the

starter box.

zero or shut the power unit down to avoid

heating and conserve energy.

: Monitor the thermometer

: The red emergency stop

Page 29

OPERATING DRIVEN

29

EQUIPMENT

The operator must know the hydraulic

requirements and limitations of the driven

equipment and the appropriate

adjustments must be made on the controls.

The introduction of other control devices

may cause system heating or may render

the system inoperative.

IMPORTANT: This power unit is

equipped with a positive displacement

gear pump. All tools must be equipped

with a control valve that allows flow

directly to return ports when not in use.

Blocking oil flow or abruptly

disconnecting the tool can send flow

over relief and potentially overheat the

system.

Instructions supplied with the driven

equipment must be followed to ensure

correct connection and operation of each

individual piece of equipment. Equipment

supplied by Diamond Products will be

capable of being connected correctly and

will be compatible with this power unit,

providing neither has been modified from

original factory configuration. With

equipment of other manufacturers, it will be

necessary to determine the following:

Correct direction of flow through the

equipment.

Correct pressure and flow required by

the equipment.

Compatibility of any valves or circuitry

and quick disconnects. Some handheld equipment uses a trigger control,

which is operated frequently. These

valves must be of the open center type

for correct operation.

IMPORTANT: The quick disconnects

must be clean when connecting hoses

and devices. Dirty connections may

result in contamination and premature

failure of system or tool components.

MAINTENANCE

INSTRUCTIONS

Oil Filter: change the filter when

indicated by the gage at the filter.

Oil Change: establishing an oil analysis

program is the preferred method of

determining oil condition and when to

change it. If the oil is kept clean, dry,

and operated at moderate

temperatures, it can last for several

years. With no analysis program an oil

change every 200 hours is

recommended. See the section

Hydraulic Fluid for specifications. A ½”

pipe thread oil drain port is at the

bottom of the hydraulic tank.

Gas Engine Oil: Change engine oil and

filter and perform other routine

maintenance as recommended in the

engine operation manual.

Inspect hoses, couplings, and fittings

daily for leaks, tighten as required.

Clean quick disconnects frequently.

Replace any leaking or defective

components immediately.

Check hydraulic oil level daily. Fill tank

to upper end of sight tube with unit off.

Grease the wheel bearings annually.

Page 30

30

TROUBLESHOOTING

PROBLEM POSSIBLE SOLUTIONS

Gas engine will not start.

1) Pull out emergency stop button.

2) Open gas line valve below gas tank.

3) Dead battery?

4) Low engine oil?

Electric motor will not start.

1) Pull out stop button on starter box.

2) Press reset button on starter box.

3) Confirm proper voltage.

Low oil flow.

Check gas engine RPM at tachometer

on front panel. Adjust governor to

3550 RPM if required. See engine

manual.

System builds high pressure with flow

control valve set to zero.

Contamination may have plugged an

orifice in the CF port of the flow valve.

Detach the valve from the front panel

and remove the fitting from the CF

port. A .015” orifice should be visible

at the bottom of the port. Push a fine

wire through the orifice and re-install.

Running with no pressure. Electric

units only.

The motor may be running backwards,

should be counter clockwise. Reverse

any 2 of the 3 power lines coming into

the starter box.

Keep this manual and the engine manual readily available at all times for reference.

Corporate Office

The engine exhaust from this product

333 Prospect St., Elyria, Ohio 44035

contains chemicals known to the State of

(216) 323-4616 • Fax: (216) 323-8689

California to cause cancer, birth defects or

Customer Service: 1-800-321-5336

Customer Service Fax: 1-800-634-4035

other reproductive harm.

Page 31

NOTES

31

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

Page 32

EQUIPMENT AND PARTS

WARRANTY

Diamond Products warrants all equipment manufactured by it against defects

in workmanship or materials for a period of one (1) year from the date of

shipment to Customer.

The responsibility of Diamond Products under this Warranty is limited to

replacement or repair of defective parts at Diamond Products’ Elyria, Ohio

factory, or at a point designated by it, of such parts as shall appear to us upon

inspection at such parts, to have been defective in material or workmanship,

with expense for transportation and labor borne by Customer.

In no event shall Diamond Products be liable for consequential or

incidental damages arising out of the failure of any Product to operate properly.

Integral units such as engines, electric motors, batteries, transmissions,

etc., are excluded from this Warranty and are subject to the prime

manufacturer’s warranty.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, AND ALL SUCH OTHER WARRANTIES ARE HEREBY

DISCLAIMED.

333 Prospect Street, Elyria, Ohio 44035

(440) 323-4616 • (800) 321-5336 • Fax (440) 323-8689

www.diamondproducts.com

Printed in U.S.A.

Loading...

Loading...